Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Extended oil change interval" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

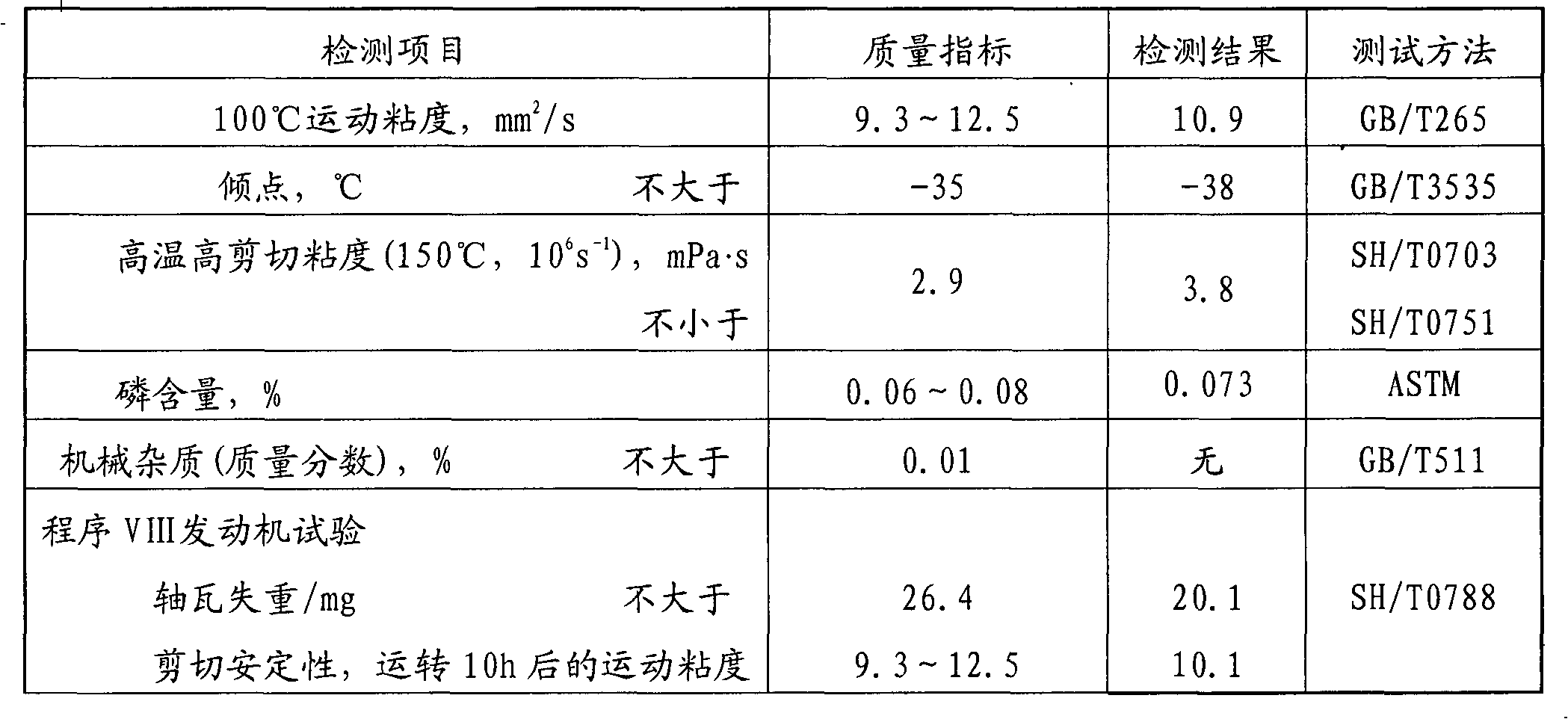

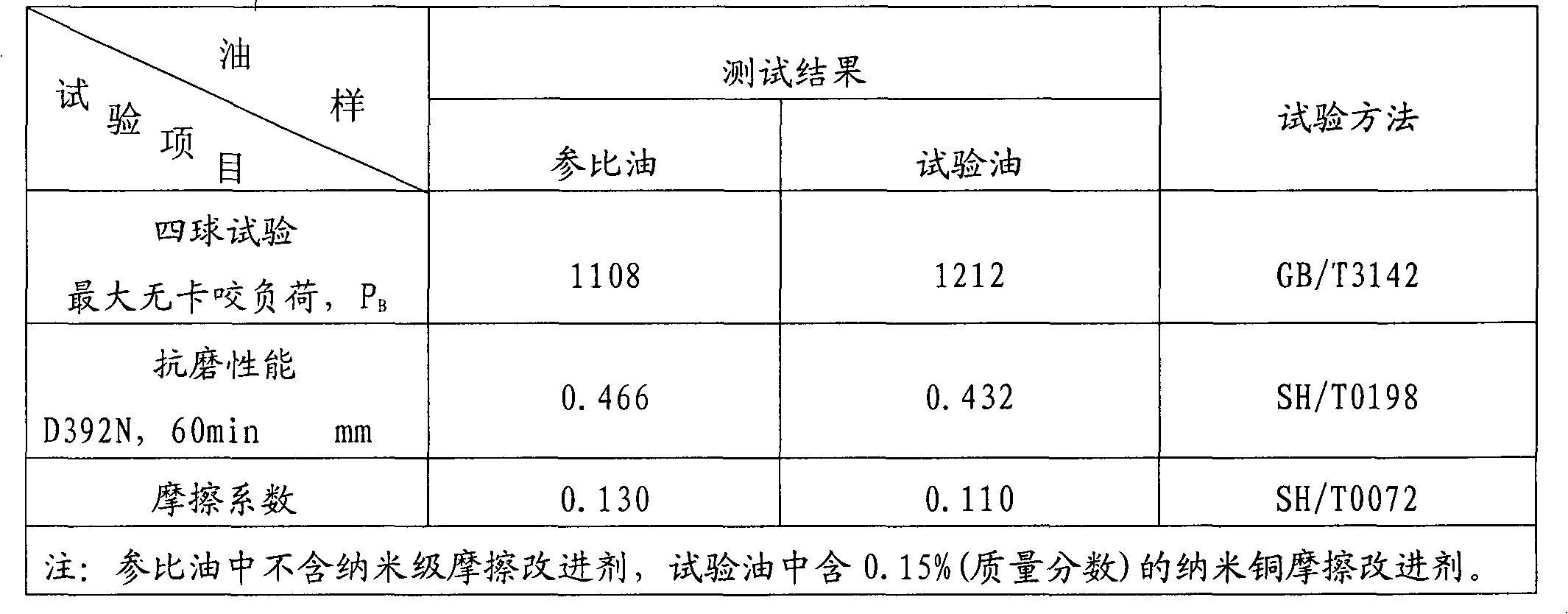

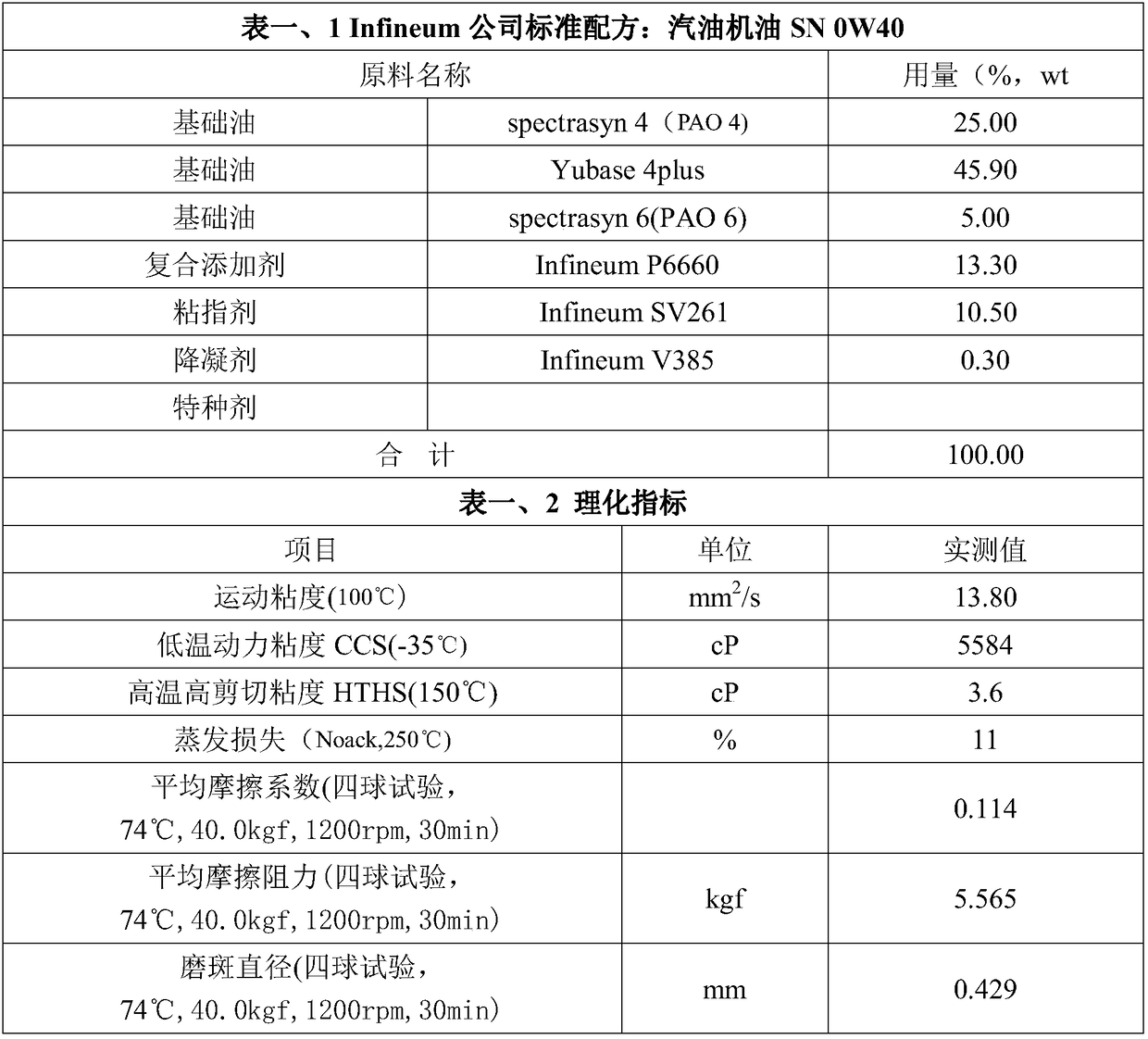

Energy-efficient long-life gasoline engine oil

InactiveCN101982534AReduce sulfur and phosphorus contentImprove carrying capacityLubricant compositionEcological environmentOil sludge

The invention discloses energy-efficient long-life gasoline engine oil prepared from the following components: synthetic base oil, a composite antioxygen, a metal cleaning agent, an ashless dispersant, a nano-level friction improver, a viscosity improver and a pour point reducer. The gasoline engine oil provided by the invention has the following advantages: requirements of API SM, ILSAC GF-4 and SAEJ300 are met and the service life is long; the complete synthetic base oil features low pour point, high viscosity index, good economy of fuel, degradability and reduced harm to the ecological environment; the phenol type antioxygen is combined with ZDDP, the anti-oxygen and antifriction properties are good and the catalyst poisoning in a tail gas processing unit is prevented; the acid neutralization capacity is good, the cleaning dispersibility is good and the oil sludge and carbon deposit are prevented from being generated; and the nano-level friction improver is added, the frictional factor is low, and the oil film features high carrying capacity and can automatically repair abraded surface and lengthen the service life of the engine.

