Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Flexible load adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Membrane seawater desalination pressurization and energy recovery integrated method and device

ActiveCN102838186AReduce initial investment costHigh priceMembranesWater treatment parameter controlEngineeringEnergy recovery

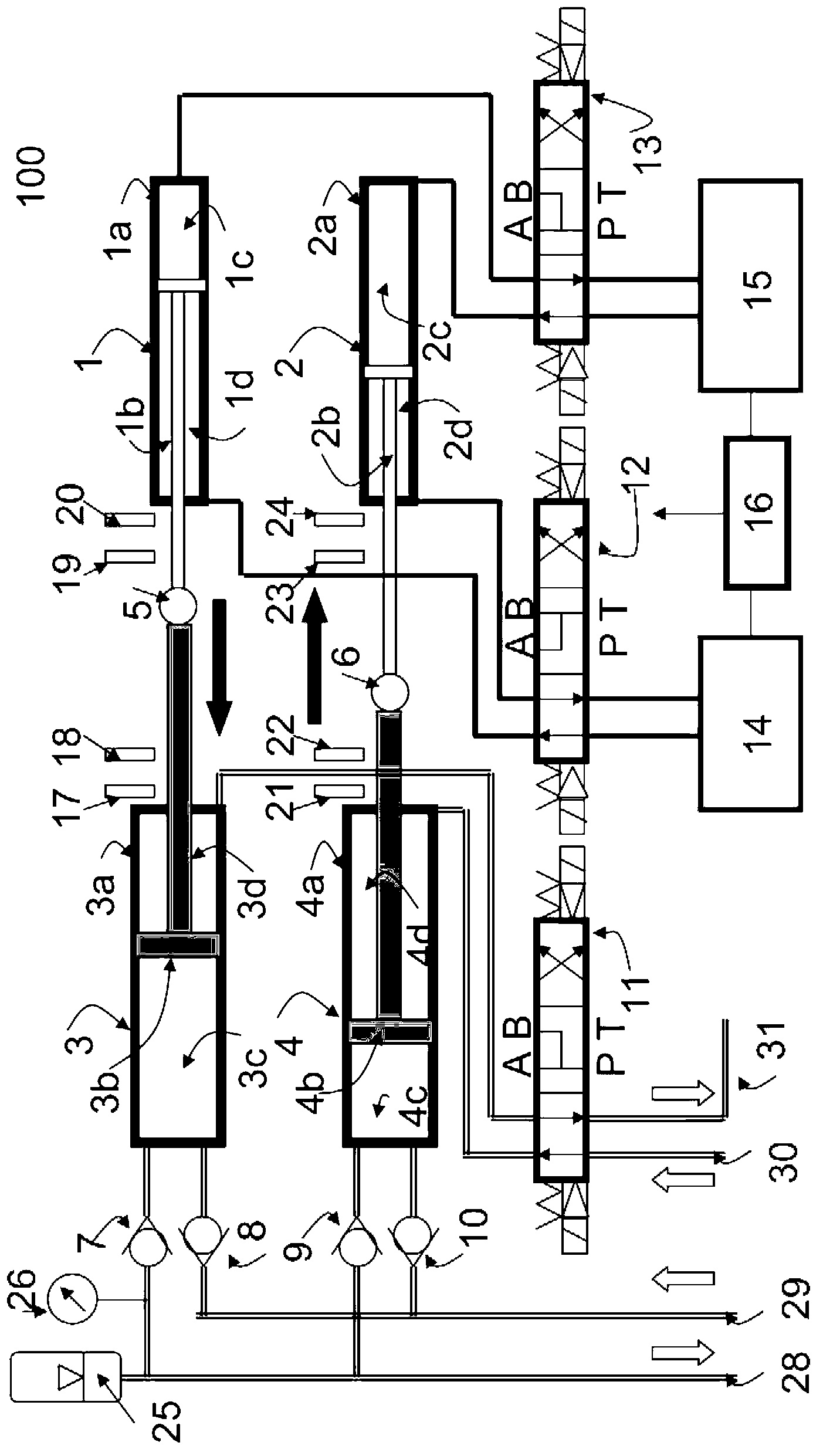

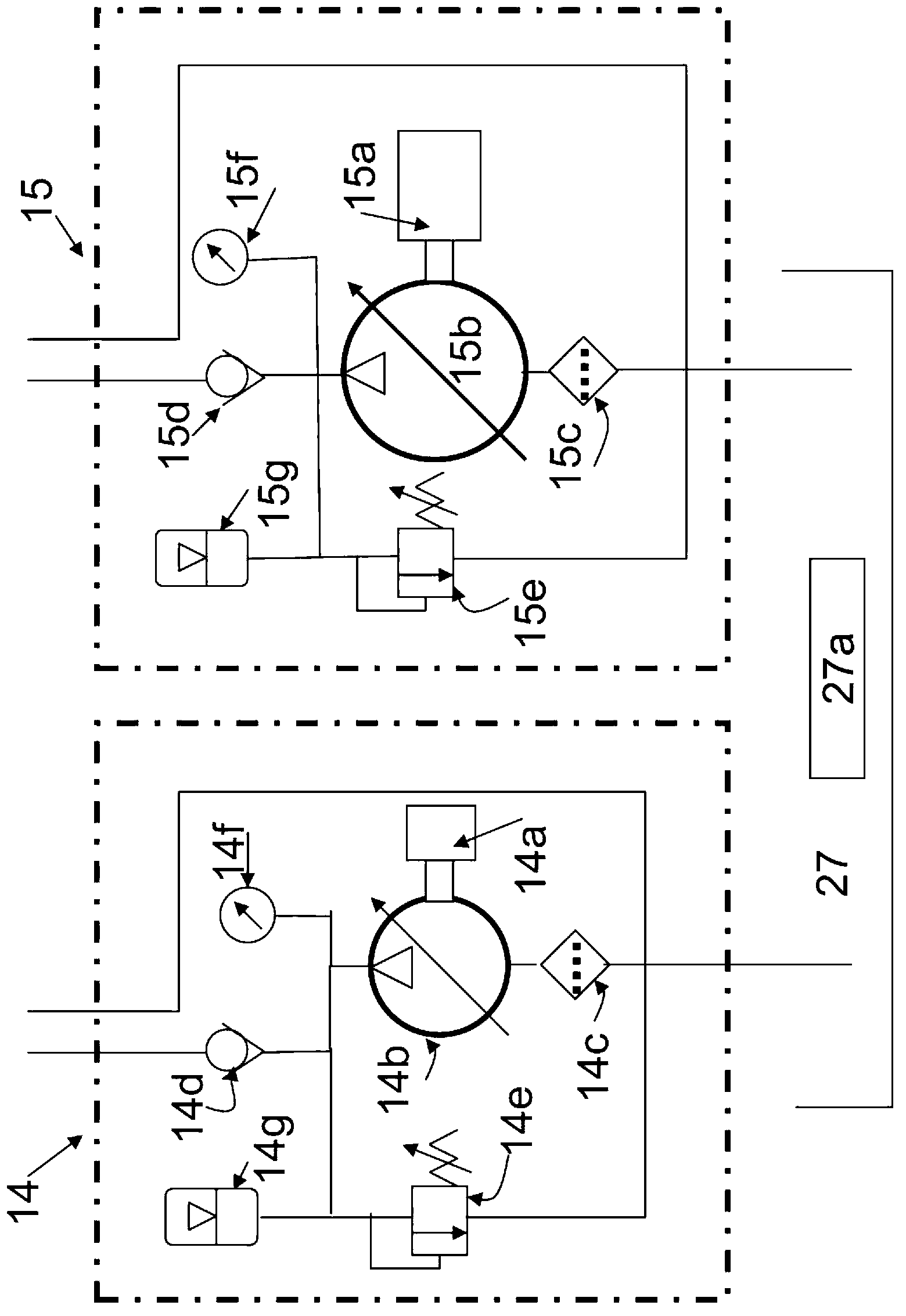

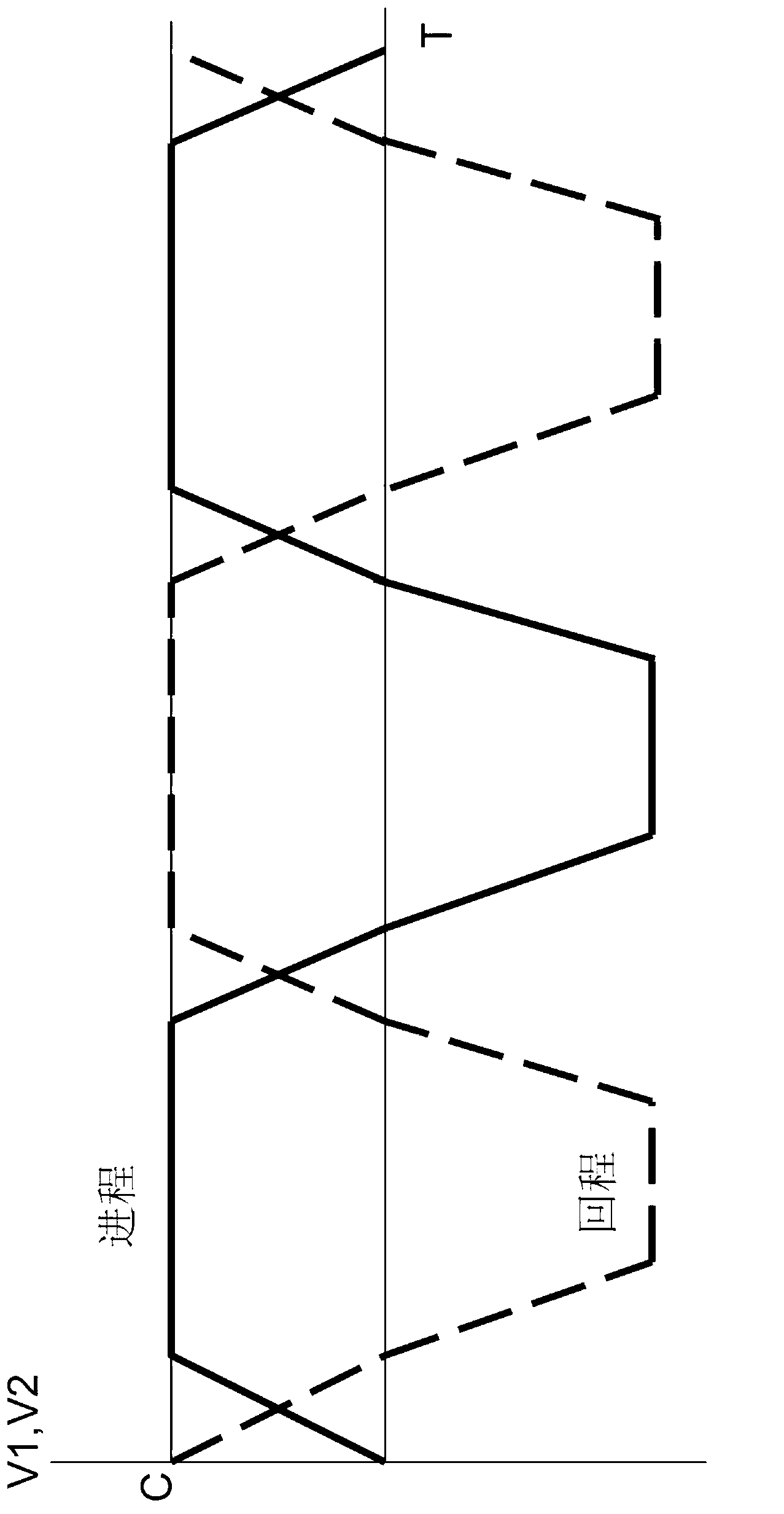

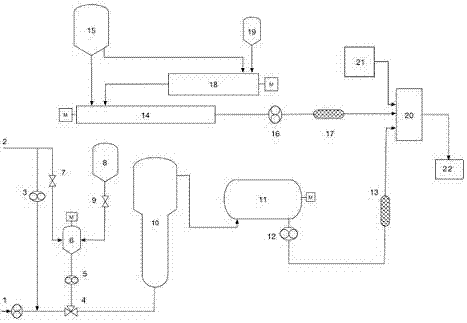

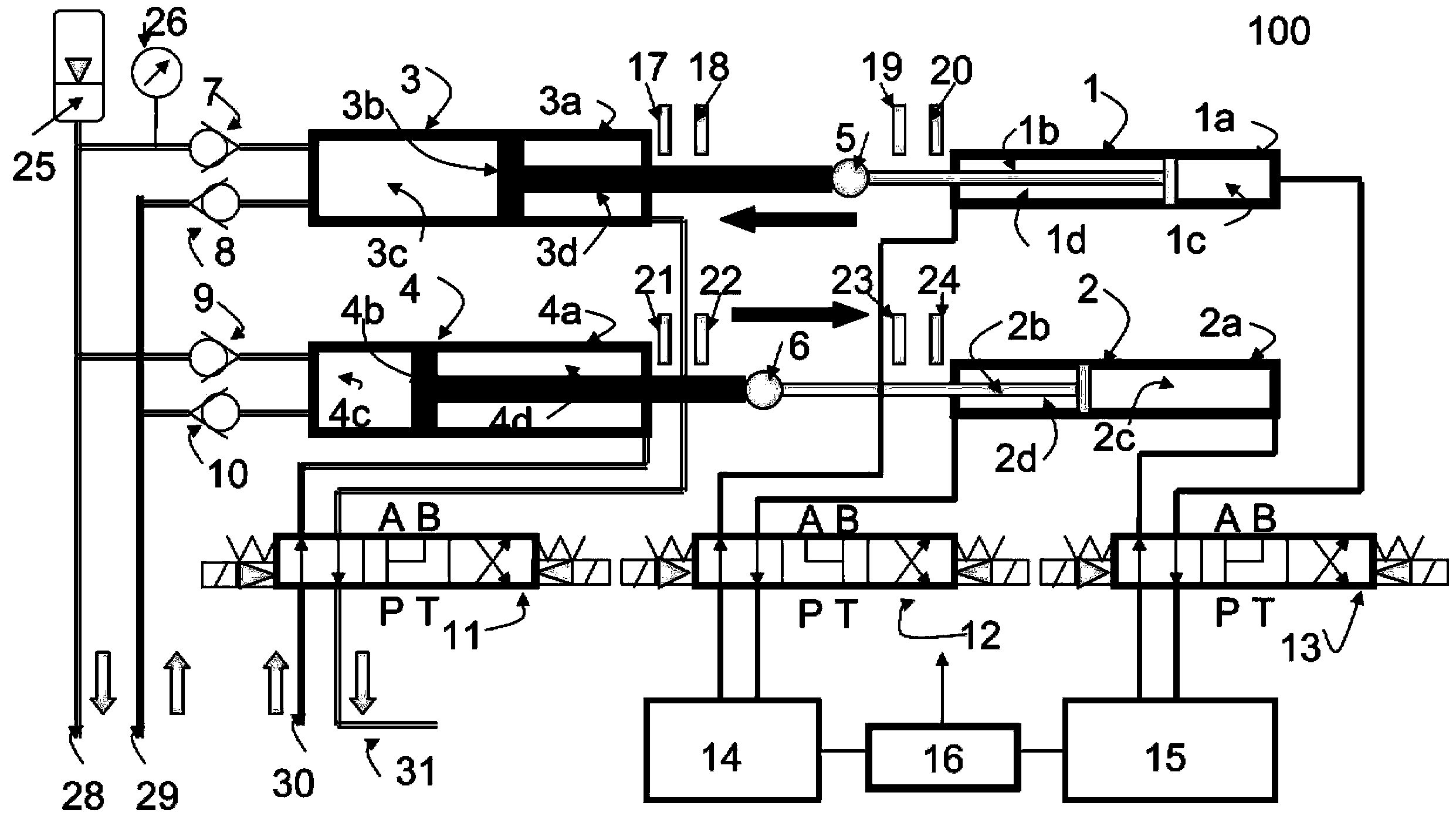

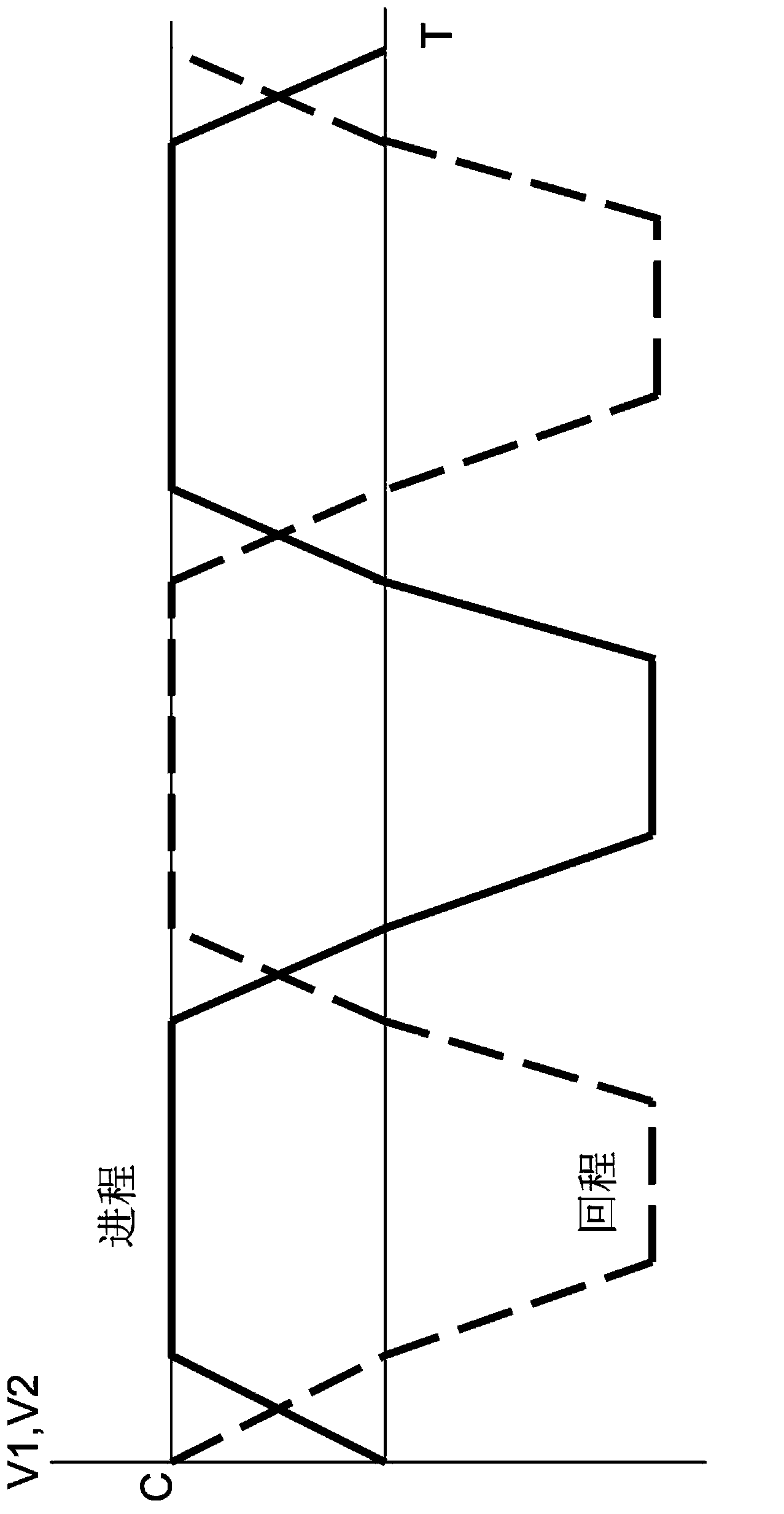

The invention relates to a membrane seawater desalination pressurization and energy recovery integrated method and a membrane seawater desalination pressurization and energy recovery integrated device. Piston rods of single-rod seawater cylinders are connected with single-rod oil cylinders to form two or more working combined bodies which operate alternately; the oil cylinders drive the seawater cylinders to move back and forth; one piston cavities of the seawater cylinders suck high pressure strong brine in the process of moving forward and drain the high pressure strong brine in the returning process; and the other piston cavities of the seawater cylinders suck raw seawater in the returning process, pressurize the raw seawater in the process of moving forward and continuously and stably output the pressurized high pressure raw seawater to a reverse osmosis membrane modulus.

