An automatic seam welding machine for oil barrels

A seam welding machine and oil drum technology, which is applied in the welding of straight seams, welding equipment, welding equipment, etc., can solve the problems of poor connection strength, low degree of automation, and inability to meet high welding performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described in conjunction with the following examples.

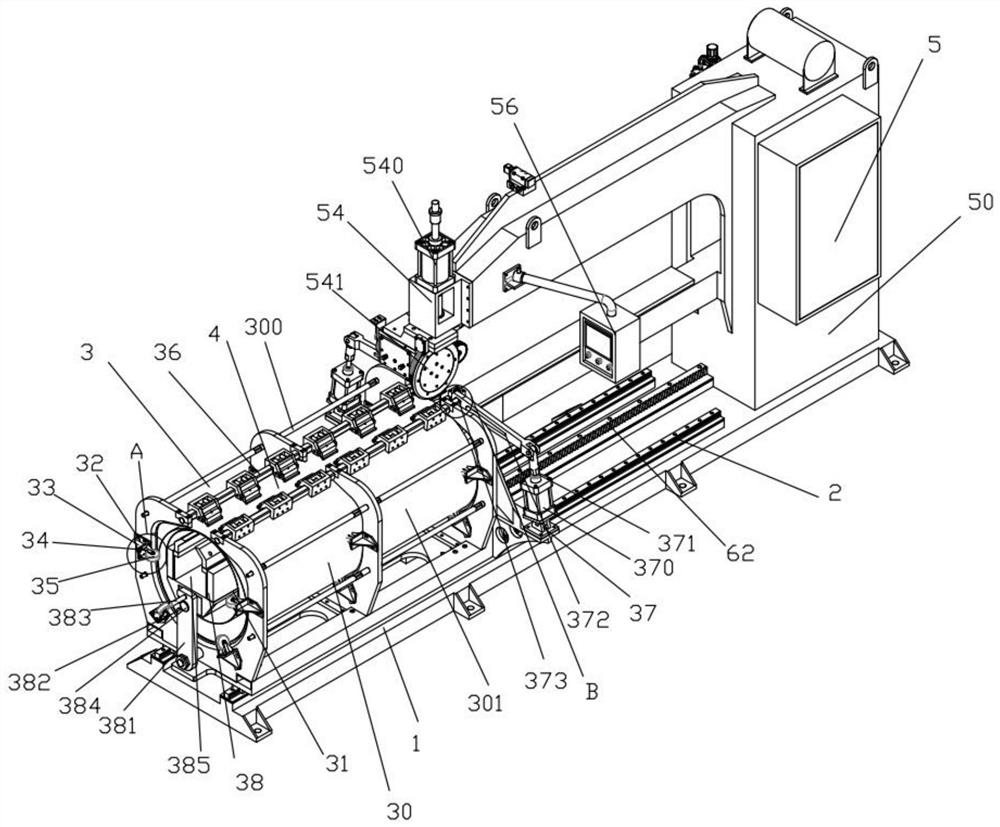

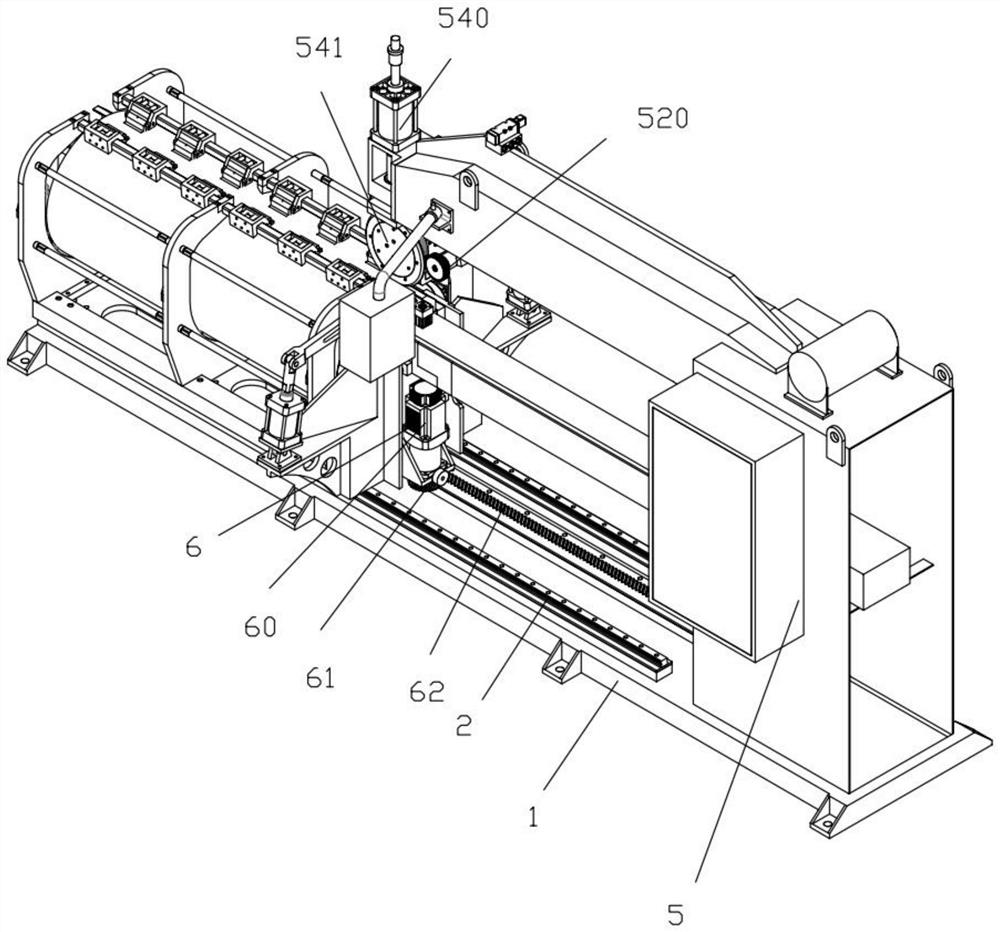

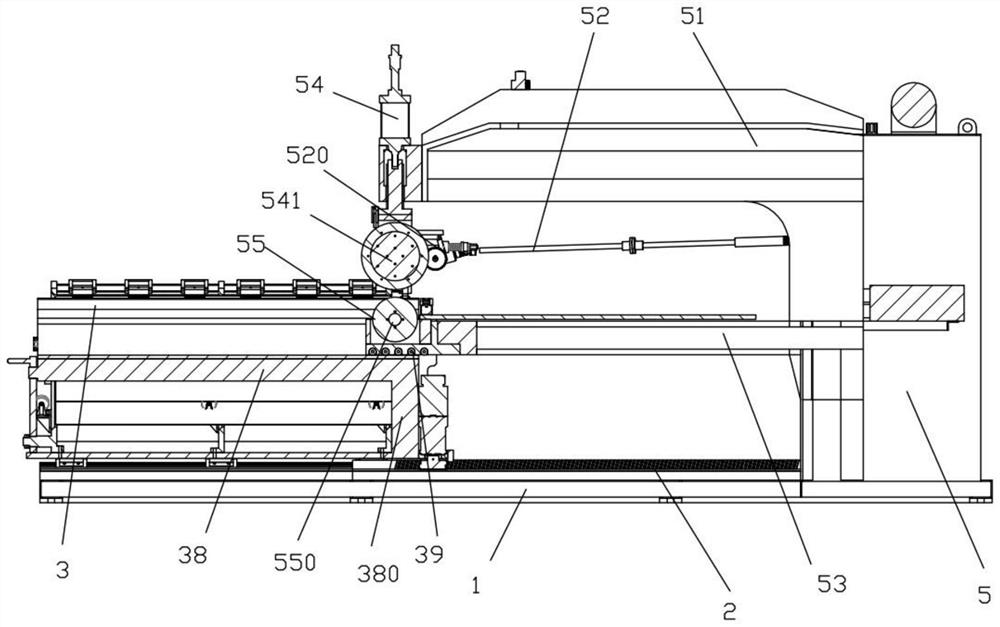

[0031] A specific embodiment of an automatic seam welding machine for oil barrels of the present invention, as Figure 1-Figure 3 As shown, the base 1 is included, the base 1 is fixed on the ground, two linear guide rails 2 extending along its length are installed on the upper surface of the base 1, the two linear guide rails 2 are arranged in parallel, and the top of the linear guide rail 2 is connected with a The positioning jig 3 for preliminary positioning of the oil barrel, the positioning jig 3 includes an elastic shell 30, the shell 30 is provided with an inner cavity 31 for accommodating the oil barrel, the oil barrel is rolled into a circle in the inner cavity 31, and the outer shell 30 The bottom is provided with a slider, which is slidingly connected with the linear guide rail 2, and the front end of the housing 30 is provided with a limiter 32, which is used to compress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com