Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Fabrication yield can be improved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

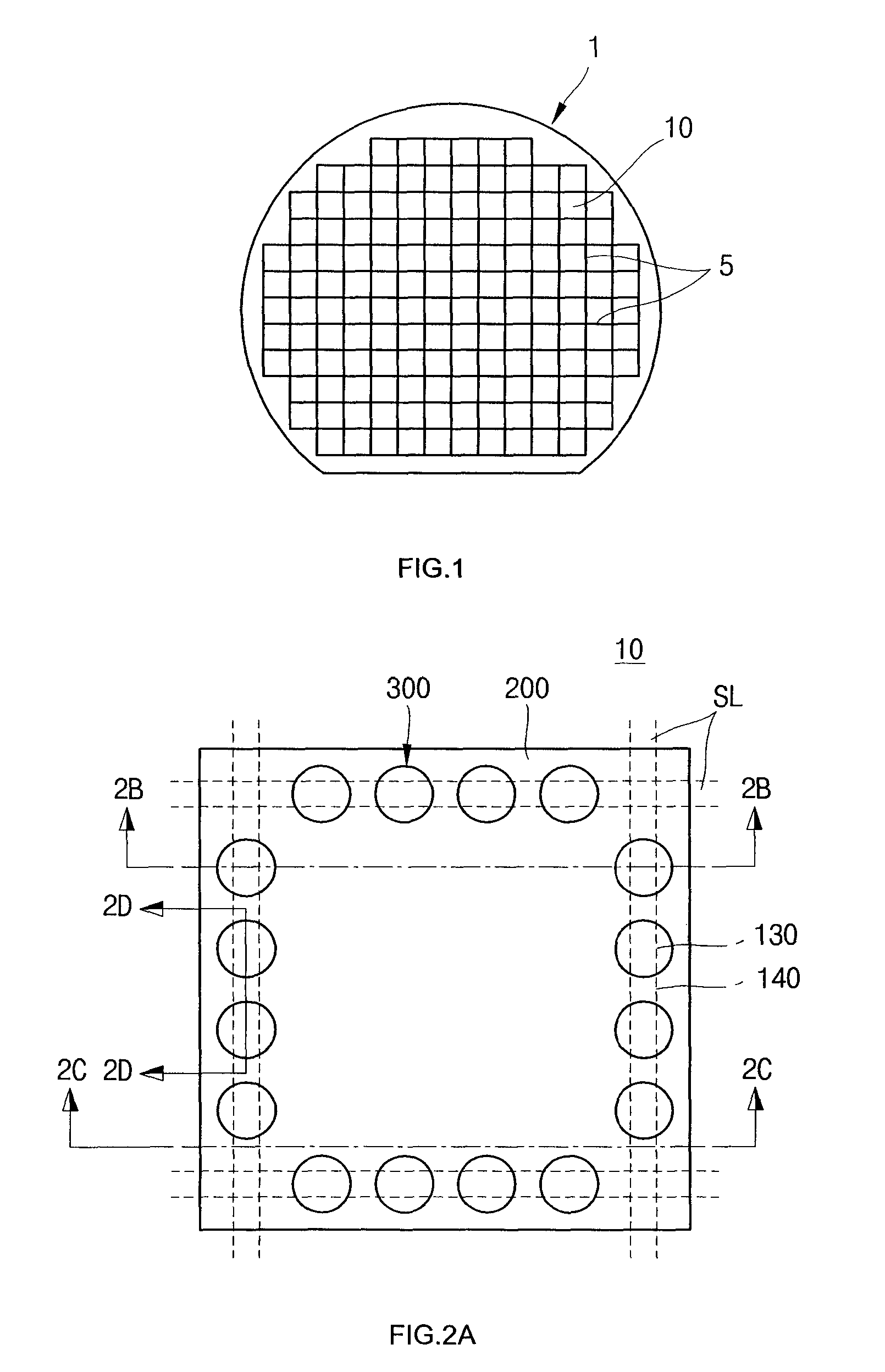

Semiconductor package having through holes

ActiveUS7843072B1Save fabrication timeFabrication yield can be improvedSemiconductor/solid-state device detailsSolid-state devicesIonLaser drilling

Disclosed is a semiconductor package. The semiconductor package is configured to form a plurality of through holes for forming a through silicon via at once using a sawing device used for wafer sawing instead of a separate laser drilling equipment or a deep reactive ion etching (DRIE) equipment. Accordingly, the semiconductor package saves fabricating time and increases fabrication yield, saves costs for a laser drilling equipment or a DRIE equipment, and prevents various defects generated in an inner portion of a through hole in the case of using the laser drilling equipment or the DRIE equipment.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