Owner:北京赛美环能科技有限公司

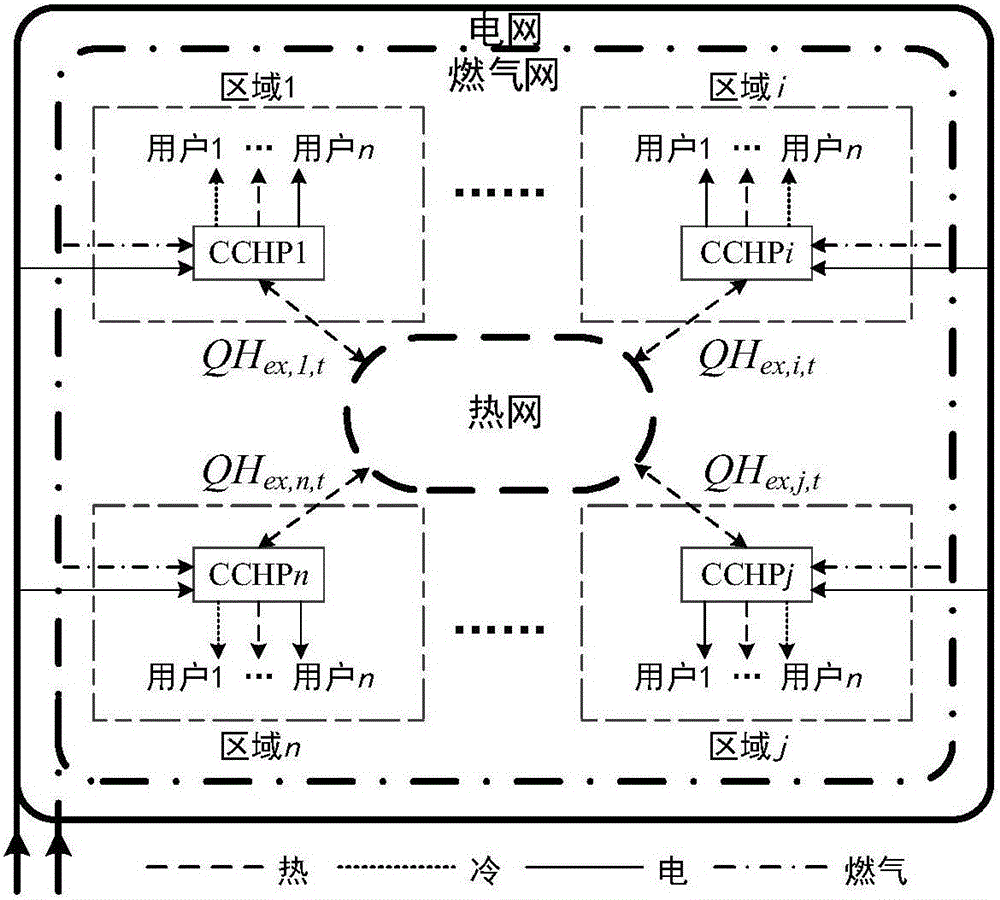

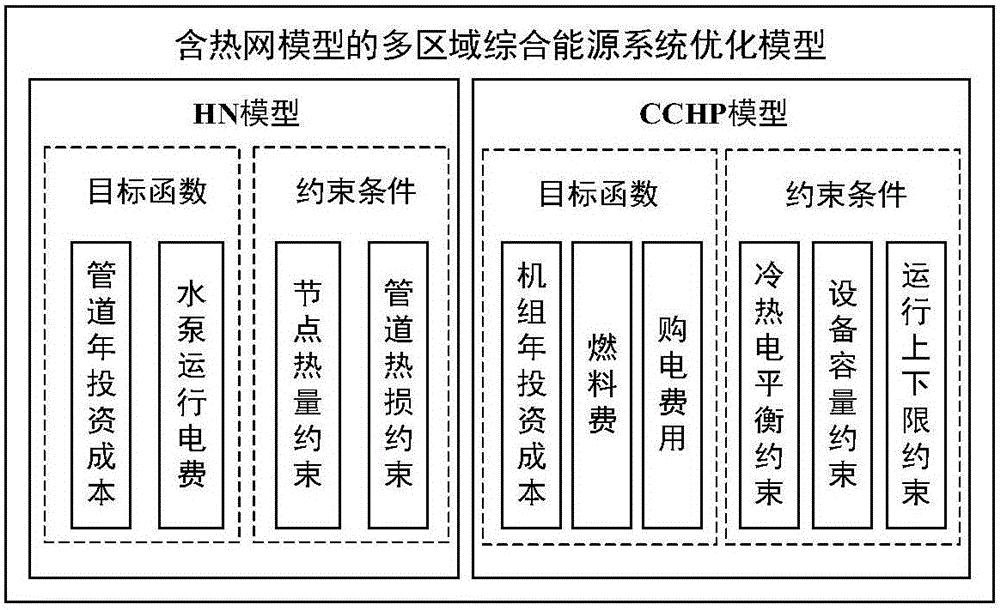

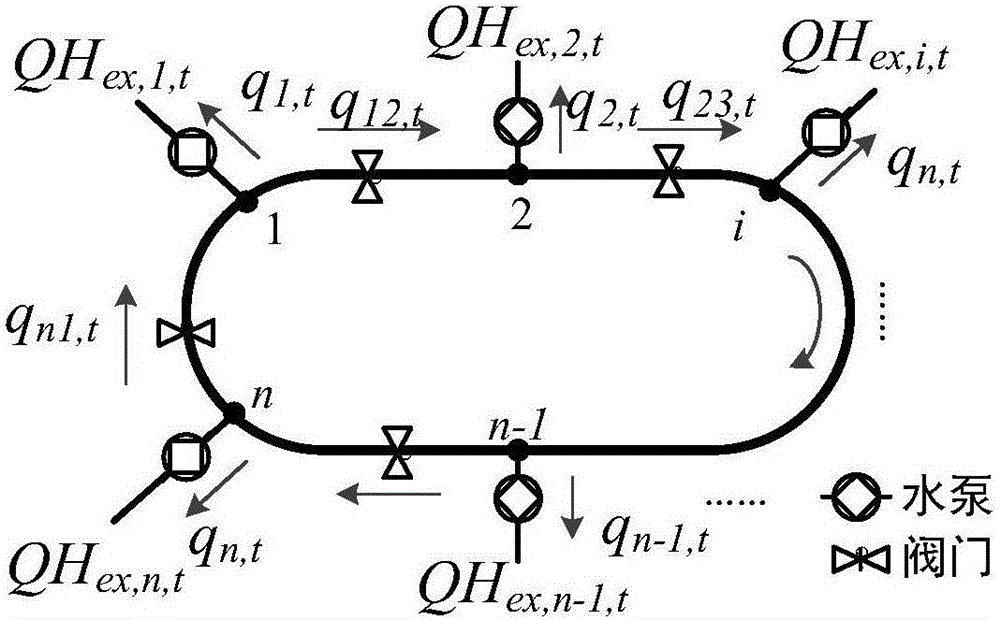

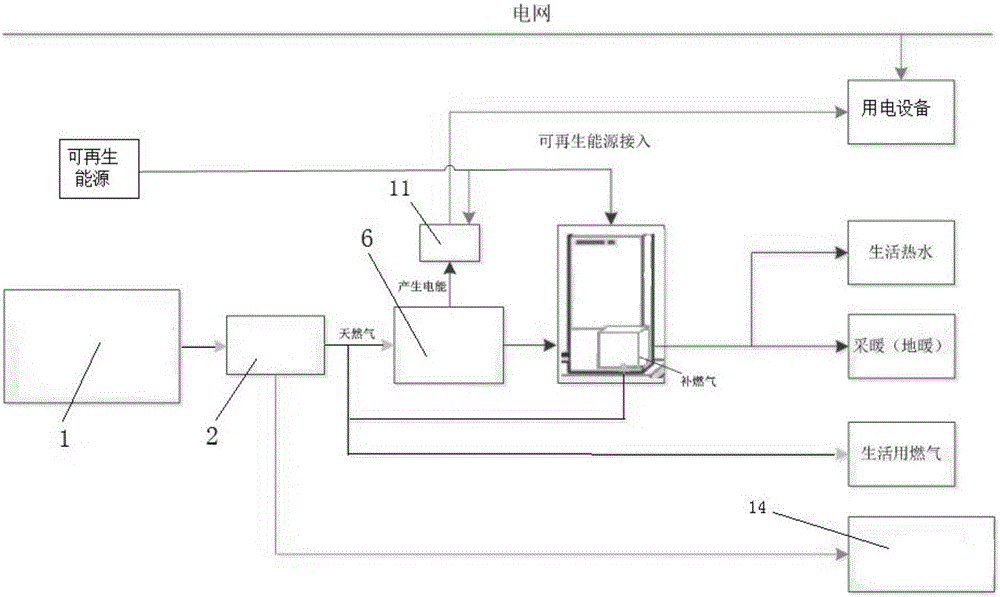

Establishment method of configuration model of multi-regional comprehensive energy system in combination with thermal network model

ActiveCN106055773AHigh annual investment costLow running costForecastingMulti-objective optimisationCost effectivenessCapacity provisioning

The invention discloses an establishment method of a configuration model of a multi-regional comprehensive energy system in combination with a thermal network model. The method comprises following steps: step 10), respectively establishing the Establishment method of configuration model of multi-regional comprehensive energy system in combination with the thermal network model and a CCHP model; step 20), combining the thermal network model and the CCHP model established to establish the configuration model. The method is capable of well utilizing obvious peak valley alternating occurrences existing cooling heating and power loads in all regions in order to achieve supply-demand complementarities of multiple energies and reducing capacity configuration. The problems such as configuration waste and low utilization rate of equipment during independent planning are solved. Overall cost-effectiveness of the system is effectively improved.

