Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "High degree of welding automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

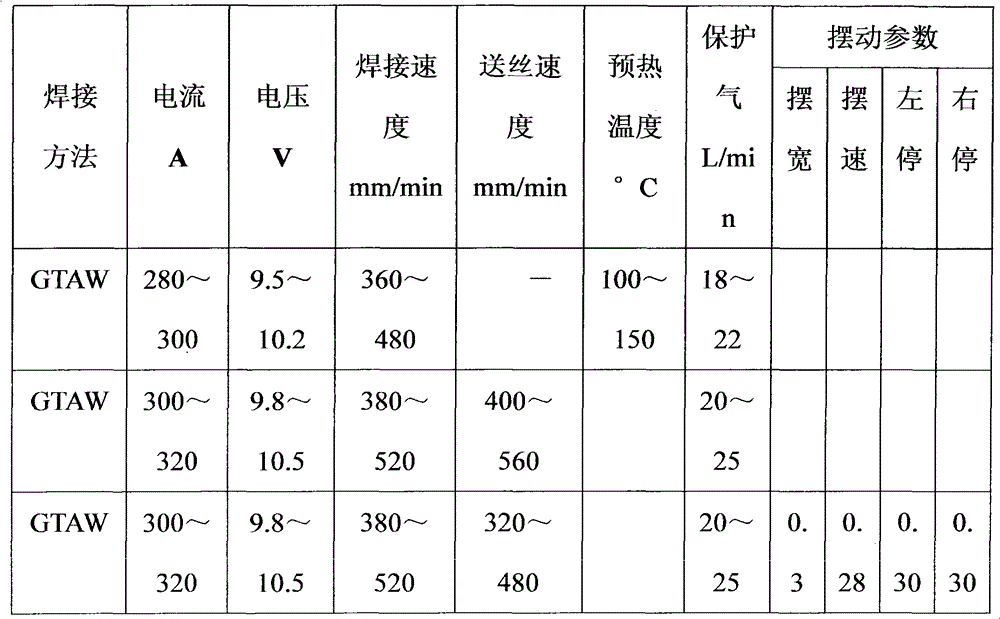

Automatic TIG (Tungsten Inert Gas) welding method for liner-free single-side welding and double-side forming of aluminum alloy butted circular seam

InactiveCN102079004AReduce distortionHigh degree of welding automationArc welding apparatusStainless steel wireAutomation

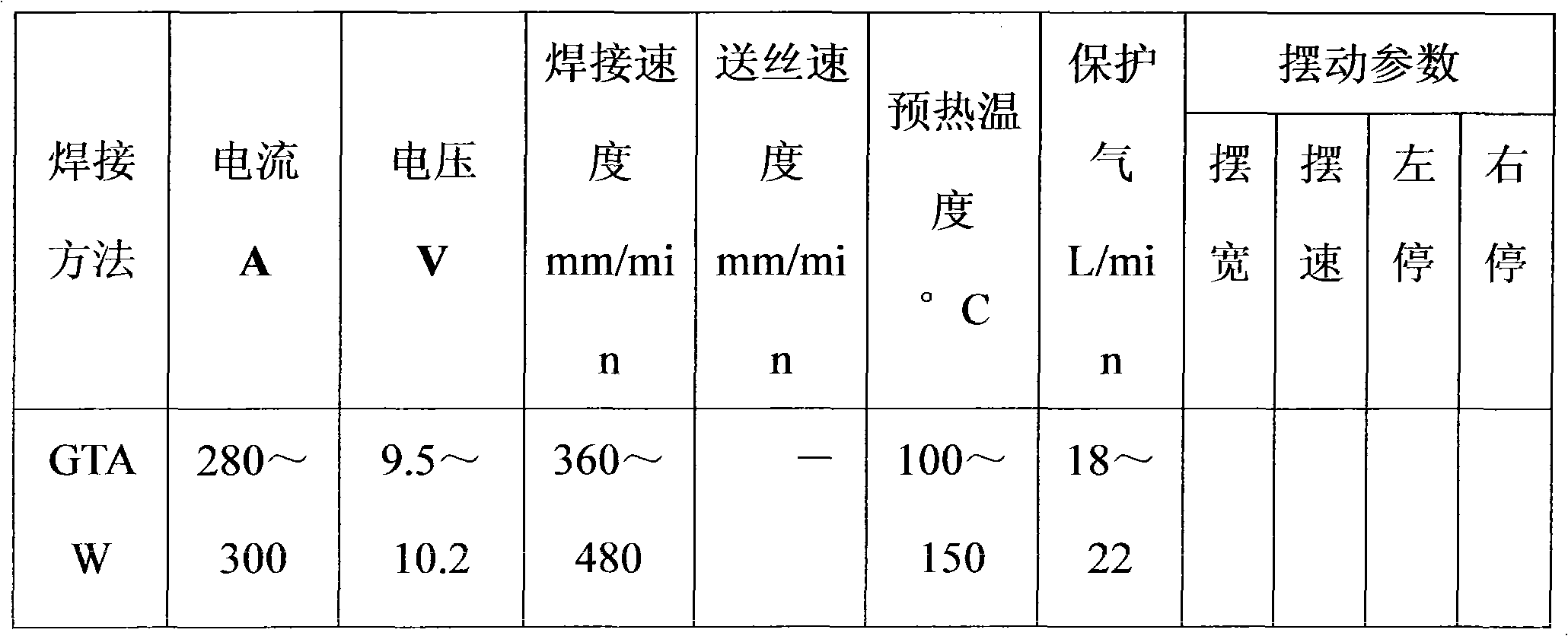

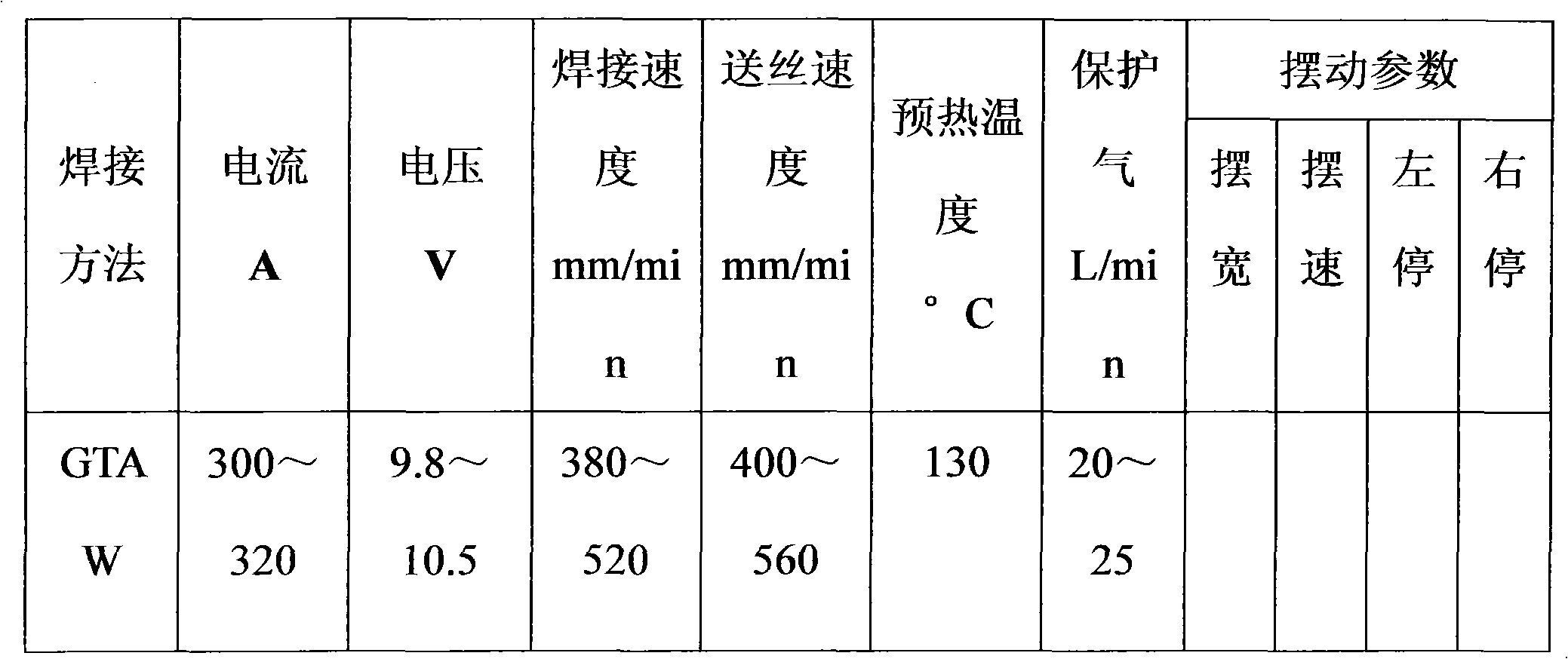

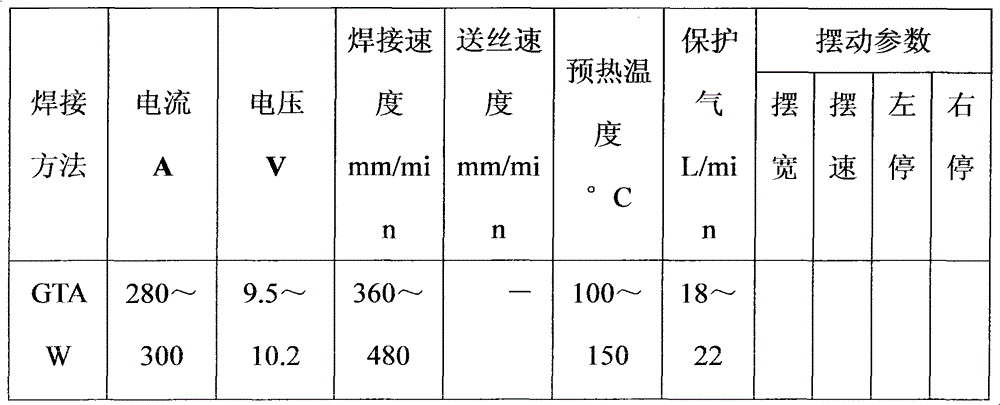

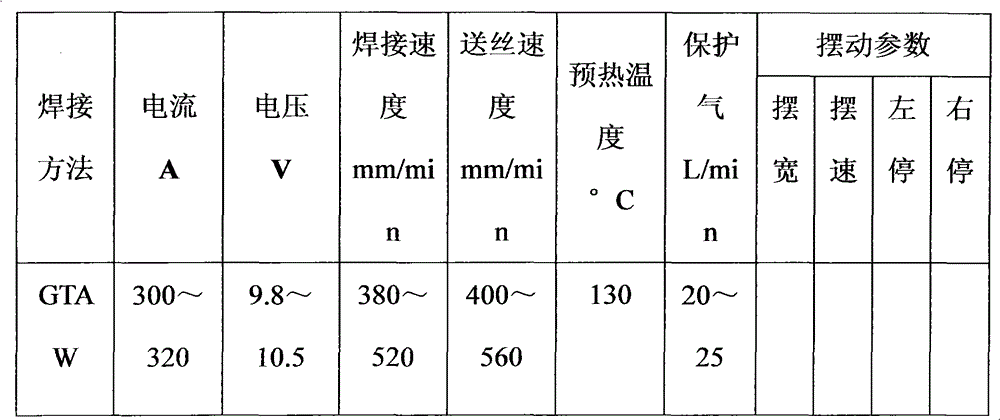

The invention relates to an automatic TIG (Tungsten Inert Gas) welding method for liner-free single-side welding and double-side forming of an aluminum alloy butted circular seam, which comprises the following steps of: before welding, cleaning greasy dirt at the periphery of a cylinder butted circular seam with acetone; removing an oxide film in the periphery of the cylinder butted circular seam by a stainless steel wire wheel; preheating before welding; debugging a control panel for controlling welding current and voltage, welding speed and wire feeding speed to match in real time; and welding by adopting an automatic TIG machine, wherein a welding wire is not added for back formation when a first layer is welded, a welding wire is added for filling when a second layer is welded, a welding wire is added when a third layer is welded, and a welding gun swings for cover surface forming. The automatic TIG welding method has the advantages of simple equipment, convenience in operation, stable welding, high welding speed, low production cost, fewer filled welding wires, fewer welding layers, small deformation, no need of correction after welding, attractive formed appearance and high welding seam quality and realizes welding automation.

Owner:陕西国德电气制造有限公司

Process method for assembling and welding pile leg of ocean platform

InactiveCN105057857AWelding quality is easy to controlDimensional accuracy is easy to controlArc welding apparatusProduction lineEngineering

The invention discloses a process method for assembling and welding a pile leg of an ocean platform. According to the method, the production speed is high, and the percent of pass of products is high. A pile leg assembly is composed of a rack and two semicircular pipes. Coming cargo examination should be carried out on the rack and the semicircular pipes carefully, and the rack and the semicircular pipes are installed through a tool. The rack is turned over through a turnover device. The assembled pile leg examined to be qualified is lifted to an electric heating furnace stage trolley, conveyed into a furnace and heated, wherein the temperature ranges from 150 DEG C to 200 DEG C. The temperature in a hearth should be kept even. The heated pile leg is placed on the ground. Two welding joints are in the horizontal state. Manual welding rods are used for backing welding. Welding is performed on the pile leg by four welding workers from the middle position. The two sides are simultaneously and symmetrically welded. After welding is finished, the pile leg is turned over and welded continuously. After the welding joints are backed for 1 to 2 layers, the pile leg is lifted to roller carriers on a submerged arc welding production line and then formally welded. The welded pile leg is conveyed into a thermal treatment furnace, the heating temperature ranges from 200 DEG C to 280 DEG C and maintained for 2 to 3 hours, and then the pile leg is delivered out of the thermal treatment furnace.

Owner:张家港润通海洋工程科技有限公司

Full-position track control method of pipeline butt weld joint

ActiveCN105458454AHigh degree of welding automationShield interferenceArc welding apparatusAutomatic controlSimulation

