Automatic welding jig for water pond of vertical machining center

A technology of automatic welding and water pan, applied in manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of insufficient penetration, low efficiency, and low degree of automatic welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

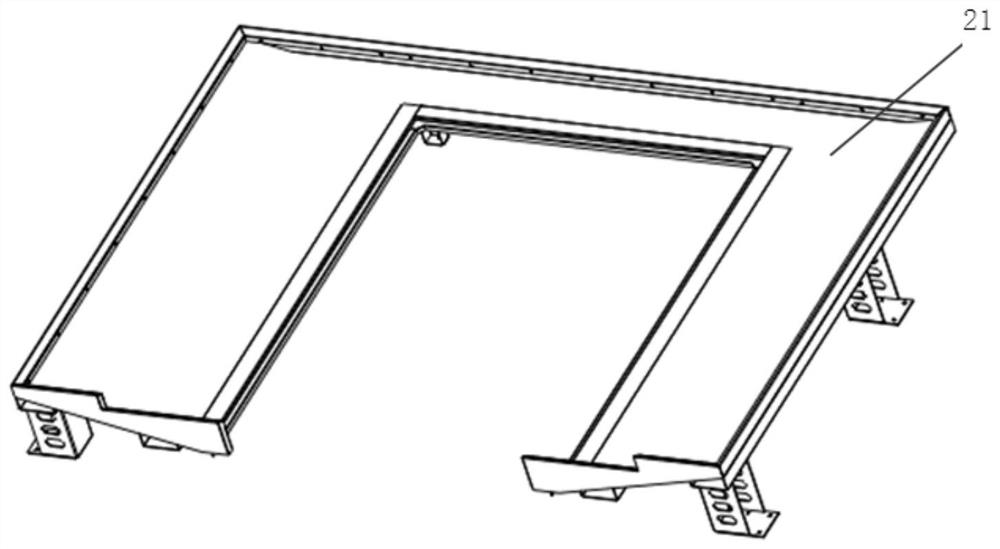

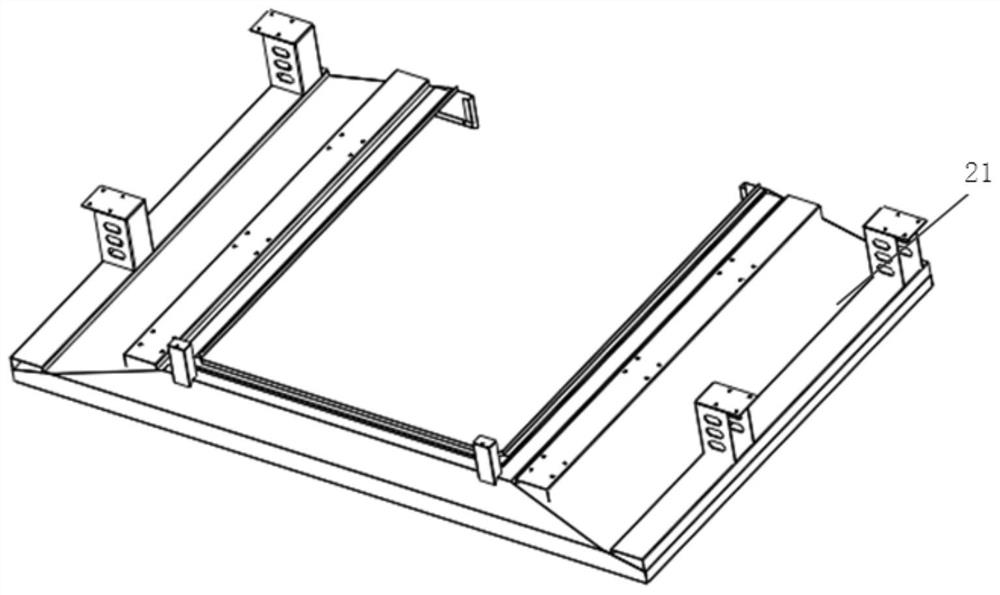

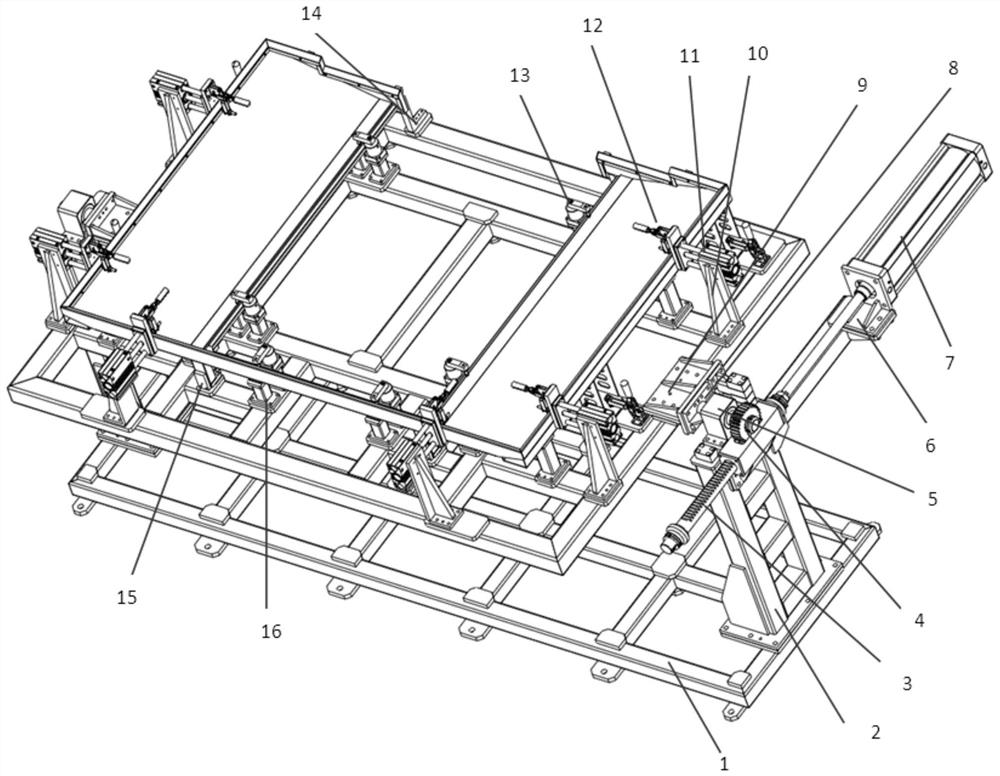

[0030] Such as figure 1 As shown, a water tray automatic welding fixture of a vertical machining center, the water tray 21 is fixedly installed on the water tray automatic welding fixture to realize the overall welding automation of the water tray, and the water tray automatic welding fixture includes welding Base 1, support arm 1, gear rod 3, spur gear 4, bearing seat 5, cylinder connecting bracket 6, cylinder 7, shaft seat 8, connecting bracket 19, cylinder bracket 10, cylinder 11, manual clamping quick clamp 12 , Pneumatic compression quick clip 13, positioning bracket one 14, positioning bracket two 15, bottom support 16, positioning bracket three 17, support arm two 18, connecting bracket two 19 and upper turning part 20.

[0031] The welding base 1 is used to carry the rest of the jig parts and welding products, and fix the position. The first support arm 2 and the second support arm 18 are respectively fixed on the left and right sides of the welding base 1 by pins and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com