Owner:SOUTHEAST UNIV

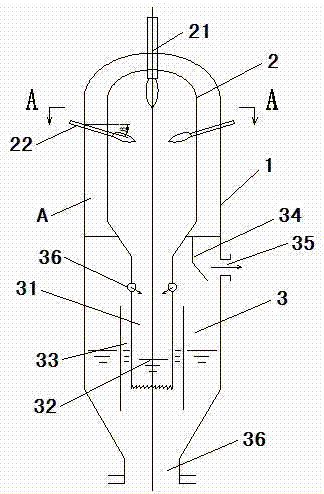

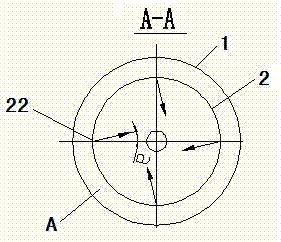

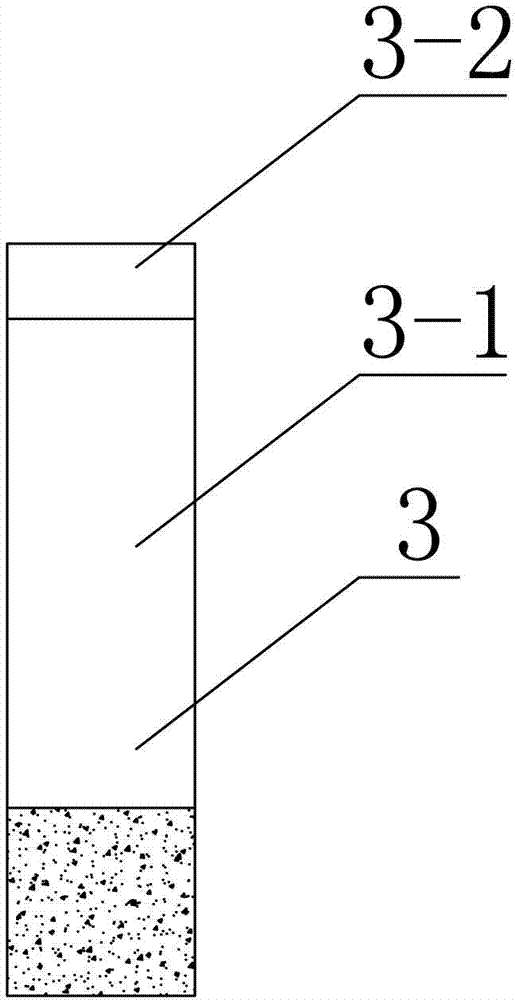

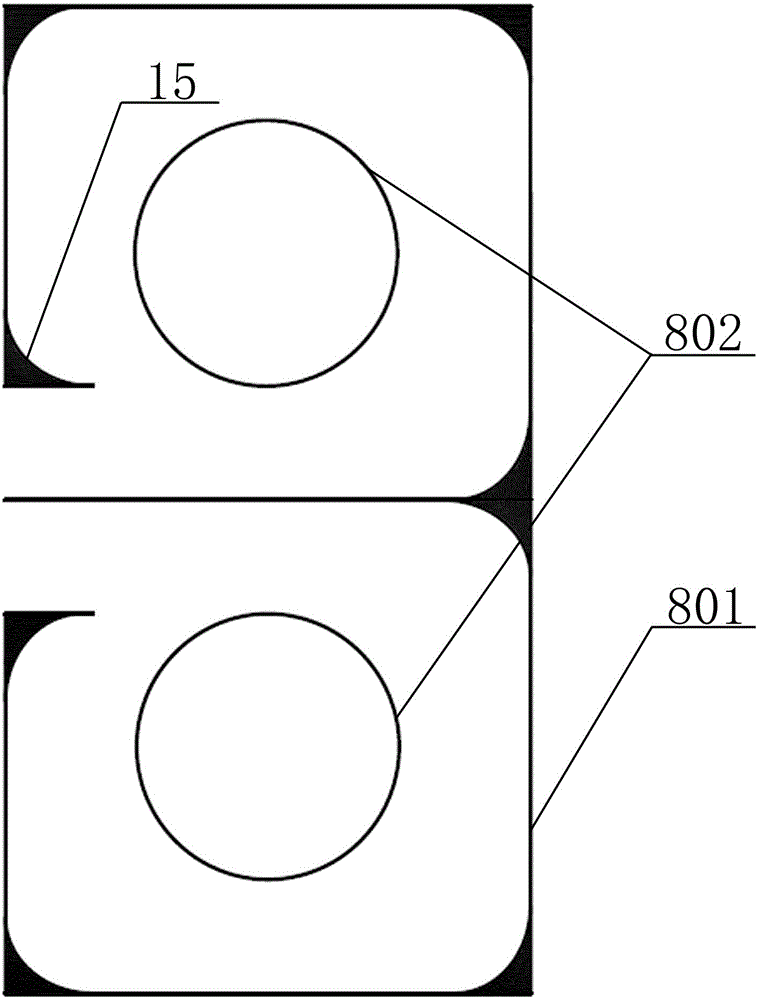

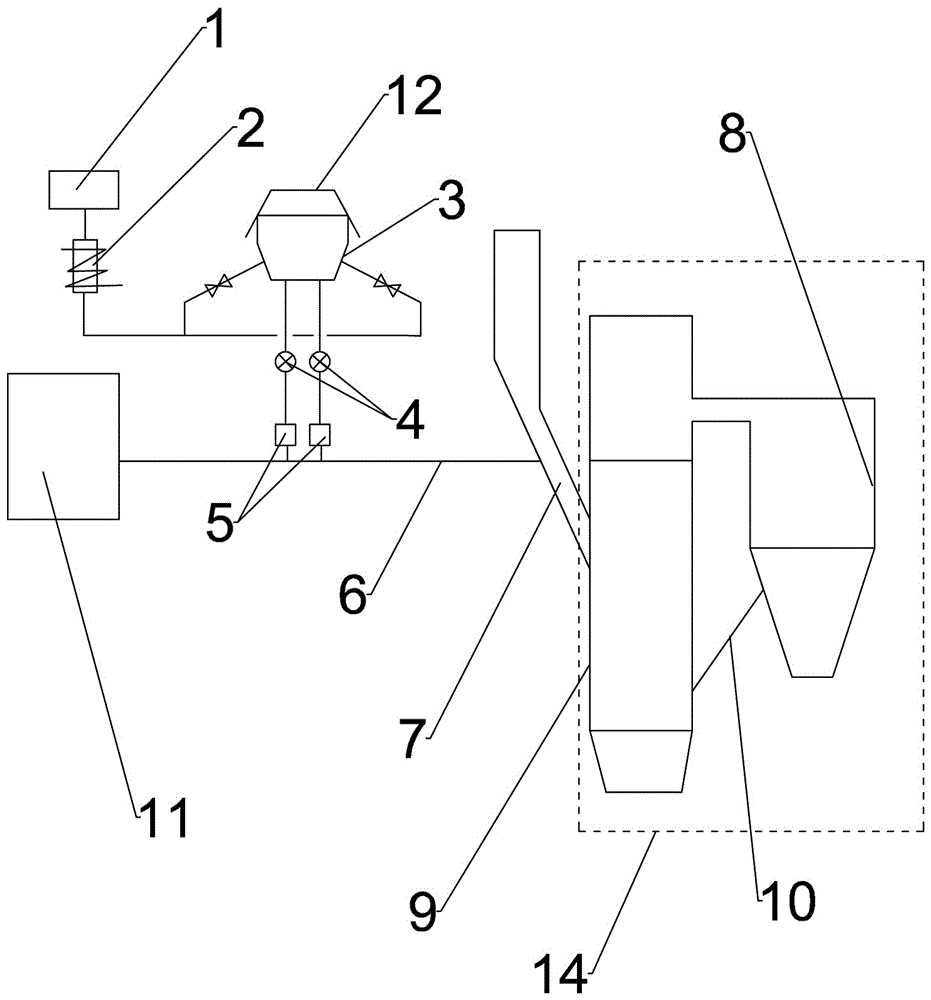

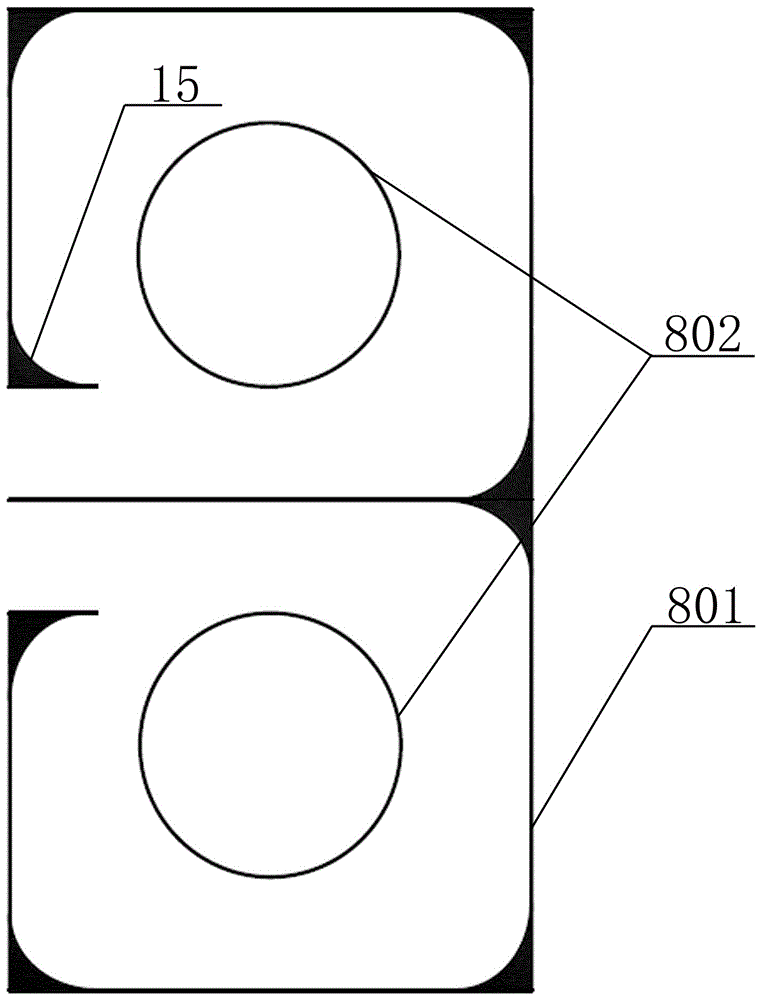

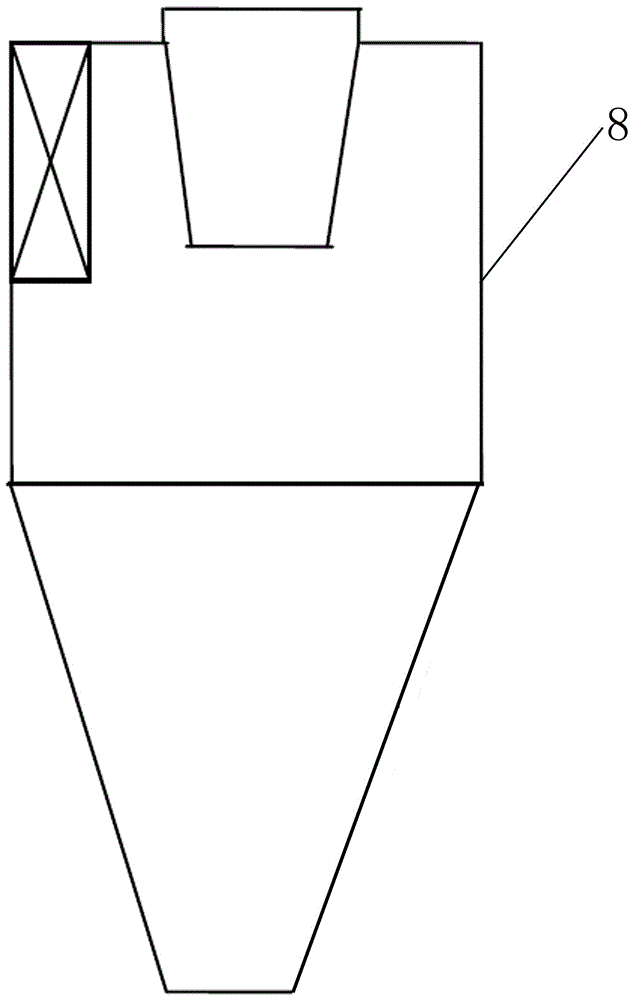

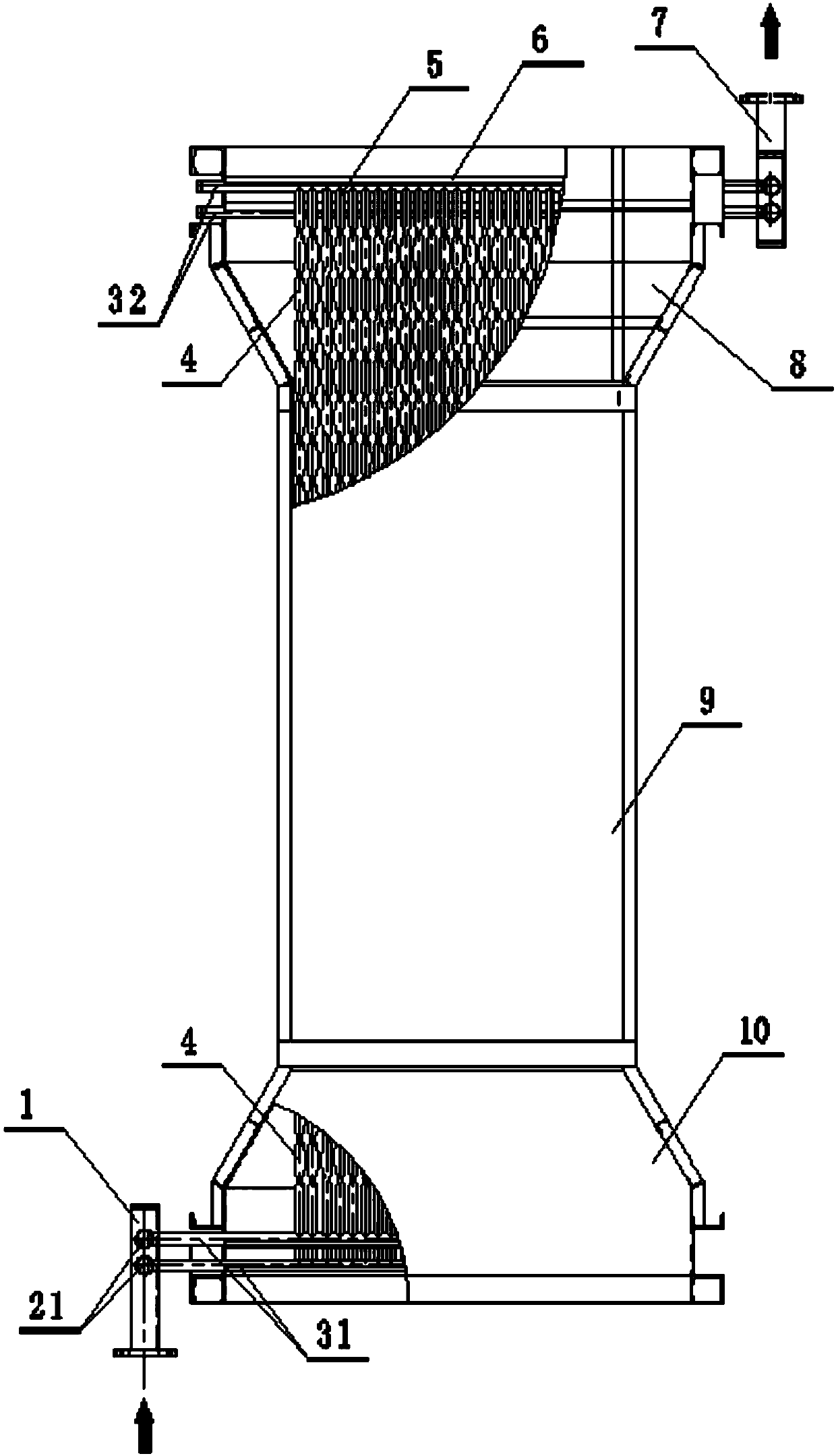

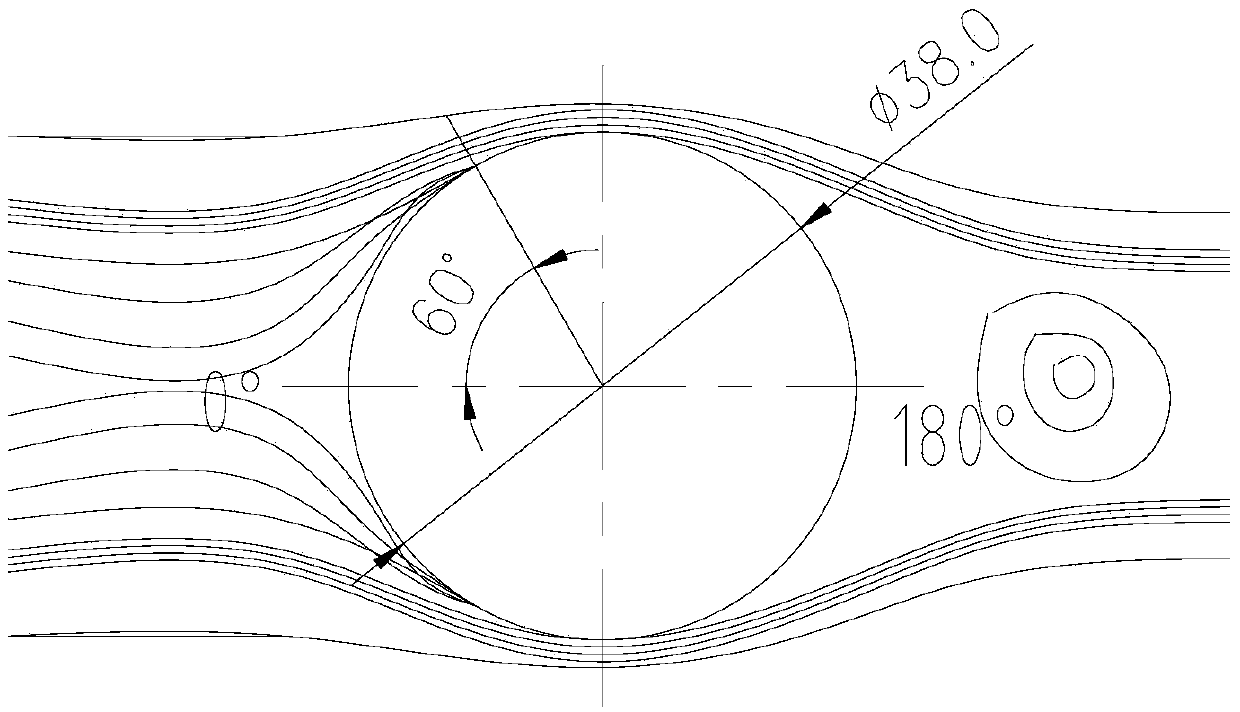

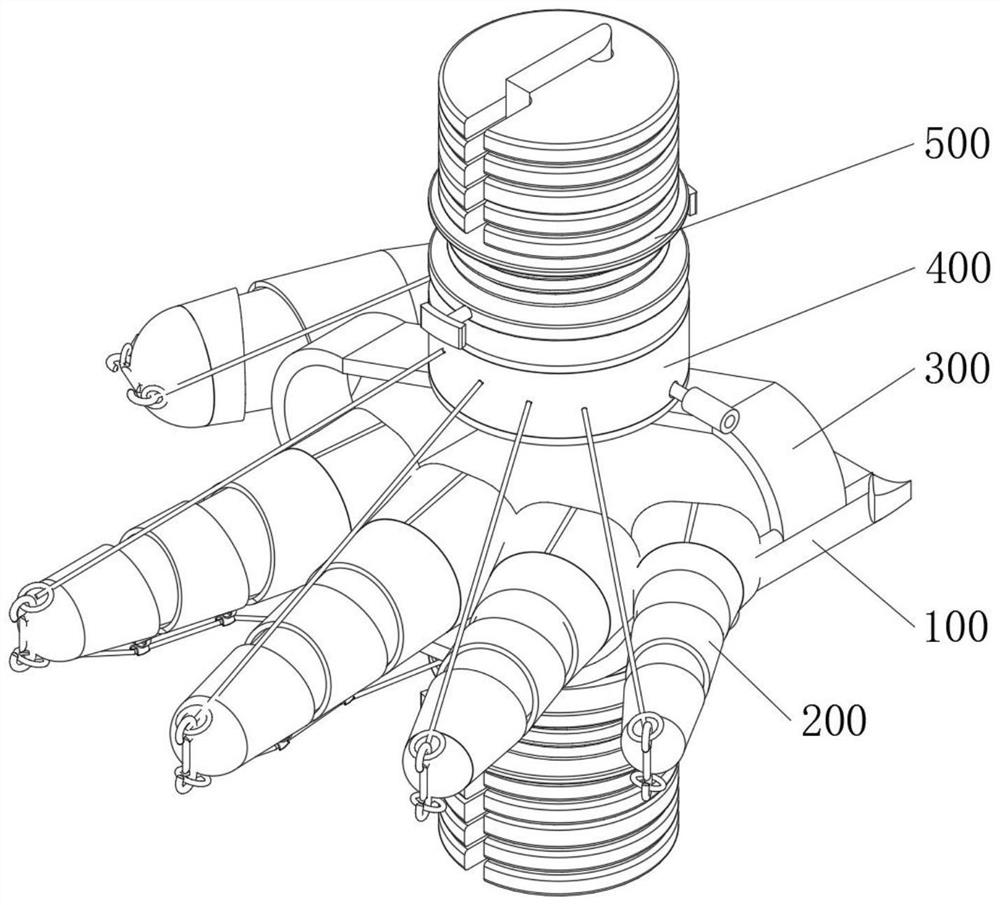

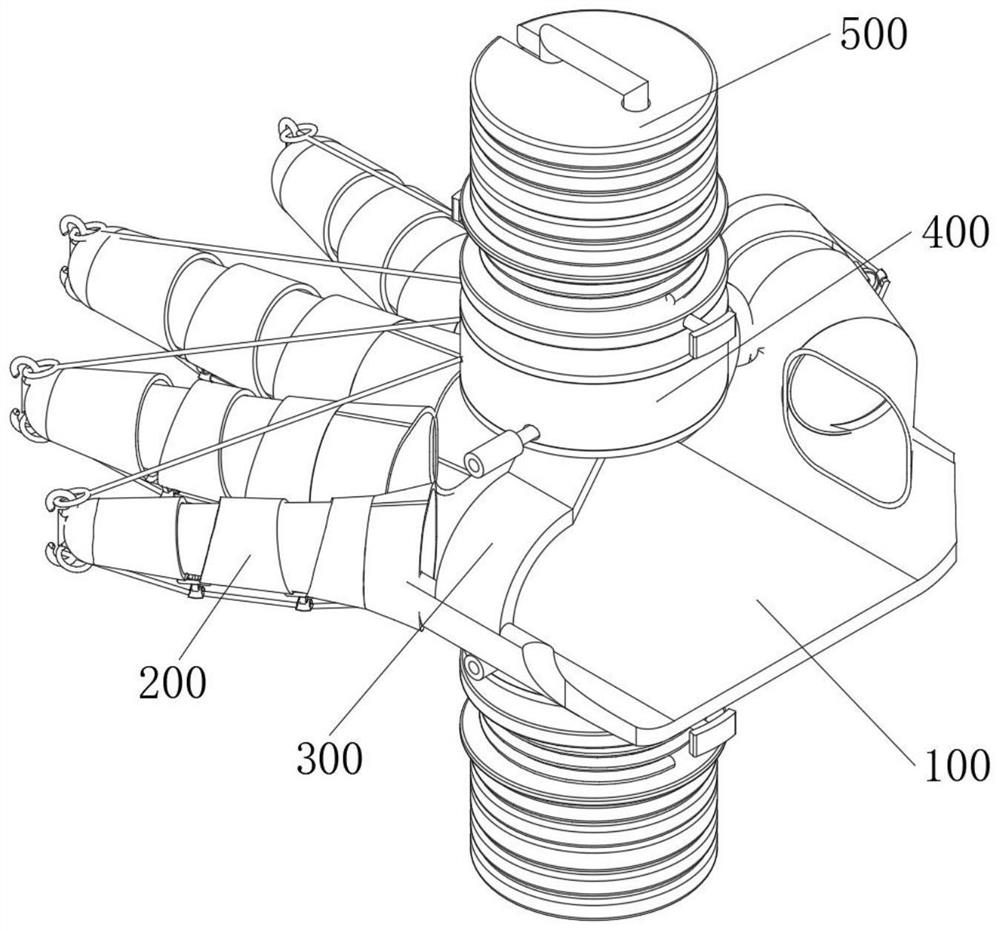

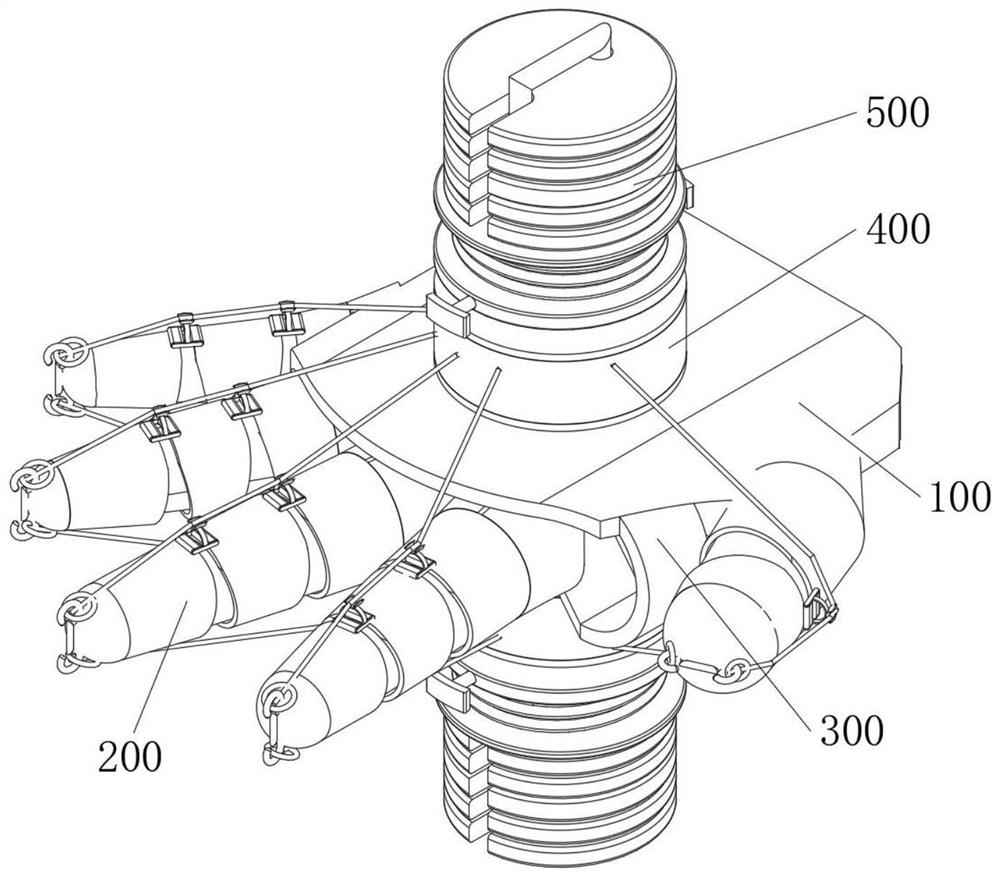

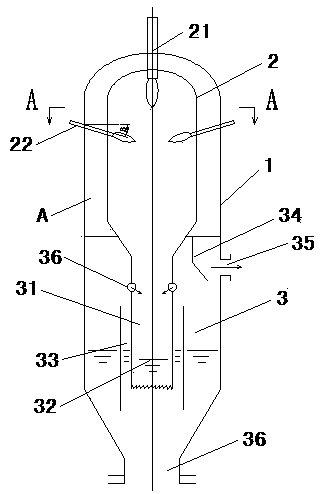

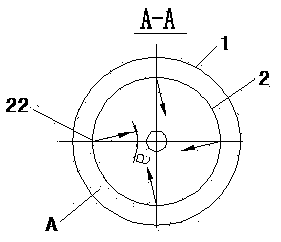

Load-adjustable step feeding type entrained flow bed gasifier

ActiveCN102827642AIncrease productionExtended stayGranular/pulverulent flues gasificationSyngasWater baths

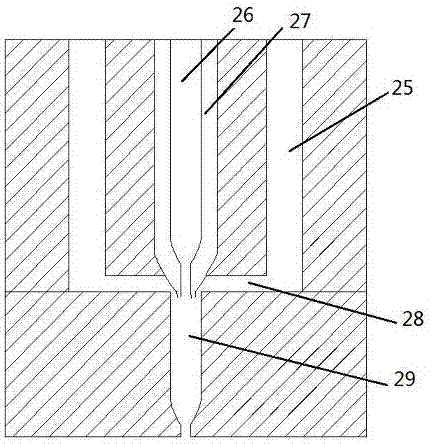

The invention discloses a load-adjustable step feeding type entrained flow bed gasifier. The load-adjustable step feeding type entrained flow bed gasifier is characterized by comprising a pressure shell body, and a reaction chamber and a cooling / dust removal / water bath chilling chamber which are supported and hung in the pressure shell body, wherein the cooling / dust removal / water bath chilling chamber is coaxially arranged at the lower part of the reaction chamber; an annular gap space is arranged between the reaction chamber and the pressure shell body; and the reaction chamber is provided with a main nozzle and a plurality of load adjustment nozzles. The cooling / dust removal / water bath chilling chamber is coaxially arranged at the lower part of the reaction chamber, the main nozzle is arranged at the top part of the gasifier, the load adjustment nozzles are symmetrically arranged in the space at the upper part of the reaction chamber, and water is used to chill high-temperature synthetic gas and clinker discharged below the reaction chamber, so that the single-gasifier yield is effectively increased, the single-gasifier production load adjustment capability is realized, and the hearth reaction region is reasonably arranged, thereby ensuring that the synthetic gas in the hearth can produce a rotational flow, the retention time is long, the reaction is thorough and the load adjustment range is wide.

Owner:中国船舶集团有限公司第七一一研究所

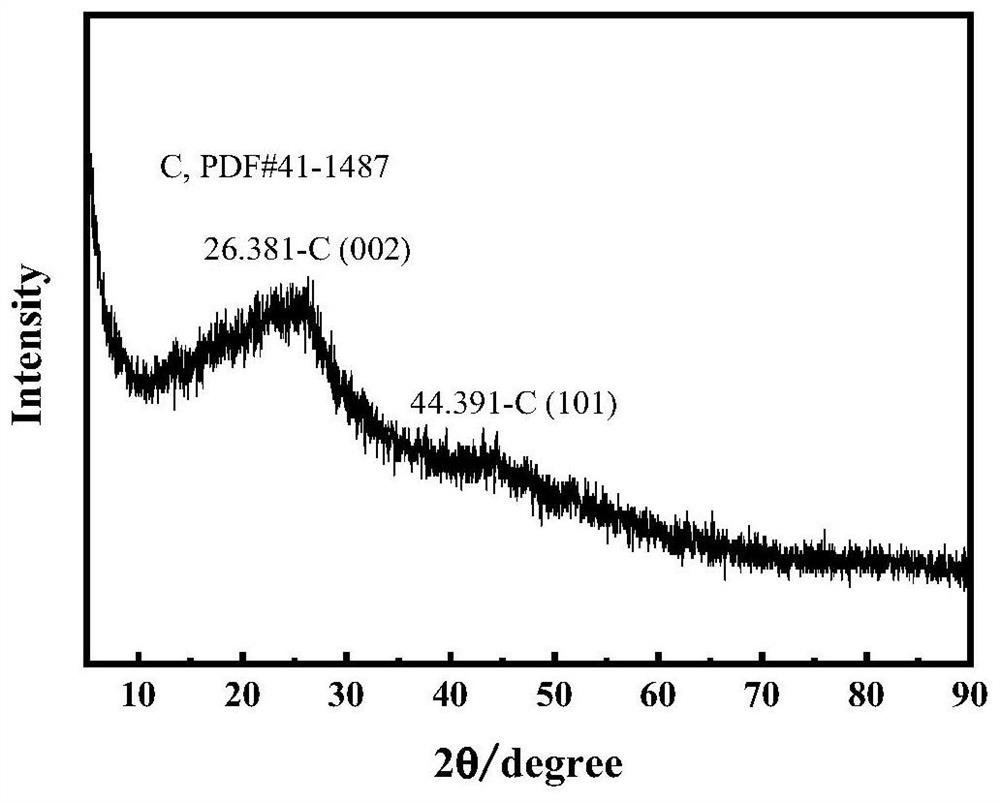

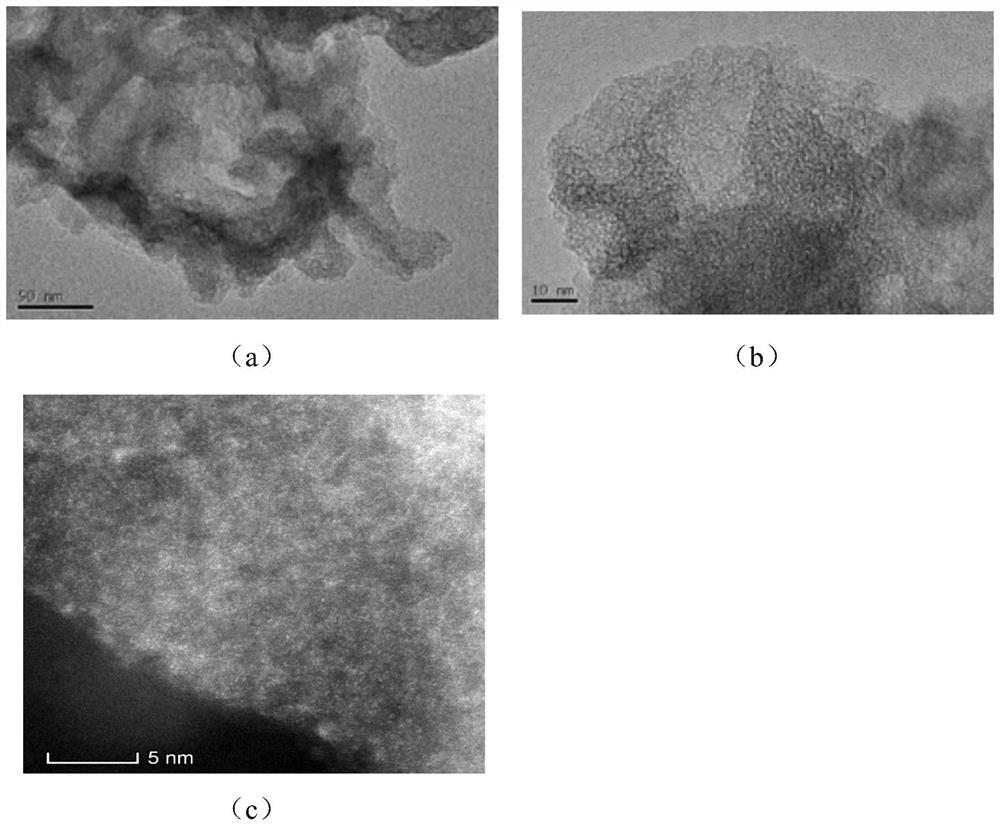

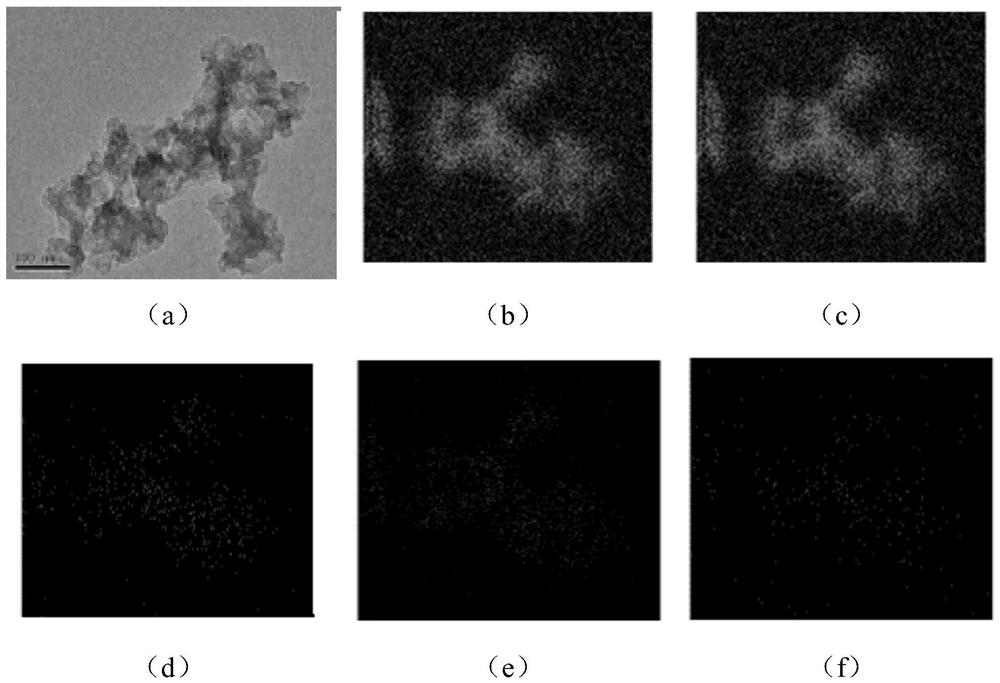

High-dispersion Co-based bimetallic catalyst based on ZIFs and preparation method thereof