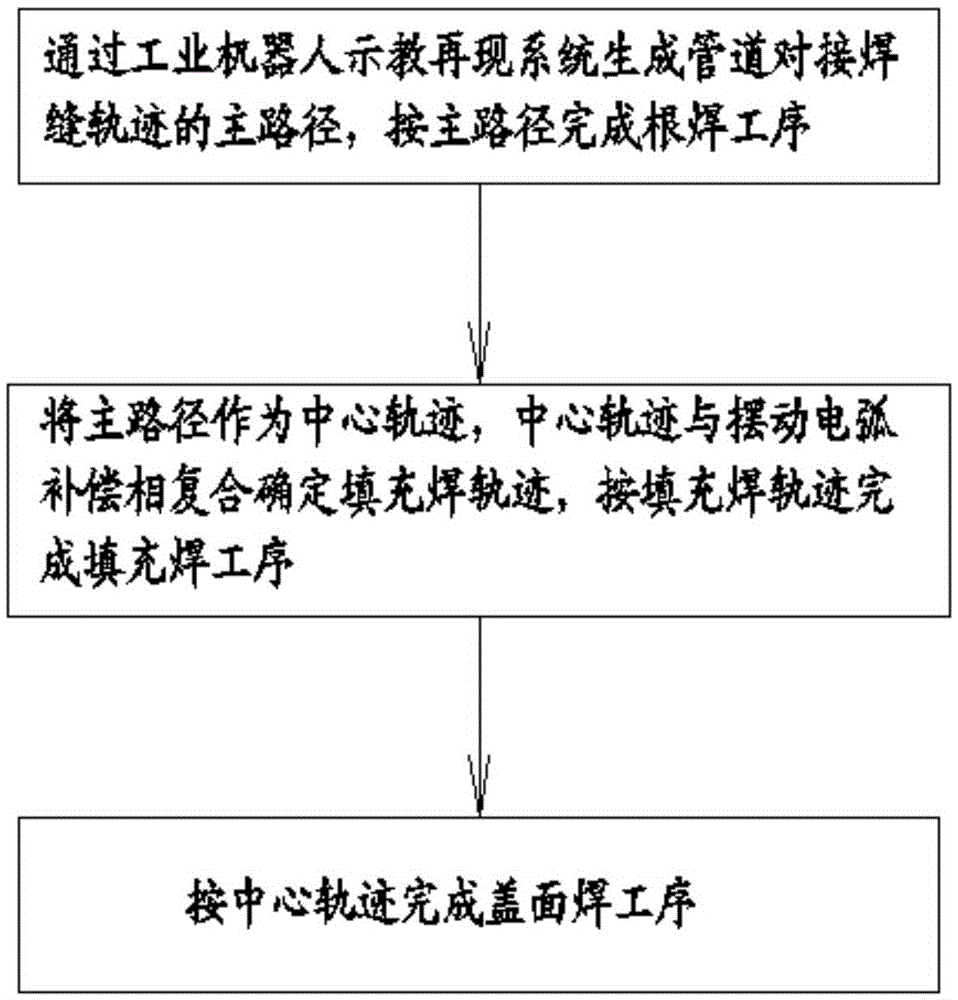

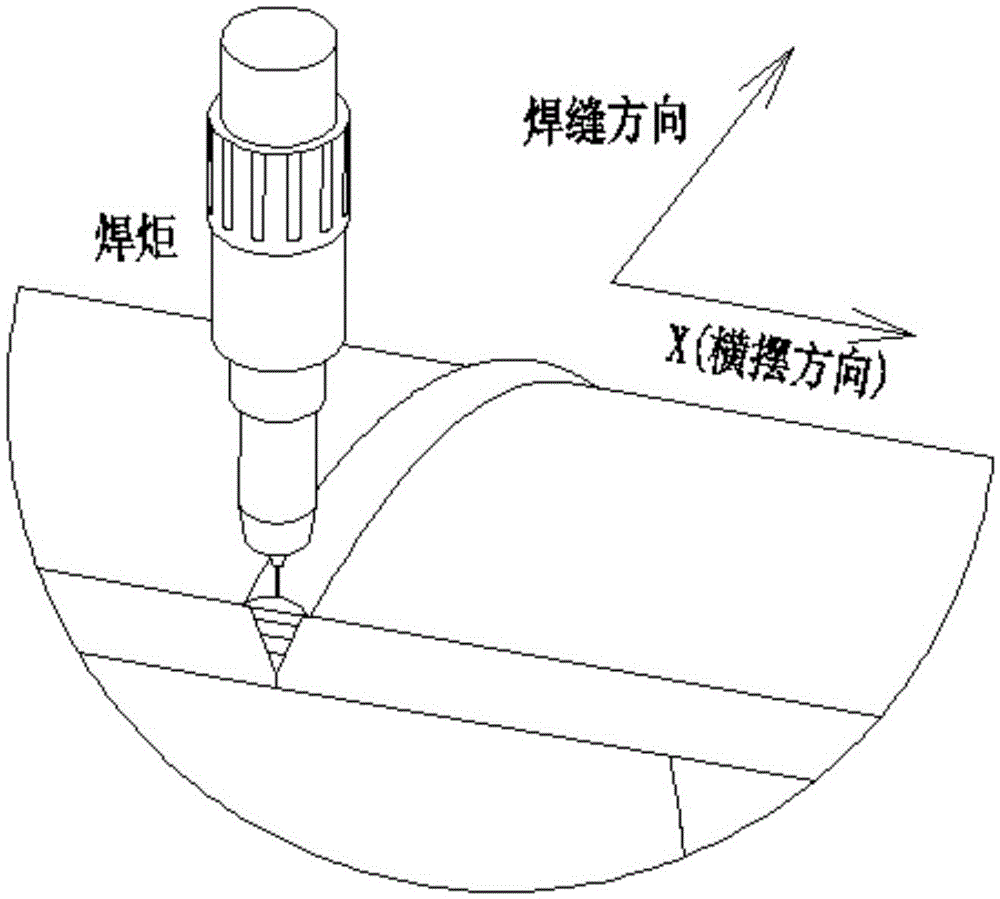

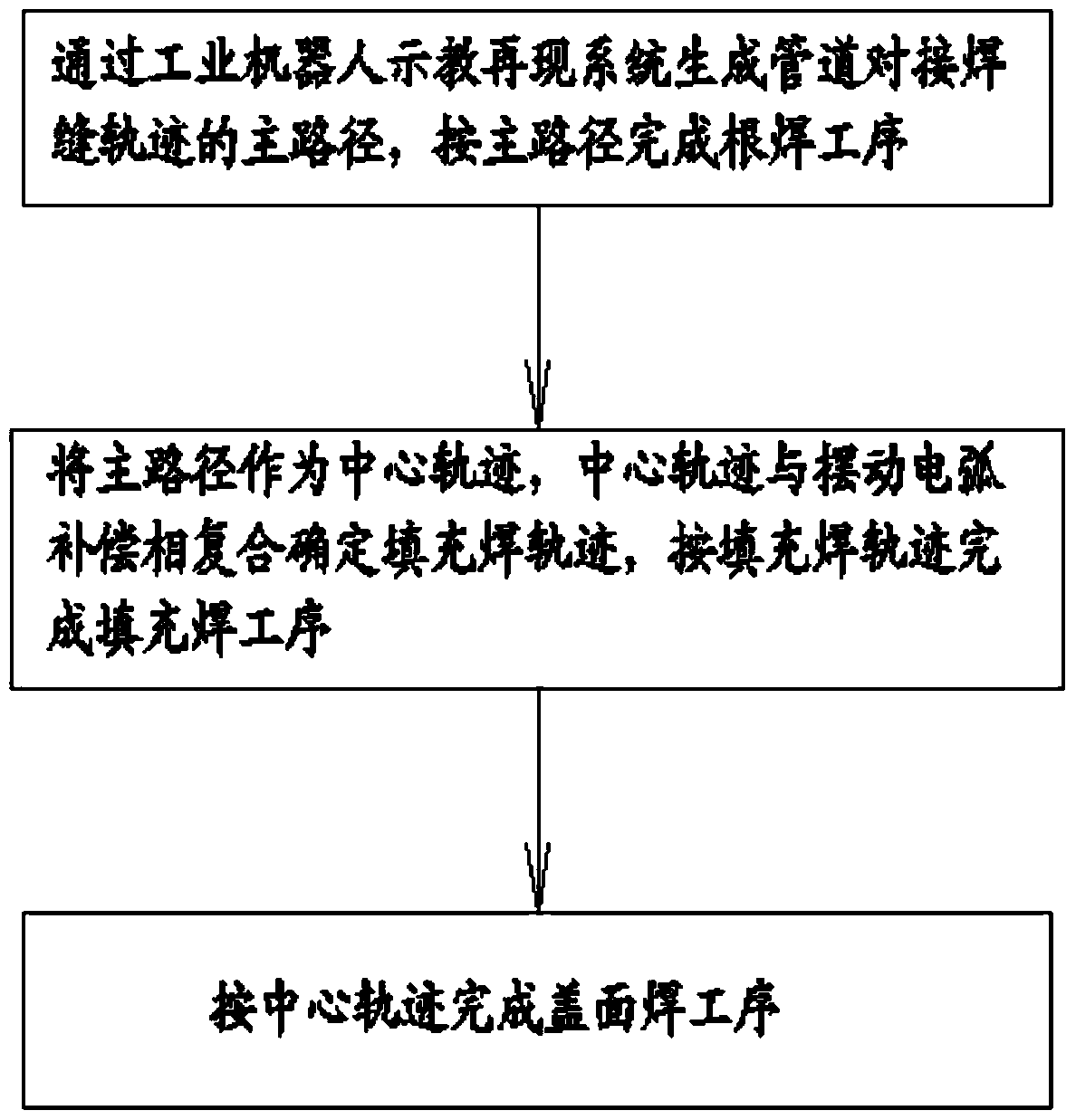

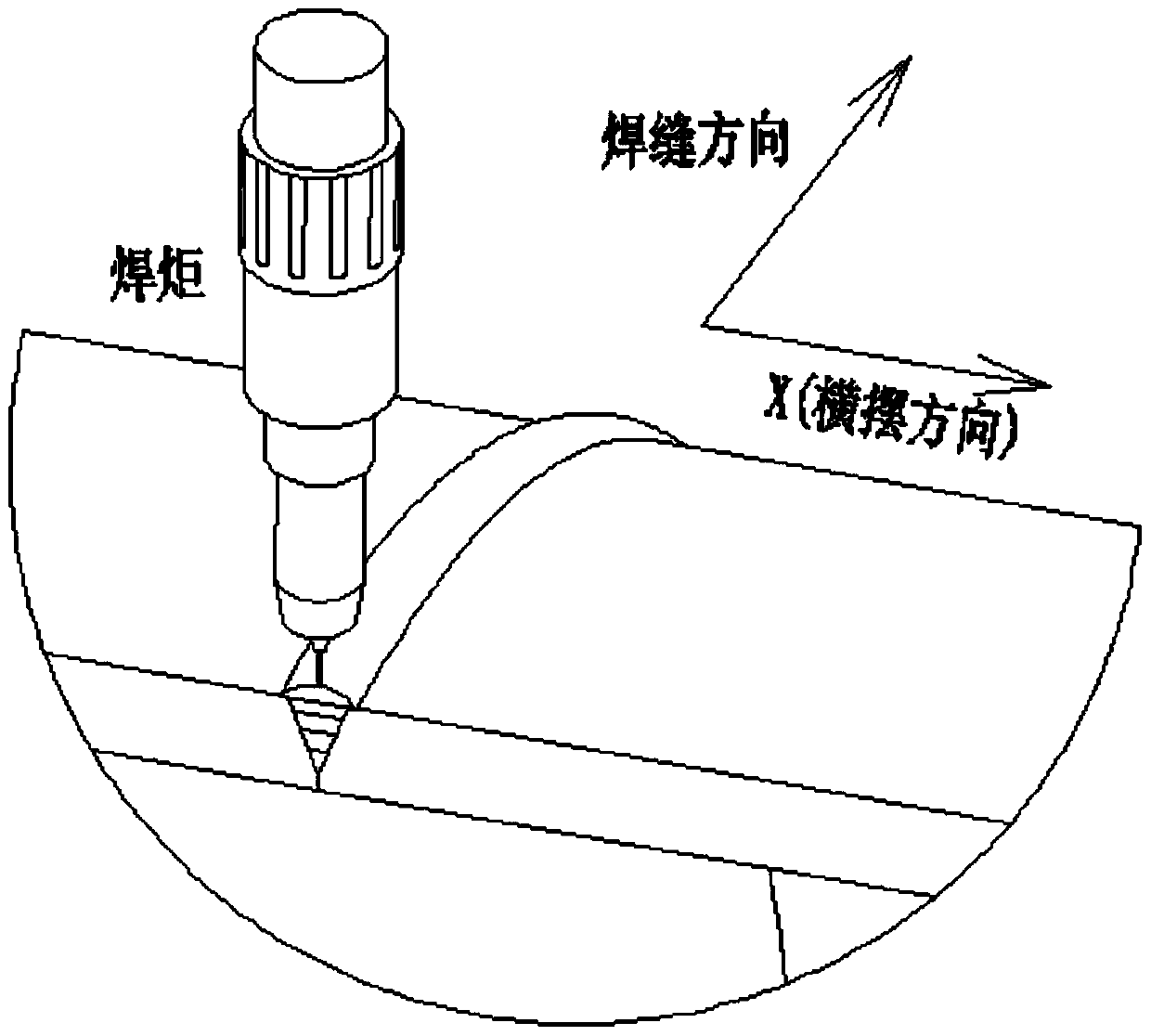

The invention relates to a full-position track control method of a pipeline butt weld joint. The method includes the steps that a main path of a pipeline butt weld joint trace is generated through an industrial robot teaching and playing-back system, and a root welding procedure is completed according to the main path. The main path serves as a center trace. The center trace and swing arc compensation are composited so that a filling weld trace can be determined. A filling weld procedure is completed according to the filling weld trace. A cosmetic welding procedure is completed according to the center trace. Automatic control over the welding trace, from root welding and filling welding to cosmetic welding, of the pipeline butt weld joint is achieved through the trace control method, the automation degree of pipeline welding is effectively improved, interference of current discrete values with a compensation valve is effectively shielded, and precision of the welding torch transverse swing compensation value is improved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

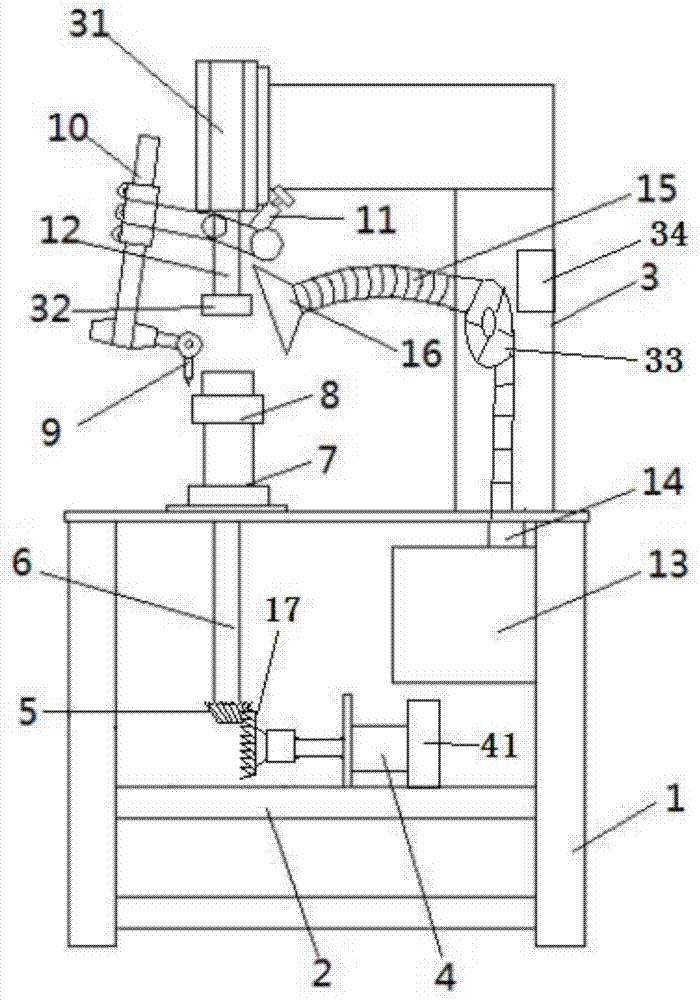

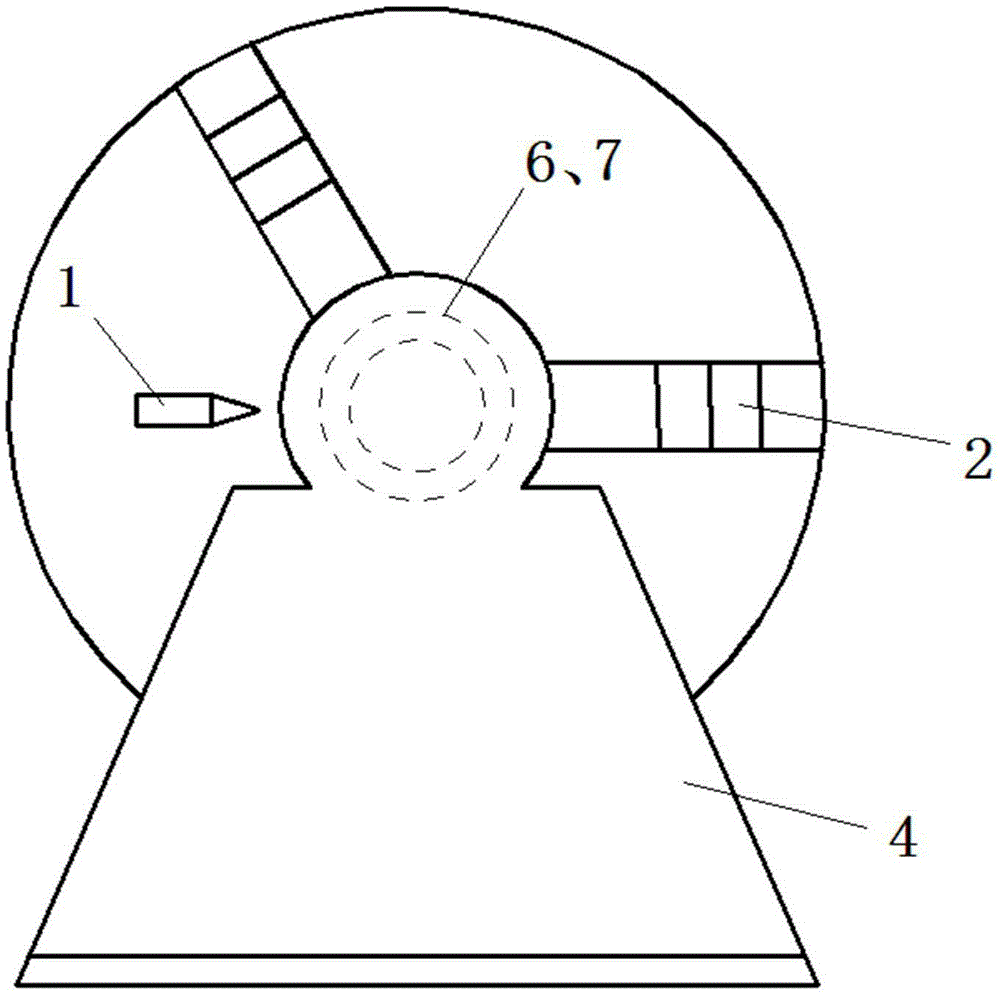

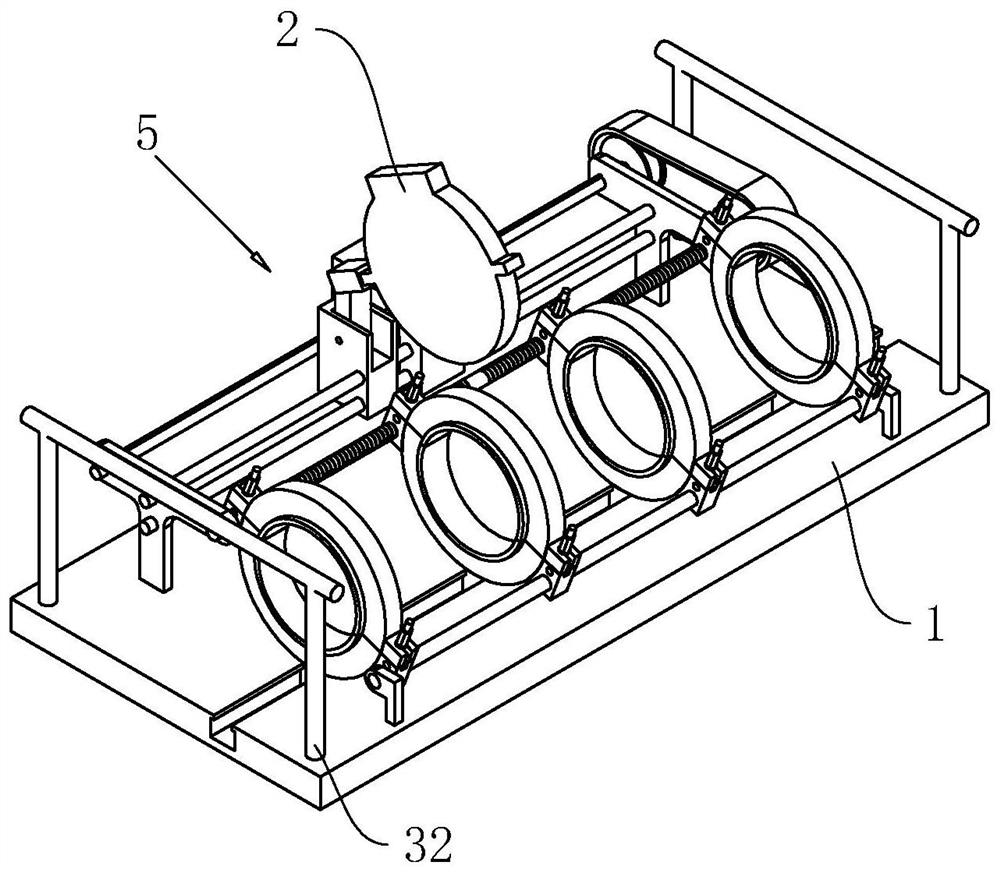

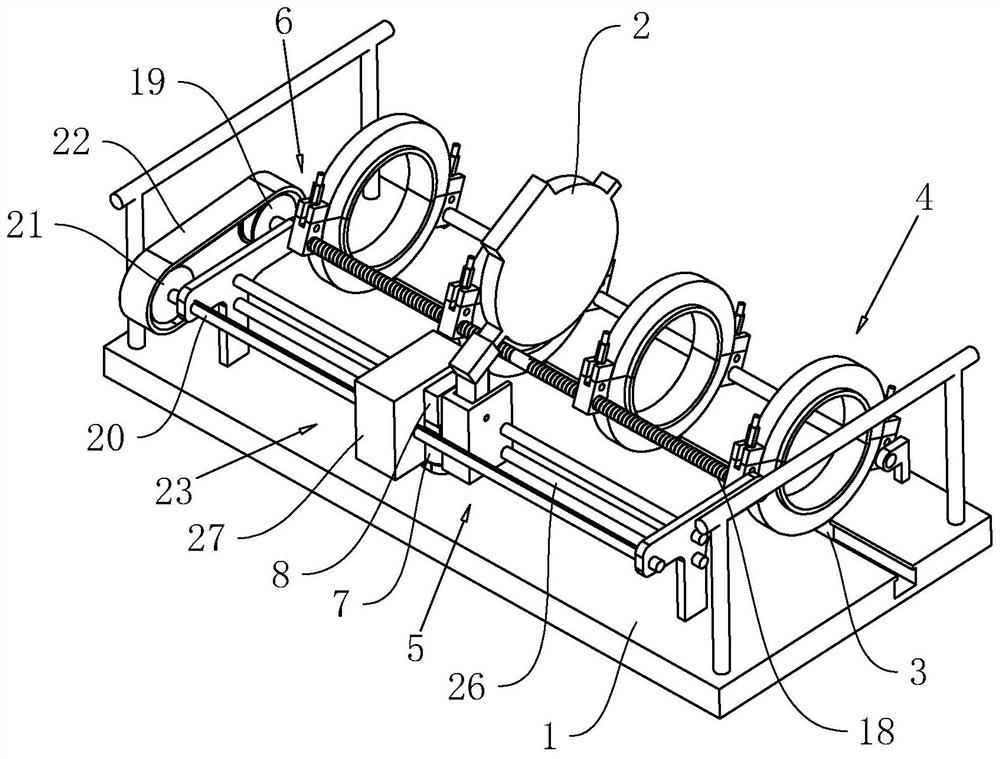

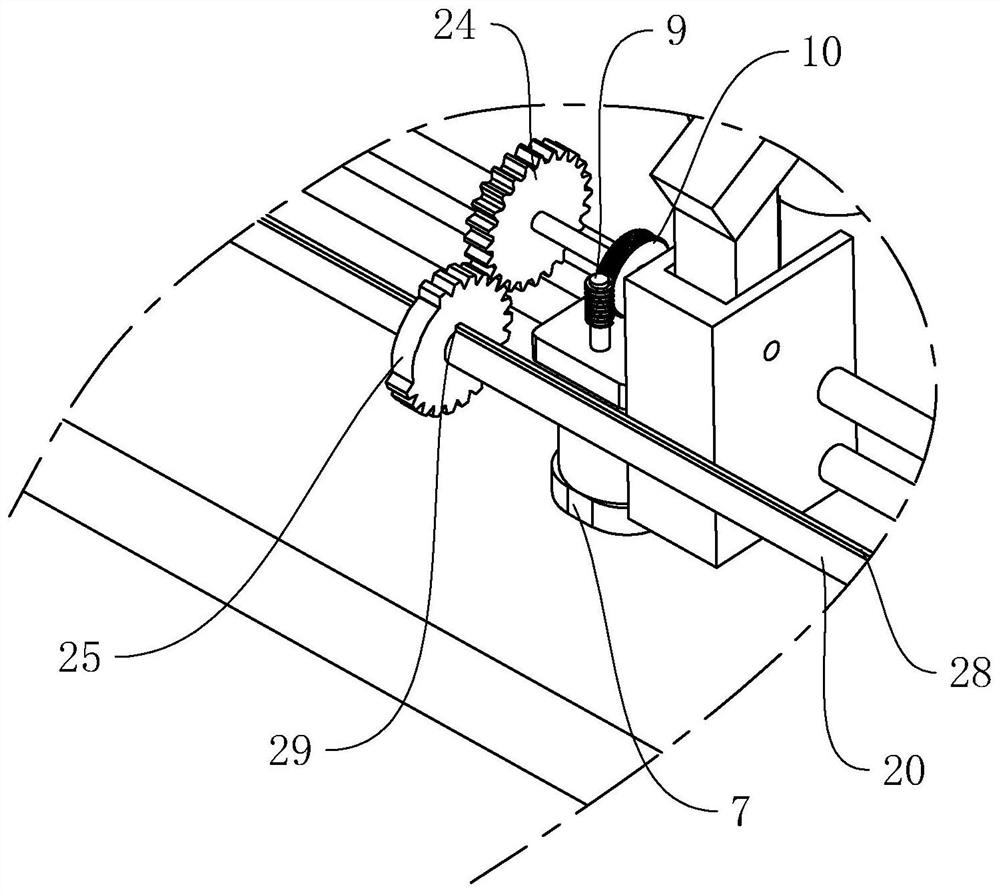

Annular safety welding device of firefighting equipment special joint

InactiveCN107335938AGuaranteed absorptionKeep healthyWelding/cutting auxillary devicesDirt cleaningGear wheelWeld seam

The invention discloses a ring-shaped safety welding device for special joints of fire-fighting equipment, which includes an operating table, a transmission mechanism, a clamping mechanism, a welding torch and a welding torch adjustment mechanism. The welding torch adjustment mechanism is used to adjust the welding position of the welding torch, and it does not need to be adjusted many times when welding the same type of fire extinguisher. It only needs to be driven by the motor to drive the bevel gear and the meshing transmission gear to complete the welding of the circular seam Operation, high degree of welding automation, saving manpower, the welding fume generated during welding is absorbed by negative pressure through the welding fume absorption hood and the gas collection box, and the absorption position can also be adjusted through the bellows to ensure the absorption effect of the welding fume. Realized by an intelligent controller, it will automatically operate when an irritating substance is detected, avoiding the damage to the body caused by the staff forgetting to turn on the exhaust equipment, thereby ensuring the health of the operator.

Owner:武晓丹

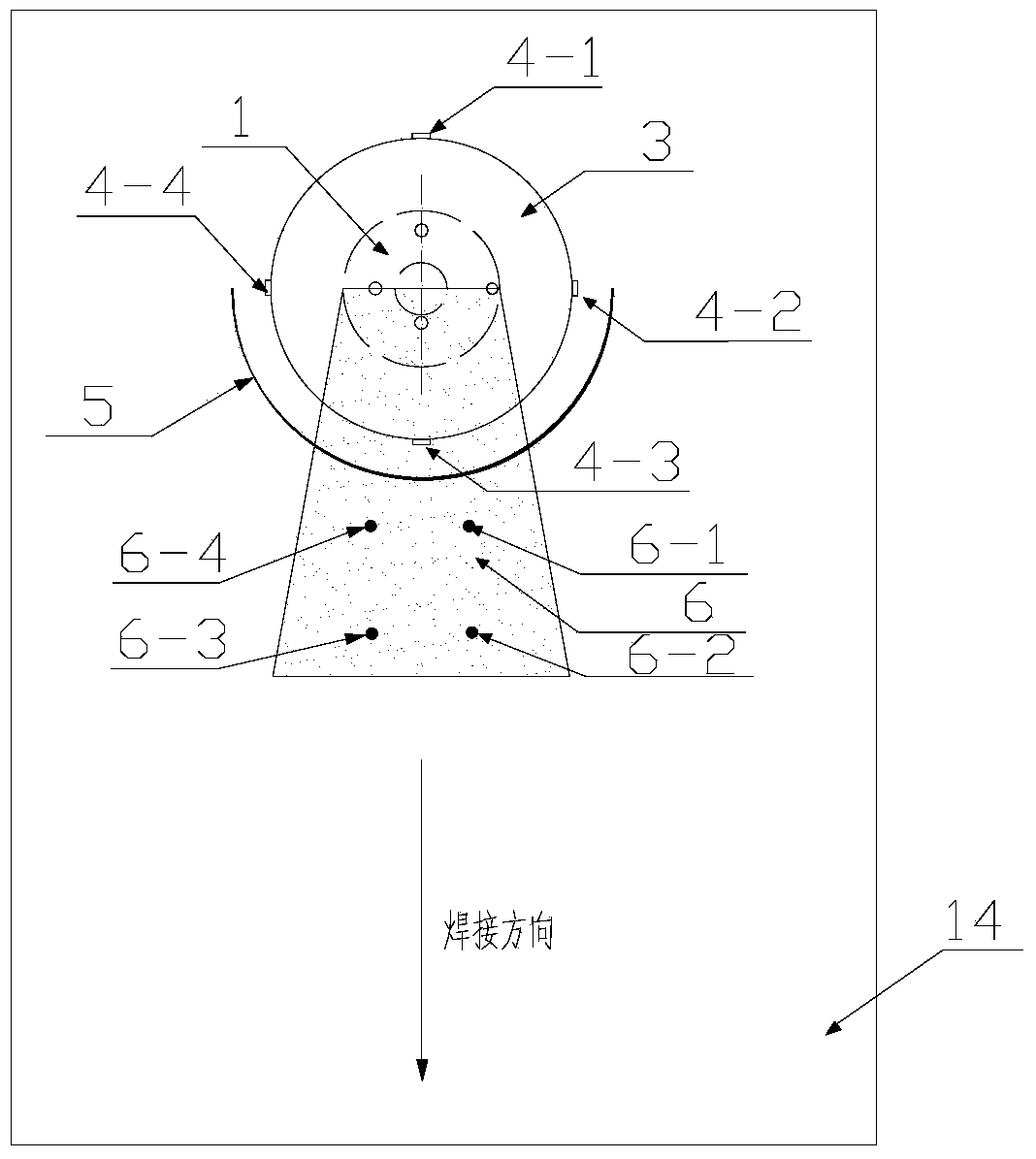

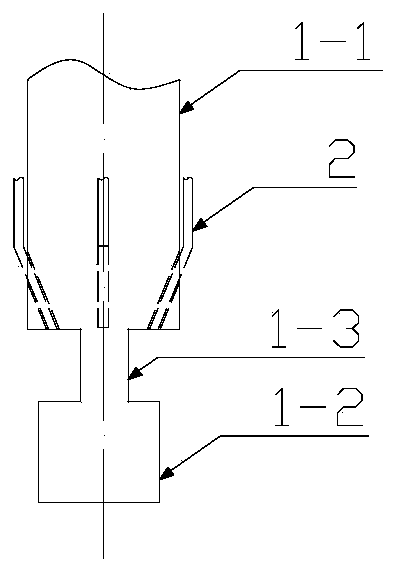

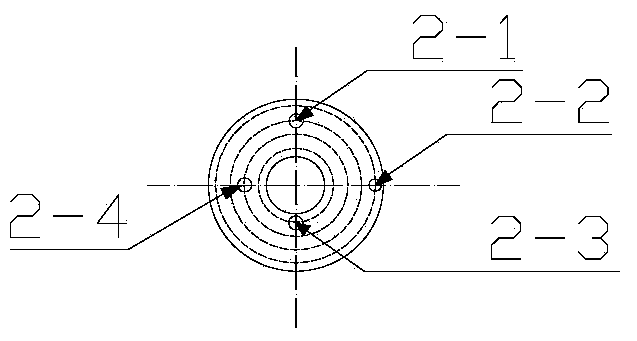

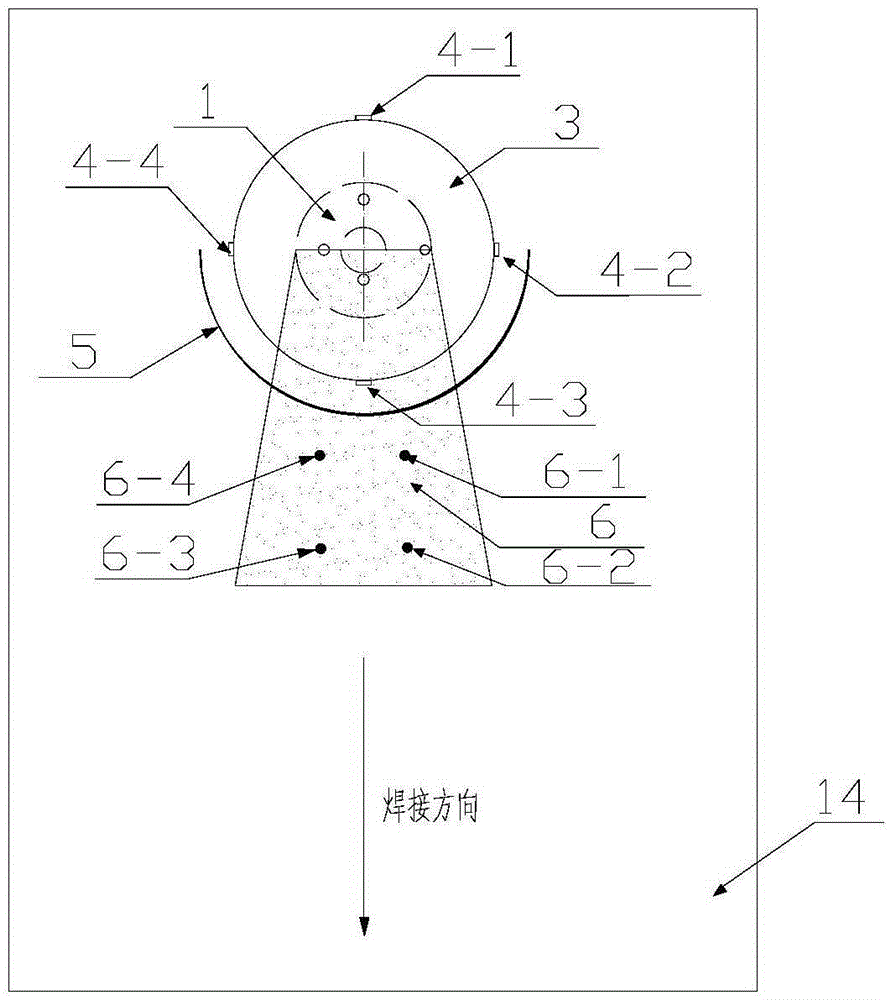

Device and method for double-shaft shoulder FSW (Friction Stir Welding) based on temperature feedback of leader region

InactiveCN104209648AImprove detection accuracyImprove welding qualityNon-electric welding apparatusWireless transmissionEngineering

The invention discloses a device and a method for double-shaft shoulder FSW (Friction Stir Welding) based on temperature feedback of a leader region. The device comprises a stirring head, a clamp holder and a handcart, wherein the stirring head is arranged on a machine head in a clamping way through the clamp holder, the machine head is fixedly provided with a semicircular arc magnetic steel piece, the clamp holder is provided with high-speed proximity switches in the circumferential direction at intervals every 90 degrees, the stirring head comprises an upper shaft shoulder, a lower shaft shoulder and a stirring needle which is located between the upper shaft shoulder and the lower shaft shoulder, the upper shaft shoulder is provided with sheathed thermocouples in the circumferential direction at intervals every 90 degrees, the radial directions of end points of the sheathed thermocouples are respectively parallel to the radial direction of a setting point of the corresponding high-speed proximity switch after the stirring head is provided with the clamp holder, and the sheathed thermocouples are connected with a controller through a wireless transmission module. The method is characterized by dynamically adjusting the welding speed and the rotating speed of the stirring head through the sheathed thermocouples and pressure spring type thermocouples. According to the device and the method for the double-shaft shoulder FSW based on the temperature feedback of the leader region, disclosed by the invention, the structure is clever, the detection accuracy is high, the welding speed is dynamically adjusted through dynamically detecting the temperature of a welding workpiece, and the welding accuracy is high.

Owner:JIANGSU UNIV OF SCI & TECH

Butt-joint pipe fitting laser welding device and welding method

InactiveCN105414751AImprove welding efficiencyImprove welding qualityMetal working apparatusLaser beam welding apparatusPipe fittingButt joint

The invention belongs to the technical field of welding, and discloses a butt-joint pipe fitting laser welding device which comprises a laser welder and a rotary mechanism, wherein butt-joint pipe fittings are respectively mounted on the rotary mechanism; butt-joint surfaces of the butt-joint pipe fittings are fitted; the laser welder is fixedly arranged at one side of the butt-joint surfaces of the butt-joint pipe fittings; the rotary mechanism drives the butt-joint pipe fittings to coaxially rotate at the same rotation speed; and the laser welder carries out laser welding on the butt-joint surfaces of the butt-joint pipe fittings. The invention further discloses a welding method for the device. According to the butt-joint pipe fitting laser welding device and the welding method, welding efficiency and quality for medium-thick pipes are improved, the welding automation degree is improved; and the butt-joint pipe fitting laser welding device and the welding method are suitable for butt-joint welding of other pipe fittings with various wall thicknesses.

Owner:上海第一机床厂有限公司

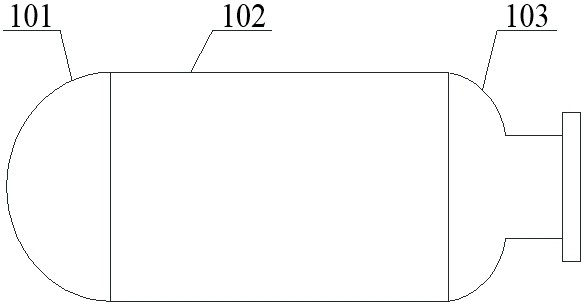

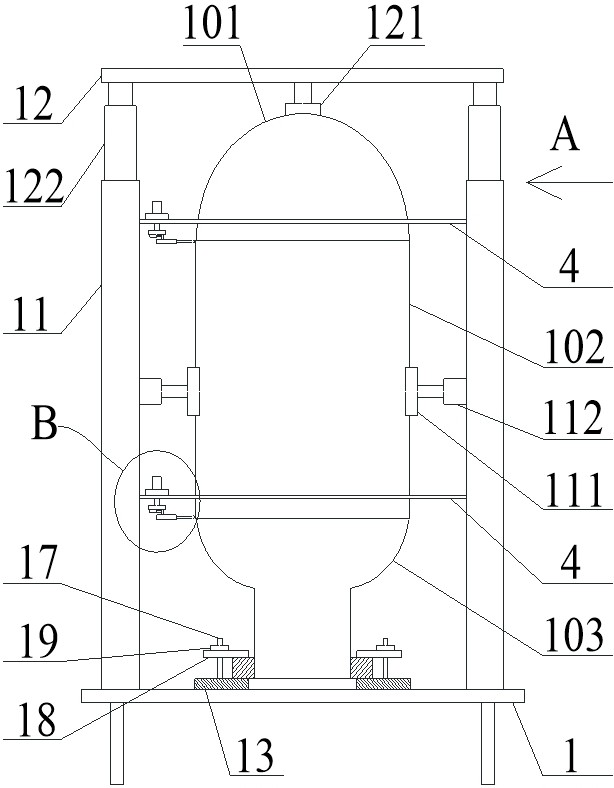

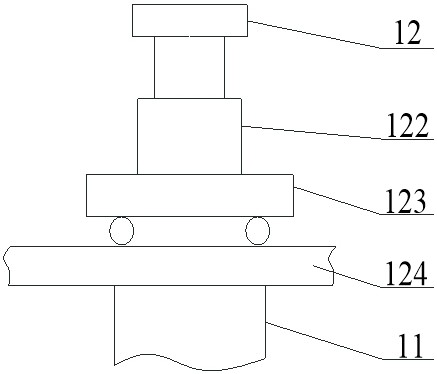

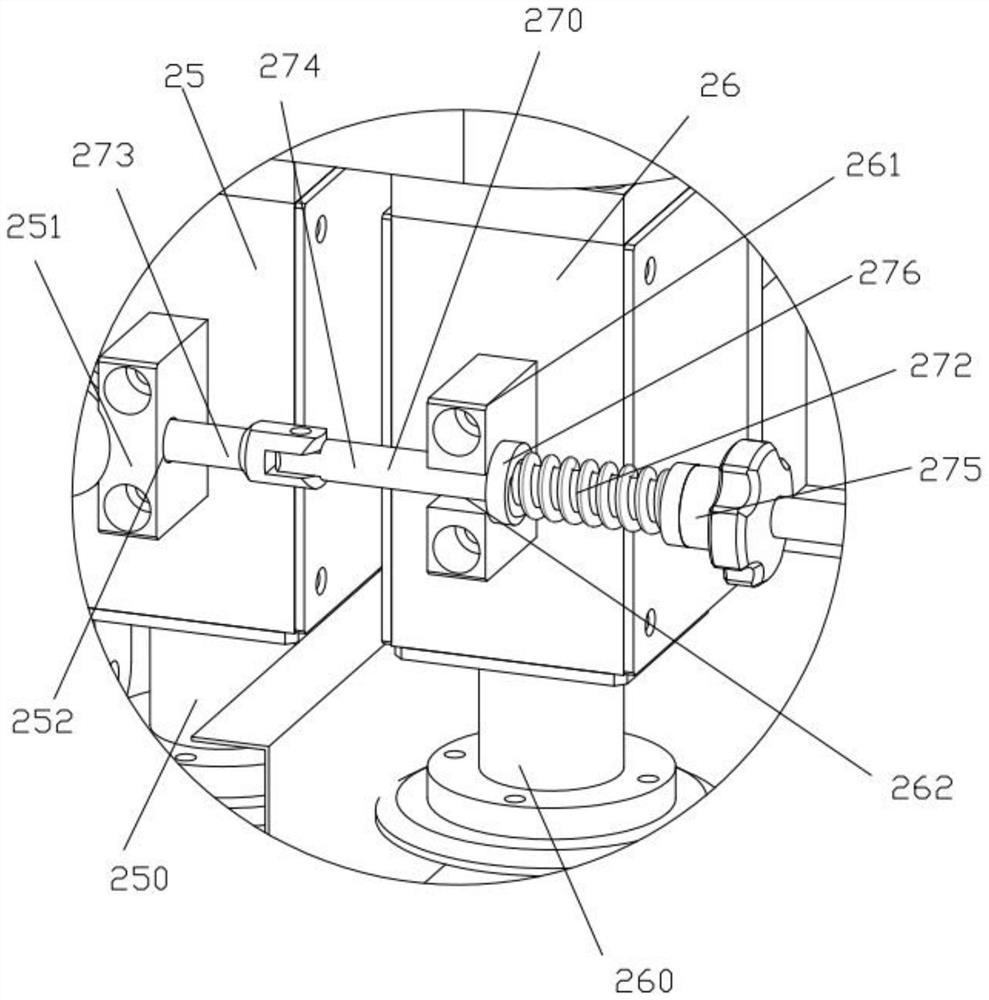

Storage tank body welding device

ActiveCN113333997AAchieve vertical fixationRealize one-time moldingWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWeld seam

The invention relates to the technical field of metal welding, and provides a storage tank body welding device which comprises a fixed platform which is provided with a rotating disc and two stand columns. Two annular rails are further fixed between the two stand columns. A welding trolley is arranged on the annular rails. An outer welding gun is arranged on the welding trolley, and outer welding seams are formed at the joint of a tank body and a tank bottom and the joint of the tank body and a tank opening respectively. A centering shaft extends into the storage tank. A centering adjusting mechanism is arranged on the centering shaft. An inner welding mechanism is further arranged on the centering shaft, and an inner welding seam is formed on the inner wall of the storage tank along with rotation of the storage tank. Therefore, a rotary table, clamping jaws and a pressure plate are arranged on the fixed platform, so that the tank opening, the tank body and the tank bottom of the storage tank are vertically fixed. The outer welding gun moves on a circular rail, so that the formation of the outer welding seams is realized. And meanwhile, the inner welding mechanism is arranged, and after the outer welding seams are formed, the inner welding seam can be conveniently formed in the storage tank. The welding automation degree is high, manual work is replaced to enter the tank for operation, the labor intensity is relieved, and the welding efficiency is improved.

Owner:诸城市众发机械有限公司

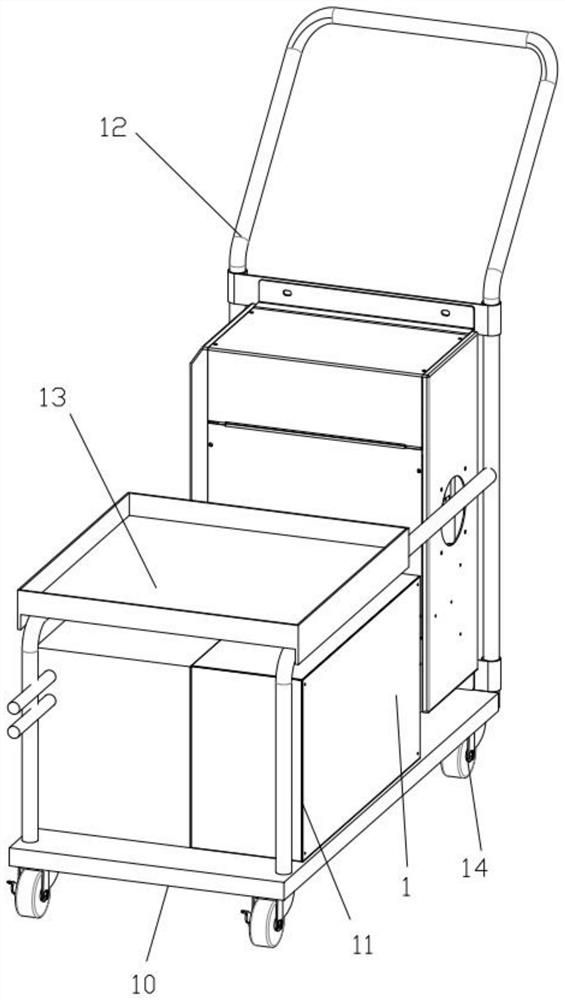

Pipeline hot melting welding machine

The invention relates to the technical field of pipeline machining, in particular to a pipeline hot melting welding machine which comprises a mounting base, a heating plate is arranged on the mounting base, the heating plate is electrically connected with an external circuit through a wire, two sliding tables are arranged on the mounting base in a sliding mode, and locking assemblies used for clamping a pipeline are arranged on the sliding tables. The mounting base is provided with a first driving assembly used for driving the heating plate to turn over, and the mounting base is further provided with a second driving assembly used for driving the two sets of sliding tables to slide in the face-to-face or back-to-back mode. The whole machining process does not need cooperative operation of multiple workers, and operation is convenient, so that a large amount of labor cost is saved.

Owner:上海海骄机电工程有限公司

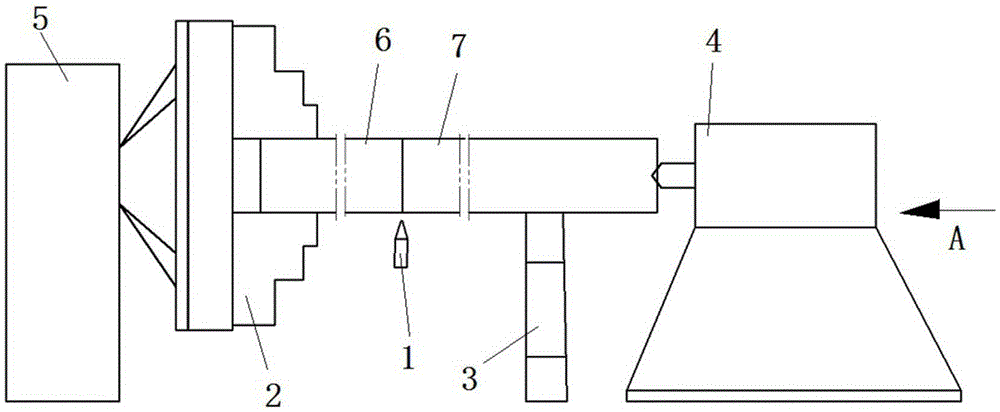

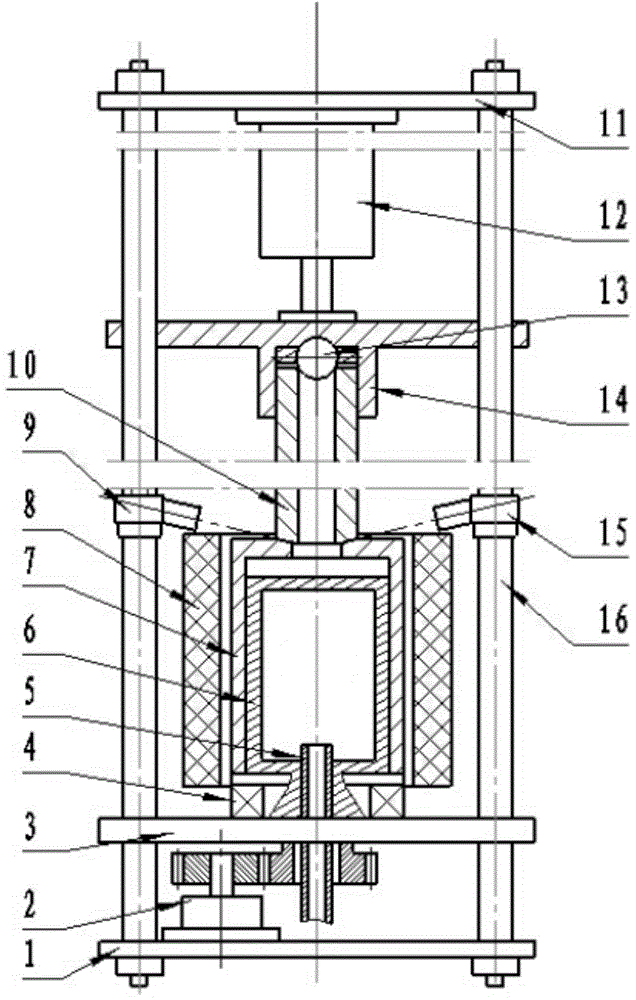

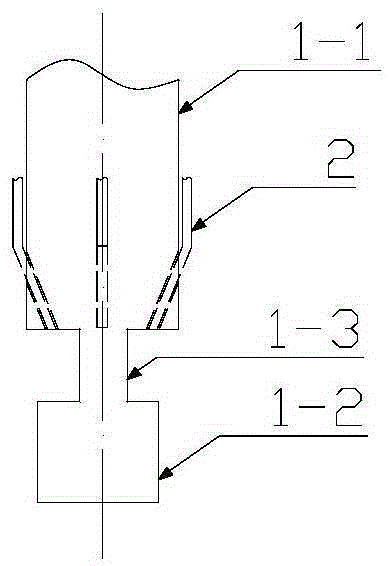

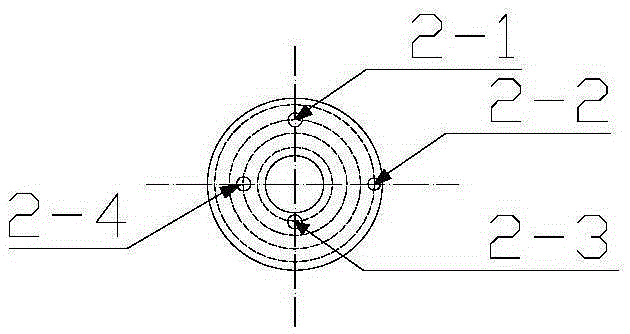

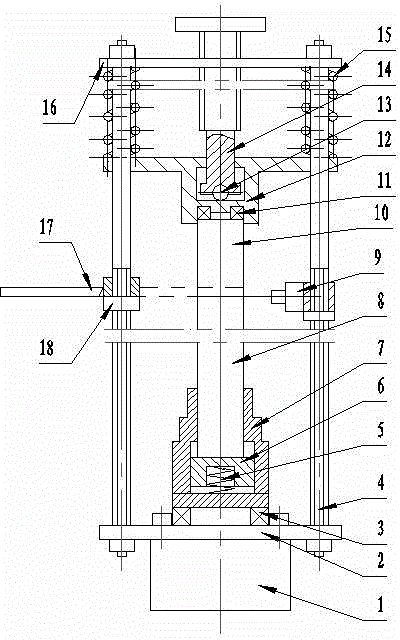

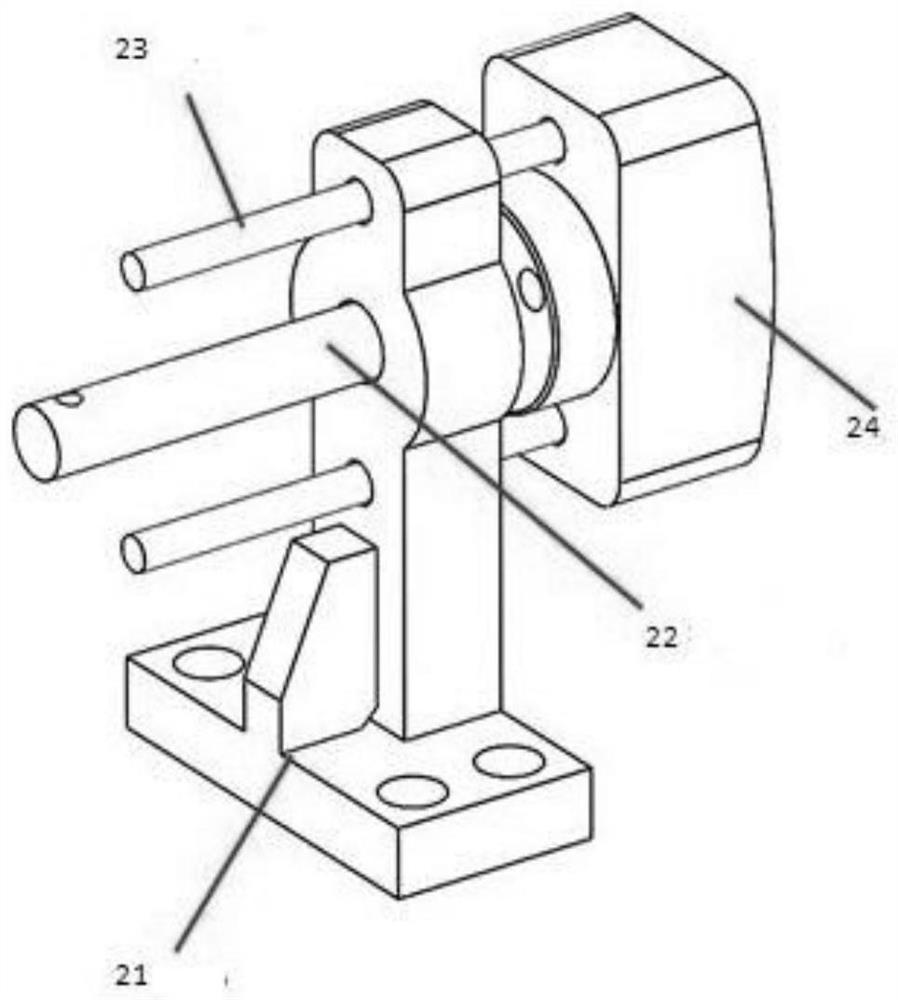

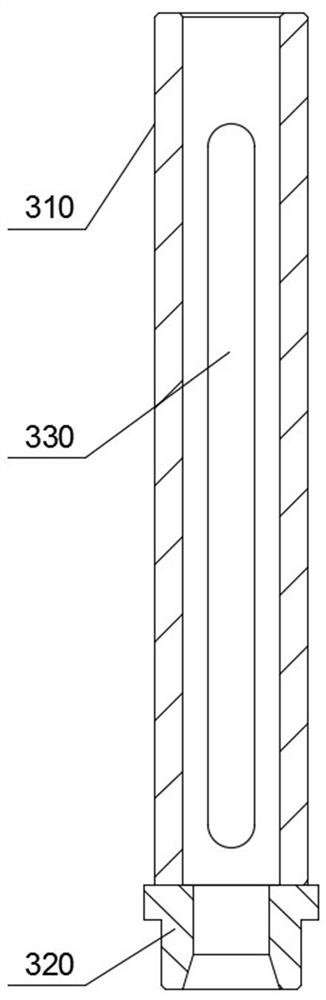

Welding tool and method of medium carbon steel hollow step bar

InactiveCN104607798AWarm up fastControllable welding processWelding/cutting auxillary devicesAuxillary welding devicesThrust bearingCoaxial line

