Manufacturing method of coiled bipolar membrane

A manufacturing method and technology of bipolar membrane, applied in the direction of coating, etc., can solve the problems of difficult to realize continuous production of bipolar membrane products, difficult to accurately control the thickness, difficult to realize automatic control, etc., so as to reduce the uncertainty. Risk, performance indicators are stable, and the effect of close integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

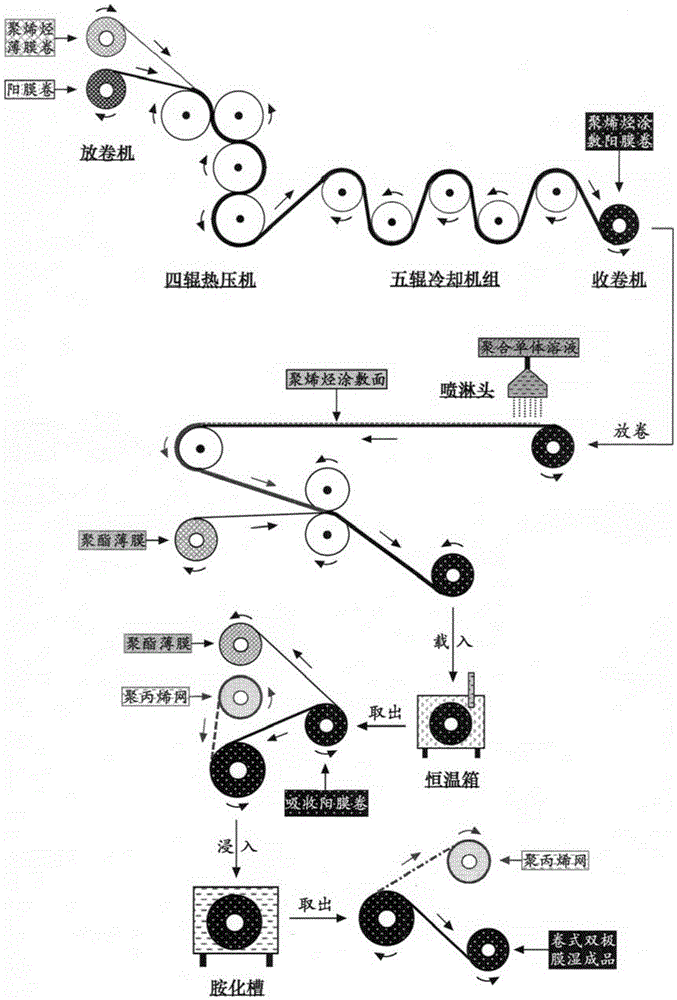

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Take the dry film roll of LCM series cation exchange homogeneous membrane (provided by Liaoning Yichen Membrane Technology Co., Ltd., the performance indicators are as follows: the width is 60.0 cm, the thickness is 0.12 mm, the length is 120 meters, and the cation exchange capacity is 2.13 Millimoles per gram of dry film) and polyolefin film rolls (the material is composed of: linear low-density polyethylene (Mitsui Chemicals, brand 4570): polyisobutylene (BASF, brand B200): POE polyolefin elastomer (Dow Chemical, brand 8452)=100:12:9 (mass ratio), the width is 63.0 centimeters, the thickness is 0.05 millimeters, and the length is 400 meters), all according to the line speed of 3.8 meters per minute. top, all covering the lower positive film) into the four-roller calender, the temperature of the four-roller is 110, 108, 106, 104°C in sequence, and the distance between each roll is accurately adjusted to 0.14-0.15 mm, and it is cooled immediately by the five-roll...

Embodiment 2

[0039] Step 1: Roll the dry film of the LCM series cation exchange homogeneous membrane (select the product of Liaoning Yichen Membrane Technology Co., Ltd., the performance indicators are as follows: the width is 60.0 cm, the thickness is 0.10 mm, the length is 100 meters, and the cation exchange capacity is 2.02 millimoles per gram of dry film) and polyolefin film rolls (the material is composed of: low-density polyethylene (Mitsui Chemicals, brand 403): polyisobutylene (BASF, brand B200): POE polyolefin elastomer (Mitsui Chemicals, brand 840 )=100:7:8 (mass ratio), the width is 63.0 cm, the thickness is 0.04 mm, and the length is 300 m), all are unwound according to the line speed of 3.0 m / min, after lamination (the polyolefin film surface is on the top , all covering the lower positive film) into the four-roller calender, the temperature of the four-roller is 107, 105, 103, 102°C in sequence, and the distance between each roll is accurately adjusted to 0.12-0.13mm, and it e...

Embodiment 3

[0044] Step 1: Take the dry film roll of LCM series cation exchange homogeneous membrane (provided by Liaoning Yichen Membrane Technology Co., Ltd., the performance indicators are as follows: the width is 60.0 cm, the thickness is 0.11 mm, the length is 130 meters, and the cation exchange capacity is 1.95 Millimoles per gram of dry film) and polyolefin film rolls (the material is composed of: metallocene linear low-density polyethylene (Exxon Chemical, brand 2018CA): EPDM rubber (U.S. Dow, brand 660)=100: 24 (mass ratio), the width is 62.0 cm, the thickness is 0.04 mm, and the length is 250 meters), all of which are unwound at a line speed of 3.0 m / min. positive film) into the four-roll calender, the temperature of the four rolls is 107, 105, 103, 102 °C in sequence, and the distance between each roll is precisely adjusted to 0.13-0.14 mm, and immediately enters the constant tension winding machine after being cooled by the five-roll cooling unit. Continuous winding, that is, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com