PendingCN112973758AHigh activityImprove thermal stabilityCatalyst activation/preparationBulk chemical productionPtru catalystHydrogenation reaction

The invention discloses a high-dispersion Co-based bimetallic catalyst based on ZIFs and a preparation method of the high-dispersion Co-based bimetallic catalyst based on ZIFs, and belongs to the technical field of synthesis of nanometer materials and catalysts, the method ingeniously utilizes the characteristics that metal nodes in ZnCo-ZIFs are high in dispersion and have periodic pore structures; first, a second active metal salt is introduced into ZIFs pore channels through a double-solvent method; then in the high-temperature calcination process, the low-boiling-point metal Zn volatilizes and plays a fence role, the distance between the active metals is increased, Co nodes and the second active metal are subjected to in-situ reduction, and the high-dispersion Co-based bimetallic catalyst loaded on the nitrogen-doped carbon carrier is obtained. The method is simple in process and convenient to operate, the composition of the obtained high-dispersion Co-based bimetallic catalyst is flexible and adjustable, metal particles are distributed in a high-dispersion form, and the high-dispersion Co-based bimetallic catalyst has good stability and is expected to be applied to hydrogenation reaction, synthesis gas conversion, alcohol selective oxidation and other reactions.

Owner:HUANENG CLEAN ENERGY RES INST +1

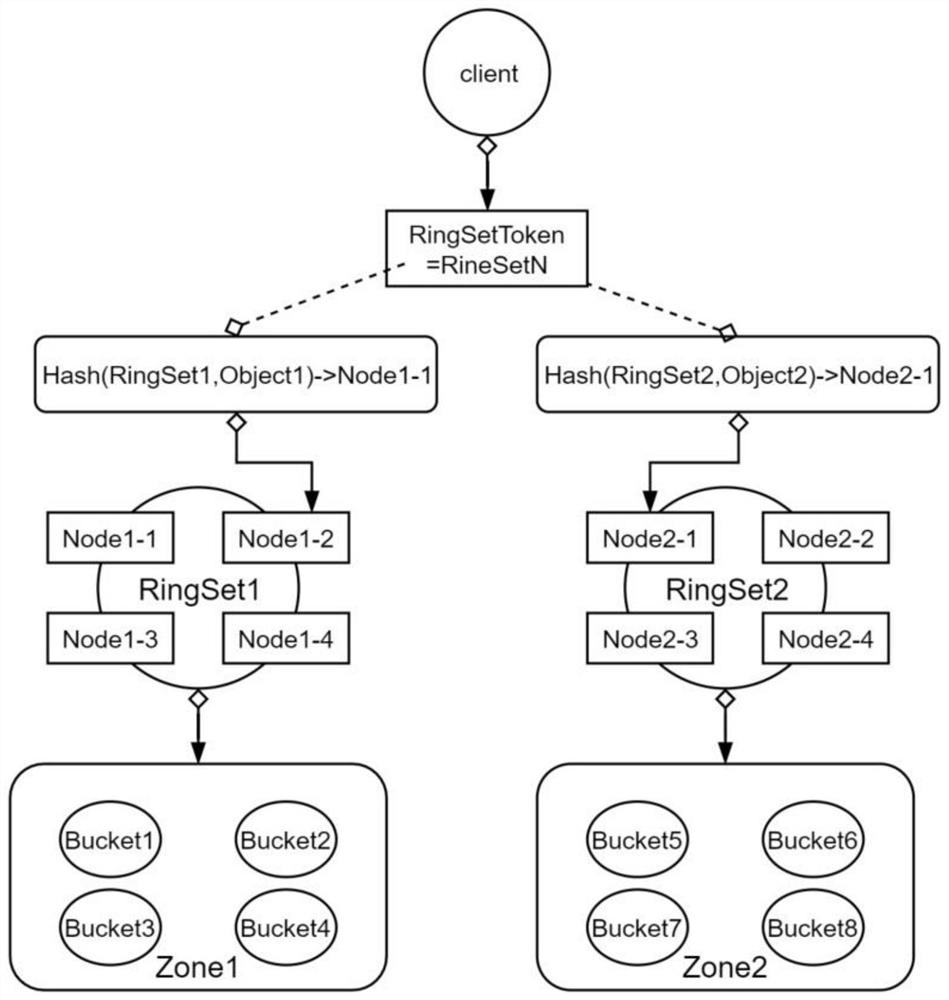

Online capacity expansion method for mass object storage

PendingCN112181309AImprove resource utilizationImprove anti-interference abilityInput/output to record carriersResource allocationObject storageAutoscaling

The invention discloses an online capacity expansion method for massive object storage, which comprises the following steps that: S1, a user creates a bucket through a resetful API, a rear end synchronously creates one or more index objects for storing the object list under the bucket; and S11, when the user inquires the bucket object list through the resetful API, the rear end outputs the objectsin the bucket by using merging sorting, the sorting algorithm increases the calculated amount and the memory along with the increase of the object scale, and the data IO performance is seriously influenced. According to the on-line capacity expansion method for mass object storage, after capacity expansion, an original user S3 interface is kept unchanged, the user can realize elastic expansion ofa storage pool without perception, and after capacity expansion, traversal search of an original S3 interface query storage bucket object mode is changed into hash calculation, so that the routing number and addressing efficiency are greatly reduced, and the loads of multiple clusters are flexibly adjusted.

Owner:SHANGHAI DATATOM INFORMATION TECH CO LTD

Efficient polyolefin-polyester sheath-core composite direct spinning system and method

ActiveCN106894102ASave deploymentFlexible load adjustmentArtificial thread manufacturing machinesFilament/thread formingPolyesterPolyolefin

The invention discloses an efficient polyolefin-polyester sheath-core composite direct spinning system. A delivery pump, a three-way valve, a pre-polycondensation kettle, a final polycondensation kettle, a discharging and boosting pump and a static stirring heat exchanger are sequentially connected and finally connected to a composite spinning box, one branch line of an ethylene glycol pipeline is connected to a pipeline arranged between the delivery pump and the three-way valve through an injection pump, the other branch line of the ethylene glycol pipeline is connected to a mixing tank, a material tank is connected to the mixing tank, and the mixing tank is connected to the three-way valve; a stock bin, a screw extruder, a boosting pump and a static mixer are sequentially connected and connected to the composite spinning box, and a plasma generation device is arranged to be connected to the composite spinning box. The invention further discloses an efficient polyolefin-polyester sheath-core composite direct spinning method. According to the system and method, the two selected polymers both do not need a drying system for removing moisture, the efficient on-line polyolefin blending modification mode is adopted, and the condition that polyolefin is degraded by multiple times of heating is avoided. An existing big polyester synthesis system can be fully utilized.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

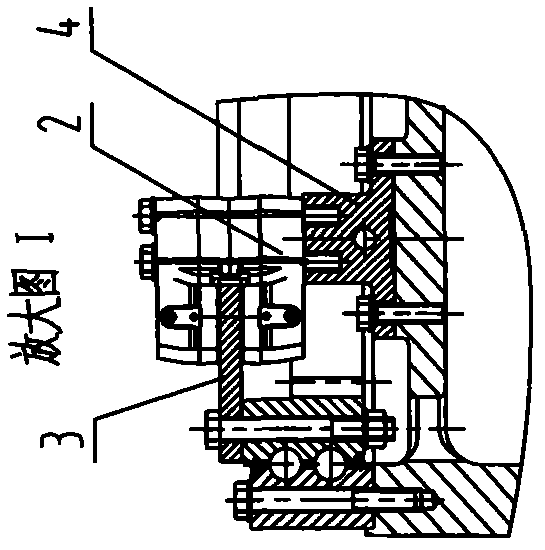

Test unit of variable-pitch system of wind generation set

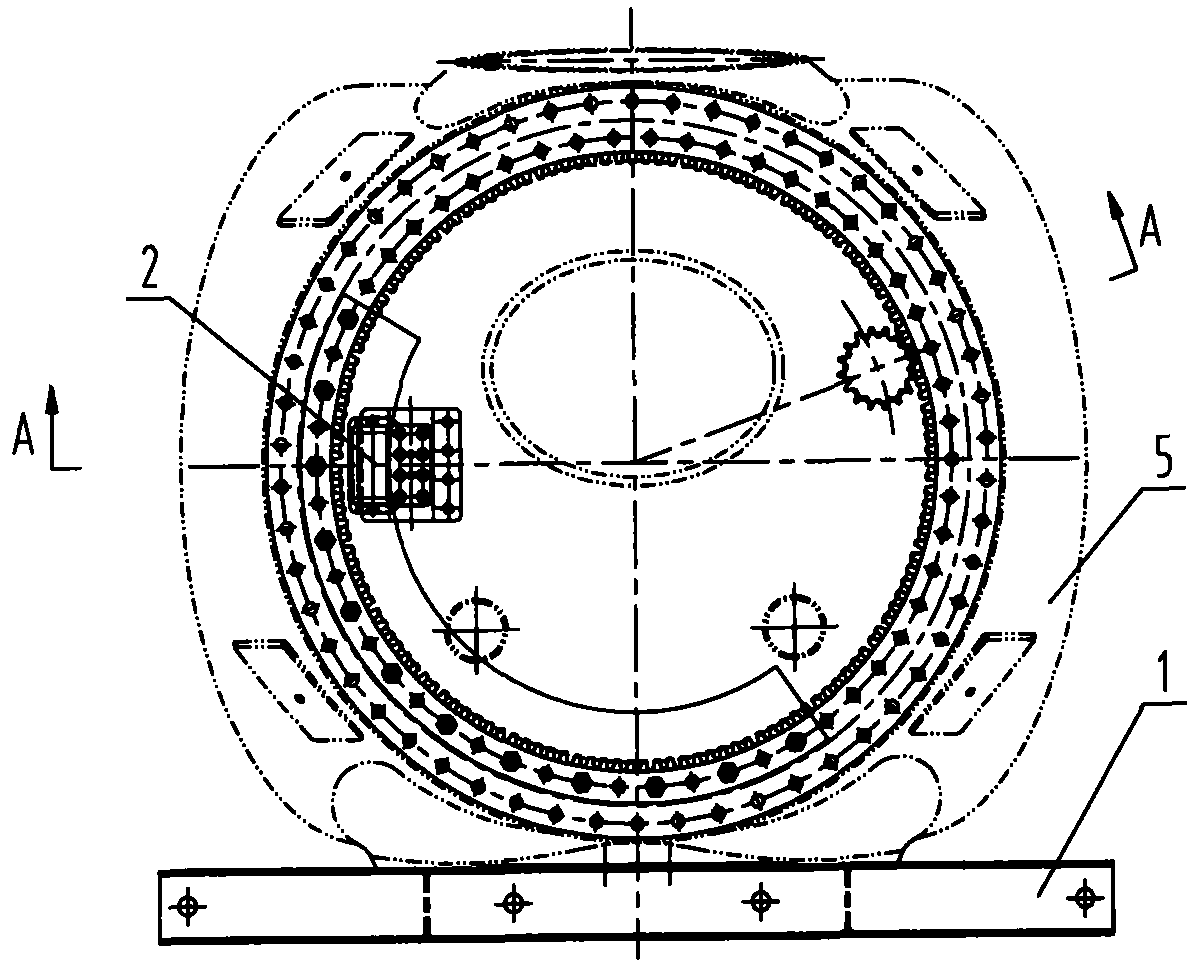

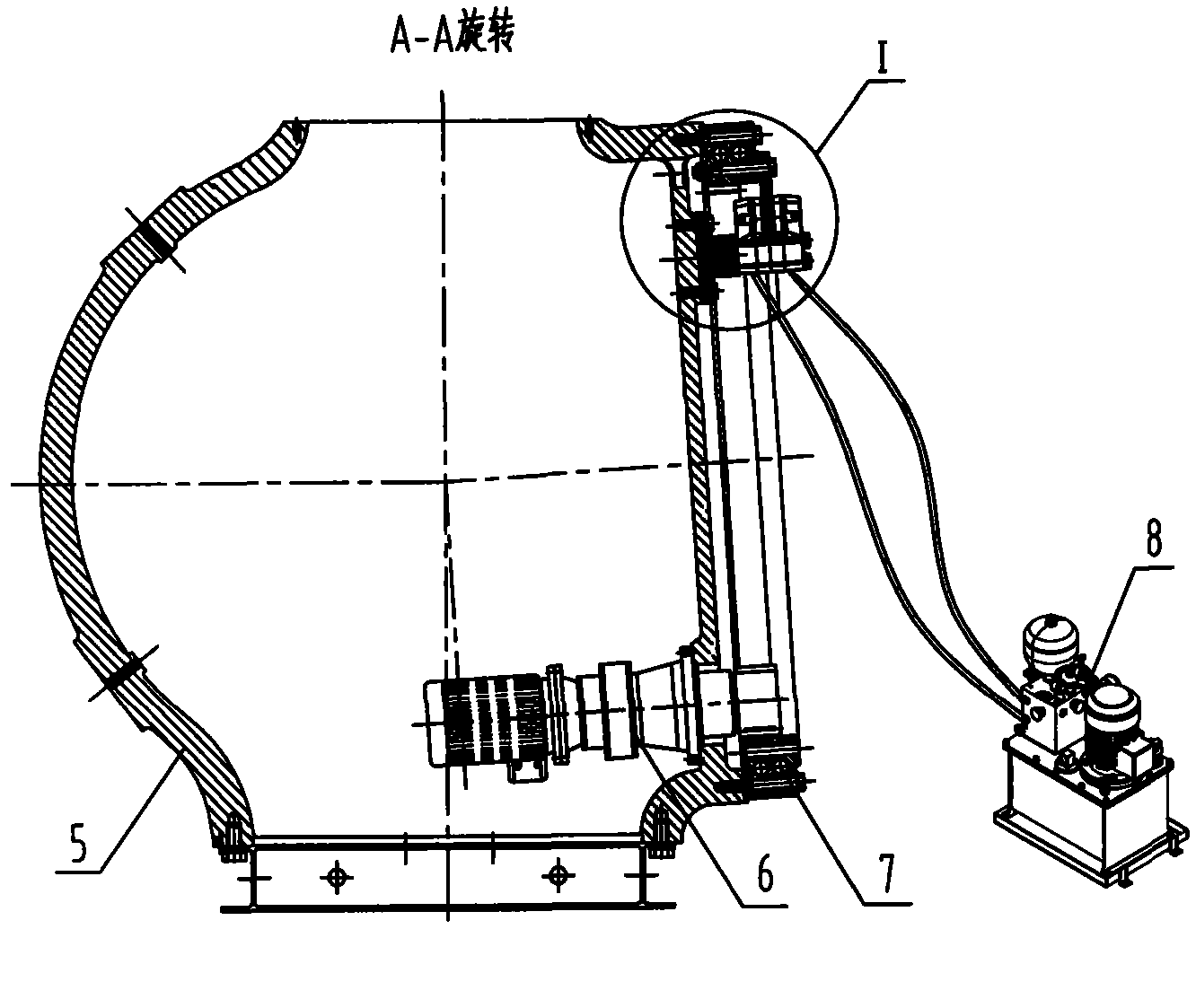

InactiveCN102519720AEasy to load testSave hoisting costsMachine gearing/transmission testingMachine bearings testingWind forceGenerating unit

A test unit of a variable-pitch system of a wind generation set relates to wind generation set equipment, and solves the technical problem of difficulty in carrying out load test on the existing variable-pitch system. The test unit comprises a hub, and a variable-pitch drive assembly and a variable-pitch bearing which are installed on the hub, and is characterized in that: the variable-pitch drive assembly drives an inner ring of the variable-pitch bearing to be connected with a brake disc, and a brake is connected with the hub through a mounting seat, and is connected with a hydraulic station. The test unit tests the wind generation set and occupies a small space, the load is flexibly adjusted, the test unit not only is time saving and labor saving and has high efficiency, but also can conveniently carry out the load test on the variable-pitch system in a workshop, can timely find the defect, is beneficial to product quality improvement, and saves the hoisting cost of a fan.

Owner:TAIYUAN HEAVY IND

Metal monatomic catalyst and preparation method thereof

ActiveCN111389394AImprove general performanceSimple preparation processMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOrganic chemistry

The invention discloses a metal monatomic catalyst and a preparation method thereof. The preparation method comprises the following steps: under the protection of inert atmosphere, dissolving a polyacetylene compound in an aprotic solvent; adding organic strong base and a metal salt precursor under the condition of -40 DEG C or below, performing heating and stirring for reaction, and then carryingout solid-liquid separation to obtain a precipitate; and washing, drying and grinding the precipitate to obtain a target product. The preparation method of the metal monatomic catalyst is simple, short in synthesis period and high in universality, and the obtained metal monatomic catalyst is good in thermal stability and high in metal monatomic loading capacity.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA +1

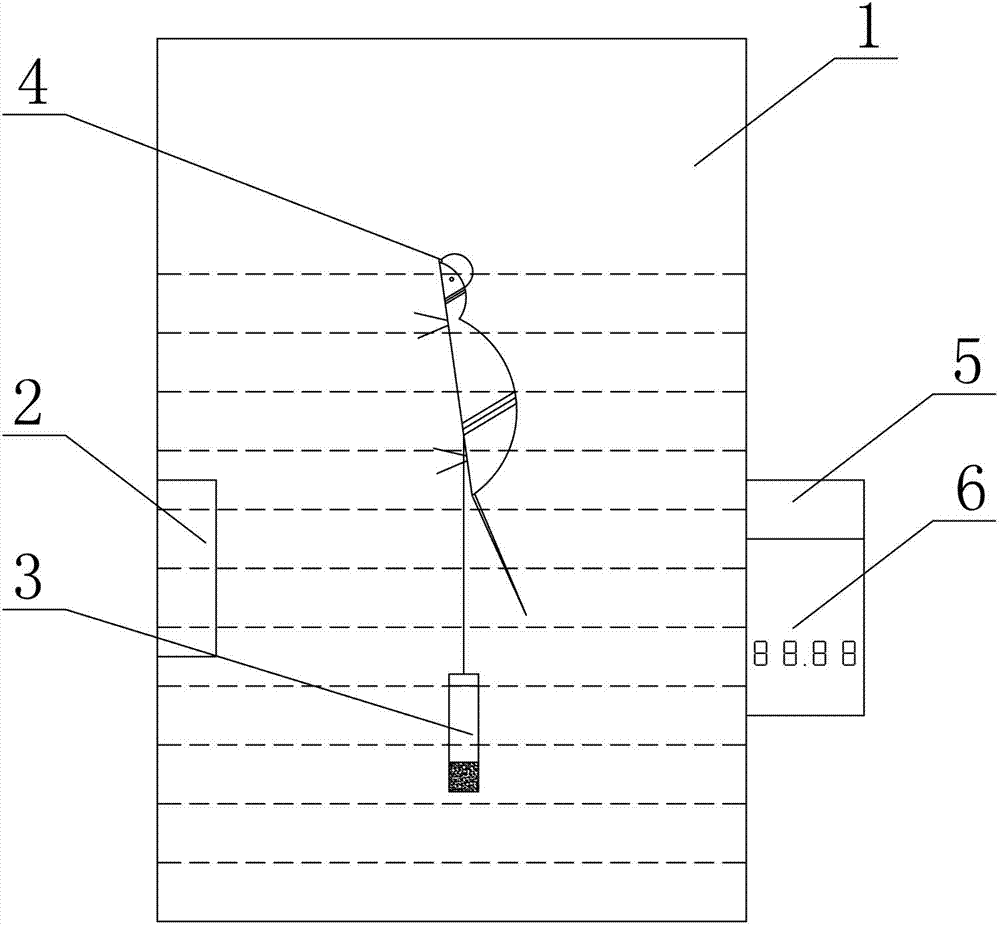

Measurement method and measurement equipment special for exhaustive swimming experiments of rats and mice

InactiveCN104720831AAccurate recordEasy to measureDiagnostic recording/measuringSensorsTemperature controlControl system

The invention provides a measurement method and measurement equipment special for exhaustive swimming experiments of rats and mice. The equipment comprises a barrel, a constant temperature control system and a load bearing device. The barrel is filled with water, the constant temperature control system controls the temperature of the water in the barrel, and the load bearing device provided with a cavity and a cover is tied to a rat or a mouse. When the cover is closed, the cavity is sealed, and the dead weight of the load bearing device is larger than or equal to the buoyancy of the load bearing device completely immersed in the water. The measurement method using the measurement equipment special for the exhaustive swimming experiments of the rats and the mice has the advantages of measurement accuracy and simple structure.

