Fabricated building component connecting device

A technology for connecting devices and building components, applied in building structures, buildings, etc., can solve the problems of inability to withstand vertical tension and lateral forces, and achieve the effect of improving connection convenience, convenient detection, and structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

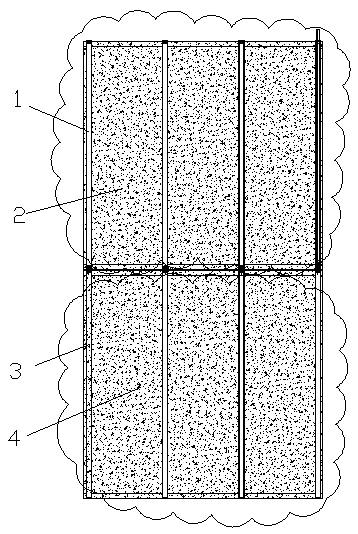

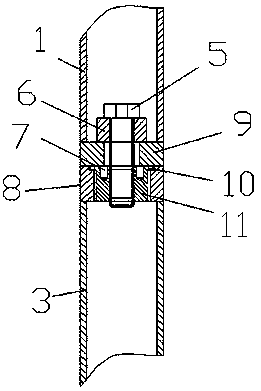

[0029] When the first member 2 and the second member 4 are prefabricated concrete members respectively, it is necessary to embed several first steel pipes 1 in the first member 2 and several second steel pipes 3 in the second member 4. The bottom of the steel pipe 1 and the second steel pipe 3 are respectively welded with a lower end plate 9 with a through hole, and the tops of the first steel pipe 1 and the second steel pipe 3 are respectively welded with an upper end plate 8 with a first internal threaded hole, and then the first steel pipe 1 And the second steel pipe 3 is poured into the corresponding concrete member to form the first member 2 and the second member 4. The specifications of the first member 2 and the second member 4 can be the same or different. After being in place, screw the nut 11 into the upper end plate 8 of the second steel pipe 3, and screw the bolt 5 in the first steel pipe 1 into the nut 11 of the second steel pipe 3 through the sleeve and the sleeve...

Embodiment 2

[0031] When the first component 2 and the second component 4 are steel structure assembled building components, the first steel pipe 1 is used to replace part of the steel columns in the first component 2, and the second steel tube 3 is used to replace part of the steel columns in the second component 4 First, weld a lower end plate 9 with a through hole at the bottom of the first steel pipe 1 and the second steel pipe 3 respectively, and weld an upper end plate 8 with the first threaded hole in the top of the first steel pipe 1 and the second steel pipe 3 respectively, and then A plurality of first members 2 and second members 4 of the same or different models are welded in the factory, screw nuts 11 into the upper end plate 8 of the second steel pipe 3, and insert the first steel pipe 1 through the sleeve and the sleeve rod. The bolt 5 is screwed into the nut 11 of the second steel pipe 3, thereby connecting the first steel pipe 1 and the second steel pipe 3 together, replaci...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap