Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "High value-added resource utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolytic manganese slag microcrystalline glass and preparation method thereof

The invention discloses electrolytic manganese slag microcrystalline glass and a preparation method thereof, which relate to microcrystalline glass prepared from industrial wastes and a method thereof. The raw materials of the electrolytic manganese slag microcrystalline glass comprise electrolytic manganese slag, calcium carbonate, quartz sand and magnesium carbonate. The method comprises the following steps: mixing the raw materials evenly; then founding basic glass; molding the basic glass; performing nucleation and crystallization on the basic glass; and annealing and processing the basic glass into a finished product. The electrolytic manganese slag microcrystalline glass has the characteristics of fewer raw material components (only four types), high content of the electrolytic manganese slag (75 to 99.7 percent), simple preparation method, low production energy consumption, environmental protection and the like. The electrolytic manganese slag microcrystalline glass prepared by the method can be widely used as architectural decorative materials.

Owner:CHONGQING UNIV

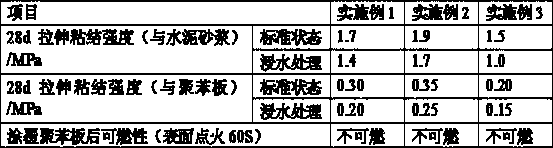

Interface mortar with ardealite-based hydraulicity composite cementing material as cementing material

The invention belongs to the technical field of building materials and particularly relates to interface mortar with an ardealite-based hydraulicity composite cementing material as a cementing material. The interface mortar is composed of ardealite, a slag powder, coal ash, metakaolin, a copper tailing slag powder, red mud, ordinary Portland cement, aluminate cement, quartz sand, a quartz powder,chesterite, calcium bentonite, a polycarboxylate-type water reducing agent, cellulose ether and latex powder. By adopting the interface mortar, the binding property of a base wall and a heat preservation layer in a wall heat preservation system can be effectively improved, the peeling risk of the heat preservation layer of a building wall can be reduced, and environment security problems caused bypiling of industrial ardealite can be also solved. When the interface mortar is produced, a great amount of industrial solid wastes such as non-calcined ardealite, coal ash, copper tailing slag powder and red mud are used, so that the interface mortar has the outstanding advantages of being low in energy consumption, low in cost, low in emission, and the like. The interface mortar is applied to heat preservation systems of various building walls, and the like.

Owner:TONGJI UNIV

Hydrogen production catalyst prepared from waste commercial vanadium titanium denitration catalyst and preparation method

InactiveCN110075841ASolve processing problemsGreat economyHydrogenMetal/metal-oxides/metal-hydroxide catalystsActive componentResource utilization

The invention discloses a hydrogen production catalyst prepared from a waste commercial vanadium titanium denitration catalyst and a preparation method. The hydrogen production catalyst uses ceramic granules as a carrier and nanogold as a catalytic active component; the ceramic granules are prepared from the waste commercial vanadium titanium denitration catalyst, diatomite, pseudo-boehmite and amoulding agent; the ceramic granular catalyst comprises the following components according to a mass ratio of the waste commercial vanadium titanium denitration catalyst, the diatomite, the pseudo-boehmite, the moulding agent and the catalytic active component of (80-90):(2-4):(1-5):(6-7):(0.1-0.5). The prepared hydrogen production catalyst not only can achieve high-added value resource utilization of the waste commercial vanadium titanium denitration catalyst, but also is applicable to a reforming hydrogen production reaction of small organic molecules such as methanol, has the advantages ofhigh H2 selectivity, small low active component load, low cost and the like and is wide in application prospect, namely, the hydrogen production catalyst has major social and economic benefits such asenvironmental protection, turning of wastes into treasures and the like.

Owner:GUODIAN SCI & TECH RES INST

Desulfurizing agent with red mud waste residues as active raw material as well as preparation method and application thereof

ActiveCN111116224ASolve secondary pollutionSolve the utilization of high value-added resourcesDispersed particle separationCeramicwarePelletizingAluminium industry

Owner:南京环福新材料科技有限公司

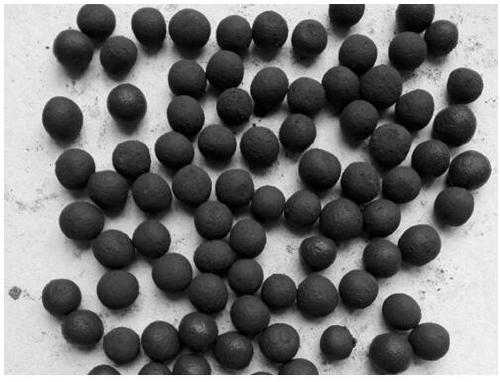

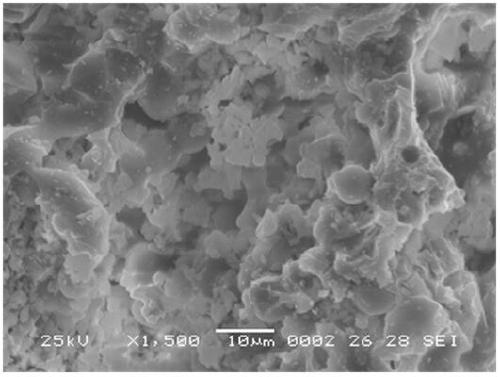

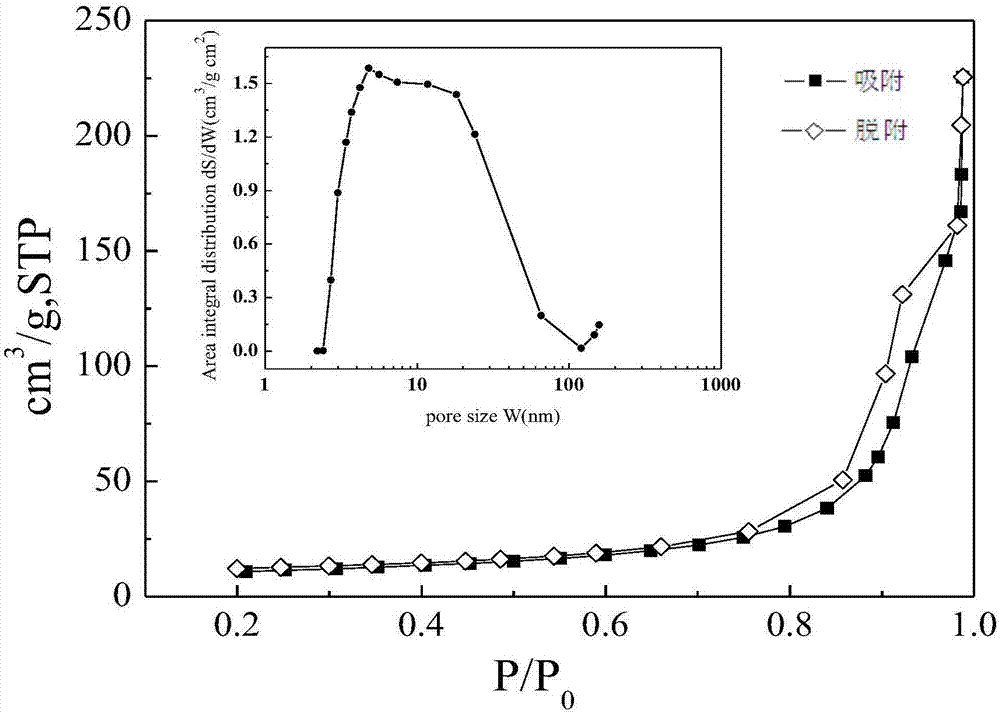

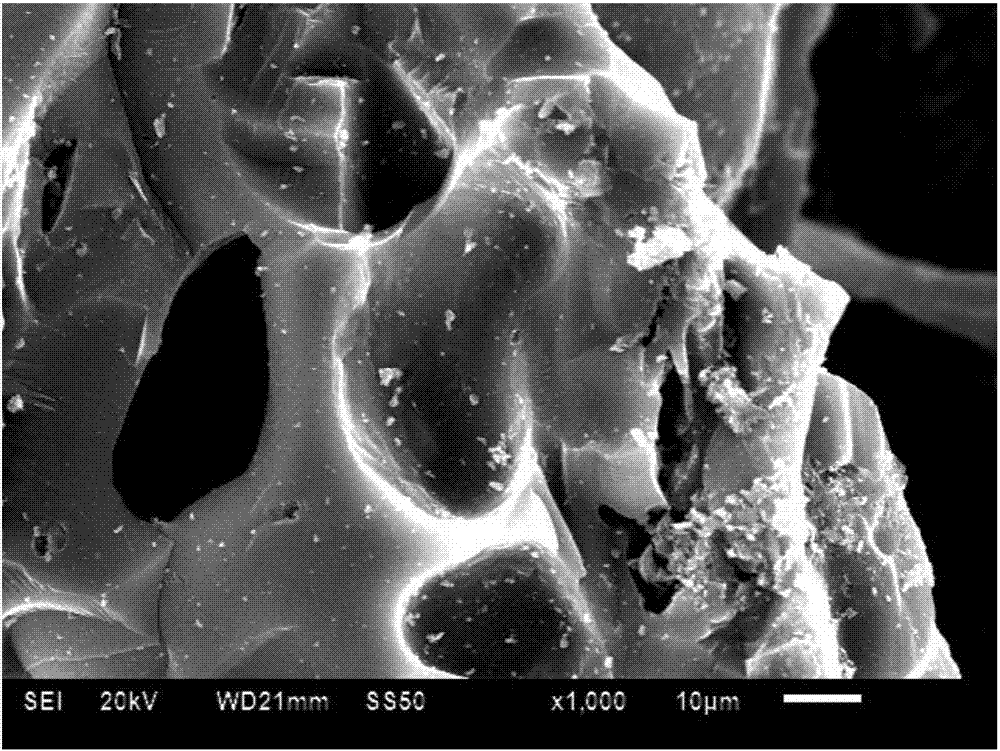

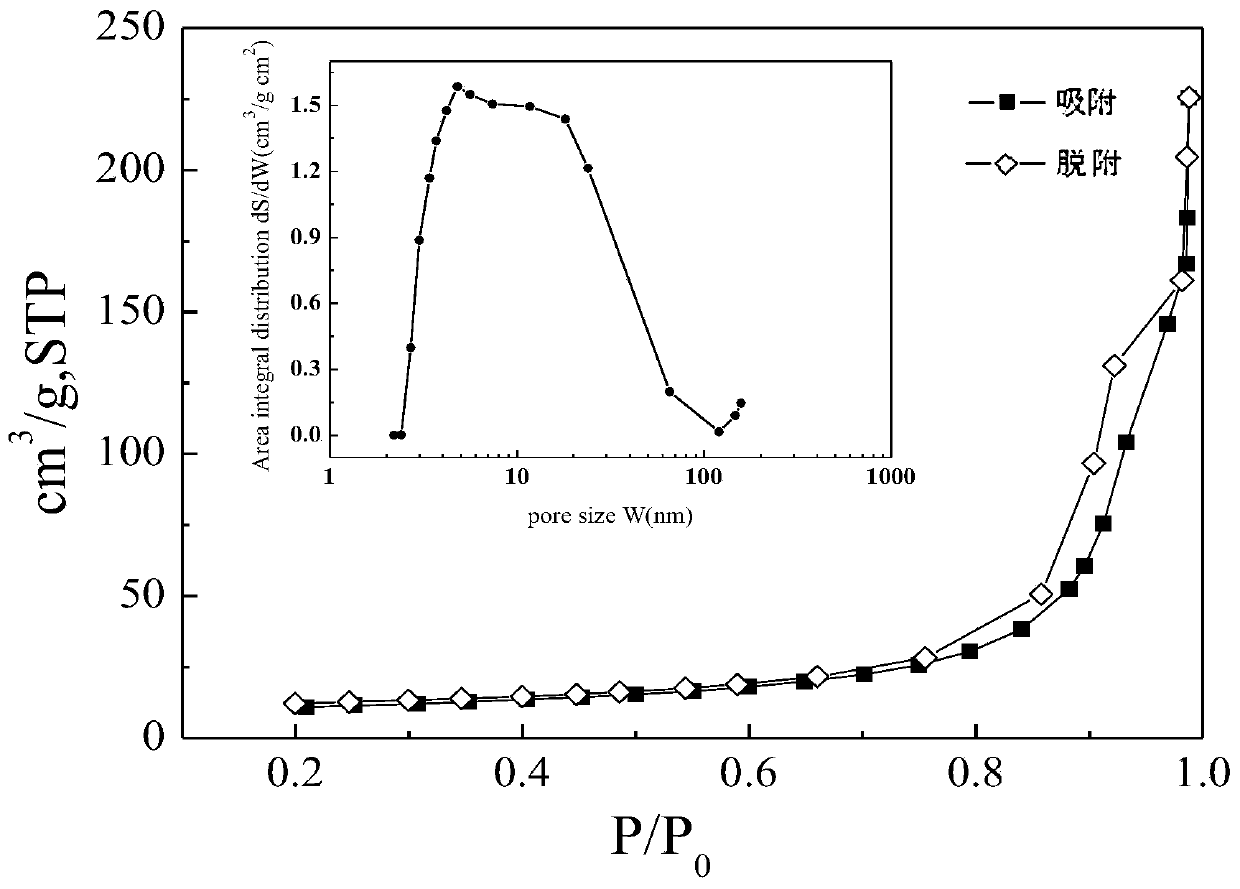

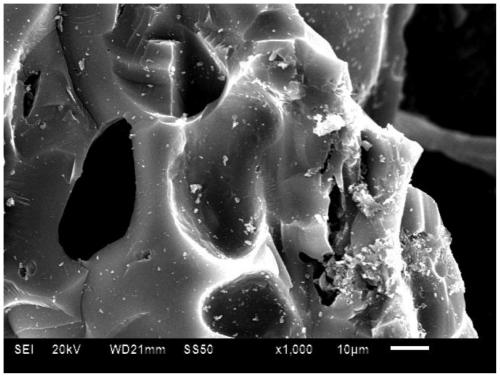

Method of preparing hierarchical pore ceramsite from red mud and coal ash

PendingCN109942274ALarge specific surface areaImprove removal efficiencyCeramic materials productionCeramicwareRed mudIon exchange

The invention discloses a method of preparing hierarchical pore ceramsite from red mud and coal ash and belongs to the technical field of solid waste reclamation and environment. The method comprisesthe following steps: uniformly mixing the coal ash, the red mud and agriculture and forestry waste residues, and adding water and uniformly stirring the mixture to obtain mixed mud B; granulating themixed mud B to obtain a ceramsite blank sample C; putting the ceramsite blank sample C at 90-120 DEG C to be treated for 60-180 min and then putting the ceramsite blank sample at 350-450 DEG C to be treated for 30-60 min at a constant temperature to obtain pre-ceramsite; putting the pre-ceramsite at 950-1150 DEG C to be roasted for 20-70 min and then carrying out furnace cooling to obtain hierarchical pore ceramsite D; and adding the hierarchical pore ceramsite D into an alkaline solution, then adding sodium metaaluminate to be uniformly mixed to obtain a ceramsite treatment system, heating the same at a uniform speed till the temperature of the ceramsite treatment system is 80-140 DEG C and treating the same for 6-24 hours, extracting the ceramsite, washing the same to be neutral and drying the ceramsite to obtain the hierarchical pore ceramsite. The hierarchical pore ceramsite has two duct structures: macropores and micropores and has good water absorption, water retaining property and ion exchange function.

Owner:KUNMING UNIV OF SCI & TECH

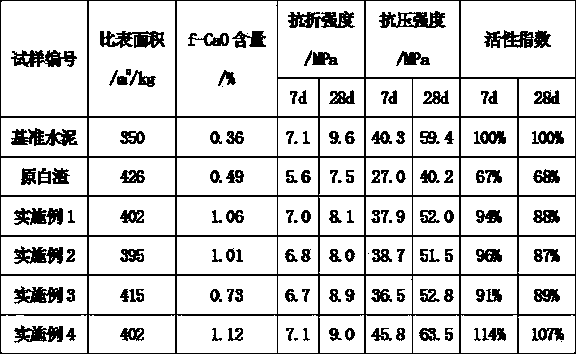

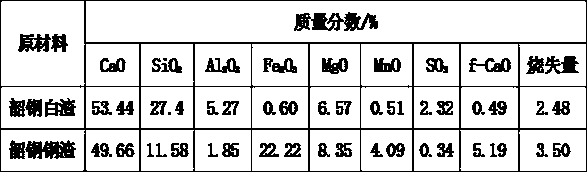

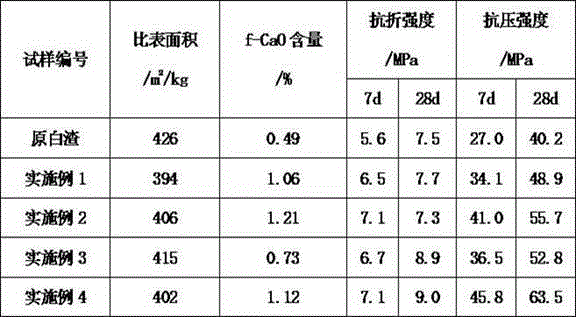

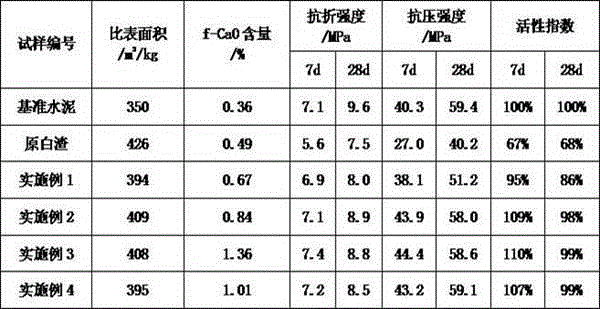

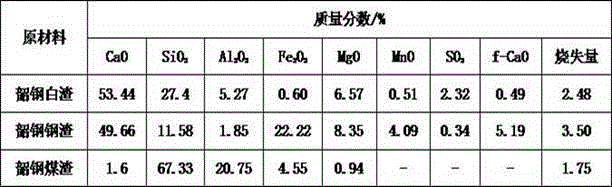

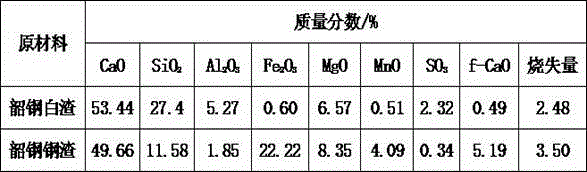

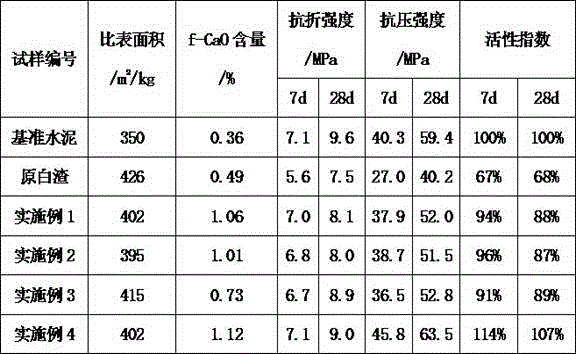

Adjusting material for carrying out high temperature activation treatment on electric furnace white slag, and application thereof

ActiveCN104016599AImprove mineral compositionImprove gelling activityCement productionCalcium in biologyChemical reaction

The invention relates to an adjusting material for carrying out high temperature activation treatment on electric furnace white slag. The adjusting material comprises the components by weight: 0-55% of converter slag, 40-100% of calcareous material (in terms of CaO) and 0-5% of auxiliary materials. When the adjusting material is in practical use, the converter slag, the calcareous material and the auxiliary materials are mixed according to the above weight proportions to be used as the adjusting material; the adjusting material is ground into fine powder; 15-35% by weight of the adjusting material and 65-85% by weight of the white slag are mixed uniformly; the mixture is calcined, so that chemical reactions occur among components; air cool or water cool are carried out after calcination; and a calcined product is broken and ground to prepare the activated white slag powder. 28 d activity indicator is higher than 85% when Blaine specific surface area is 400-500 m<2> / kg. Mineral composition of the white slag is optimized essentially; gelatinization activity of the white slag is increased; high value-added resource utilization rate of the white slag and steel slag solid wastes is increased; and environment protection is facilitated.

Owner:SHAOGUAN COLLEGE

Rare earth loaded function material prepared from rare-earth tailings and preparation method of material

InactiveCN104069806AEfficient use ofEffectively useOther chemical processesAlkali metal oxides/hydroxidesStructure of the EarthExpanded clay aggregate

The invention aims at solving the problems of low resource utilization rate of rare-earth tailings and low values of resource products in China and discloses a particle rare earth loaded function material prepared from tailings as main raw materials. A preparation method of the particle rare earth loaded function material comprises the following main key processes: (1) preparing ceramsites of the rare-earth tailings; (2) zeolitizing the ceramsites; and (3) loading rare earth on the zeolitized ceramsites. The prepared porous particle rare-earth loaded function material comprises developed pore structures and rare earth function components and has the advantages of large specific surface area, strong adsorption capacity and easiness in solid-liquid separation and the like.

Owner:INNER MONGOLIA UNIVERSITY

Masonry mortar made from mine tailings

InactiveCN102260066ASolving resource constraintsAchieve scale developmentSolid waste managementRural landSoil science

The invention belongs to the technical field of building materials, in particular to a masonry mortar made from tailings. It is characterized in that the production of masonry mortar made of tailings that meets M2.5-M10 has the following proportions by weight: 100-245 parts of Portland cement, 1270 parts of tailings, 234-56 parts of lime paste, and 1 part of water reducing agent. -1.36 parts, water 277 parts. The present invention uses tailings with a particle size of 0.15-0.3 mm, which is obtained by grading through screening equipment in the gravity separation and magnetic separation processes, and its purpose is to avoid the incorporation of harmful components and the fluidity of the mortar with too fine tailings particle size, which cannot construction. Its production cost is about 20 yuan per cubic meter, about 60 yuan can be saved per cubic meter, and the annual benefit is about 180 million yuan. In addition, the replacement of river sand with tailings can also reduce the discharge of mine tailings, extend the service life of tailings ponds, reduce the damage to natural rivers caused by the mining of river sand, and ultimately achieve the purpose of less rural land occupation and environmental protection.

Owner:ANSTEEL GRP MINING CO LTD

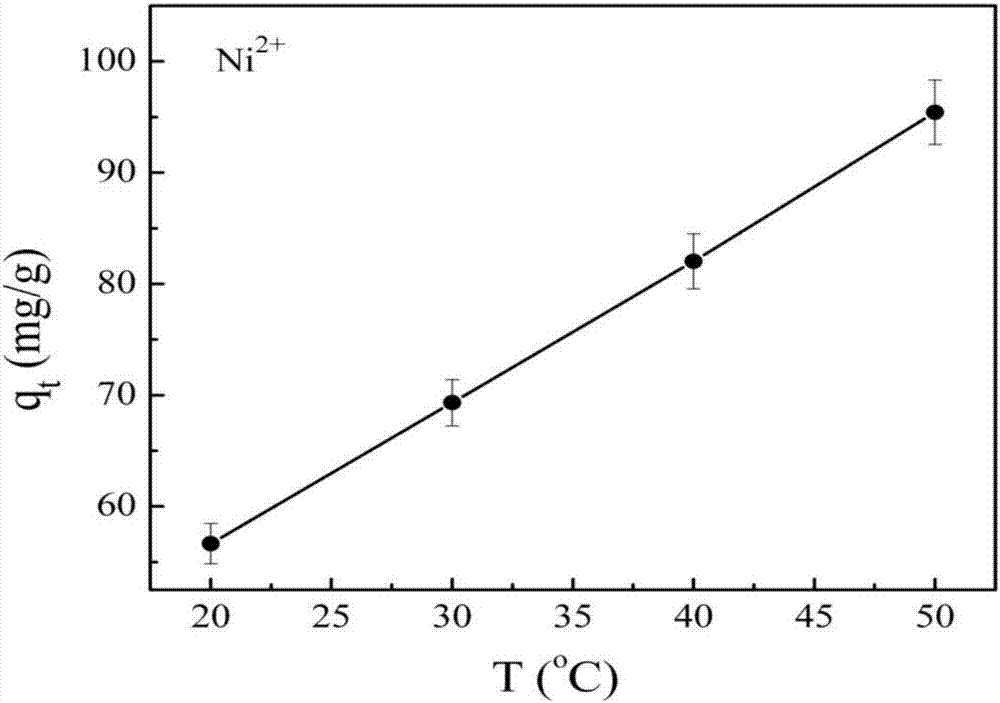

Method for preparing magnetic adsorbent by using waste zinc manganese batteries and biomass

ActiveCN107321312ARaw materials are easy to getHigh value-added resource utilizationOther chemical processesWater contaminantsEnvironmental resistanceSorbent

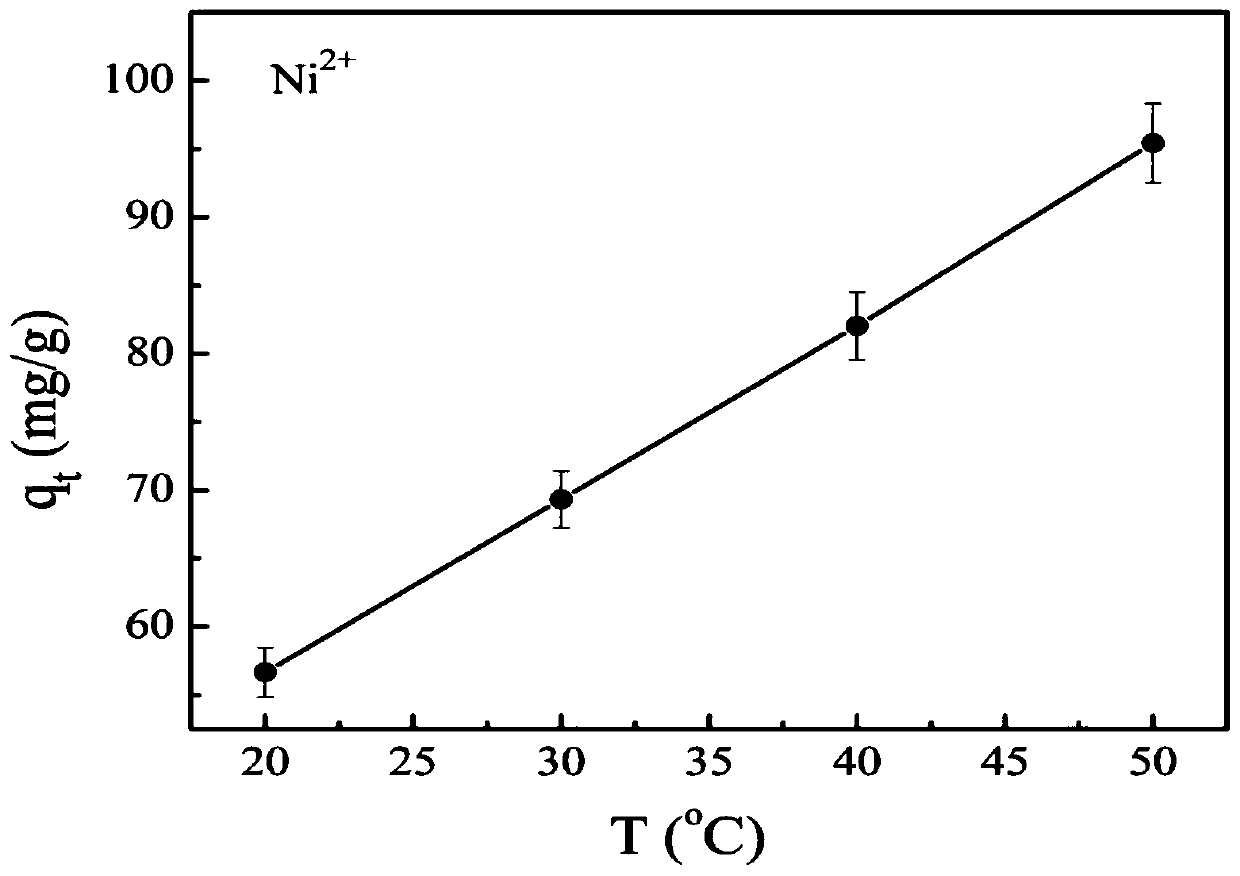

The invention discloses a method for preparing a magnetic adsorbent by using waste zinc manganese batteries and biomass. The method is characterized by including the steps of firstly, preprocessing the electrode materials of the waste zinc manganese batteries to prepare a biological leaching solution; secondly, conducting indirect biological leaching; finally, conducting hydrothermal carbonization and synthesis to obtain the magnetic adsorbent. Zinc manganese metal in the waste zinc manganese batteries is leached by using a sulphur-oxidising bacteria and ferrous-oxidizing bacteria filtrate, and the method has the advantages of easy availability of raw materials, simple operation, high efficiency and environmental protection; the waste zinc manganese batteries and the biomass are translated into biological activated carbon with magnetic adsorption properties, and the high value-added resource utilization of the waste batteries and the waste biomass can be achieved.

Owner:YANAN UNIV

Electric furnace white slag performance optimization treatment method

ActiveCN104058610AImprove mineral compositionImprove gelling activityCement productionChemical reactionSlag

The invention relates to an electric furnace white slag performance optimization treatment method which comprises the following processing steps: taking a certain amount of electric furnace white slag; adding the following materials in percentage by weight into the electric furnace white slag, 20-35% of calcium-based material (measured by CaO), 0-2% of aluminum-based material (measured by Al2O3), 0-5% of iron-based material (measured by Fe2O3) and 0-2% of fluxing agent (measured by CaF2); mixing, and then grinding into fine powder; calcining the fine powder at high temperature to ensure that the components are subjected to chemical reaction; after calcining is finished, quickly cooling through air cooling; and then, crushing and milling the mixture to finally obtain white slag having high gelation activity. Thus, the mineral composition of the white slag is optimized; the gelation activity of the white slag is improved; and meanwhile, the recycling utilization ratio of the white slag solid waste is increased, thereby being beneficial to environment protection.

Owner:SHAOGUAN COLLEGE

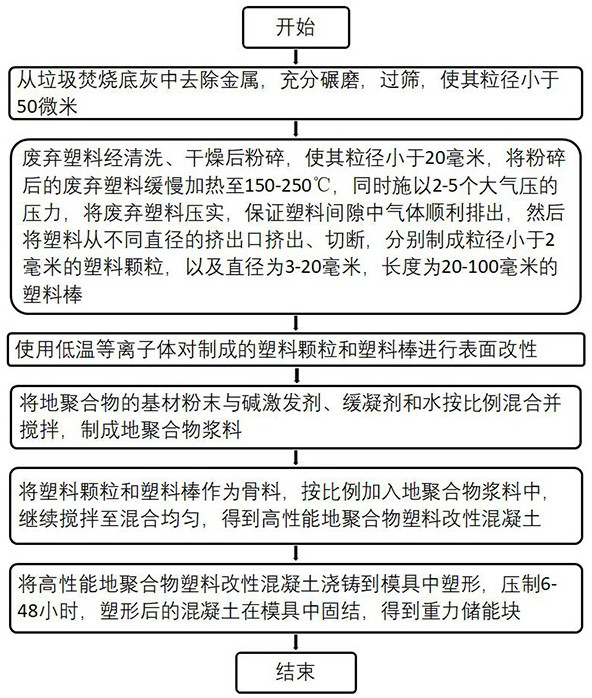

Method for preparing gravity energy storage block by using waste incineration bottom ash and waste plastic

PendingCN114772991AHigh value-added resource utilizationReduce consumptionCeramic shaping apparatusCompression moldingBottom ash

The invention discloses a method for preparing a gravity energy storage block by using waste incineration bottom ash and waste plastics. The method comprises the following steps: (1) preparing base material powder of a geopolymer from the waste incineration bottom ash; (2) preparing the waste plastic into fine aggregate and coarse aggregate of the modified concrete; (3) carrying out surface modification on the prepared plastic particles and plastic rods by using low-temperature plasma; (4) preparing geopolymer slurry; (5) preparing high-performance geopolymer plastic modified concrete; and (6) compression molding of the gravity energy storage block. According to the method, high-added-value resource utilization of solid waste is achieved, and a new thought is provided for harmless resource treatment of the waste incineration bottom ash and the waste plastic.

Owner:CHINA TIANYING

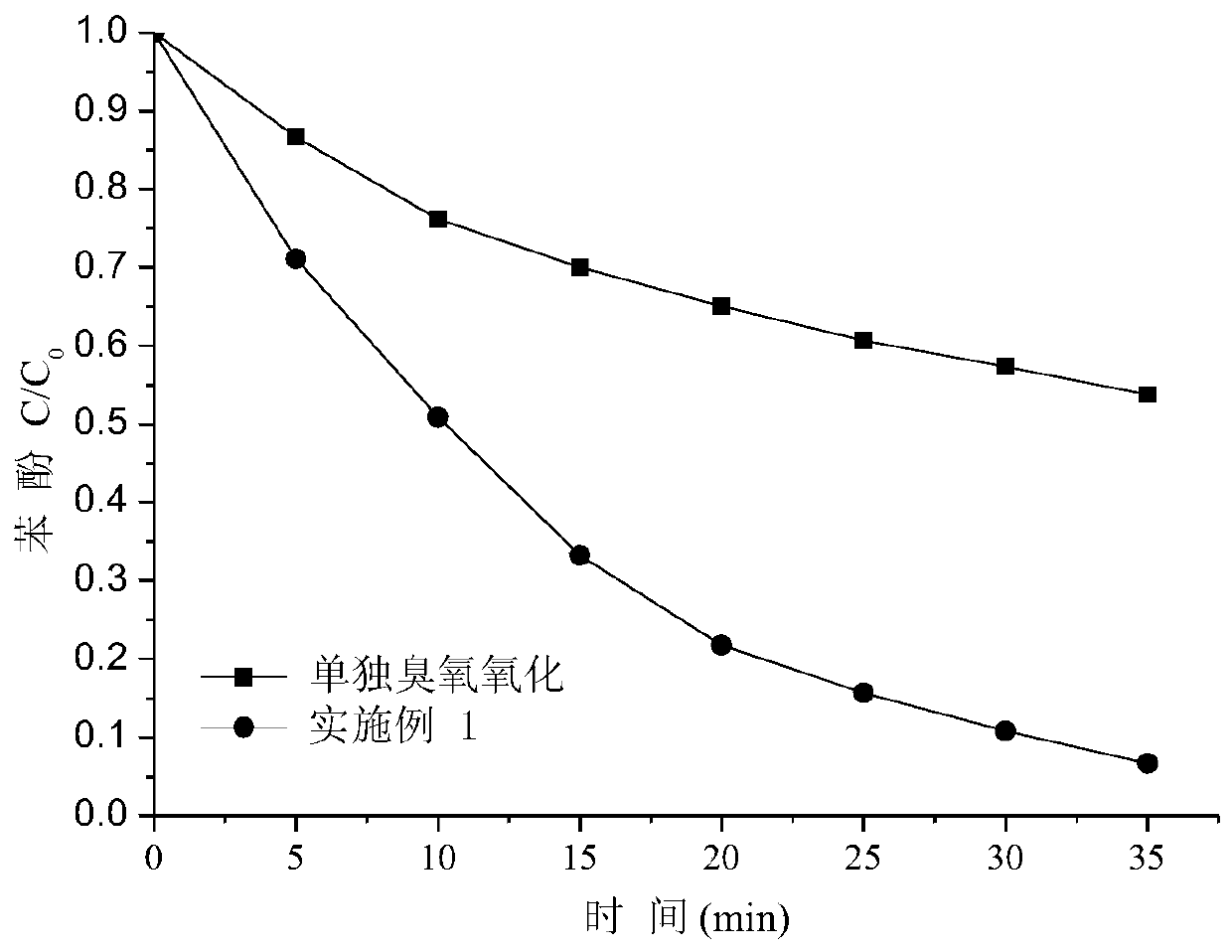

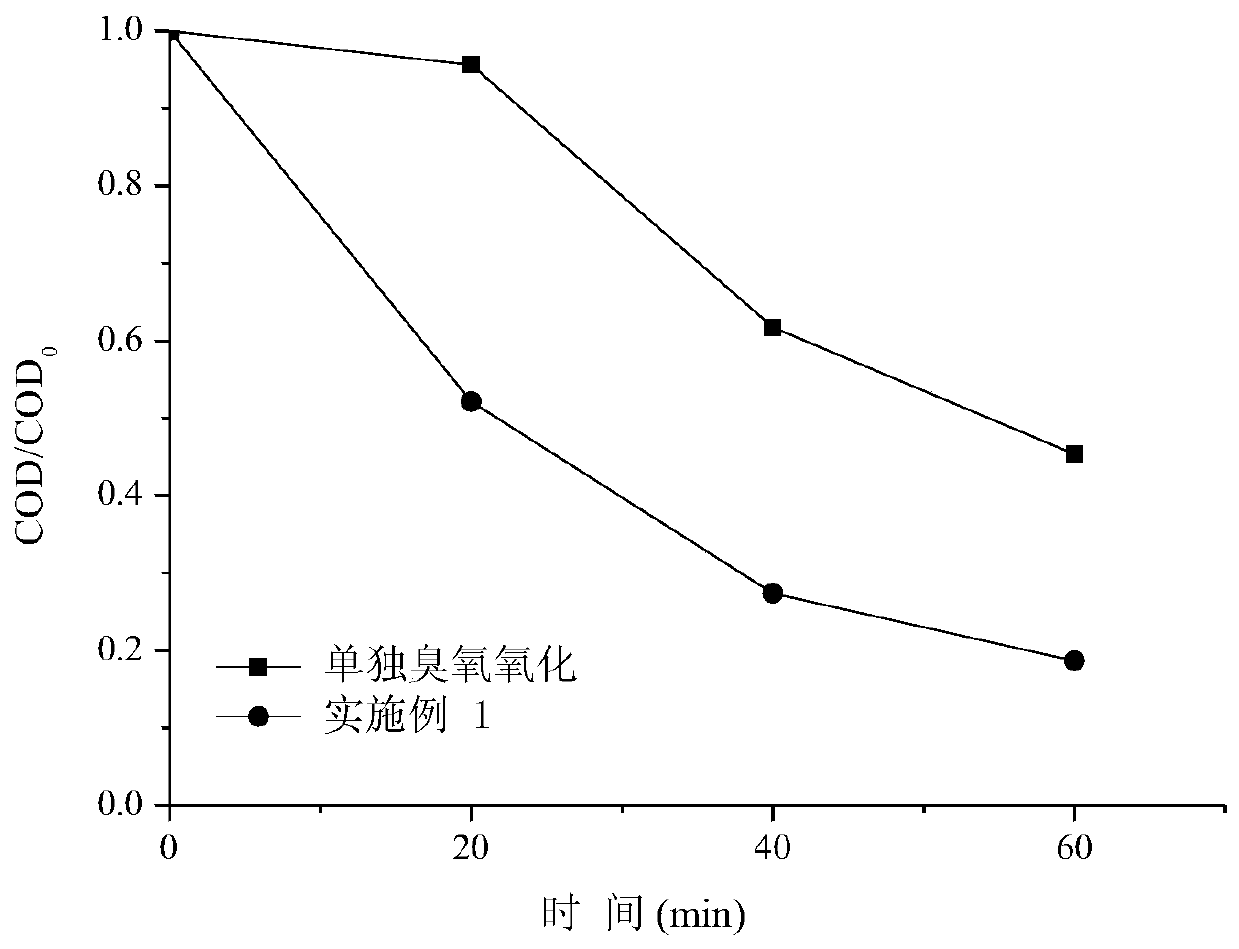

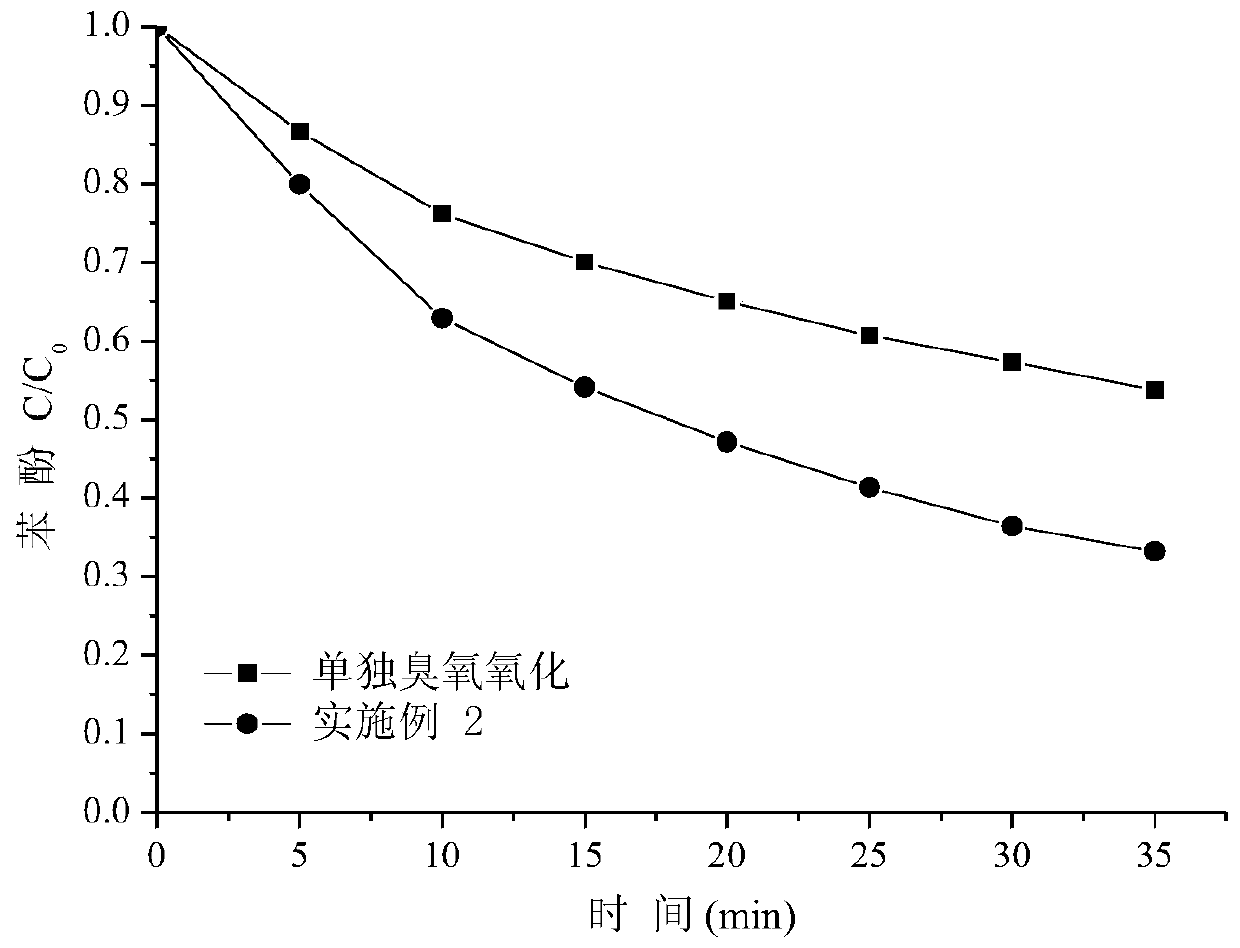

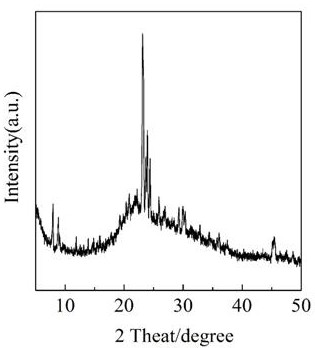

Composite-carrier catalyst for ozone oxidation as well as preparation method and application of catalyst

InactiveCN110013859AHigh value-added resource utilizationPromote resource utilizationWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsResource utilizationCarbonization

The invention discloses a composite-carrier catalyst for ozone oxidation as well as a preparation method and application of the catalyst, and belongs to the technical fields of water treatment and agricultural waste resource utilization. The composite-carrier catalyst for the ozone oxidation comprises a composite carrier, active components and auxiliary agents; the composite carrier is obtained bymixing the catalyst carrier and pretreated and activated agricultural waste straw, performing granulation and performing carbonization; the active components are Fe and Mn; and the auxiliary agents are Ce and Ti. The composite-carrier catalyst for the ozone oxidation provided by the invention has the characteristics of high catalytic efficiency, environmental friendliness of the active componentsand uneasy dissolution, not only solves the problems of high costs of a catalyst for ozone oxidation and low treatment efficiency of wastewater in the prior art, but also realizes resource utilization of the agricultural waste straw.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Preparation method and application of adjusting material for electric furnace white slag thermal refining treatment

The invention relates to an adjusting material for electric furnace white slag thermal refining treatment. The adjusting material comprises the following components in percentage by weight: 25-35% of steel slag, 12-17% of coal cinder, 50-60% of a calcium material (based on CaO) and 0-2% of an auxiliary material, wherein the sum of the components is 100%. The converter steel slag, the coal cinder, the calcium material and a small amount of auxiliary material are mixed to form the adjusting material; and after the adjusting material is mixed with white slag uniformly, chemical reaction happens at a high temperature, so that the mineral composition of the white slag is substantially optimized, the gelatinization activity of the white slag is improved, meanwhile, high additional value recycle rate of solid wastes such as the white slag, steel slag and coal cinder is increased, and the adjusting material is favorable for environmental protection.

Owner:SHAOGUAN COLLEGE

Method for resource utilization of waste copper adsorbent

ActiveCN112316896AEliminate pollutionHigh industrial applicabilityOther chemical processesWater contaminantsEnvironmental chemistryCatalytic degradation

The invention discloses a method for resource utilization of a waste copper adsorbent. The method is characterized in that the waste copper adsorbent obtained after copper adsorption is subjected to vacuum drying and roasting and is then used for catalytic degradation of rhodamine B. According to the method disclosed by the invention, the degradation time of rhodamine B can be greatly reduced, andthe removal rate of rhodamine B can be up to 99% or above, so the purpose of treating the waste with the waste is achieved, and good application prospects are obtained.

Owner:KUNMING UNIV OF SCI & TECH

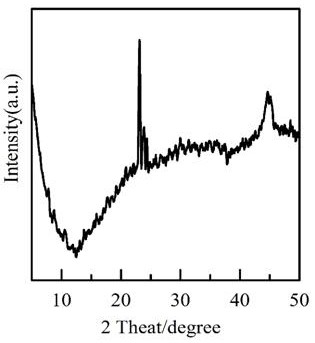

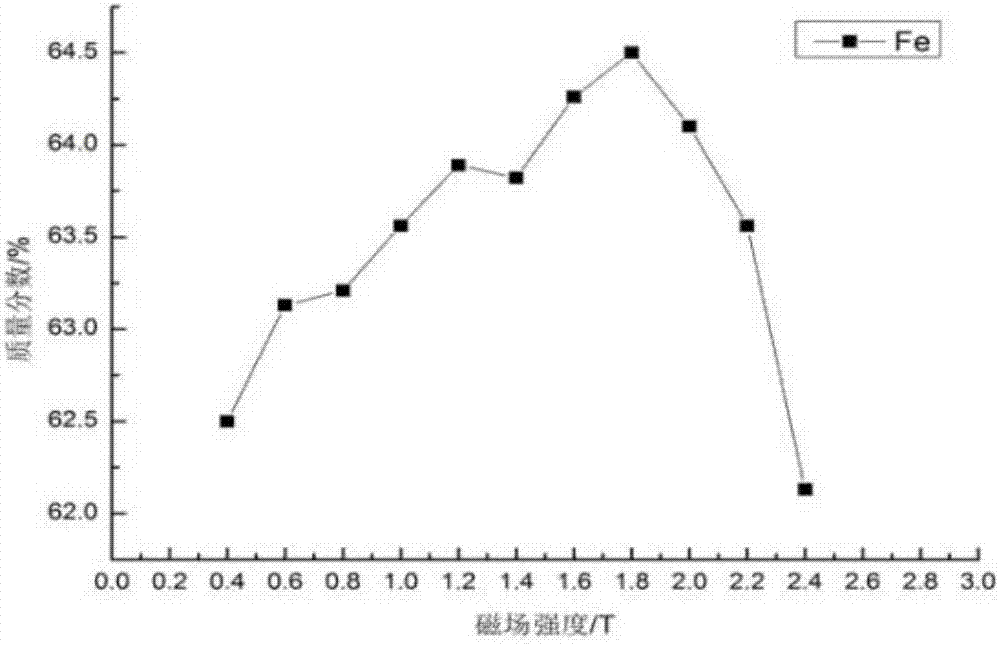

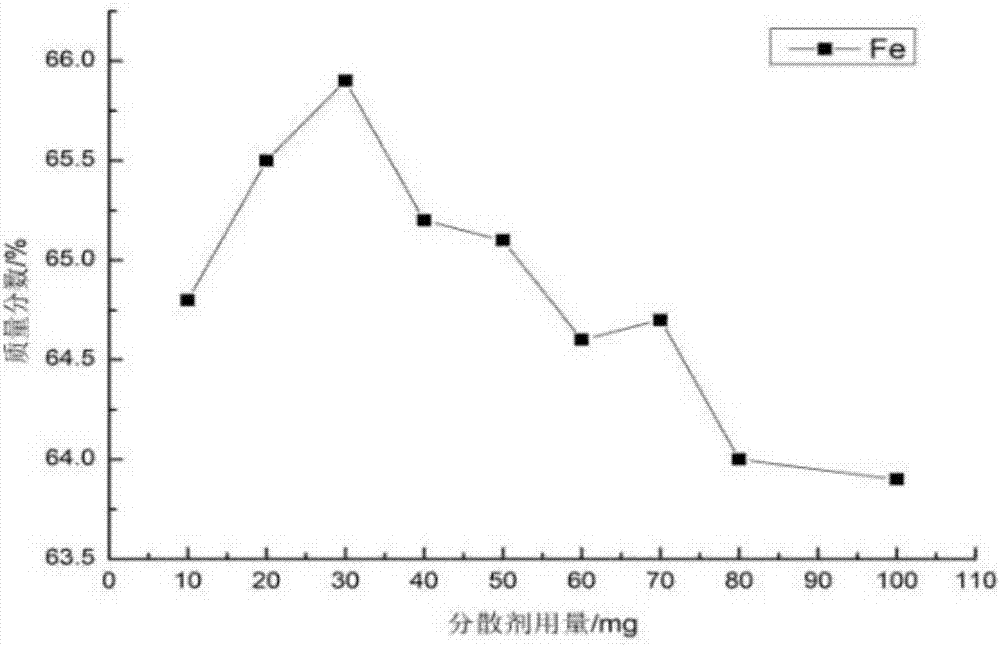

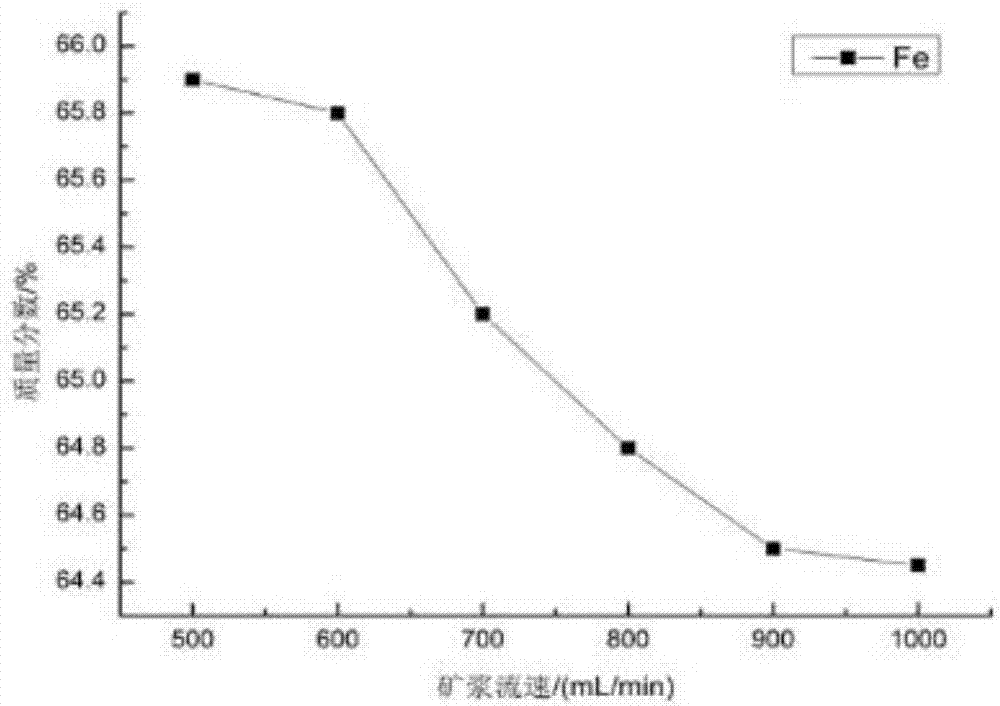

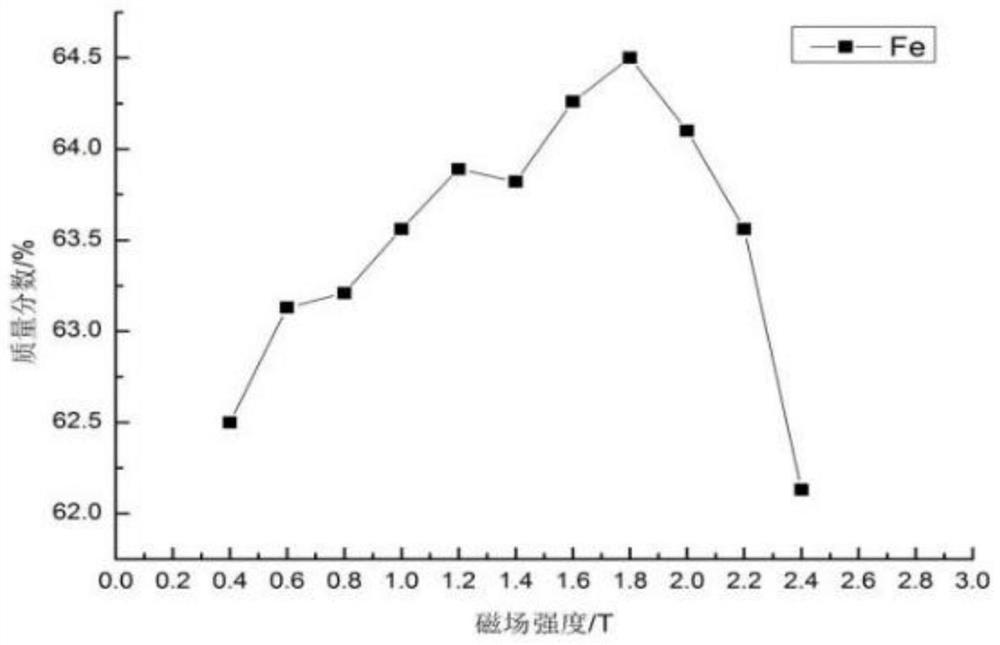

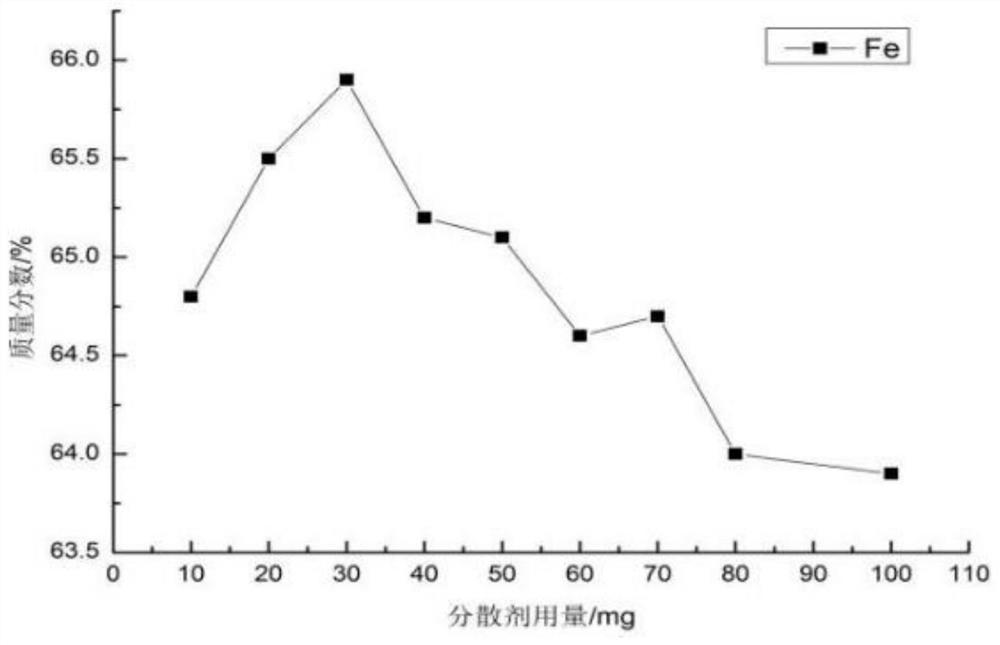

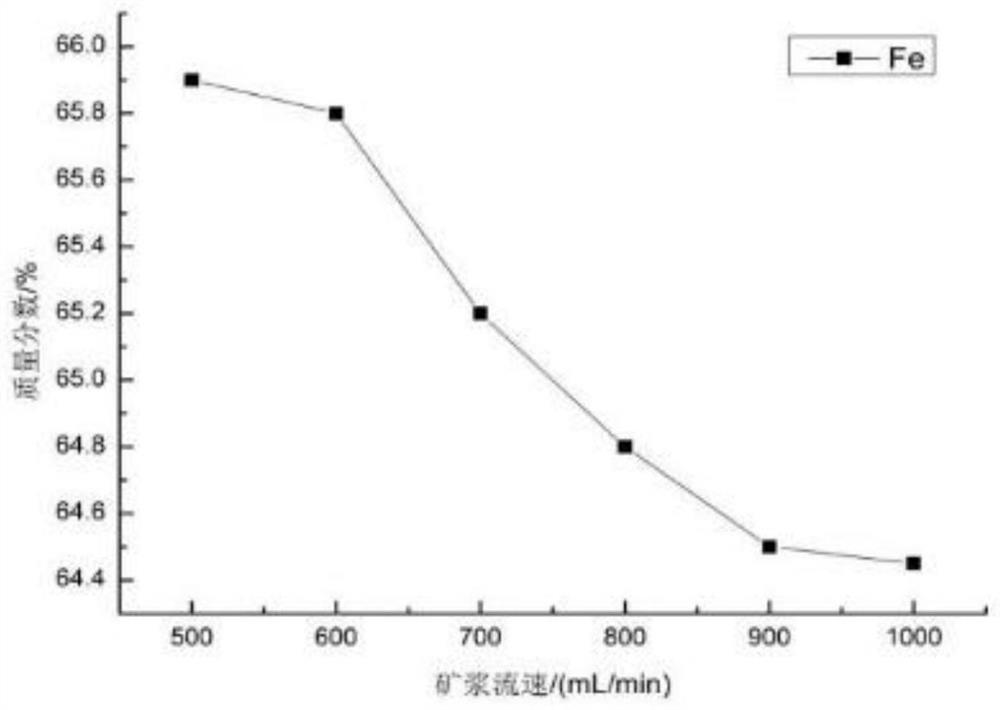

Method for preparing high-purity iron oxide with converter dedusting ash using superconduction high gradient magnetic separation (HGMS) technology

ActiveCN107309082AReduce energy consumptionGood effectHigh gradient magnetic separatorsResource utilizationAdditional values

The invention provides a method for preparing high-purity iron oxide with converter dedusting ash using a superconduction high gradient magnetic separation (HGMS) technology. According to the method, the HGMS technology is used for separating the converter dedusting ash so that the iron oxide can be extracted, then the iron oxide is roasted to prepare high-purity iron oxide red, and cyclic utilization of the converter dedusting ash at the outside of a steel mill can be realized; and moreover, the additional value of the iron oxide red is high, large-scale and high-additional-value resource utilization of waste is achieved, iron elements can be enriched to 65% or above, the number reaches 93% or above when the iron elements are converted into Fe2O3, and the recovery rate of the iron elements reaches 95% or above. The method for preparing the high-purity iron oxide with the converter dedusting ash using the superconduction HGMS technology has ultrahigh separation and extraction capacity and ultralow energy consumption (the energy consumption accounts for 1 / 10-1 / 4 that of a conventional magnetic separation method), the effect is good and energy can be saved obviously; and the method is particularly suitable for enrichment, separation and extraction of the iron elements in iron-containing solid powder such as the converter dedusting ash.

Owner:UNIV OF SCI & TECH BEIJING

Method for co-producing glucose and dietary fibers from multiple high-solid enzymes of sweet potato residues through synergetic enzymatic hydrolysis

InactiveCN106222213ASimple unit operationLow costFermentationFood scienceHigh concentrationHydrolysate

The invention provides a method for co-producing glucose and dietary fibers from multiple high-solid enzymes of sweet potato residues through synergetic enzymatic hydrolysis, and aims to provide a coupling integrated technology for co-producing high-concentration glucose and high-protein-content dietary fibers from the multiple high-solid enzymes of the sweet potato residues through synergetic enzymatic hydrolysis. The method comprises the steps of impurity removal and smashing of the sweet potato residues, pre-enzymatic hydrolysis of high solids of the sweet potato residues, liquefaction and sugaring of pre-enzymatic hydrolysate, solid-liquid separation of the enzymatic hydrolysate, preparation of a glucose solution from the enzymatic hydrolysate and preparation of the dietary fibers from enzymatic hydrolysis residues. According to the technical scheme provided by the invention, high-solid enzymatic hydrolysis with the sweet potato residue substrate content of 20 to 28.6 percent can be realized; the substrate conversion rate from the sweet potato residues into the glucose can be over 65 percent, and the high-purity sweet potato residue dietary fibers can be obtained. The method can assist in solving the problems that the deep processing technology for the sweet potato residues is in a low grade, produces single and low-value products, is short in industrial chain and the like, and a technical reference is supplied to the deep processing industries for the sweet potato residues, and even sweet potatoes, in China.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

A kind of titanium-based ceramics and its green preparation method

ActiveCN108341657BAvoid secondary pollutionHigh value-added resource utilizationCeramic materials productionClaywaresResource utilizationNational standard

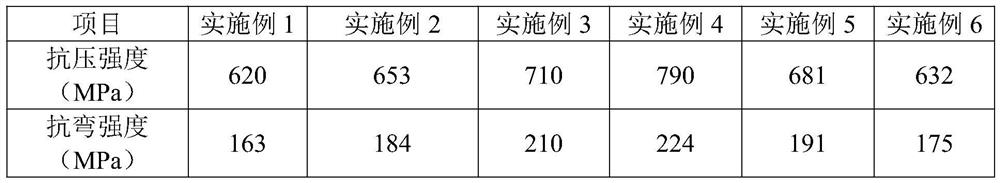

The invention discloses a titanium-based ceramic and a green preparation method thereof. The titanium-based ceramic is prepared through the following raw material components in parts by mass: 50-80 parts of a waste vanadium-titanium denitration catalyst, 3-10 parts of Al2O3, 1-6 parts of ZrO2, 0.2-1.5 parts of Co3O4, 0.5-1.5 parts of TiB2, 8-15 parts of CaO, and 0.5-1.2 parts of a V-element solidsolvent. The titanium-based ceramic integrates the compressive strength and the flexure strength; the compressive strength is 653MPa or more, and the flexure strength is 184MPa or more; the V elementleaching rate is far less than that of the limit value required by national standard; and high added-value resource utilization of the wasted toxic vanadium-titanium denitration catalyst is achieved.

Owner:广东恒创陶瓷有限公司

Electrolytic manganese slag glass-ceramic and preparation method thereof

Owner:CHONGQING UNIV

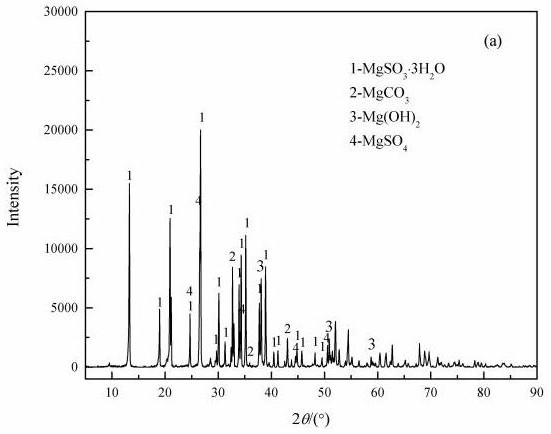

Method for synergistically degrading azo dye by ultrasonic-ultraviolet-semi-dry desulfurization ash

PendingCN112897781AHigh value-added resource utilizationTo achieve the purpose of treating waste with wasteWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsReduction treatmentUltraviolet lights

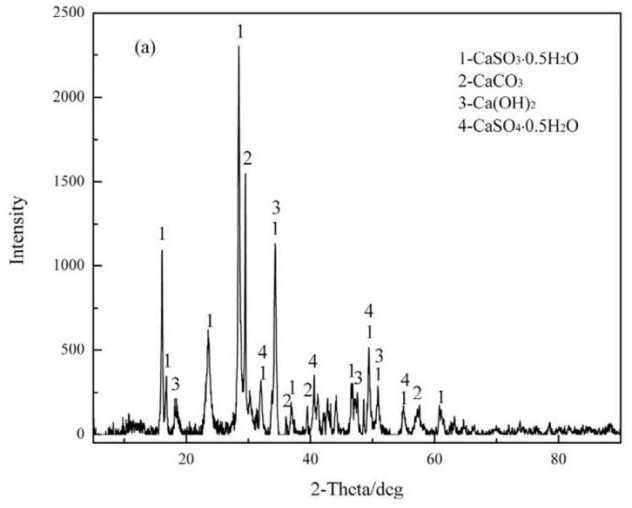

The invention belongs to the technical field of solid waste resource utilization and wastewater advanced reduction treatment, and particularly relates to a method for synergistically degrading an azo dye through ultrasonic-ultraviolet-semi-dry desulfurization ash. The azo dye in the wastewater is degraded and removed by utilizing strong reducing free radicals generated by an advanced reduction system consisting of ultrasound, ultraviolet and desulfurized fly ash under the synergistic effect of ultrasound and ultraviolet light. The method mainly comprises the following steps: (1) grinding and sieving wastes (desulfurized fly ash) generated by a stably operated semi-dry calcium flue gas desulfurization system, and bagging sieved powder for later use; (2) putting a certain amount of azo dye wastewater into a reaction tank, adding a certain amount of pretreated desulfurized fly ash, adjusting the reaction pH of the solution, and treating the wastewater under ultrasonic and ultraviolet lamp irradiation conditions; and (3) adjusting the treated wastewater to be neutral, standing for a period of time, and filtering the effluent. According to the process, high-added-value resource utilization of the waste is achieved while harmless treatment is conducted on the waste water and the waste, the purpose of treating waste with waste is achieved, and remarkable economic benefits, social benefits and environmental benefits are achieved.

Owner:SHENYANG UNIV

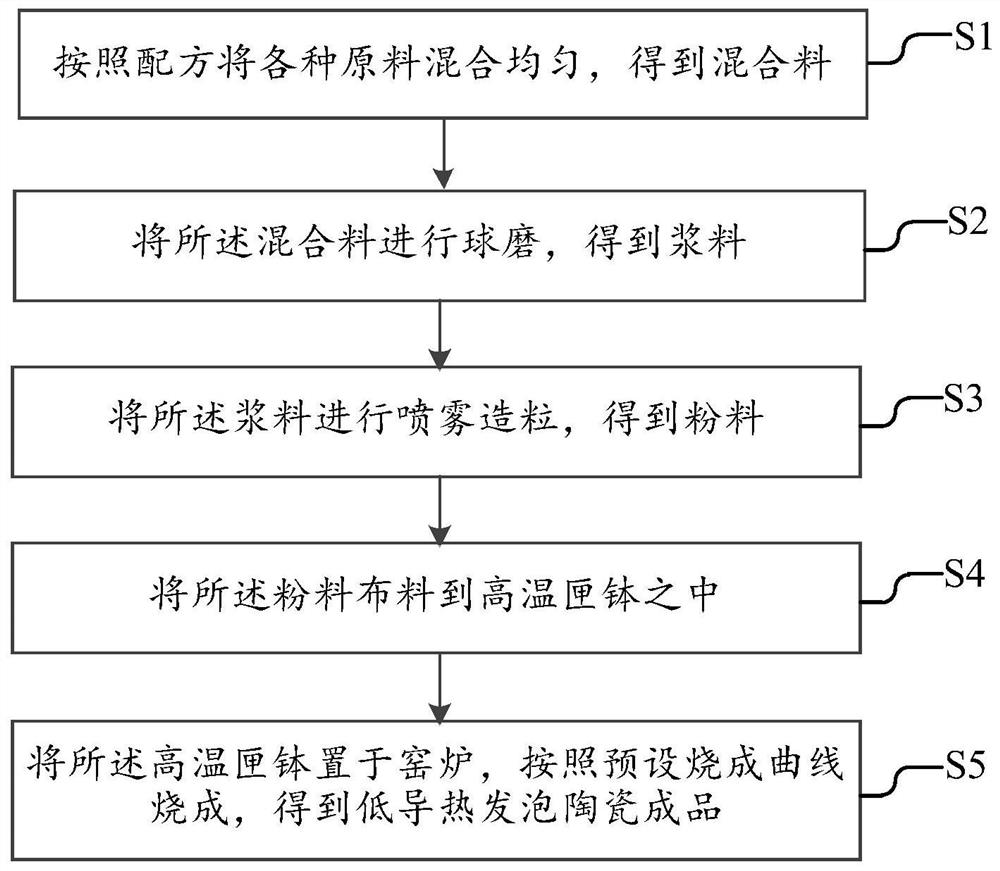

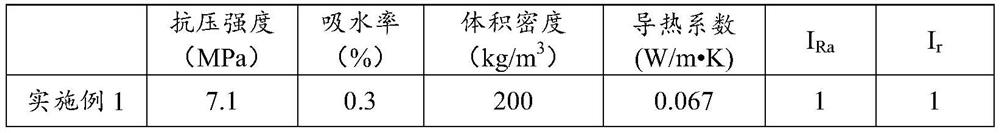

A kind of foamed ceramic produced by using tailings of iron and steel plant and preparation method thereof

The invention discloses a foamed ceramic produced by using the tailing slag of a steel plant, which is mainly made of the following raw materials in parts by weight: 50-60 parts of Luoyuan red tailings, 15-20 parts of furnace slag, 10-20 parts of steel slag, quartz sand 5-10 parts, 4-10 parts of clay, 0.5-5 parts of foaming agent, 0.1-1 part of stabilizer; the sum of the parts by weight of each raw material is 100 parts; in the steel slag, CaO+MgO≥65wt%, In the slag, SiO 2 +Al 2 o 3 ≥80wt%. The invention realizes the high value-added resource utilization of the tailing slag of the iron and steel plant by compounding the steel slag and the furnace slag. Correspondingly, the present invention also discloses a method for preparing the above-mentioned foamed ceramics produced by using tailings from iron and steel plants.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

A rare earth-loaded functional material prepared from rare earth tailings and its preparation process

InactiveCN104069806BEfficient use ofEffectively useOther chemical processesAlkali metal oxides/hydroxidesResource utilizationRare earth

Aiming at the dilemma that the degree of resource utilization of rare earth tailings in my country is very low and the value of resource products is not high, the invention proposes to use the tailings as the main raw material to prepare granular rare earth-loaded functional materials. The key technical process mainly includes: (1) preparation of rare earth tailings ceramsite; (2) zeolite process of ceramsite; (3) zeolite ceramsite rare earth loading process. The prepared porous granular rare earth-loaded functional material contains developed pore structure and rare earth functional components, and has the advantages of large specific surface area, strong adsorption capacity, and easy solid-liquid separation.

Owner:INNER MONGOLIA UNIVERSITY

A kind of zeolite ceramsite prepared by using coal gangue and construction waste and its preparation technology

InactiveCN104083945BReduce harm to the environmentHigh value-added resource utilizationOther chemical processesSustainable biological treatmentExpanded clay aggregateBiological filter

The invention discloses zolite ceramic prepared by utilizing coal gangue and construction waste and a preparation technology thereof. Construction waste and coal gangue are taken as main raw materials, and technological means such as sintering, hydro-thermal processing and the like are utilized for preparing the zeolite ceramic filter material. The technology comprises two key points: 1, sintering construction waste and coal gangue to form an internally-porous ceramic particle material; and 2, performing alkali hydro-thermal processing, so as to change the surfaces of the ceramic particles into a zeolite structure. The prepared porous biological filter material has a multi-stage pore structure and has the density close to the density of water. The prepared porous biological filter material is applicable to technologies of aeration biological filter tanks, oxidation tanks and the like in field of sewage processing, and also has functions of biofilm colonization, adsorption and removal of heavy metal ions, and the like.

Owner:INNER MONGOLIA UNIVERSITY

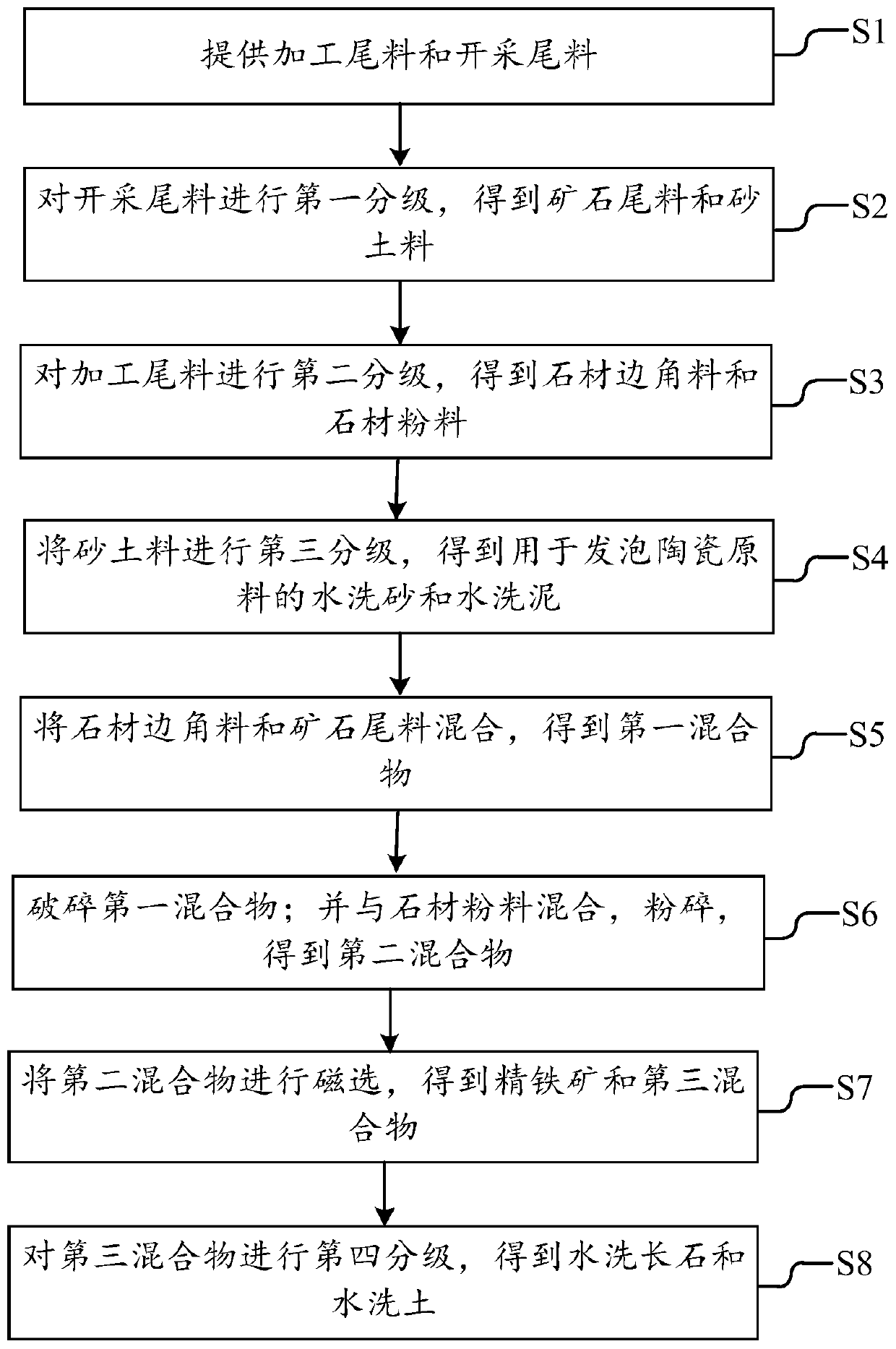

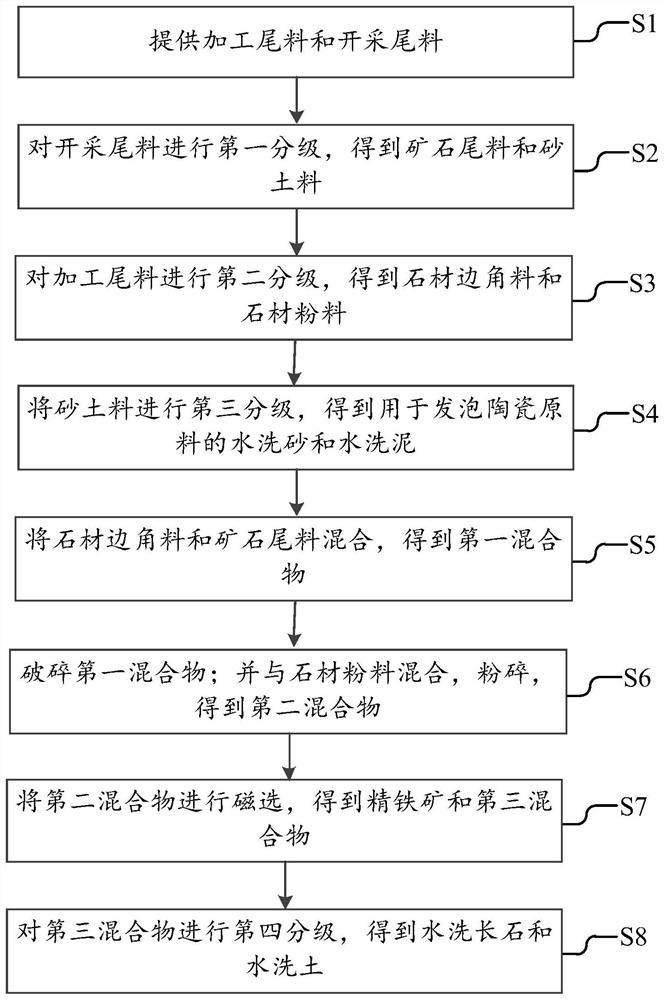

Comprehensive utilization method of Luoyuan red tailings

ActiveCN110563444ATake advantage ofHigh purityCeramic materials productionClaywaresNatural resourceBrick

The invention discloses a comprehensive utilization method of Luoyuan red tailings. The method comprises the following steps: performing first classification on mining tailings to obtain ore tailingsand a sandy soil material; performing second classification on processing tailings to obtain stone left overs and a stone powder; performing third classification on the sandy soil material to obtain washed sand and washed mud used as raw materials for foamed ceramics; mixing and crushing the stone left overs and the ore tailings, mixing the crushed materials with the stone powder, crushing the mixed materials, performing magnetic separation and classification on the crushed materials to obtain fine iron ore, washed feldspar and washed soil for producing foamed ceramics or ceramic tiles. According to the method, by means of ordered matching of classification, crushing and magnetic separation, the Luoyuan red processing tailings and the mining tailings are fully utilized, and natural resources of minerals are utilized to the maximum extent.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Efficient desulfurizer taking industrial waste residues as active raw material as well as preparation method and application thereof

PendingCN112791581AHigh precisionLow costDispersed particle separationGaseous fuelsSocial benefitsProcess engineering

The invention discloses an efficient desulfurizer taking industrial waste residues as an active raw material and a preparation method and application thereof, and belongs to the field of materials. The preparation method of the material comprises the following steps of: adding a forming agent and water into an active raw material with the particle size of 100-200 meshes and a cocatalyst with the particle size of 100-200 meshes, and uniformly stirring and mixing to obtain a mixture; and extruding the mixture into a strip-shaped sample with the diameter of 3mm by using an extruder through an extrusion molding process, and drying and granulating the sample to obtain the desulfurizer product. The desulfurizer disclosed by the invention is high in low-concentration H2S removal precision, long in service life, simple in preparation process and wide in application range, synergistically solves the problem of resource utilization of industrial waste residues, and has great economic, environmental and social benefits.