The invention provides a welding tool of a medium carbon steel hollow step bar. The welding tool comprises a bearing strength frame, a clamping mechanism and a pre-heat welding system, wherein the bearing strength frame comprises a stand column, and the stand column is provided with an upper support plate, a middle support plate and a lower support plate; the clamping mechanism comprises a clamping cylinder installed under the upper support plate and a locating sleeve detachably connected with the clamping cylinder, the inner diameter of the locating sleeve matches with the outer diameter of a thin hollow rod, a steel ball used for assisting to rotate is arranged in the locating sleeve, a hollow locating piece is arranged below the locating sleeve, the hollow locating piece and the locating sleeve are arranged in a coaxial line, the inner diameter of the hollow locating piece matches with the outer diameter of a thick hollow rod, the hollow locating piece is arranged on the middle support plate through a thrust bearing, and an actuating motor connected with the hollow locating piece in a shaft mode is arranged below the hollow locating piece; the pre-heat welding system comprises an electromagnetic induction heater, a laser welder and a temperature sensor. The welding tool and a welding method have the advantages that the pre-heating process is linked with the welding process, the tool welding automation degree and working efficiency are improved, and the manufacturing technique of tools is simplified.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Column welding method of q420b steel building steel structure for heavy and large

ActiveCN104741744BImprove impact toughnessReduce the occurrence of cold cracksArc welding apparatusEngineeringSlow cooling

The invention discloses a vertical column welding method for a heavy and large Q420B steel building steel structure. The method comprises the steps of manufacturing a web welding part and a wing flange plate welding part; forming a grooving opening in a weld joint; dehumidifying the web welding part and the wing flange plate welding part; performing full penetration welding to abut and weld the web welding part to obtain a web; performing full penetration welding to abut and weld the wing flange plate welding part to obtain a wing edge plate; performing local penetration welding for a T joint for combining the web and the wing edge plate; performing temperature maintenance and slow cooling treatment for the weld joint. According to the method, the automatic submerged arc welding multi-layer multi-weld process is utilized, so that the automation degree of welding is high; extremely less cold cracks occur in the weld joint structure, and thus the welding quality is high; the labor intensity in welding process is reduced, little welding is performed, so that the welding hours can be greatly reduced; the demand of construction of the heavy and large building steel structure can be comprehensively met by the welding process.

Owner:CHINA 19TH METALLURGICAL CORP

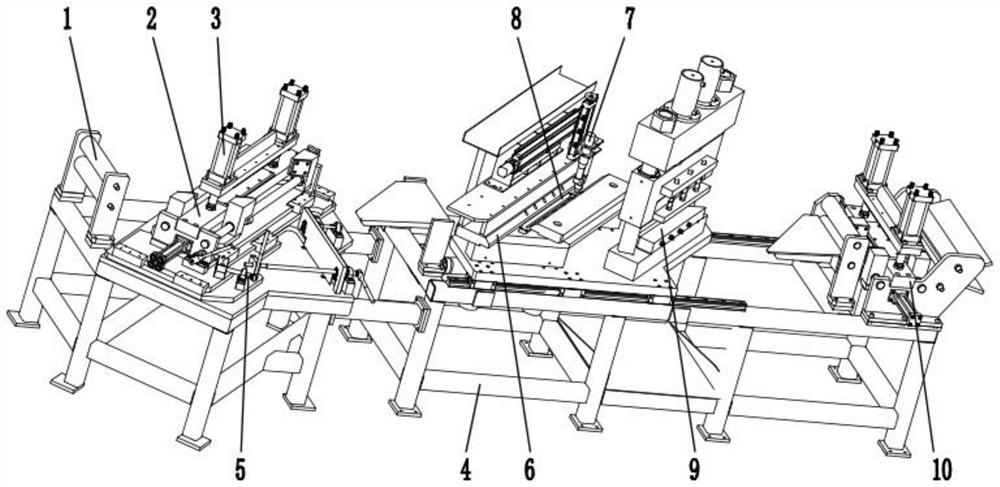

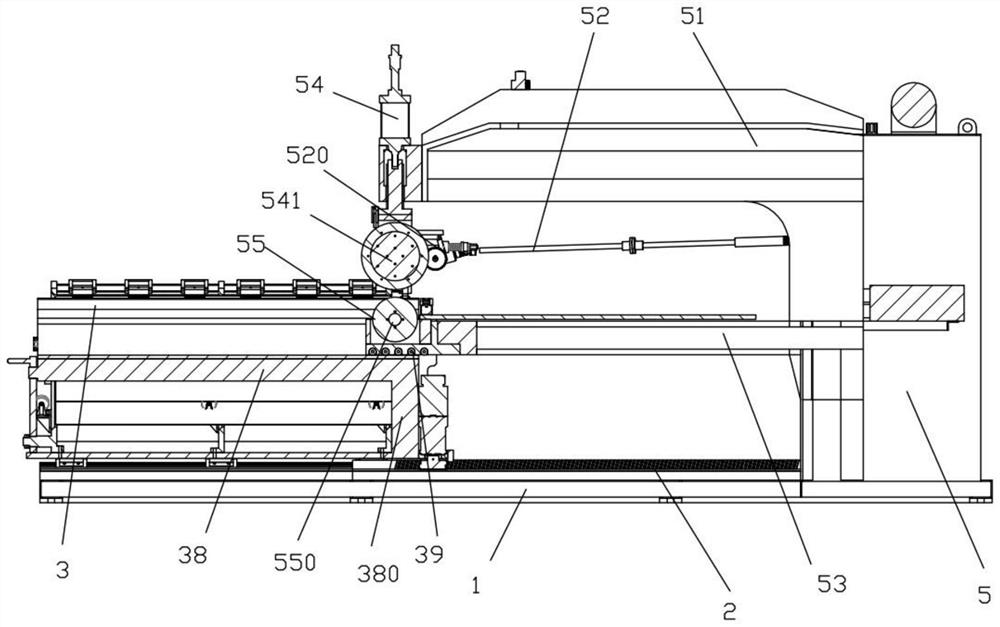

Coiled tubing plate-plate butt welding equipment and welding method

PendingCN112621252AGuarantee welding qualitySmall thermal sensing areaOther manufacturing equipments/toolsPlasma welding apparatusButt weldingCoiled tubing

The invention discloses a coiled tubing plate-plate butt welding equipment and welding method. The coiled tubing plate-plate butt welding equipment comprises a support, a steel belt straightening wheel, a steel belt position adjusting device, a steel belt welding and clamping device, a plasma welding gun, a steel belt cutting device and a steel belt clamping device, wherein the steel belt straightening wheel, the steel belt position adjusting device, the steel belt welding and clamping device, the plasma welding gun, the steel belt cutting device and the steel belt clamping device are sequentially arranged on the support from left to right. The steel belt position adjusting device is provided with a steel belt position adjusting knob and an air pressure driving device, the steel belt position adjusting knob can adjust the position of a steel belt, and the air pressure driving device can push and press the steel belt after pressurization. According to the coiled tubing plate-plate butt welding equipment and welding method, the welding quality can be guaranteed, through plasma welding, a thermal induction area is smaller, the welding thickness range is wider, beveling is not needed in welding, the welding automation degree is high, and welding is more standardized.

Owner:XINDA KECHUANG TANGSHAN PETROLEUM EQUIP CO LTD

Dual-shaft shoulder friction stir welding device and method based on temperature feedback of leading zone

InactiveCN104209648BImprove detection accuracyImprove welding qualityNon-electric welding apparatusWireless transmissionThermocouple

The invention discloses a device and a method for double-shaft shoulder FSW (Friction Stir Welding) based on temperature feedback of a leader region. The device comprises a stirring head, a clamp holder and a handcart, wherein the stirring head is arranged on a machine head in a clamping way through the clamp holder, the machine head is fixedly provided with a semicircular arc magnetic steel piece, the clamp holder is provided with high-speed proximity switches in the circumferential direction at intervals every 90 degrees, the stirring head comprises an upper shaft shoulder, a lower shaft shoulder and a stirring needle which is located between the upper shaft shoulder and the lower shaft shoulder, the upper shaft shoulder is provided with sheathed thermocouples in the circumferential direction at intervals every 90 degrees, the radial directions of end points of the sheathed thermocouples are respectively parallel to the radial direction of a setting point of the corresponding high-speed proximity switch after the stirring head is provided with the clamp holder, and the sheathed thermocouples are connected with a controller through a wireless transmission module. The method is characterized by dynamically adjusting the welding speed and the rotating speed of the stirring head through the sheathed thermocouples and pressure spring type thermocouples. According to the device and the method for the double-shaft shoulder FSW based on the temperature feedback of the leader region, disclosed by the invention, the structure is clever, the detection accuracy is high, the welding speed is dynamically adjusted through dynamically detecting the temperature of a welding workpiece, and the welding accuracy is high.

Owner:JIANGSU UNIV OF SCI & TECH

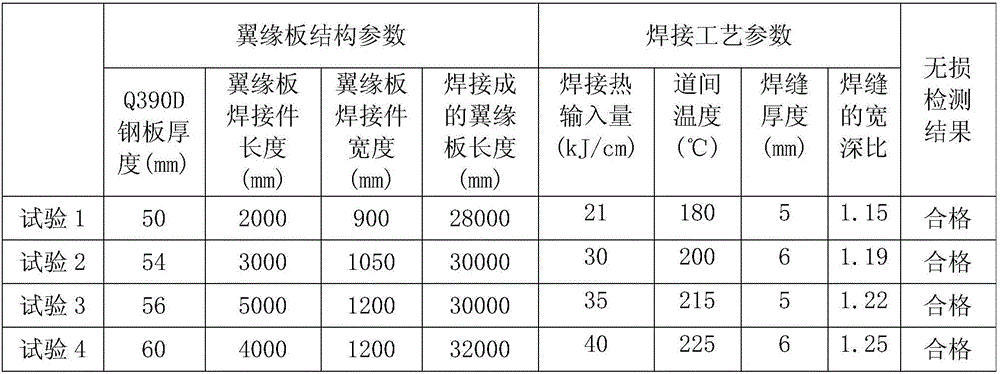

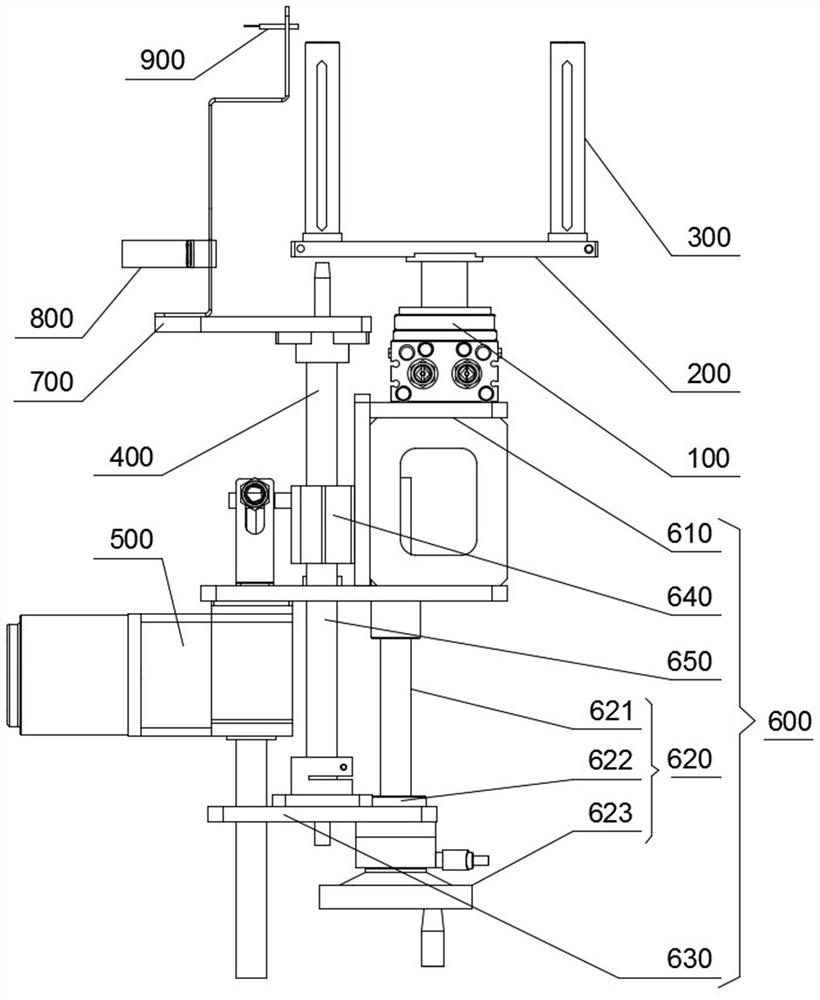

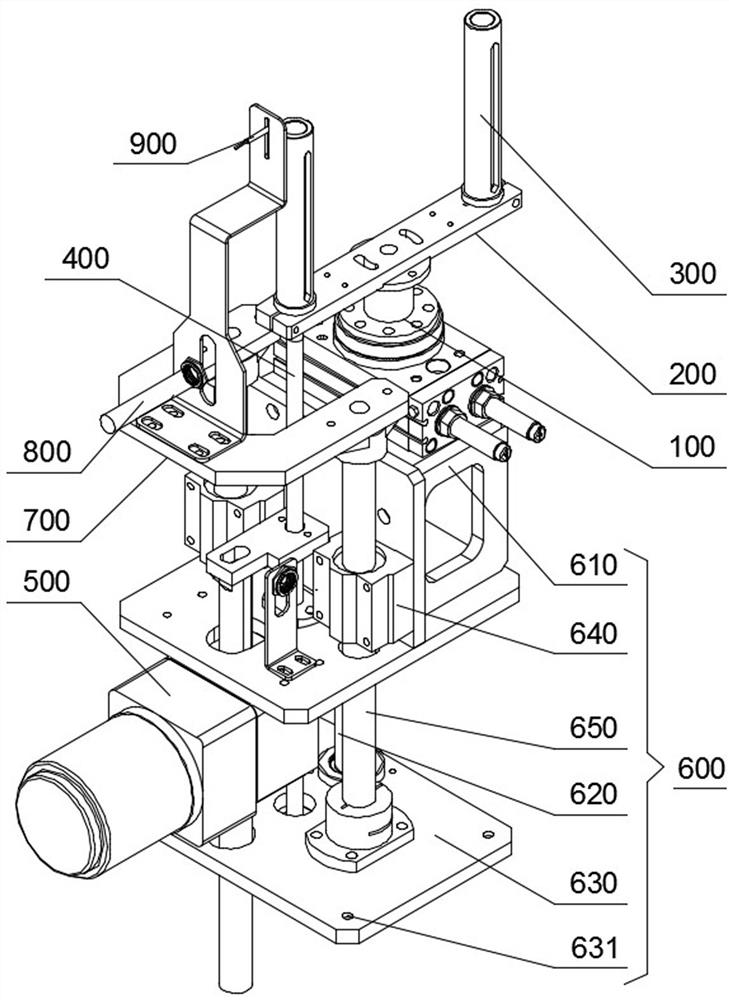

Welding method of flange plate and web plate of q390d steel crane girder in heavy work system

ActiveCN104759767BImprove impact toughnessReduce consumptionWelding/soldering/cutting articlesMetal working apparatusButt weldingEngineering

The invention discloses a flange plate and web welding method for a heavy derrick Q390D steel crane beam. The method comprises the six steps of manufacturing web welding parts and flange plate welding parts with butt welding grooves, dehumidifying the web welding parts and the flange plate welding parts, welding the web welding parts in a butting and full penetration mode to form a web, welding the flange plate welding parts in a butting and full penetration mode to form a flange plate, performing heat preservation and slow cooling on a web sealing joint an a flange plate sealing joint, combing and welding the web and the flange plate in a T shape in a full penetration mode, and performing heat preservation and slow cooling on a crane beam welding joint. In the process of manufacturing the web or the flange plate, the web welding parts and the flange plate welding parts are not preheated before welding; in the crane beam manufacturing process, the web and the flange plate are not preheated before welding. According to the flange plate and web welding method, the automatic submerged arc welding multi-layer and multi-pass welding technology is adopted, the welding automation degree is high, few cold cracks exist in a welding joint structure, the welding quality is high, the labor intensity of welding work is low, the welding cost is low, and welding time is greatly shortened.