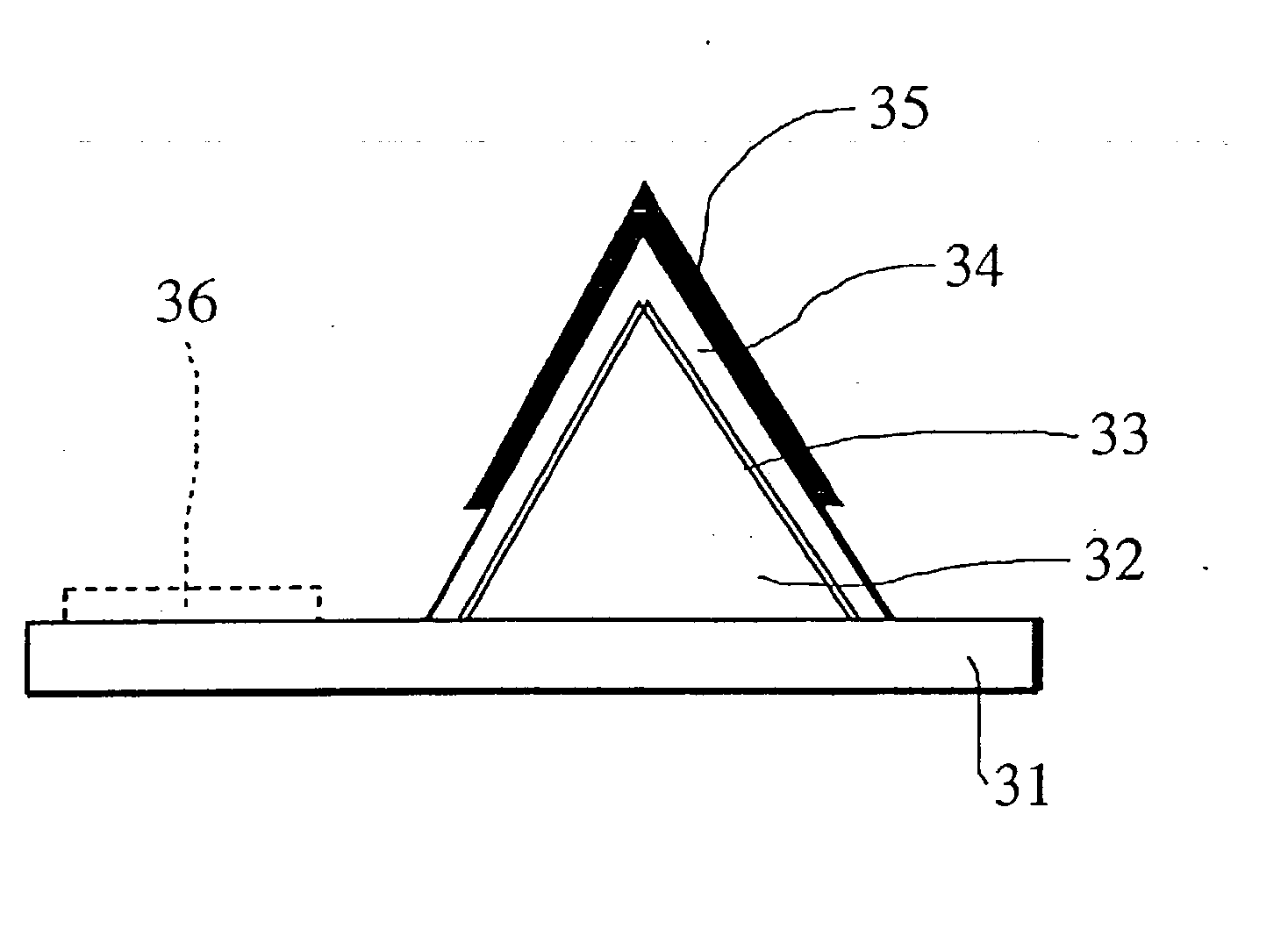

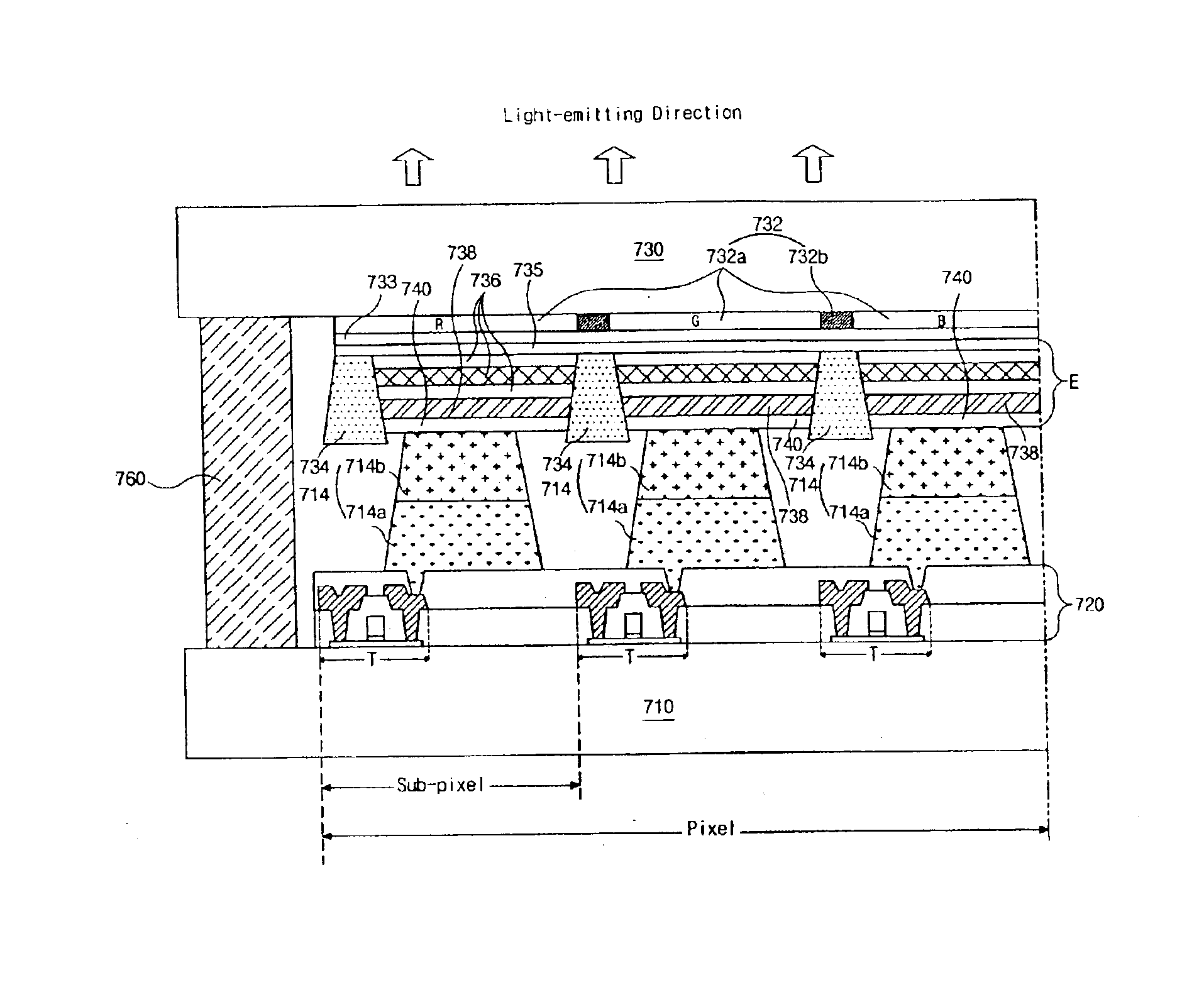

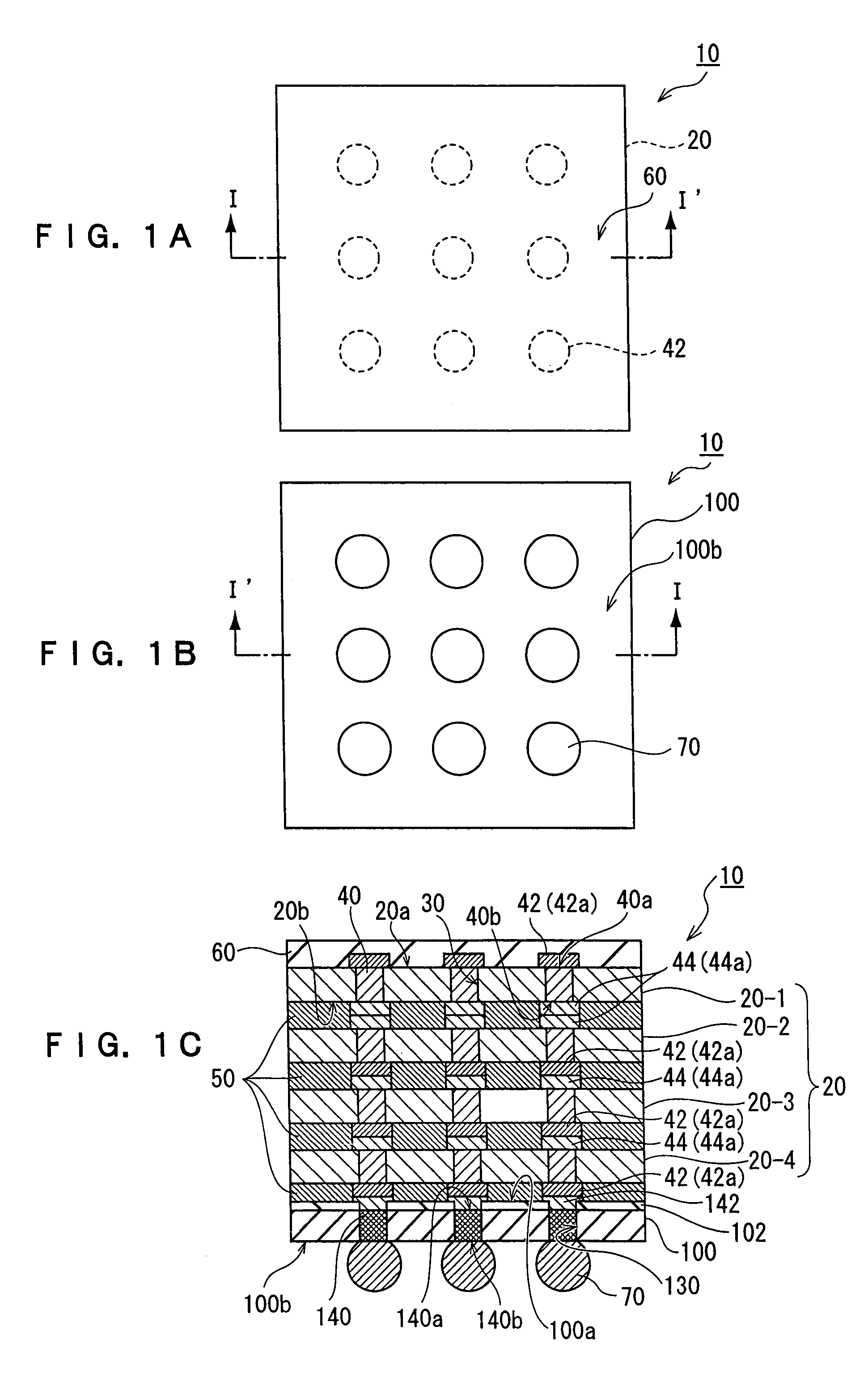

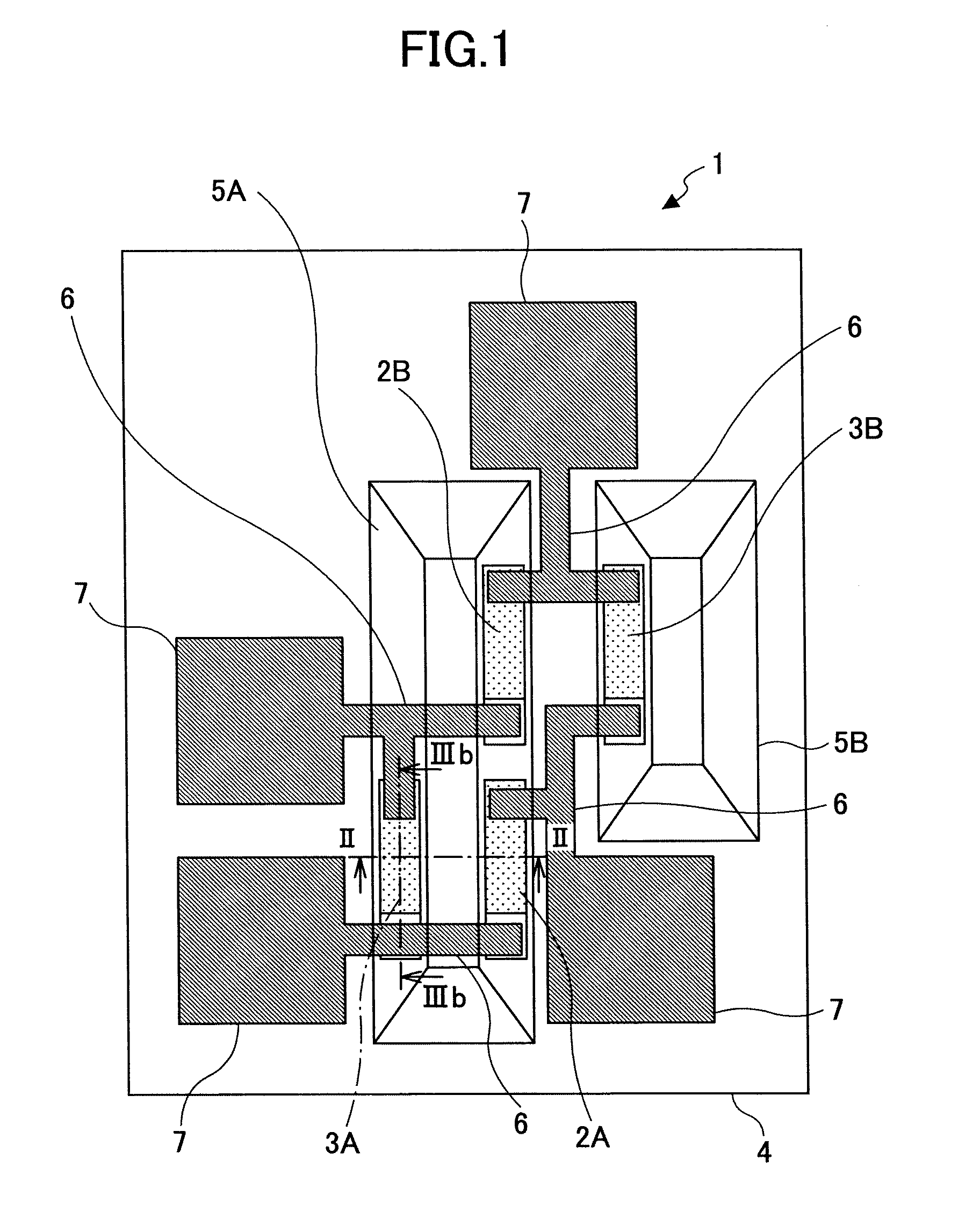

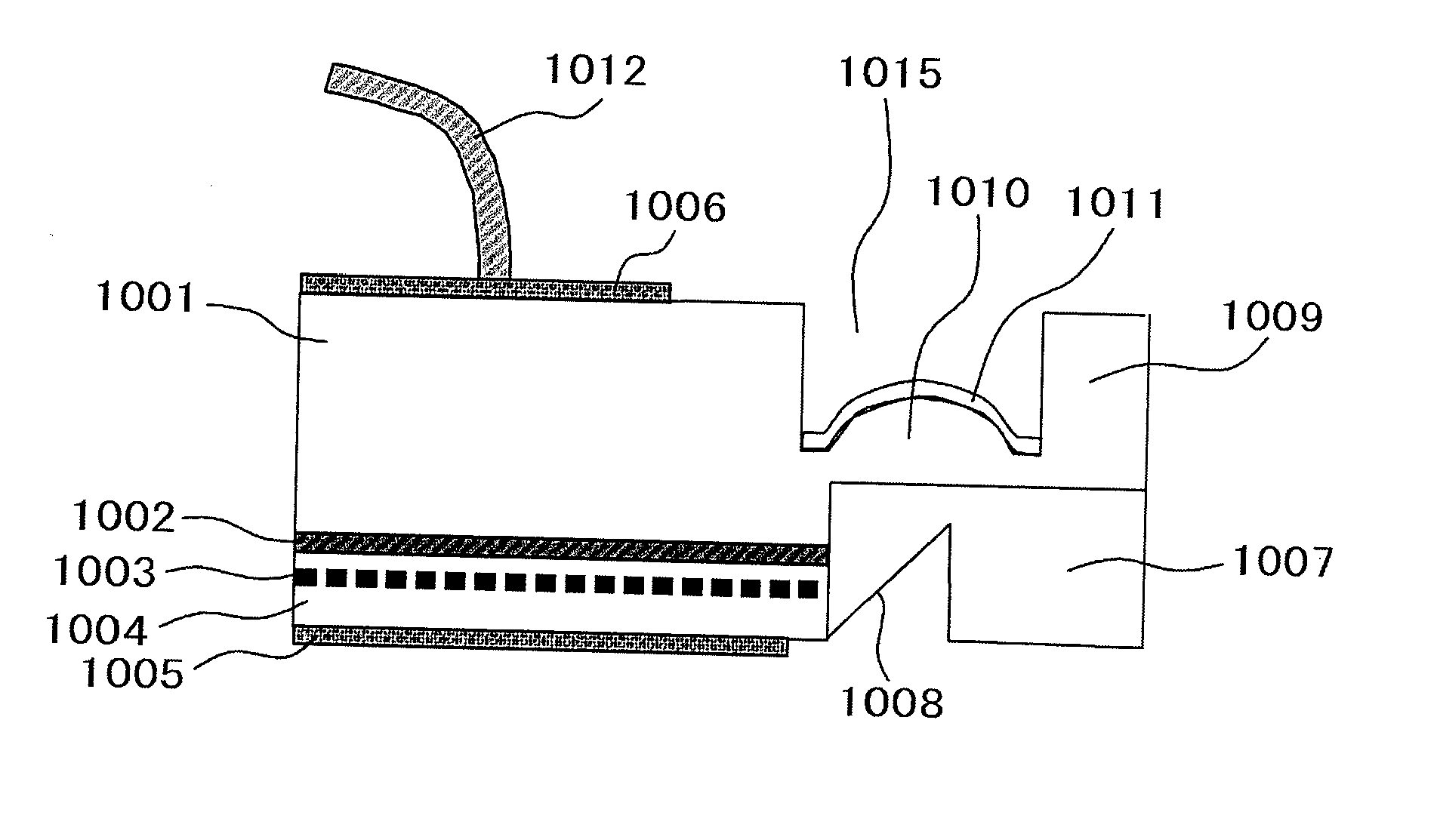

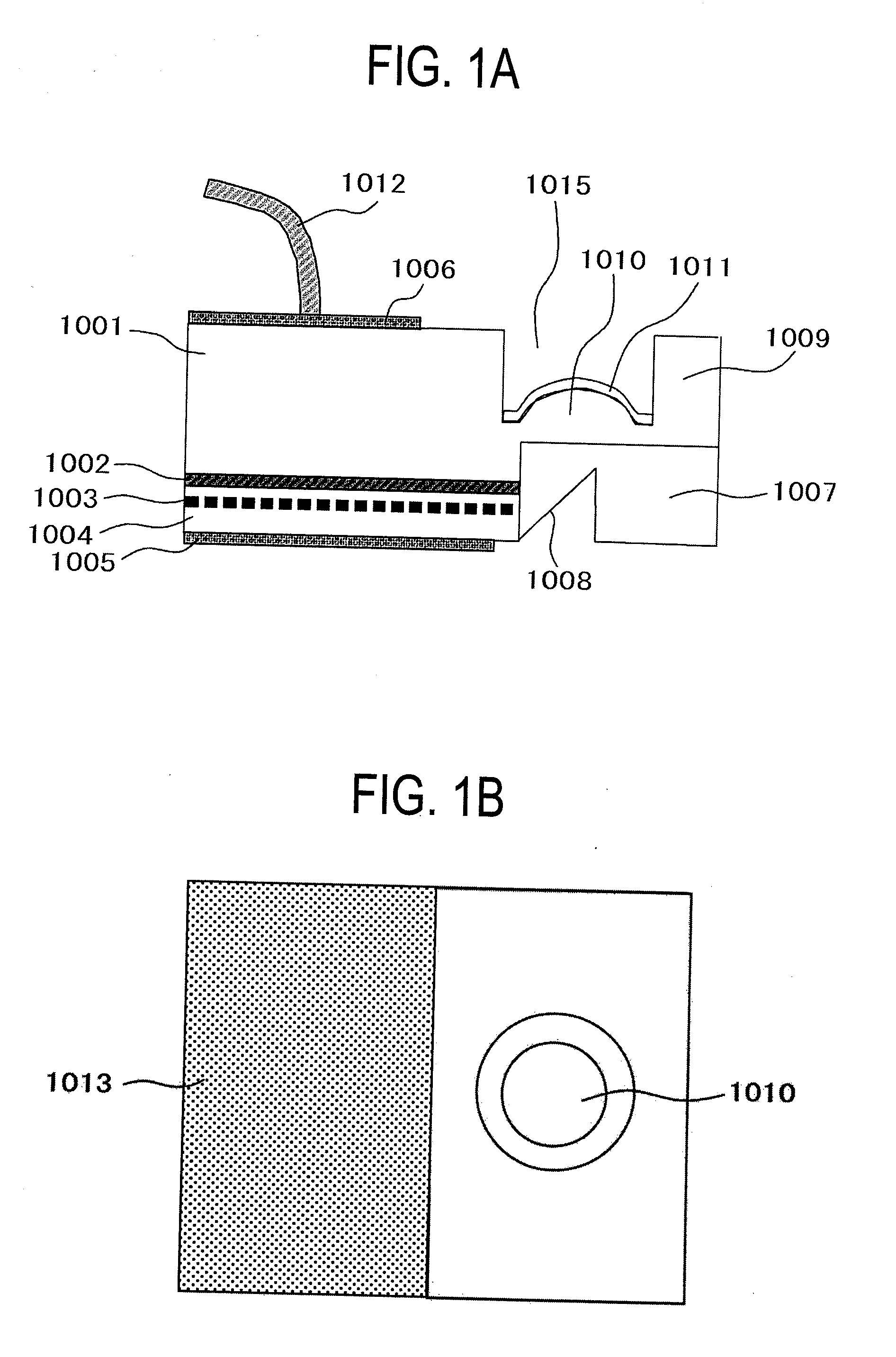

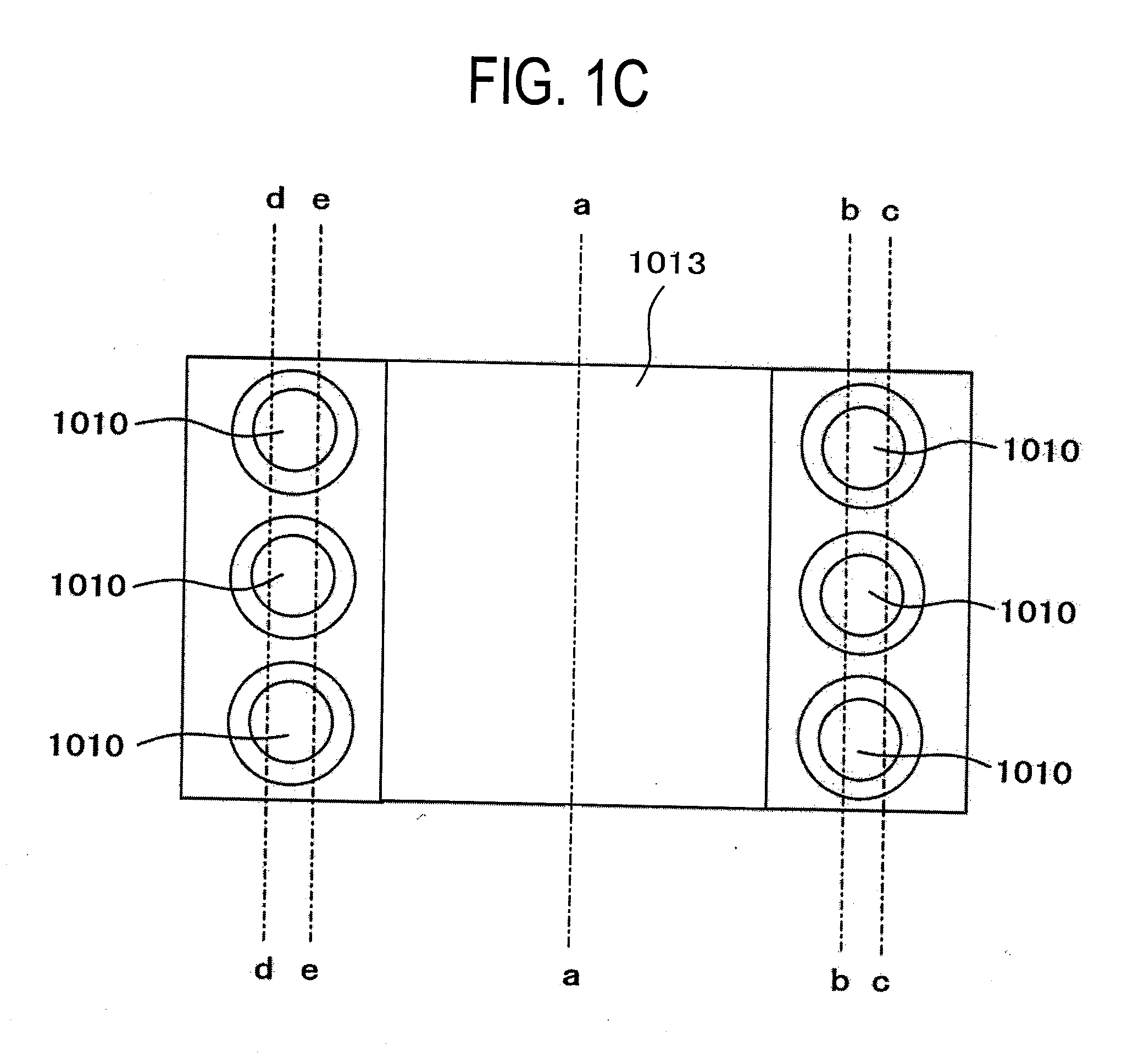

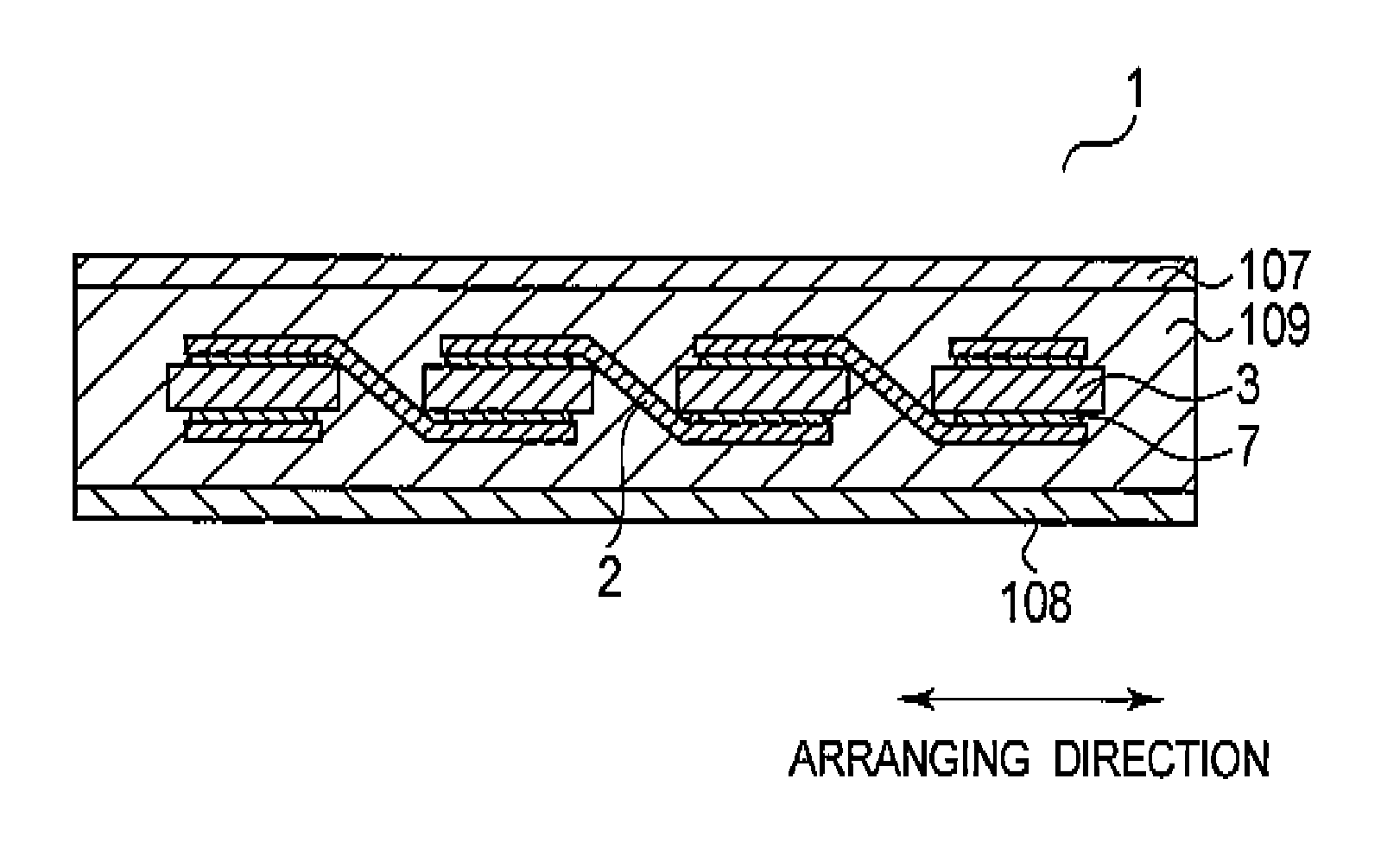

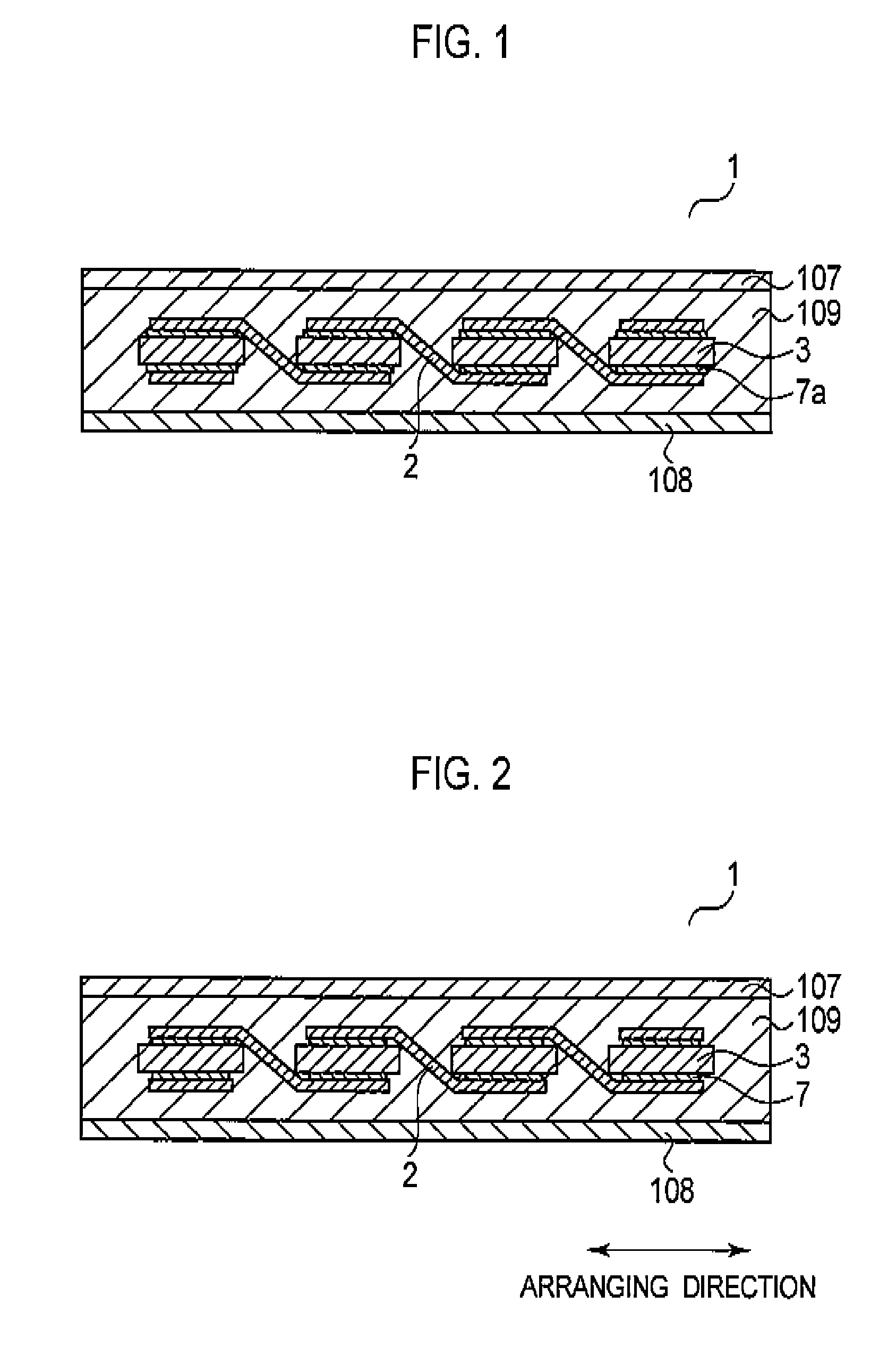

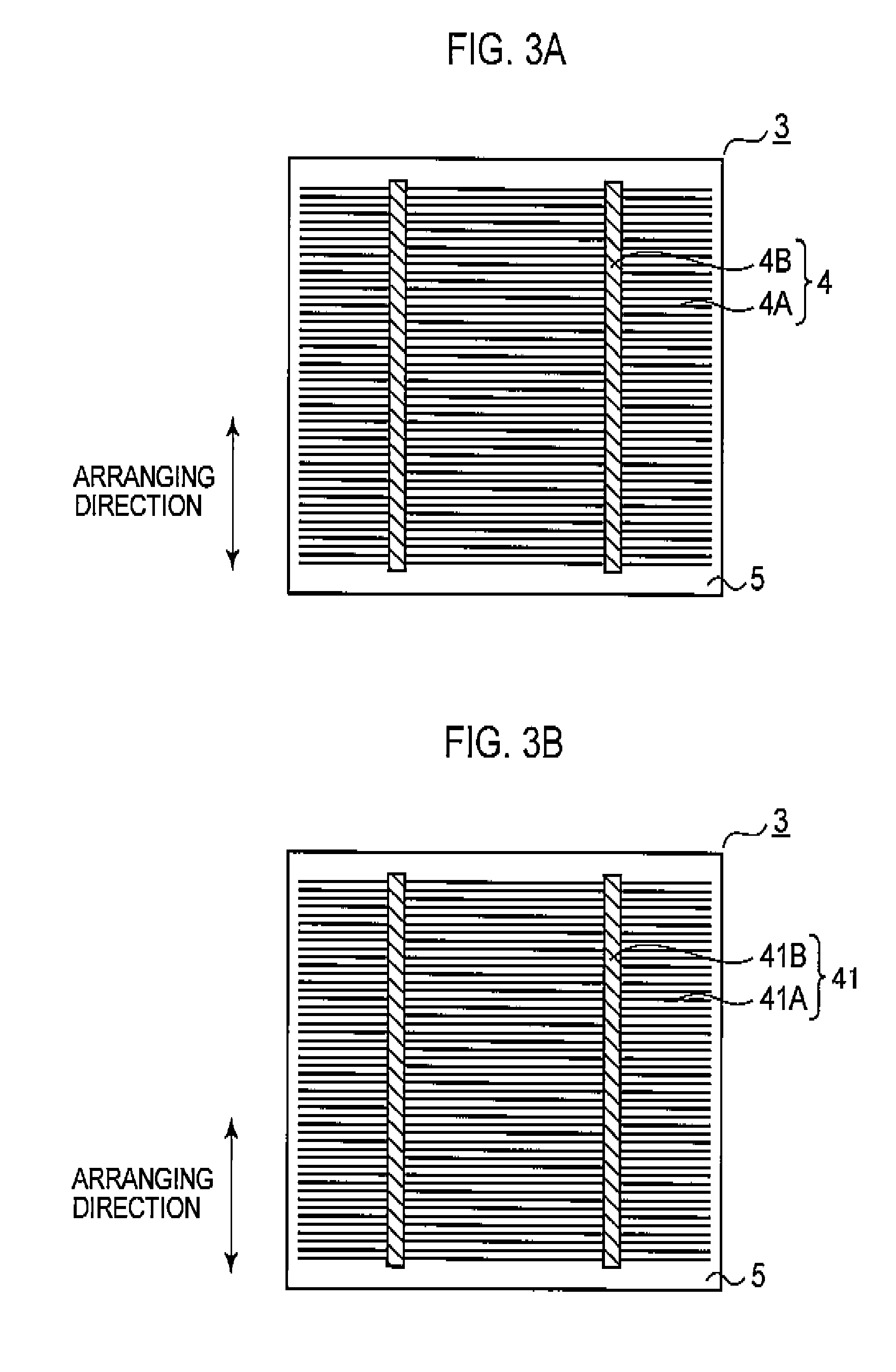

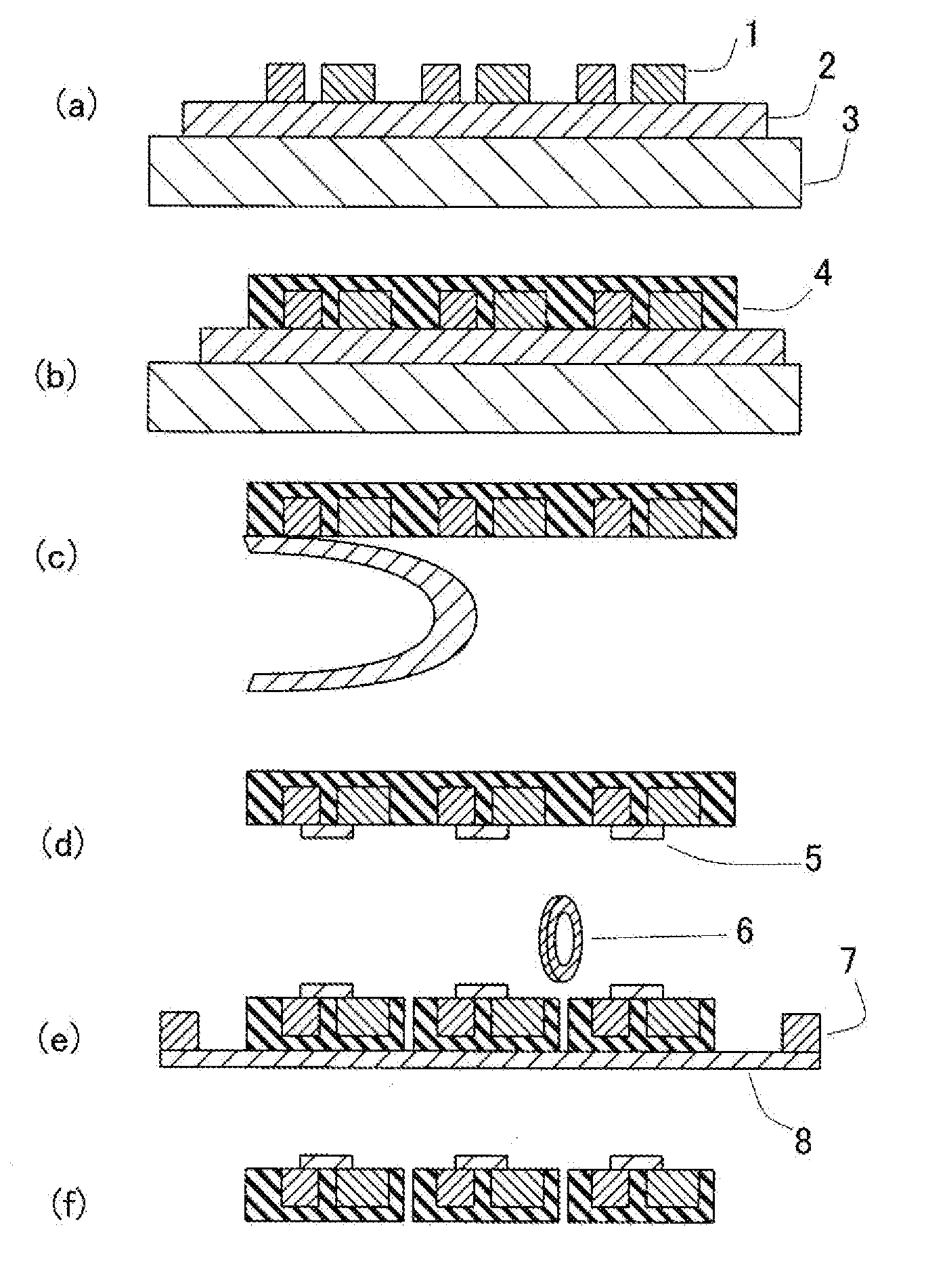

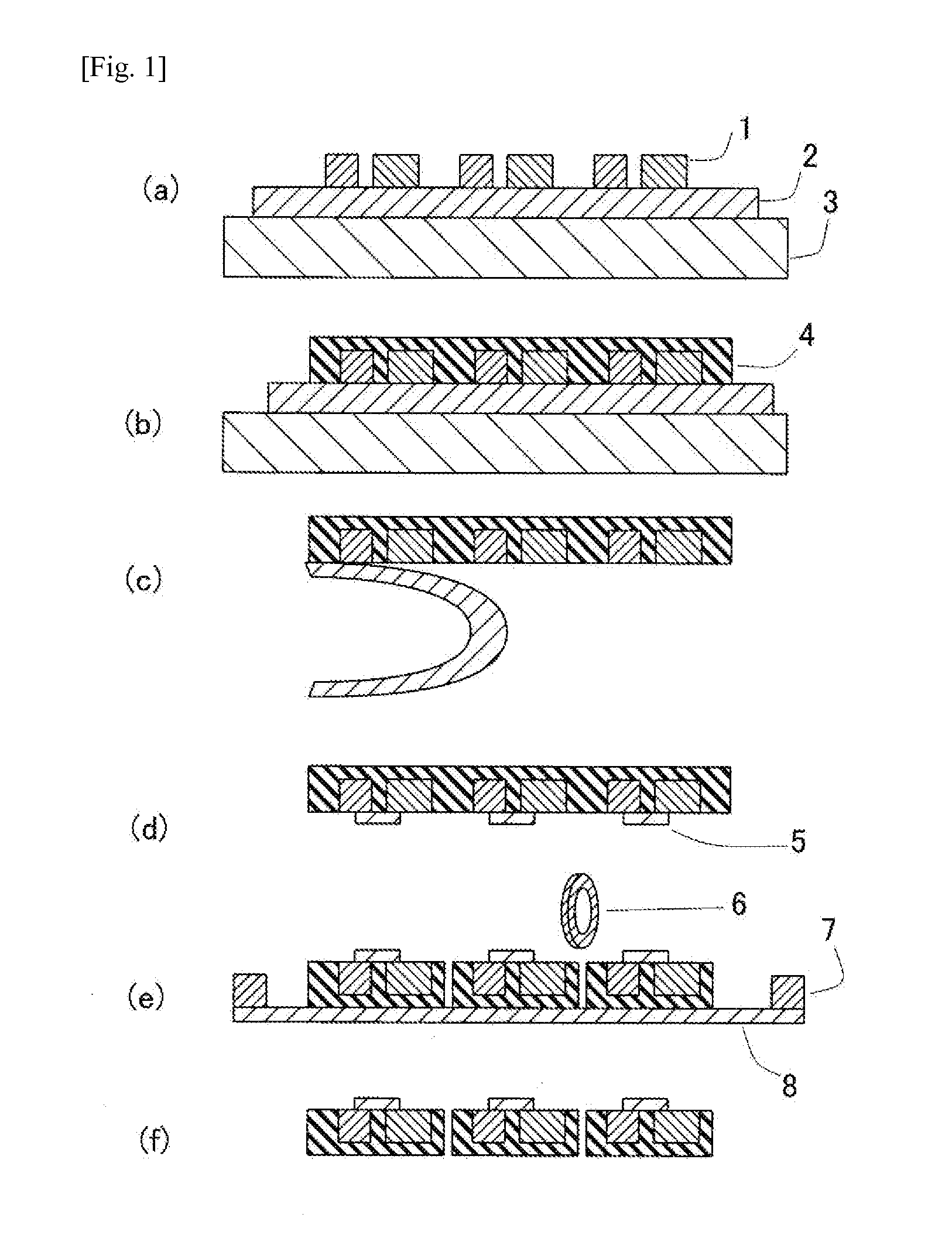

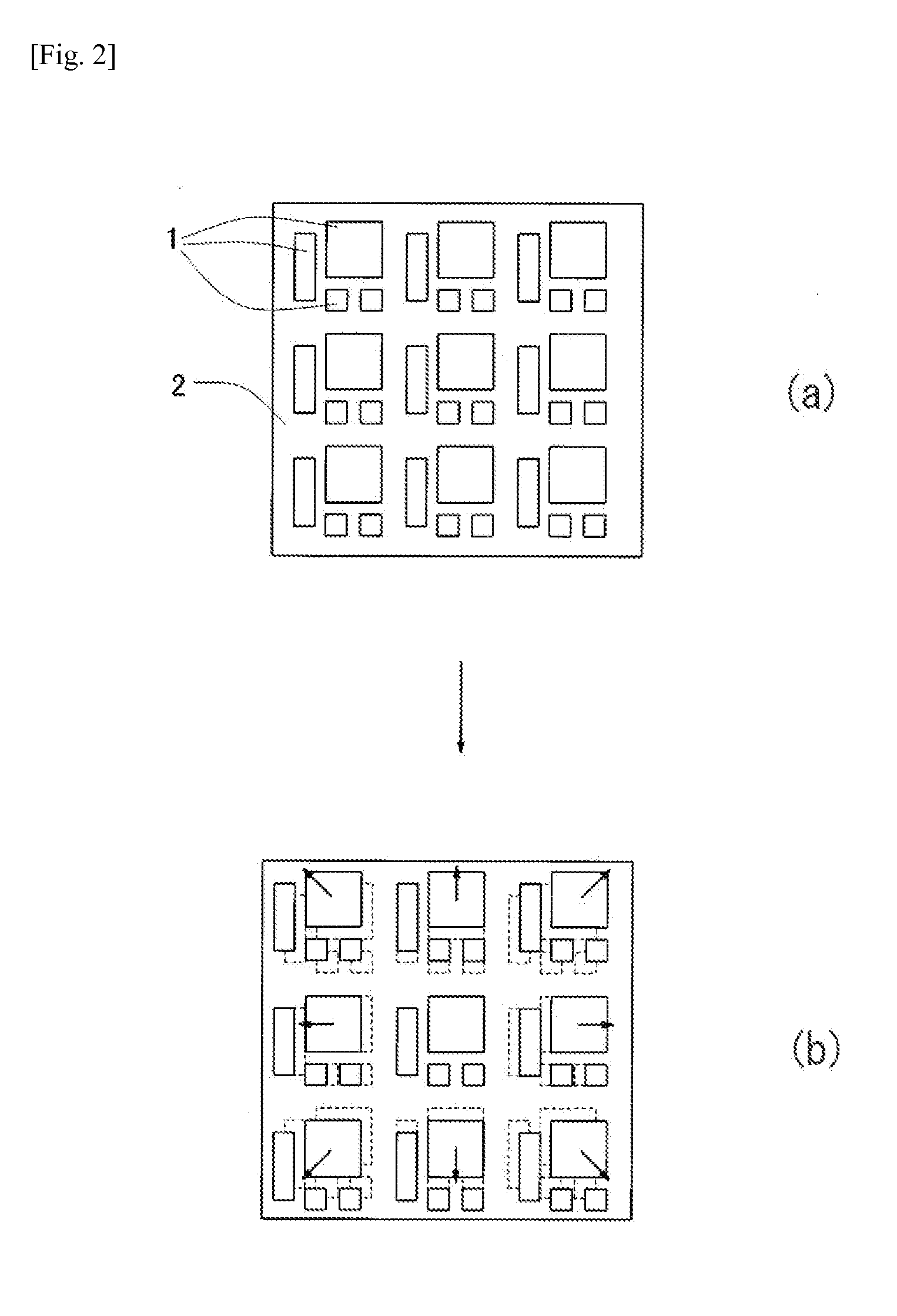

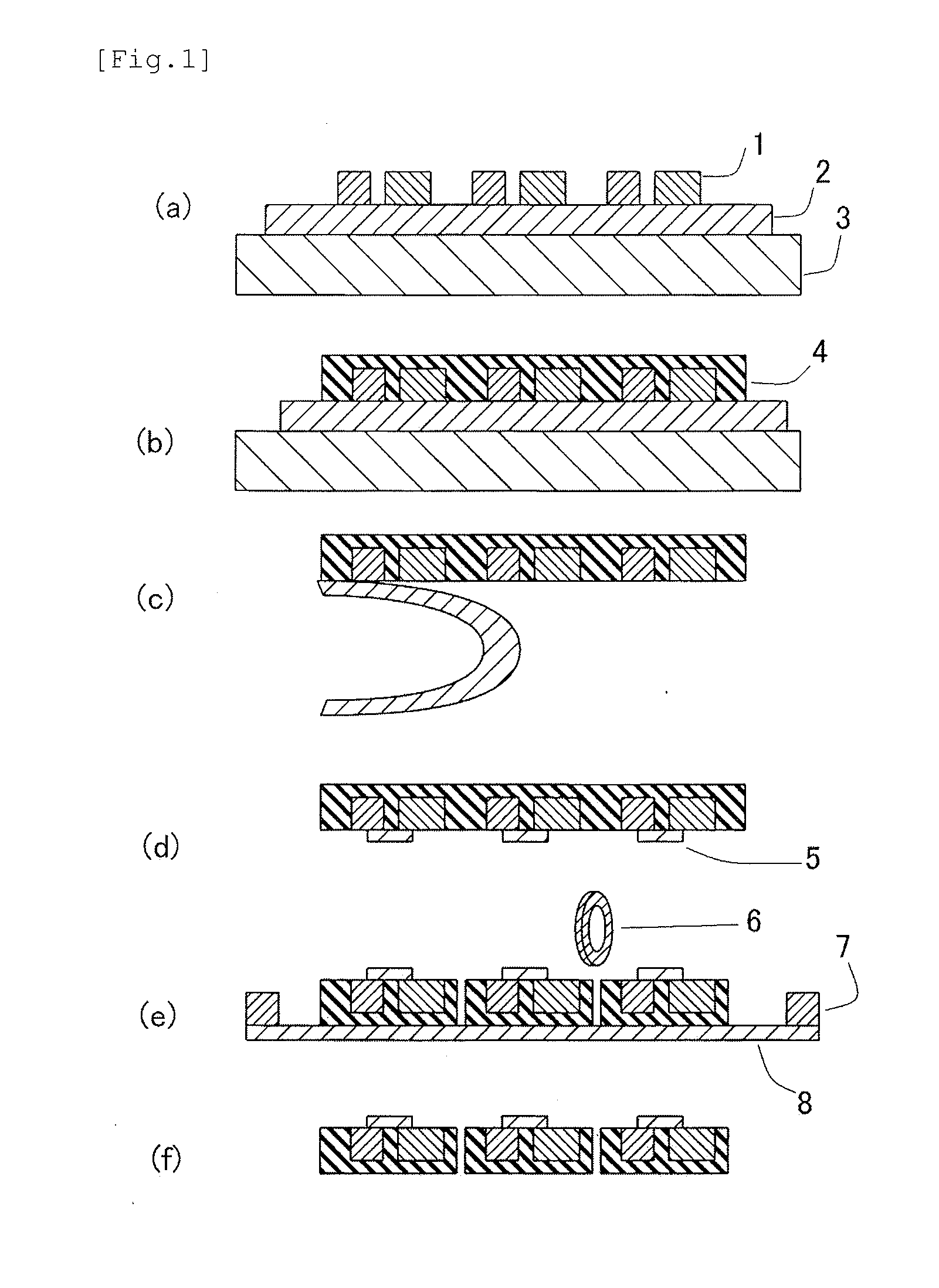

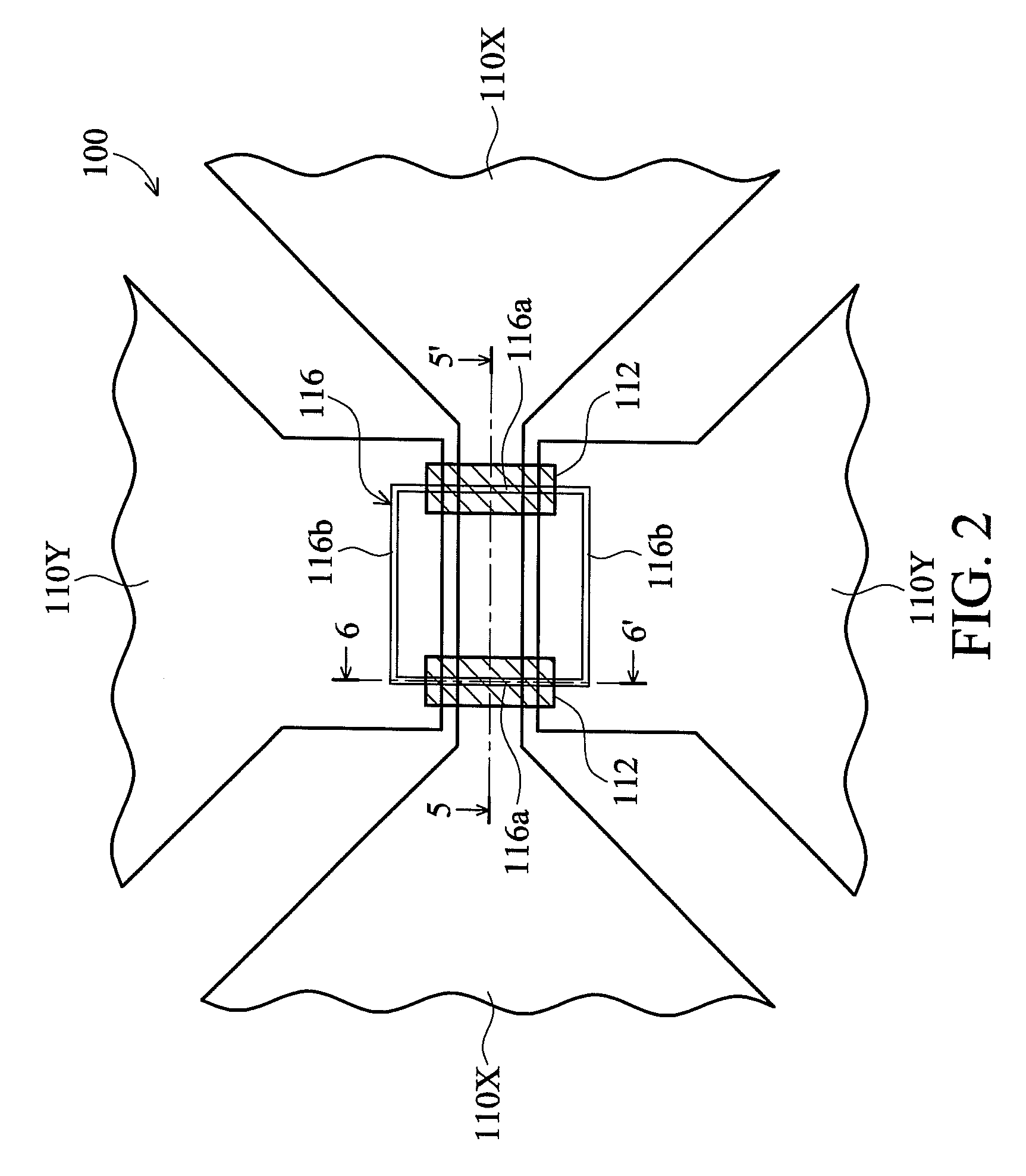

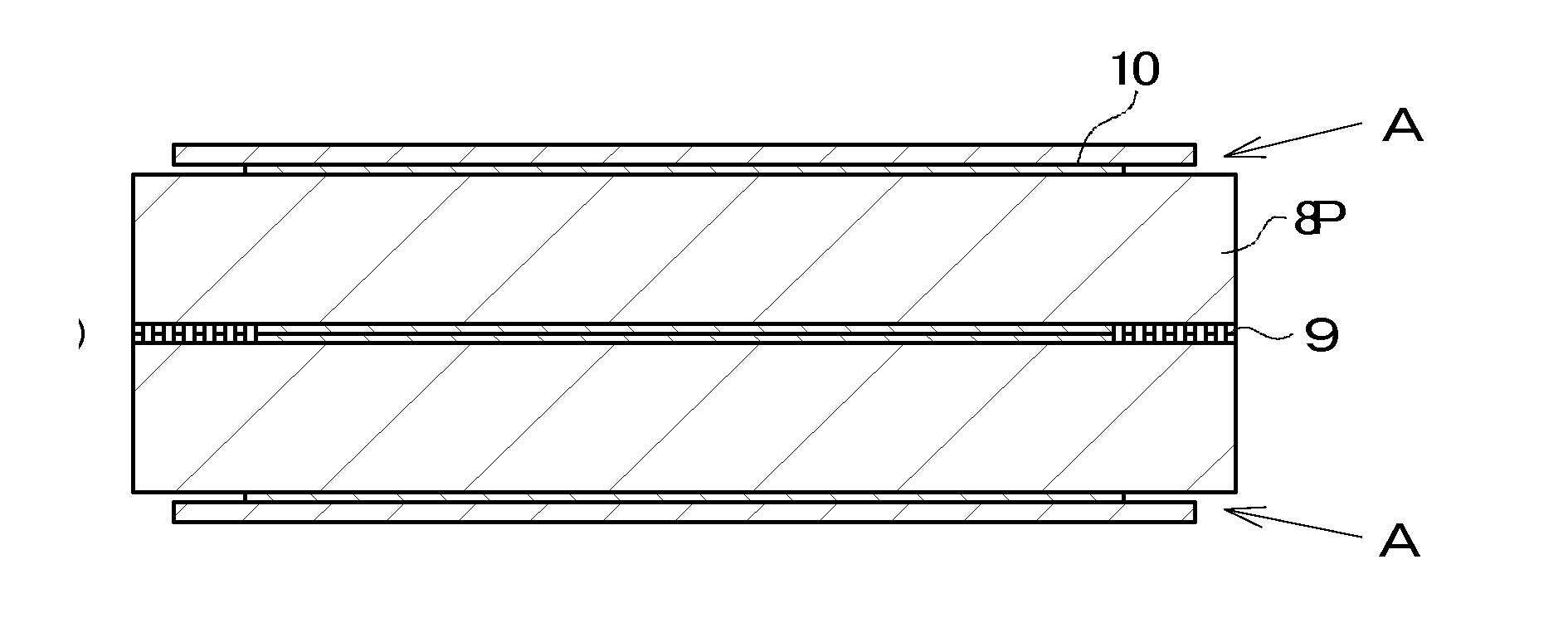

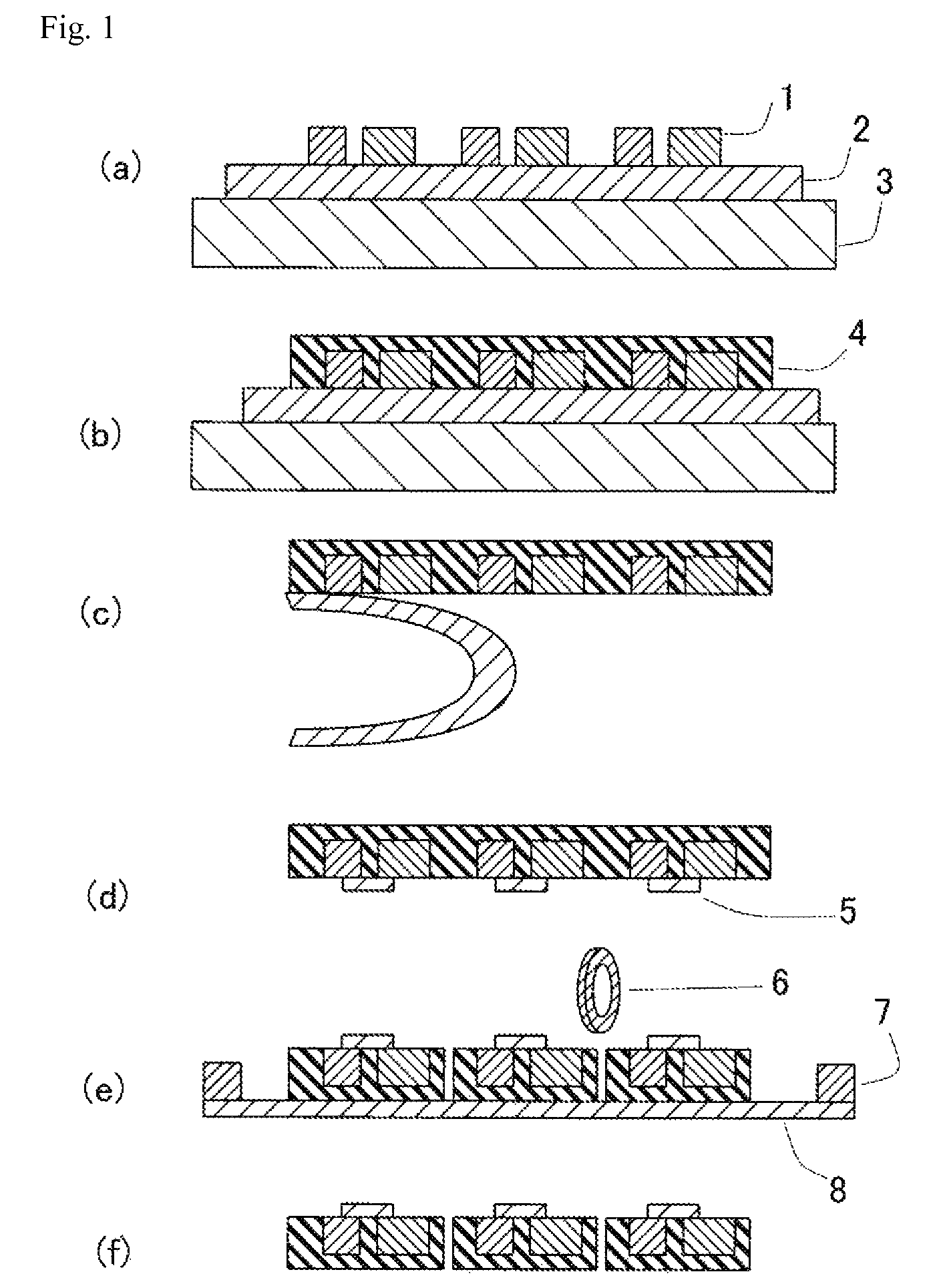

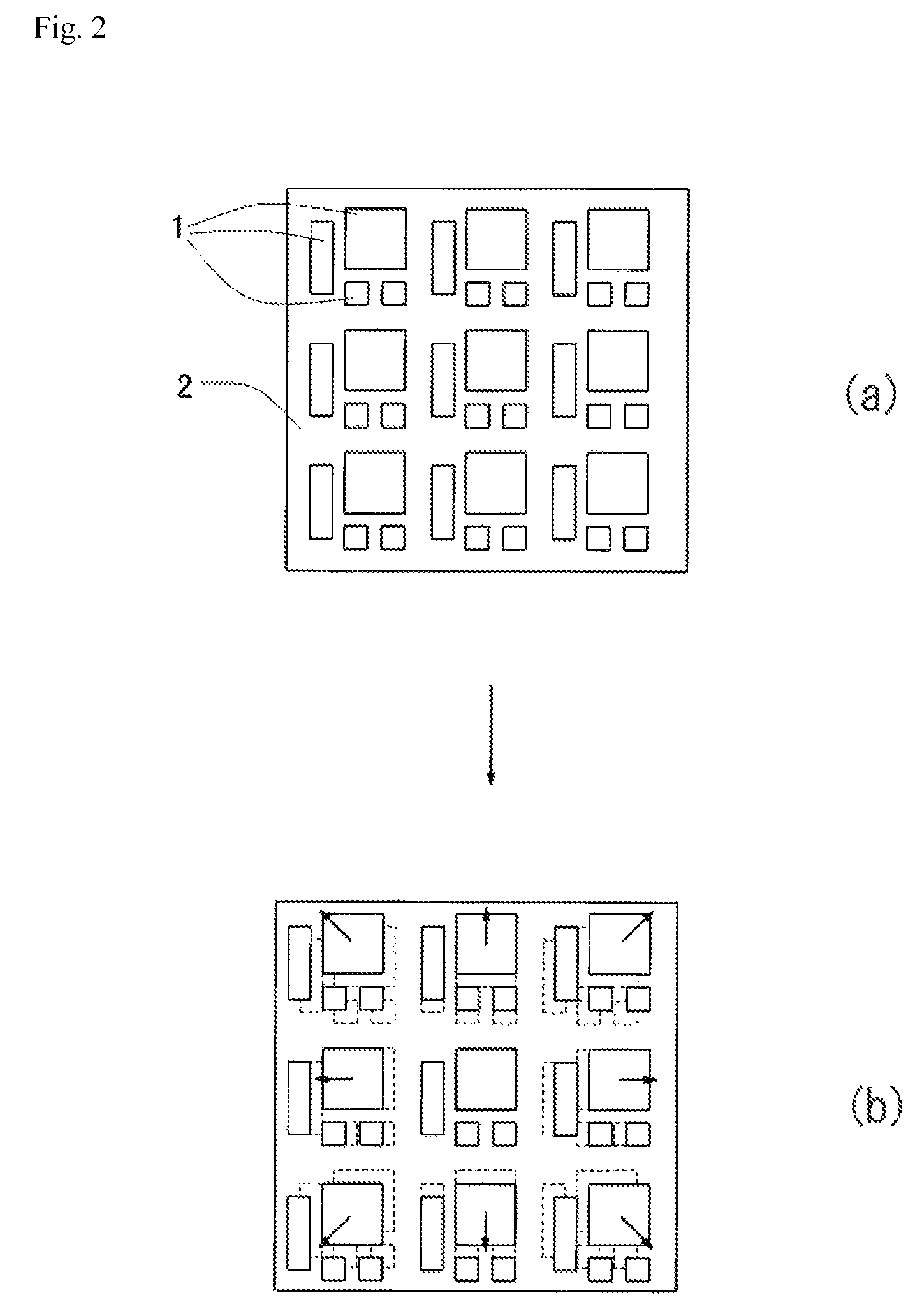

Element transfer method, element arrangmenet method using the same, and image display

InactiveUS20030162463A1Fabrication yield can be improvedLow costDecorative surface effectsSolid-state devicesIrradiationAdverse effect

A method of selectively transferring devices arrayed on a first substrate to a second substrate on which an adhesive resin layer is previously formed is disclosed. The method includes steps of selectively heating the adhesive resin layer on the second substrate by laser irradiation from the back surface side of