Owner:NANJING UNIV OF TECH +1

A method for preparing magnetic adsorbent by using waste zinc-manganese batteries and biomass

ActiveCN107321312BRaw materials are easy to getHigh value-added resource utilizationOther chemical processesWater contaminantsBiological activated carbonElectrical battery

Owner:YANAN UNIV

Method for preparing high-purity iron oxide by superconducting high-gradient magnetic separation converter dust removal

ActiveCN107309082BReduce energy consumptionGood effectHigh gradient magnetic separatorsDust controlSteel mill

The invention provides a method for preparing high-purity iron oxide with converter dedusting ash using a superconduction high gradient magnetic separation (HGMS) technology. According to the method, the HGMS technology is used for separating the converter dedusting ash so that the iron oxide can be extracted, then the iron oxide is roasted to prepare high-purity iron oxide red, and cyclic utilization of the converter dedusting ash at the outside of a steel mill can be realized; and moreover, the additional value of the iron oxide red is high, large-scale and high-additional-value resource utilization of waste is achieved, iron elements can be enriched to 65% or above, the number reaches 93% or above when the iron elements are converted into Fe2O3, and the recovery rate of the iron elements reaches 95% or above. The method for preparing the high-purity iron oxide with the converter dedusting ash using the superconduction HGMS technology has ultrahigh separation and extraction capacity and ultralow energy consumption (the energy consumption accounts for 1 / 10-1 / 4 that of a conventional magnetic separation method), the effect is good and energy can be saved obviously; and the method is particularly suitable for enrichment, separation and extraction of the iron elements in iron-containing solid powder such as the converter dedusting ash.

Owner:UNIV OF SCI & TECH BEIJING

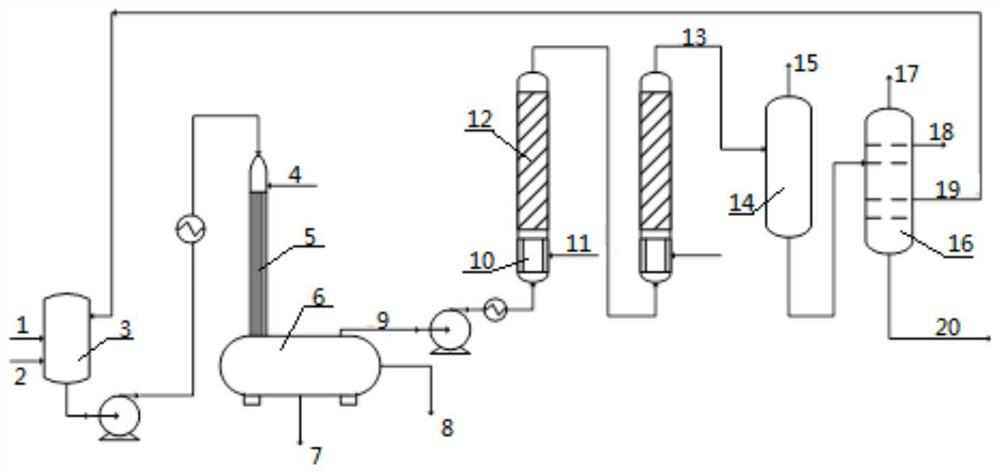

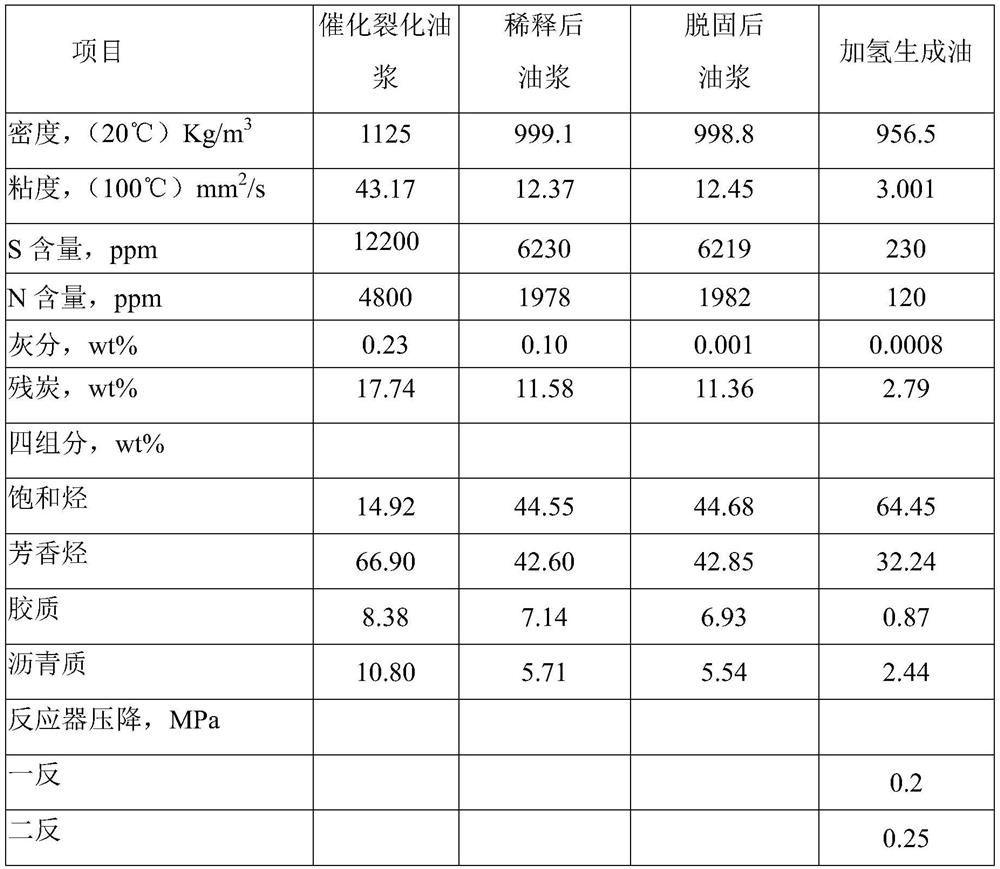

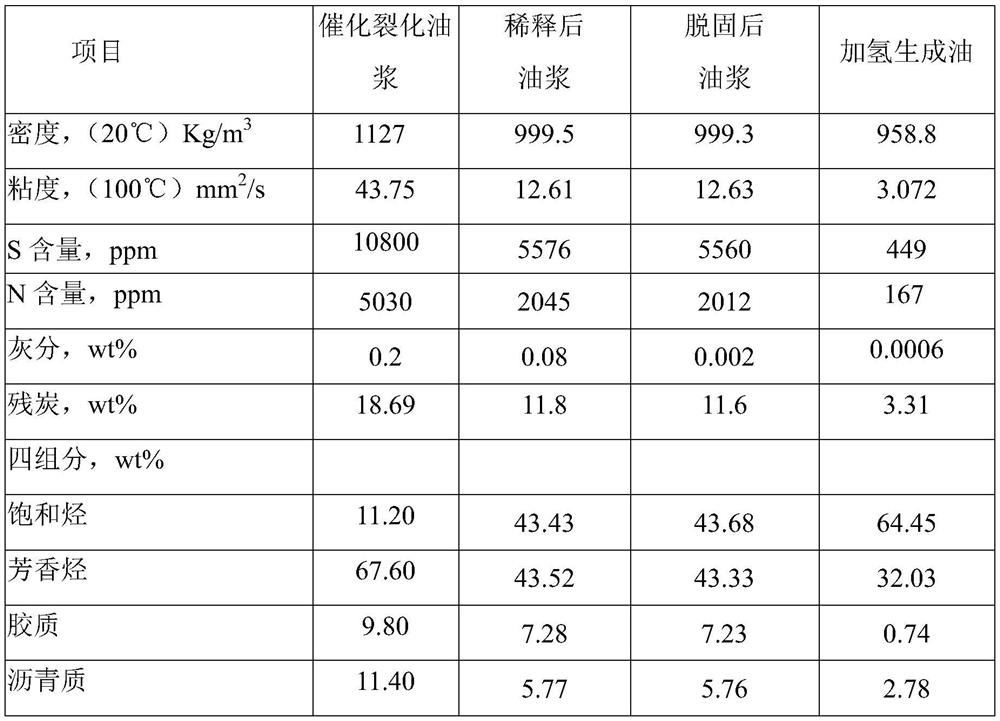

Combination processing method of catalytic cracking oil slurry

ActiveCN110093186BDesolidification is fully realizedImprove hydrophilicityTreatment with hydrotreatment processesFiberActive agent

Owner:CHINA PETROLEUM & CHEM CORP +2

A kind of comprehensive utilization method of Luoyuan red tailings

ActiveCN110563444BTake advantage ofHigh purityCeramic materials productionClaywaresMining engineeringSoil material

The invention discloses a method for comprehensive utilization of Luoyuanhong tailings, which comprises: first classifying the mining tailings to obtain ore tailings and sandy soil materials; second classifying the processed tailings to obtain stone scraps and stone powder material; carry out the third classification of the sand and soil material to obtain washed sand and washed mud for foaming ceramic raw materials; after mixing and crushing stone scraps and ore tailings, they are mixed with stone powder, crushed, magnetically separated and classified Get iron ore concentrate and washed feldspar and washed soil for the production of foamed ceramics or ceramic tiles. In the present invention, through the orderly coordination of means of grading, crushing and magnetic separation, both the Luoyuanhong processing tailings and mining tailings are fully utilized, and mineral natural resources are utilized to the greatest extent.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Application of an adjusting material for high temperature activation treatment of electric furnace white slag

ActiveCN104016599BImprove mineral compositionImprove gelling activityCement productionChemical reactionResource utilization

The invention relates to an adjusting material for carrying out high temperature activation treatment on electric furnace white slag. The adjusting material comprises the components by weight: 0-55% of converter slag, 40-100% of calcareous material (in terms of CaO) and 0-5% of auxiliary materials. When the adjusting material is in practical use, the converter slag, the calcareous material and the auxiliary materials are mixed according to the above weight proportions to be used as the adjusting material; the adjusting material is ground into fine powder; 15-35% by weight of the adjusting material and 65-85% by weight of the white slag are mixed uniformly; the mixture is calcined, so that chemical reactions occur among components; air cool or water cool are carried out after calcination; and a calcined product is broken and ground to prepare the activated white slag powder. 28 d activity indicator is higher than 85% when Blaine specific surface area is 400-500 m<2> / kg. Mineral composition of the white slag is optimized essentially; gelatinization activity of the white slag is increased; high value-added resource utilization rate of the white slag and steel slag solid wastes is increased; and environment protection is facilitated.

Owner:SHAOGUAN COLLEGE

Method for advanced reduction degradation of azo dye by using ultraviolet/magnesium process desulfurization slag

PendingCN112811507AHigh value-added resource utilizationTo achieve the purpose of treating waste with wasteWater/sewage treatment by irradiationWater contaminantsEnvironmental chemistryFlue-gas desulfurization

The invention belongs to the technical field of solid waste resource utilization, and particularly relates to a method for advanced reductive degradation of azo dye by using ultraviolet / magnesium process desulfurization slag, which comprises the following steps of: taking wet magnesium process flue gas desulfurization slag as a reducing agent; and degrading and removing the azo dye in the wastewater by utilizing strong reducing free radicals generated by the UV / desulfurization slag advanced reduction system under the promotion action of ultraviolet light. The method mainly comprises the following steps: (1) drying, grinding and sieving wastes (desulfurization residues) generated by a stably operated wet-type magnesium oxide flue gas desulfurization system, and bagging sieved powder for later use; (2) putting a certain amount of azo dye wastewater into a reaction tank, adding a certain amount of pretreated desulfurized fly ash, adjusting the reaction pH of the solution, and irradiating the reaction solution with an ultraviolet lamp; and (3) adjusting the treated wastewater to be neutral, standing for a period of time, and filtering the effluent. According to the process, high-added-value resource utilization of the waste is achieved while harmless treatment is conducted on the waste water and the waste, the purpose of treating waste with waste is achieved, and remarkable economic benefits, social benefits and environmental benefits are achieved.

Owner:SHENYANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com