Owner:CHINA 19TH METALLURGICAL CORP

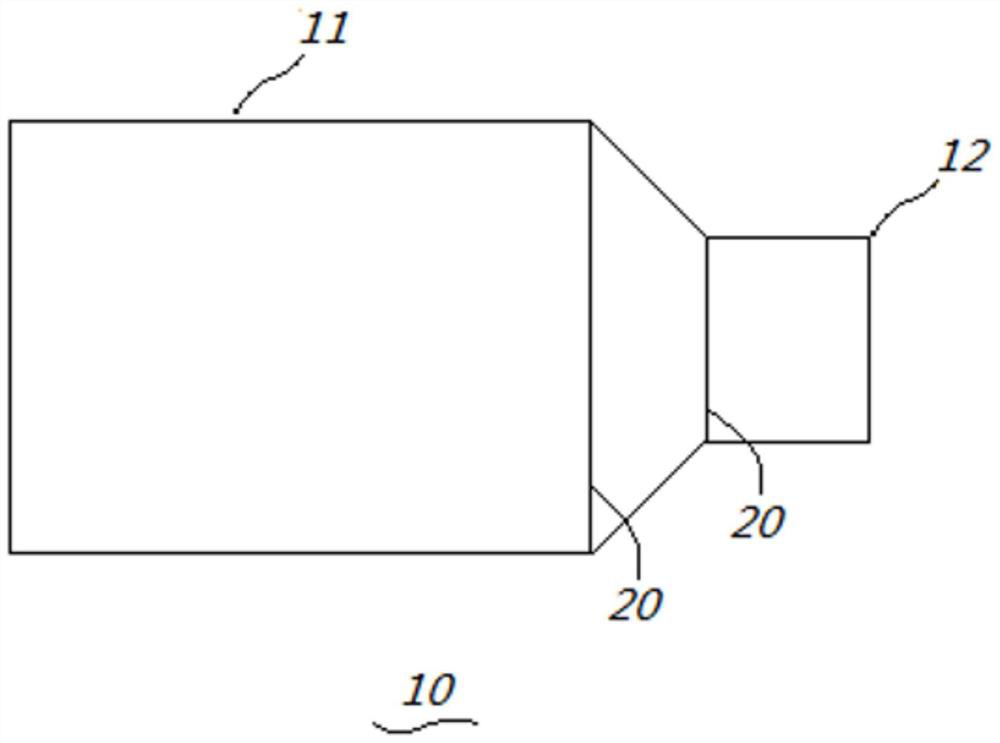

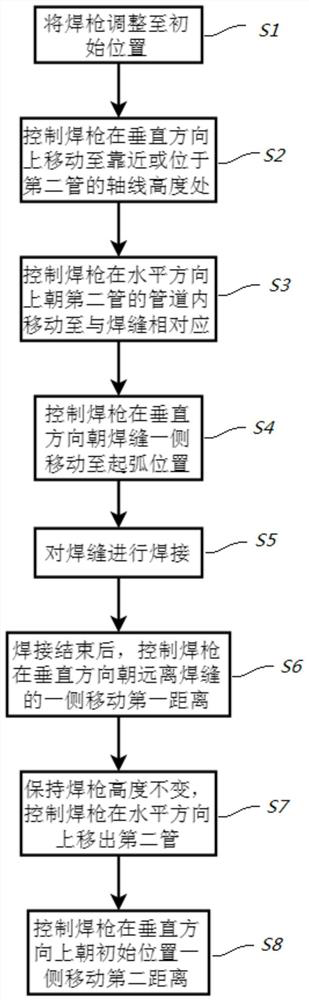

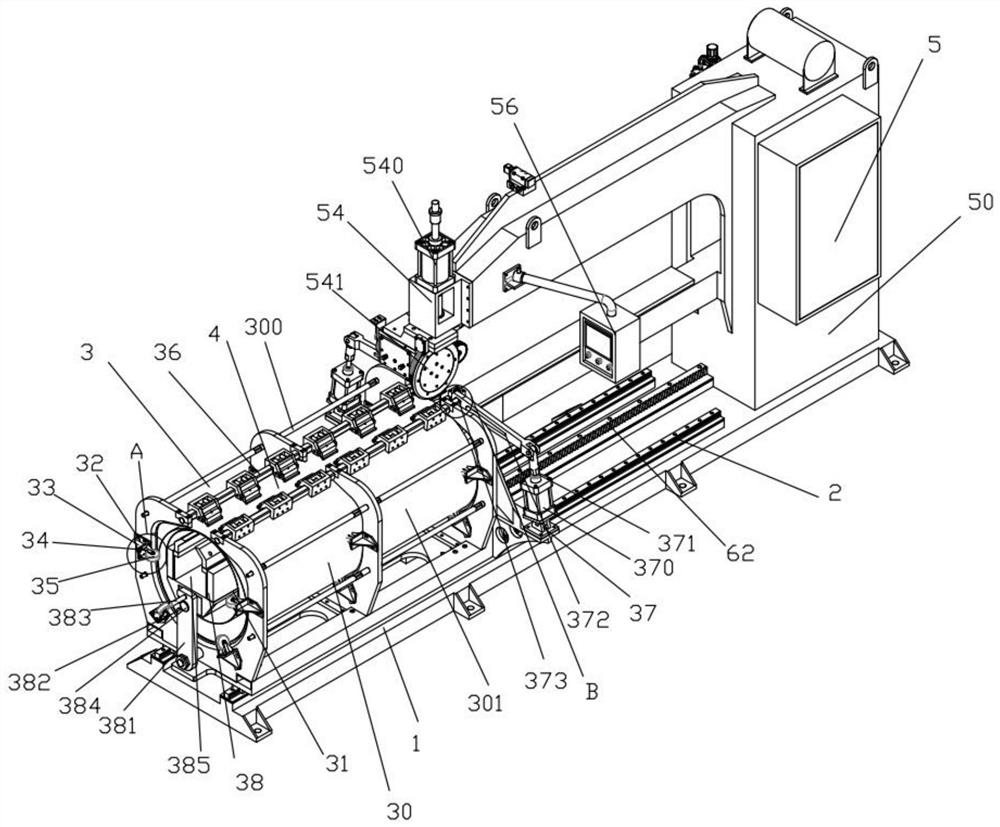

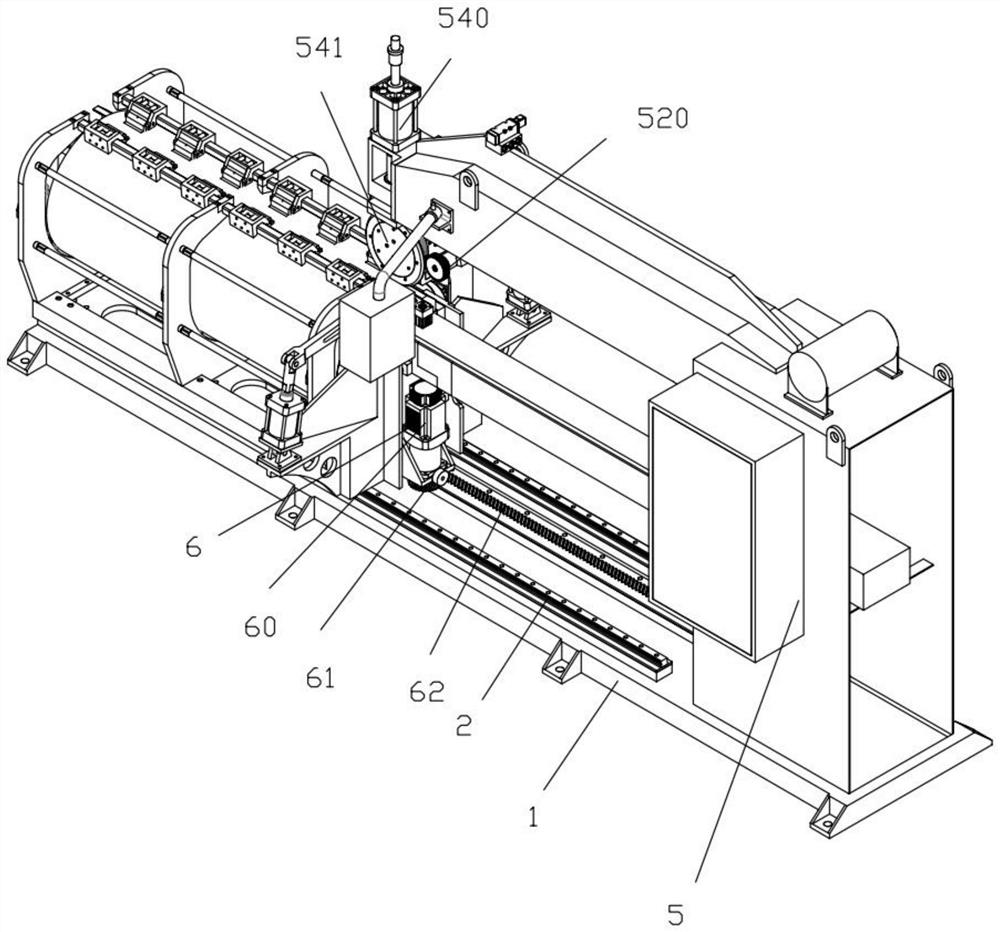

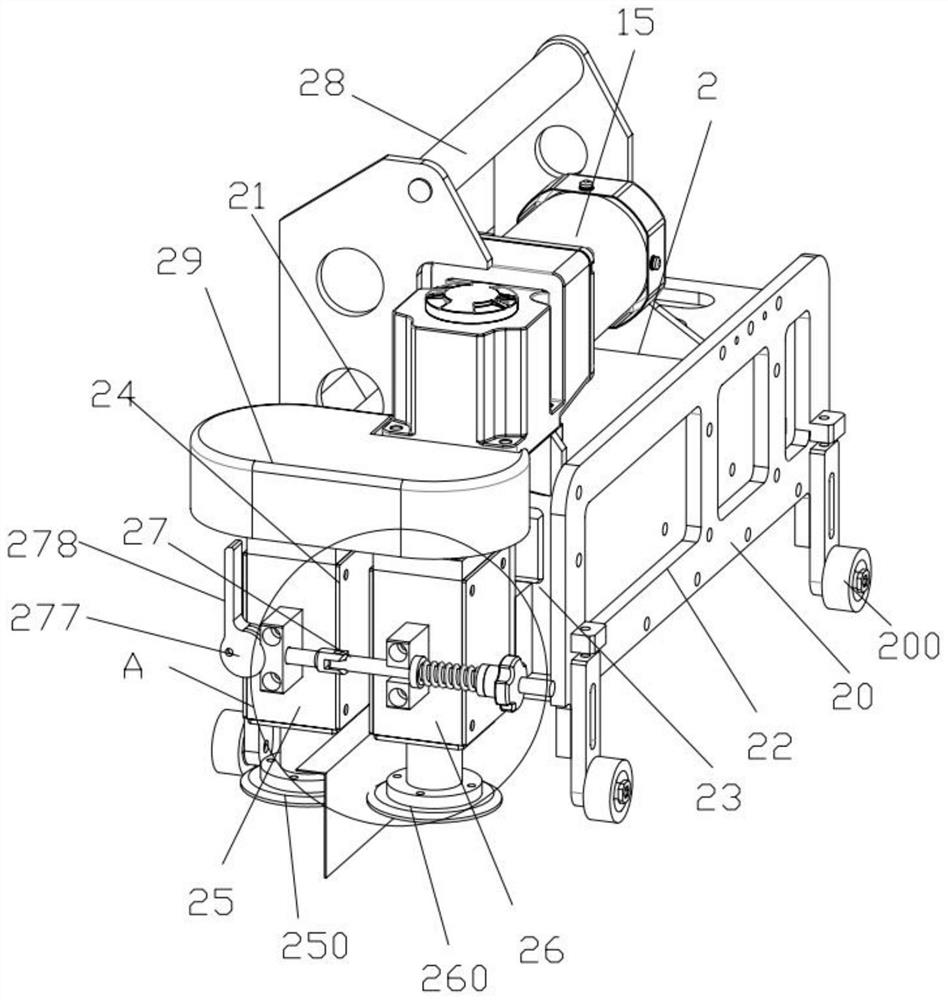

Control method of welding system of composite pipe

ActiveCN109967825BRealize automatic positioningGuaranteed positioningWelding/cutting auxillary devicesElectrode supporting devicesEngineeringWeld seam

The invention proposes a control method for a welding system of a composite pipe. The composite pipe includes a first pipe and a second pipe whose axes coincide in the horizontal direction, wherein the diameter of the first pipe is larger than that of the second pipe, and the diameter of the second pipe is larger than that of the second pipe. A weld seam is formed at the junction of the first pipe and the second pipe, the welding system includes a welding torch, and the welding torch is equipped with at least one tungsten electrode. The composite pipes interfere with each other; control the welding torch to move vertically close to or at the height of the axis of the second pipe; keep the height of the welding torch unchanged, and control the welding torch to move horizontally toward the second pipe to the same height as the second pipe The welding seam is corresponding; the welding torch is controlled to move to the arc starting position in the vertical direction toward the side of the welding seam; and the welding seam is welded. The control method reduces the labor intensity of operators, improves the degree of welding automation, effectively ensures the positioning and even forming of welding seams, and improves welding efficiency.

Owner:HUAHENG WELDING +2

An automatic seam welding machine for oil barrels

ActiveCN110039164BUniform welding rateGood welding performanceWelding/cutting auxillary devicesRectilinear seam weldingEngineeringSeam welding

The invention relates to the field of oil barrel processing, in particular to an automatic seam welding machine for oil barrels, which includes a base, a positioning jig for fixing the oil barrel, a driving mechanism for driving the positioning jig to move relative to the base, and a positioning jig for A welding machine for welding oil drums. The welding machine includes a welding frame connected to the end of the base. The welding frame is provided with an upper arm and a lower arm extending toward the direction of the positioning fixture. The free end of the upper arm is connected with an upper arm. The electrode assembly, the lower electrode assembly includes the lower electrode. By setting the upper and lower electrodes, it is also provided with a positioning jig capable of positioning the oil drum and a driving mechanism for driving the positioning jig to move, so that the upper and lower electrodes can be aligned with the oil drum. The joints are welded continuously, the welding automation is high, the welding efficiency is high, and the positional relationship between the oil drum and the upper and lower electrodes is stable, and the welding speed is uniform, so the welding performance is excellent.

Owner:HUASHI POWER SUPPLY TECH JIANGXI CO LTD

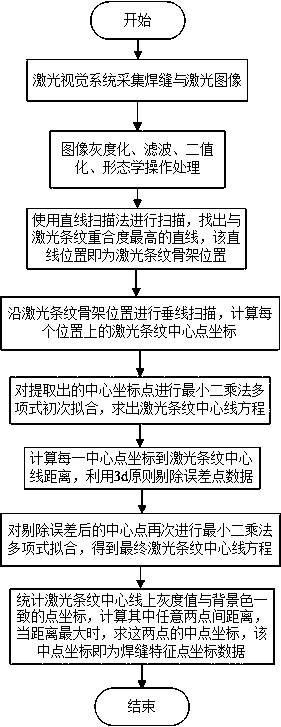

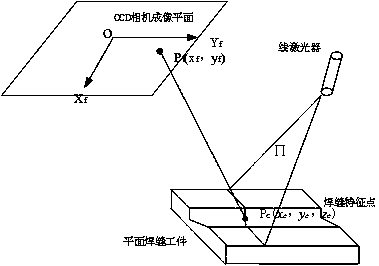

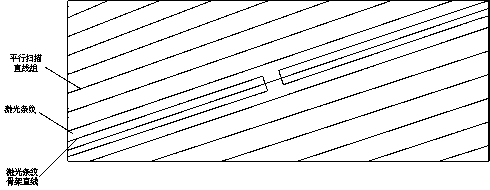

A Method of Extracting Feature Points of Plane Weld Based on Laser Vision System

InactiveCN108132017BThe experiment process is simpleHigh precisionUsing optical meansRectilinear ScanImaging Feature

