Method for preparing gravity energy storage block by using waste incineration bottom ash and waste plastic

A waste incineration and waste plastic technology, applied in the field of waste resource utilization, can solve the problems of weak bond strength between plastic aggregate and concrete matrix, no specific information on optimal material ratio, and inability to obtain gravity energy storage blocks. Achieve the effect of realizing harmless disposal, benefiting environmental protection, improving compressive strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

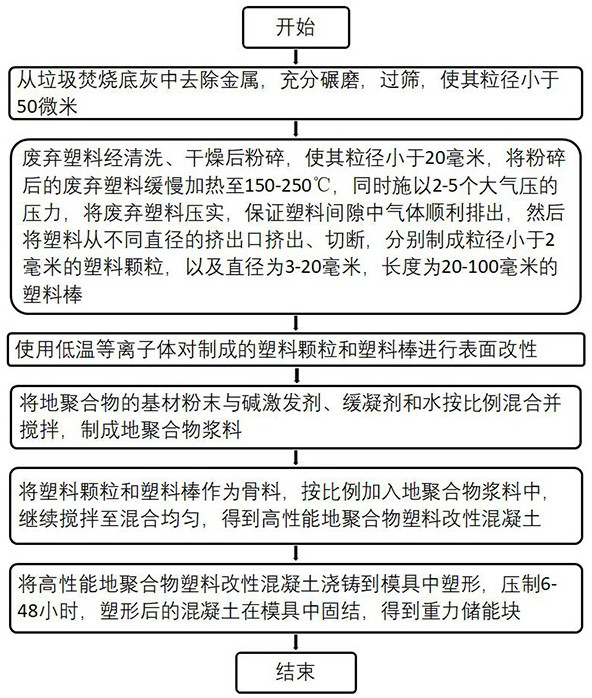

Method used

Image

Examples

Embodiment 1

[0054] When the waste incineration bottom ash contains 30% silica, 25% alumina and 25% calcium oxide, the method for preparing a gravity energy storage block includes the following steps:

[0055] (1) Metals are removed from the bottom ash of waste incineration, and then fully milled and sieved to make the particle size less than 50 microns.

[0056] (2) The waste plastics are washed and dried, and then pulverized so that the particle size is less than 20 mm; the pulverized waste plastics are then slowly heated to 230 ° C, and a pressure of 5.0 atmospheres is applied to them during the control process, and the The waste plastic is compacted to ensure the smooth discharge of the gas in the plastic gap; then the plastic is extruded and cut from extrusion ports of different diameters, and then made into plastic particles with a particle size of about 1.5 mm and a diameter of about 5.0 mm, respectively. Gear cylindrical plastic rods approximately 50mm in length.

[0057] (3) Surf...

Embodiment 2

[0063] When the waste incineration bottom ash contains 35% silica, 15% alumina and 30% calcium oxide, the method for preparing a gravity energy storage block includes the following steps:

[0064] (1) Remove metals from waste incineration bottom ash, add metakaolin with a weight ratio of 15%, and then fully grind and sieve to make the particle size less than 50 microns.

[0065] (2) The waste plastics are washed, dried and then pulverized so that the particle size is less than 20 mm. The pulverized waste plastics are slowly heated to 220°C, and a pressure of 3.0 atmospheres is applied to them during the control process. The plastic is compacted to ensure the smooth discharge of the gas in the plastic gap; then the plastic is extruded and cut from extrusion ports of different diameters to make plastic particles with a particle size of about 2.0 mm, and a diameter of about 7.0 mm and a length of about 2.0 mm. It is a 60mm square prismatic plastic rod.

[0066] (3) Surface modif...

Embodiment 3

[0072] When the waste incineration bottom ash contains 20% silica, 35% alumina and 35% calcium oxide, the method for preparing a gravity energy storage block includes the following steps:

[0073] (1) Remove metals from the bottom ash of waste incineration, add quartz sand with a weight ratio of 15%, and then fully grind and sieve to make the particle size less than 50 microns.

[0074] (2) Wash and dry the waste plastics and pulverize them so that the particle size is less than 20 mm. Slowly heat the pulverized waste plastics to 250°C, and apply a pressure of 4.0 atmospheres to them during the control process. The plastic is compacted to ensure the smooth discharge of the gas in the plastic gap; then the plastic is extruded and cut from extrusion ports of different diameters to make plastic particles with a particle size of about 1.8 mm, and a diameter of about 8.0 mm and a length of about 1.8 mm. 80mm cylindrical plastic rod.

[0075] (3) Surface modification of the fabrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com