the second substrate, and curing the selectively heated portions of the adhesive resin layer, thereby adhesively bonding those to be transferred of the devices to the second substrate. At this time, portions, corresponding to the devices, of the adhesive layer is heated directly or indirectly via the devices or wiring portions by laser irradiation from the back surface side of the substrate. The heated portions of the adhesive resin layer selectively exhibit the adhesive forces. The heated portions of the adhesive layer are then cured, so that only the devices to be transferred are selectively transferred to the second substrate. As a result, only the devices to be transferred can be certainly, efficiently, and accurately transferred without exerting adverse effect on other parts.

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

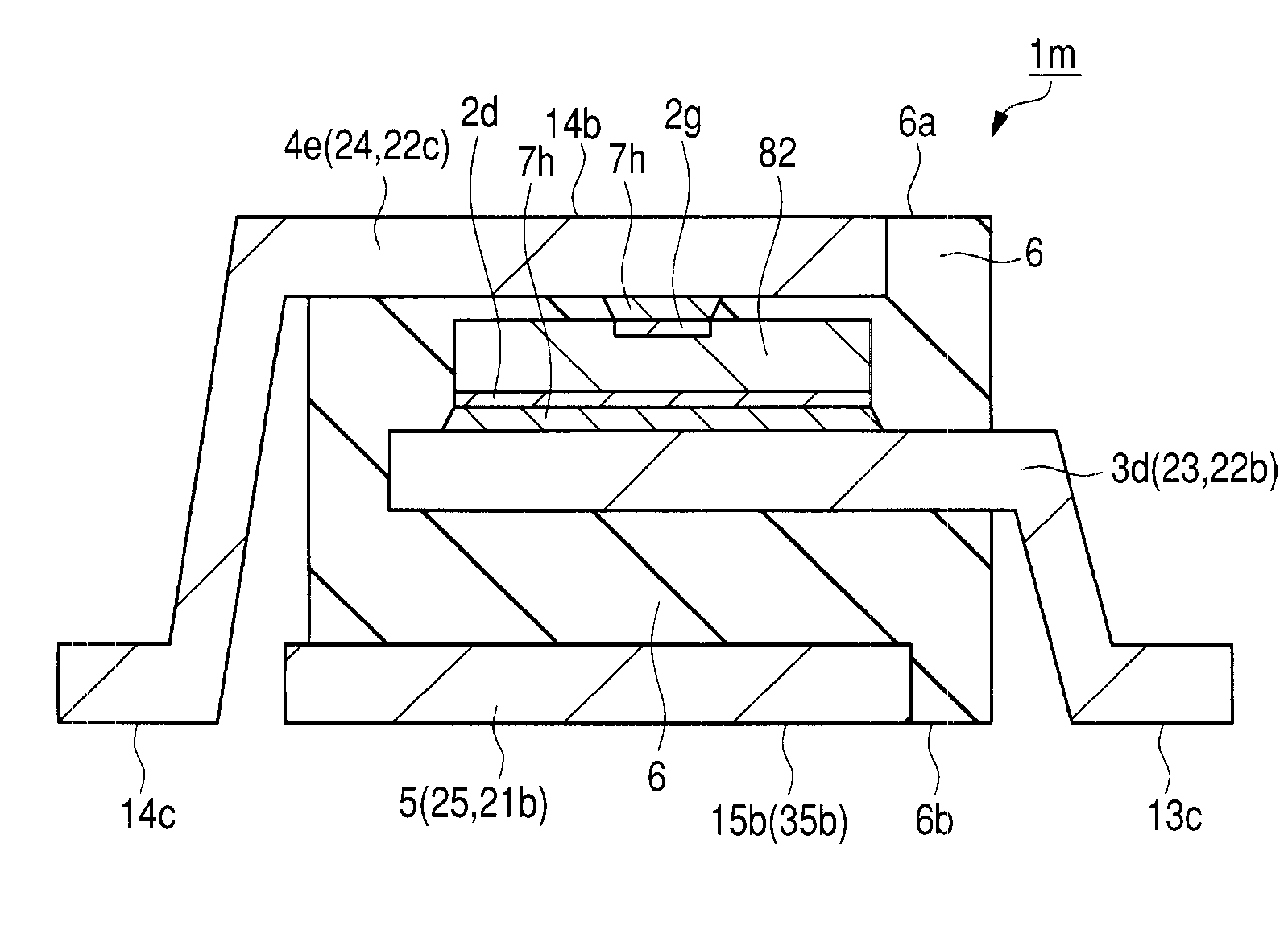

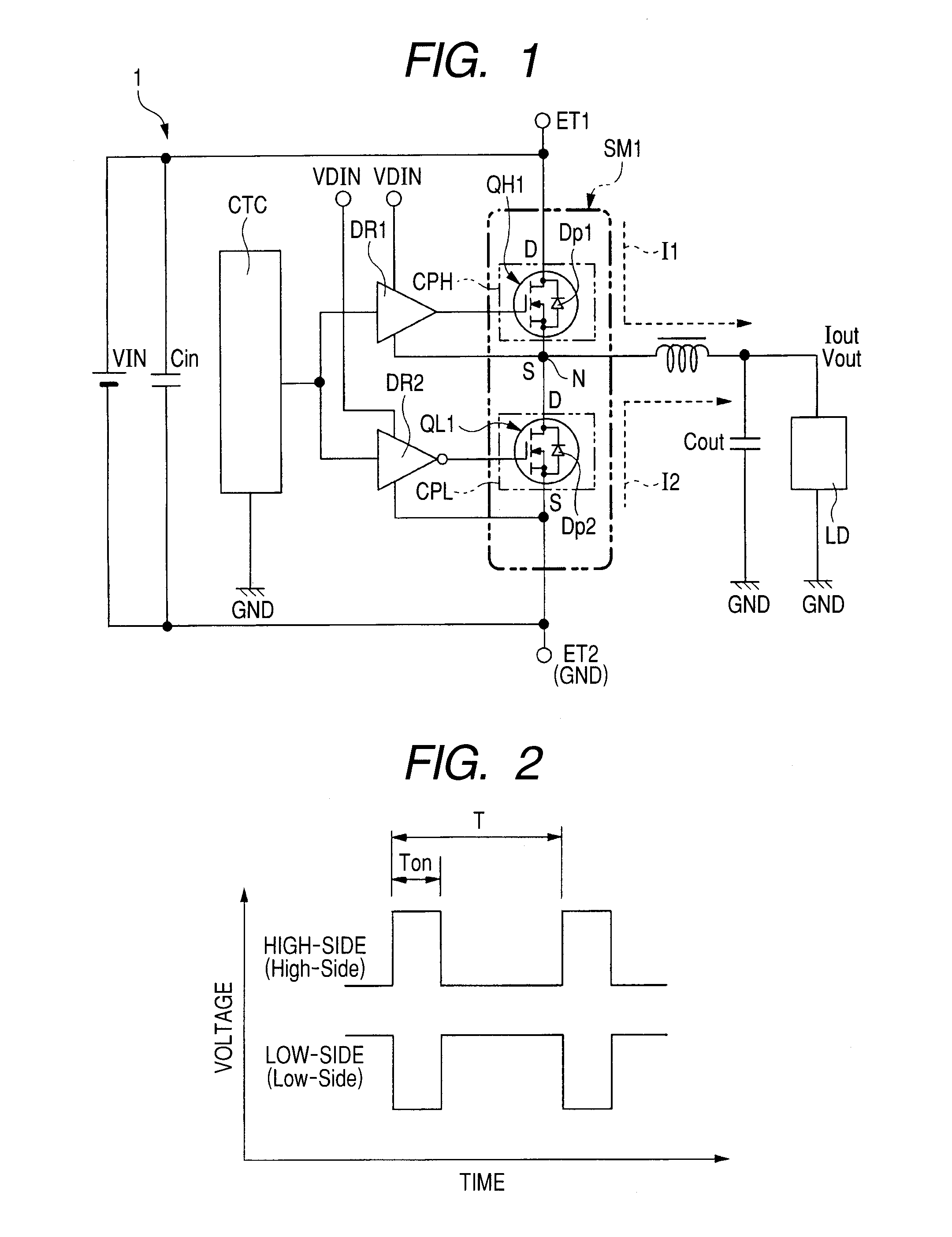

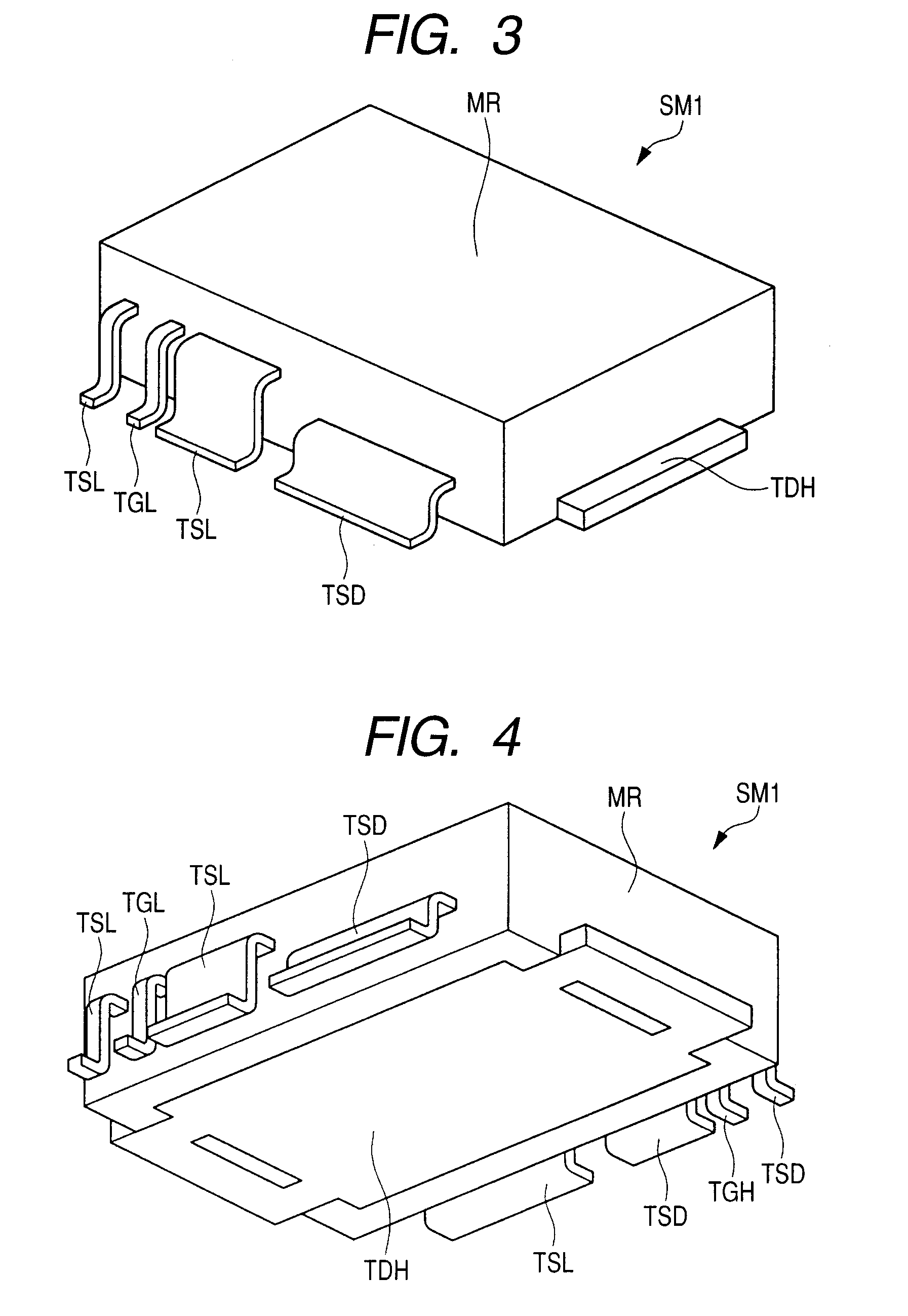

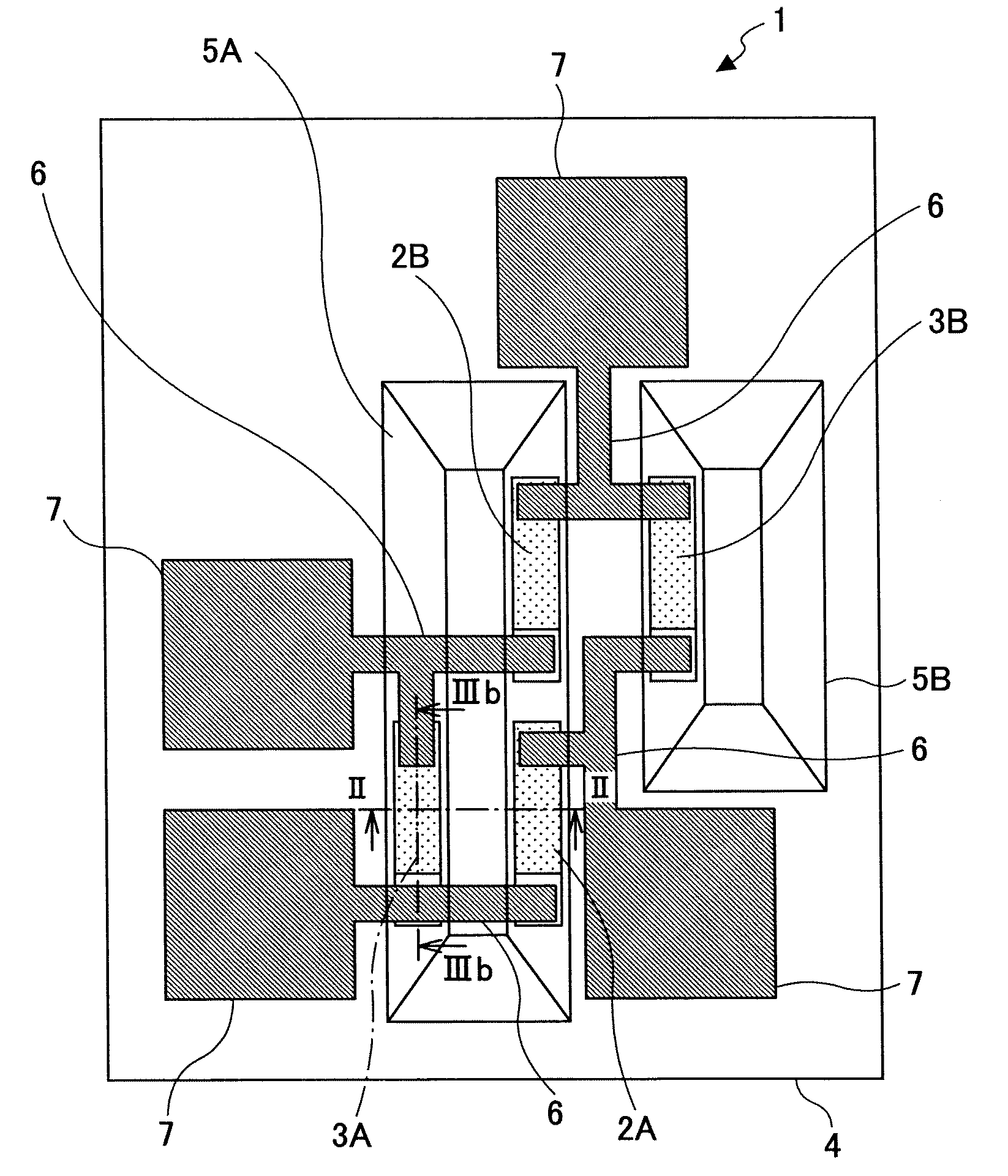

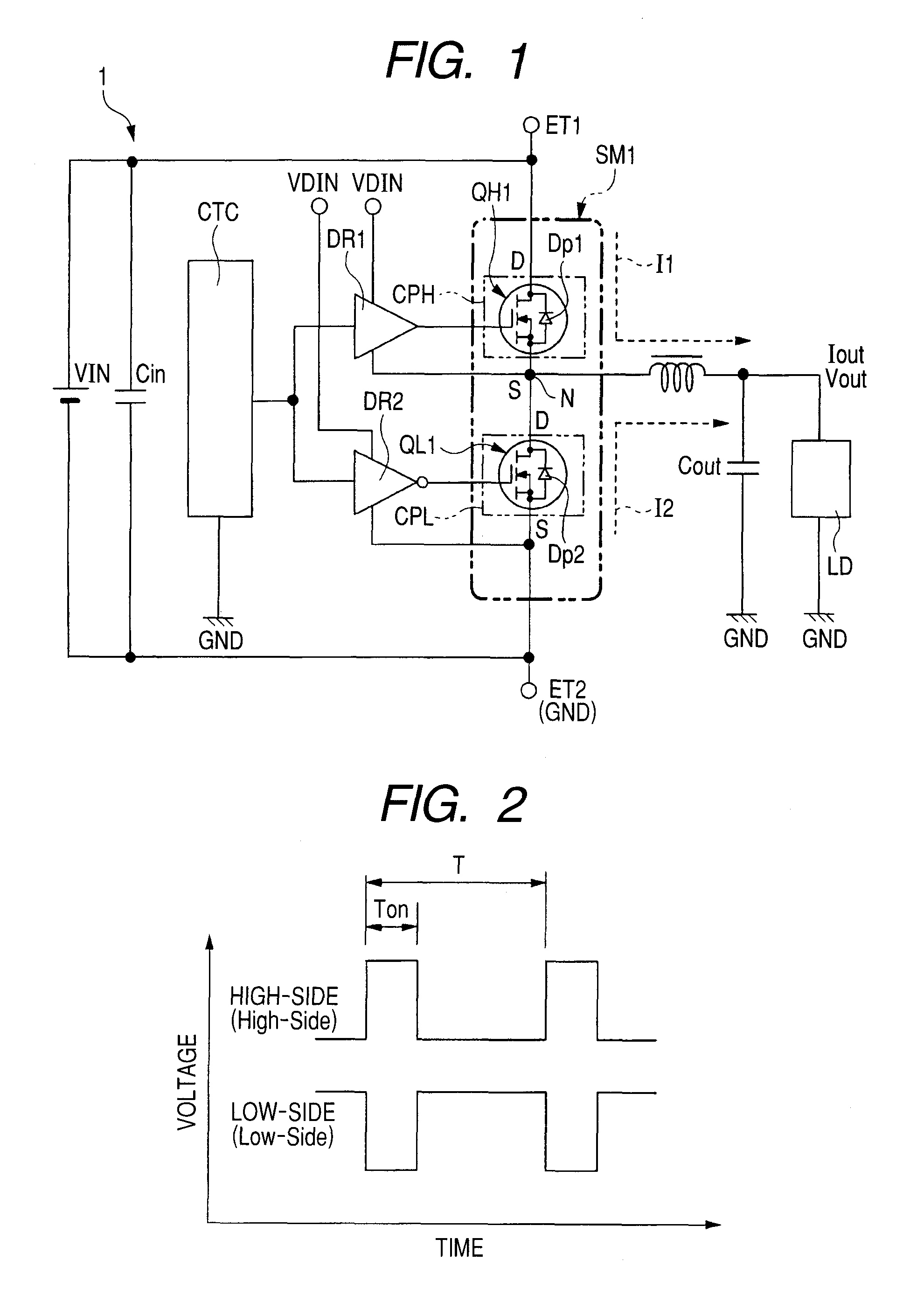

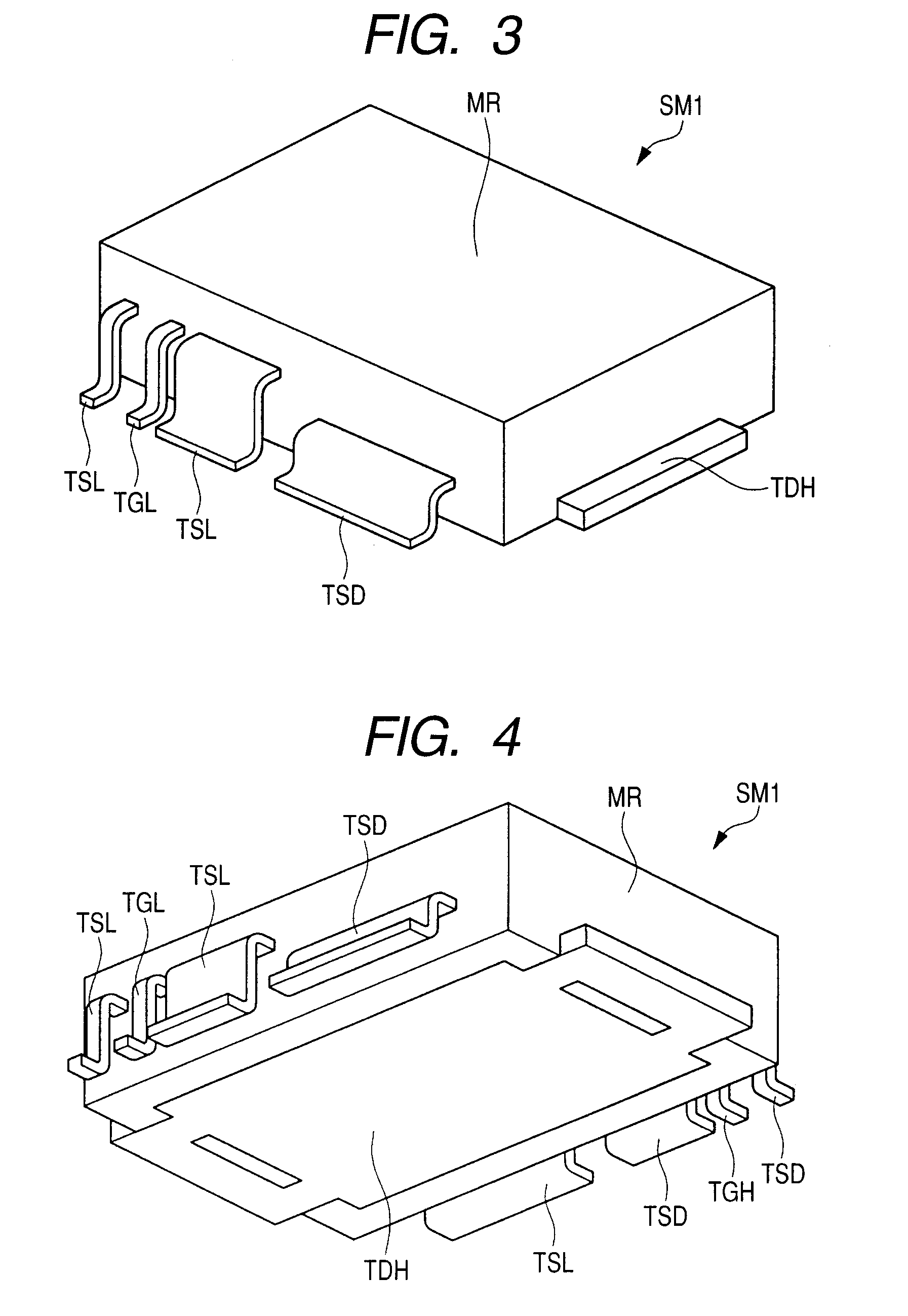

Manufacturing method of semiconductor device

InactiveUS20090215230A1Fabrication yield can be improvedImproved heat radiation characteristicSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