Owner:GUANGDONG SANVO CHEM IND TECH

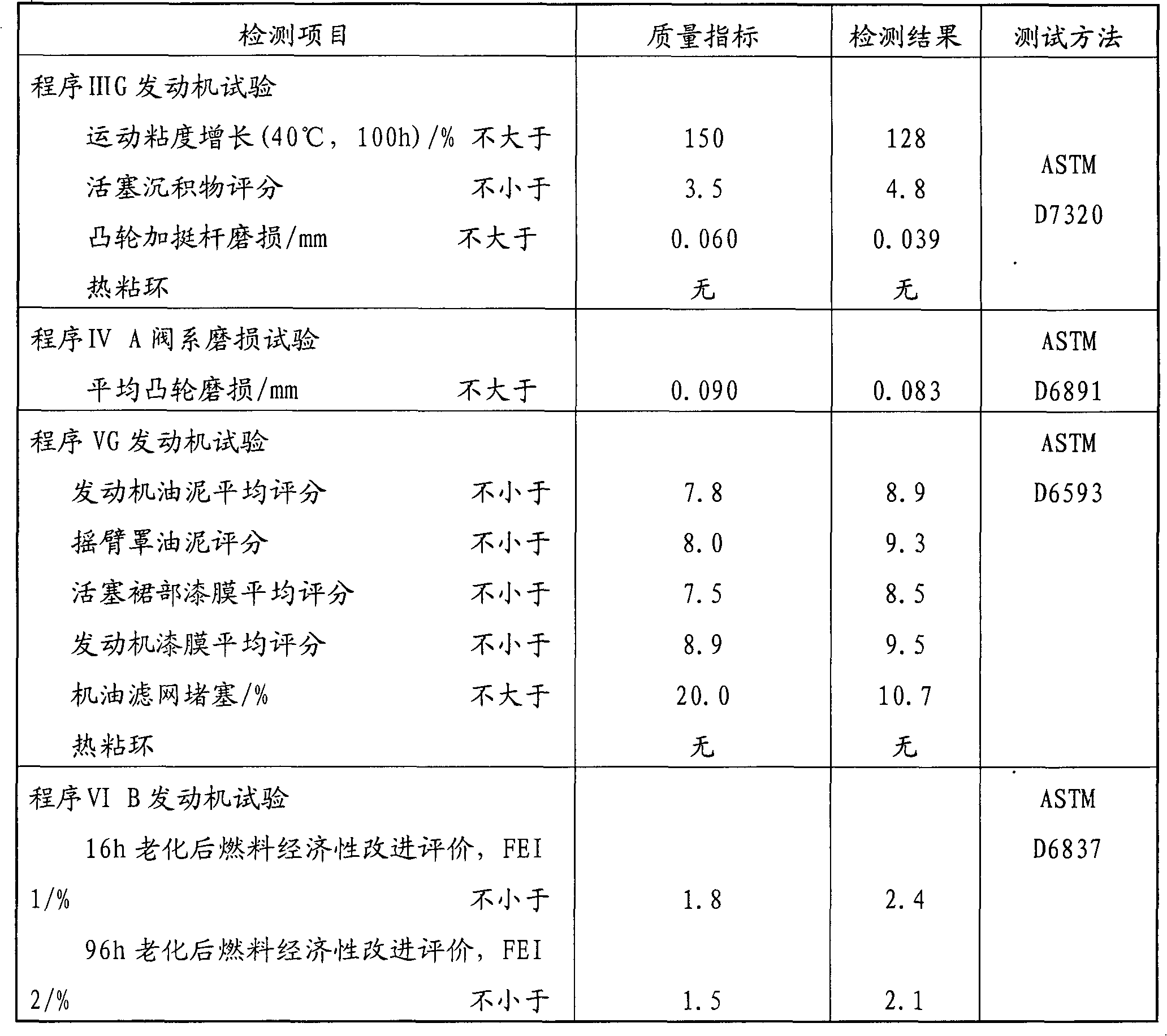

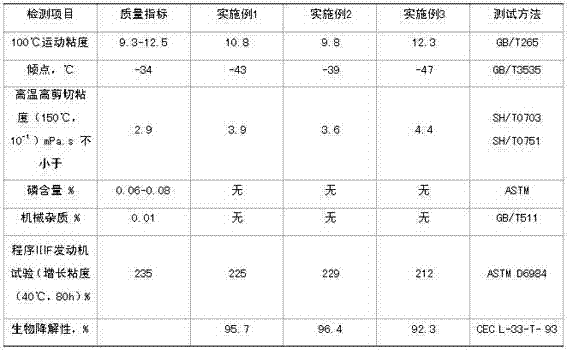

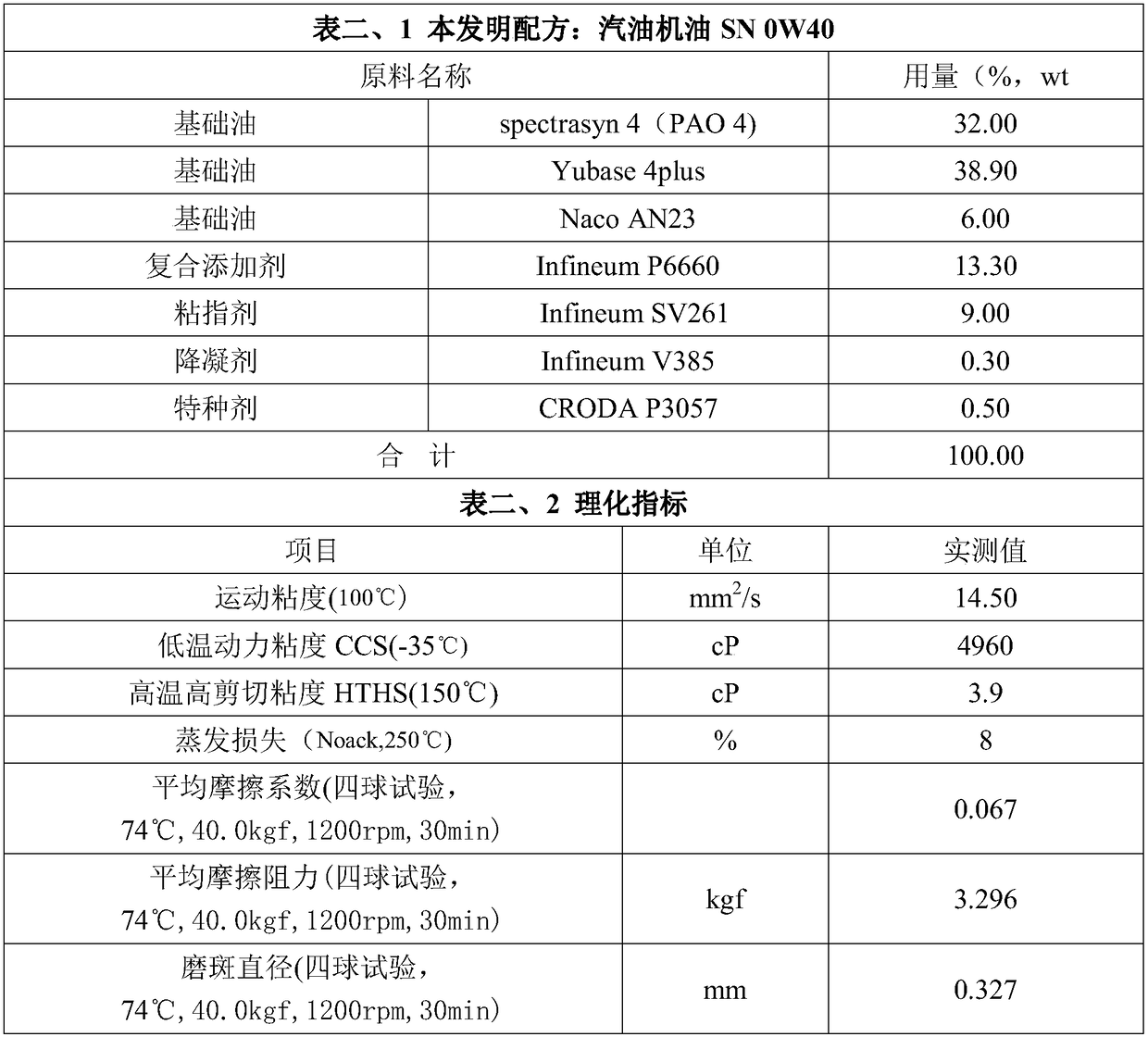

Environment-friendly and energy-saving gasoline engine oil and preparation method thereof

The invention discloses environment-friendly and energy-saving gasoline engine oil and a preparation method thereof. The environment-friendly and energy-saving gasoline engine oil is prepared from the following raw materials in parts by weight: 70-85 parts of environment-friendly base oil, 0.8-3.0 parts of a complex antioxidant, 3.7-6.7 parts of a metal detergent, 5.8-7.8 parts of an ashless dispersant, 0.7-1.5 parts of a nanoscale friction modifier, 4.0-10.0 parts of a viscosity index improver and 0.2-1.0 part of a pour-point depressant. The preparation method comprises the following steps: feeding the environment-friendly base oil to an adjustable dehydrator; sequentially feeding the pour-point depressant, the viscosity index improver, the complex antioxidant, the metal detergent and the ashless dispersant when stirring at 58-65 DEG C, and stirring evenly; and feeding the nanoscale friction modifier, keeping at 58-65 DEG C, further stirring for 1.5 hours, and standing for 0.5 hour, so as to obtain the environment-friendly and energy-saving gasoline engine oil which meets the API SN / GF-5 requirements and is long in service life.

Owner:SHANGHAI INST OF TECH +1

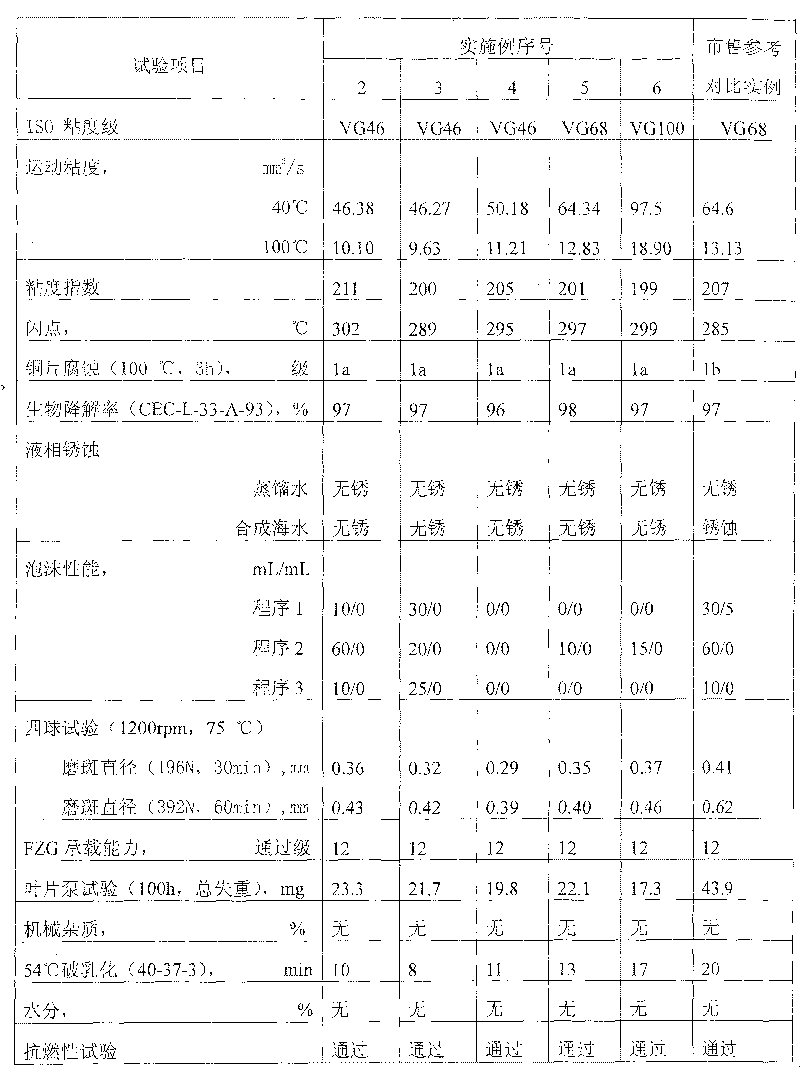

Ester flame-proof hydraulic-oil containing nano abrasion-resistant additive and production method thereof

ActiveCN101113383AExtended service lifeReduce use costAdditivesBase-materialsOrganic chemistryRaw material

The invention relates to ester type flame retardant hydraulic oil containing nano antiwear additive. The mixture ratio by weight of the raw materials is that: 90-95 percent of synthetic ester compound base oil, 1.0-5.0 percent of synthetic multifunctional additive and 1.0-5.0 percent of nano antiwear additive. The production method is that: first, the synthetic ester compound base oil is heated up to 100-120 DEG C, antioxidant is added and stirred for 1-2 hours at 100-120 DEG C until the solid is completely dissolved, then antirust agent and demulsifying agent are added, finally the finished products are filtered to be used; second, the synthetic ester compound base oil is heated up to 60-80 DEG C, and the synthetic multifunctional additive, the nano antiwear additive and antifoamer are added and stirred for 1-3 hours at a constant temperature of 60-80 DEG C, then heating is stopped, and sample is selected for analysis and packaged into finished products after the analysis. The beneficial effects of the invention are that: high temperature using performance and long time lubricant performance of the products are greatly promoted, the service life of hydraulic systems and oil change period can be greatly prolonged.

