Heating fuel cost allocation method based on process division for gas-steam combined cycle cogeneration unit

A combined heat and power generation unit and combined cycle technology, which is applied to steam engine devices, mechanical equipment, machines/engines, etc., can solve the problems of no clear applicable heating cost allocation method, lack of heating cost, etc., and improve cascade utilization efficiency , Improve utilization efficiency and increase power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

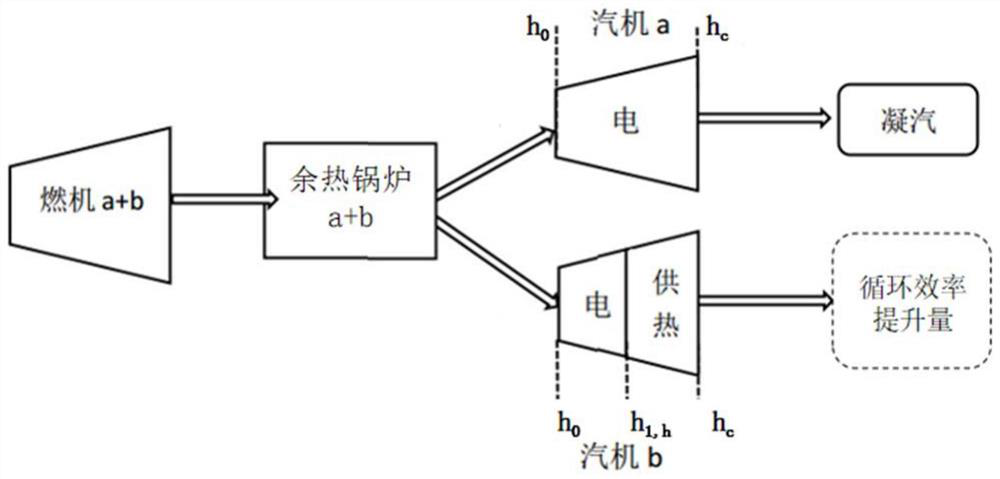

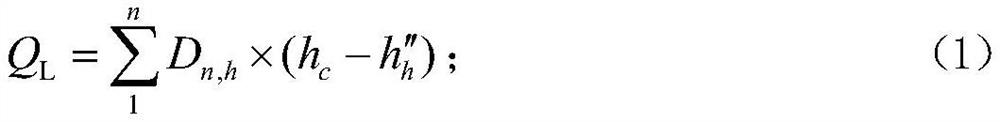

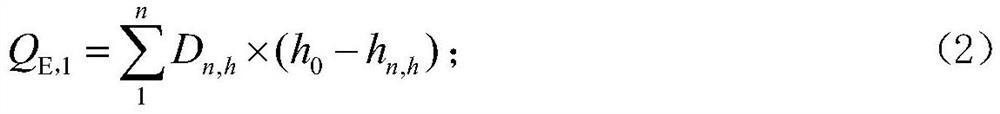

[0032] The calculation parameters involved in the present invention are all easy to obtain and have strong operability, and the specific implementation method is as follows. A method for calculating the fuel cost sharing ratio of gas-steam combined cycle extraction and heating. Firstly, the combined cycle cogeneration process is divided into gas turbine-waste heat boiler-steam turbine-condenser and gas turbine-waste heat boiler-steam turbine-supply Heat (turbine part) - heat supply (former condenser part) two processes; then based on the extracted two process processes, calculate the increase in thermal cycle efficiency obtained by combined heat and power; The ratio of the respective heat consumption to the total heat consumption is used to distribute the increase in thermal cycle efficiency between heat and electricity, and then to correct the heat supply consumption; After the consumption is combined, the cost sharing ratio of heating fuel is calculated. Take a unit as an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com