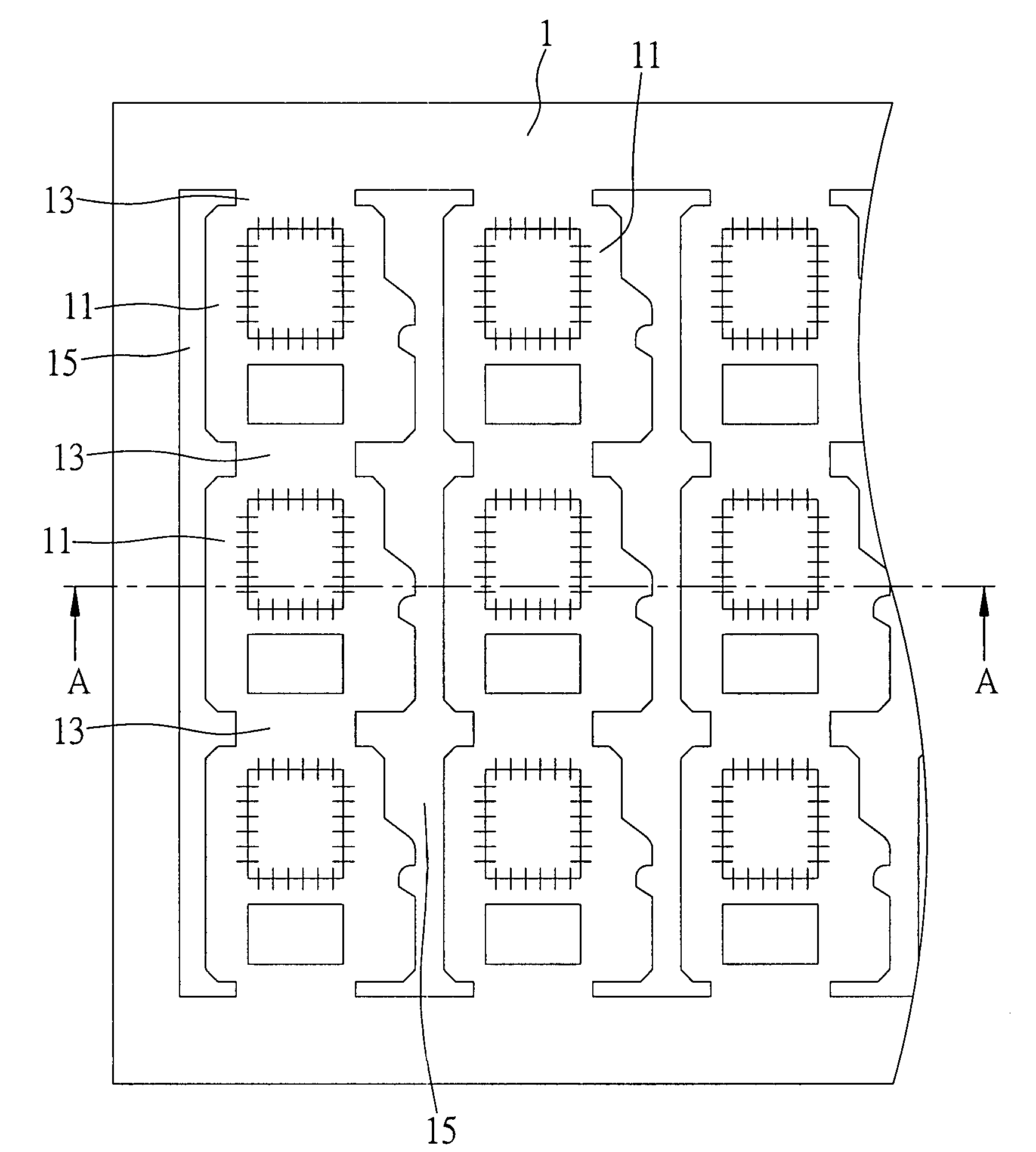

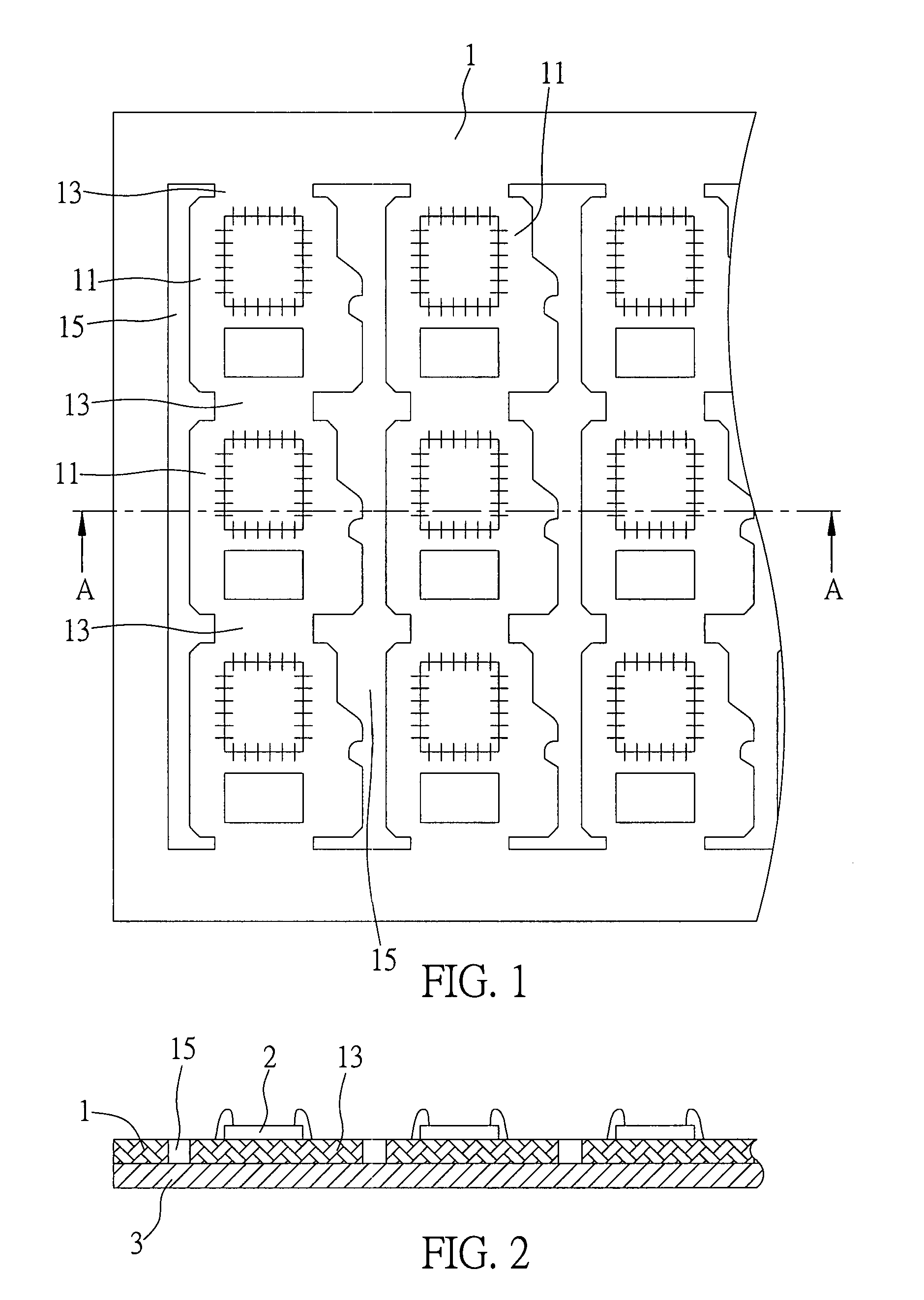

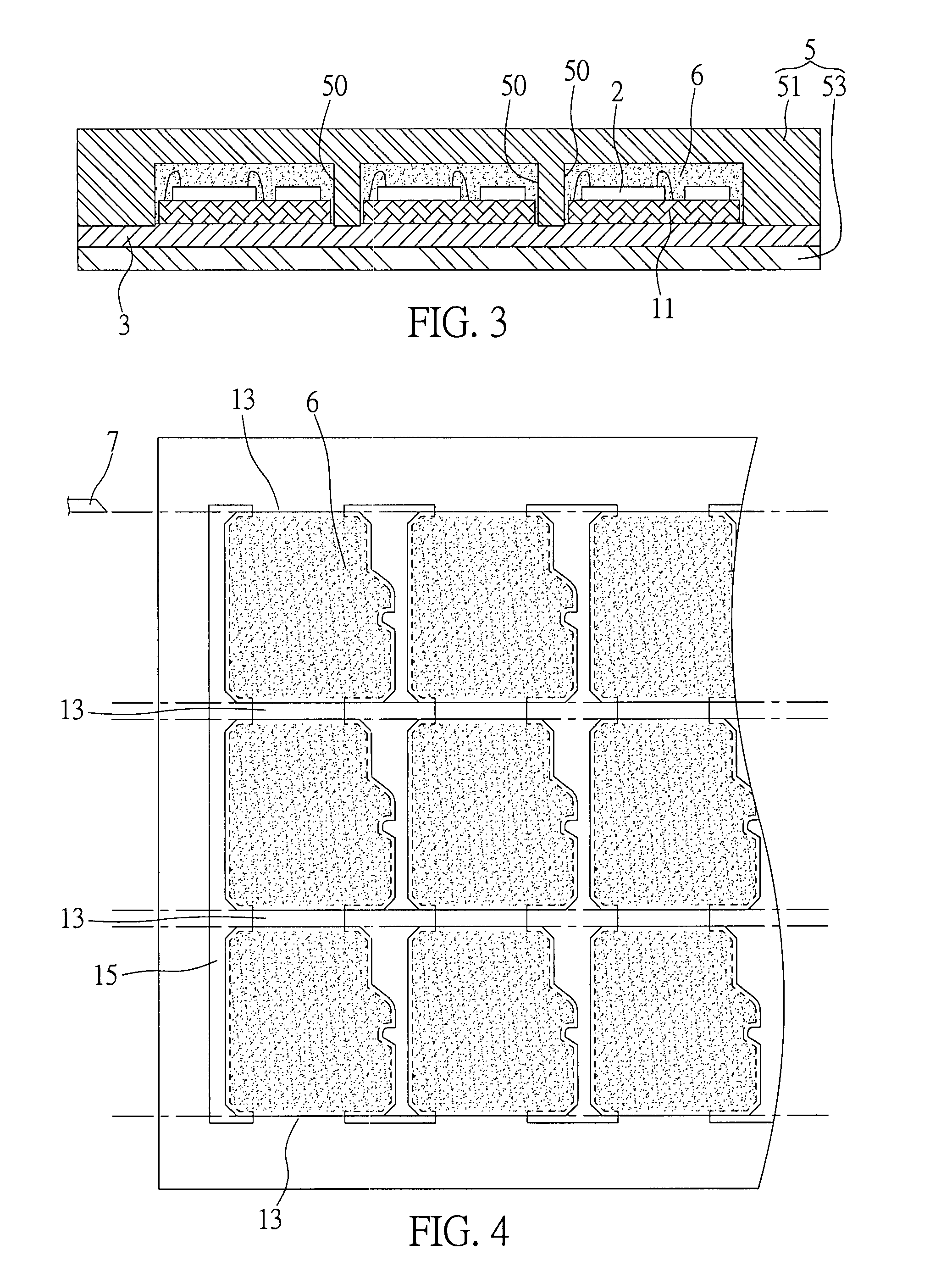

The radiation performance of a resin sealed semiconductor package is enhanced and further the fabrication yield thereof is enhanced. A drain terminal coupled to the back surface drain electrode of a semiconductor chip is exposed at the back surface of an encapsulation resin section. Part of the following portion and terminal is exposed at the top surface of the encapsulation resin section: the first portion of a source terminal coupled to the source pad electrode of the semiconductor chip and a gate terminal coupled to the gate pad electrode of the semiconductor chip. The remaining part of the second portion of the source terminal and the gate terminal is exposed at the back surface of the encapsulation resin section. When this semiconductor device is manufactured, bonding material and a film member are placed between the drain terminal and the semiconductor chip. At the same time, paste-like bonding material and a film member are placed between the source terminal 3 and gate terminal and the semiconductor chip. The paste-like bonding material is cured and turned into bonding material. As the result of use of the film members, variation in the thickness of the bonding material is suppressed.