Owner:杭州新港润滑科技有限公司

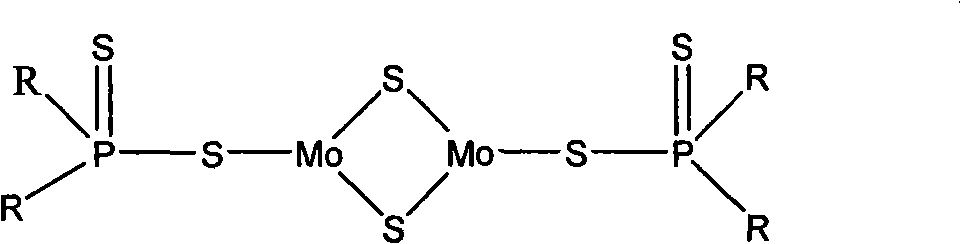

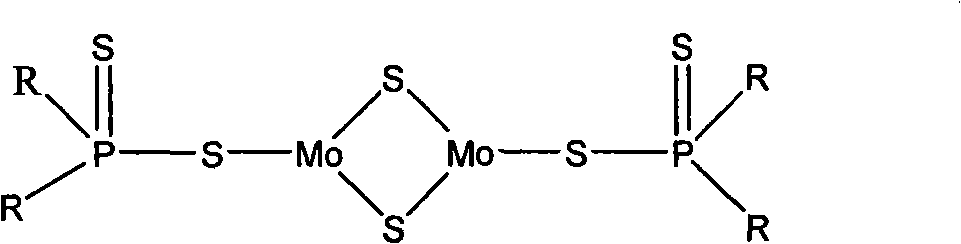

Composite of engine lubricant and preparation method thereof

The invention relates to a composite of lubricant and a preparation method thereof, in particular to a composite of engine lubricant and a preparation method thereof, which belong to the lubricant technical field. Alkyl naphthalene and naphthenic bright stock are added to base oil and at the same time thiophosphoric acid molybdenum additive containing nitrogen, a shless dispersing agent boride, hydrostyrene-isoprene VI improver (Infineum SV 261) and the like are added. Through the mutual coordination of the components, the lubricant composite has obvious compatibility adaptability of a rubber sealing ring, engine oil leakage is avoided, gas blow by is prevented, the dynamic property of the engine is improved, engine oil consumption is reduced, the emission property of the engine is improved and the oil draining period of engine oil and the service life of the engine are prolonged. The invention is particularly applicable to the vehicles which have run more than 100000km or have been overhauled.

Owner:JIANGSU LOPALTECH

Double anti-wear automobile lubricating oil

ActiveCN102229846AExtended oil change intervalImprove starting wearLubricant compositionAlcoholPolyolefin

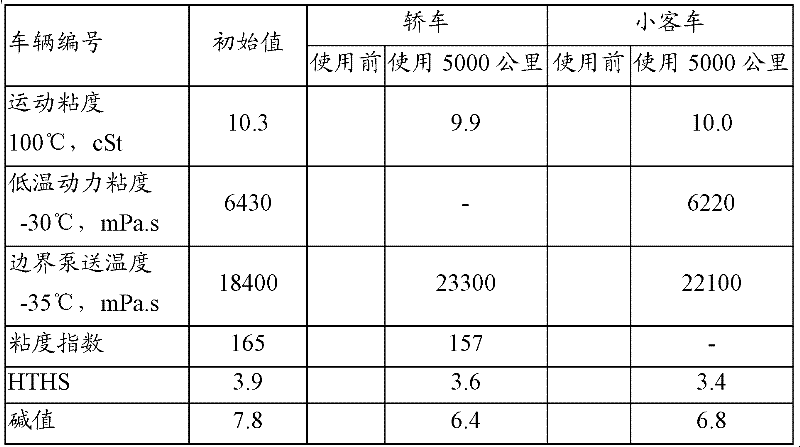

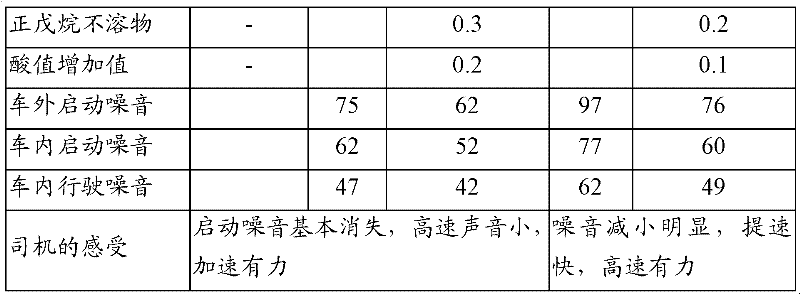

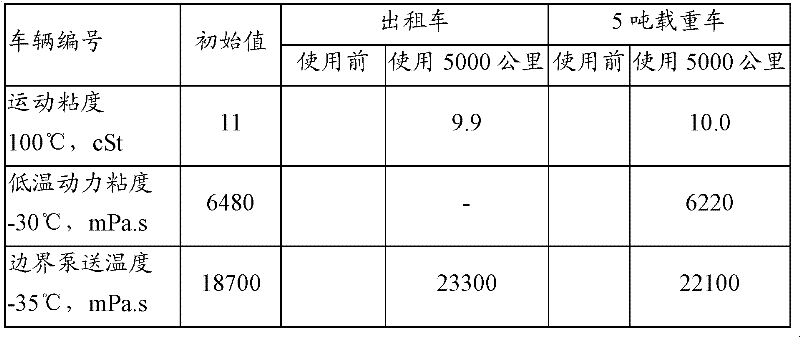

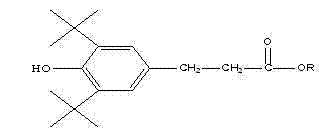

The invention discloses double anti-wear automobile lubricating oil. The lubricating oil comprises, by mass, A), 35-94 parts of a low-viscosity base oil having a high viscosity index, B), 2-15 parts of a engine oil composite agent, C), 0.01-3 parts of a organic molybdenum mixture, D), 0.5-5 parts of a saturated and high-viscosity complex lipid, E), 0.5-10 parts of a diester, F), 0.5-10 parts of ahigh-viscosity polyolefin, G), less than or equal to 2 parts of a alcohol blocked phenolic ester having high molecular weight and H) 2-10 parts of a viscosity index improver with high shearing performance. The double anti-wear automobile lubricating oil provided by the present invention is used for engines of the automobiles, such that starting wear of the engine is substantially improved, the wear of the engine in a operation condition of high rotary speed and high torsional moment is reduced. In addition, according to the present invention, a starting noise level is reduced by 12%; an outside noise level is reduced by 6.8% and an interior noise level is reduced by 8.4% during a high-speed operation; a oil change period of the engine oil is prolonged more than one time.

Owner:QUANZHOU CITY OUMEI LUBRICANT PRODS

Ester-type fire resistant hydraulic oil and production method thereof

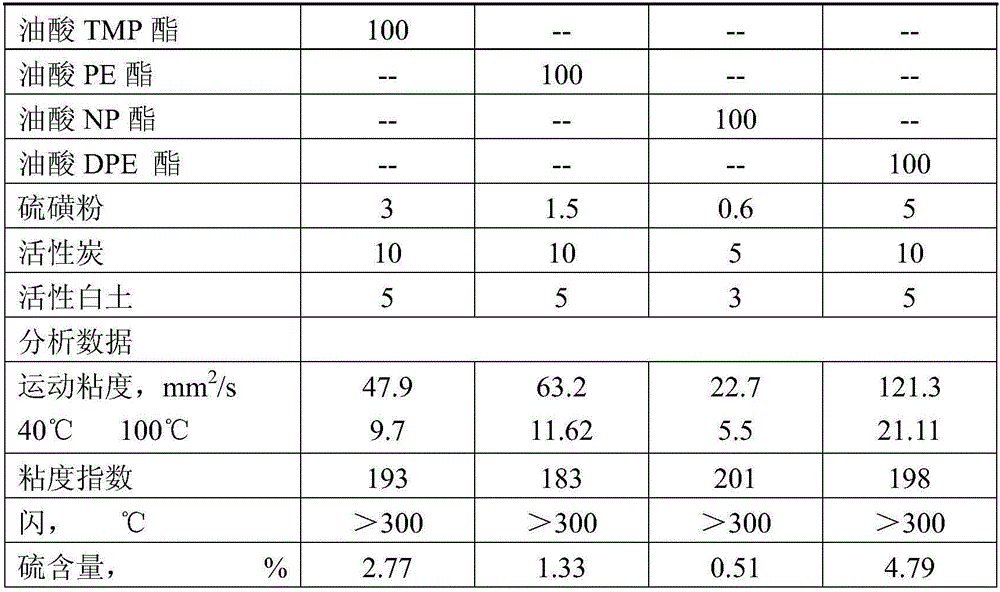

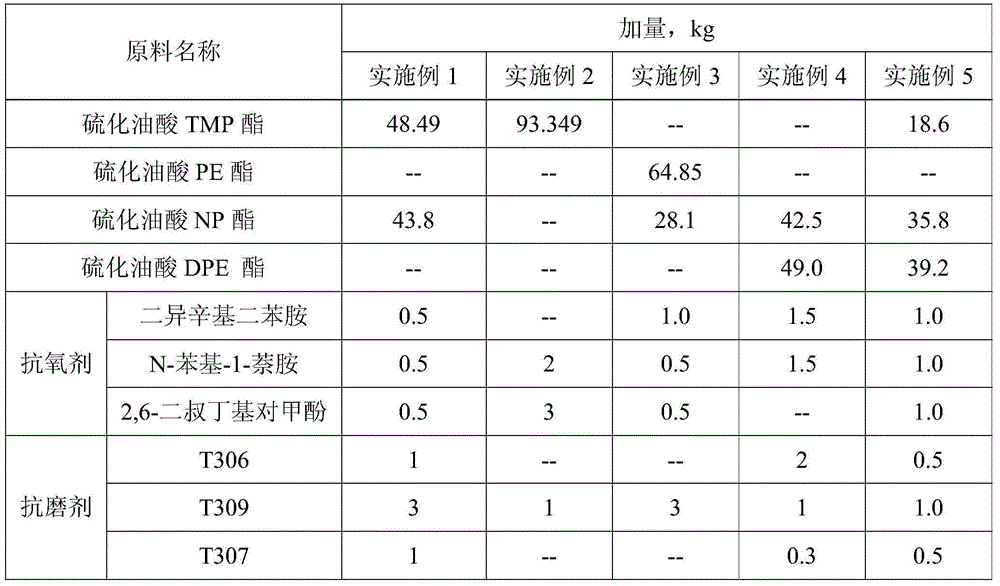

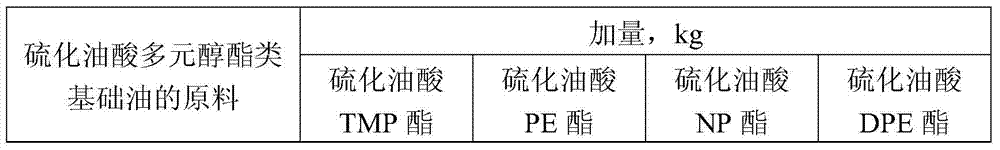

ActiveCN105001946AEasy to oxidizeImprove antioxidant capacityLubricant compositionAntioxidantSulfide