Owner:THE FIRST AFFILIATED HOSPITAL OF WENZHOU MEDICAL UNIV

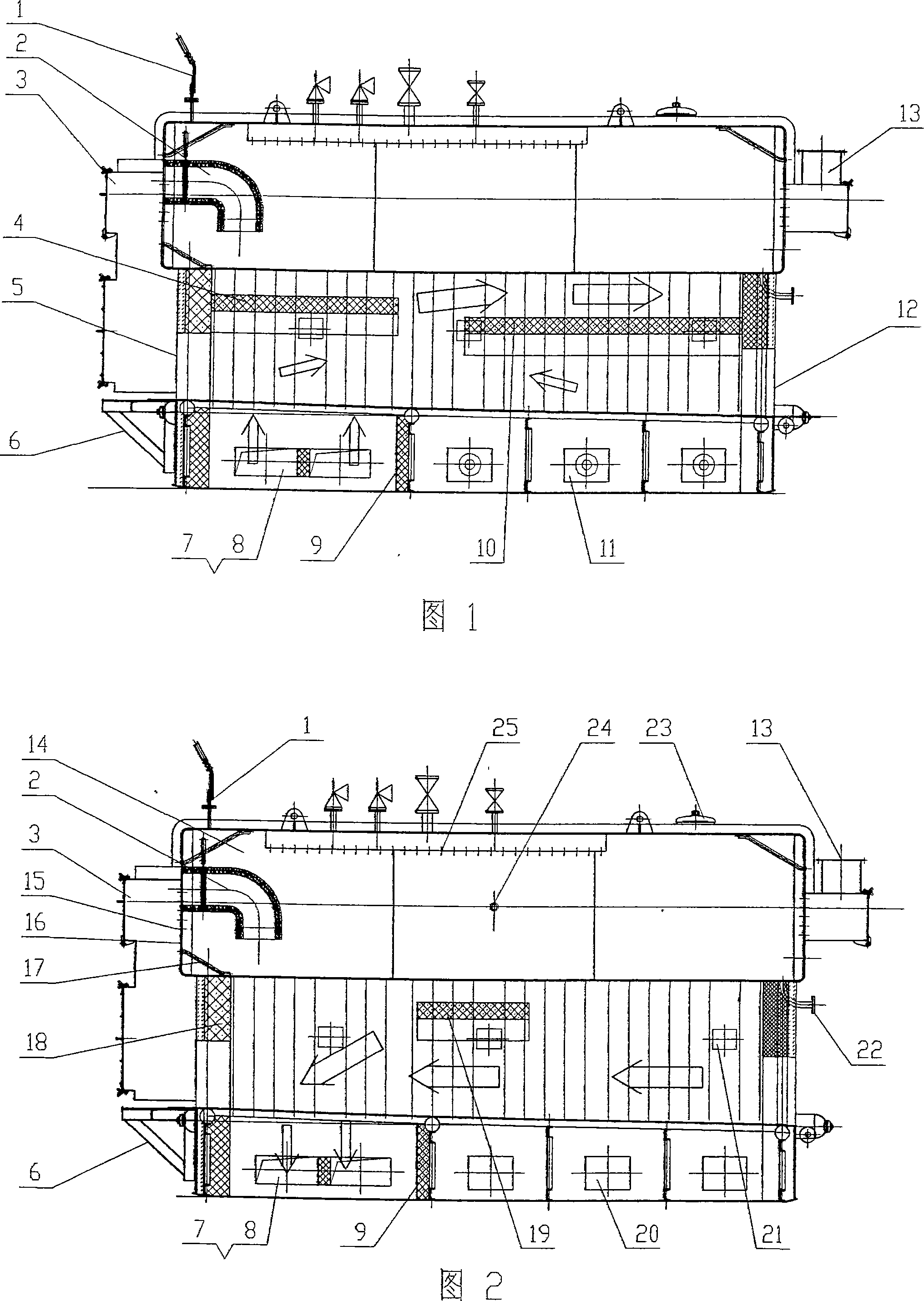

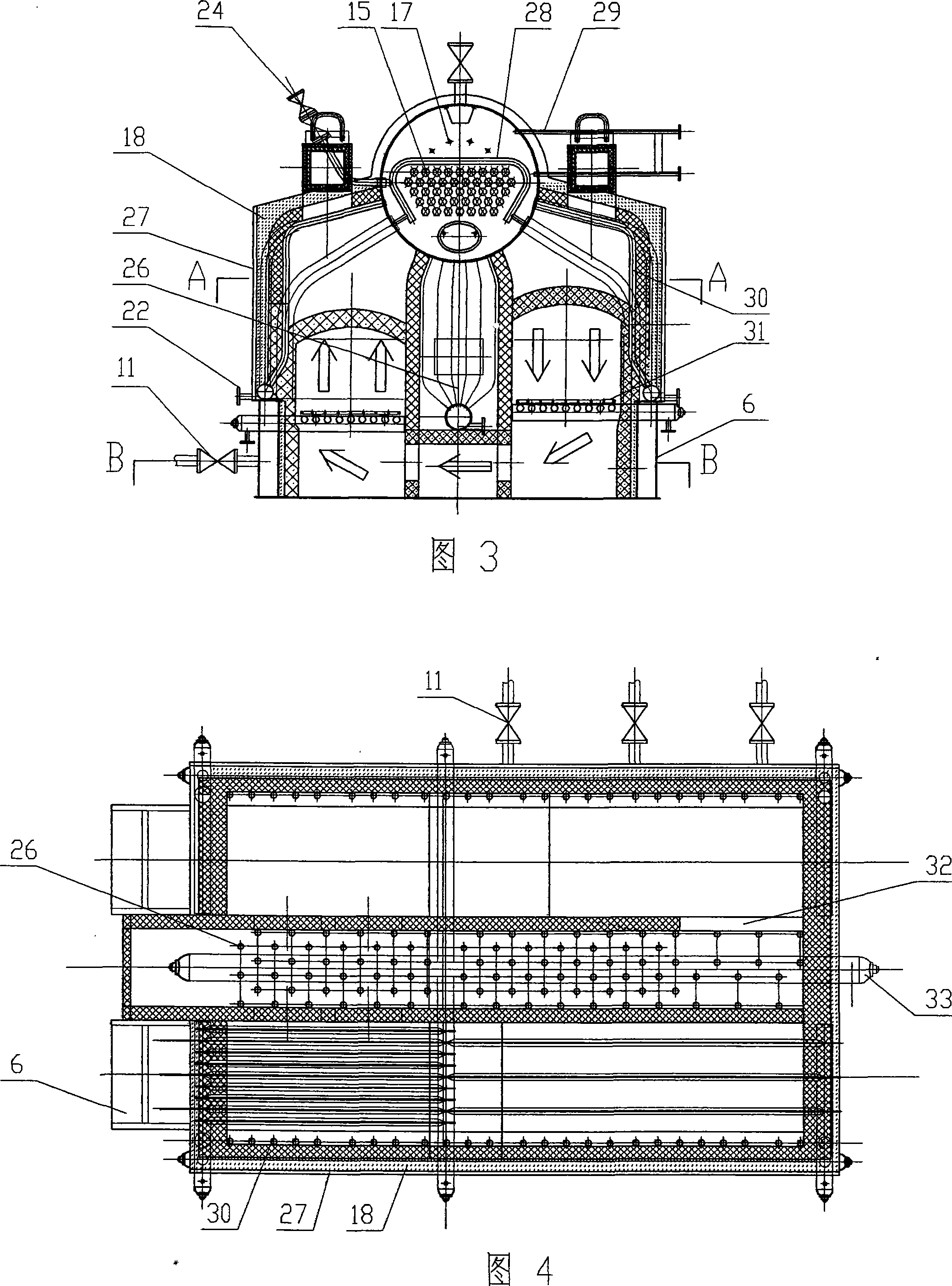

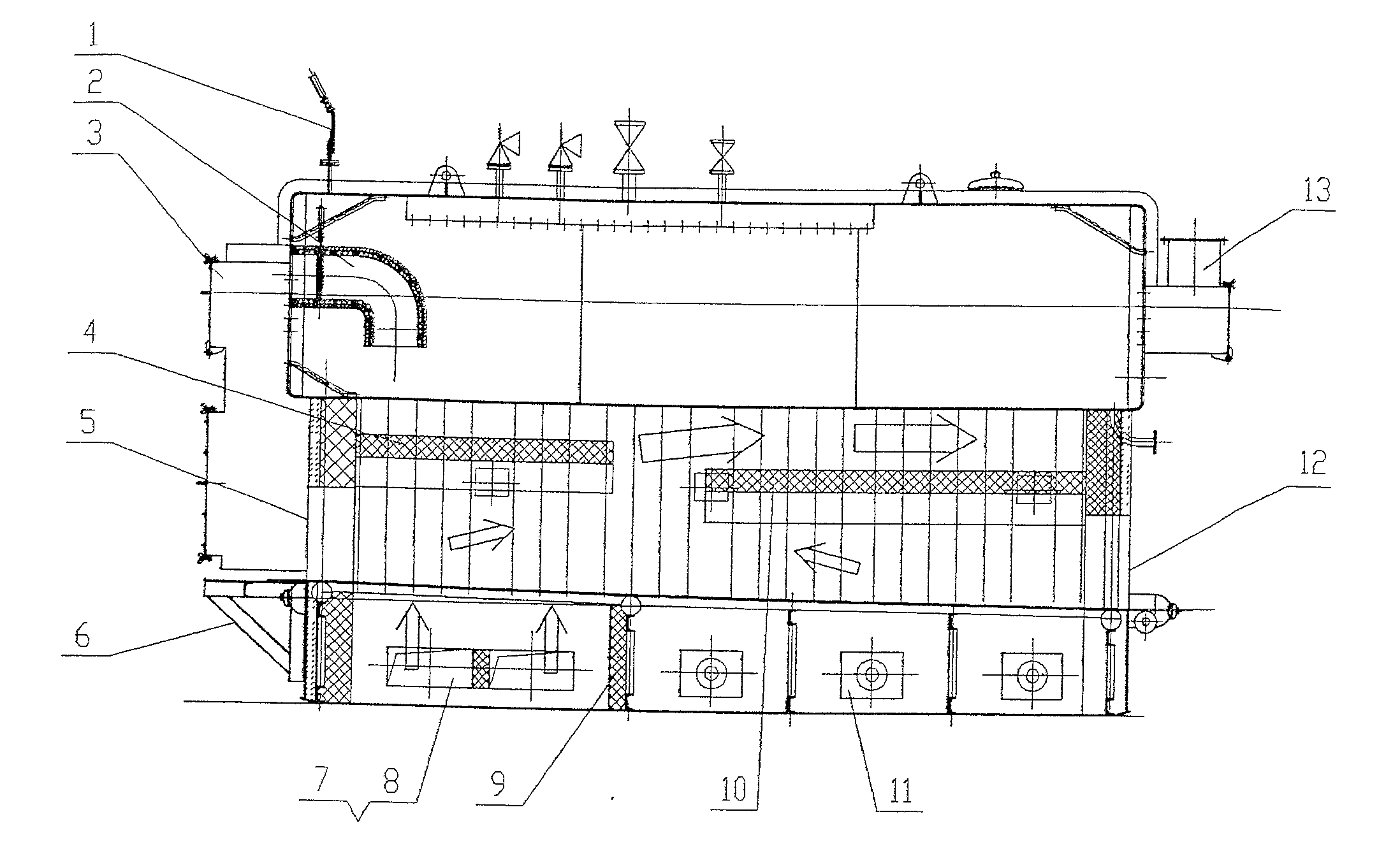

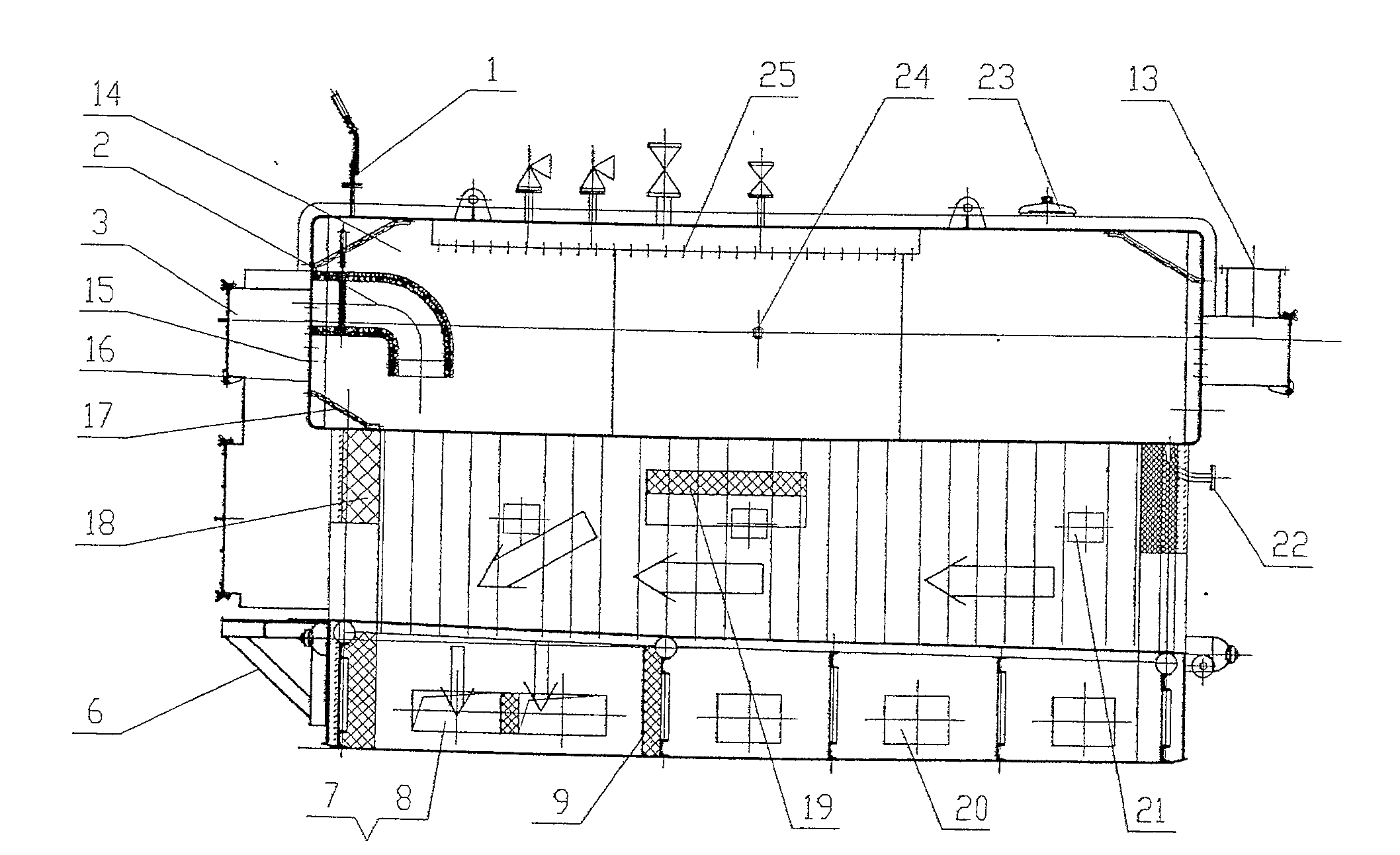

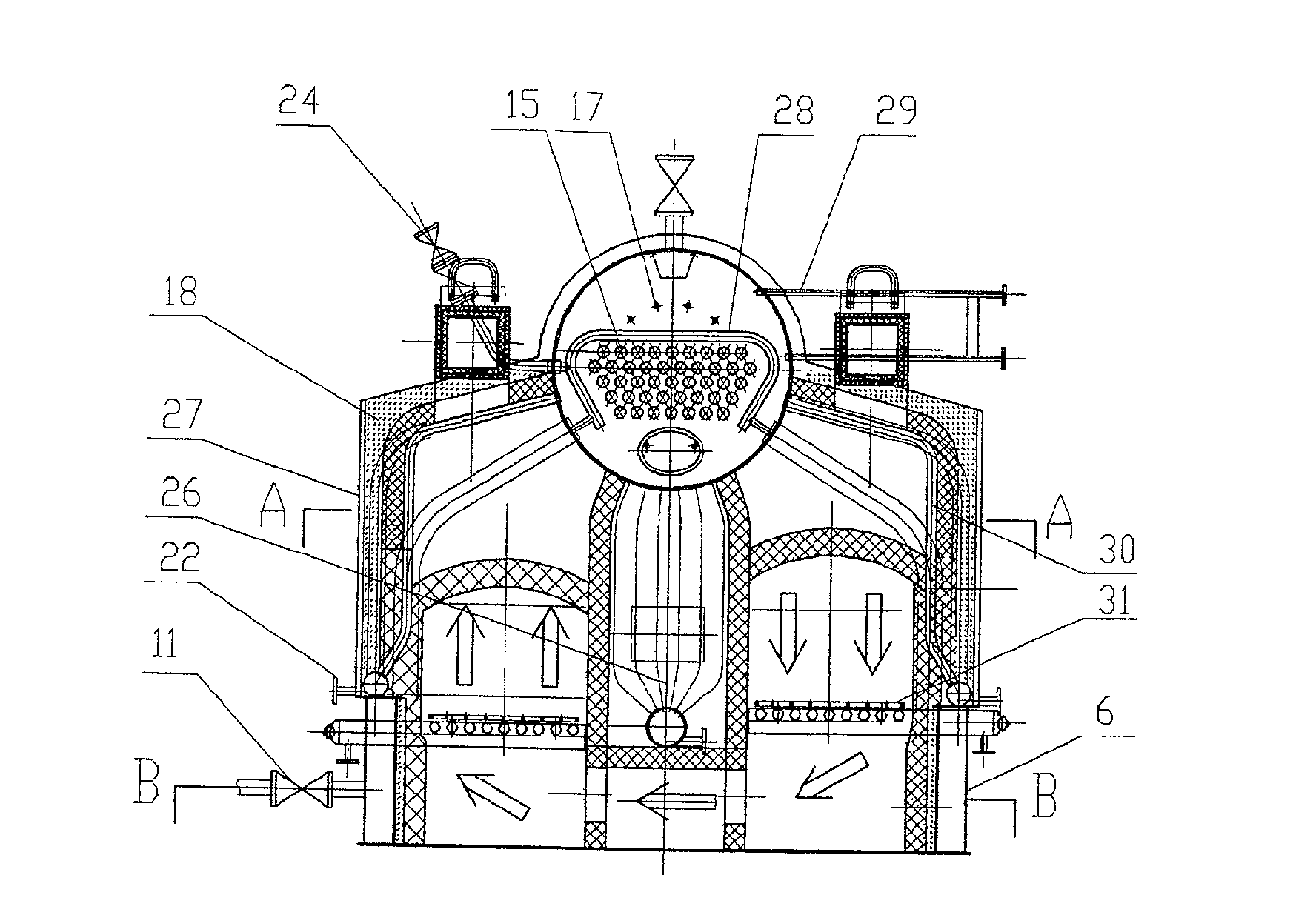

Hot flue gas bidirectional firing, high anthrax adaptability and variable load honeycomb type coal boiler

InactiveCN101206075ABurn fasterGrate effective area savingWater-tube boilersWater heatersBriquetteHoneycomb

A honeycomb type coal boiler with hot flue gas bidirectional ignition, high-rank coal adaptability and variable load belongs to the boiler technical field, in particular relates to stream for burning honeycomb type coal and a hot-water boiler. A right hearth of the invention is provided with a right side hearth hogging; the left hearth is provided with a left side hearth face arch and a left side hearth rear arch; the structures of the left hearth and the right hearth are asymmetrical; the flue gas channels of the left hearth and the right hearth are also asymmetrical; the invention adopts the mode that the hot flue gas downwards the right hearth and upwards the left hearth ignites bituminous coal in the boiler; the invention solves the following problems that: 1. After the whole hot flue gas is downward to ignite the bituminous coal in the boiler, the flue gas directly enters to the subordinate heating surface for cooling and causes the problems that black smoke is emitted from the boiler, coal tar is condensed from the tube wall of the tail heating surface condenses and causes the block, the shut down of the boiler and the decrease of the thermal efficiency; 2. The desulphurization degree in the coal boiler is low; 3. The coal boiler has poor load adjusting performance; 4. The coal has slow burning speed, high manufacturing cost and large occupied area; 5. The coal boiler is uneasy to be large-sized. The invention has the advantages of higher burning efficiency, stronger coal-rank adaptability, better environmental protection and more reliable operation.