Owner:CHINA JILIANG UNIV

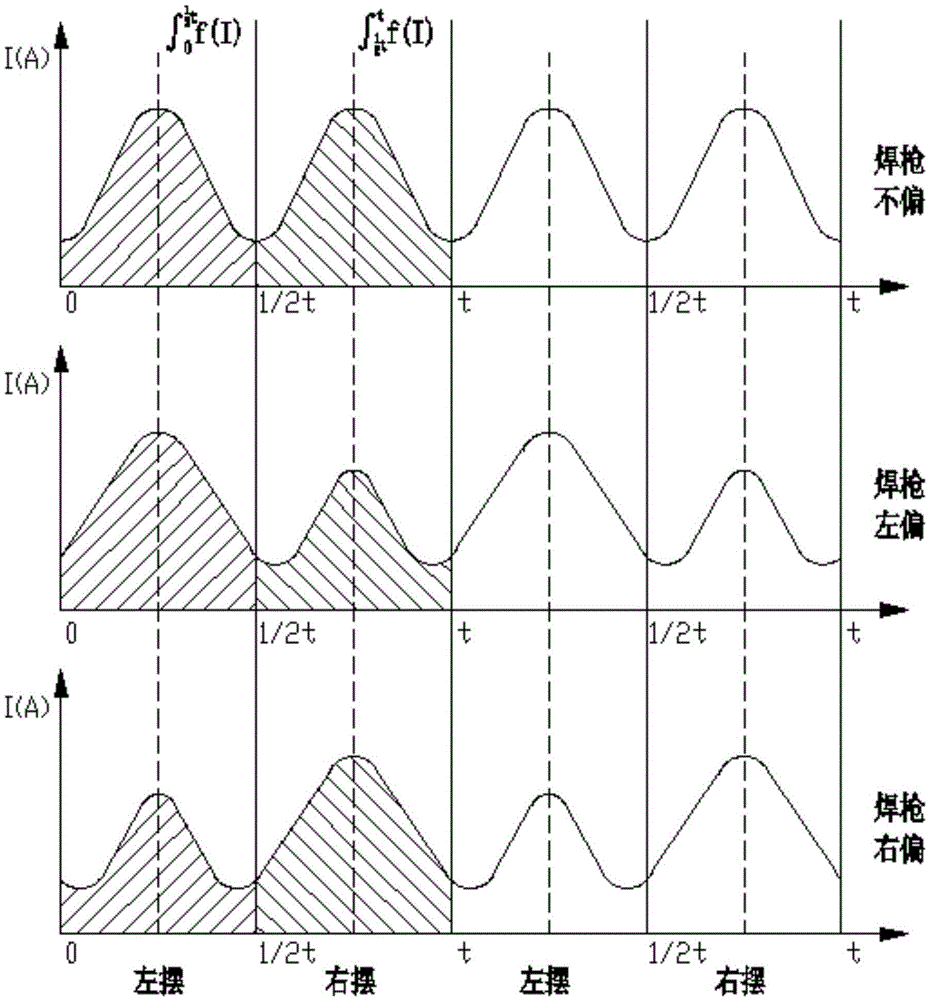

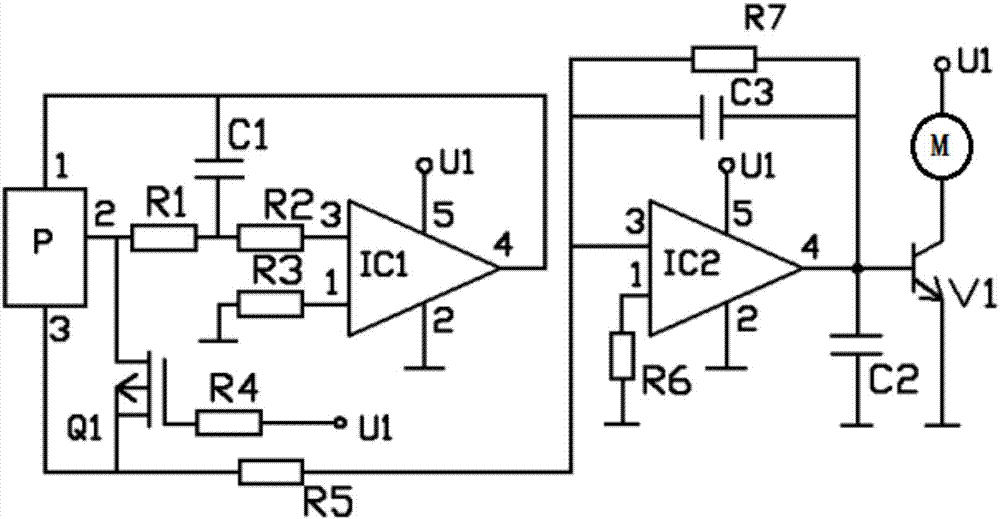

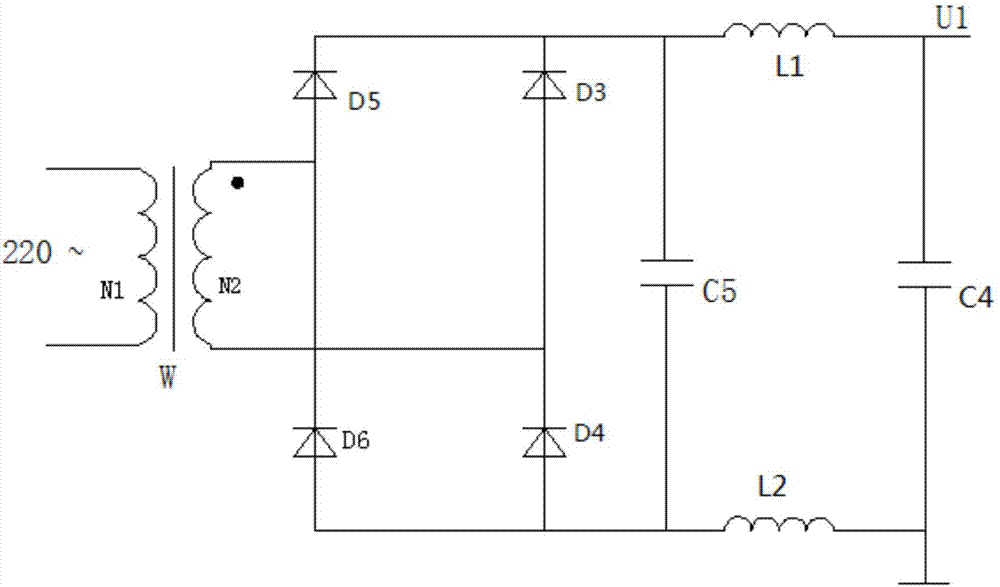

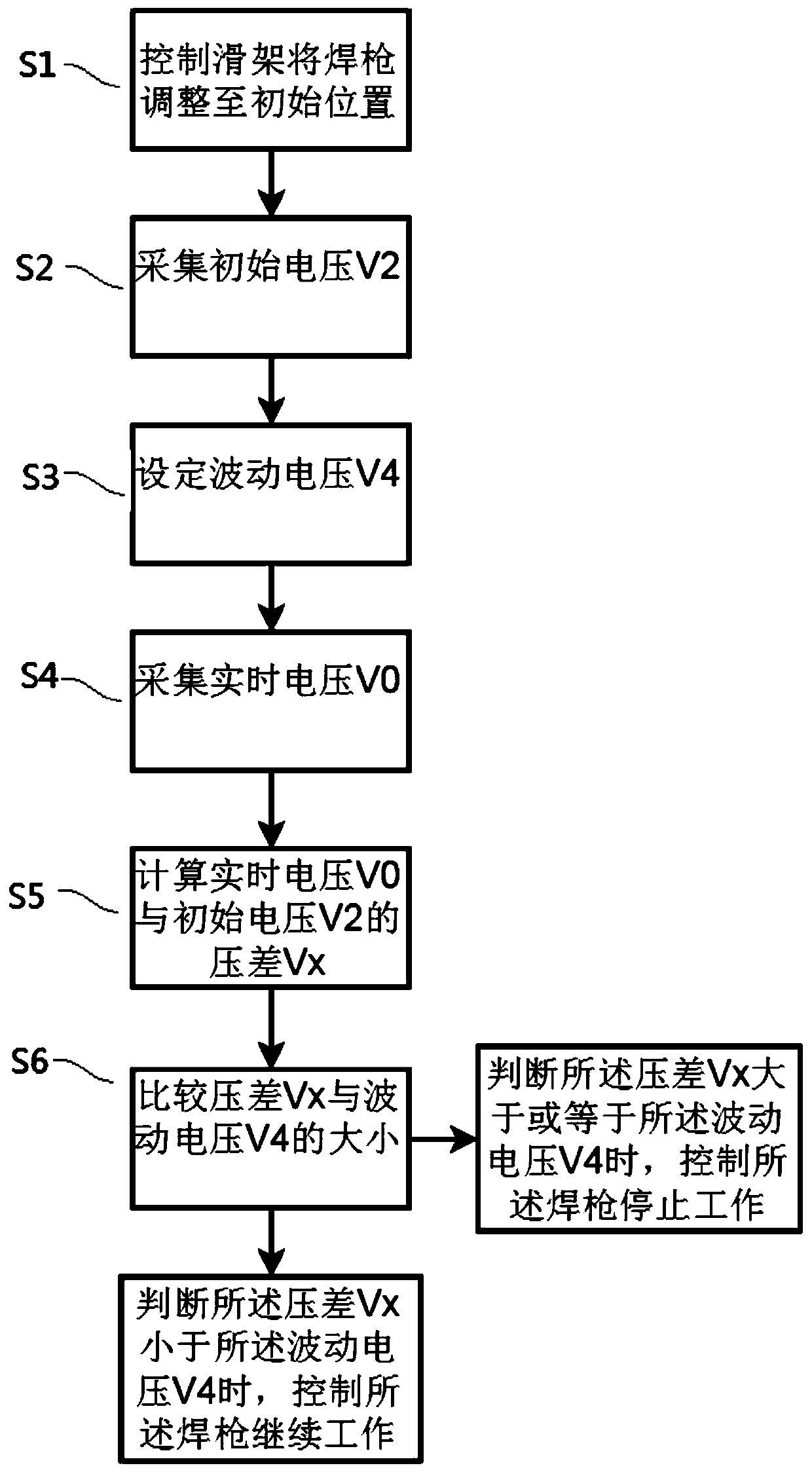

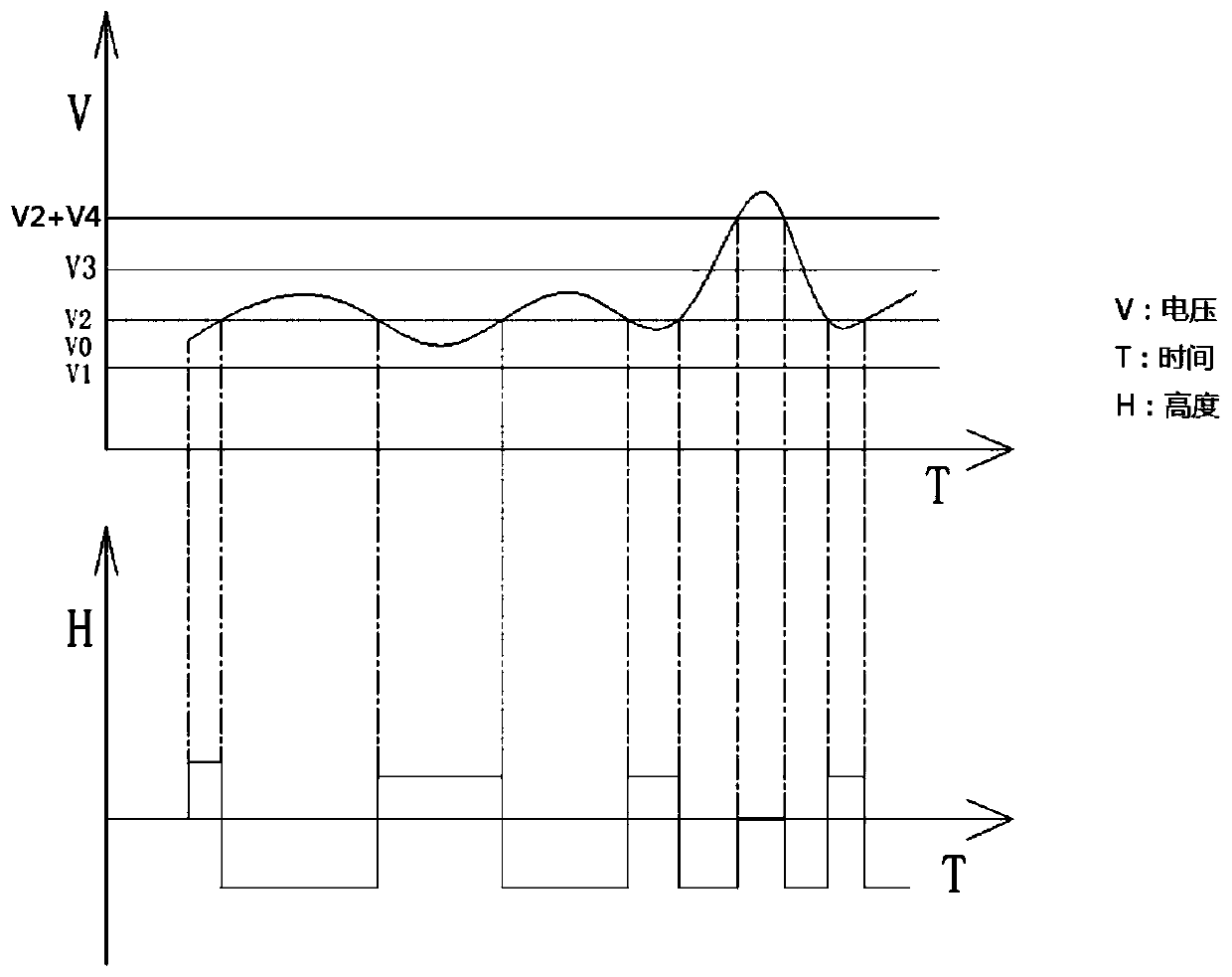

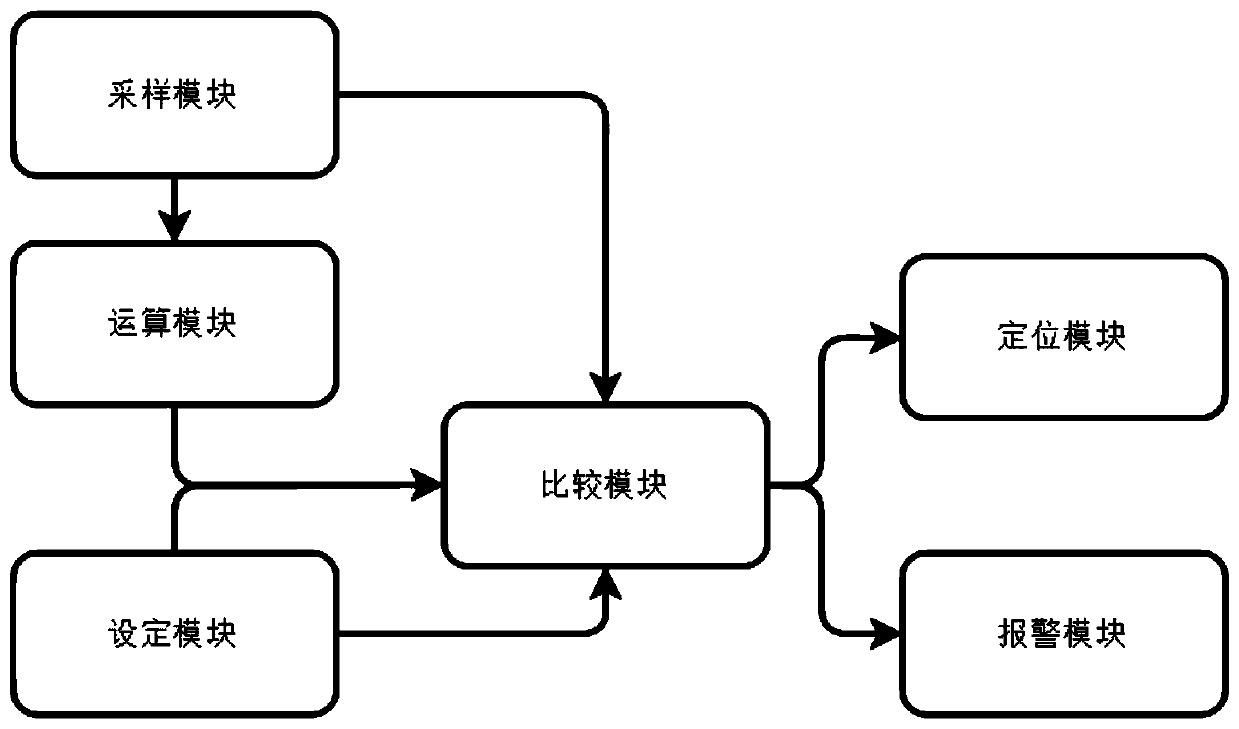

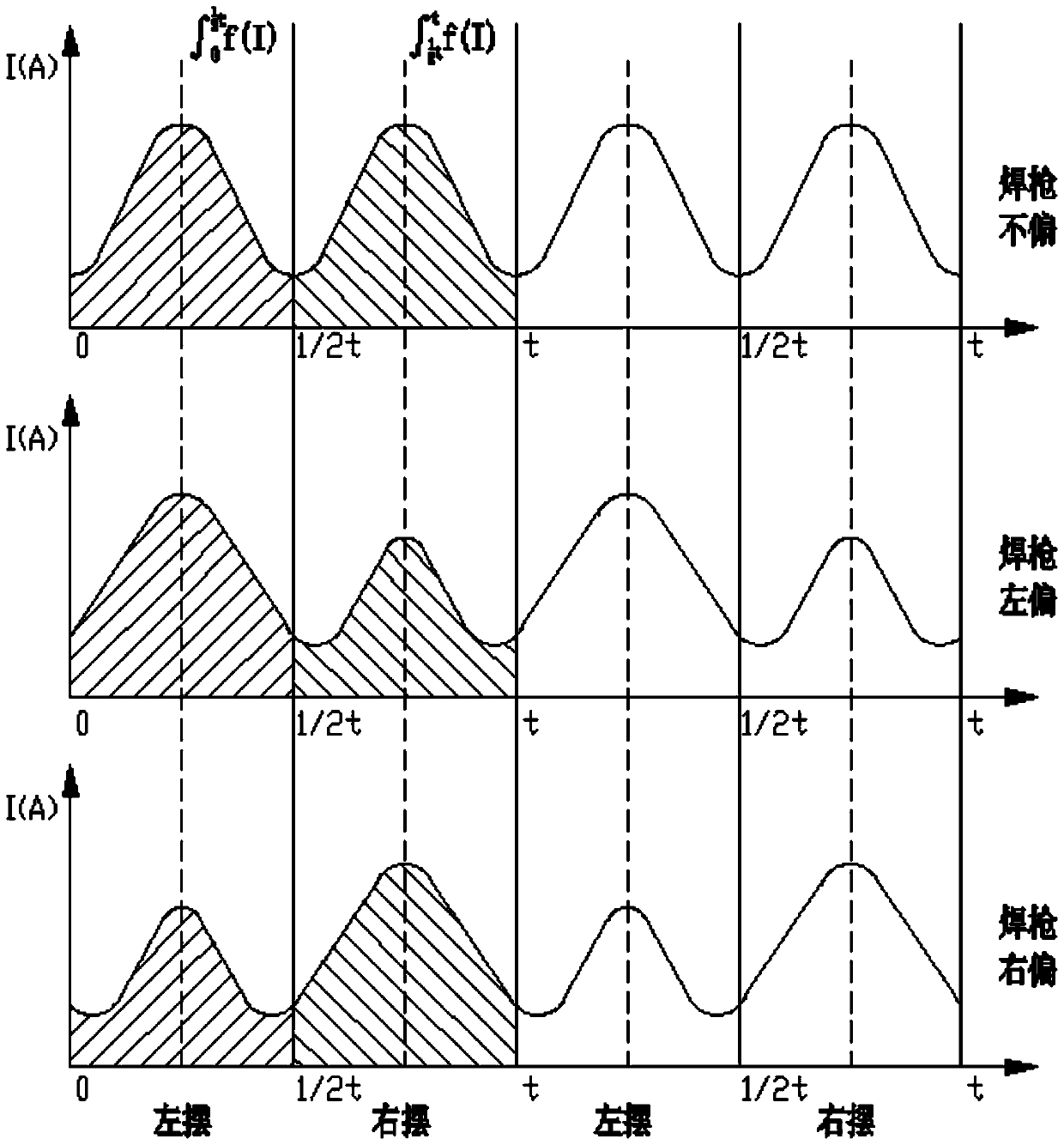

Welding gun control method and control system thereof

InactiveCN109877421AReduce requirements and labor intensityHigh degree of welding automationWelding accessoriesElectric arcEngineering

The invention provides a welding gun control method and a control system thereof. A welding gun is controlled by a sliding frame to carry out tracking welding. The control method comprises the following steps of controlling the sliding frame to adjust the welding gun to an initial position; turning on a power supply, collecting and recording the initial voltage V2 of electric arcs generated when the welding gun is located at the initial position; setting the fluctuation voltage V4; starting welding, tracking and collecting the real-time voltage V0 of electric arcs generated by the welding gunaccording to the real-time height of the welding gun in operation; calculating the voltage difference VX between the real-time voltage V0 and the initial voltage V2; when it is judged that the voltagedifference VX is smaller than the fluctuation voltage V4, controlling the welding gun to continue working; and controlling the welding gun to stop working when it is judged that the voltage difference VX is greater than or equal to the fluctuation voltage V4. The welding gun control method greatly reduces the degree of human intervention caused by burning through of workpieces in the welding process, improves the welding automation degree, improves the working efficiency, avoids the danger of welding gun falling, saves the production cost, and is more economical and efficient.

Owner:HUAHENG WELDING +2

A Portable Roof Seam Welder

ActiveCN109877435BHigh degree of welding automationImprove welding efficiencyElectrode featuresWelding with roller electrodesElectric machinerySeam welding

The invention relates to the technical field of seam welding machines, and specifically to a portable roof seam welding machine, which includes an independent power supply car and a welding machine. The welding machine is connected to the power supply car through lines. The welding machine includes a base and an electrode fixed on the base. assembly, adjustment mechanism and control device. The roof panel is located between the first electrode pressing wheel of the first electrode assembly and the second electrode pressing wheel of the second electrode assembly of the welding machine. After the welding machine is connected to the power supply vehicle through lines and energized, so that The first electrode pressing wheel and the second motor pressing wheel can weld the roof panel, with a high degree of welding automation, increased welding efficiency and stable welding performance.