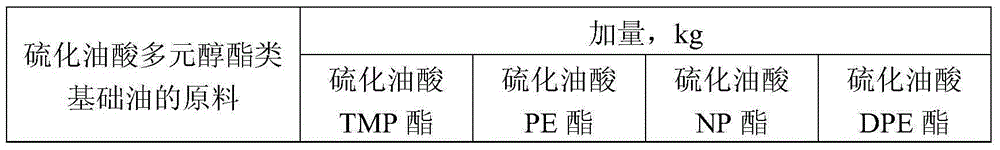

The invention relates to ester-type fire resistant hydraulic oil and a production method thereof. The ester-type fire resistant hydraulic oil comprises, by weight, the following raw materials of 90-95% of sulfide oleic acid polyol ester base oil, 0.1-5.0% of antioxidants, 1-5.0% of antiwear agents, 0.1-1.0% of clearing agents, 0.01-1.0% of demulsifier, 0.001-0.1% of anti-foaming agents and 0.05-0.5% of metal deactivator. According to the ester-type fire resistant hydraulic oil and the production method thereof, the novel sulfide oleic acid polyol ester base oil is adopted, unsaturated bonds in oleic acid polyol esters are partially or fully saturated, the problem that the unsaturated bonds are extremely prone to being oxidized is solved, and therefore the oxidation resistance of the ester-type fire resistant hydraulic oil is significantly improved; the oil change period is significantly prolonged, and the use cost of the oil is low; the extreme pressure property is improved, the bearing capacity of the oil is significantly improved, and the lubrication requirements of a high-speed heavy-load gear oil pump are met.

Owner:SHANDONG NORTH ZITE SPECIAL OIL

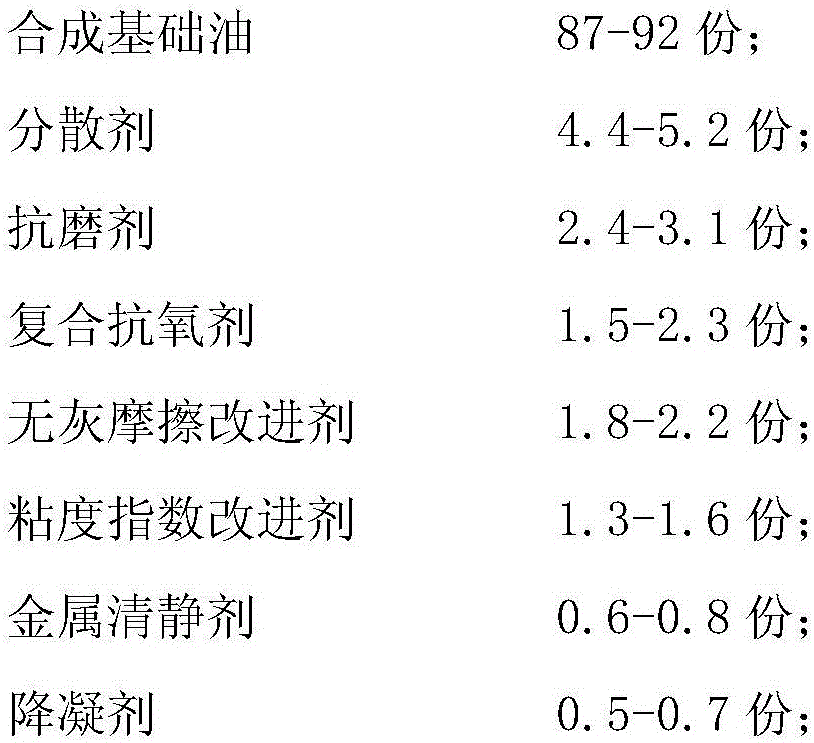

Preparation method for energy-saving and environment-friendly diesel engine oil

InactiveCN106566617AEmission reductionReduce energy consumptionLubricant compositionAntioxidantEngineering