Owner:RENESAS ELECTRONICS CORP

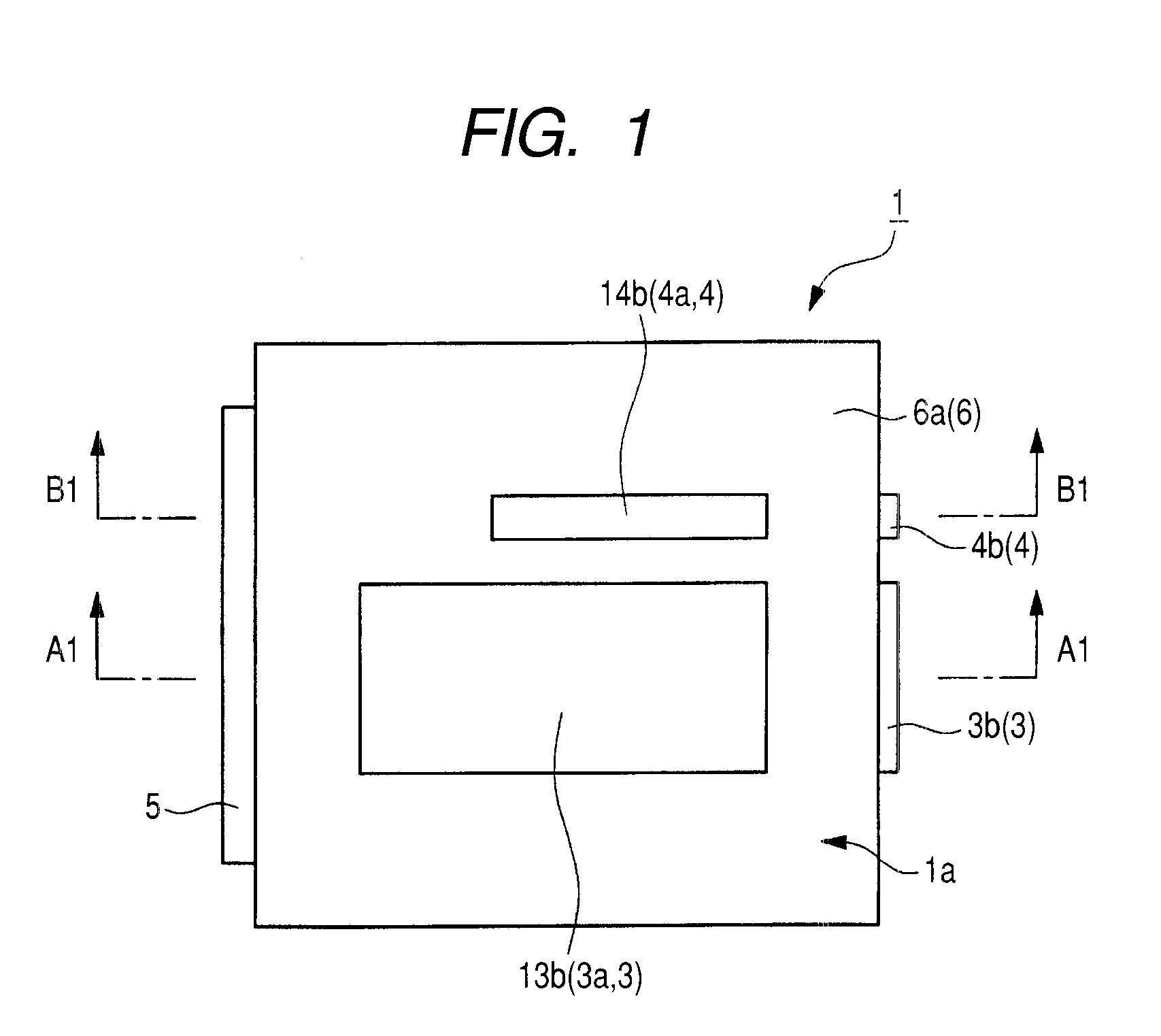

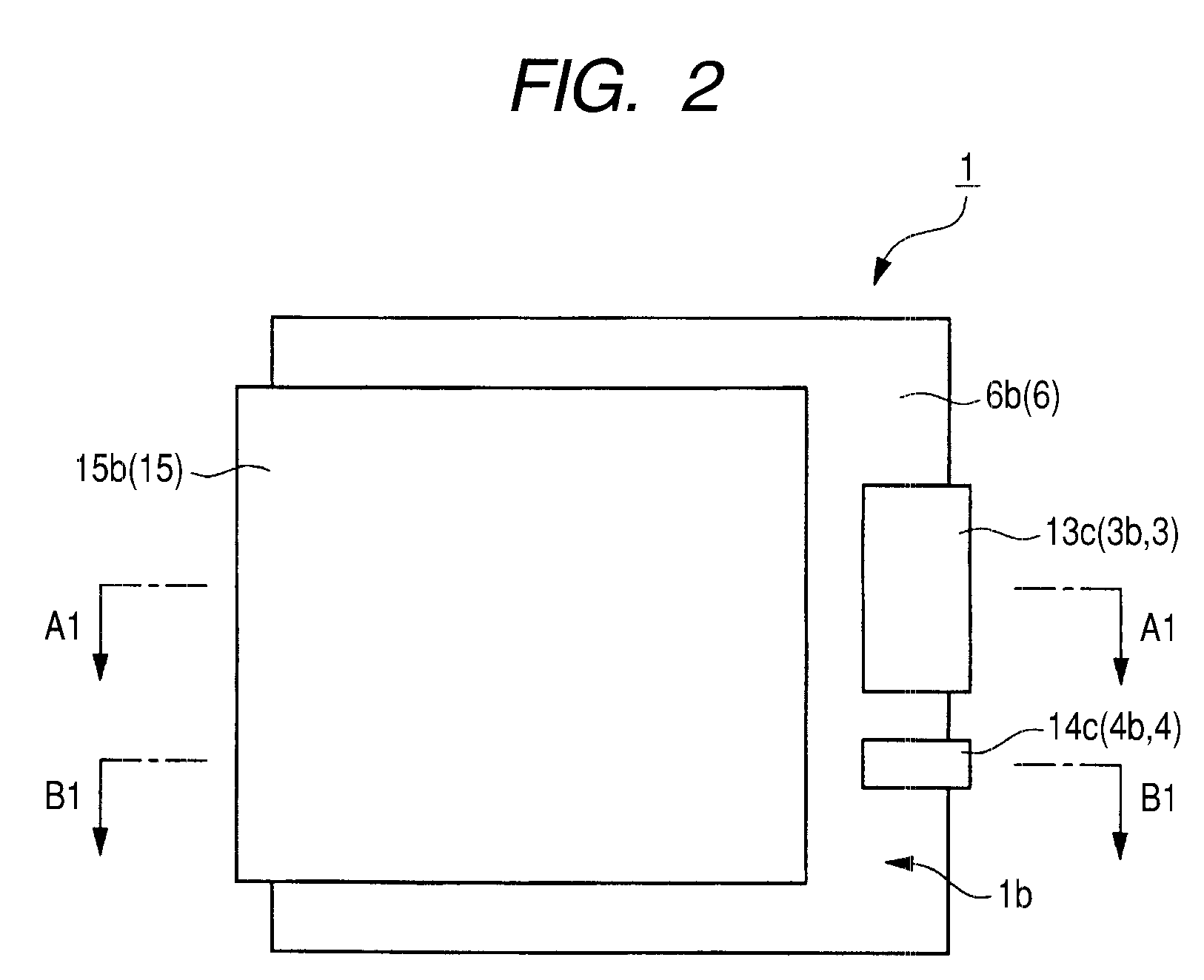

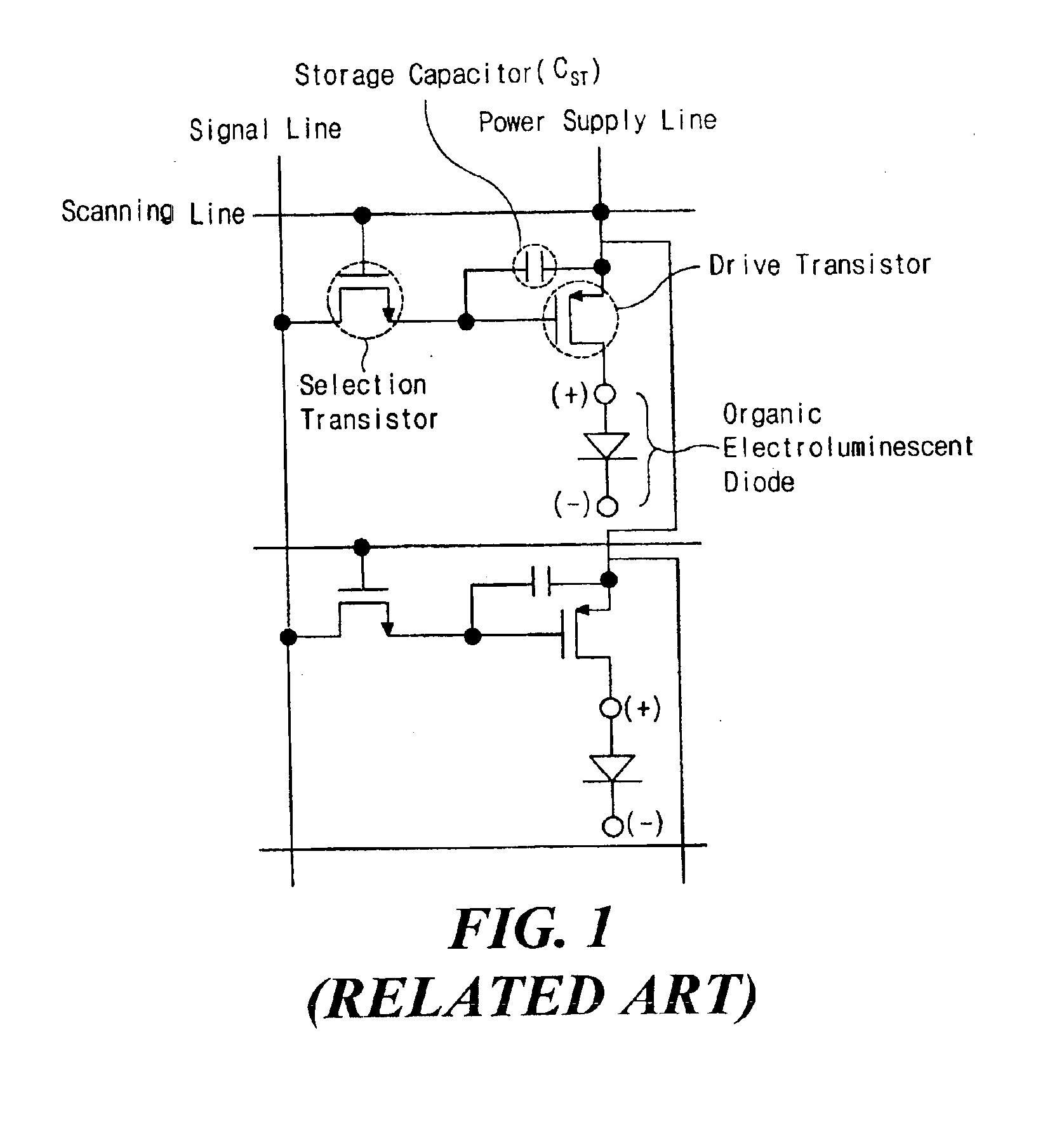

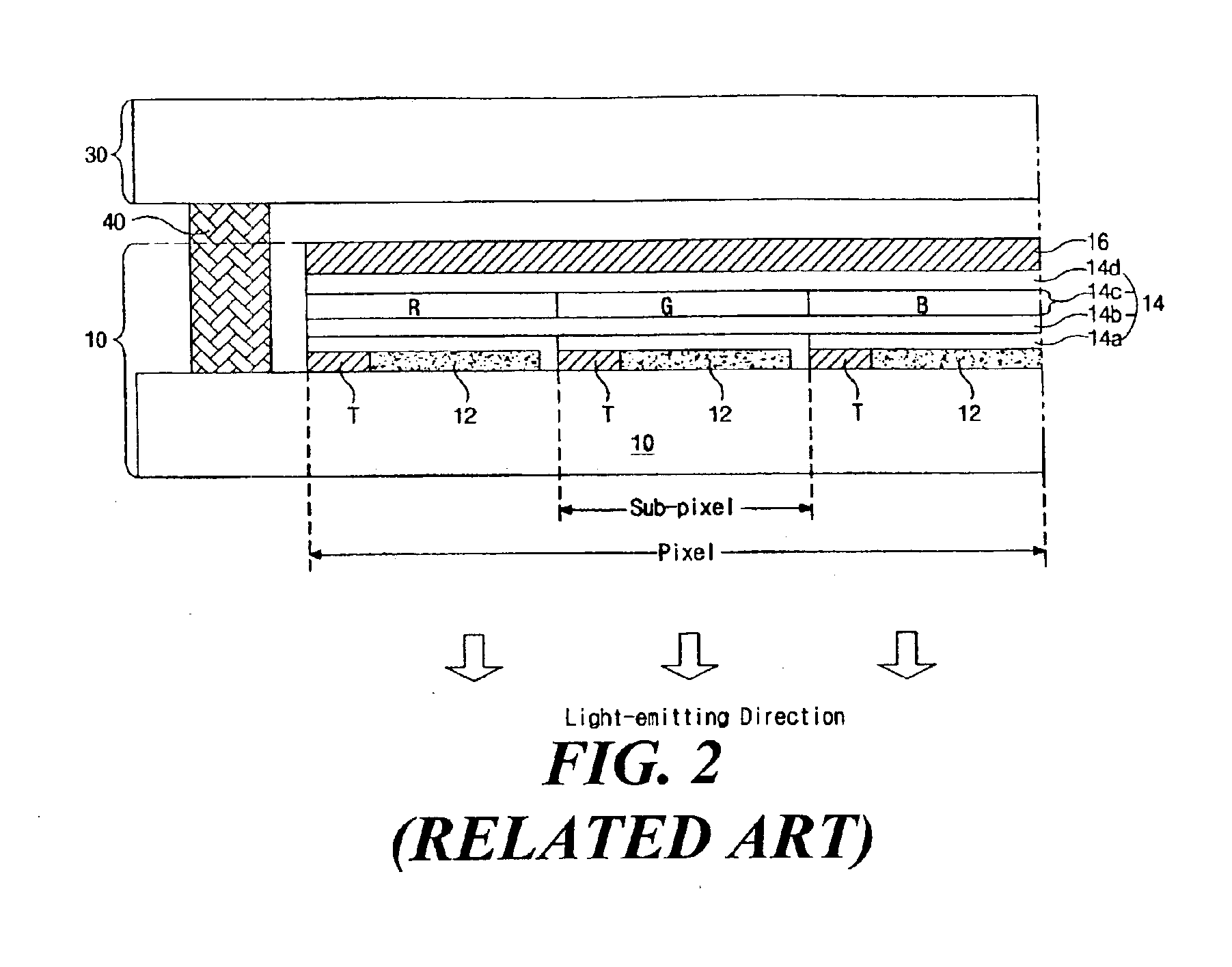

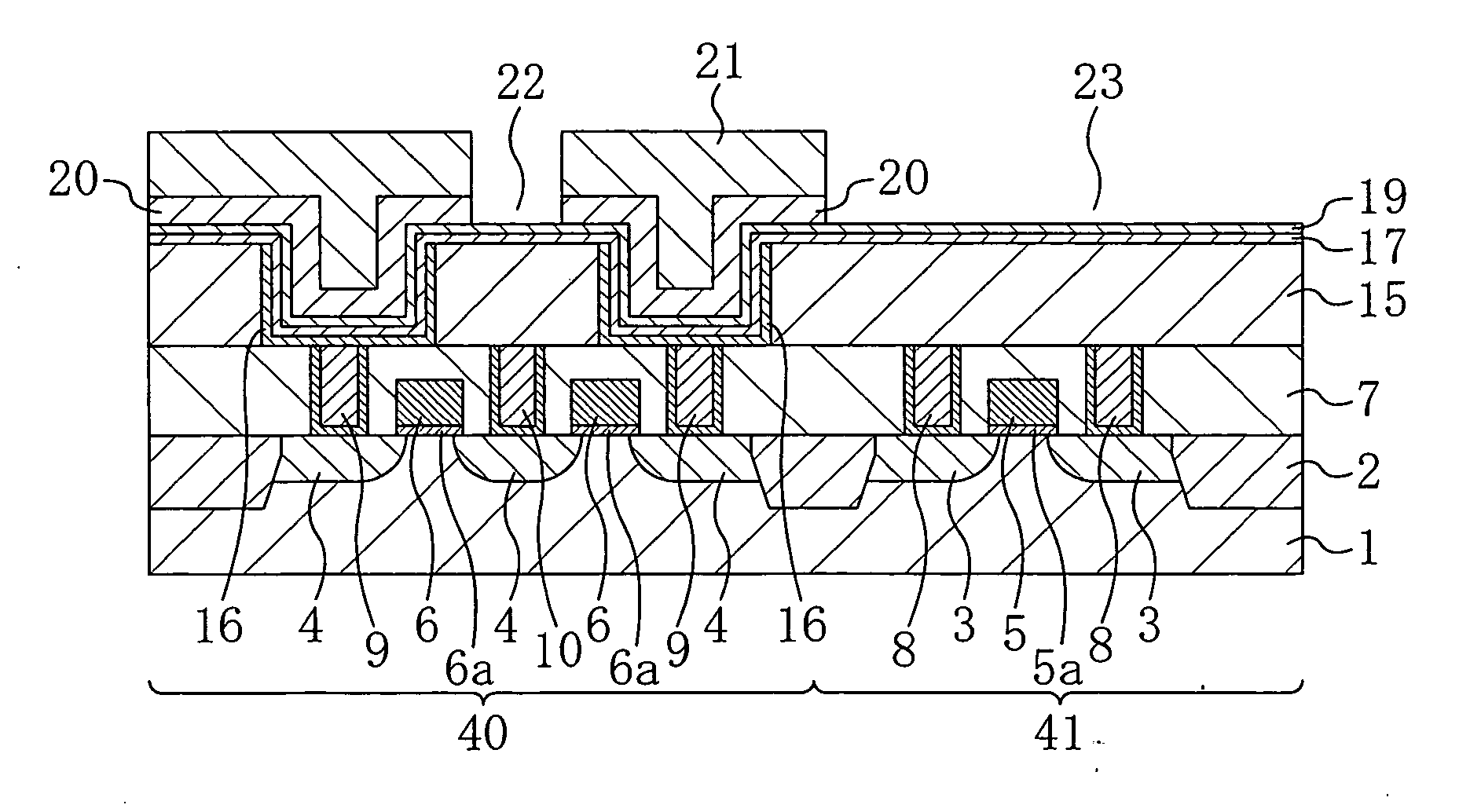

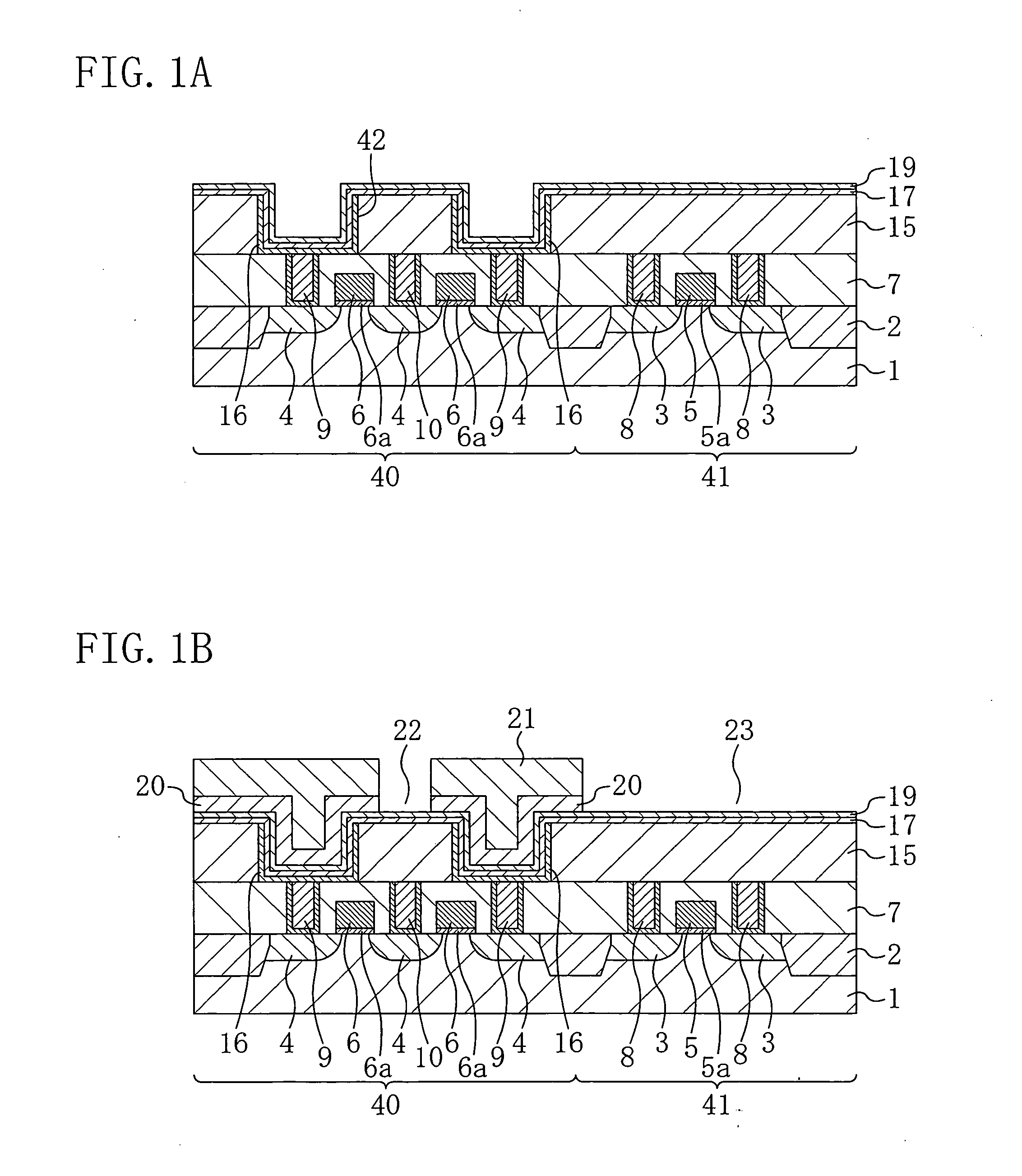

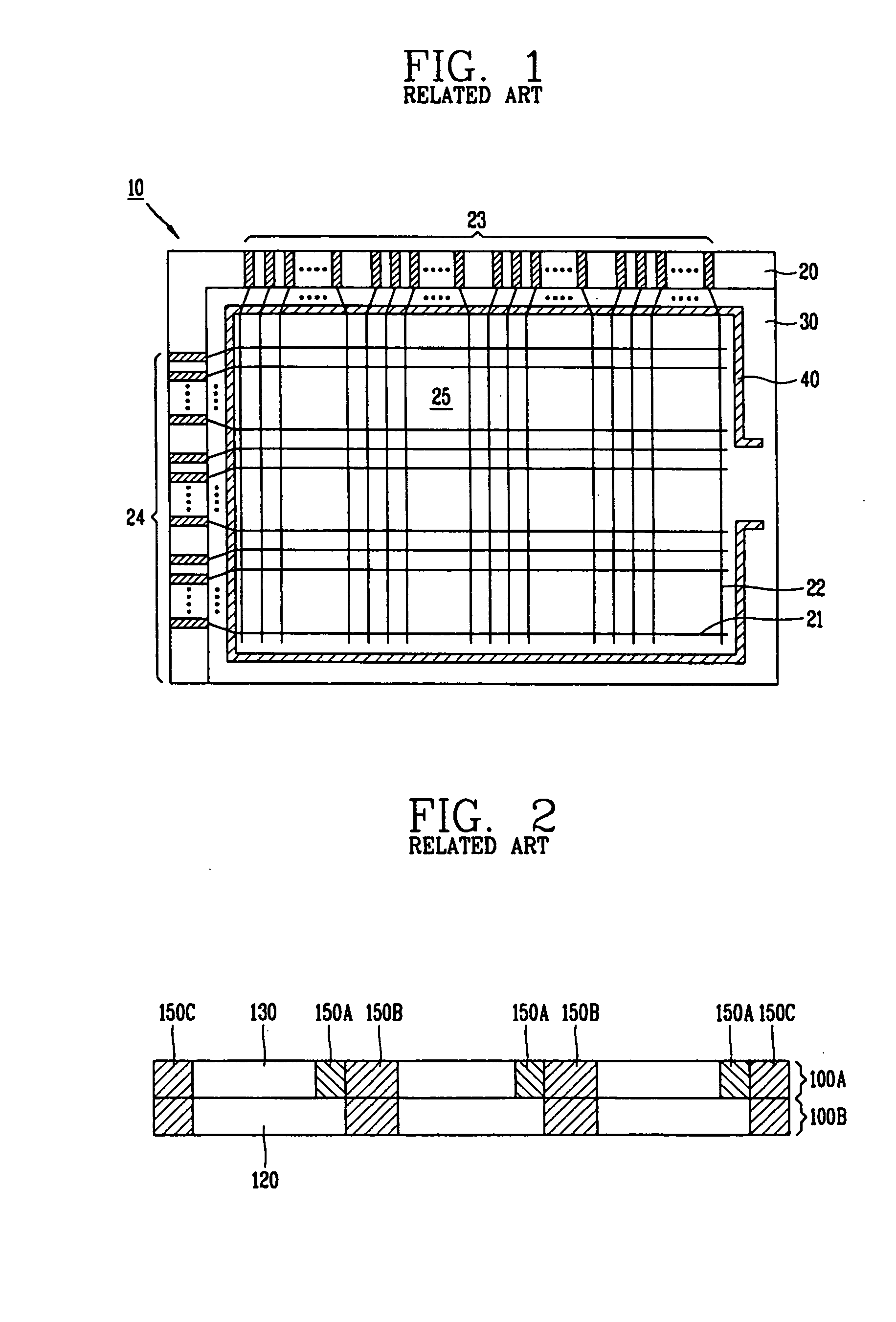

Organic electroluminescent display device

InactiveUS6870186B2Fabrication yield can be improvedHigh resolutionElectroluminescent light sourcesSolid-state devicesEngineeringArray element

An organic electroluminescent device includes first and second substrates attached by a seal pattern, array elements including a plurality of thin film transistors formed on the first substrate, a first electrode formed on a rear surface of the second substrate, a plurality of electrode separators formed on the rear surface of the first electrode, wherein the plurality of electrode separators is made of an insulating material defining sub-pixel regions that correspond to each thin film transistor, an organic electroluminescent layer formed on a rear surface of the first electrode in each of the sub-pixel regions, a second electrode formed on a rear surface of the organic electroluminescent layer in each of sub-pixel regions, a conductive connector formed between the first and second substrates in each sub-pixel region for connecting to the second electrode of a sub-pixel region.

Owner:LG DISPLAY CO LTD

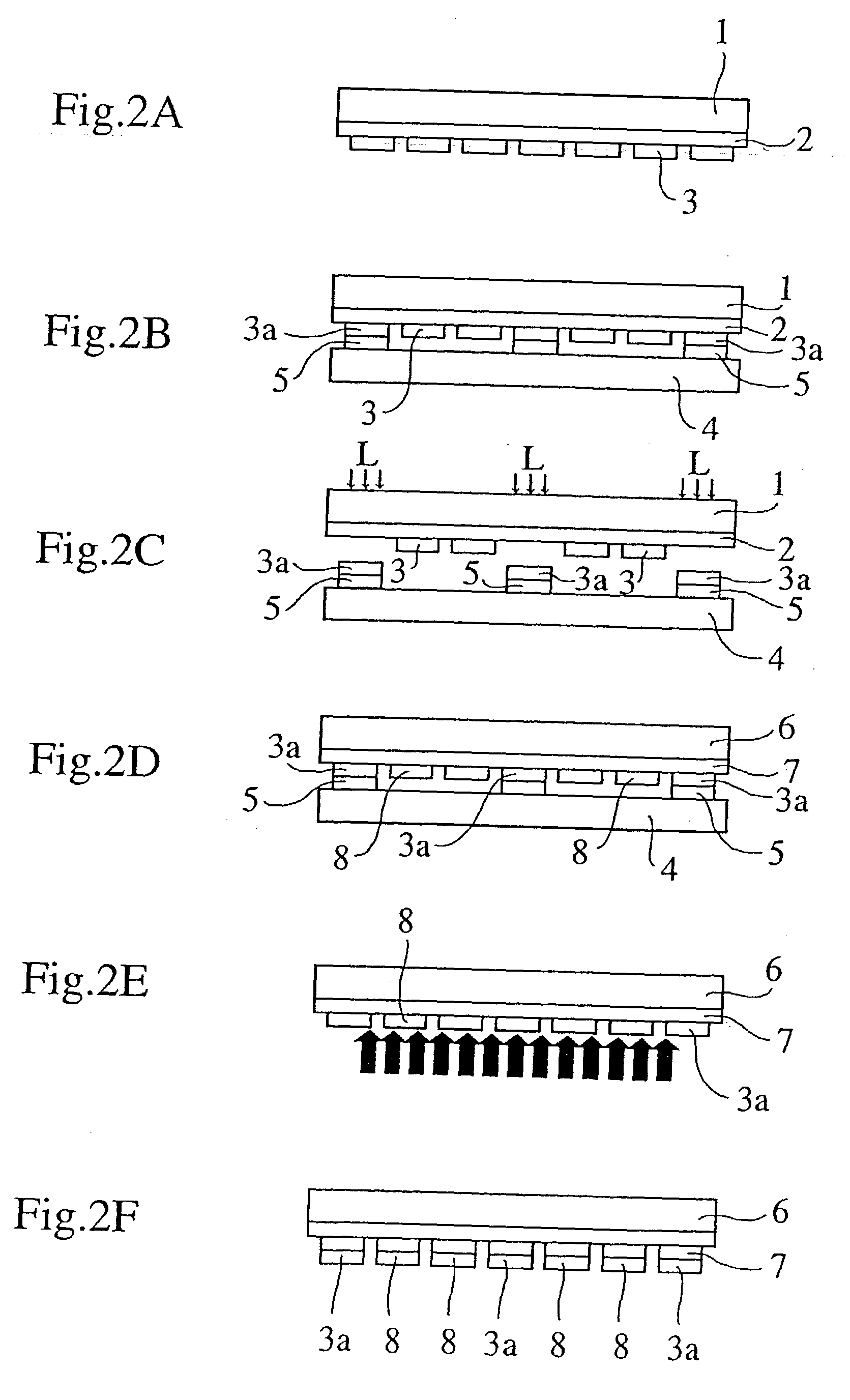

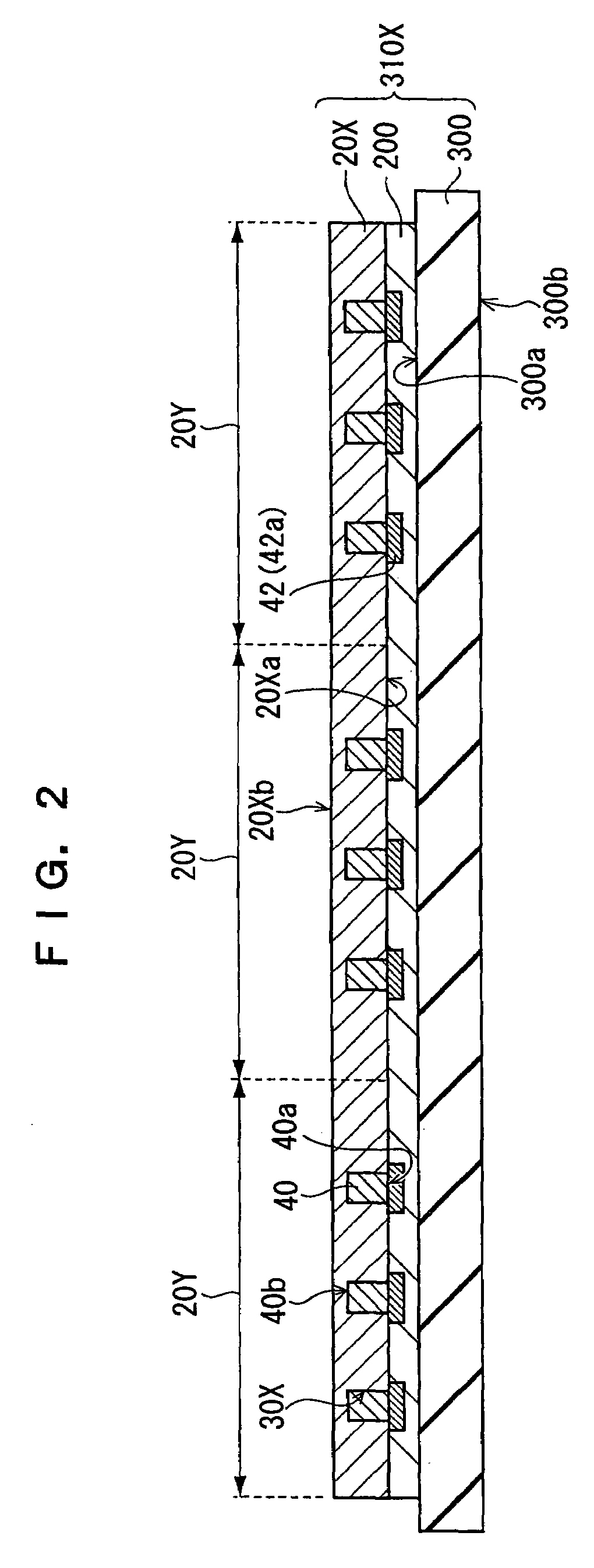

Semiconductor device fabricating method

InactiveUS20070231966A1Prevent be breakGood electrical connectionSemiconductor/solid-state device detailsSolid-state devicesEngineeringLaminated composites

To improve the fabrication yield of semiconductor devices. A semiconductor device where a desired number of semiconductor chips are laminated in the thickness direction thereof is fabricated by repeating, an arbitrary number of times such as one time or two or more times, a step of bonding and mounting another support substrate laminate on first bumps exposed by separating and removing one support substrate from a support substrate laminate composite where second bumps of two support substrate laminates including plural semiconductor wafers mounted on support substrates have been made to face each other and are electrically connected.

Owner:TAIWAN SEMICON MFG CO LTD

Memory card and method for fabricating the same

ActiveUS20080273299A1Prevent leakageSimplify the manufacturing processWave amplification devicesDigital data processing detailsState of artEngineering

A memory card and method for fabricating the same are disclosed, which includes mounting and electrically connecting at least a chip to a circuit board unit having a predefined shape of a memory card; attaching a thin film to the surface of the circuit board unit opposed to the surface with the chip mounted thereon; covering the circuit board unit and the thin film by a mold so as to form a mold cavity having same shape as the circuit board unit but bigger size; filling a packaging material in the mold cavity so as to form an encapsulant encapsulating the chip and outer sides of the circuit board unit, thus integrally forming a memory card having the predefined shape. The present invention eliminates the need to perform a shape cutting process by using water jet or laser as in the prior art, thus reducing the fabricating cost and improving the fabricating yield.

Owner:UTAC HEADQUARTERS PTE LTD

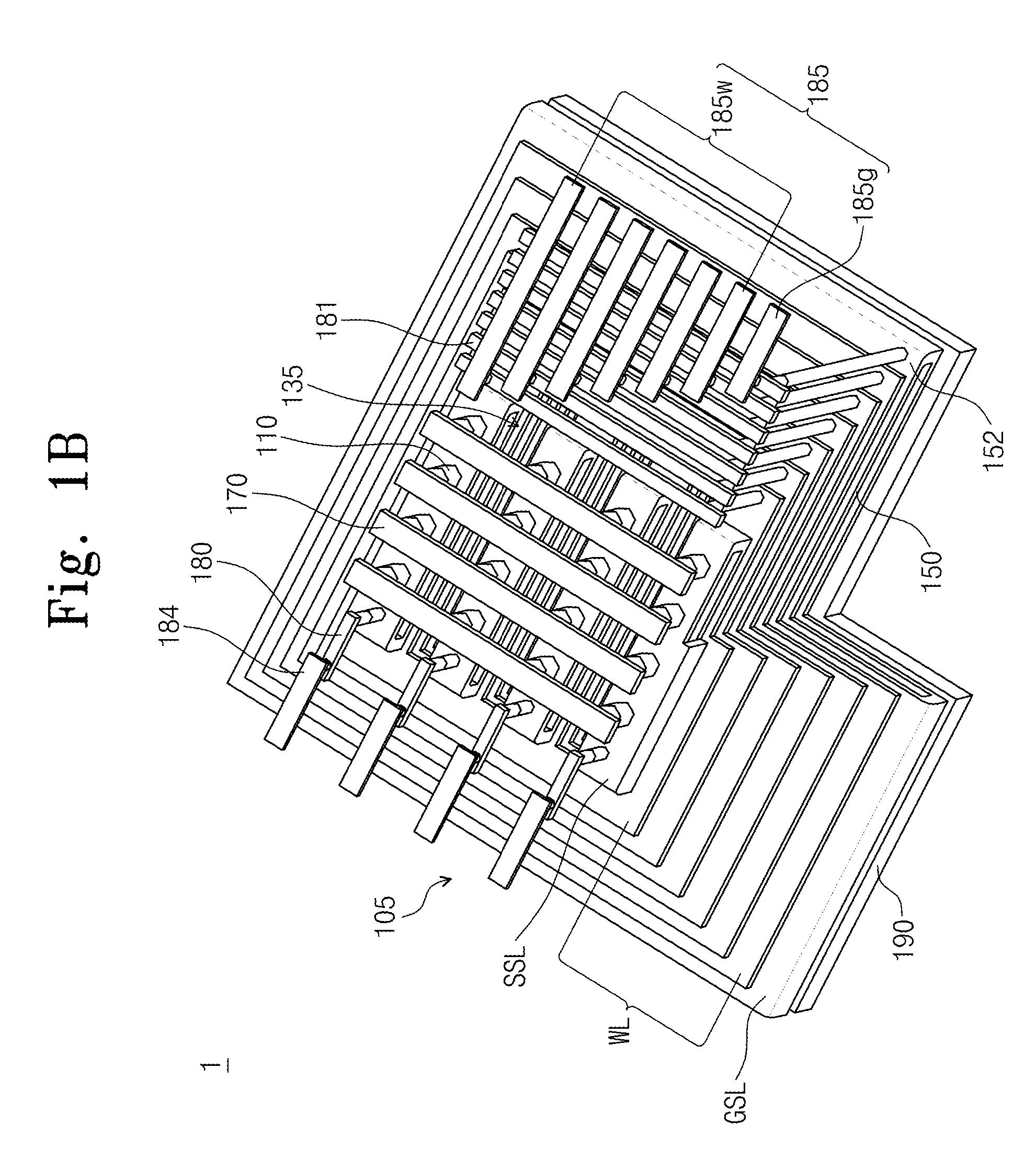

3D semiconductor devices and methods of fabricating same

ActiveUS8564050B2Fabrication yield can be improvedPrevent and minimize errorTransistorSolid-state devicesPower semiconductor deviceInter layer

Owner:SAMSUNG ELECTRONICS CO LTD

Manufacturing method for semiconductor devices

InactiveUS20110081750A1Enhance characteristicImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceEngineering

The reliability of a semiconductor device is enhanced. A first lead frame, a first semiconductor chip, a second lead frame, and a second semiconductor chip are stacked over an assembly jig in this order with solder in between and solder reflow processing is carried out to fabricate their assembly. Thereafter, this assembly is sandwiched between first and second molding dies to form an encapsulation resin portion. The upper surface of the second die is provided with steps. At a molding step, the second lead frame is clamped between the first and second dies at a position higher than the first lead frame; and a third lead frame is clamped between the first and second dies at a higher position. The assembly jig is provided with steps at the same positions as those of the steps in the upper surface of the second die in positions corresponding to those of the same.

Owner:RENESAS ELECTRONICS CORP

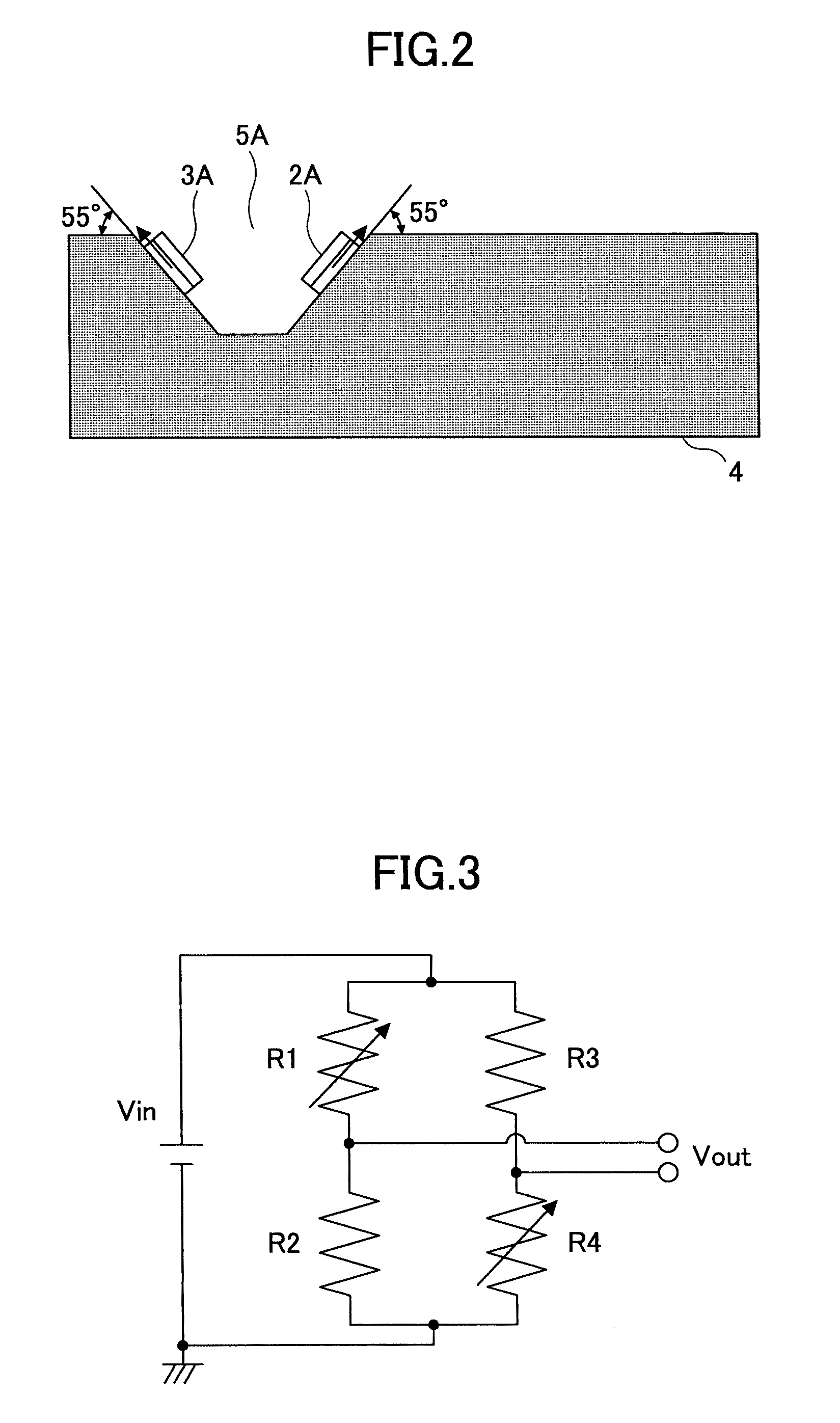

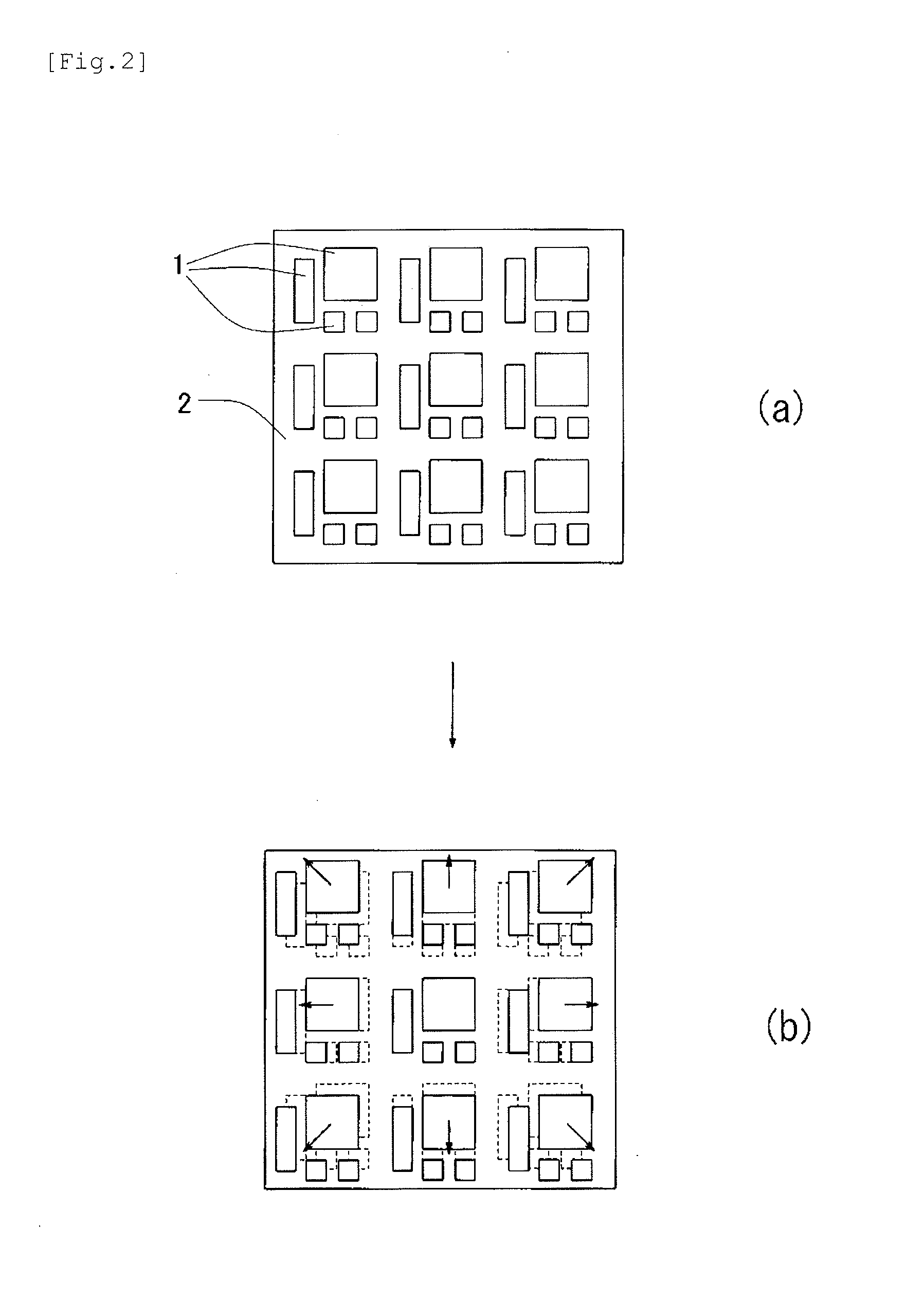

Magnetic sensor and production method thereof

InactiveUS20090015251A1Reduce in quantityFabrication yield can be improvedNanomagnetismWave amplification devicesMagnetizationResistor

A magnetic sensor is disclosed that has plural axes at the same time, able to be fabricated in a small number of steps. The magnetic sensor includes a substrate; and plural sensor bridge circuits each including a pair of magnetic field detectors and a pair of fixed resistors on the substrate, the pair of the magnetic field detectors and the pair of the fixed resistors being connected to form a bridge circuit, each of the magnetic field detectors being formed of a magneto-resistance effect element, and magnetization directions of the magnetic field detectors intersect with each other in a three-dimensional manner. The substrate has plural inclined surfaces, normal directions of the inclined surfaces intersect with each other in a three-dimensional manner, and the pair of the magnetic field detectors in each of the sensor bridge circuits is arranged on the same inclined surface.

Owner:RICOH KK

Horizontal cavity surface emitting laser diodes, vertical illuminated photodiodes, and methods of their fabrication

InactiveUS20120183009A1Satisfactory yieldReduce manufacturing costLaser optical resonator constructionSolid-state devicesWaveguidePhotodiode

The horizontal cavity surface emitting laser includes a cavity structure portion including a stacked structure of a first conduction type clad layer, an active layer and a second conduction type clad layer stacked over a semiconductor substrate and causing light generated by the active layer to be reflected or resonated, an optical waveguide layer provided at part of the semiconductor substrate and guiding the light, a reflector provided in the optical waveguide layer, for reflecting the light and emitting the light from the back surface of the semiconductor substrate, and a condensing lens provided at the back surface thereof and focusing the reflected light. The back surface thereof has a groove provided with the condensing lens and a terrace-like portion disposed below the cavity structure portion and has a terrace shape with the cleavage direction along a longitudinal direction thereof provided along a cleavage direction of the semiconductor substrate.