Owner:袁福林

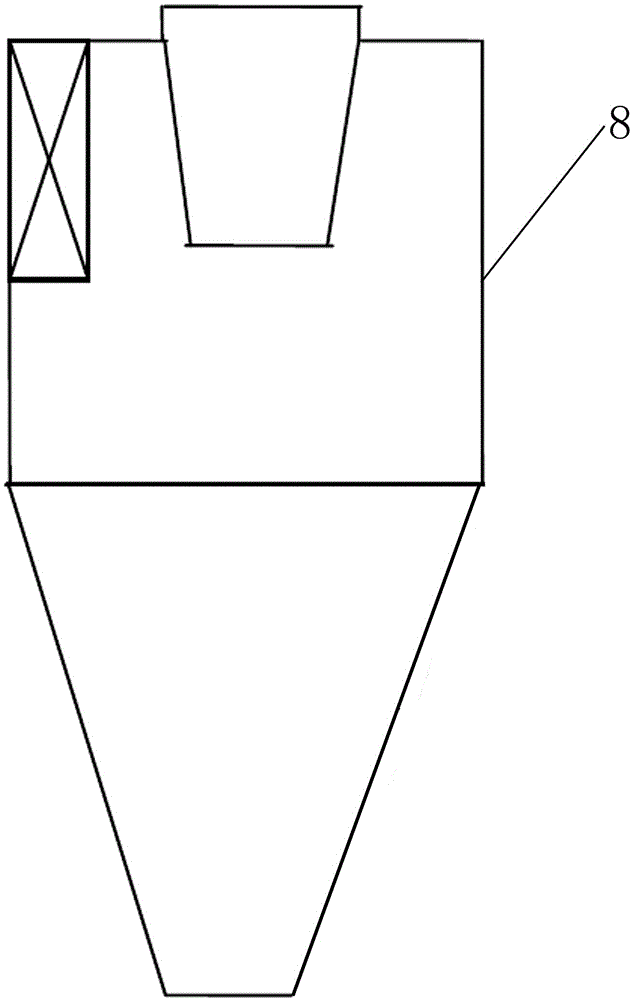

Desulfurization device and desulfurization method

ActiveCN104548920AImprove gas-solid separation efficiencyImprove desulfurization effectLighting and heating apparatusDispersed particle separationFluidized bedEconomic benefits

The invention provides a desulfurization device. The desulfurization device comprises a draught fan, a lime stone cabin, a gas storage tank and a circulating fluidized bed boiler, and is characterized in that the circulating fluidized bed boiler comprises a hearth, a material returning pipe and a square separator, wherein the upper part of the square separator is communicated with the upper part of the hearth; the lower part of the square separator is connected with the lower part of the hearth by the material returning pipe and a coal falling pipe is arranged on the hearth; the draught fan is connected with the bottom of the lime stone cabin by a heating device; the upper part of the lime stone cabin is connected with a bag dust remover and the lower end of the lime stone cabin is connected with a feeding machine by an unloading valve; the feeding machine is connected with a feeding pipe; the gas storage tank is connected with the feeding pipe and the feeding pipe is connected with the coal falling pipe. The invention further provides a desulfurization process utilizing the desulfurization device; the conveying speed of lime stones is 12m / s-14m / s and the gas-solid ratio is 1 to (3-6). The production cost of the equipment is reduced, the desulfurization effect of the circulating fluidized bed boiler is improved and the economic benefits are good.

Owner:HENAN SHENMA NYLON CHEM

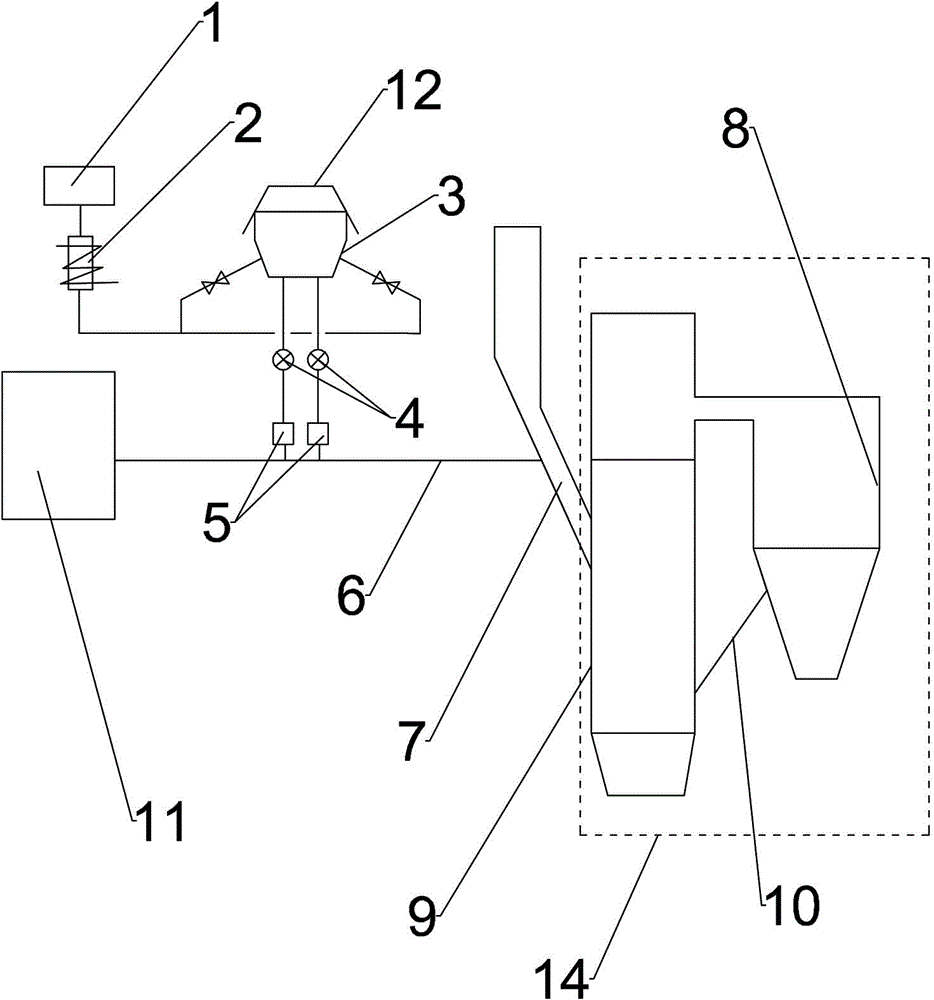

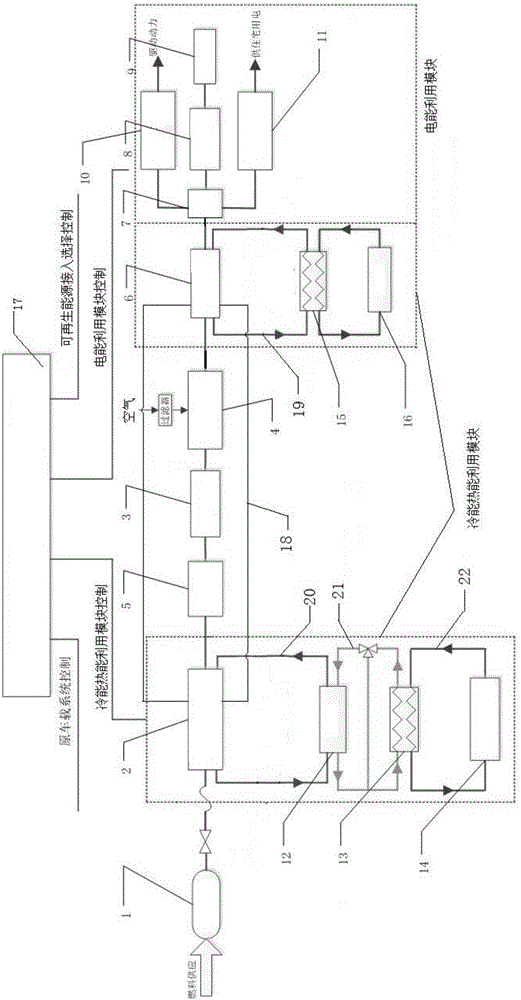

Small vehicle-mounted distributed energy station

ActiveCN106166979AImprove energy efficiencyFirmly connectedLighting and heating apparatusPower network operation systems integrationThermal energyEngineering

The invention relates to a small vehicle-mounted distributed energy station. The small vehicle-mounted distributed energy station comprises a cold energy and heat energy utilization unit and a gas supply unit, an electric energy utilization unit and a vehicle-mounted control center (17) which are arranged on a motor vehicle; the gas supply unit comprises an LNG storage tank (1) and an LNG gasifier (2); the cold energy and heat energy utilization unit comprises a heat supplying heat exchanger (15), a cold supplying heat exchange device, a first cycle fluid loop (18), a second cycle fluid loop (19) and a third cycle fluid loop (20); the electric energy utilization unit comprises an additionally-installed electric generator (11); the vehicle-mounted control center (17) controls the state of the motor vehicle to be switched between a motor vehicle function state and a vehicle-mounted energy station function state. Compared with the prior art, the small vehicle-mounted distributed energy station mainly adopts natural gas and takes other renewable energy into account, meets transportation and agriculture production and has electric generation, heat supplying, cold supplying and gas supplying functions and the like to achieve the purposes of reducing energy consumption, protecting the environment and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Energy-feedback type shaft system torsional vibration testing system

ActiveCN108225696ARealize measurementRealize transmissionVibration testingFrequency changerElectric machine

The invention relates to an energy-feedback type shaft system torsional vibration testing system. The energy-feedback type shaft system torsional vibration testing system comprises a frequency converter, a variable-frequency and variable-speed motor controlled by the frequency converter, a double-fed motor linked with the variable-frequency and variable-speed motor, a rotor-side converter and a grid-side converter which connect the double-fed motor to a power grid, a torsional vibration signal collecting assembly and a torsional vibration monitoring and testing system connected with the torsional vibration signal collecting assembly, wherein a plurality of linkage mechanisms to be tested are connected between the variable-frequency and variable-speed motor and the double-fed motor, the torsional vibration signal collecting assembly is used for detecting torsional vibration information of the linkage mechanisms to be tested, and the torsional vibration monitoring and testing system is used for receiving and displaying the torsional vibration information. The energy-feedback type shaft system torsional vibration testing system has an effect of testing the torsional vibration of various excitation factors of various linkage mechanisms in various environments.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

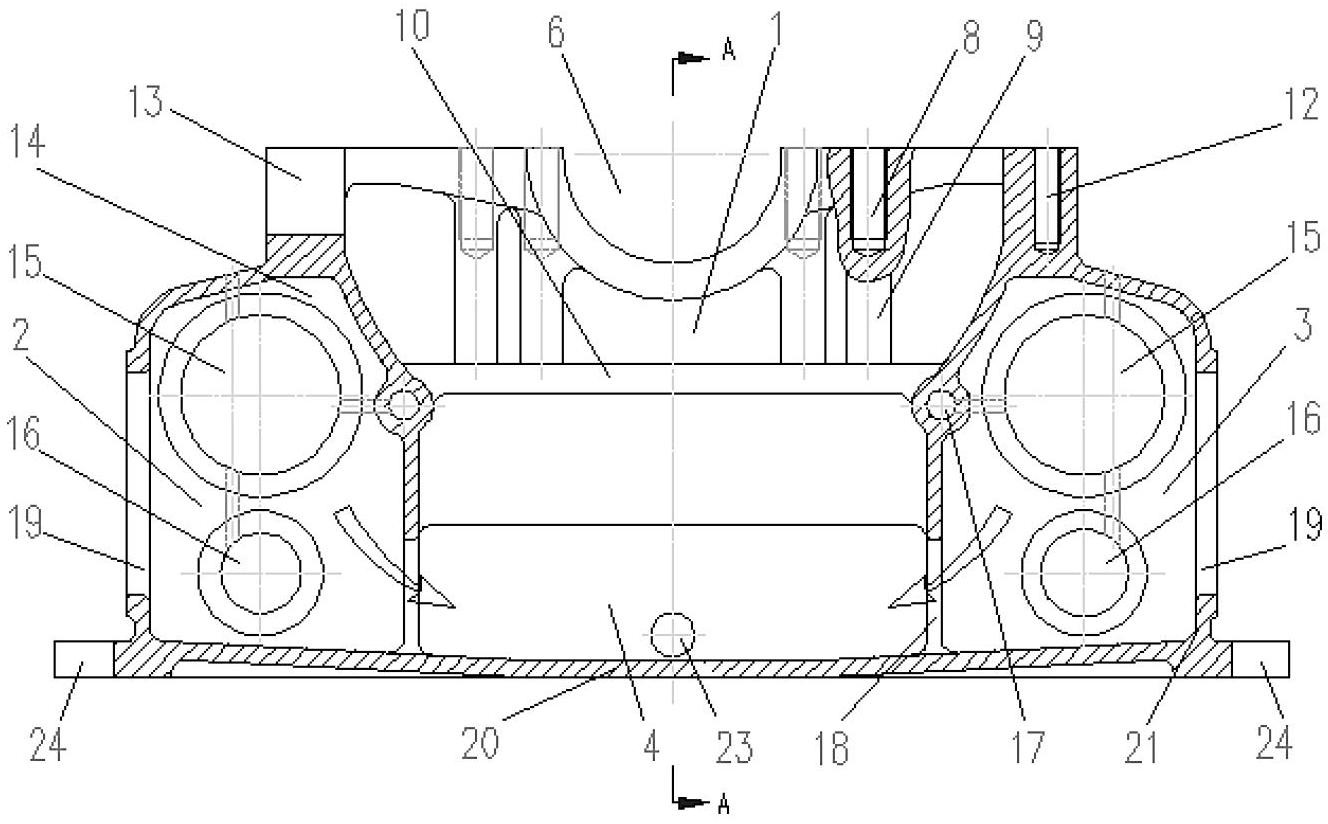

Integrated single-cylinder engine base structure

InactiveCN102644522ASmall radius of motionOptimizing Load RegulationCasingsMachines/enginesWhole bodyThrust bearing

The invention relates to an integrated single-cylinder engine base structure which comprises a lower crankcase (1), a left balance chamber (2), a right balance chamber (3) and an oil pan (4), wherein the left balance chamber (2) and the right balance chamber (3) are symmetrically arranged at left and right sides of the lower crankcase (1); and the oil pan (4) is arranged at the lower parts of the left balance chamber (2) and the right balance chamber (3). According to the invention, the integrated single-cylinder engine base structure integrates a plurality of functions into a whole body and has high integration degree; three chambers are transversely arranged and three clapboards are longitudinally arranged, so that the longitudinal and transverse size proportion is proper, the integral rigidity is high, and the stability is high; a three-gear crankshaft bearing base is divided into a load-carrying bearing base and a thrust bearing base; the function division is clear; the load distribution is reasonable; the high working rigidity of a crankshaft and the working intensity of a bearing bush are ensured; and finally, the working intensity of the whole machine is improved.

Owner:NO 70 INST OF CHINA NORTH IND GRP

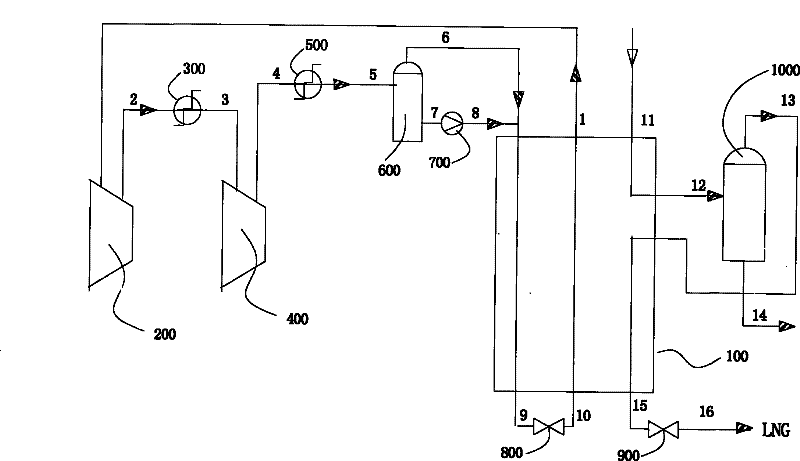

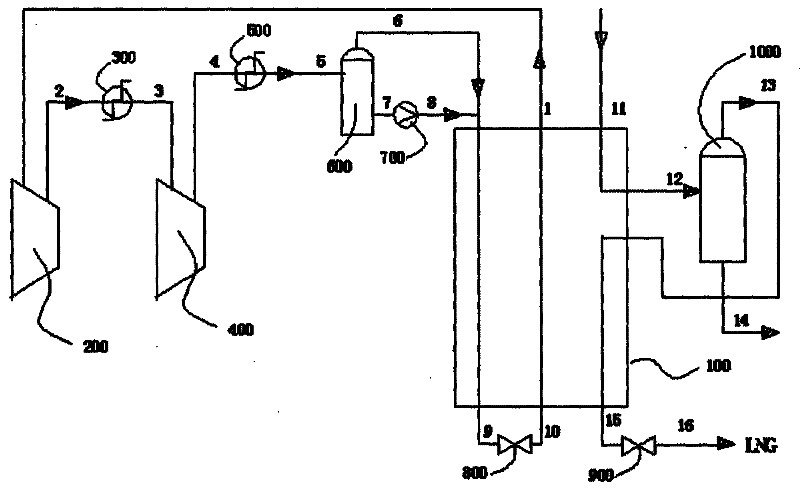

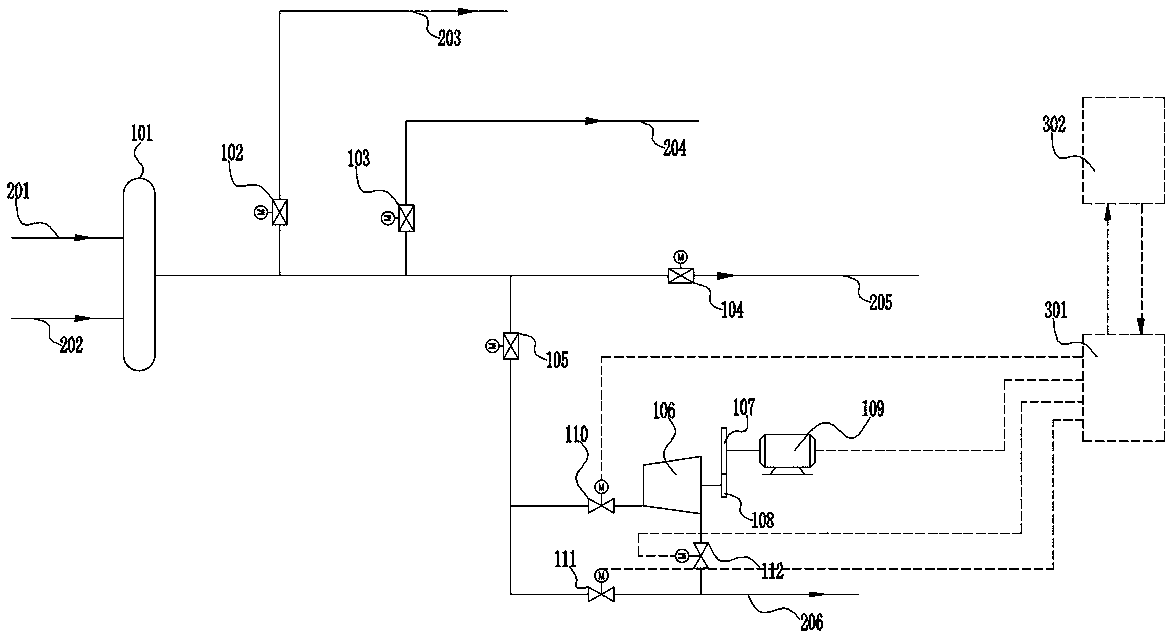

Gas liquefying process for mixed refrigerant and mixed refrigerant

The invention relates to a gas liquefying process for mixed refrigerant, which comprises the following steps: providing the mixed refrigerant which comprises the following components in percentage by mole: 5 to 10 percent of nitrogen, 30 to 40 percent of methane, 5 to 10 percent of ethylene, and 45 to 60 percent of propane; feeding the mixed refrigerant to a single refrigerant circulating system to carry out closed cycle to produce cold energy required by cooling gas; and exchanging heat of the gas needing to be liquefied and the refrigerant circulating system through a gas liquefying system so that the gas is cooled and liquefied. The process flow is simple, the components of the refrigerant are reasonable, and a liquefying device has the advantages of safe and reliable operation, simplework, flexible load adjustment and low energy consumption.

Owner:LIAONING CIMC HASHENLENG GAS LIQUEFACTION EQUIP CO LTD

Dual-tower parallel urea synthesizing device

InactiveCN101659633AReduce production intensityHigh synthetic conversion rateUrea derivatives preparationProductsTowerUltimate tensile strength

The invention relates to a dual-tower parallel urea synthesizing device, comprising two urea synthesizing towers. Each urea synthesizing tower is communicated with respective liquid ammonia feed pipe,carbon dioxide feed pipe and nail liquid feed pipe; discharge pipes are respectively arranged at the tops of the two urea synthesizing towers; two discharge pipes are connected together and then communicated with a discharge main pipe; and the size and the specification of the two urea synthesizing towers are same. The dual-tower parallel urea synthesizing device reduces the production strength of the urea synthesizing towers, prolongs the stay time of materials in the synthesizing towers, improves the urea synthesizing conversion rate and the yield capacity, has less investment and quick extension and production, saves labor force and matched facilities, allows to repair synthesizing towers having faults or stop the overhaul of any one synthesizing tower under the condition of not stopping production and has simples operation and flexible adjustment.

