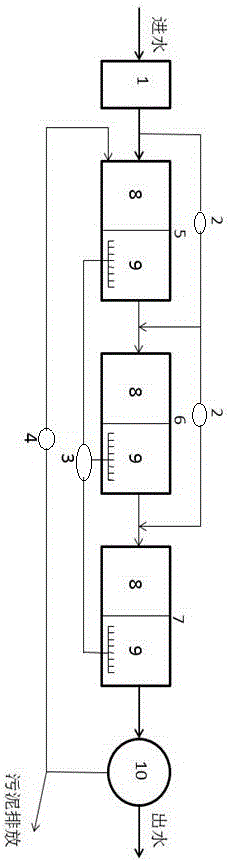

Method for treating high ammonia-nitrogen wastewater through multipoint dispersed water injection three-stage compound A/O (Anoxic/Oxic) process

A compound, high-ammonia-nitrogen technology, applied in the field of environmental protection, can solve the problems of high ammonia nitrogen and organic matter concentration, ammonia nitrogen and total nitrogen are difficult to meet the standards, and achieve the effect of large biomass, convenient maintenance and improved removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Use the above-mentioned multi-point dispersed water injection three-stage composite A / O system (volume 60L) to treat the coking wastewater with high ammonia nitrogen, and the influent COD concentration is 3000mg / L; NH 4 + - The concentration of N is 150mg / L; the concentration of TN is 200mg / L, the total hydraulic retention time of the three-stage compound A / O system is controlled to 60h, and the influent ratios are 40%, 35%, and 25% respectively. The results show that: the system has an effect on COD, NH 4 + The removal rates of -N and TN are 95%, 98% and 76% respectively, and the main effluent pollutants can meet the coking chemical industry pollutant discharge standard (GB16171-2012).

Embodiment 2

[0028] Use the above-mentioned multi-point dispersed water injection three-stage composite A / O system (volume 100L) to treat the actual high-concentration coal chemical wastewater, and the influent COD concentration is 3500mg / L; NH 4 + - The concentration of N is 200mg / L; the concentration of TN is 300mg / L, the total hydraulic retention time of the three-stage compound A / O system is controlled to 55h, and the influent ratios are 60%, 25%, and 15% respectively. The results of the small test show that: the system is effective for COD, NH 4 + The removal rates of -N and TN are up to 88%, 93% and 78% respectively, and the main effluent pollutants can meet the petrochemical industry pollutant discharge standard (GB31571-2015).

Embodiment 3

[0030] Use the above-mentioned multi-point dispersed water injection three-stage composite A / O system (volume 120L) to treat actual high-concentration pharmaceutical wastewater, and the influent COD concentration is 5000mg / L; NH 4 + - The concentration of N is 800mg / L; the concentration of TN is 950mg / L, the total hydraulic retention time of the control three-stage compound A / O system is 90h, and the proportion of water inflow is 45%, 28%, and 17% respectively. The results of the small test show that: the three-stage composite A / O system is effective for COD, NH 4 + The removal rates of -N and TN are up to 92%, 97% and 80% respectively, and the main effluent pollutants can meet the water pollutant discharge standard of traditional Chinese medicine pharmaceutical industry (GB 21906-2008).

[0031] The three-stage composite A / O system of the present invention is composed of a first-stage A / O biofilm reactor 5, a second-stage A / O biofilm reactor 6 and a third-stage A / O biofilm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com