Owner:HITACHI LTD

Semiconductor device and method for fabricating the same

InactiveUS20060076600A1Increase parasitic capacitanceAvoid height differenceTransistorSolid-state devicesDevice materialCapacitor

In a method for fabricating a semiconductor device according to the present invention, a groove is formed in a second interlayer insulating film, and then a storage electrode is formed which covers bottom and side surfaces of the groove. A capacitor insulating film is formed on the storage electrode, and a CVD method at a low temperature of 400° C. or lower and annealing with ammonia are repeated to form a TiOxNy film on the capacitor insulating film. A TiN film is formed on the TiOxNy film, and the TiN film is etched using the TiOxNy film as a stopper. The exposed TiOxNy film is then removed to form a plate electrode made of the TiOxNy film and the TiN film.

Owner:PANASONIC CORP

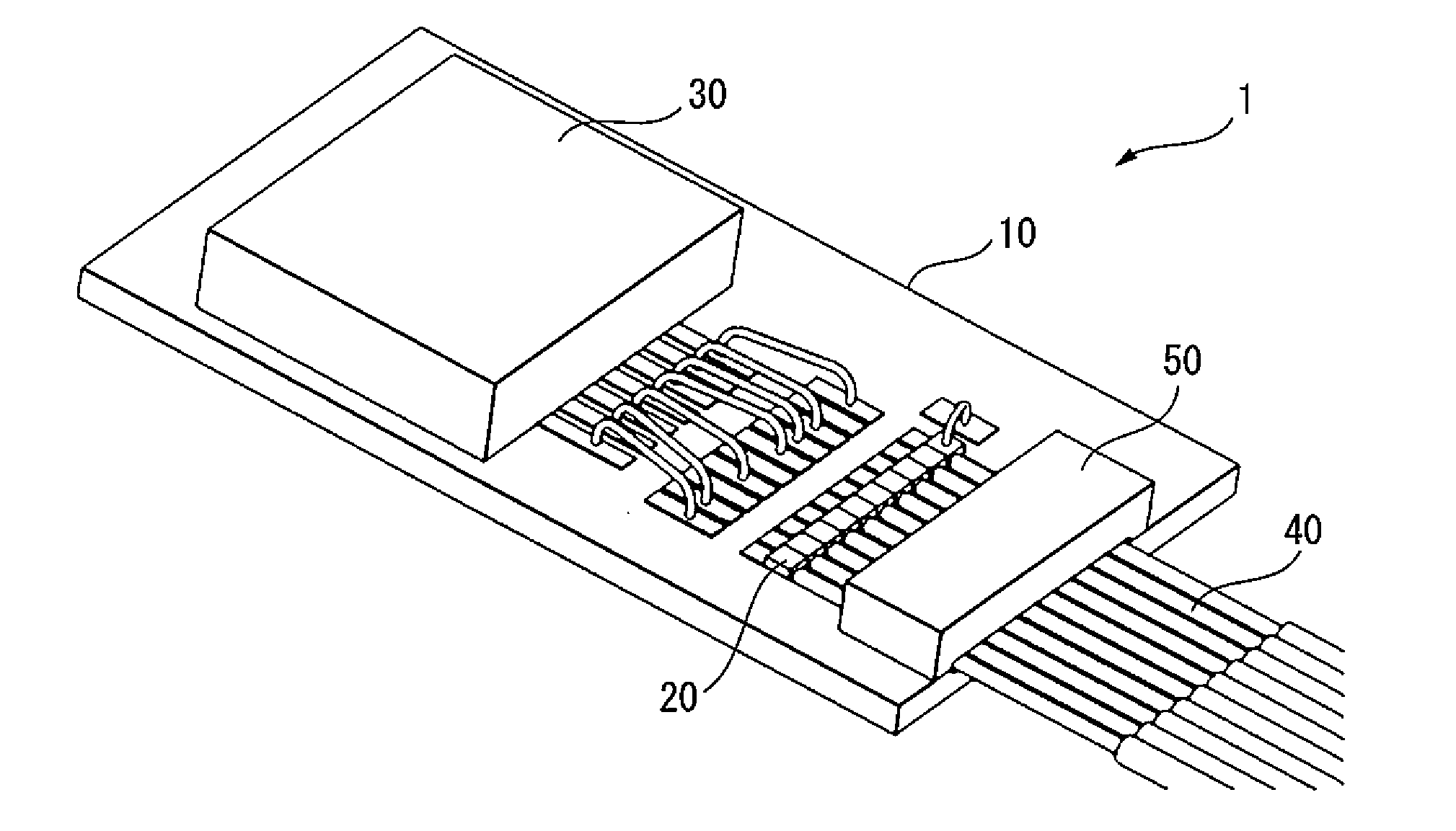

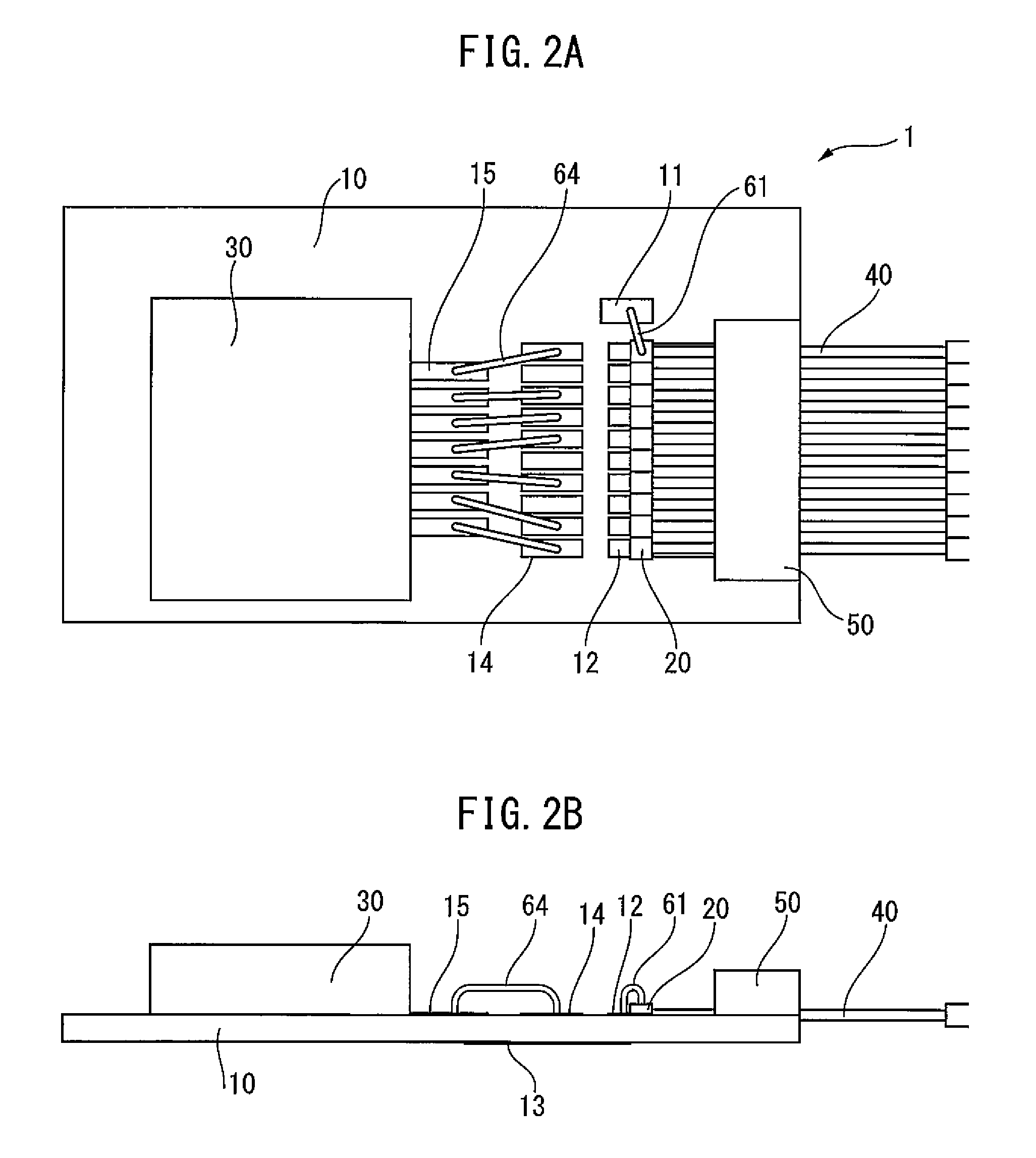

Laser module, light source device, and method for fabricating laser module

InactiveUS20150236472A1Improve yieldFabrication yield can be improvedCosmonautic condition simulationsSemiconductor/solid-state device testing/measurementComputer moduleLaser light

Provided is a laser module wherein any defective laser device can be isolated by performing burn-in on laser devices mounted on a mounting substrate. The laser module includes laser devices that emit laser light, a driver IC for driving the laser devices, a mounting substrate on which the laser devices and the driver IC are mounted, a common electrode terminal to which a common electrode of the laser devices is connected, individual electrode terminals to which individual electrodes of the laser devices are respectively connected, driver terminals to which the driver IC is connected, and test terminals which are respectively connected to the common electrode terminal and the individual electrode terminals, and to which an external power supply is to be connected when performing burn-in of the laser devices, wherein the number of the laser devices and the number of the test terminals are each larger than the number of the driver terminals.

Owner:CITIZEN WATCH CO LTD

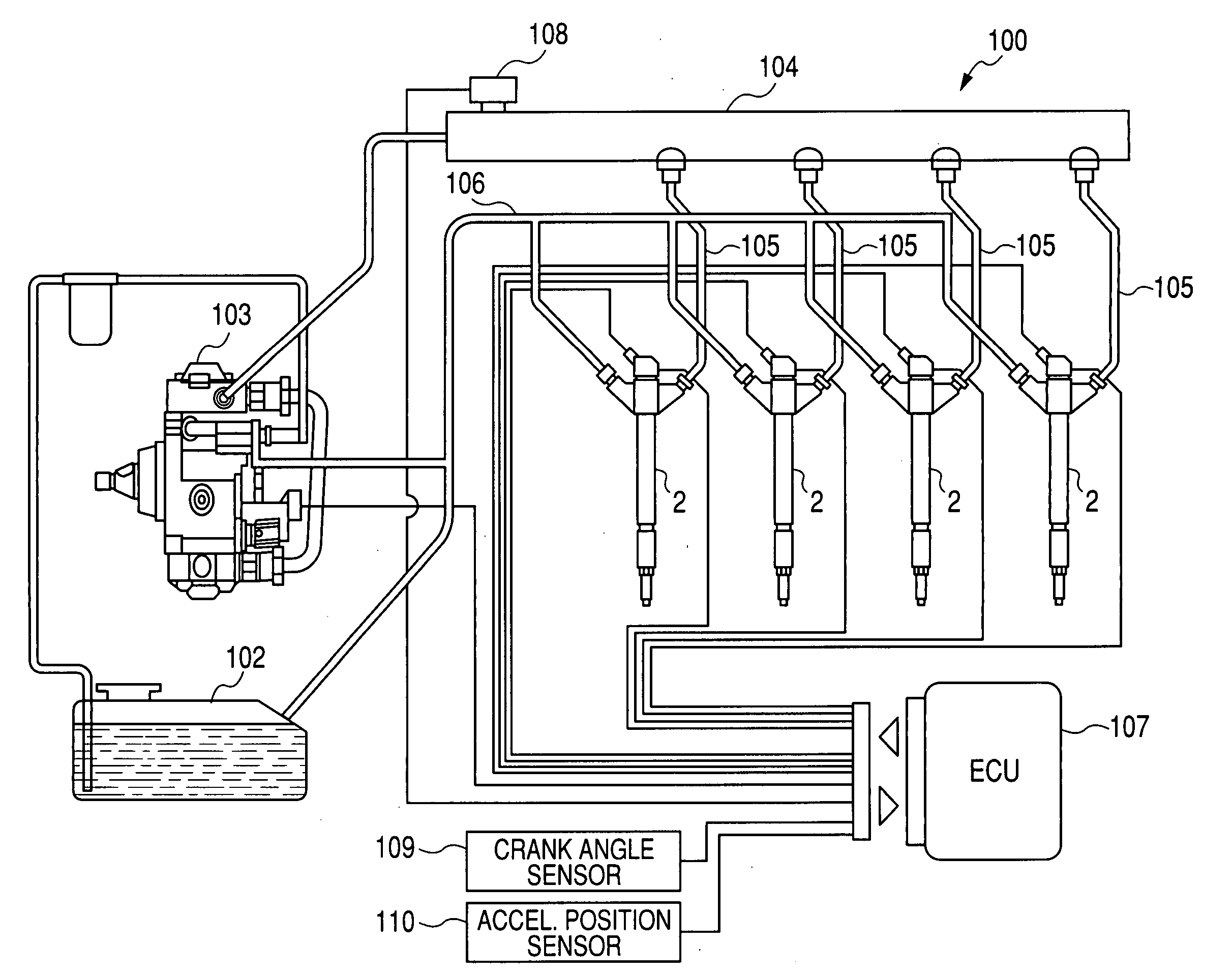

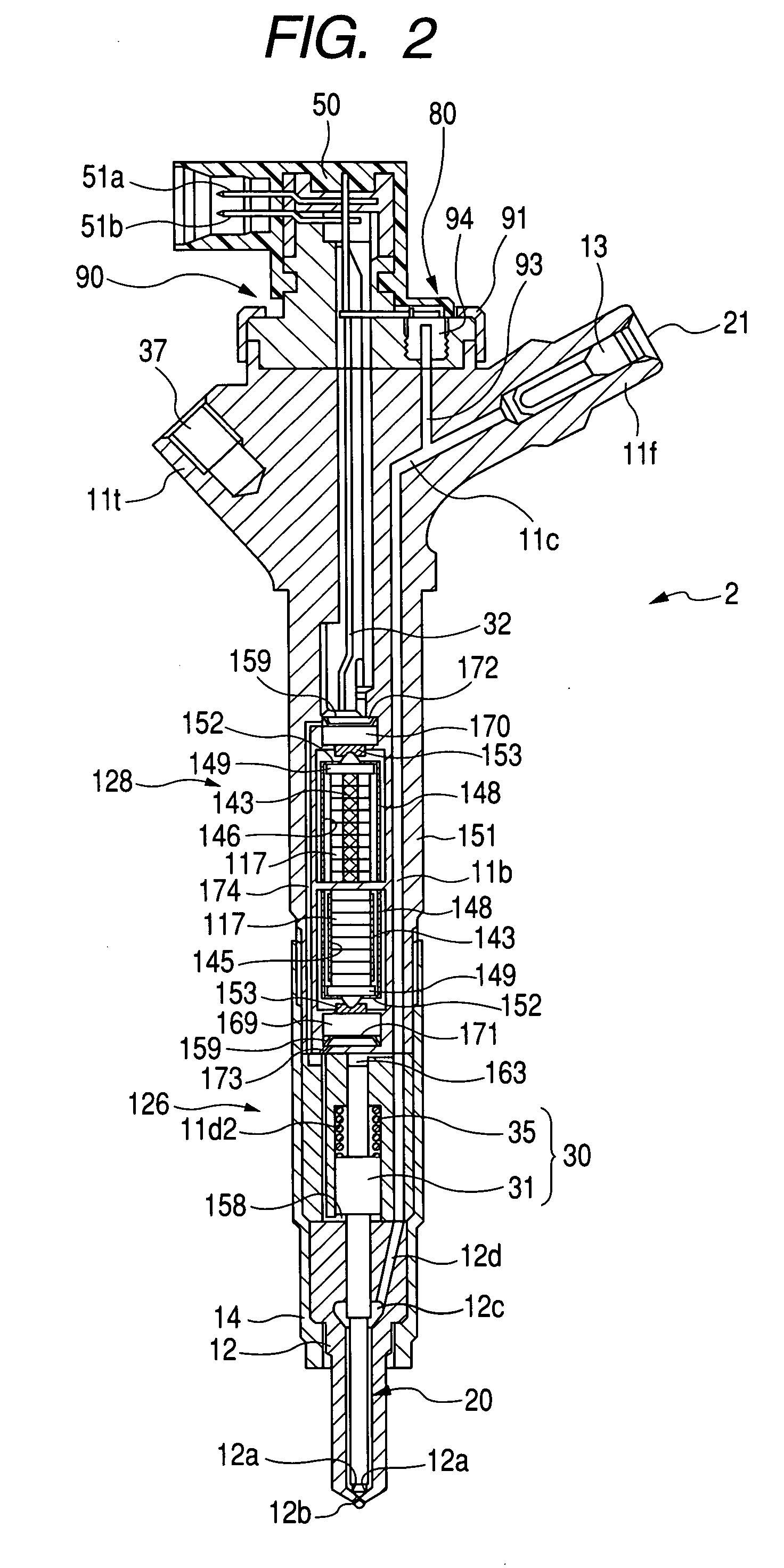

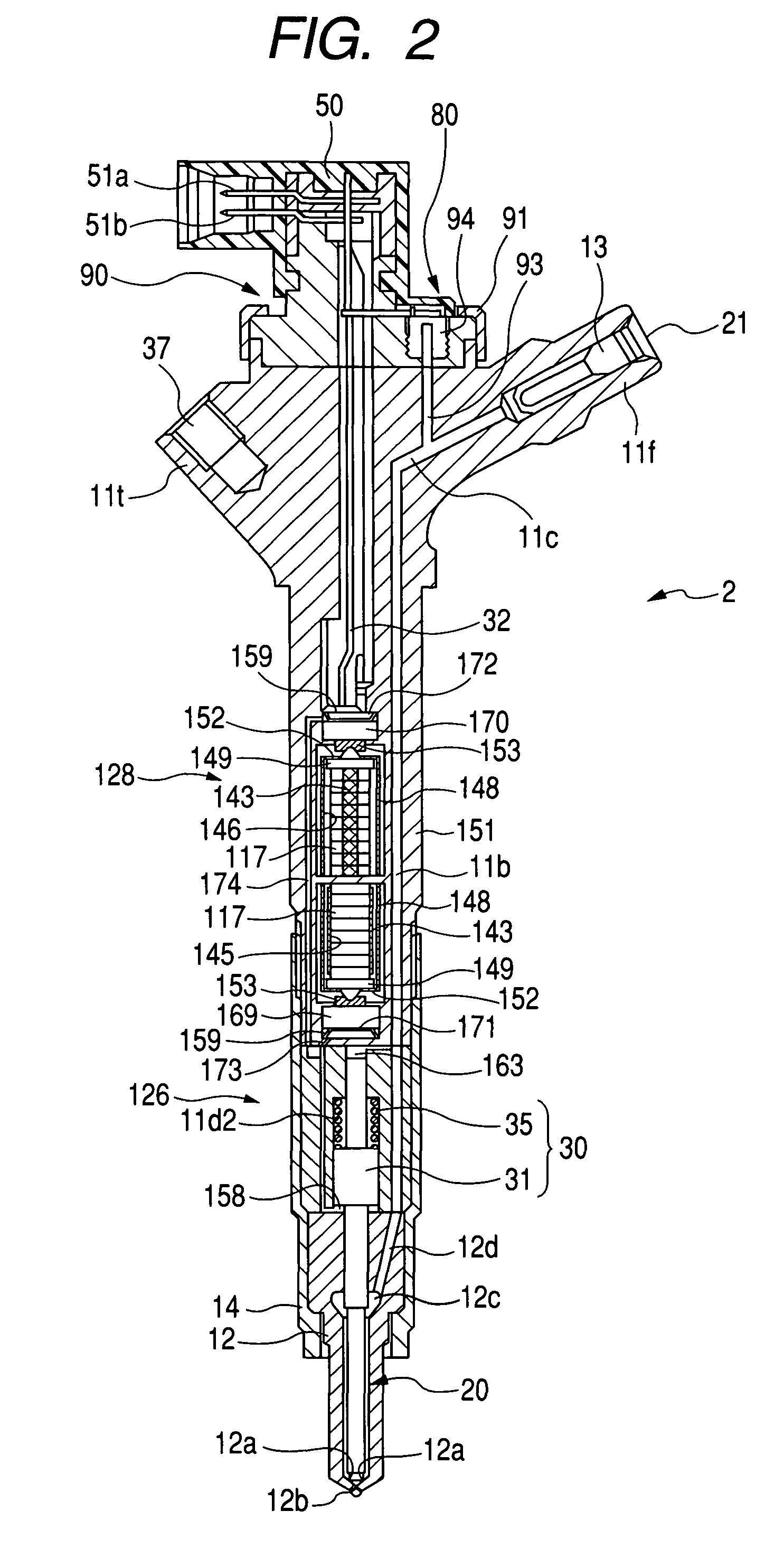

Fuel injector with fuel pressure sensor

ActiveUS20100096480A1Improve productivityGuaranteed accuracyInternal-combustion engine testingSpray nozzlesInjectorProduction rate

A fuel injector which may be employed in injecting fuel into an internal combustion engine. The fuel injector includes an injector body and a head body formed to be separate from the injector body. The head body has installed therein a fuel pressure sensor working to measure the pressure of fuel in the fuel injector and is joined detachably to the injector body. The fuel injector alternatively includes an injector body and a fuel pressure-sensing unit equipped with a fuel pressure sensor. The fuel pressure-sensing unit is installed detachably on the injector body. This structure provides enhanced productivity of the fuel injector and facilitate the ease of replacement of the fuel pressure sensor.

Owner:DENSO CORP

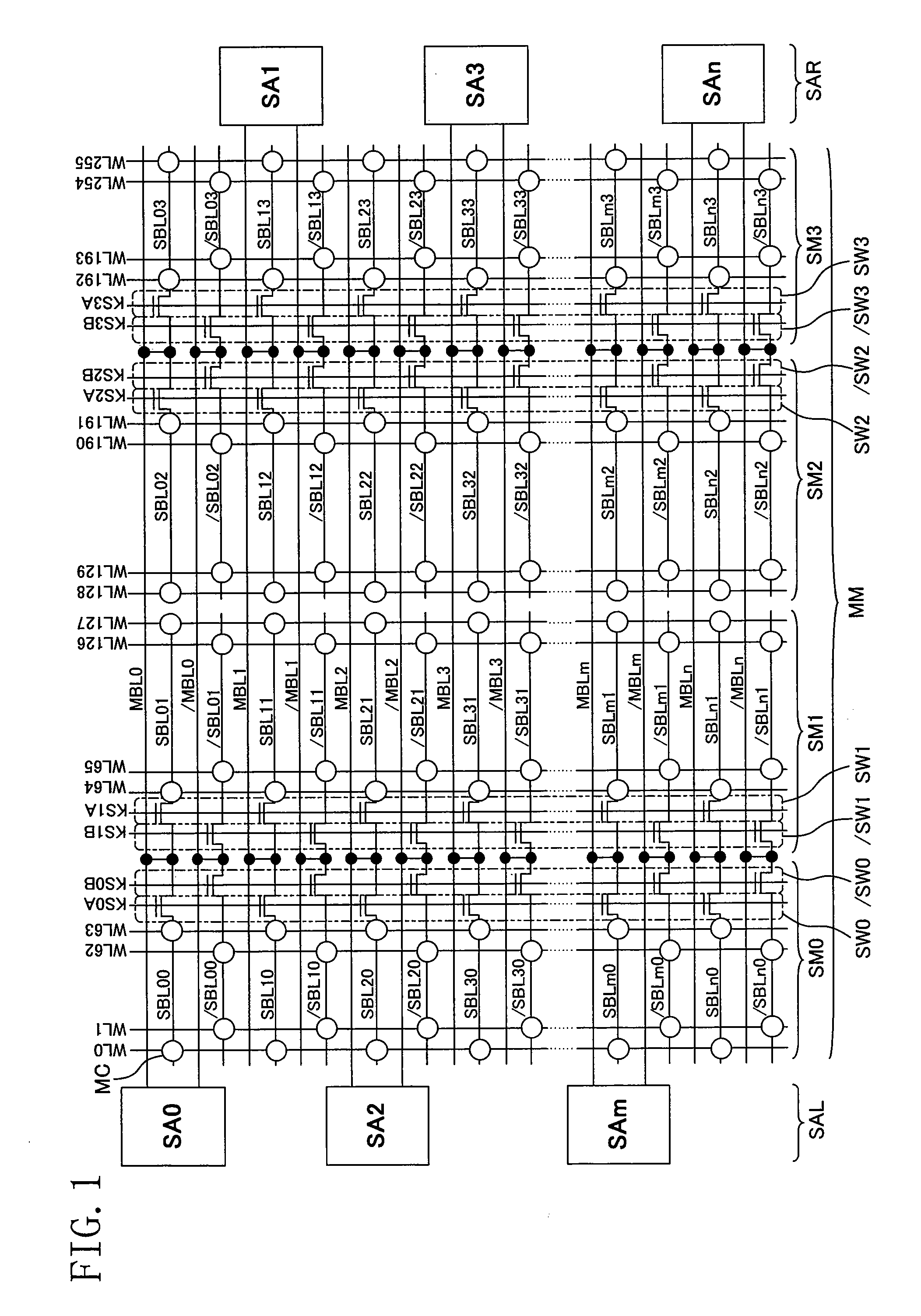

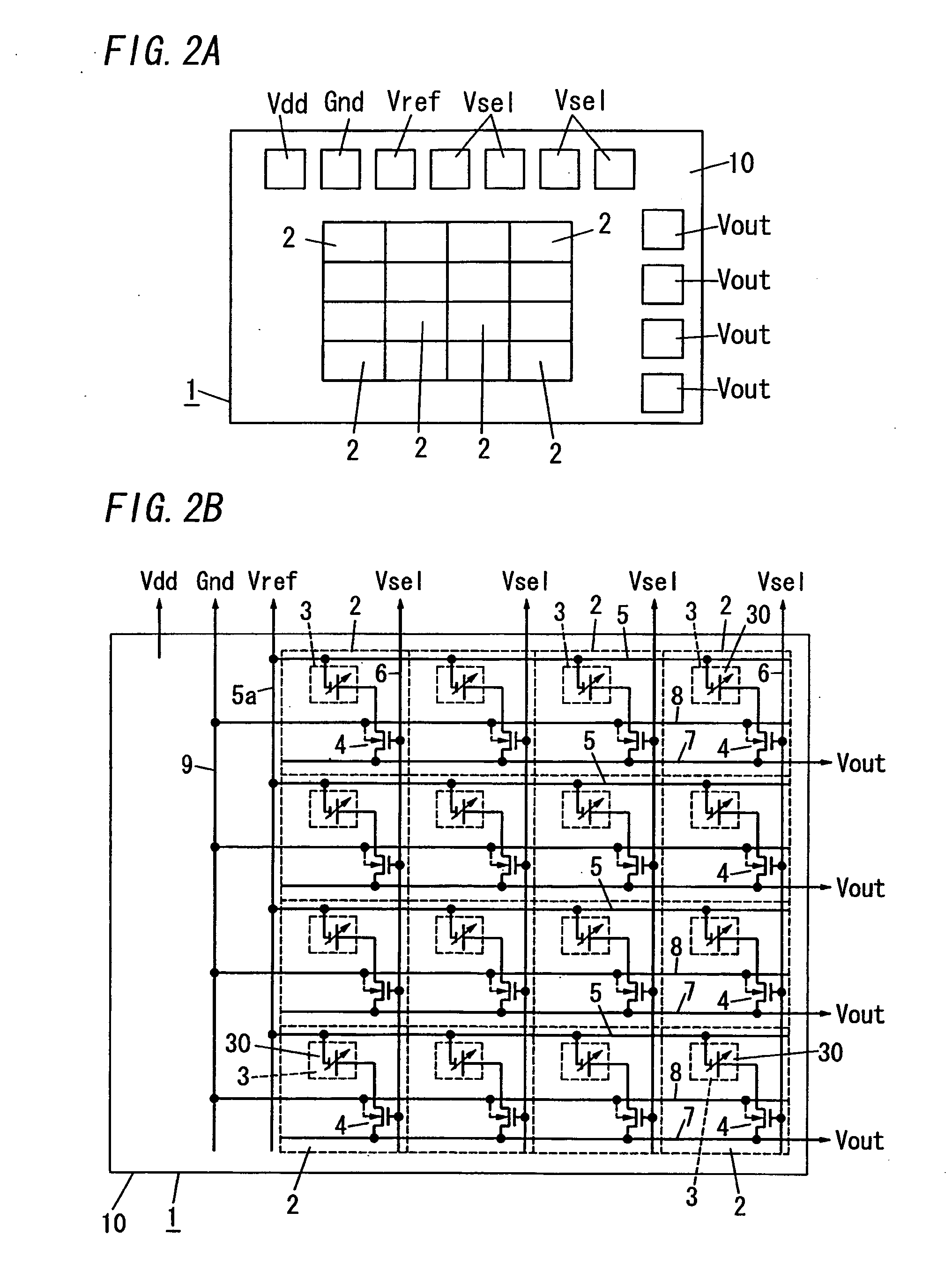

Semiconductor storage device

ActiveUS20090135639A1Enhance uniformityLayout area be reduceSolid-state devicesDigital storageStorage cellSemiconductor memory

In a semiconductor storage device, either two memory cell gates TG or a memory cell gate TG and a bit-line connecting gate SW are formed in every set of n-type doped regionsOOD at the intersections with word lines WL or bit-line selecting lines KS. A portion near the center of the set of n-type doped regions OD serves as a source / drain region shared by two gates, whereas portions near both ends thereof serve as source / drain regions for respective gates. Each of the source / drain regions is connected to a storage electrode SN of a memory cell capacitor via a storage contact CA or is connected to a sub bit line or a main bit line via a sub-bit-line contact CH and / or a via of a metal interconnection. A pattern formed of four memory cell gates TG and four bit-line connecting gates SW is repeated.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

Solar cell module and method of manufacturing the same

ActiveUS20090194144A1Avoid failureAvoid defectsPV power plantsSemiconductor/solid-state device manufacturingEngineeringSolar cell

Owner:SANYO ELECTRIC CO LTD

Heat-resistant adhesive sheet for substrateless semiconductor package fabrication and method for fabricating substrateless semiconductor package using the adhesive sheet

InactiveUS20110151625A1Fabrication yield can be improvedReduce pollutionSemiconductor/solid-state device detailsSolid-state devicesAdhesion strengthSemiconductor chip

The present invention is intended to solve the following problems with a method for fabricating a substrateless semiconductor package using an adhesive sheet as a temporary fixing supporter. A chip can be displaced from a specified position by pressure during resin encapsulation because the chip is not properly held by the adhesive sheet. If such displacement occurs, the relative positional relationship between the chip and an interconnect to be connected to a specified position in a subsequent wiring step also changes by the displacement of the chip from the specified position. Another problem is that if adhesive deposits occur during peeling of the adhesive sheet and the surface of a package is contaminated with the adhesive deposits, adhesive components left on the surface of the chip can inhibit connection between the interconnect and the chip in a subsequent wiring step. To solve these problems, the present invention provides an adhesive sheet for semiconductor device fabrication that is attached to a substrateless semiconductor chip when the chip is encapsulated with resin. The adhesive sheet includes a base material layer and an adhesive layer. The adhesive layer has a specific adhesion strength and peel strength.