Owner:HUAQIANG CHEM GRP

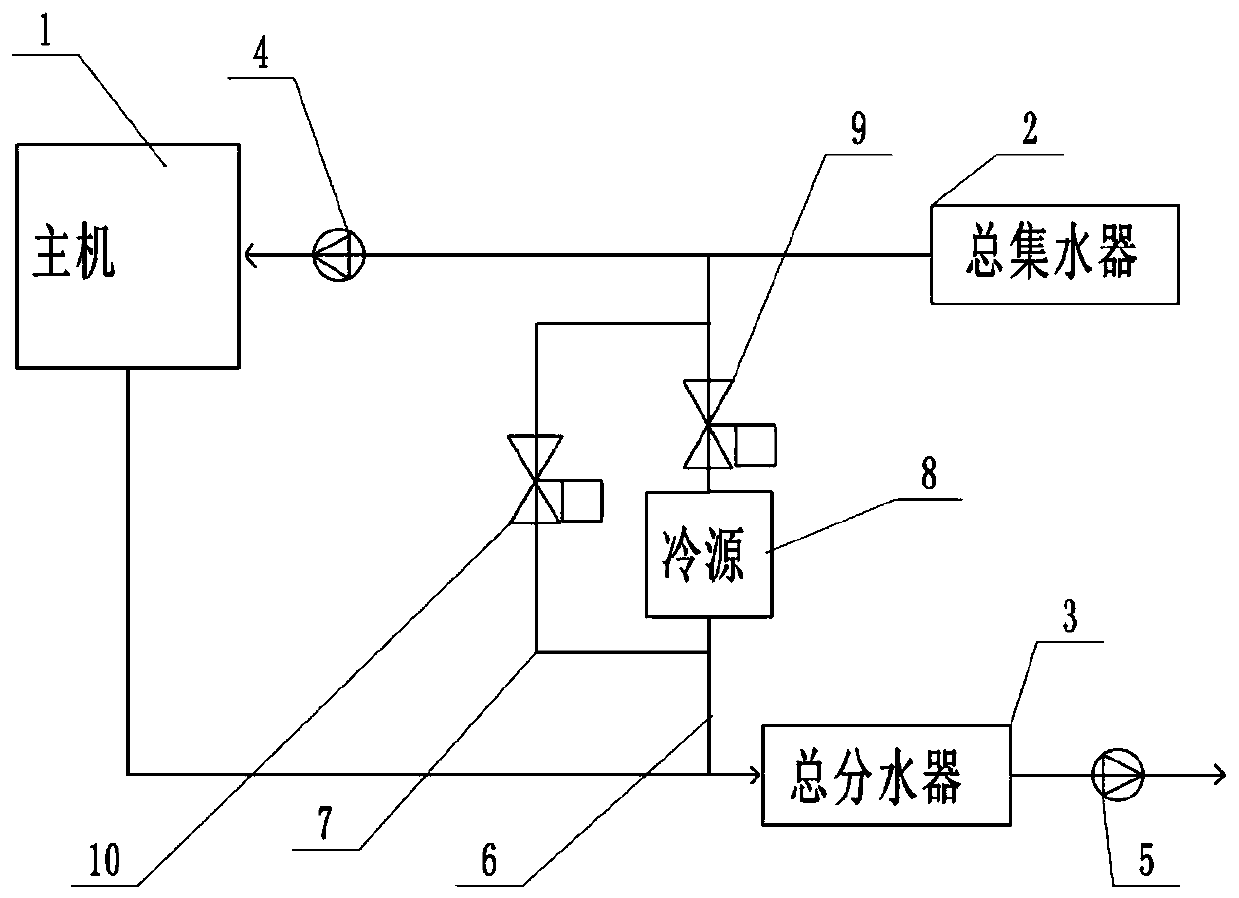

Balanced energy-saving control device based on secondary pump system of central air-conditioner

PendingCN110160244AMeet the needs of useFlexible load adjustmentMechanical apparatusPulp and paper industryCooling capacity

The invention belongs to the field of technical equipment of air conditioners and in particular discloses a balanced energy-saving control device based on a secondary pump system of a central air-conditioner. The device comprises a main machine, a general water collector, a general water separator and an axle tube. The input end of the main machine is connected to the general water collector, theoutput end of the main machine is connected to the general water segregator, and a primary pump is arranged between the main machine and the general water collector; the secondary pump is arranged atthe output end of the general water segregator, and the axle tube is connected between the output end of the general water collector and the input end of the general segregator; an energy-saving control unit is arranged on the axle tube, and a bypass pipe is arranged at each of two ends of the energy-saving control unit; and a bypass valve is additionally mounted on the bypass pipe. According to the scheme, an existing air conditioner system is improved. By additionally mounting the energy-saving control unit of the secondary pump system, the time of a refrigerating main machine in a low efficiency working condition is shortened and the efficiency of the refrigerating main machine is improved while meeting the demand on cooling capacity.

Owner:浙江大冲能源科技股份有限公司

Phase change type high-pressure electrode boiler

PendingCN111322597AImprove thermal efficiencyFast heatingSteam/vapor condensersElectrode boilersThermodynamicsEngineering

The invention discloses a phase change type high-pressure electrode boiler. The phase change type high-pressure electrode boiler comprises supporting legs, a boiler shell, a phase change heat exchanger, a plurality of supporting seats, insulation heat-resisting seats, an inner cylinder, a plurality of high-pressure electrodes, water distributing plates, U-shaped distributing pipes, a water pipe, awater return pipe and a load adjusting pump; the boiler shell is arranged on the supporting legs; the phase change heat exchanger is arranged at the top; the plurality of supporting seats are arranged on the inner wall of the boiler shell; the insulation heat-resisting seat is arranged on each supporting seat correspondingly; the inner cylinder provided with water distributing holes and water dropping holes at the bottom is arranged on the insulation heat-resisting seats; the plurality of high-pressure electrodes are connected with an external circuit, positioned in a cavity of the inner cylinder and hung on the inner cylinder through insulators; the water distributing plates are arranged above water inlets at the bottom of the inner cylinder; the U-shaped water distributing pipes communicate with the water inlets at the bottom of the inner cylinder and are arranged at the bottom of the inner cylinder; the water pipe communicates with the bottom of the U-shaped water distributing pipes, and is connected with and extends out of the bottom of the boiler shell; the water return pipe is arranged at the bottom of the boiler shell; and the load adjusting pump is connected with the end of the water pipe and the end of the water return pipe, and can perform variable frequency control and adjust circulating water volume of the boiler. The phase change type high-pressure electrode boiler is reliable in operation, flexible in load adjustment and high in safety, and is widely applicable to clean energy consumption and power plate flexible modification.

Owner:QINGDAO DANENG ENVIRONMENTAL PROTECTION INC

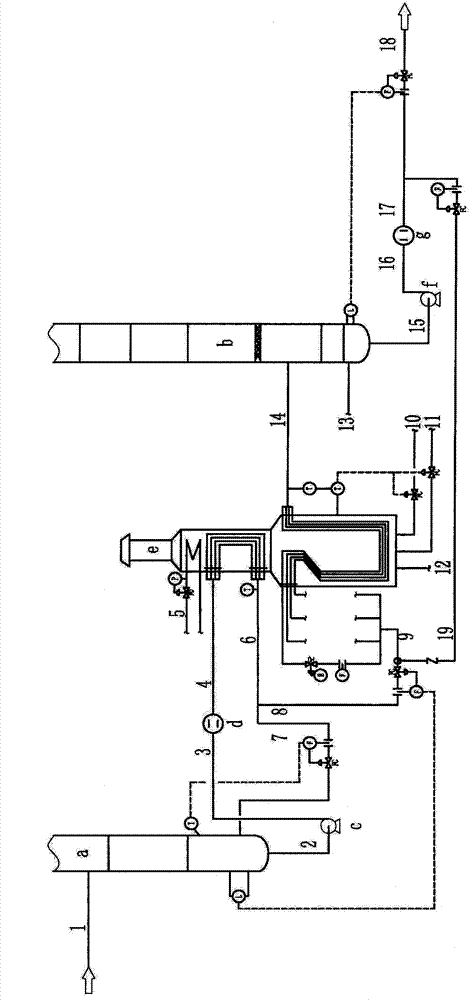

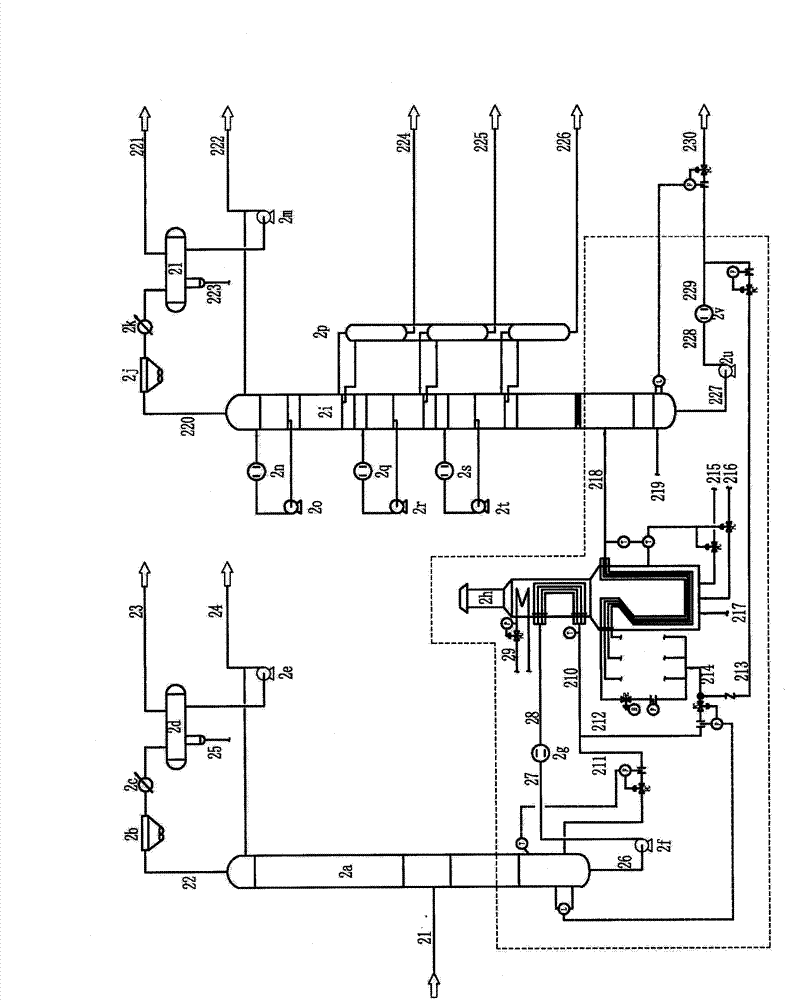

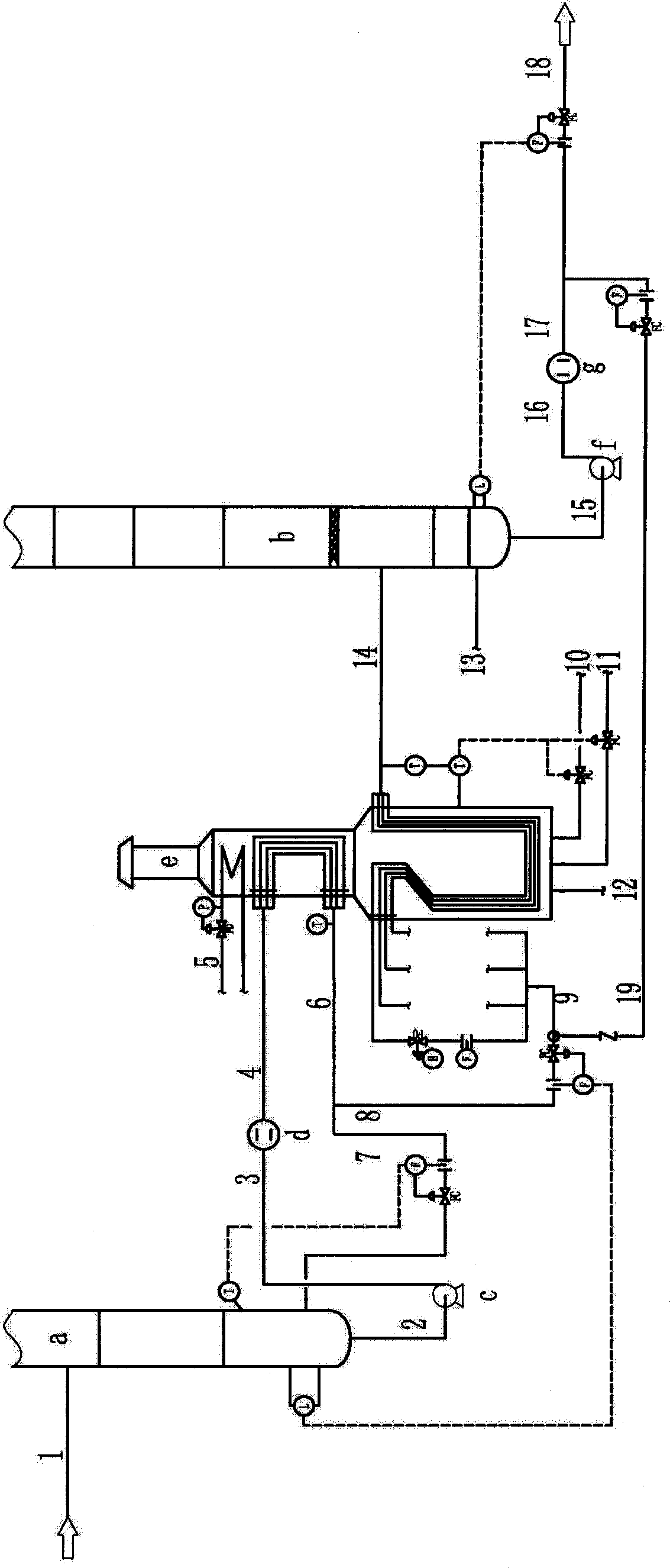

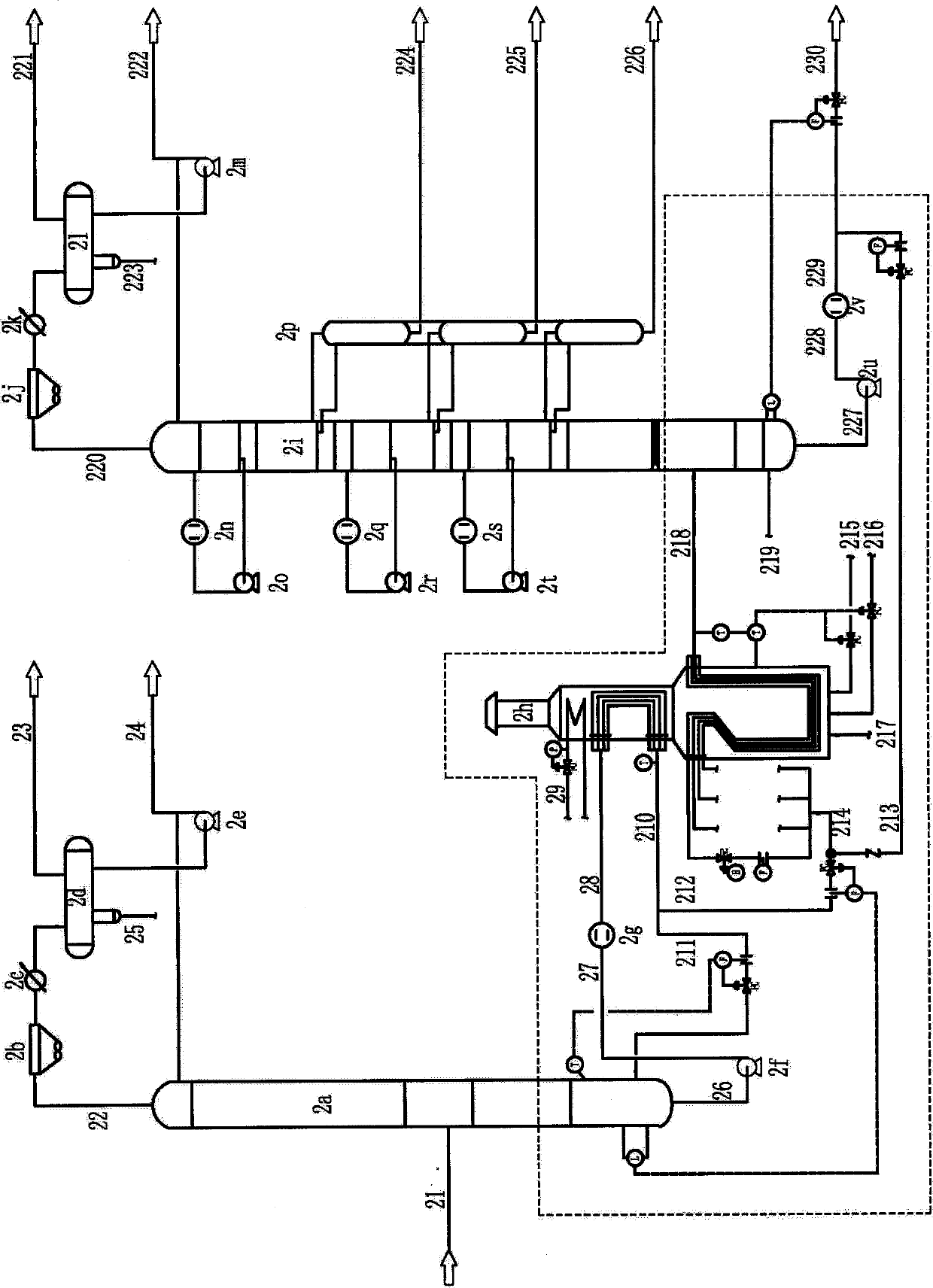

Reboiling and feeding heating two-in-one heating furnace and fractionation method thereof

ActiveCN102788505AFlexible load adjustmentSolve the problem of high vaporization rateHydrocarbon distillationFurnace typesFractionationVaporization

The invention relates to a reboiling and feeding heating two-in-one heating furnace and a fractionation method thereof. A reboiling furnace and a feeding heating furnace are combined to control a flow, the two-in-one furnace replaces the reboiling furnace and the feeding heating furnace which are respectively arranged, a convection chamber of the two-in-one furnace serves as the reboiling furnace, and a radiation chamber of the two-in-one furnace serves as the feeding heating furnace. Base oil of a fractionating tower a enters the convection chamber of the two-in-one furnace to be heated, the base oil is divided into two paths after heating, one path of the base oil serves as tower bottom reboiling oil to return to the bottom of the tower a, and the other path of the base oil serves as feeding of the radiation chamber of the two-in-one furnace. The two-in-one furnace can flexibly adjust loads of the reboiling furnace and the feeding heating furnace by adjusting quantity of reboiling oil (one path entering the radiation chamber) at the bottom of the fractionating tower a and recycle oil at the bottom of a fractionating tower b. Partial heavy materials at the bottom of the fractionating tower b return to an inlet of the radiation chamber of the two-in-one furnace to be mixed with the feeding of one path of the radiation chamber of the two-in-one furnace at the bottom of the fractionating tower to serve as mixed feeding of the radiation chamber of the two-in-one furnace, and vaporization rate of an outlet of the radiation chamber is controlled in an appropriate scope.

Owner:CHINA PETROCHEMICAL CORP +1

Reboiling and feeding heating two-in-one heating furnace and fractionation method thereof

ActiveCN102788505BFlexible load adjustmentSolve the problem of high vaporization rateHydrocarbon distillationFurnace typesFractionationVaporization

The invention relates to a reboiling and feeding heating two-in-one heating furnace and a fractionation method thereof. A reboiling furnace and a feeding heating furnace are combined to control a flow, the two-in-one furnace replaces the reboiling furnace and the feeding heating furnace which are respectively arranged, a convection chamber of the two-in-one furnace serves as the reboiling furnace, and a radiation chamber of the two-in-one furnace serves as the feeding heating furnace. Base oil of a fractionating tower a enters the convection chamber of the two-in-one furnace to be heated, the base oil is divided into two paths after heating, one path of the base oil serves as tower bottom reboiling oil to return to the bottom of the tower a, and the other path of the base oil serves as feeding of the radiation chamber of the two-in-one furnace. The two-in-one furnace can flexibly adjust loads of the reboiling furnace and the feeding heating furnace by adjusting quantity of reboiling oil (one path entering the radiation chamber) at the bottom of the fractionating tower a and recycle oil at the bottom of a fractionating tower b. Partial heavy materials at the bottom of the fractionating tower b return to an inlet of the radiation chamber of the two-in-one furnace to be mixed with the feeding of one path of the radiation chamber of the two-in-one furnace at the bottom of the fractionating tower to serve as mixed feeding of the radiation chamber of the two-in-one furnace, and vaporization rate of an outlet of the radiation chamber is controlled in an appropriate scope.

Owner:CHINA PETROCHEMICAL CORP +1

A desulfurization device and desulfurization method

ActiveCN104548920BImprove gas-solid separation efficiencyImprove desulfurization effectLighting and heating apparatusDispersed particle separationFluidized bedEngineering

The invention provides a desulfurization device. The desulfurization device comprises a draught fan, a lime stone cabin, a gas storage tank and a circulating fluidized bed boiler, and is characterized in that the circulating fluidized bed boiler comprises a hearth, a material returning pipe and a square separator, wherein the upper part of the square separator is communicated with the upper part of the hearth; the lower part of the square separator is connected with the lower part of the hearth by the material returning pipe and a coal falling pipe is arranged on the hearth; the draught fan is connected with the bottom of the lime stone cabin by a heating device; the upper part of the lime stone cabin is connected with a bag dust remover and the lower end of the lime stone cabin is connected with a feeding machine by an unloading valve; the feeding machine is connected with a feeding pipe; the gas storage tank is connected with the feeding pipe and the feeding pipe is connected with the coal falling pipe. The invention further provides a desulfurization process utilizing the desulfurization device; the conveying speed of lime stones is 12m / s-14m / s and the gas-solid ratio is 1 to (3-6). The production cost of the equipment is reduced, the desulfurization effect of the circulating fluidized bed boiler is improved and the economic benefits are good.