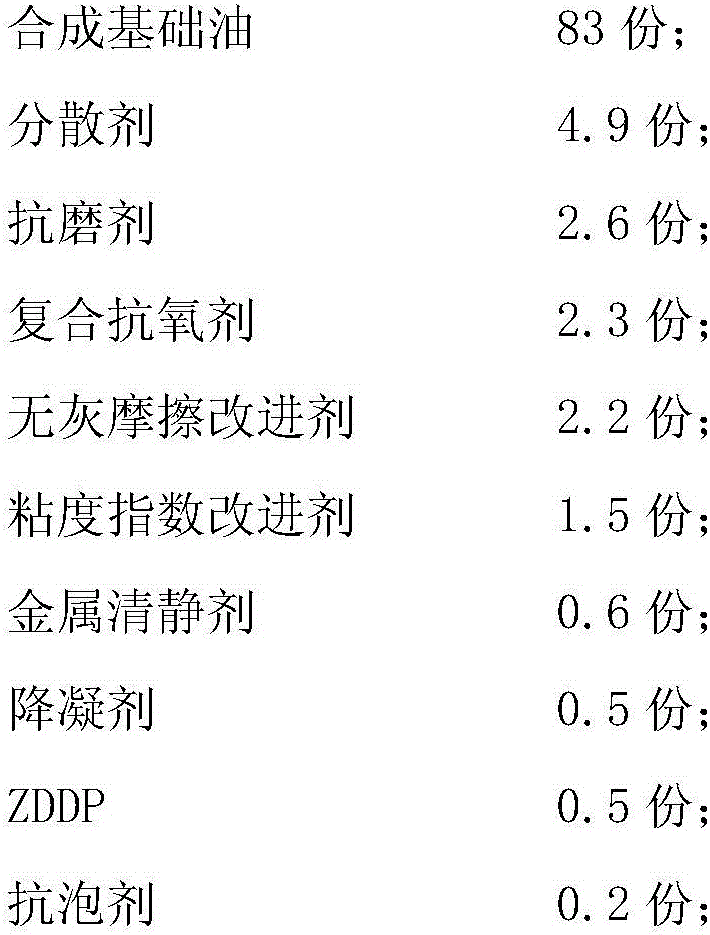

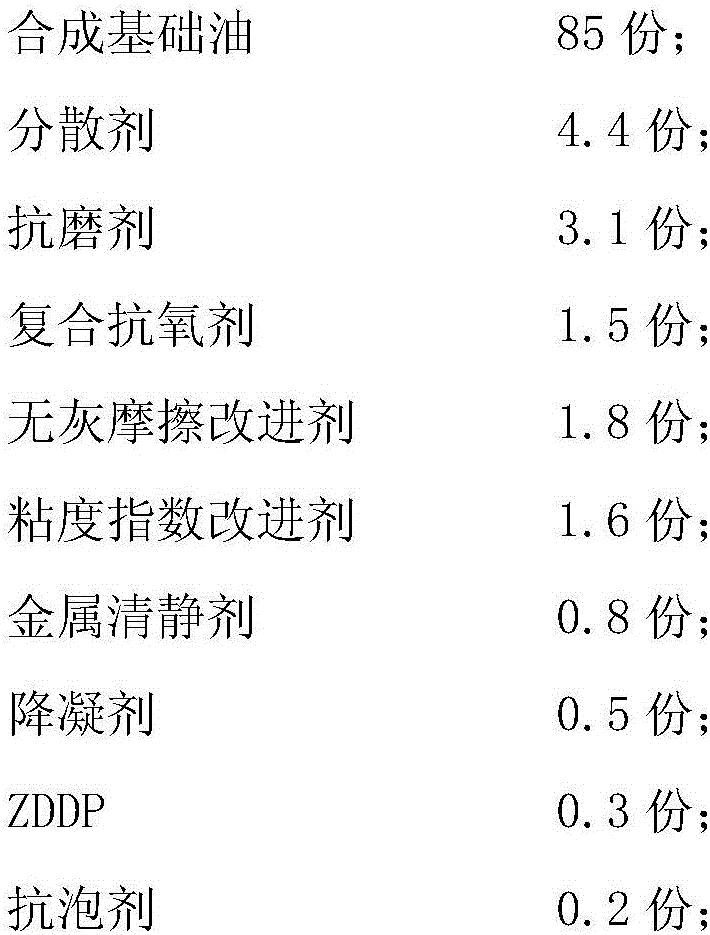

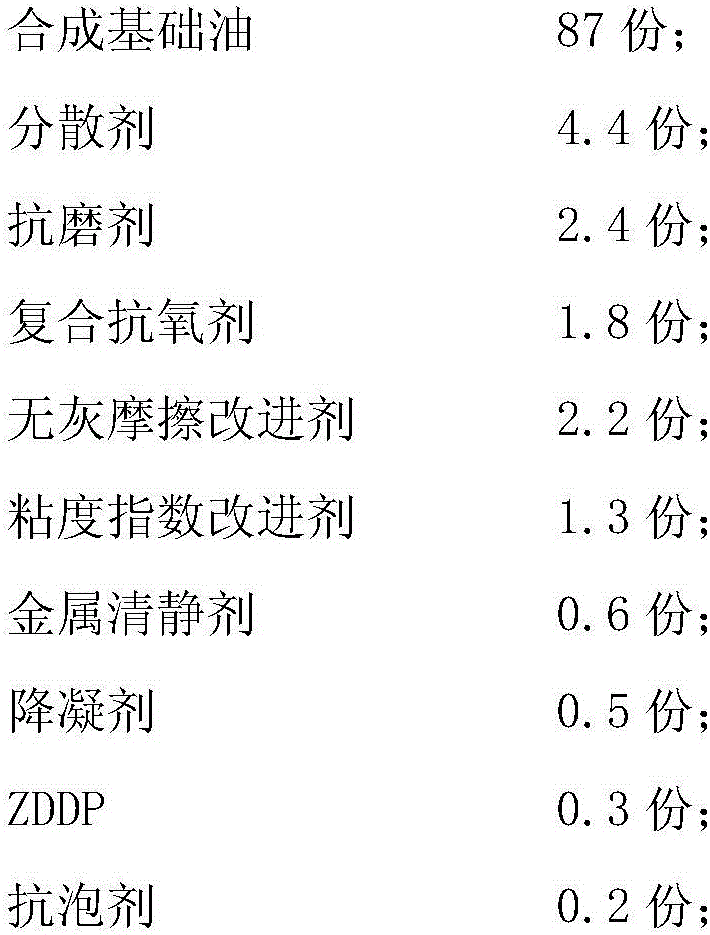

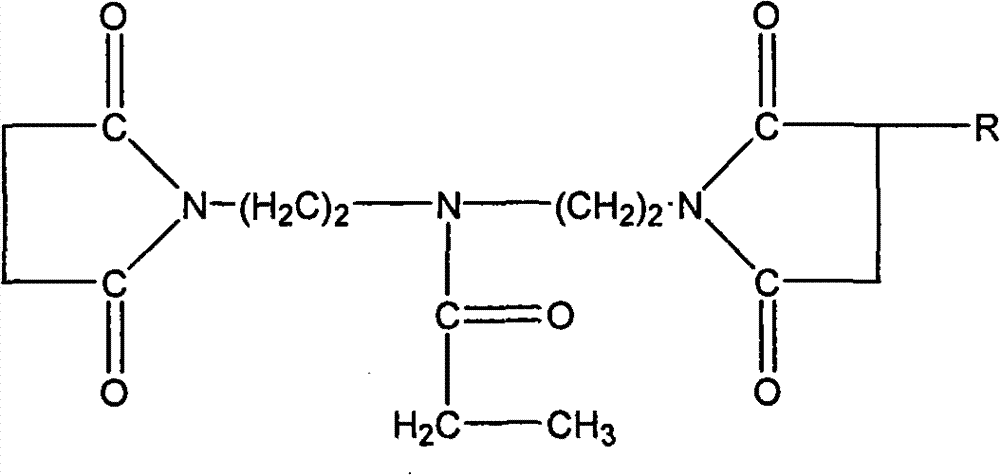

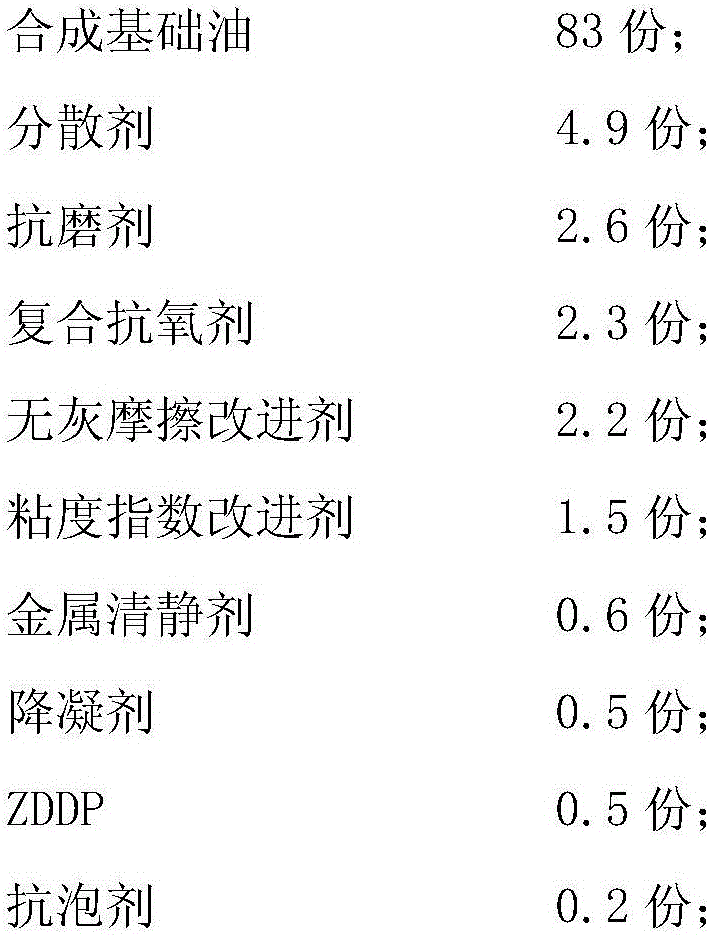

The invention relates to a preparation method for energy-saving and environment-friendly diesel engine oil. The diesel engine oil is prepared from the raw materials: 87-92 parts of synthetic base oil, 4.4-5.2 parts of dispersant, 2.4-3.1 parts of anti-wear agent, 1.5-2.3 parts of composite antioxidant, 1.8-2.2 parts of ashless friction modifier, 1.3-1.6 parts of viscosity index improver, 0.6-0.8 part of metal cleaning agent, 0.5-0.7 part of pour point depressant, 0.3-0.5 part of ZDDP and 0.2-0.3 part of antifoamer. The preparation method comprises the following steps of adding the synthetic base oil into a blending kettle, sequentially adding the dispersant, the anti-wear agent, the composite antioxidant, the viscosity index improver, the metal cleaning agent, the pour point depressant and the ZDDP into the blending kettle with stirring at the temperature of 60 DEG C to 65 DEG C, carrying out uniform stirring, then, sequentially adding the ashless friction modifier and the antifoamer into the blending kettle, continuing to carry out stirring for 1.5 to 2 hours while maintaining the temperature to 60 DEG C to 65 DEG C, and then, carry out standing for 0.5 to 1 hour, thereby obtaining the energy-saving and environment-friendly diesel engine oil.

Owner:徐洁

Wear-resisting energy-saving agent for lubricating oil, its preparation method and application

The present invention provides an antiwear energy-saving agent containing refined mineral oil, zinc dialkyl dithiophosphate and deactivator for lubricating oil, it possesses excellent functions of reducing friction, reducing wear, resisting rust, resisting corrosion and resisting oxidation, and has strong cleaning dispersing power and good extreme pressure resistance and long-acting lubricating property and excellent compatibility with lubricant. This invention also provides its preparation method and application to lubricating oil and soaking field.

Owner:臧玉蓉 +1

Composite of engine lubricant and preparation method thereof

ActiveCN101880586BGood dispersionImprove thermal stabilityLubricant compositionIsopreneMaterials science

The invention relates to a composite of lubricant and a preparation method thereof, in particular to a composite of engine lubricant and a preparation method thereof, which belong to the lubricant technical field. Alkyl naphthalene and naphthenic bright stock are added to base oil and at the same time thiophosphoric acid molybdenum additive containing nitrogen, ashless dispersing agent boride, hydrostyrene-isoprene VI improver (Infineum SV 261) and the like are added. Through the mutual coordination of the components, the lubricant composite has obvious compatibility adaptability of a rubber sealing ring, engine oil leakage is avoided, gas blowby is prevented, the dynamic property of the engine is improved, engine oil consumption is reduced, the emission property of the engine is improved and the oil draining period of engine oil and the service life of the engine are prolonged. The invention is particularly applicable to the vehicles which have run more than 100000km or have been overhauled.

Owner:JIANGSU LOPALTECH

High-efficiency wear-resistant energy-saving lubricating oil composition and preparation method thereof

InactiveCN108690698AHigh affinityReduce friction and wearLubricant compositionPolyesterWear resistant

The invention discloses a high-efficiency wear-resistant energy-saving lubricating oil composition and a preparation method thereof. The high-efficiency wear-resistant energy-saving lubricating oil composition is prepared from the following raw materials in parts by weight: 40-60 parts of polyester base oil, 10-20 parts of pentaerythritol ester base oil, 5-10 parts of modified nano graphite, 0.5-1.5 parts of emulsifying agent, 1.5-3.5 parts of friction modifier, 2.5-4.5 parts of petroleum calcium sulfonate, 1-3 parts of octadecylamine, 0.4-0.6 part of composite antioxidant, 0.7-0.9 part of extreme-pressure antiwear agent, 0.6-0.8 part of preservative and 0.6-0.9 part of anti-foaming agent. The high-efficiency wear-resistant energy-saving lubricating oil composition has better wear-resistant and wear-reducing properties, and can repair and reduce wear; meanwhile, due to addition of the preservative, rusting of metal parts can be prevented and the service life of a car is prolonged.

Owner:薛士军

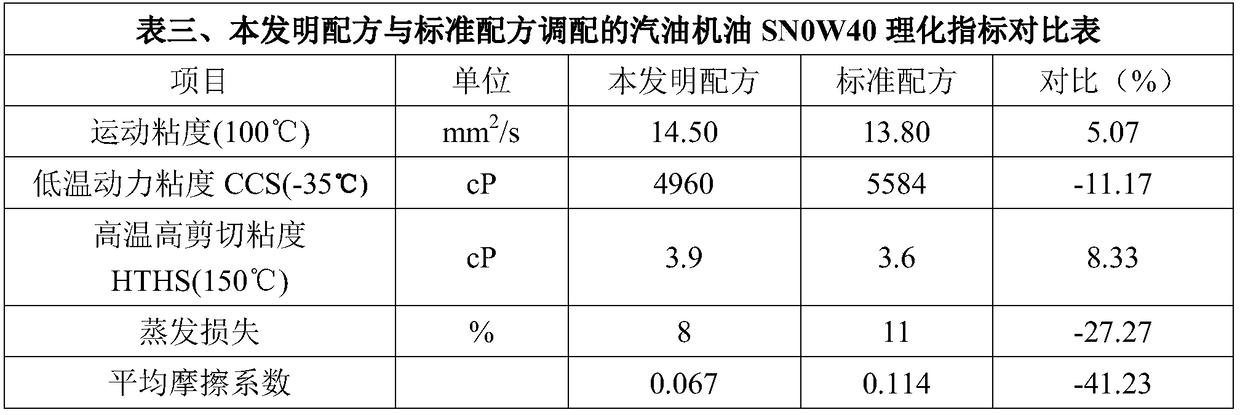

Automobile engine lubricating oil with effects of simultaneously reducing consumption of engine oil and fuel oil and preparation method of automobile engine lubricating oil

ActiveCN108949325AGood shear stabilityGood sealing performanceLubricant compositionFuel oilPetroleum

The invention discloses automobile engine lubricating oil with effects of simultaneously reducing consumption of engine oil and fuel oil. The automobile engine lubricating oil contains a standard composite additive passing API (American Petroleum Institute) formula authentication, a pour point depressant required by a certification formula, a viscosity index improver required by the certificationformula, two to three kinds of base oil required by the certification formula, alkyl naphthalene synthetic base oil and an organic polymer friction modifier. The materials are blended into refined oilproducts according to the standard production process of lubricating oil; and the refined oil product blended by the materials meets the API corresponding level requirements, wherein the kinematic viscosity of the refined oil product at 100 DEG C meets the medium upper value requirement in the viscosity grade. Compared with standard formula engine oil passing through API certification, the engineoil blended by the invention has high shear stability and low friction coefficient in addition to the capacity of reaching the quality standard of API, and also has the effects of simultaneously reducing the consumption of automobile engine oil and fuel oil. In addition, the oil change mileage is prolonged.

Owner:蔡洪涛

Preparation process of lubricating oil with high wear-resistant extreme pressure and wear-resistant antifriction property

The invention relates to a preparation process of lubricating oil with high wear-resistant extreme pressure and wear-resistant antifriction property. The preparation process comprises the following steps: mixing 35%-45% of hydroisomerization dewax type-III base oil with 35%-45% of poly-alpha olefin PAO, stirring at a uniform speed, heating the mixture to 48-58 DEG C within 10 minutes, and thermally insulating for 20 minutes, so as to obtain base oil; preparing a tungsten disulfide particle additive, adding the tungsten disulfide particle additive into the base oil, and stirring at a uniform speed for 15 minutes, wherein tungsten disulfide particles account for 1.5%-2.5% of the total components; preparing a nitrogen-containing boric acid ester additive, and stirring at a uniform speed for 15 minutes; adding a viscosity index improver, thermally insulating, stirring until the kinematic viscosity and the pour point meet standards, and continuing to thermally insulate; adding 2%-3% of a clean dispersing agent; adding 1.5%-2% of an oxidation and corrosion inhibitor; adding 0.3%-0.7% of a pour point depressant; adding 0.01% of an antifoaming agent; and continuing to stir at a uniform speed, heating to 62-66 DEG C within 10 minutes, and thermally insulate for 30 minutes, so as to obtain a finished product.