Owner:GUANGDONG HWASHI TECH INC

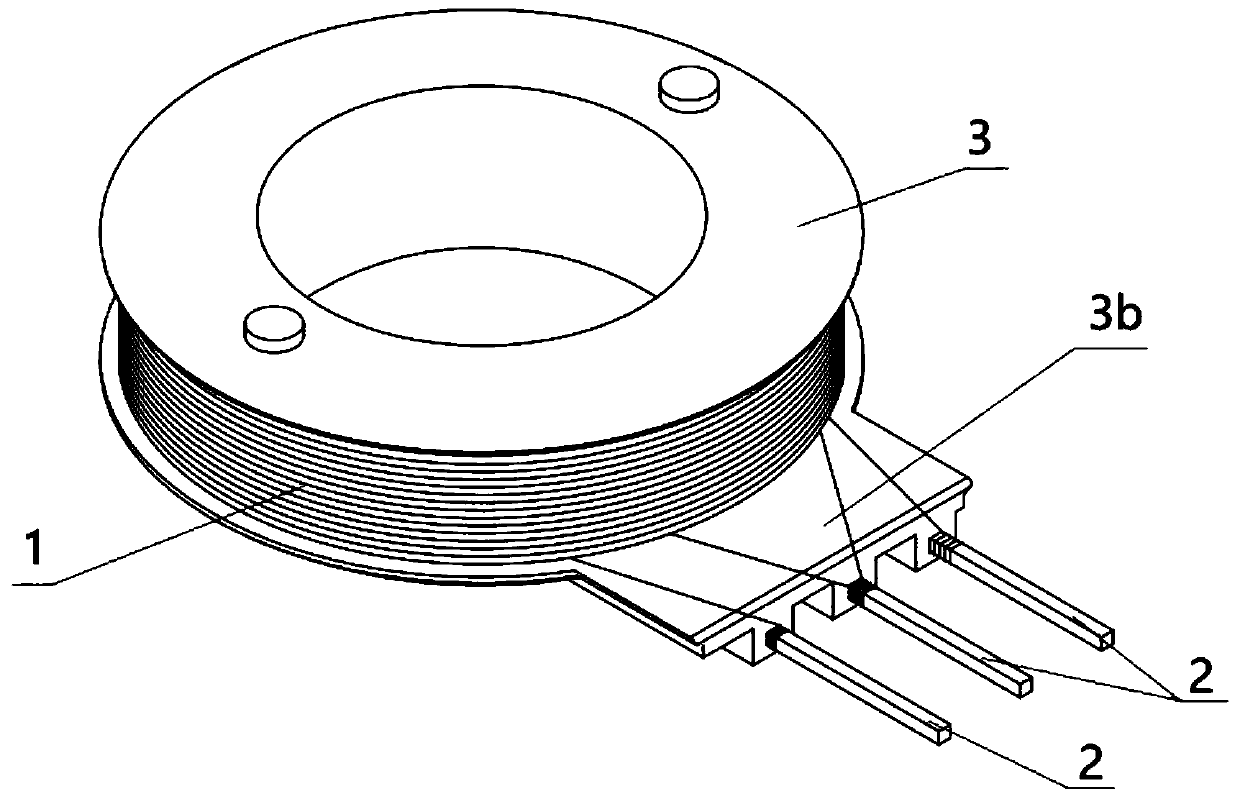

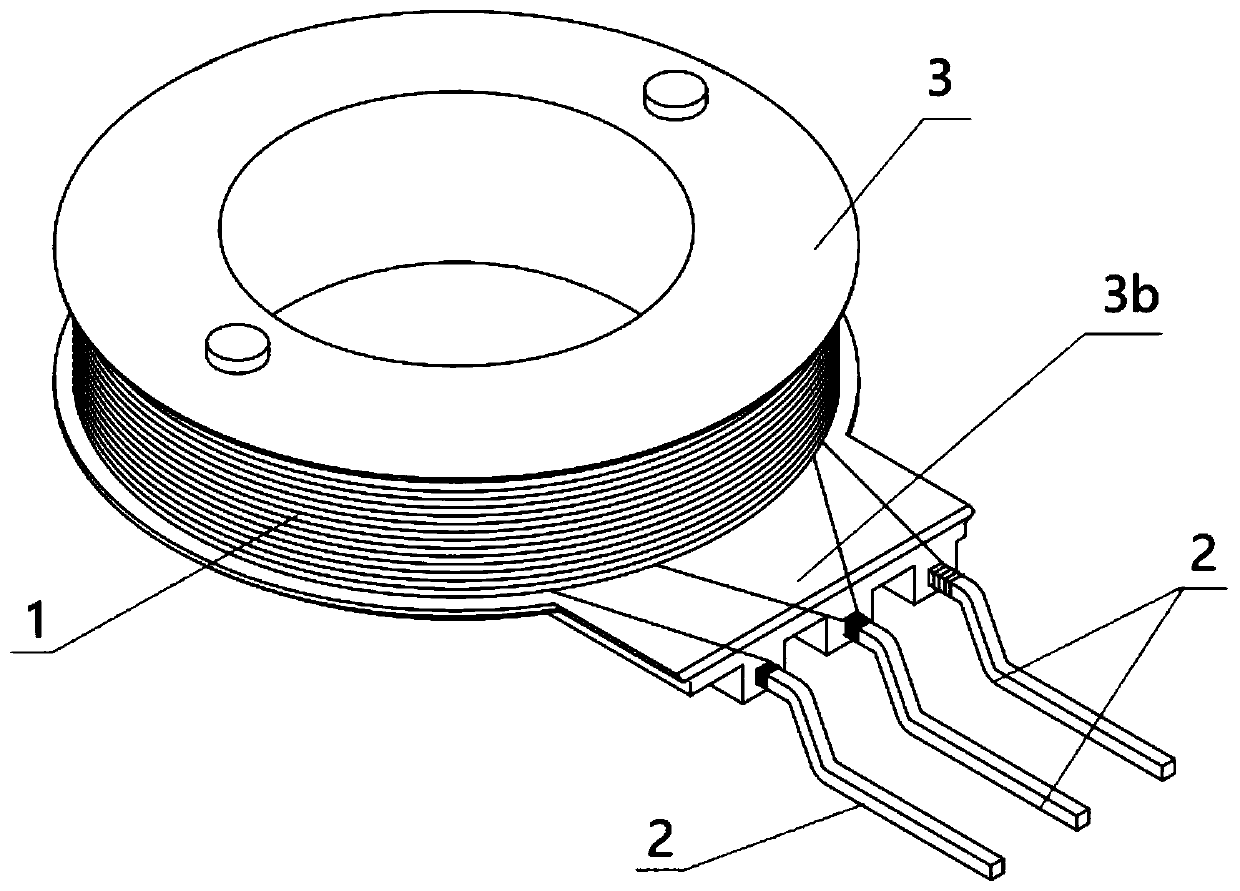

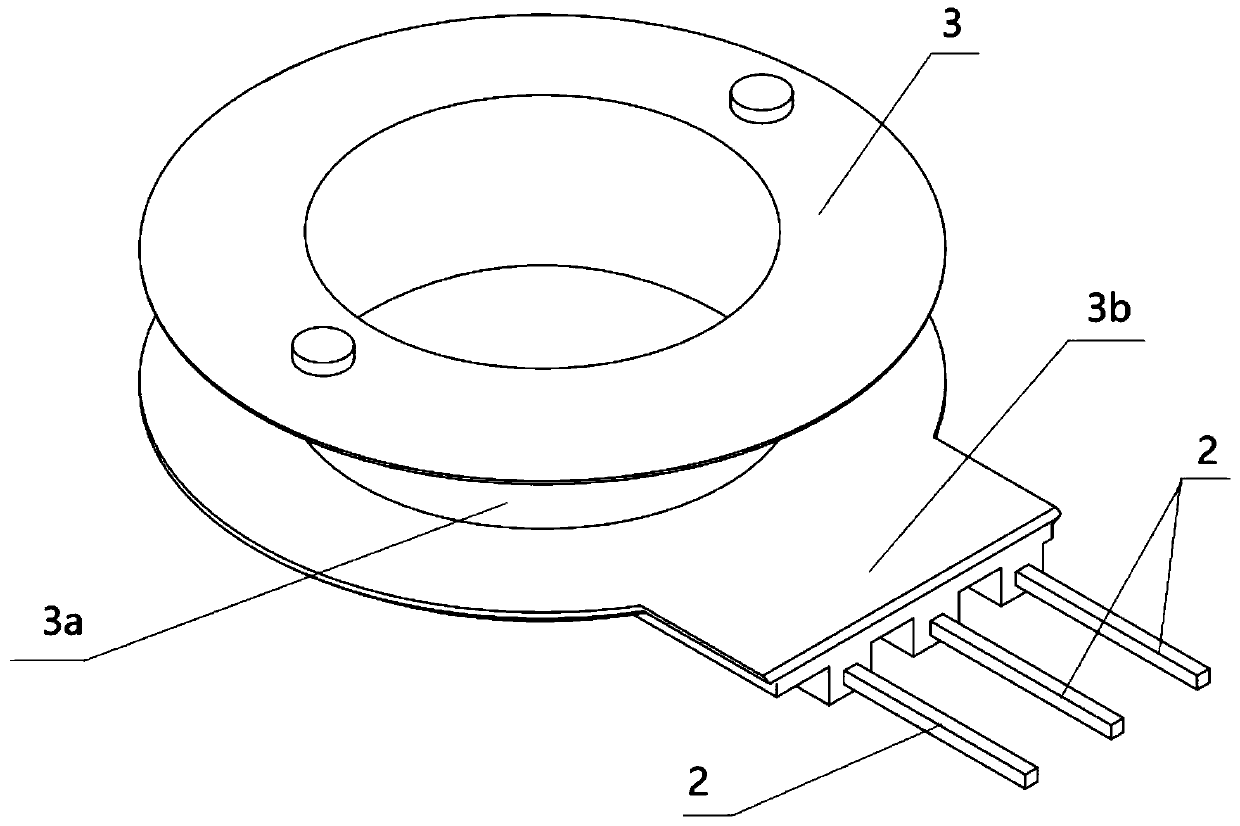

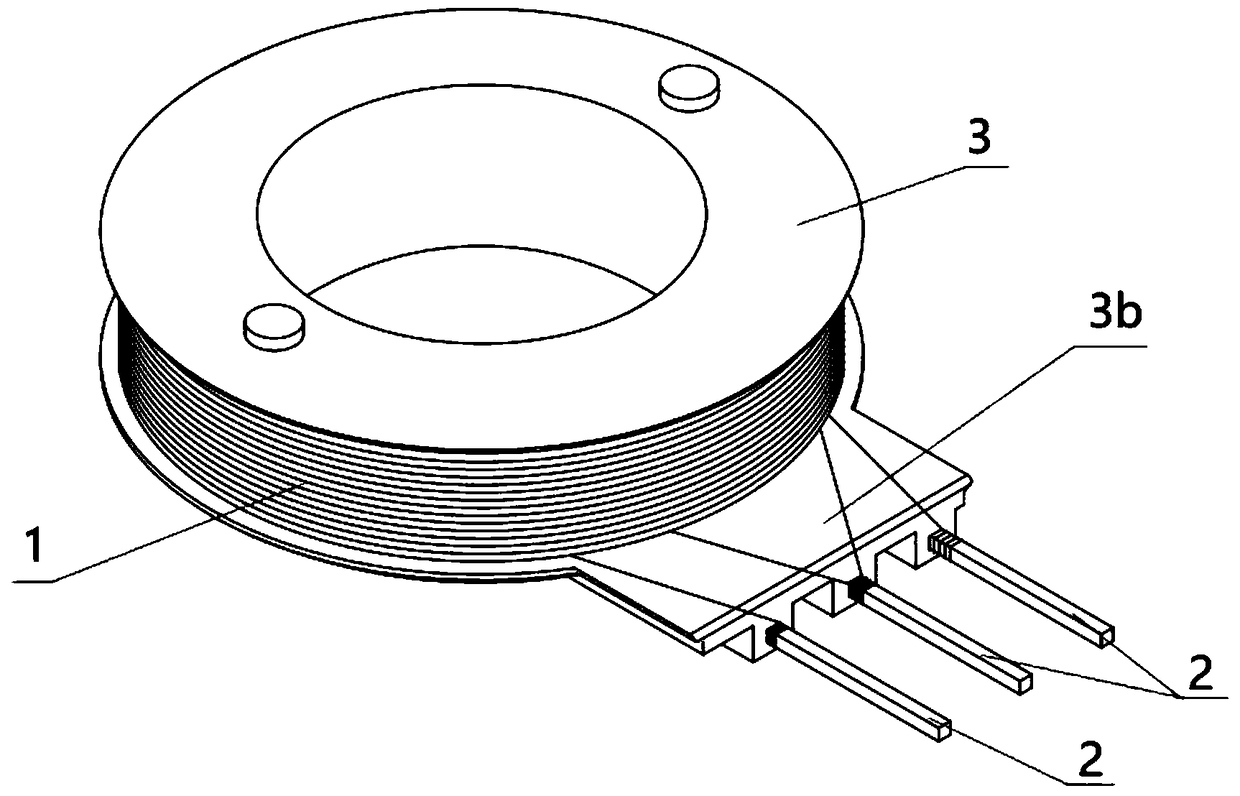

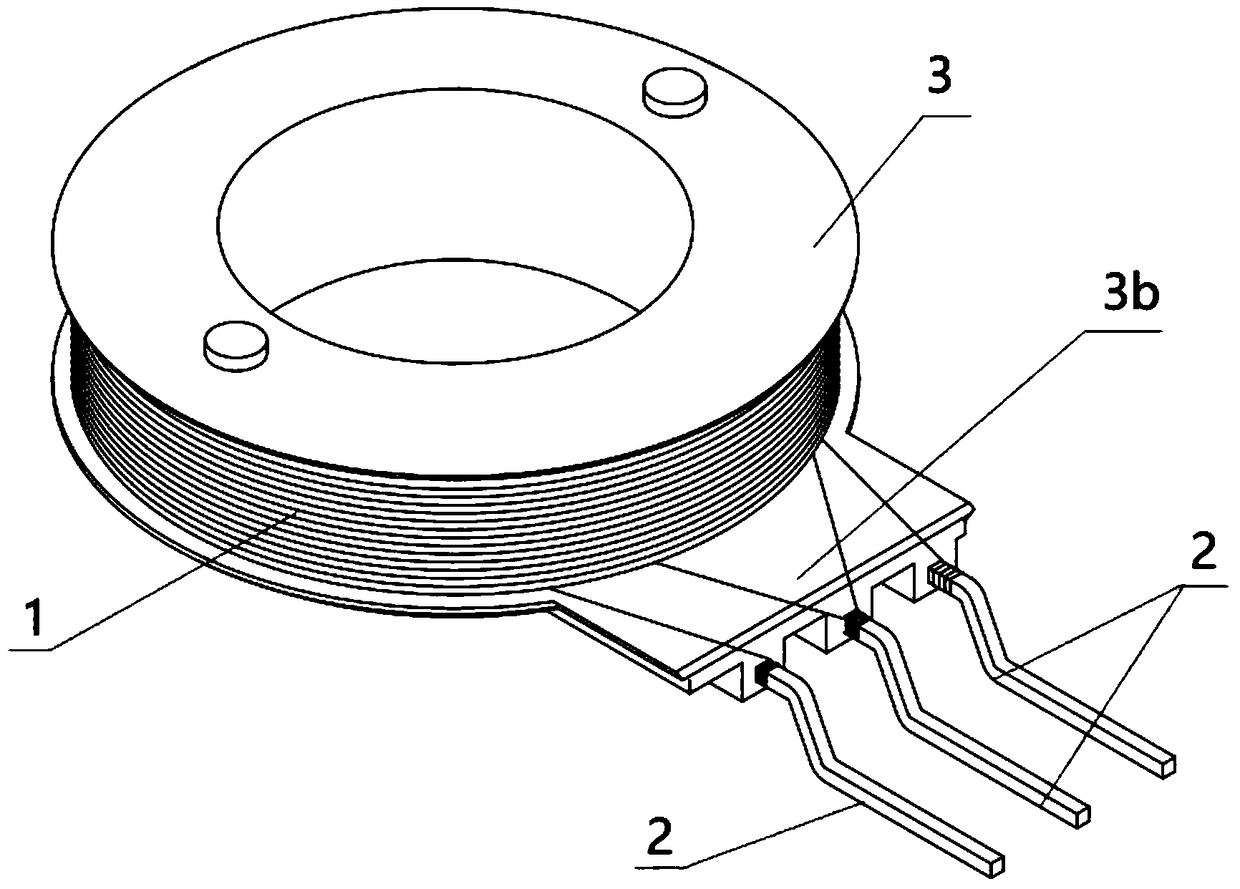

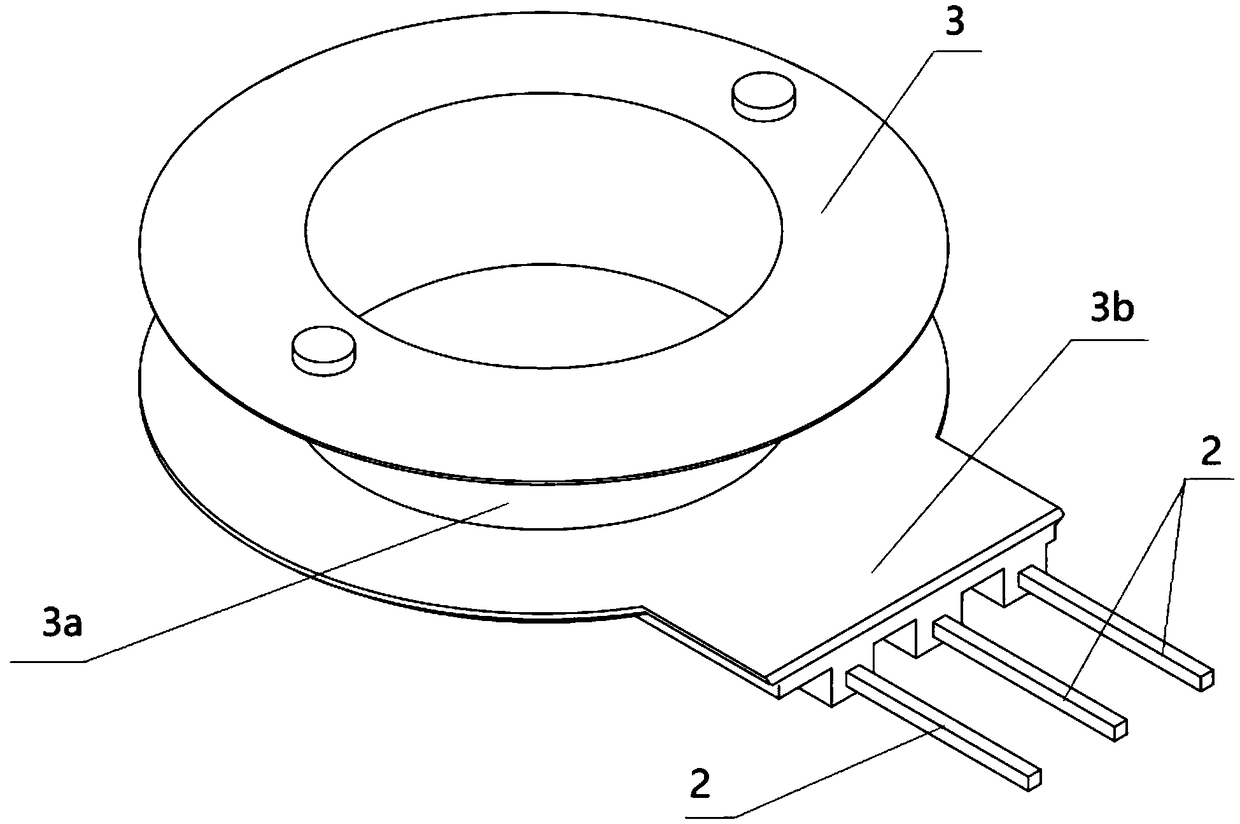

Electromagnetic coil

ActiveCN108777223BPrecise positioningEasy to implement weldingTransformers/inductances coils/windings/connectionsEngineeringWire wrap

Owner:江苏华阳智能装备股份有限公司

Friction Welding Method for Standard Section Web Rod of Tower Crane

ActiveCN104259649BQuality improvementAvoid uneven qualityNon-electric welding apparatusFriction weldingEngineering

The invention discloses a friction welding method for a standard section web of a tower crane. The web is welded by a steel pipe and an end plate. The friction heating process is divided into two stages of primary friction and secondary friction, and the two stages rotate the main shaft The rotation speeds of the first and second frictions are equal, the first-order friction pressure and friction time are fixed; the second-order friction pressure is greater than the first-order friction pressure and fixed, when the total friction deformation of the first-order friction and the second-order friction reaches the preset value, the second-stage friction heating ends; After the stage friction is over, the rotating fixture is braked, and after the main shaft holding the end plate stops rotating, the moving fixture holding the steel pipe is fed for upsetting, and the friction welding process is completed after upsetting and maintaining pressure. The invention omits the process of "grooving and turning the boss" in the existing processing flow; the rotating speed in the friction heating stage is fixed, which is easy to control; the amount of friction deformation can be controlled, which improves the stability of the welding length of the web; improves the production efficiency and reduce production costs.

Owner:SICHUAN CONSTR MACHINERY GRP

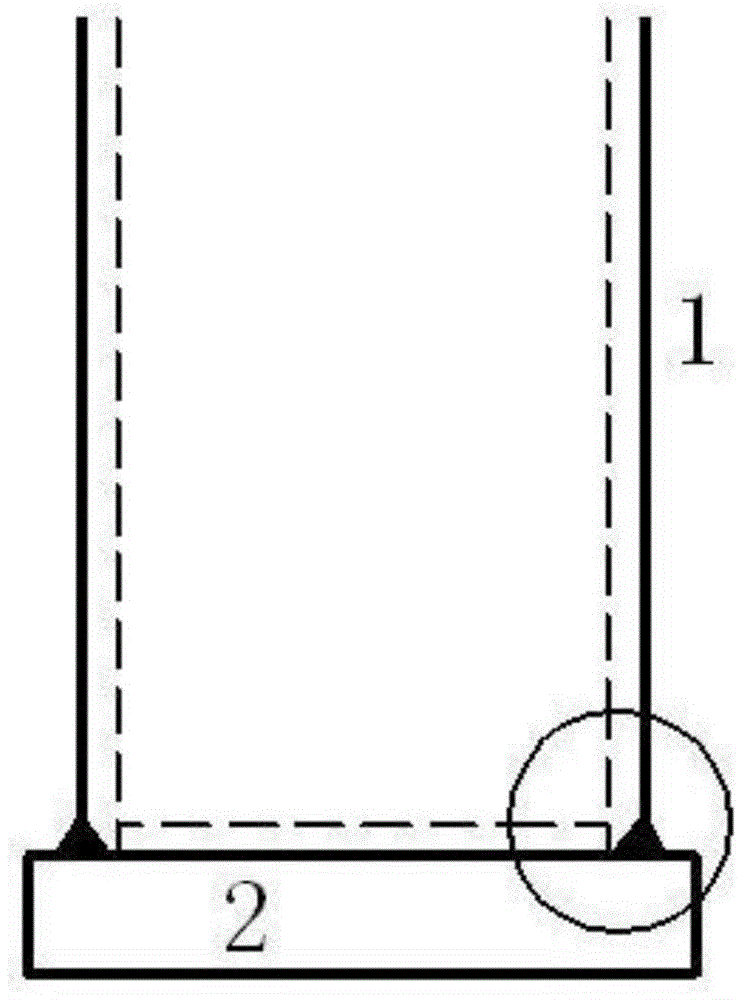

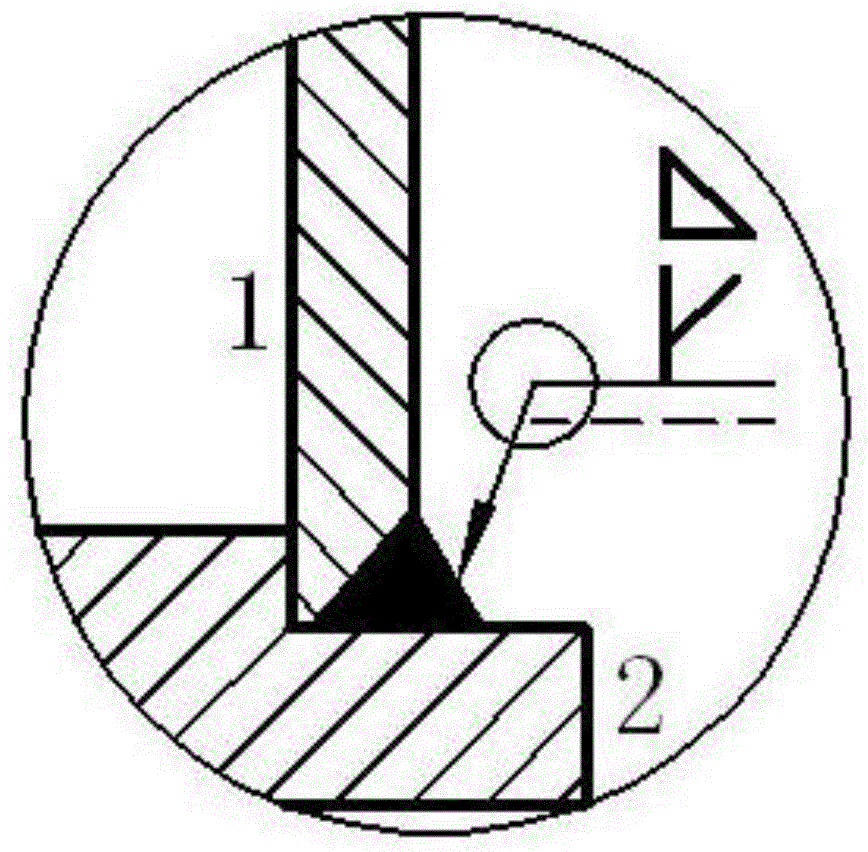

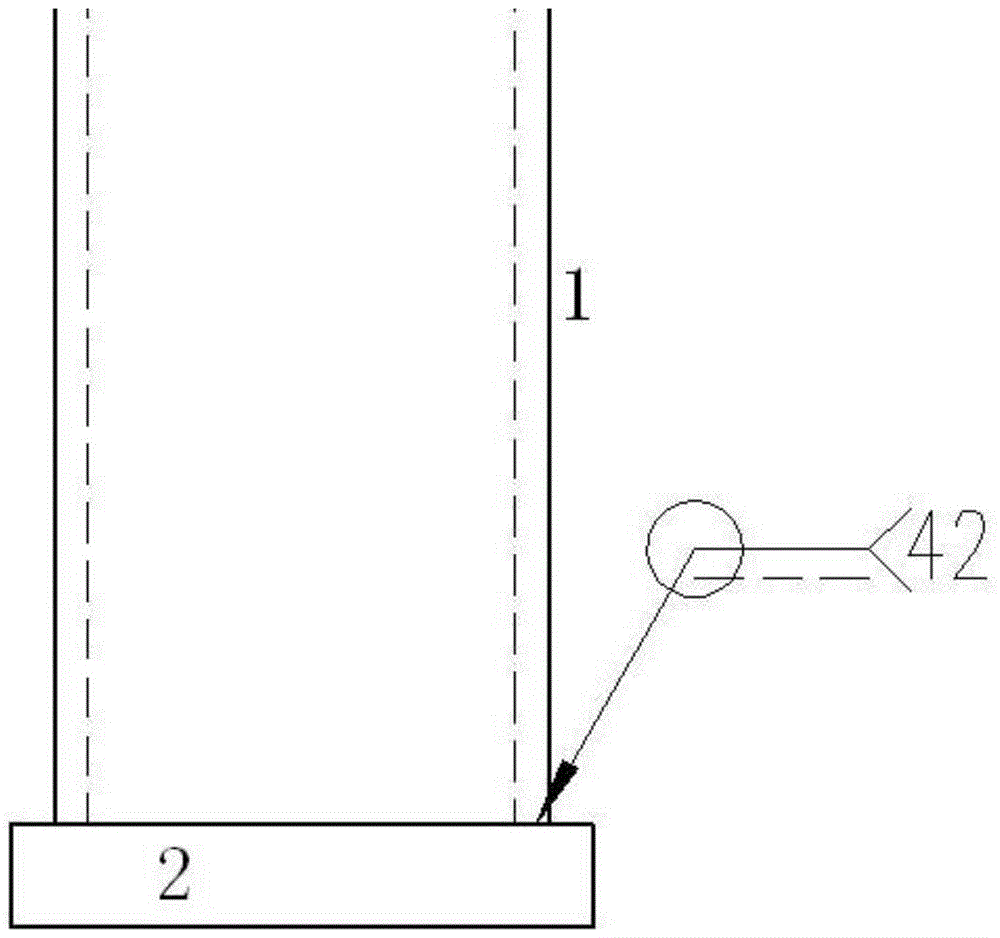

A tool for automatic welding of thick-walled hollow rods

InactiveCN103639635BAvoid frequent adjustmentsHigh degree of welding automationWelding/cutting auxillary devicesArc welding apparatusWeld seamThick wall

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

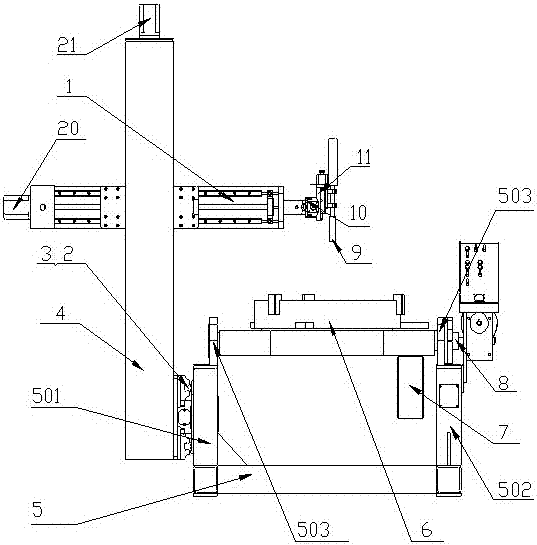

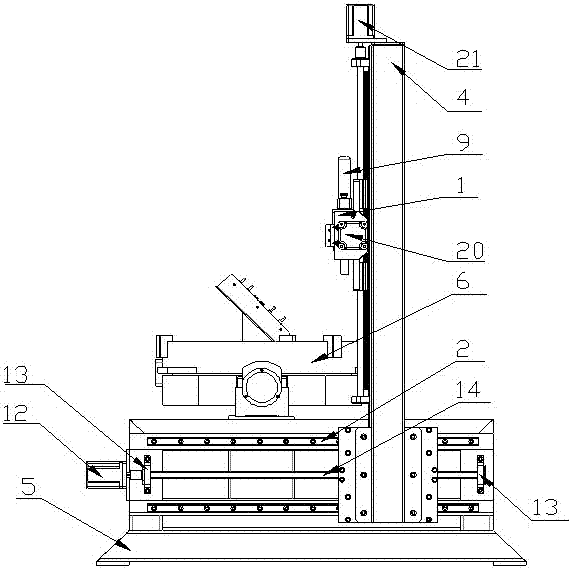

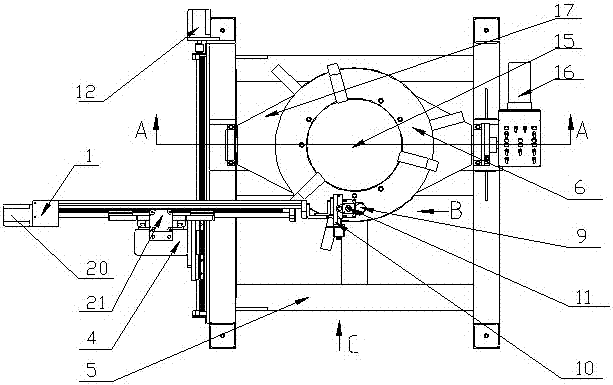

One-piece flange automatic welding equipment with central through hole

ActiveCN105269116BReduce labor intensityImprove welding efficiencyWelding/cutting auxillary devicesElectrode holder supportersAutomatic test equipmentClosed loop

The invention discloses an integral flange automatic welding device with a central through hole. The welding cross arm is slidably connected to the base of the positioner, and can move forward and backward relative to the base; the welding chuck is connected to the main motor through the rotary support fixed on the turning frame; the turning frame has a central through hole, and the workpiece can pass through the center through the hole The welding chuck can hold any part of the workpiece, so that the positioner, welding power supply and welding torch can be integrated structure, not only suitable for long pipe welding, but also when there are multiple welds on the workpiece, no need Repeatedly changing the relative position of the welding cross arm and the positioner can complete the welding of all welds on the workpiece. The welding cross arm is equipped with a welding oscillator and an arc length regulator. The welding torch is installed on the arc length regulator, which can automatically realize the swing and up and down adjustment, and is suitable for weldments with groove requirements and workpieces with obvious ellipticity. Welding, without human adjustment or intervention, realizes closed-loop control, and the welding quality is easy to guarantee.

