Retrofit method of supercharging and reducing steam extraction parameters of steam compressor in steam supply branch network

A technology of steam compressor and steam supply branch, which is used in steam engine installations, mechanical equipment, engine components, etc., can solve the problems of poor operating economy, difficulty in long-distance transportation, and large energy loss, and achieve the effect of energy-saving load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

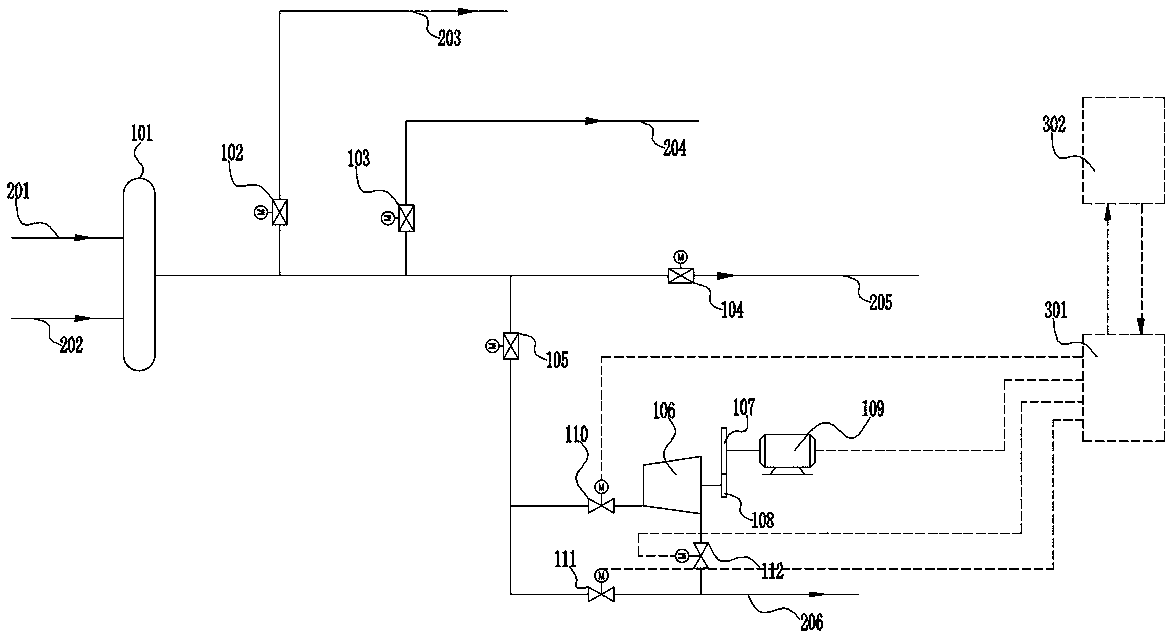

[0035] Next, the specific implementation manner of the present invention will be further described in conjunction with the accompanying drawings. figure 1 ,

[0036] Invented a kind of energy-saving technology of steam compressor industrial steam supply branch network pipeline pressurization to reduce steam turbine extraction parameters, and provided the system configuration and transformation operation method of the present invention. The system configuration mainly includes an industrial steam supply header 101, a regulating valve 102 for a low-pressure heat user, a second regulating valve 103 for a low-pressure heat user, a third regulating valve 104 for a low-pressure heat user, a regulating valve 105 for a high-pressure heat user, and a steam compressor 106, Gearbox low-speed shaft 107, gearbox high-speed shaft 108, driving variable frequency motor 109, steam compressor front isolation valve 110, steam compressor bypass cut-off valve 111, steam compressor rear isolation v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com