Friction Welding Method for Standard Section Web Rod of Tower Crane

A friction welding, standard section technology, applied in welding equipment, non-electric welding equipment, metal processing equipment and other directions, can solve the problems of unsatisfactory product appearance quality, low production efficiency, difficult processing, etc., to achieve beautiful molding, stable and reliable quality , The effect of improving the degree of welding automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described below by taking Φ76X5, Φ89X5, and Φ108X8 steel pipes as examples.

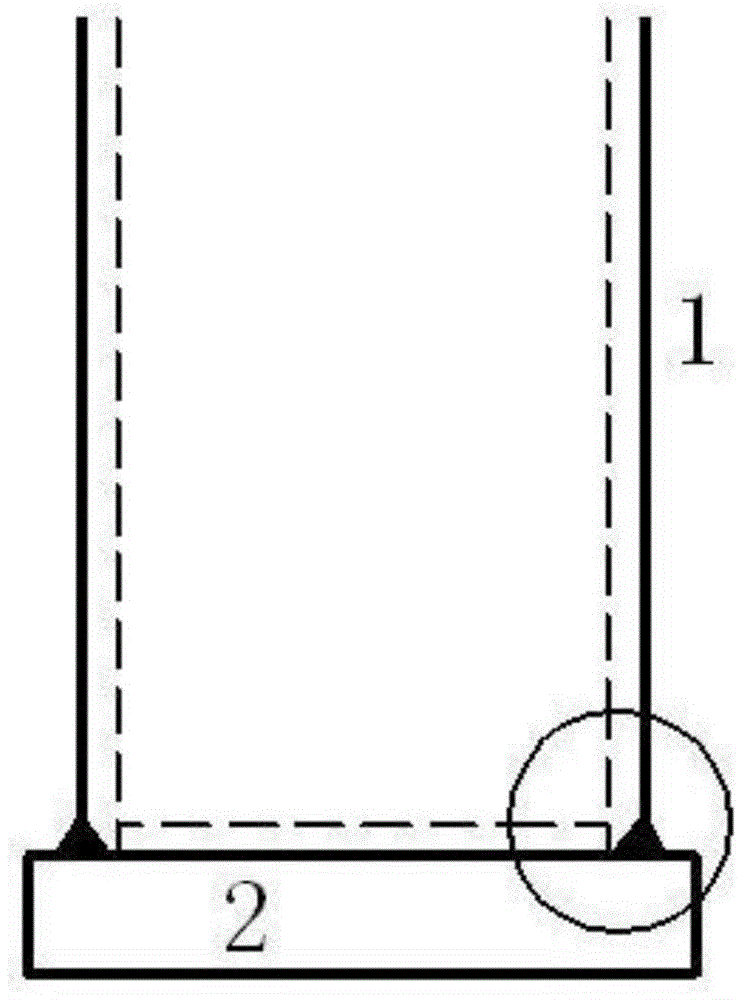

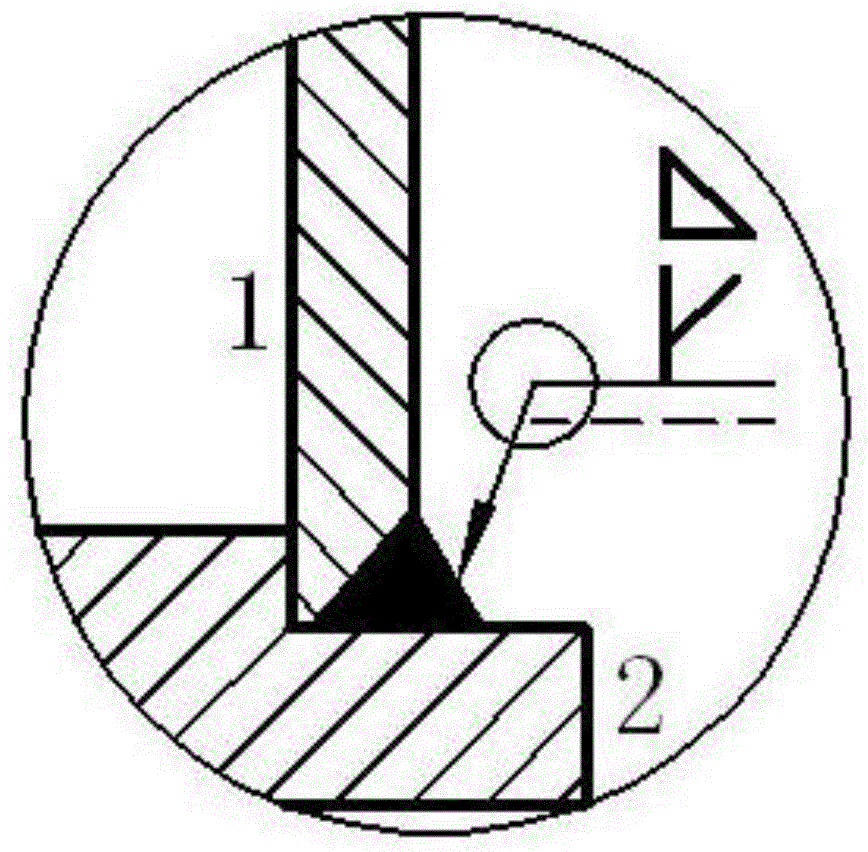

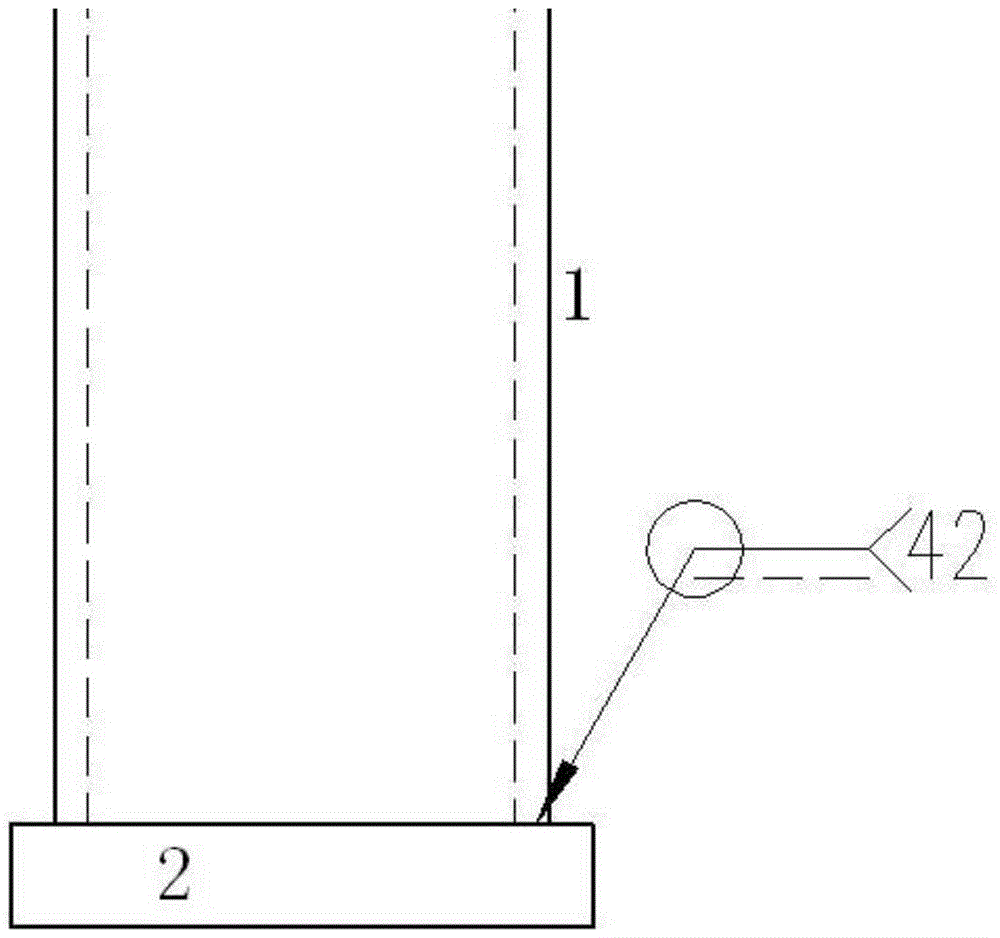

[0024] The standard section webs of the tower crane are welded by the steel pipe 1 and the end plate 2, and the friction welding method includes the following steps:

[0025] A. Preparation before welding: Saw the steel pipe 1 into shape. For the steel pipe 1 that needs to be welded at both ends, it is necessary to consider the amount of friction and deformation at both ends of the steel pipe 1 before sawing the shape. No oil, rust and other dirt; the end plate 2 is cut and blanked by means of a CNC flame cutting machine, and the side of the end plate 2 that needs friction welding is sandblasted or shot blasted to remove oil, rust and other impurities. The residual amount of dirt on the surface of the steel plate shall not exceed 5%, especially the strict decontamination on the friction weld ring of the end plate.

[0026] B. Clamp and fix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com