Owner:NITTO DENKO CORP

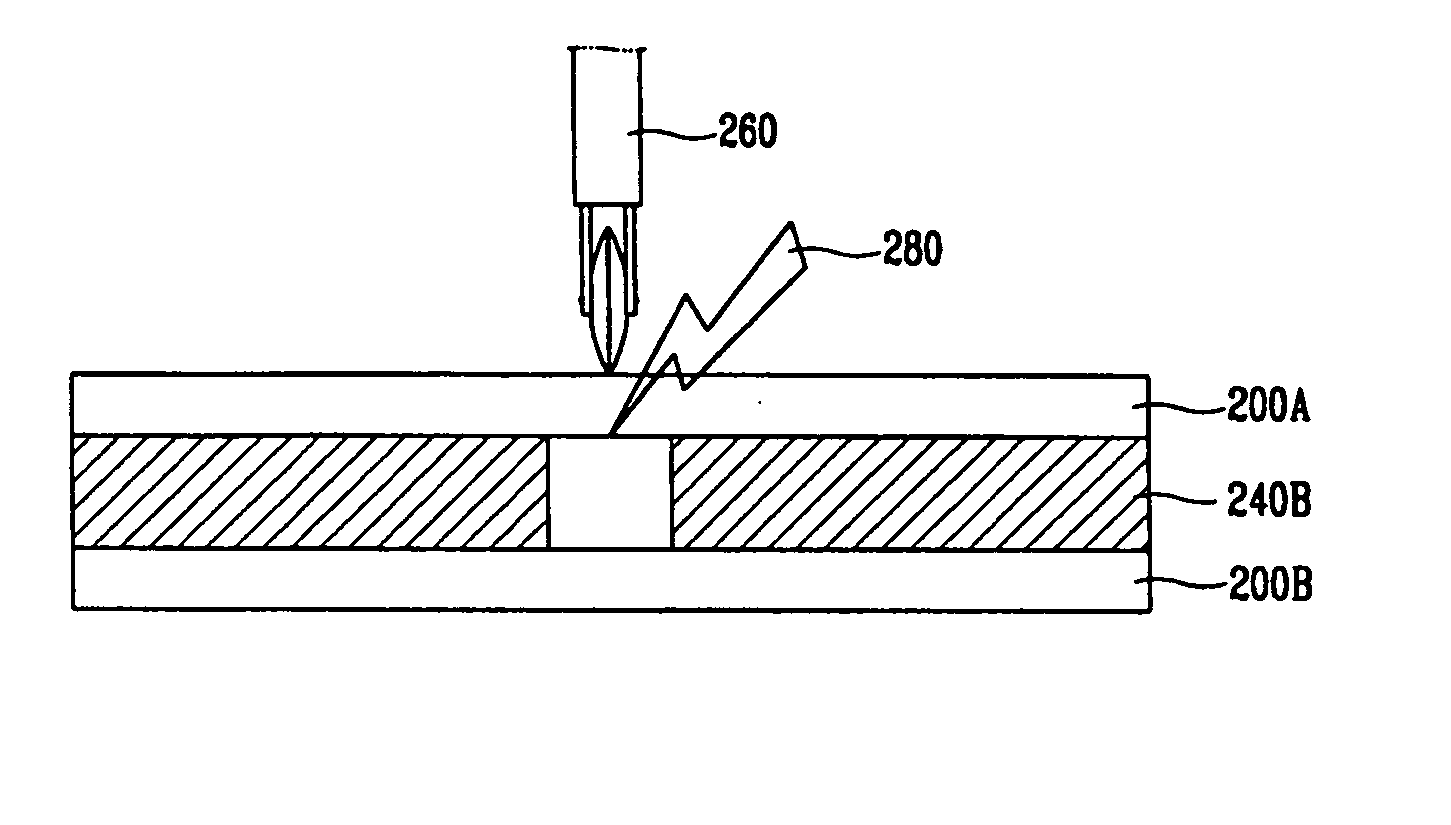

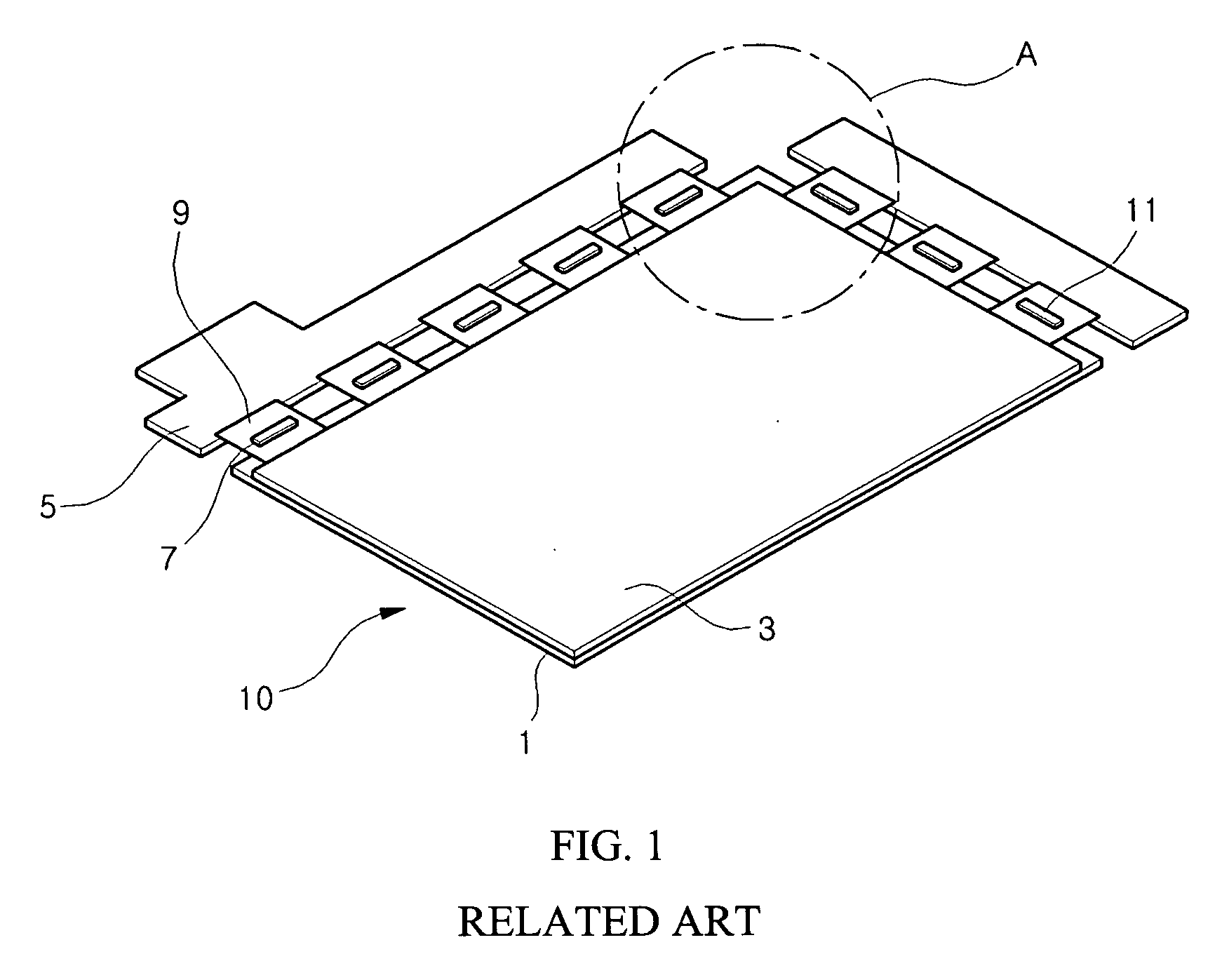

Method for cutting liquid crystal display panel

ActiveUS20050118921A1Evenly brokenFabrication yield can be improvedVessels or leading-in conductors manufactureFine working devicesLiquid-crystal displayEngineering

A method for cutting a liquid crystal display panel includes providing first and second mother substrates, forming a scribing line on the first and second mother substrates, removing a portion of a seal line being overlapped with the scribing line, the seal line formed on one of the first and second mother substrates, and dividing the first and second mother substrates into a plurality of unit liquid crystal display panels along the scribing line.

Owner:LG DISPLAY CO LTD

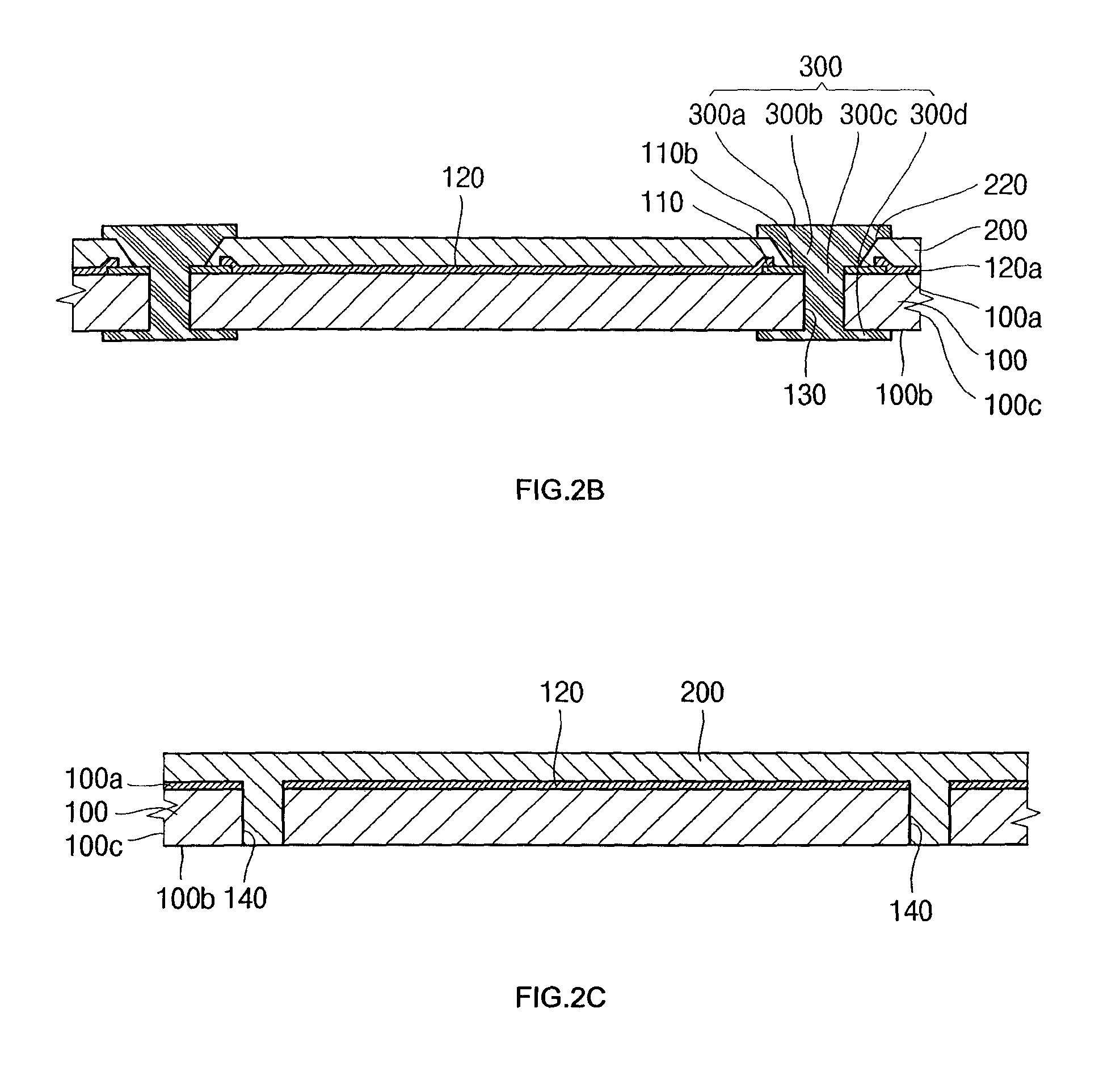

Infrared Sensor

InactiveUS20110175145A1Avoid breakingFabrication yield can be improvedPhotometrySolid-state devicesInfraredThermal insulation

The infrared sensor (1) includes a base (10), and an infrared detection element (3) formed over a surface of the base (10). The infrared detection element (3) includes an infrared absorption member (33) in the form of a thin film configured to absorb infrared, a temperature detection member (30) configured to measure a temperature difference between the infrared absorption member (33) and the base (10), and a safeguard film (39). The infrared element (3) is spaced from the surface of the base (10) for thermal insulation. The temperature detection member (30) includes a p-type polysilicon layer (35) formed over the infrared absorption member (33) and the base (10), an n-type polysilicon layer (34) formed over the infrared absorption member (33) and the base (10) without contact with the p-type polysilicon layer (35), and a connection layer (36) configured to electrically connect the p-type polysilicon layer (35) to the n-type polysilicon layer (34). The safeguard film (39) is a polysilicon layer formed on an infrared incident surface defined as an opposite surface of the infrared absorption member (33) from the base (10) to cover the infrared incident surface.

Owner:PANASONIC CORP

Fuel injector with fuel pressure sensor

ActiveUS8100344B2Improve productivityDesired accuracy in measuring the pressure of fuelEngine testingSpray nozzlesProduction ratePressure sense

A fuel injector which may be employed in injecting fuel into an internal combustion engine. The fuel injector includes an injector body and a head body formed to be separate from the injector body. The head body has installed therein a fuel pressure sensor working to measure the pressure of fuel in the fuel injector and is joined detachably to the injector body. The fuel injector alternatively includes an injector body and a fuel pressure-sensing unit equipped with a fuel pressure sensor. The fuel pressure-sensing unit is installed detachably on the injector body. This structure provides enhanced productivity of the fuel injector and facilitate the ease of replacement of the fuel pressure sensor.

Owner:DENSO CORP

Heat-resistant adhesive sheet for semiconductor device fabrication, adhesive used for the sheet, and method for fabricating semiconductor device using the sheet

InactiveUS20110143552A1Fabrication yield can be improvedReduced flexibilityLayered productsFilm/foil adhesivesEpoxyDevice material

The present invention provides a heat-resistant adhesive sheet for semiconductor device fabrication that is attached to a substrateless semiconductor chip when the chip is encapsulated with resin. The adhesive sheet includes a base material layer and an adhesive layer. The adhesive layer contains a rubber component and an epoxy resin component. The proportion of the rubber component in an organic substance in the adhesive is in the range of 20 to 60 wt %.

Owner:NITTO DENKO CORP

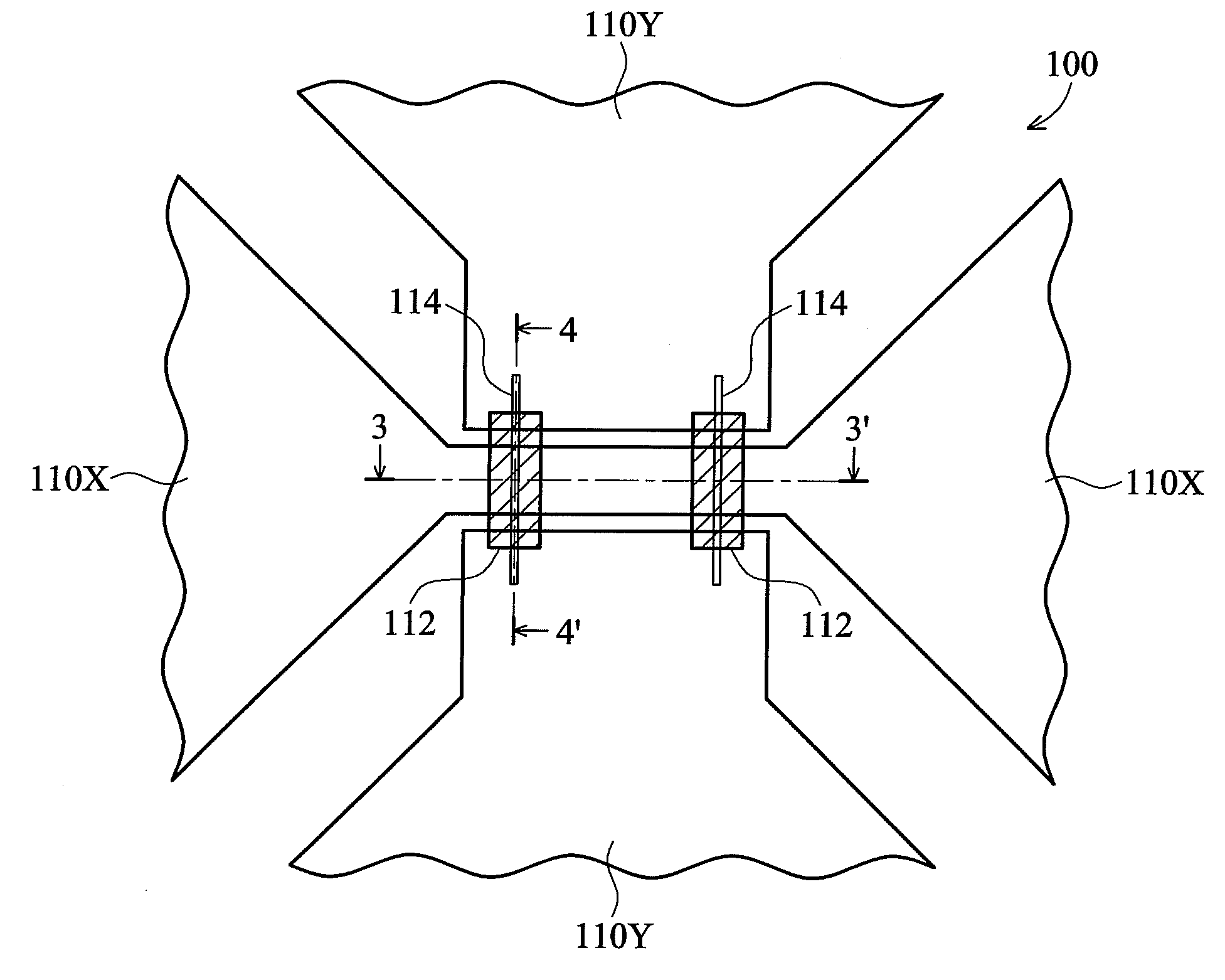

Touch display device

InactiveUS20120319990A1Fabrication yield can be improvedSimple structureInput/output processes for data processingDisplay deviceComputer science

A touch display device is provided. The touch display device includes a touch panel disposed on a display panel. The touch panel includes a plurality of first conductive patterns arranged along a first direction, wherein the first conductive patterns are separated from each other. A plurality of second conductive patterns is arranged along a second direction perpendicular to the first direction, wherein the second conductive patterns are connected with each other. An isolation structure is disposed between any two adjacent first conductive patterns. A plurality of conductive bridge structures is disposed on the isolation structure for electrically connecting any two adjacent first conductive patterns.

Owner:HANNSTAR DISPLAY CORPORATION

Method for manufacturing wiring board

ActiveUS20140182126A1Improve productivitySection is preventedSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorMetal foil

A method for manufacturing a wiring board according to the present invention includes the steps of preparing a supporting substrate having a product forming region and a marginal region; preparing a separable metal foil whose area is larger than that of the product forming region and is smaller than that of the supporting substrate; fixing the separable metal foil to the supporting substrate by burying into the supporting substrate; forming a build-up section on the buried separable metal foil; integrally cutting out the supporting substrate, the separable metal foil and the build-up section; obtaining a laminated body for wiring board composed of the second metal foil and the build-up section by separating the first metal foil and the second metal foil; and forming the wiring conductor layer by removing a part of the second metal foil.

Owner:KYOCERA CORP

Driving circuit and liquid crystal display device including the same

ActiveUS20070284763A1Easy alignmentImprove picture qualitySemiconductor/solid-state device detailsPrinted circuit aspectsLiquid-crystal displayEngineering

A tape carrier package (TCP) includes a film, a plurality of output leads and a plurality of input leads on the film, the plurality of output leads and the plurality of input leads being disposed on different sides, first and second TCP alignment marks arranged on opposing sides of the plurality of output leads, and a third TCP alignment mark at a central portion of the plurality of output leads.

Owner:LG DISPLAY CO LTD

Manufacturing method for semiconductor devices

InactiveUS8017440B2Improve reliabilityFabrication yield can be improvedSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

The reliability of a semiconductor device is enhanced. A first lead frame, a first semiconductor chip, a second lead frame, and a second semiconductor chip are stacked over an assembly jig in this order with solder in between and solder reflow processing is carried out to fabricate their assembly. Thereafter, this assembly is sandwiched between first and second molding dies to form an encapsulation resin portion. The upper surface of the second die is provided with steps. At a molding step, the second lead frame is clamped between the first and second dies at a position higher than the first lead frame; and a third lead frame is clamped between the first and second dies at a higher position. The assembly jig is provided with steps at the same positions as those of the steps in the upper surface of the second die in positions corresponding to those of the same.

Owner:RENESAS ELECTRONICS CORP

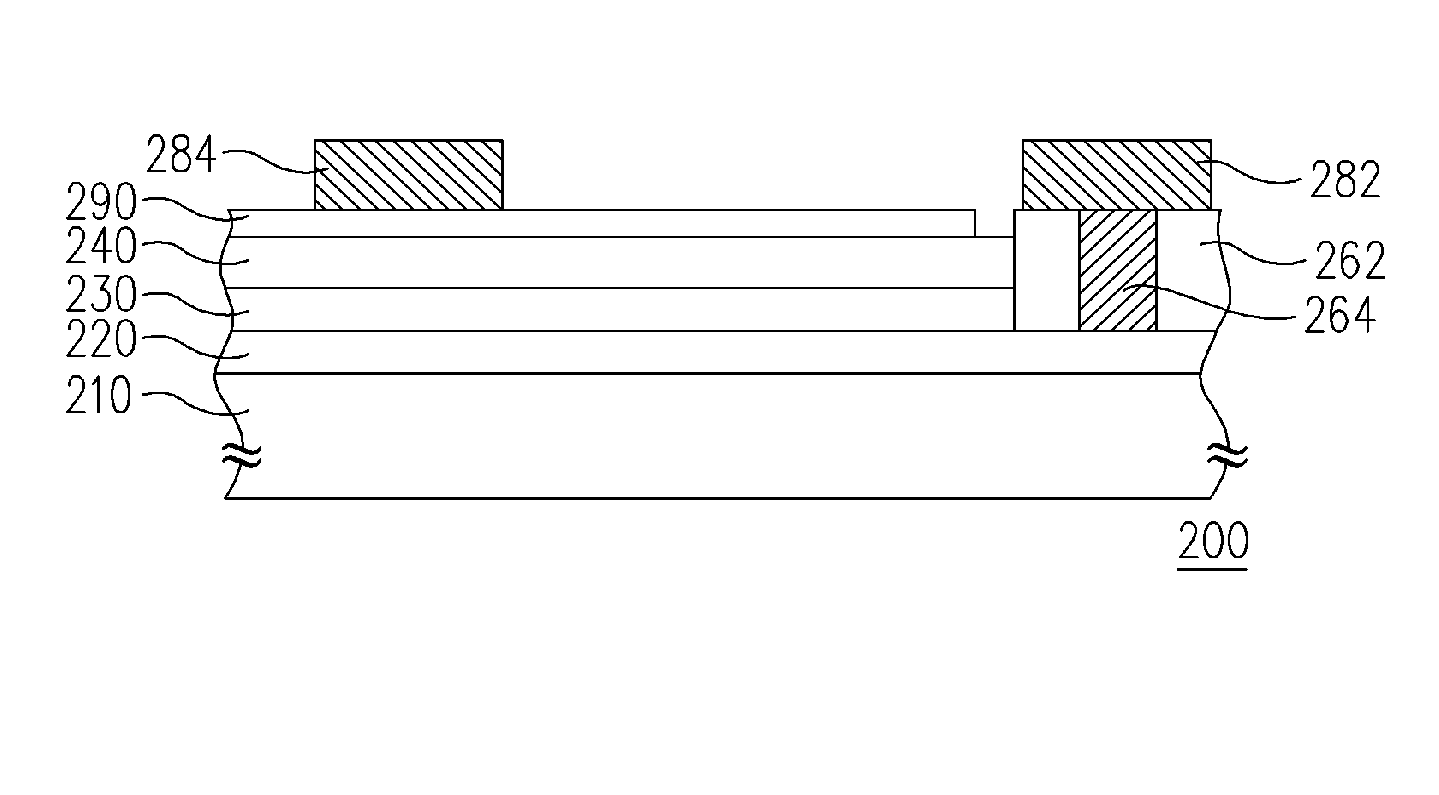

Light emitting diode and fabricating method thereof

InactiveUS20080121907A1Increase the light areaAdded fabricationSemiconductor devicesLight-emitting diodeDielectric layer

An LED includes a substrate, a first type doping semiconductor layer, a first electrode, a light emitting layer, a second type doping semiconductor layer, a second electrode, a first dielectric layer and a first conductive plug. The first type doping semiconductor layer is formed on the substrate, and the light emitting layer, the second type doping semiconductor layer and the second electrode are formed on a portion of the first type doping semiconductor layer in sequence. The first dielectric layer is formed on another portion of the first type doping semiconductor layer where is not covered by the light emitting layer. The first electrode formed on the first dielectric layer is electrically connected with the first type doping semiconductor layer through the first conductive plug formed in the first dielectric layer. Furthermore, the second electrode is electrically connected with the second type doping semiconductor layer.

Owner:FORMOSA EPITAXY INCORPORATION

Semiconductor packages and methods of manufacturing semiconductor packages

InactiveUS20130256916A1Fabrication yield can be improvedReduce manufacturing costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductor chipSemiconductor package

A semiconductor package including a mounting substrate, a first semiconductor chip mounted on an upper surface of the mounting substrate, a unit package stacked on the first semiconductor chip may be provided. The unit package includes a package substrate and a second semiconductor chip mounted on the package substrate. A plurality of bonding wires connects bonding pads of the mounting substrate and connection pads of the unit package, thereby electrically connecting the first and second semiconductor chips to each other. A molding member is provided on the mounting substrate to cover the first semiconductor chip and the unit package.

Owner:SAMSUNG ELECTRONICS CO LTD

Heat-resistant adhesive sheet for substrateless semiconductor package fabrication and method for fabricating substrateless semiconductor package using the adhesive sheet

InactiveUS8436481B2Fabrication yield can be improvedReduce pollutionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

The present invention is intended to solve the following problems with a method for fabricating a substrateless semiconductor package using an adhesive sheet as a temporary fixing supporter. A chip can be displaced from a specified position by pressure during resin encapsulation because the chip is not properly held by the adhesive sheet. If such displacement occurs, the relative positional relationship between the chip and an interconnect to be connected to a specified position in a subsequent wiring step also changes by the displacement of the chip from the specified position. Another problem is that if adhesive deposits occur during peeling of the adhesive sheet and the surface of a package is contaminated with the adhesive deposits, adhesive components left on the surface of the chip can inhibit connection between the interconnect and the chip in a subsequent wiring step. To solve these problems, the present invention provides an adhesive sheet for semiconductor device fabrication that is attached to a substrateless semiconductor chip when the chip is encapsulated with resin. The adhesive sheet includes a base material layer and an adhesive layer. The adhesive layer has a specific adhesion strength and peel strength.

