Method for synergistically degrading azo dye by ultrasonic-ultraviolet-semi-dry desulfurization ash

A semi-dry desulfurization and azo dye technology, which is applied in the field of solid waste resource utilization and advanced reduction treatment of wastewater, can solve problems such as difficulty in comprehensive utilization, complex and changeable components of desulfurization products, etc., and achieve significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method of ultrasonic-ultraviolet-semi-dry desulfurization ash synergistically degrading azo dyes in this embodiment is carried out according to the following steps:

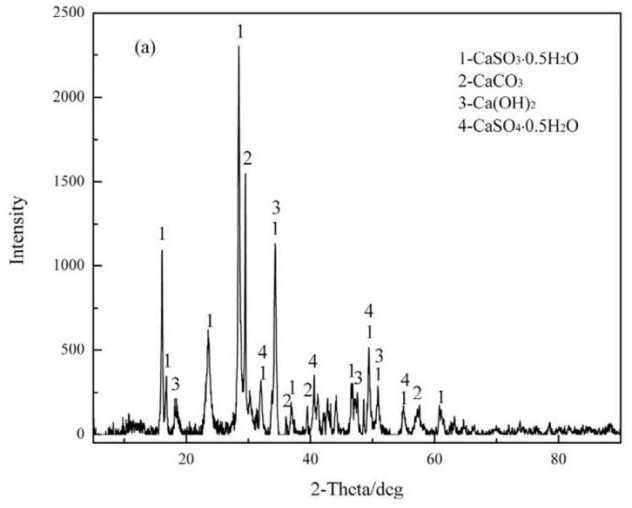

[0018] (1) Grind the desulfurization ash from the semi-dry calcium flue gas desulfurization system in stable operation and pass it through an 80-mesh sieve, then take the powder under the sieve and pack it into bags for later use;

[0019] (2) Take 150 mL of methyl orange wastewater with a concentration of 100 mg / L in the reaction tank, add 0.8 g of pretreated desulfurization ash, and adjust the reaction pH of the solution to 2.5. React for 3.0 h under the conditions of 80kHz ultrasound and 60W ultraviolet lamp irradiation;

[0020] (3) Adjust the pH of the treated wastewater to 7.0, and after standing for a period of time, filter the water.

[0021] After treatment, the removal rate of methyl orange in wastewater can reach more than 90%.

Embodiment 2

[0023] A method of ultrasonic-ultraviolet-semi-dry desulfurization ash synergistically degrading azo dyes in this embodiment is carried out according to the following steps:

[0024] (1) Grind the desulfurization ash from the semi-dry calcium flue gas desulfurization system in stable operation and pass it through an 80-mesh sieve, then take the powder under the sieve and pack it into bags for later use;

[0025] (2) Take 200 mL of methyl orange wastewater with a concentration of 200 mg / L in the reaction tank, add 2.5 g of pretreated desulfurization ash, and adjust the reaction pH of the solution to 3.0. React for 3.0 h under the conditions of 100kHz ultrasound and 60W ultraviolet lamp irradiation;

[0026] (3) Adjust the pH of the treated wastewater to 7.0, and after standing for a period of time, filter the water.

[0027] After treatment, the removal rate of methyl orange in wastewater can reach more than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com