Owner:昆山中润信息科技有限公司

Diesel engine oil being energy-saving and environment-friendly

InactiveCN106590862AEmission reductionReduce energy consumptionLubricant compositionCleansers skinViscosity index

Diesel engine oil being energy-saving and environment-friendly is composed of, by mass, 87-92 parts of synthetic basic oil, 4.4-5.2 parts of a dispersant, 2.4-3.1 parts of an anti-wear agent, 1.5-2.3 parts of composite antioxidant, 1.8-2.2 parts of an ash-free friction improver, 1.3-1.6 parts of a viscosity index improver, 0.6-0.8 parts of a metal cleanser, 0.5-0.7 parts of a pour point depressant, 0.3-0.5 parts of ZDDP, and 0.2-0.3 parts of an anti-foamer.

Owner:徐洁

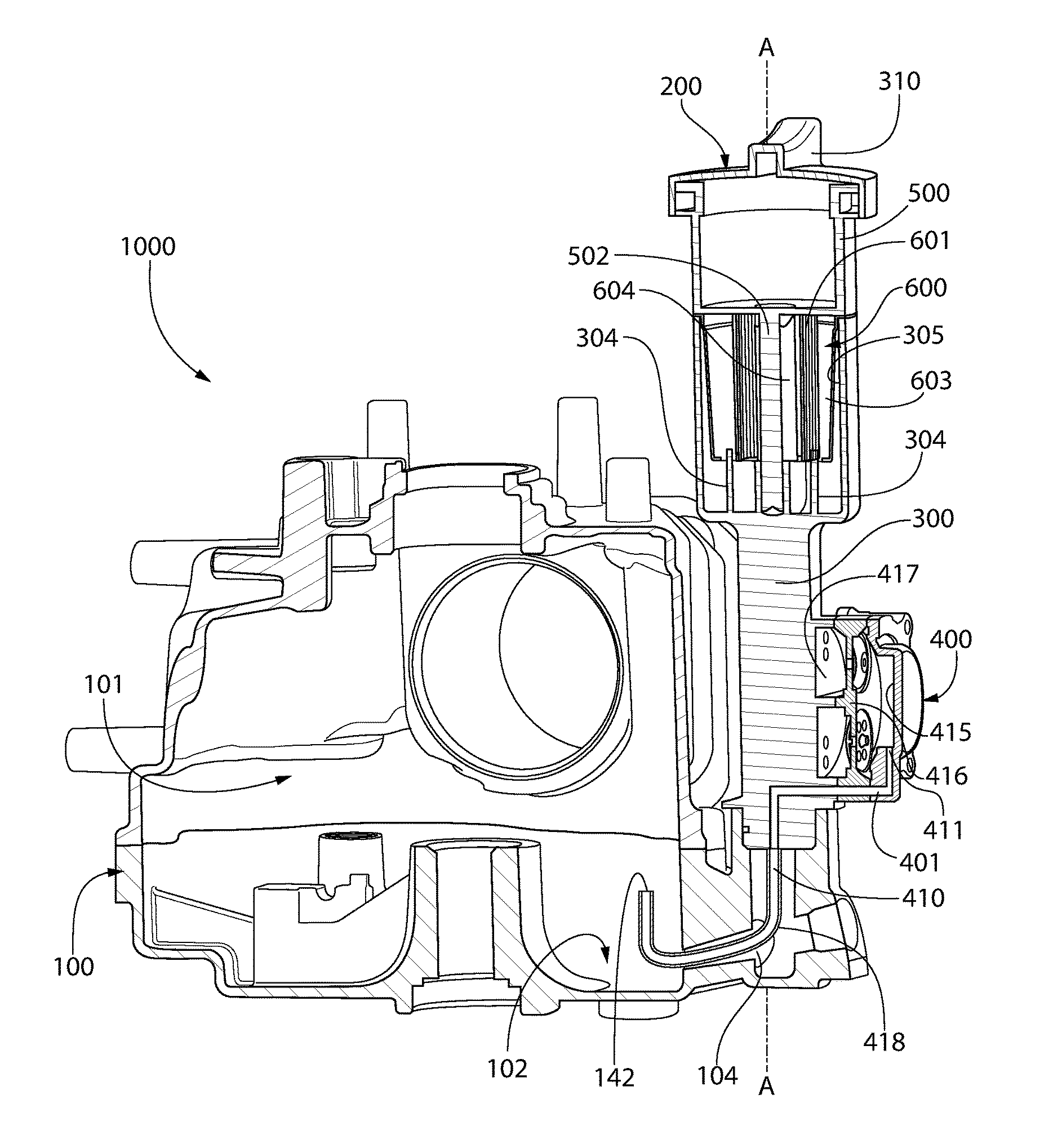

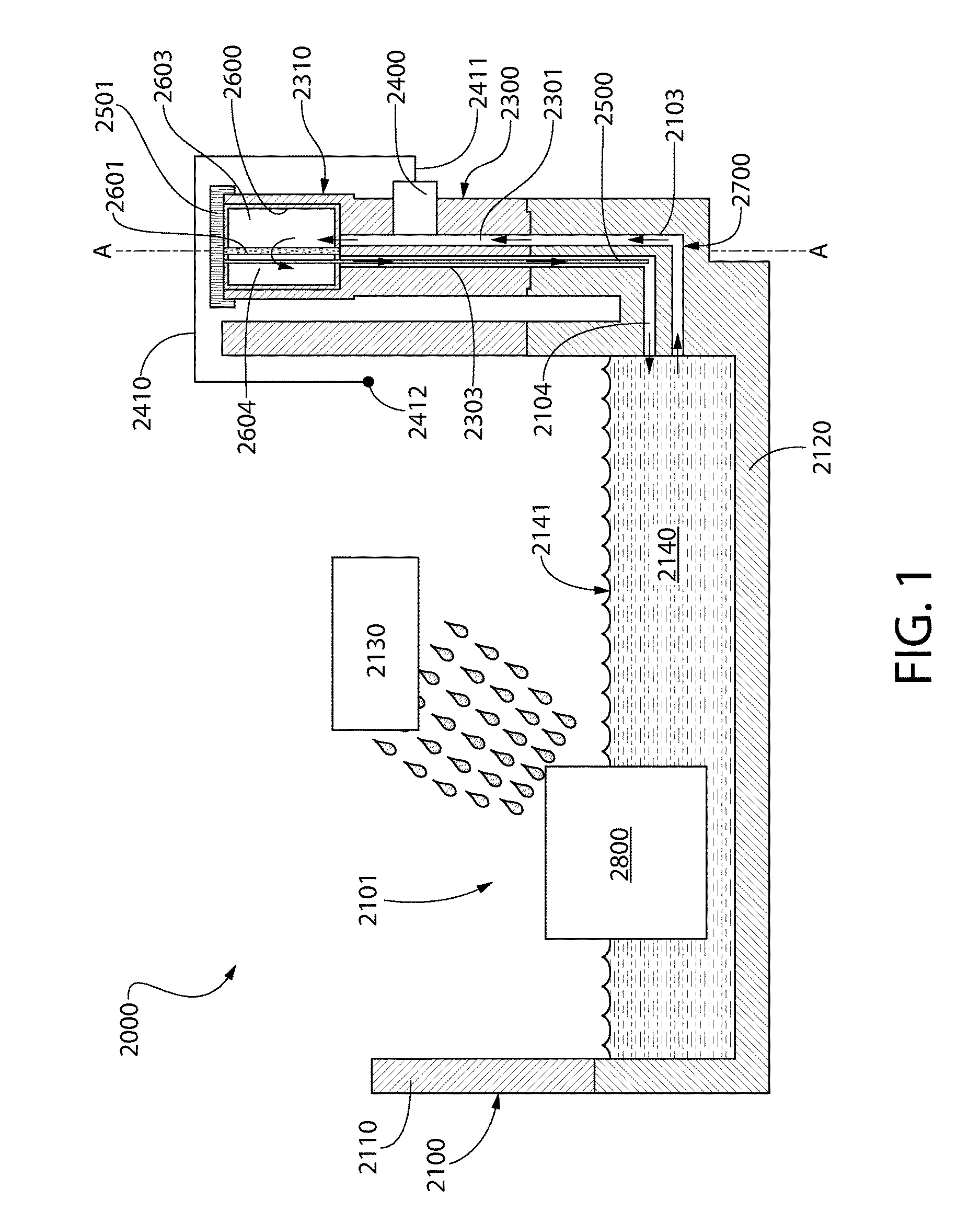

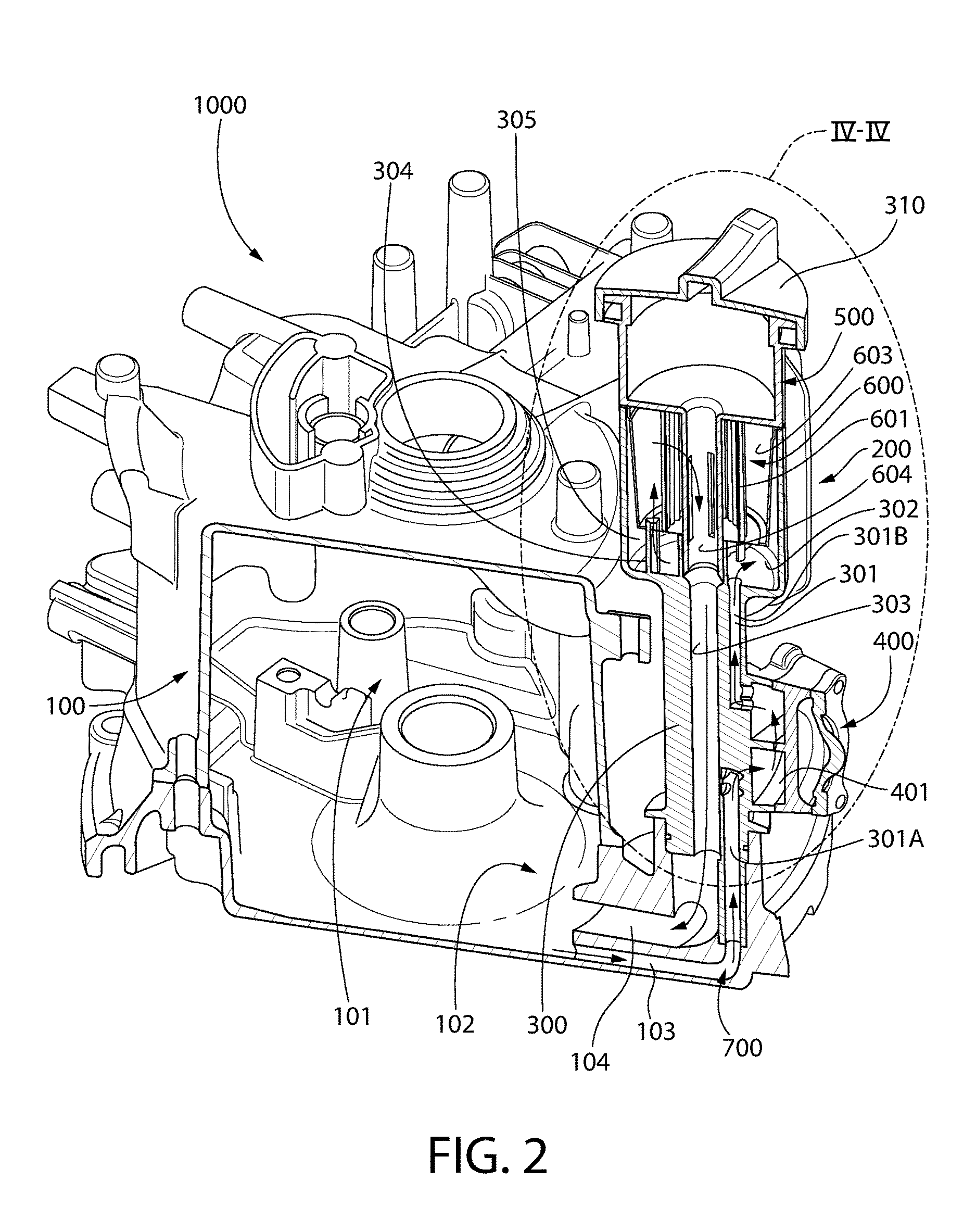

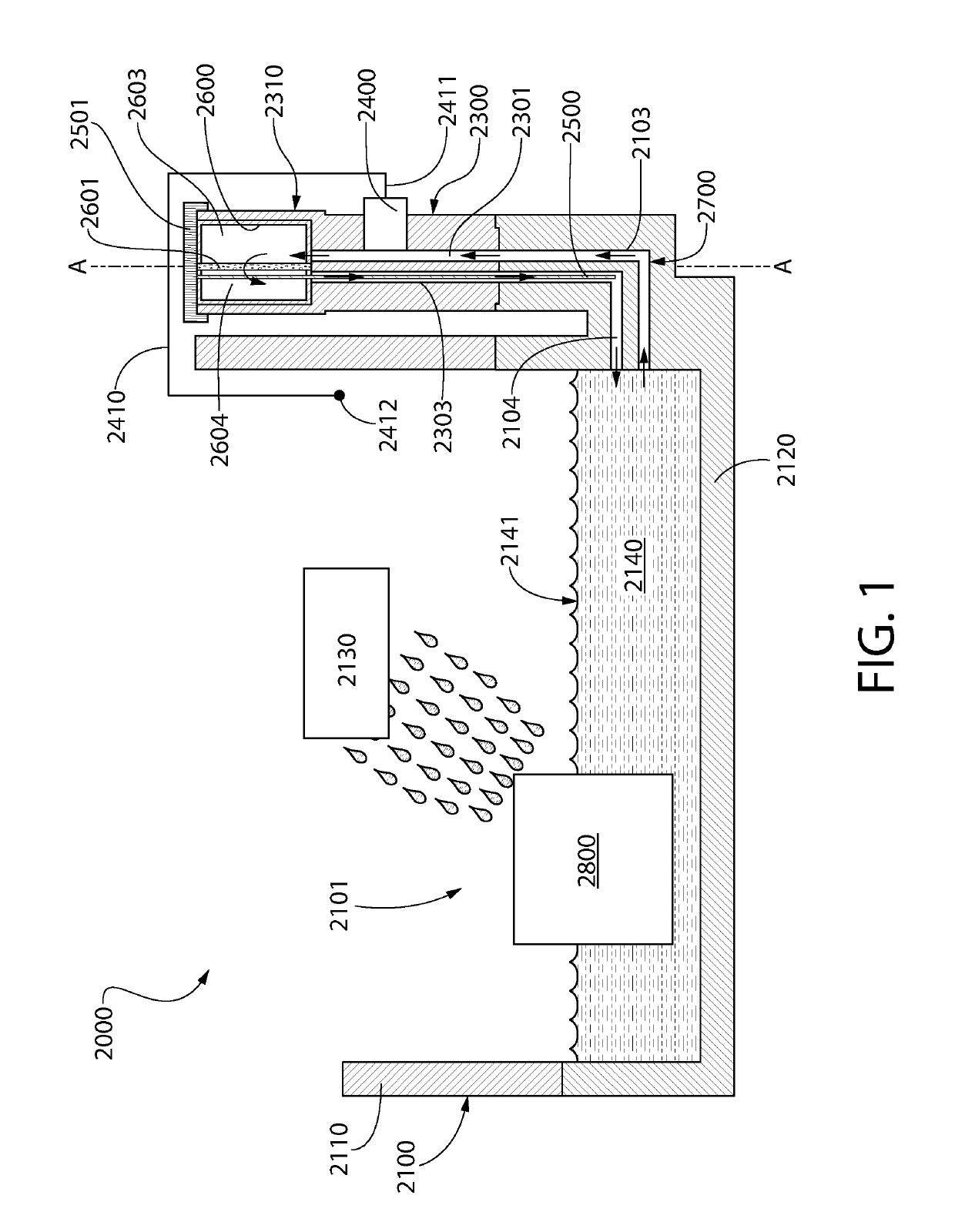

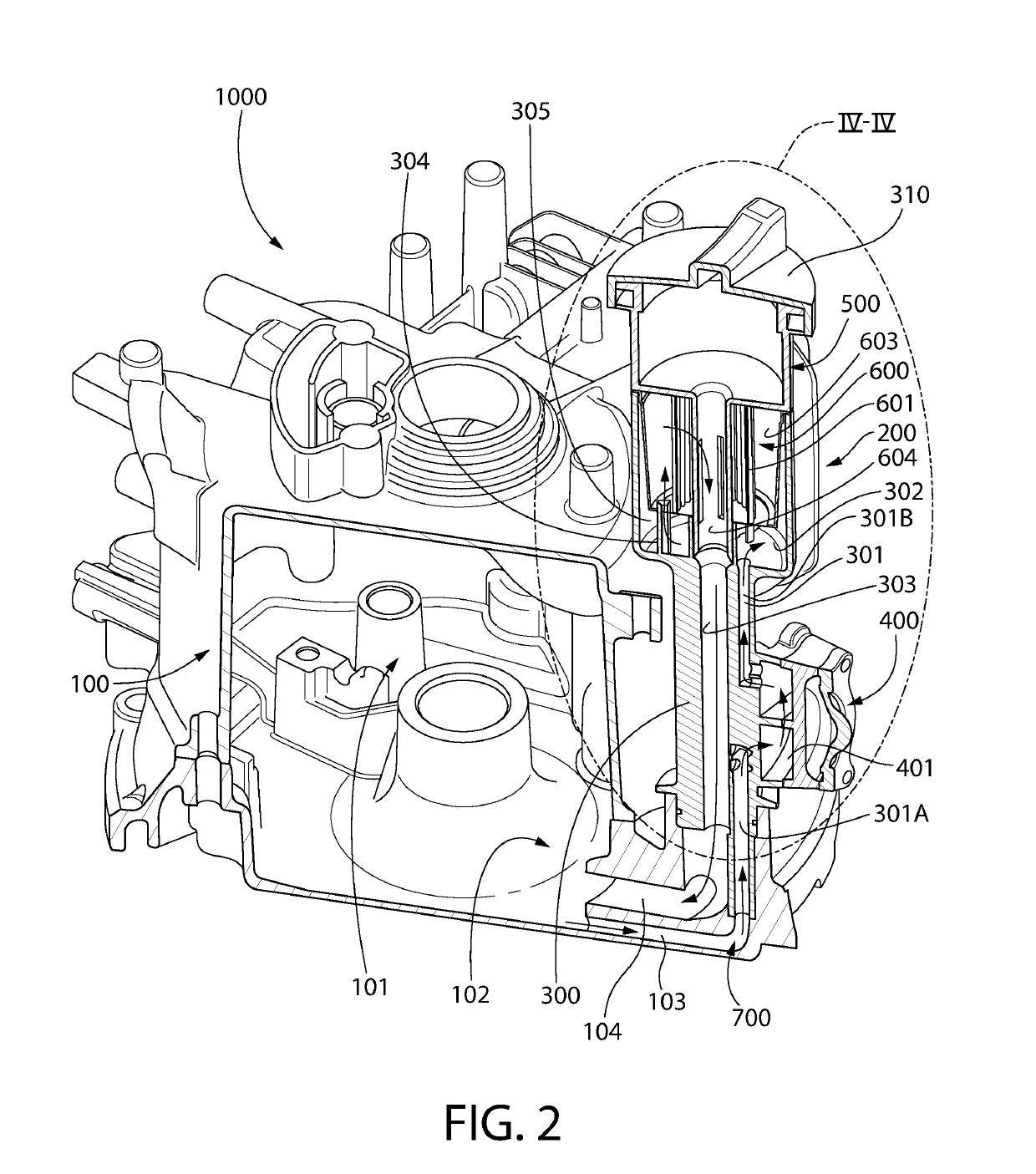