Owner:HENAN SHENMA NYLON CHEM

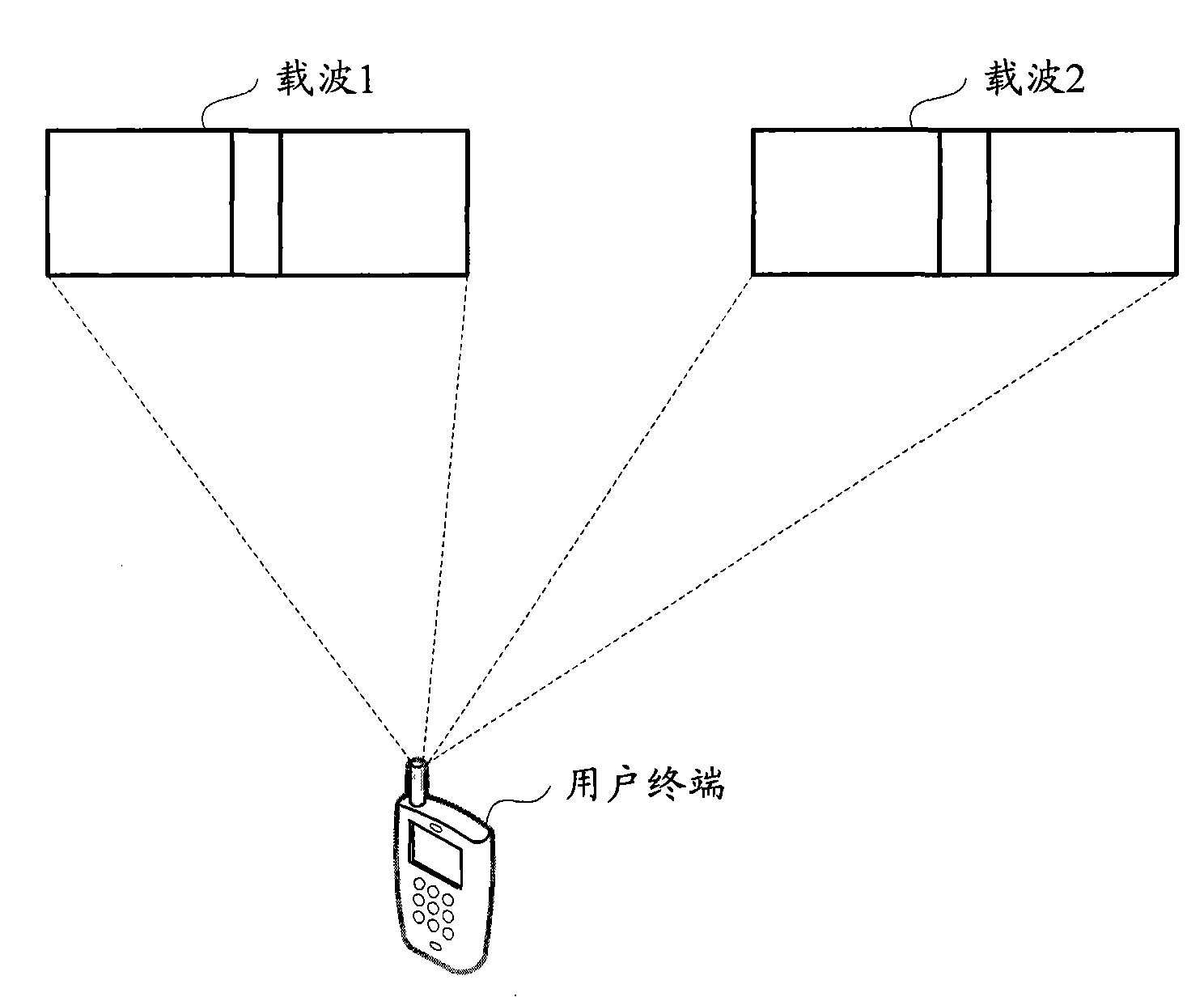

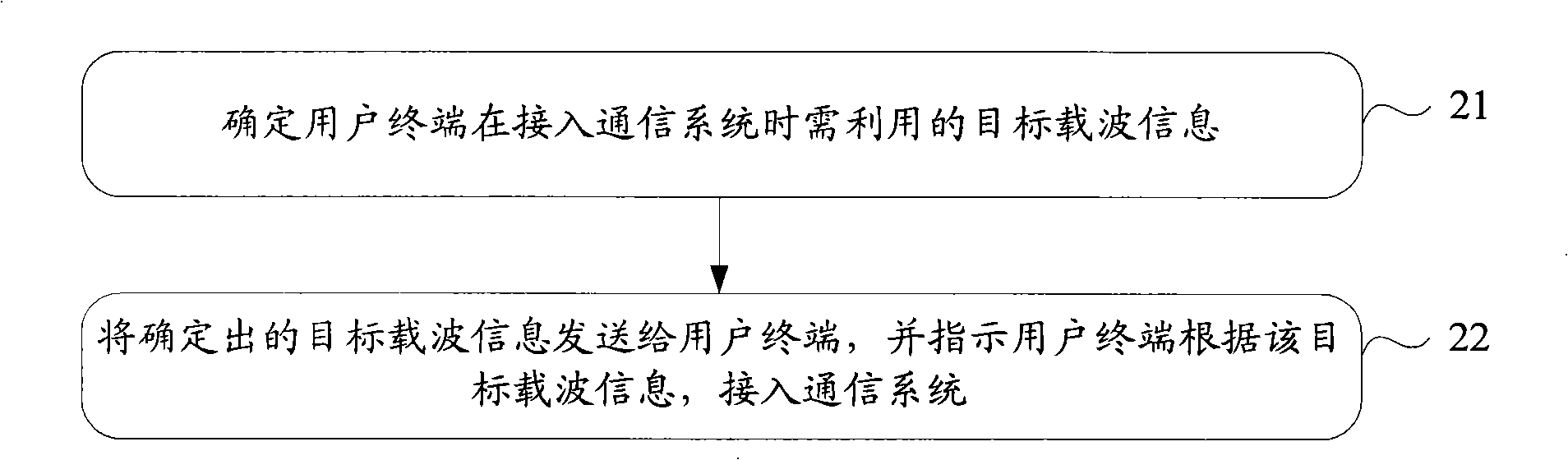

System access method, communication system, user terminal and network side equipment

InactiveCN101835200BSolve the problem of blind uncontrollable stateLoad balancingNetwork traffic/resource managementAssess restrictionCommunications systemCarrier signal

The invention discloses a system access method, a communication system, a user terminal and network side equipment, which are used for controlling the user terminal to access an LTE-Advanced system by using a target carrier wave. In the invention, the system access method provided by the invention comprises the following steps of: determining target carrier wave information, which is required when the user terminal accesses the communication system, by a network side; and sending the target carrier wave information to the user terminal and indicating the user terminal to access the communication system according to the target carrier wave information.

Owner:CHINA MOBILE COMM GRP CO LTD

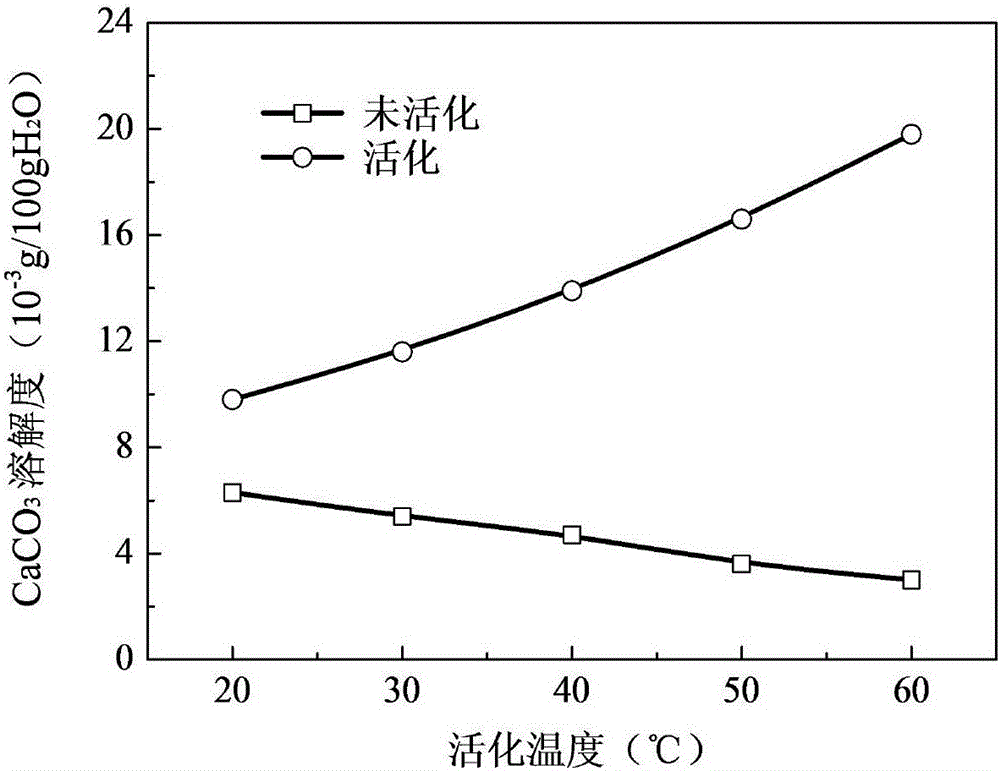

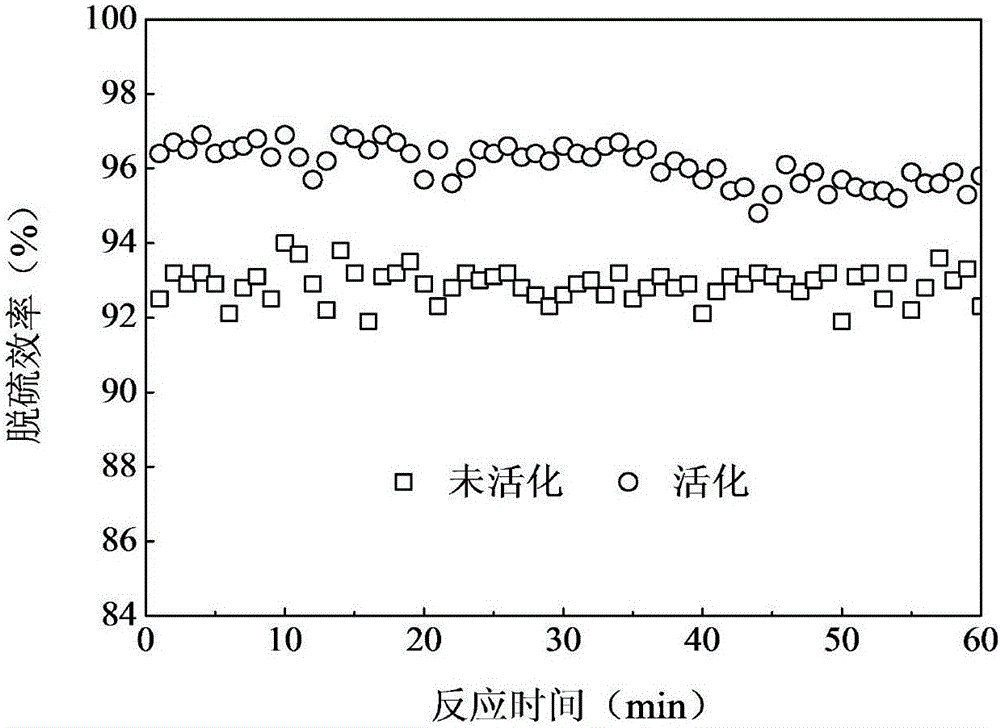

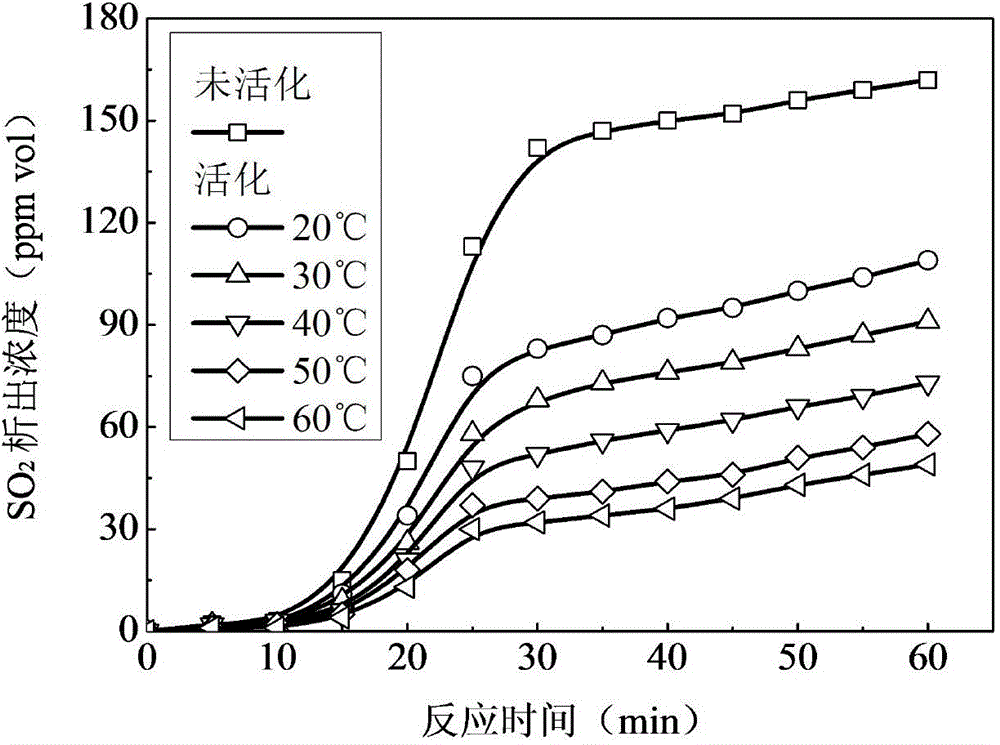

A method for strengthening the activity of limestone-gypsum wet flue gas desulfurization slurry

ActiveCN104437067BIncrease dissolution rateImprove solubilityDispersed particle separationHigh concentrationSlurry

The invention relates to a method for strengthening the activity of limestone-gypsum wet-method flue gas desulfurization slurry, and belongs to the technical field of flue gas desulfurization processes. An activation pipe network is arranged at the bottom of a limestone slurry box; a rear smoke channel of an oxygen-enriched combustion boil system feeds a part of system-captured high-concentration CO2 gas into the activation pipe network to activate the desulfurization slurry in the limestone slurry box; the activated limestone slurry is fed into an absorption tower and is subjected to countercurrent contact and absorption with the SO2 gas; activated and leaked CO2 gas returns to the rear smoke channel of the oxygen-enriched combustion boil system through a CO2 gas overflow opening at the top of the limestone slurry box. The method for strengthening the activity of the limestone-gypsum wet-method flue gas desulfurization slurry improves the reaction efficiency of CaCO3 and the SO2 by facilitating the dissolution of CaCO3 and the SO2.

Owner:武汉光谷环保科技股份有限公司

Seawater desalination pressurization and energy recovery integrated method and device using membrane method

ActiveCN102838186BReduce initial investment costHigh priceWater treatment parameter controlMembranesHydraulic cylinderMembrane method

A membrane seawater desalination pressurization and energy recovery integrated method. Piston rods of single-rod piston-type seawater cylinders are connected with single-rod piston-type hydraulic cylinders to form two or more than two working combined bodies which operate alternately. In a process that the hydraulic cylinders drive the seawater cylinders to move back and forth, one piston cavity of a seawater cylinder sucks high pressure strong brine in the process of moving forward and drains the high pressure strong brine in the returning process; and the other piston cavity of the seawater cylinder sucks raw seawater in the returning process, pressurizes the raw seawater in the process of moving forward and continuously and stably outputs the pressurized high pressure raw seawater to a reverse osmosis membrane module. Meanwhile, a membrane seawater desalination pressurization and energy recovery integrated device is further disclosed.

Owner:北京赛美环能科技有限公司

Retrofit method of supercharging and reducing steam extraction parameters of steam compressor in steam supply branch network

ActiveCN106968736BReduce extraction parametersLoad adjustmentEngine componentsSteam engine plantsLow speedGas compressor

Owner:北京源深能源科技有限责任公司

Hot flue gas bidirectional firing, high anthrax adaptability and variable load honeycomb type coal boiler

InactiveCN100565030CCoal tar condensation does not occurImprove environmental performanceWater-tube boilersWater heatersFlue gasHoneycomb

A honeycomb type coal boiler with hot flue gas bidirectional ignition, high-rank coal adaptability and variable load belongs to the boiler technical field, in particular relates to stream for burning honeycomb type coal and a hot-water boiler. A right hearth of the invention is provided with a right side hearth hogging; the left hearth is provided with a left side hearth face arch and a left side hearth rear arch; the structures of the left hearth and the right hearth are asymmetrical; the flue gas channels of the left hearth and the right hearth are also asymmetrical; the invention adopts the mode that the hot flue gas downwards the right hearth and upwards the left hearth ignites bituminous coal in the boiler; the invention solves the following problems that: 1. After the whole hot flue gas is downward to ignite the bituminous coal in the boiler, the flue gas directly enters to the subordinate heating surface for cooling and causes the problems that black smoke is emitted from the boiler, coal tar is condensed from the tube wall of the tail heating surface condenses and causes the block, the shut down of the boiler and the decrease of the thermal efficiency; 2. The desulphurization degree in the coal boiler is low; 3. The coal boiler has poor load adjusting performance; 4. The coal has slow burning speed, high manufacturing cost and large occupied area; 5. The coal boiler is uneasy to be large-sized. The invention has the advantages of higher burning efficiency, stronger coal-rank adaptability, better environmental protection and more reliable operation.

Owner:袁福林

Pure countercurrent modular combined heat exchanger

PendingCN111059928AMaximum outflow temperatureLow outflow temperatureStationary tubular conduit assembliesCounter flowMechanical engineering

The invention discloses a pure countercurrent modular combined heat exchanger. The heat exchanger is arranged by adopting a vertical or horizontal square flue pipe and comprises a steam inlet main pipe, an inlet large header, an outlet large header, an inlet small header, an outlet small header, a plurality of heat exchange pipe sets arranged in a combined mode, a steam outlet main pipe, a contraction inlet section cylinder body, an expansion outlet section cylinder body and a steady flow straight section cylinder body. Each heat exchange pipe set is composed of a plurality of heat exchange pipes with high specific surface areas. The contraction inlet section cylinder body and the expansion outlet section cylinder body are respectively arranged at two ends of the steady flow straight section cylinder body; the inlet small header is located in the expansion outlet section cylinder body, and the outlet small header is located in the contraction inlet section cylinder body; the steam inlet main pipe is connected with the inlet large header, and the steam outlet main pipe is connected with the outlet large header. The heat exchanger is small in size and lower in operation resistance; when vertical arrangement is adopted, the phenomenon of smoke dust blockage can be completely avoided; a plurality of groups are respectively controlled in parallel to realize flexible load adjustment.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Grip strength recovery training device with tightness adjusting function for rehabilitation department

ActiveCN113577703AAdjustable tightnessImprove applicabilityResilient force resistorsWeightsPhysical medicine and rehabilitationMedizinische rehabilitation

The invention relates to the technical field of medical rehabilitation equipment, in particular to a grip strength recovery training device with a tightness adjusting function for the rehabilitation department, comprising a back plate, the outer side of the back plate is fixedly connected with five sets of fingerstall assemblies in sequence, the top of the back plate is fixedly connected with a transverse plate, and a contraction assembly is fixedly mounted in the middle of the top of the transverse plate; and the contraction assembly comprises a cylindrical shell. According to the device, a spring is elastically connected between a shaft rod and a sleeve, so that the sleeve can be subjected to elastic resistance generated by winding of the spring when the sleeve is rotated by an inhaul cable, resistance is applied to fingers in the finger sleeve assembly, and rehabilitation training is carried out in cooperation with the fingers; by setting the gear meshing transmission between a worm gear and a worm, and the worm can drive the worm gear to rotate when rotating, so that the shaft rod is driven to rotate, the interior of the spring is tightened, the internal tightness of the device is effectively and flexibly adjusted, and the applicability and adjustment flexibility of the device are conveniently improved.

Owner:陈志成

Method for strengthening activity of limestone-gypsum wet-method flue gas desulfurization slurry

ActiveCN104437067AIncrease dissolution rateImprove solubilityDispersed particle separationHigh concentrationDissolution

The invention relates to a method for strengthening the activity of limestone-gypsum wet-method flue gas desulfurization slurry, and belongs to the technical field of flue gas desulfurization processes. An activation pipe network is arranged at the bottom of a limestone slurry box; a rear smoke channel of an oxygen-enriched combustion boil system feeds a part of system-captured high-concentration CO2 gas into the activation pipe network to activate the desulfurization slurry in the limestone slurry box; the activated limestone slurry is fed into an absorption tower and is subjected to countercurrent contact and absorption with the SO2 gas; activated and leaked CO2 gas returns to the rear smoke channel of the oxygen-enriched combustion boil system through a CO2 gas overflow opening at the top of the limestone slurry box. The method for strengthening the activity of the limestone-gypsum wet-method flue gas desulfurization slurry improves the reaction efficiency of CaCO3 and the SO2 by facilitating the dissolution of CaCO3 and the SO2.

Owner:武汉光谷环保科技股份有限公司

A Load Adjustable Sectional Feeding Type Entrained Bed Gasification Device

ActiveCN102827642BIncrease productionExtended stayGranular/pulverulent flues gasificationSyngasWater baths

The invention discloses a load-adjustable step feeding type entrained flow bed gasifier. The load-adjustable step feeding type entrained flow bed gasifier is characterized by comprising a pressure shell body, and a reaction chamber and a cooling / dust removal / water bath chilling chamber which are supported and hung in the pressure shell body, wherein the cooling / dust removal / water bath chilling chamber is coaxially arranged at the lower part of the reaction chamber; an annular gap space is arranged between the reaction chamber and the pressure shell body; and the reaction chamber is provided with a main nozzle and a plurality of load adjustment nozzles. The cooling / dust removal / water bath chilling chamber is coaxially arranged at the lower part of the reaction chamber, the main nozzle is arranged at the top part of the gasifier, the load adjustment nozzles are symmetrically arranged in the space at the upper part of the reaction chamber, and water is used to chill high-temperature synthetic gas and clinker discharged below the reaction chamber, so that the single-gasifier yield is effectively increased, the single-gasifier production load adjustment capability is realized, and the hearth reaction region is reasonably arranged, thereby ensuring that the synthetic gas in the hearth can produce a rotational flow, the retention time is long, the reaction is thorough and the load adjustment range is wide.

Owner:中国船舶集团有限公司第七一一研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com