Owner:NITTO DENKO CORP

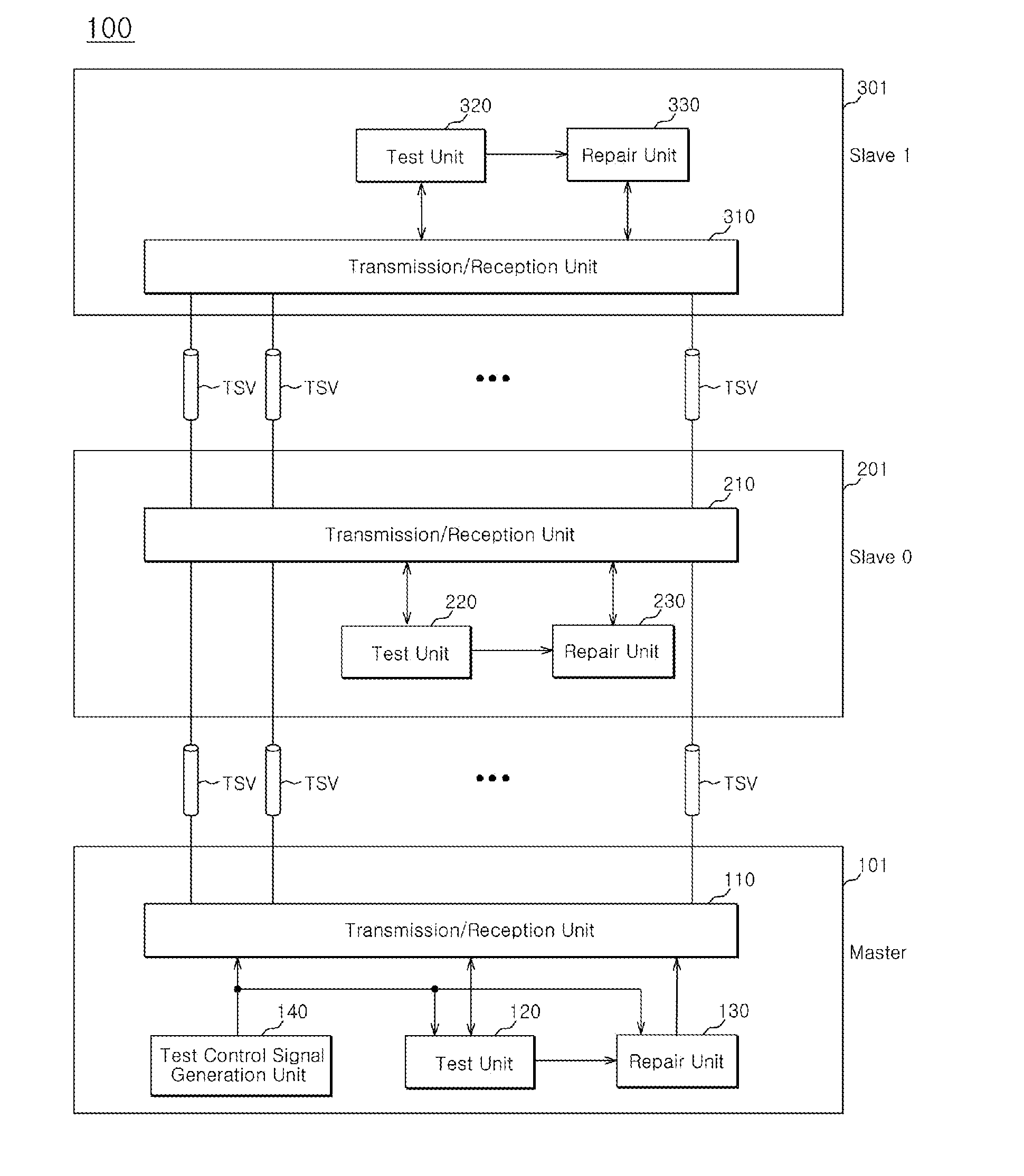

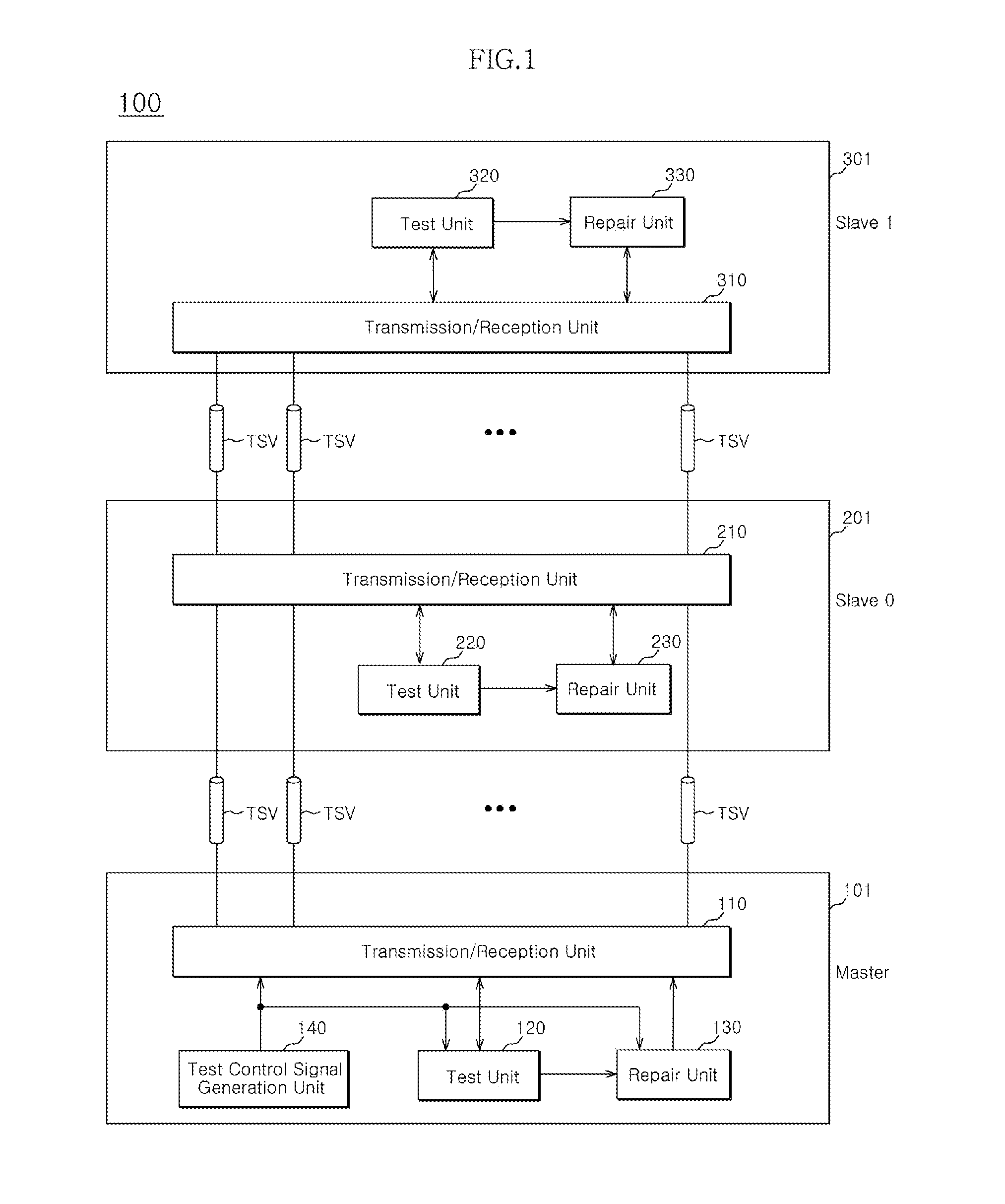

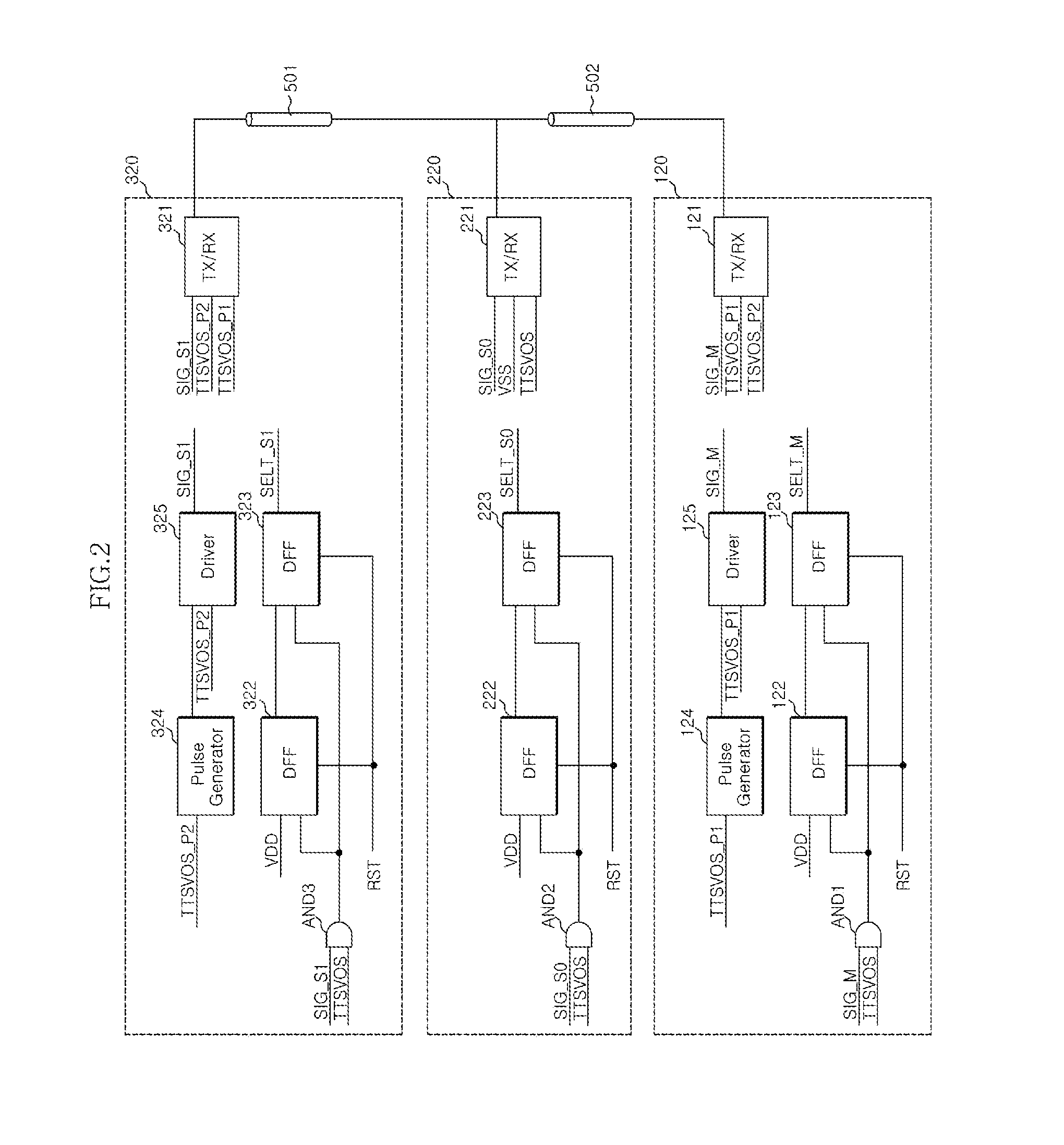

Semiconductor integrated circuit

ActiveUS20130207685A1Fabrication yield can be improvedReduce repairSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductor chipEngineering

A semiconductor integrated circuit includes a plurality of semiconductor chips coupled to one another through vias, wherein a lowermost semiconductor chip of the plurality of semiconductor chips is configured to generate a first test pulse signal and transmit the first test pulse signal through the via, an uppermost semiconductor chip of the plurality of semiconductor chips is configured to generate a second test pulse signal while substantially maintaining a time difference with the first test pulse signal, and to transmit the second test pulse signal through the via, and the plurality of semiconductor chips are configured to generate test result signals for determining whether the vias are defective in response to the first test pulse signal and the second test pulse signal.

Owner:SK HYNIX INC

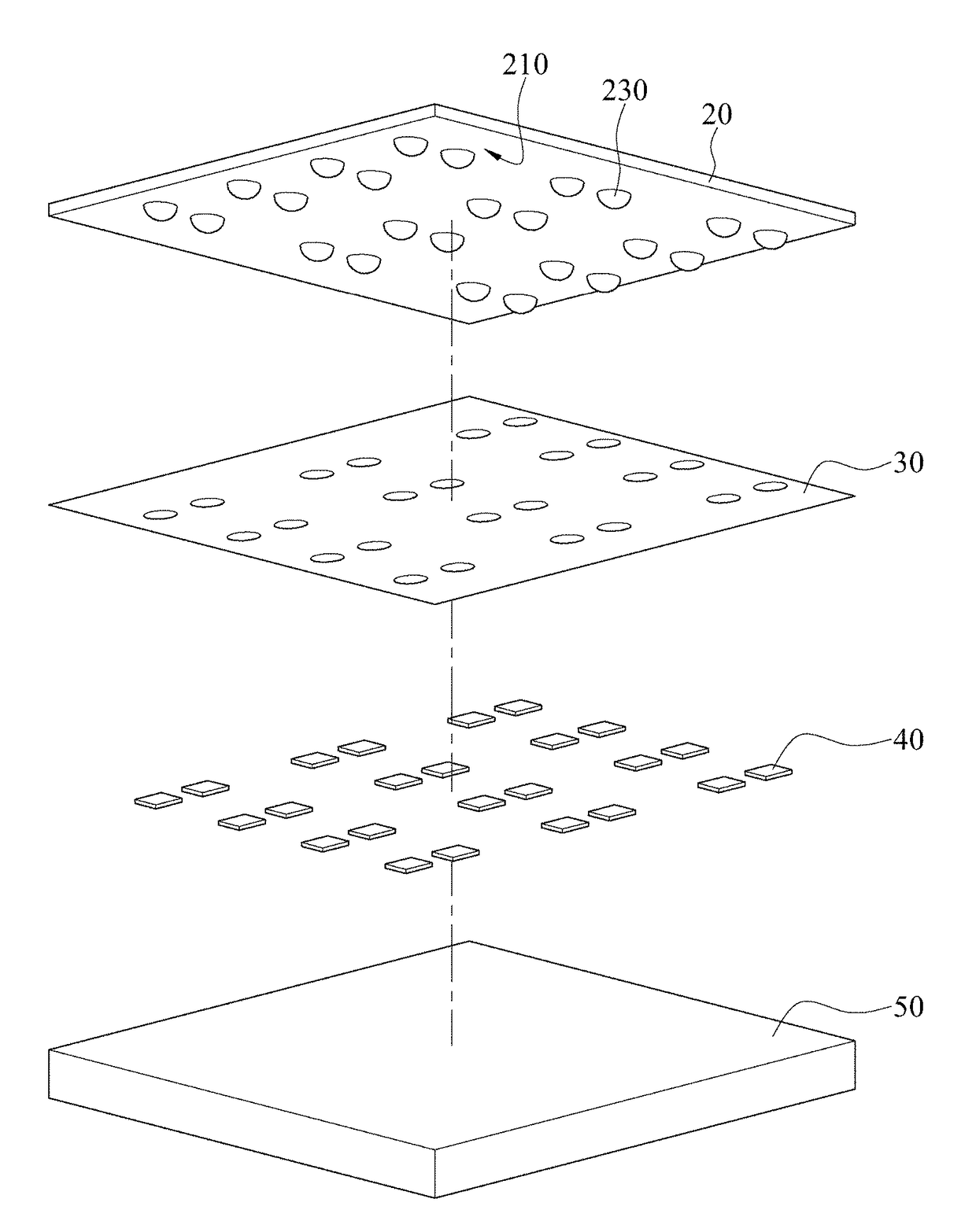

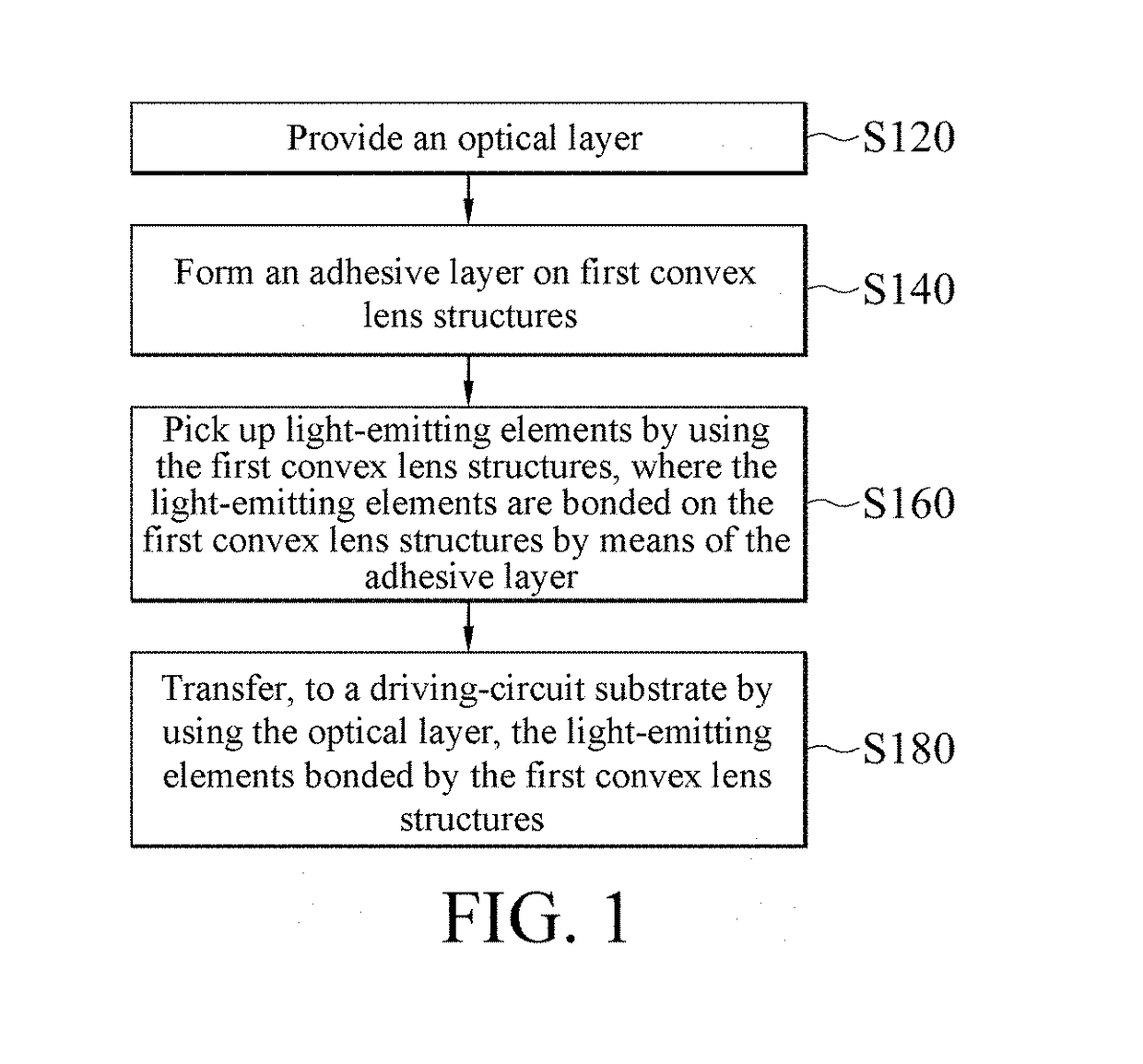

Electronic device and method for fabricating the same

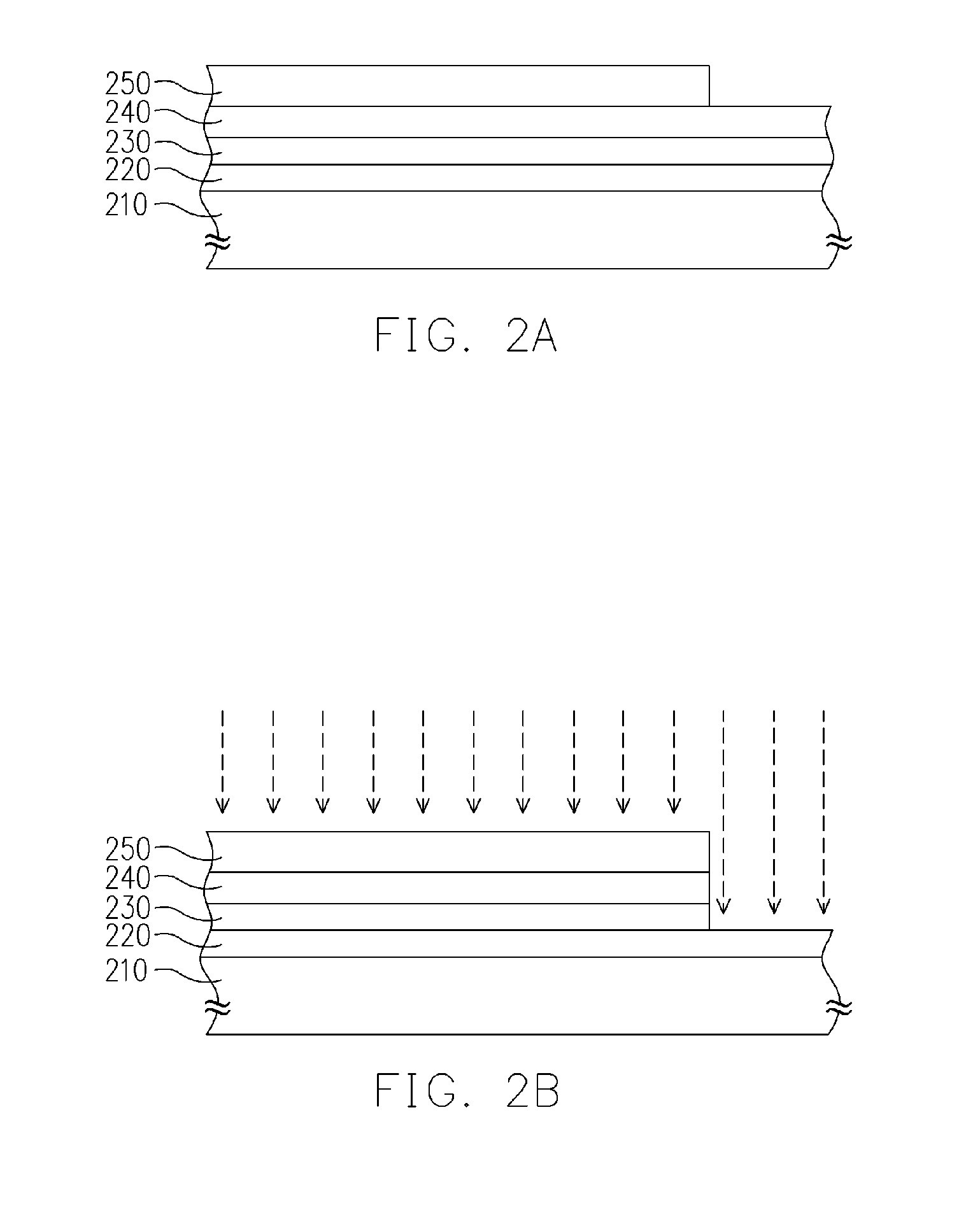

ActiveUS20180114886A1Fabrication yield be improveImprove efficiencyPlanar light sourcesSolid-state devicesEngineeringOptical layer

The present invention provides an electronic device and a method for fabricating the same. The electronic device includes a driving-circuit substrate, light-emitting elements, an optical layer, and an adhesive layer. The light-emitting elements are disposed on the driving-circuit substrate, and the optical layer is disposed on the light-emitting elements. The adhesive layer is disposed between the optical layer and the light-emitting elements. The optical layer includes a first surface and a second surface that are opposite to each other. The first surface of the optical layer has a plurality of first convex lens structures, and at least a part of the first convex lens structures are at least partially overlapped with the light-emitting elements in the vertical projection direction.

Owner:AU OPTRONICS CORP

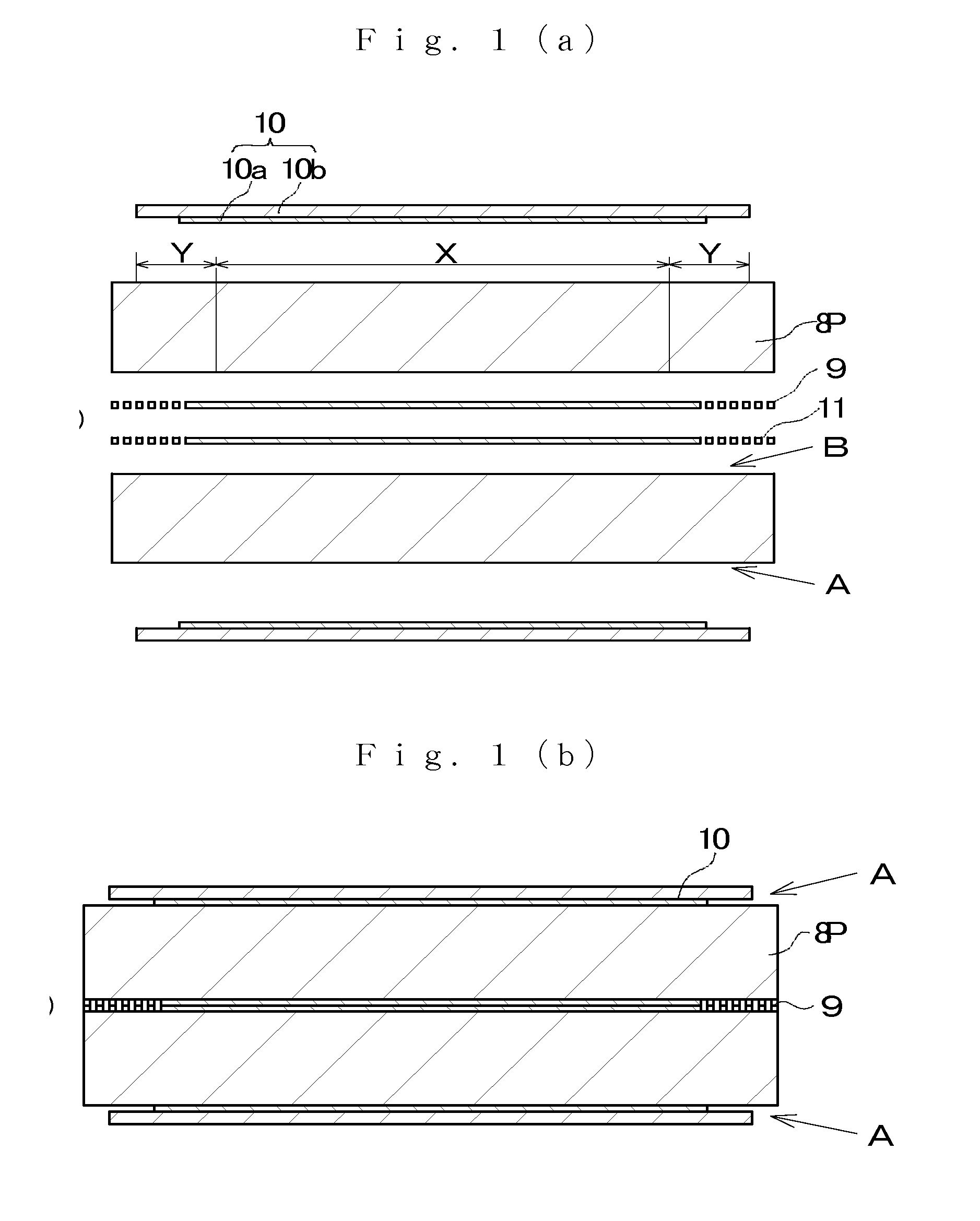

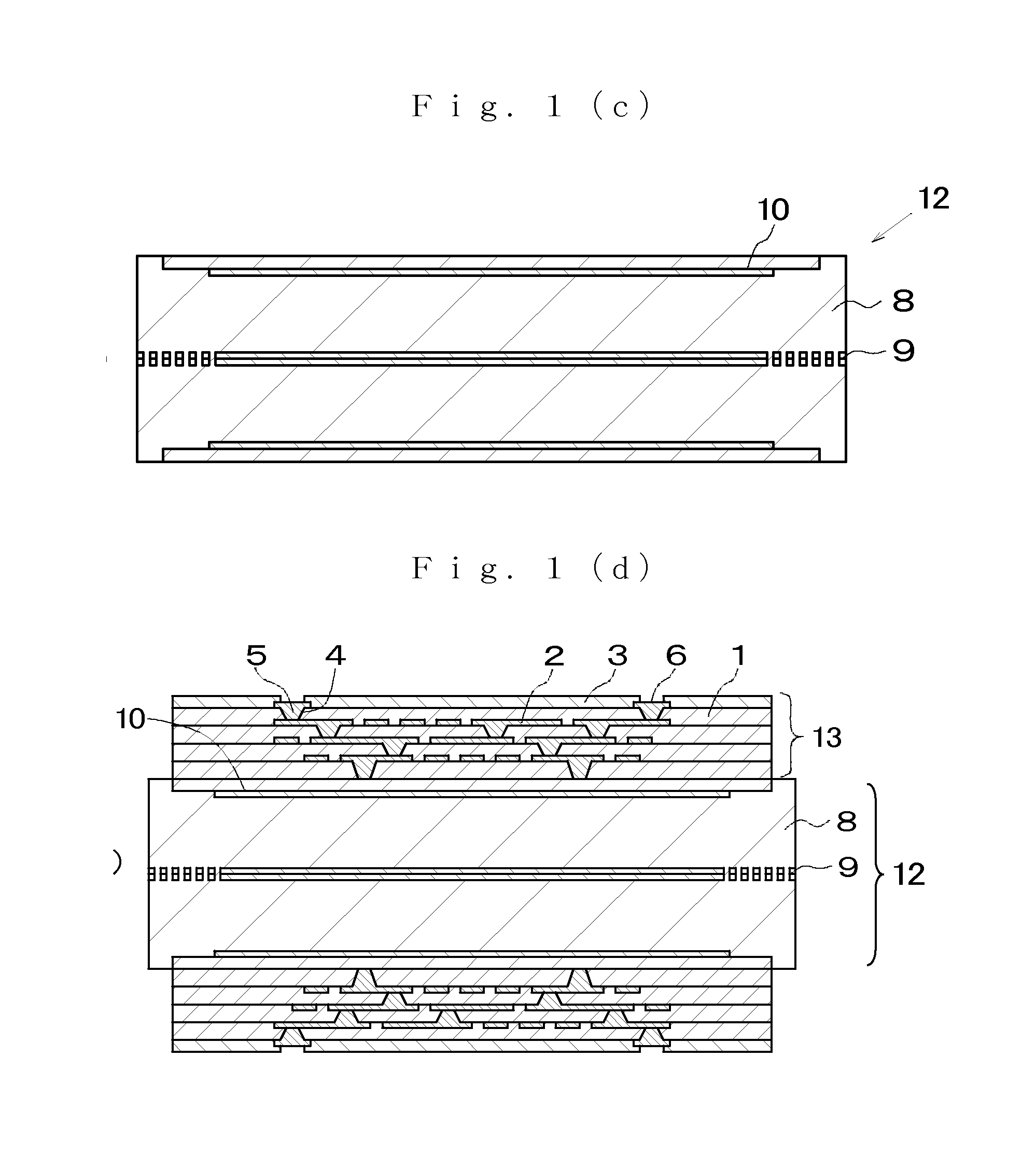

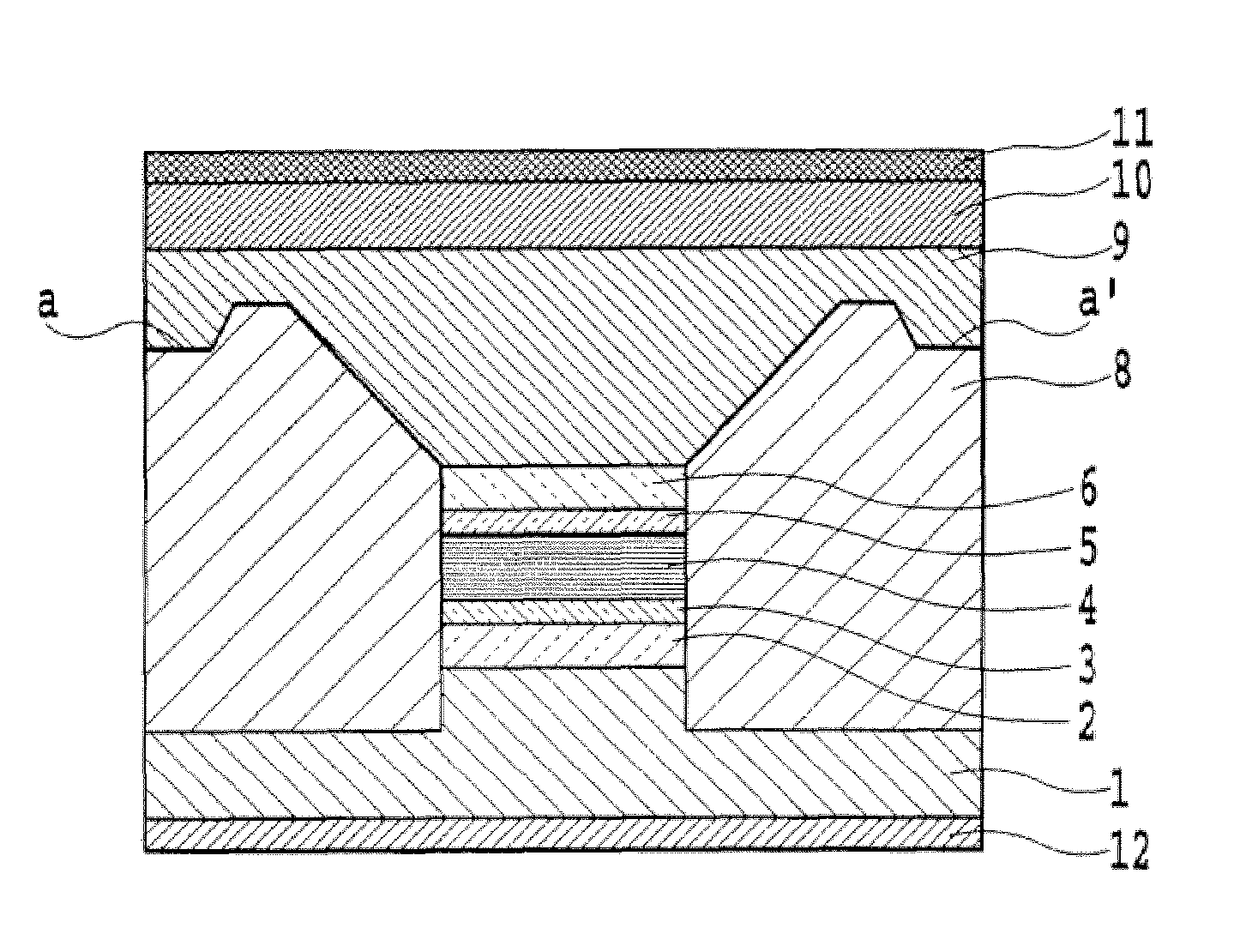

Semiconductor Optical Element and Manufacturing Method Thereof

ActiveUS20080137703A1Improve device characteristicsFabrication yield can be improvedLaser detailsLaser optical resonator constructionEngineeringContact layer

In order to provide excellent device characteristics and enhance fabrication yield and run-to-run reproducibility in a buried device structure using a low mesa on a p-type substrate, a cross sectional configuration before growth of a contact layer of a device, i.e., after growth of an over-cladding layer is flattened so as not to cause a problem in crystal quality of the contact layer. A mesa-stripe stacked body including at least a p-type cladding layer (2), an active layer (4) and an n-type cladding layer (6) is formed on a p-type semiconductor substrate (1), a current-blocking layer (8) is buried in both sides of the stacked body, and an n-type over-cladding layer (9) and an n-type contact layer (10) are disposed on the current-blocking layer (8) and the stacked body. The n-type over-cladding layer (9) is made of a semiconductor crystal having a property for flattening a concavo-convex shape of upper surfaces of the current-blocking layer (8) and the stacked body.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com