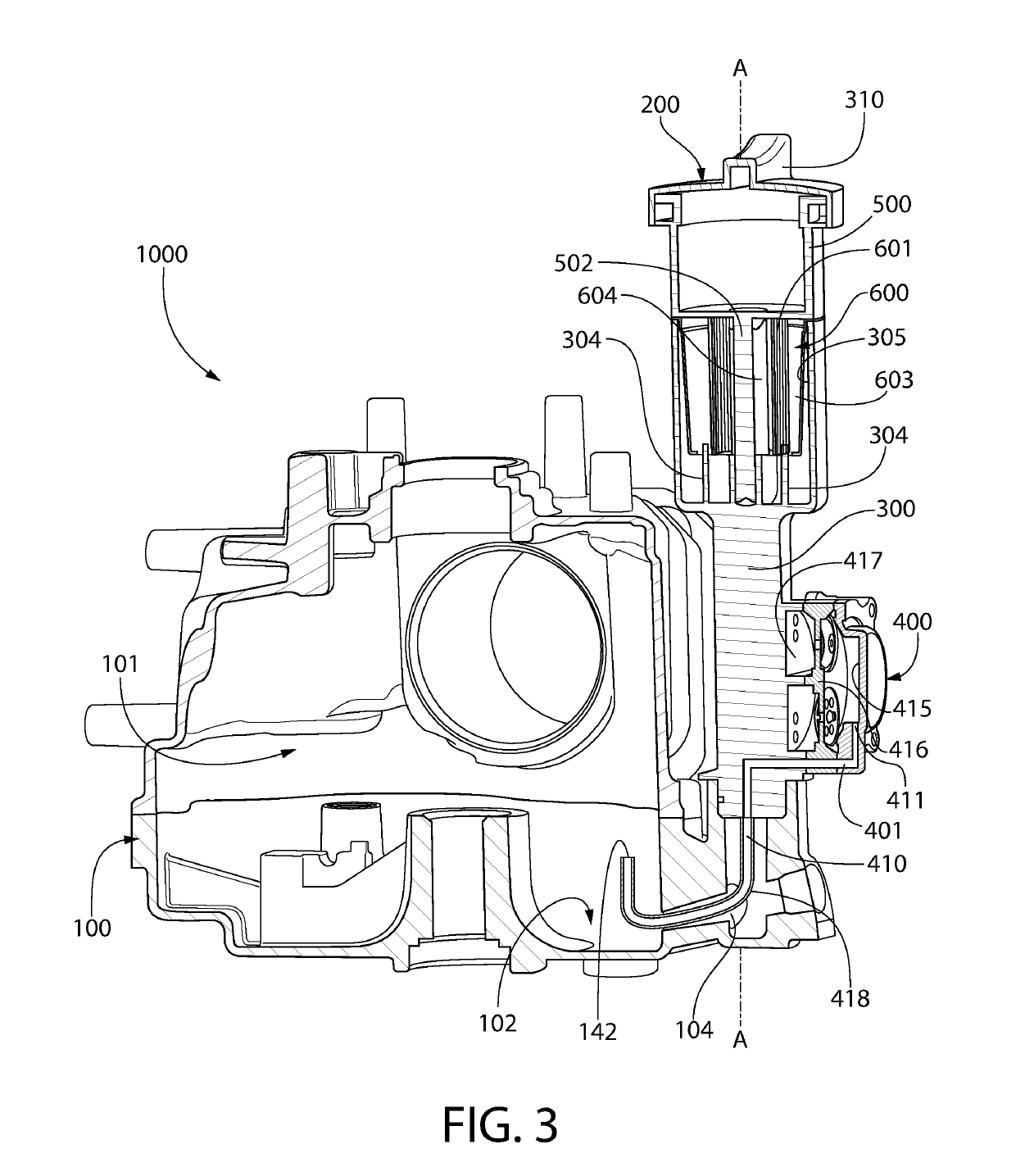

Internal combustion engine and oil treatment apparatus for use with the same

ActiveUS20170044938A1Minimal redesignEasy to insertDrip or splash lubricationOilsumpsExternal combustion engineInternal combustion engine

An internal combustion engine having an improved oil treatment system. The internal combustion engine may be a splash lubrication engine in which oil is flowed through an oil circulation circuit by a passive pump. In another aspect, a dipstick tube may be provided that includes a portion of the oil circulation circuit. In a further aspect, the internal combustion engine comprises one or more protuberances that automatically penetrate an oil treatment apparatus upon the oil treatment apparatus being mounted to the internal combustion engine, thereby fluidly coupling the oil treatment apparatus to the oil circulation circuit.