Owner:JINAN JINLUDING WELDING TECH CO LTD

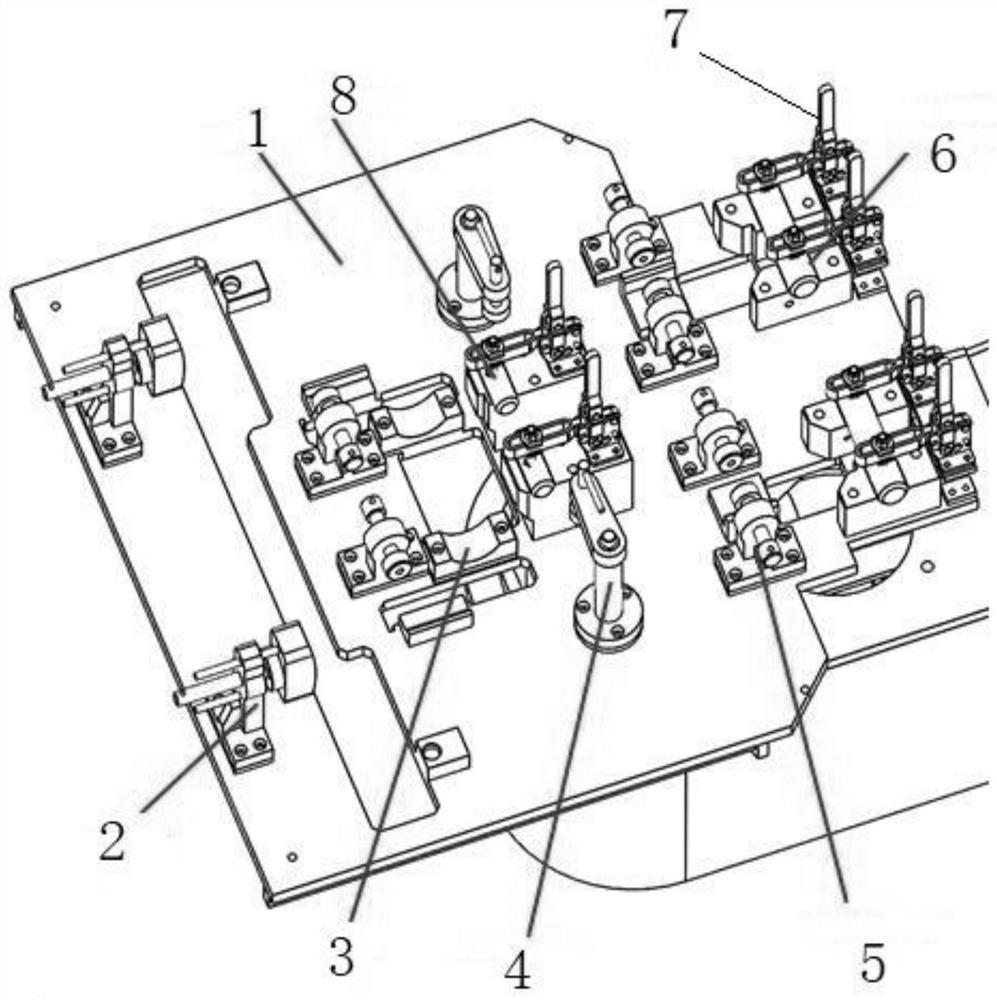

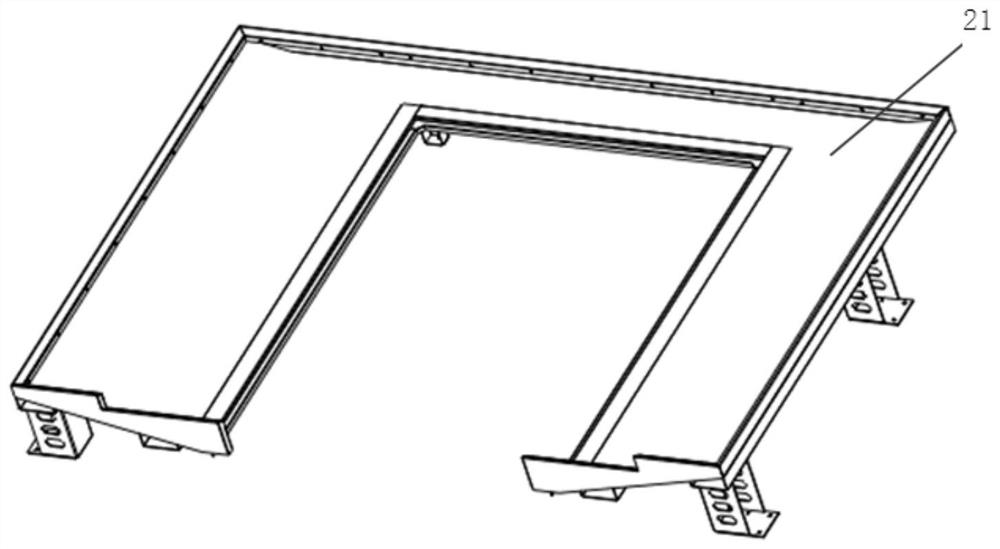

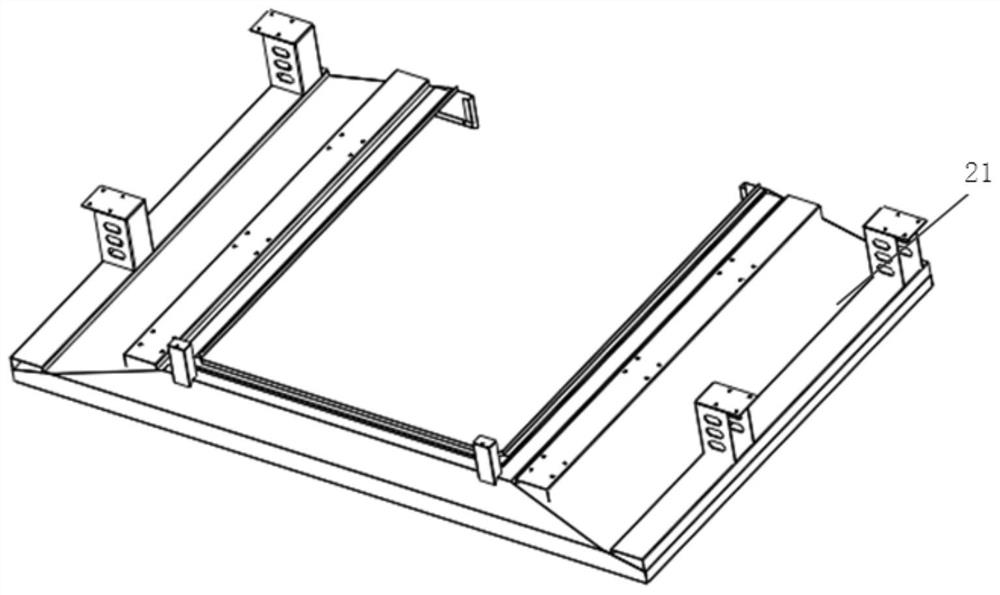

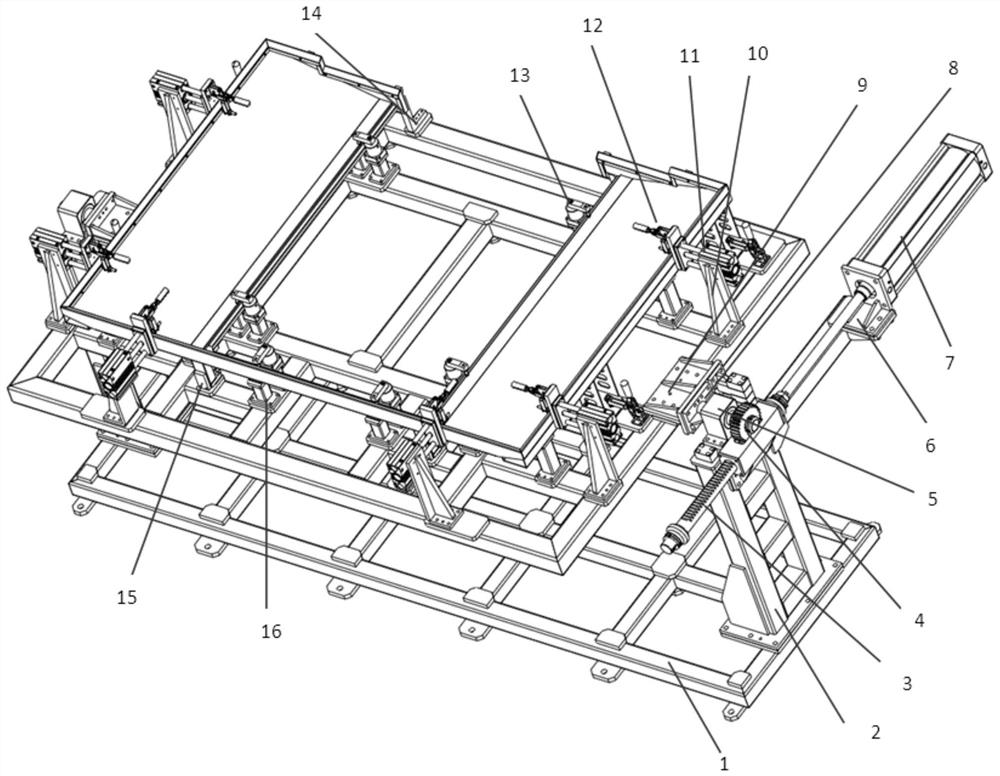

Automatic welding jig for engineering machinery excavating equipment

PendingCN113102920APrecise positioningAvoid displacementWelding/cutting auxillary devicesAuxillary welding devicesThermal deformationCantilever

The invention discloses an automatic welding jig for engineering machinery excavating equipment, which comprises a welding base, wherein the welding base comprises a bottom plate and a support; a shovel plate pressing device, a supporting tube positioning reference, a supporting arm vertical pressing device, a supporting arm horizontal pressing device, a bearing seat positioning shaft, an oil cylinder lug plate positioning shaft and a vertical pressing quick clamp are arranged on the bottom plate; the shovel plate pressing device comprises a shovel plate base support pushing screw rod, a guide rod and a pressing block; the supporting tube positioning reference is fixed on the welding base; the supporting arm vertical pressing device comprises a support, a cantilever and a pressing screw rod I; the support is fixed on the welding base; the pressing screw rod I is connected with the cantilever; the supporting arm horizontal pressing device comprises a bracket I and a pressing screw rod II; the bracket I is fixed on the welding base; and the pressing screw rod II is connected with the bracket I. According to the jig, overall welding automation can be achieved, the jig can accurately position all parts and is provided with the pressing devices, therefore, part displacement caused by welding thermal deformation can be avoided, and pressing is convenient and fast.

Owner:NANTONG GUOSHENG PRECISION MACHINERY

Automatic tig welding method for single-side welding and double-side forming of aluminum alloy butt ring seam without backing

InactiveCN102079004BReduce distortionHigh degree of welding automationArc welding apparatusSurface layerEngineering

Aluminum alloy butt circular seam without liner single-sided welding double-sided forming automatic TIG welding method, use acetone to clean the oil around the butt circular seam of the cylinder body before welding, and use stainless steel wire wheel to remove the inner oxide film around the butt ring seam of the cylinder body. Preheating, debugging the control panel to control the welding current, voltage, welding speed, wire feeding speed matching in real time, using automatic tungsten argon arc welding machine welding, welding the first layer without adding wire back forming, adding welding wire filling in the second layer, Three layers of welding wire are added, and the welding torch is oscillated to form the cover surface. The invention adopts simple equipment, convenient operation, realizes welding automation, stable welding, fast welding speed, low production cost, less filler wire, less welding layers, and less deformation after welding. No correction is required, the appearance is beautiful and the welding seam quality is high.

Owner:陕西国德电气制造有限公司

A Method for Controlling Full Position Trajectory of Pipeline Butt Weld

ActiveCN105458454BHigh degree of welding automationShield interferenceArc welding apparatusAutomatic controlSimulation

The invention relates to a method for controlling the full position trajectory of a pipeline butt weld, comprising: generating a main path of the pipeline butt weld trajectory through an industrial robot teaching reproduction system, and completing a root welding process according to the main path. The main path is taken as the center trajectory, the center trajectory is combined with the swing arc compensation to determine the filling welding trajectory, and the filling welding process is completed according to the filling welding trajectory. Complete the cover welding process according to the center trajectory. The trajectory control method realizes the automatic control of the welding trajectory of the pipeline butt weld from root welding, filling welding to cover welding, effectively improves the automation of pipeline welding, effectively shields the interference of current discrete values on compensation values, and improves the welding torch sway The precision of the compensation value.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Welding method of flange plate of q390d steel crane girder in heavy work system

ActiveCN104759768BImprove impact toughnessReduce cold cracksArc welding apparatusMetal working apparatusSheet steelEngineering

The invention discloses a flange plate welding method for a heavy derrick Q390D steel crane beam. A Q390D steel plate with the thickness of 50-60 mm is cut to be flange plate welding parts for H-shaped steel, and then the flange plate welding parts are welded in a butting and full penetration mode to form a flange plate. The method comprises the five steps of manufacturing flange plate welding parts, forming grooves in a welding connector, dehumidifying the flange plate welding parts, welding the flange plate welding parts in the butting and full penetration mode to form the flange plate, and performing heat preservation and slow cooling on a welding joint. According to the flange plate welding method, no preheating working procedure performed before welding or heat preservation working procedure performed after welding is provided, the automatic submerged arc welding multi-layer and multi-pass welding technology is adopted, the welding automation degree is high, few cold cracks exist in a welding joint structure, the welding quality is high, the labor intensity of welding work is low, the welding cost is low, and welding time is greatly shortened, so that the welding technology meets the requirement for the heavy level better on the whole, particularly the heavy derrick crane beam flange plate welding requirement.

Owner:CHINA 19TH METALLURGICAL CORP

Continuous soldering flake feeding device and method for welding composite piece drill bit

PendingCN111687566AHigh skill requirementsReduce production efficiencyWelding/cutting auxillary devicesAuxillary welding devicesSolderingMaterials science

The invention discloses a continuous soldering flake feeding device and method for a welding composite piece drill bit. The continuous soldering flake feeding device for the welding composite piece drill bit comprises a rotary module; a bracket is arranged on the rotary module; a plurality of soldering flake feeding pipes are uniformly arranged on the bracket in the circumferential direction by taking the rotating center of the rotary module as an axis; soldering flakes are stacked and placed in the soldering flake feeding pipes; a soldering flake ejecting rod is arranged on the side of the rotary module; and the soldering flake ejecting rod is driven to stretch and retract up and down by a linear telescopic module, and is used for ejecting the soldering pieces in the soldering flake feeding pipe out one by one and resetting downwards. The continuous soldering flake feeding device and method for the welding composite piece drill bit can not only complete continuous feeding of the soldering flakes automatically, but also greatly improve the welding automation degree, the production efficiency and the product quality stability of the composite piece drill bit.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

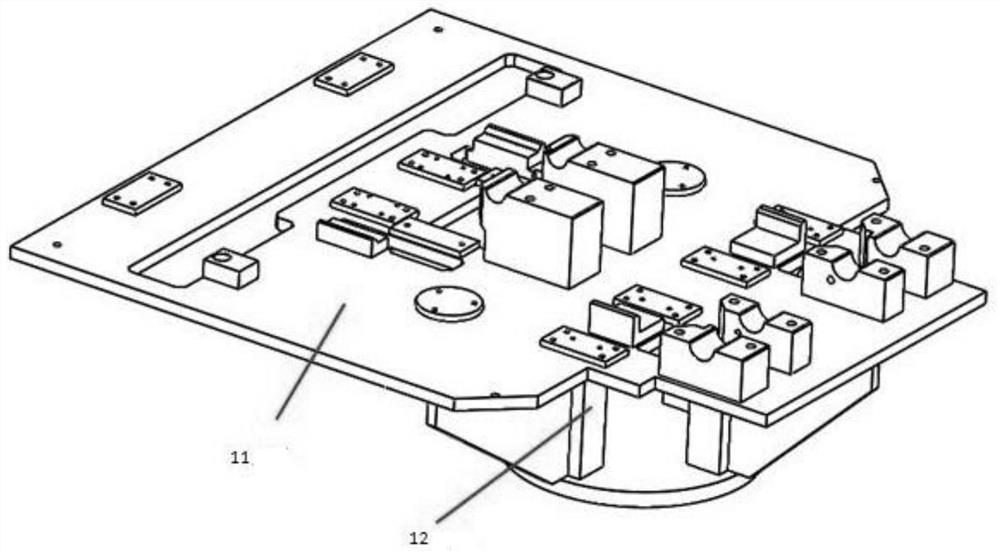

Automatic welding jig for water pond of vertical machining center

PendingCN113369769APrecise positioningAvoid displacementWelding/cutting auxillary devicesAuxillary welding devicesThermal deformationMachining

The invention discloses a water pond installing and welding tooling of a vertical machining center. A water pond is fixedly installed on a water pond automatic welding jig, overall welding automation of the water pond is achieved, and a welding base is used for bearing other jig parts and welding products and fixing the positions of the other jig parts and the welding products; a supporting arm I and a supporting arm II are fixed to the left side and the right side of the welding base through pins and bolts correspondingly; and a connecting support I and a connecting support II are fixedly installed on the top of the supporting arm I and the top of the supporting arm II respectively, and an upper overturning part is fixedly installed between the connecting support I and the connecting support II and used for fixing the water pond. According to the jig of the invention, overall welding automation can be achieved, the jig can accurately position all parts and is provided with pressing devices, part displacement caused by welding thermal deformation is avoided, pressing is convenient and fast, and the welding automation degree is obviously improved.

Owner:NANTONG GUOSHENG PRECISION MACHINERY

Electromagnetic coil assembling method

ActiveCN108777231APrecise positioningEasy to implement weldingTransformers/inductances coils/windings/connectionsCoils manufactureConductor CoilAutomation

The invention discloses an electromagnetic coil assembling method. An electromagnetic coil comprises two frameworks. Each framework comprises a winding part, two knife-edge-shaped parts and a holdingpart, wherein the two knife-edge-shaped parts are arranged at the two ends of the winding part in parallel, the holding part is arranged on the periphery of one knife-edge-shaped part and is oppositeto the other knife-edge-shaped part, the holding part comprises a plurality of protruding parts which are arranged at intervals in parallel, every two adjacent protruding parts are separated from eachother to form a notch part, and each protruding part is provided with a through hole running through the axial direction of the winding part. The assembling method includes the steps that S1, a plurality of pins are inserted in the axial direction of the through holes; S2, each pin is processed so that the two ends of the pin are bent to the end away from the corresponding knife-edge-shaped part;S3, the two knife-edge-shaped parts with the holding part in the two frameworks are oppositely arranged, and the protruding parts of one framework are inserted into the notch parts of the other framework; S4, the pins on the two frameworks are connected with inner and outer leading-out wire ends. The electromagnetic coil assembling method is easy to operate, and automation of winding and weldingcan be realized.

Owner:江苏华阳智能装备股份有限公司

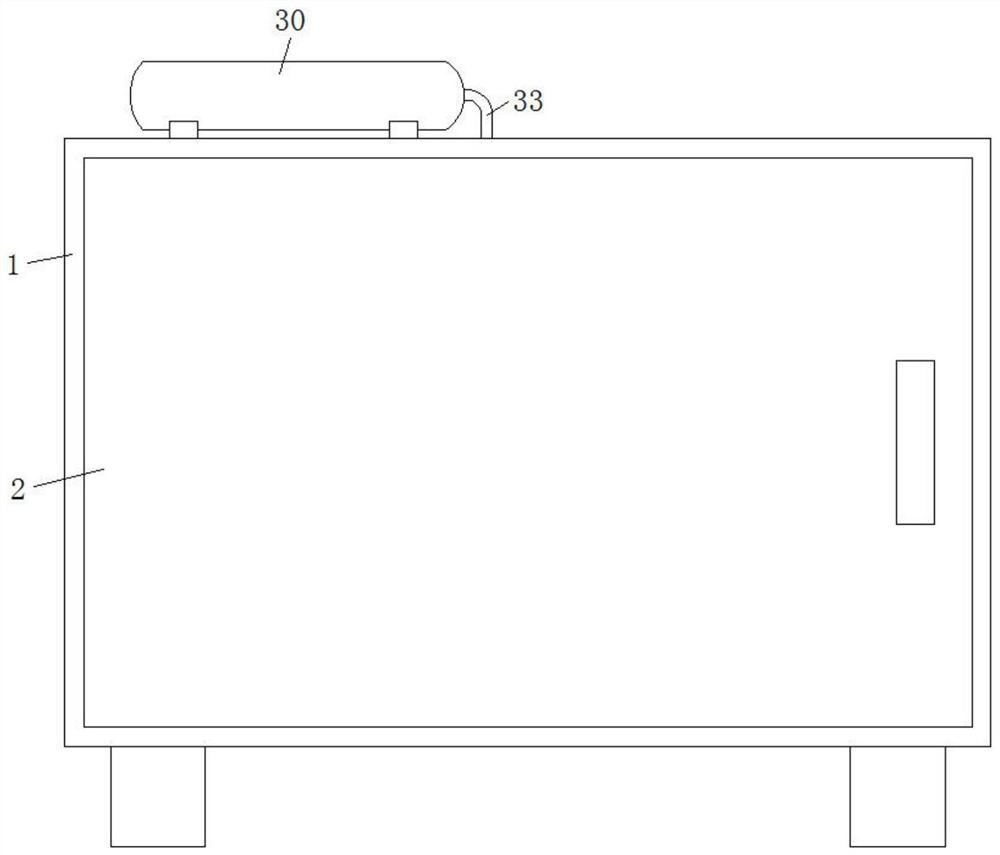

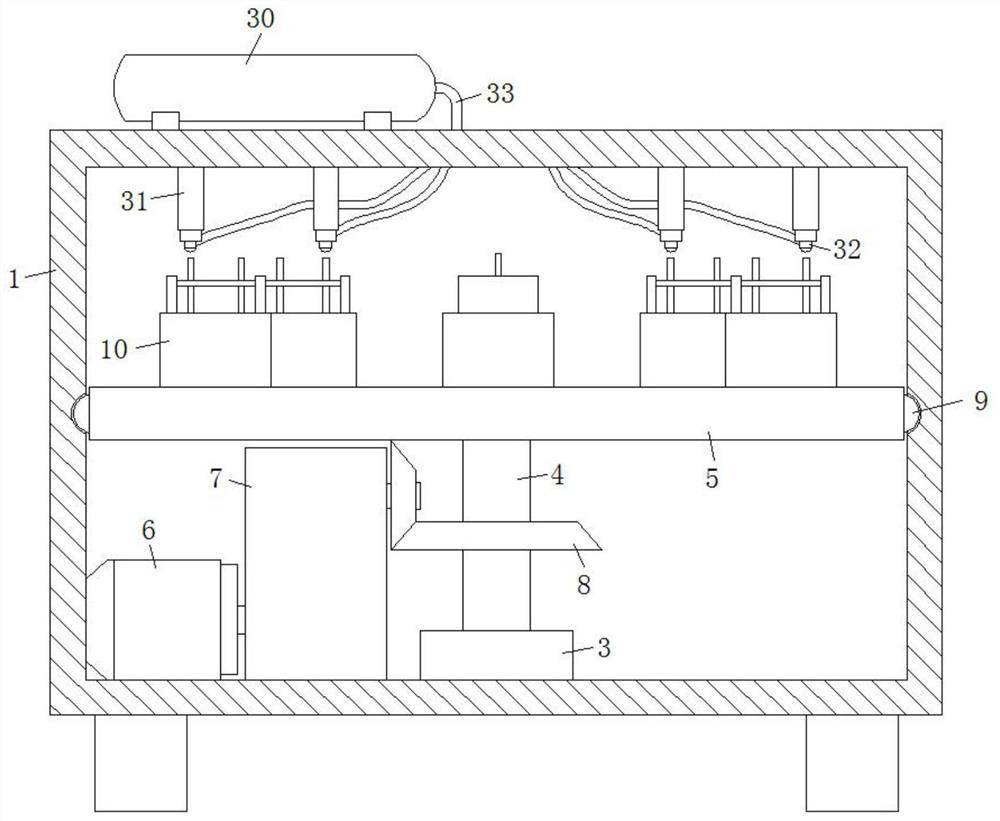

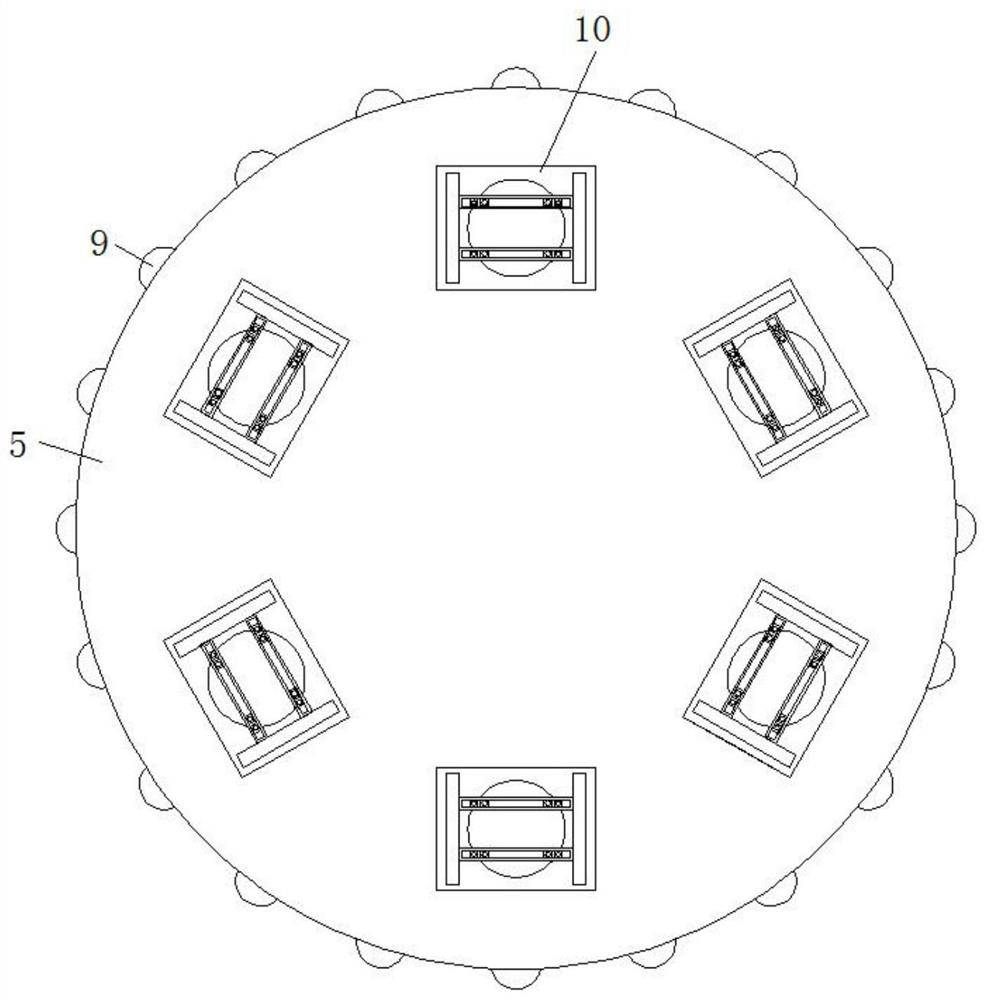

Novel welding device for producing capacitors

InactiveCN111790997AHigh degree of welding automationMeet the work requirements of mass productionWelding/cutting auxillary devicesAuxillary welding devicesRolling-element bearingReduction drive

The invention discloses a novel welding device for producing capacitors. The novel welding device comprises a machining box body. A door body is connected to one side of the front end of the machiningbox body in a rotary manner through hinges. A mounting block is fixed to the middle of the bottom face inside the machining box body. A mounting rod is connected to the upper end of the mounting block in a rotary manner through a rolling bearing. A containing plate is fixed to the top end of the mounting rod. A servo motor is further fixed to the inner wall of one side of the machining box. A reducer is arranged at one side of the servo motor. The output end of the servo motor is fixedly connected to the input end of the reducer. The output end of the reducer is connected with the mounting rod through a bevel gear set in a rotary manner. The side wall of the containing plate is provided with rolling balls. A rolling groove is formed in the middle of the inner wall of the machining box body. All the rolling balls are arranged in the rolling groove. The novel welding device is reasonable in design and great in innovation; the capacitor welding automation degree is high; the work requirement of mass production of the capacitors is well met; and the capacitor welding efficiency is greatly improved.

Owner:铜陵市凯瑞特电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com