Owner:KOHLER CO

Ester flame-proof hydraulic-oil containing nano abrasion-resistant additive and production method thereof

ActiveCN101113383BExtended service lifeReduce use costAdditivesBase-materialsRaw materialAntiwear additive

The invention relates to ester type flame retardant hydraulic oil containing nano antiwear additive. The mixture ratio by weight of the raw materials is that: 90-95 percent of synthetic ester compoundbase oil, 1.0-5.0 percent of synthetic multifunctional additive and 1.0-5.0 percent of nano antiwear additive. The production method is that: first, the synthetic ester compound base oil is heated upto 100-120 DEG C, antioxidant is added and stirred for 1-2 hours at 100-120 DEG C until the solid is completely dissolved, then antirust agent and demulsifying agent are added, finally the finished products are filtered to be used; second, the synthetic ester compound base oil is heated up to 60-80 DEG C, and the synthetic multifunctional additive, the nano antiwear additive and antifoamer are added and stirred for 1-3 hours at a constant temperature of 60-80 DEG C, then heating is stopped, and sample is selected for analysis and packaged into finished products after the analysis. The beneficial effects of the invention are that: high temperature using performance and long time lubricant performance of the products are greatly promoted, the service life of hydraulic systems and oil changeperiod can be greatly prolonged.

Owner:杭州新港润滑科技有限公司

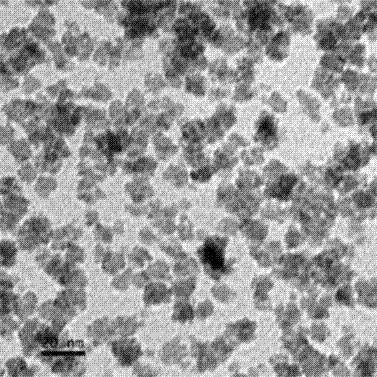

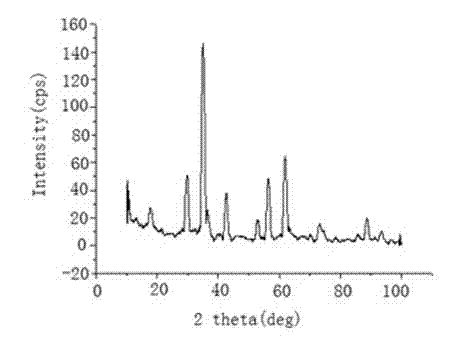

Magnetic liquid based on oxidation-resistant alpha olefin synthetic oil and preparation method thereof

InactiveCN103177839AStrong oxidation abilityStrong magnetic propertiesMagnetic liquidsOxidation resistantMagnetic liquids

The invention relates to the field of nanoscale science and technology, and discloses magnetic liquid based on oxidation-resistant alpha olefin synthetic oil and a preparation method of the magnetic liquid based on the oxidation-resistant alpha olefin synthetic oil. The magnetic liquid comprises magnetic nano-particles, surfactants and carrier liquid, and is characterized in that the magnetic nano-particles are ferrite-class magnetic particles DxM1-xFe2O4, wherein the D and the M are Co, Mn, Ni, Mg or Zn, and x=0-1, and the carrier liquid is the alpha olefin synthetic oil or mixed oil with the alpha olefin synthetic oil and other basic oil. According to the magnetic liquid based on the oxidation-resistant alpha olefin synthetic oil and the preparation method of the magnetic liquid based on the oxidation-resistant alpha olefin synthetic oil, the DxM1-xFe2O4 magenetic particles are small in particle diameter, overcome the defects that existing magnetic liquid is poor in oxidation resistance and stability, and the like, are good in oxidation resistance, good in modification effect, and are capable of being dispersed in the carrier liquid, and good magnetic performance can be kept for a long time under a high-temperature environment. The preparation method of the magnetic liquid based on the oxidation-resistant alpha olefin synthetic oil is simple in operation, high in production efficiency, and low in requirement on equipment, and has good application prospects.

Owner:SUN YAT SEN UNIV

Long life wind power fluorine grease

InactiveCN102703175BSolve long-term lubricationExtended oil change intervalLubricant compositionRare earthSilicon dioxide

The invention discloses a long-life fluorine lubricating grease for wind power generation, which is composed of base oil, a thickening agent and an additive, wherein the base oil is one or more of perfluoro polyether oil, perfluoro ester oil, perfluoro hydrocarbon oil and perfluoro silicone oil; the thickening agent is one or more of composite metal soap, inorganic soap, polytetrafluoroethylene, perfluoro-ethylene-propylene copolymer, fluorocarbon wax, carbon black, silicon dioxide, titanium dioxide, molybdenum disulfide, rare earth fluoride, nano graphite, fluoridized graphite and fluoridized resin; and the additive is one or more of antioxidant, anti-corrosion antirusting agent, extreme-pressure passivating agent, metal passivator, and AD complexing agent. With the use of the lubricating grease, the oil draining period of the lubricating parts in the wind power generation industry is improved by 3-10 times; and the lubricating grease is suitable for lubricating of all-weather corroded and other harsh environments, and greatly saves materials and manpower.

Owner:上海相推环保科技有限公司

Lubricating oil for engine and preparation method thereof

InactiveCN108913302AHigh affinityReduce friction and wearLubricant compositionFoaming agentPreservative

The invention discloses lubricating oil for an engine and a preparation process thereof. The lubricating oil is prepared from the following raw materials in parts by weight: 49 to 69 parts of polyalkylene glycol base oil, 15 to 35 parts of PAO base oil, 0.5 to 1.5 parts of a tackifier, 1.5 to 3.5 parts of a friction modifier, 2.5 to 4.5 parts of organic molybdenum, 1 to 3 parts of borate additive,0.4 to 0.6 part of a complex antioxidant, 0.7 to 0.9 part of an anti-wear reagent at extreme pressure, 0.6 to 0.8 part of a preservative and 0.6 to 0.9 part of an anti-foaming agent. The lubricatingoil for the engine provided by the invention has better wear resistance, and can repair abrasion and reduce abrasion.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

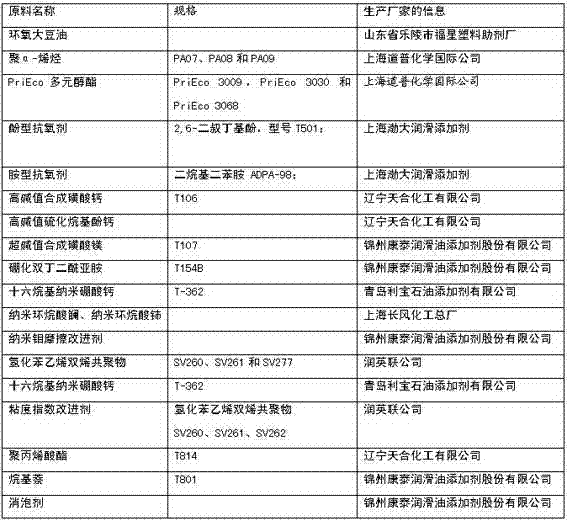

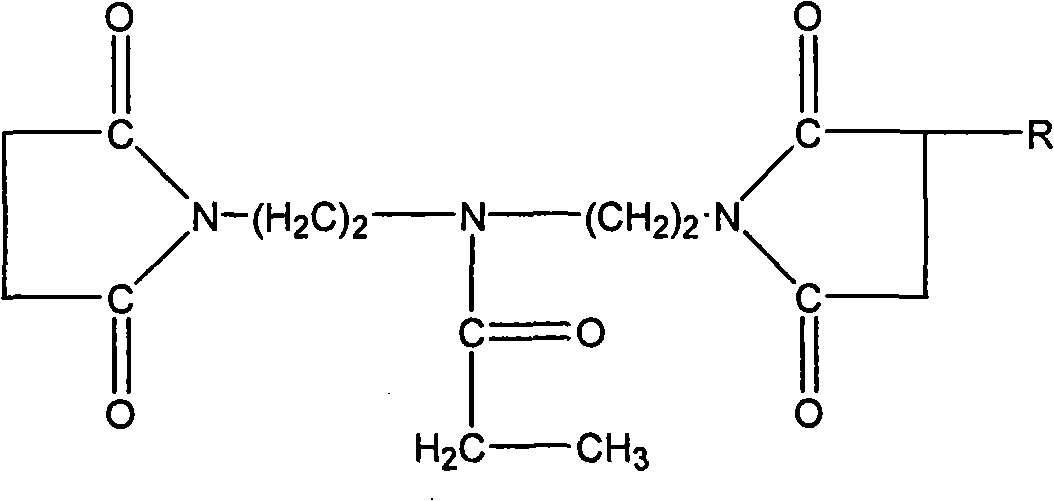

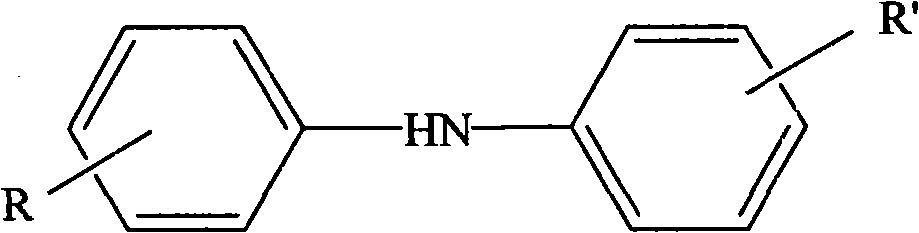

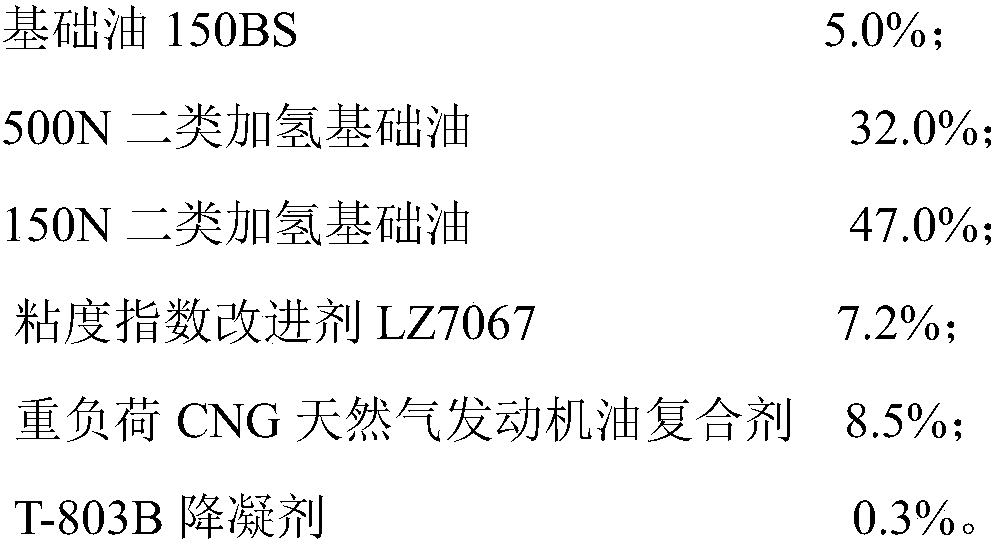

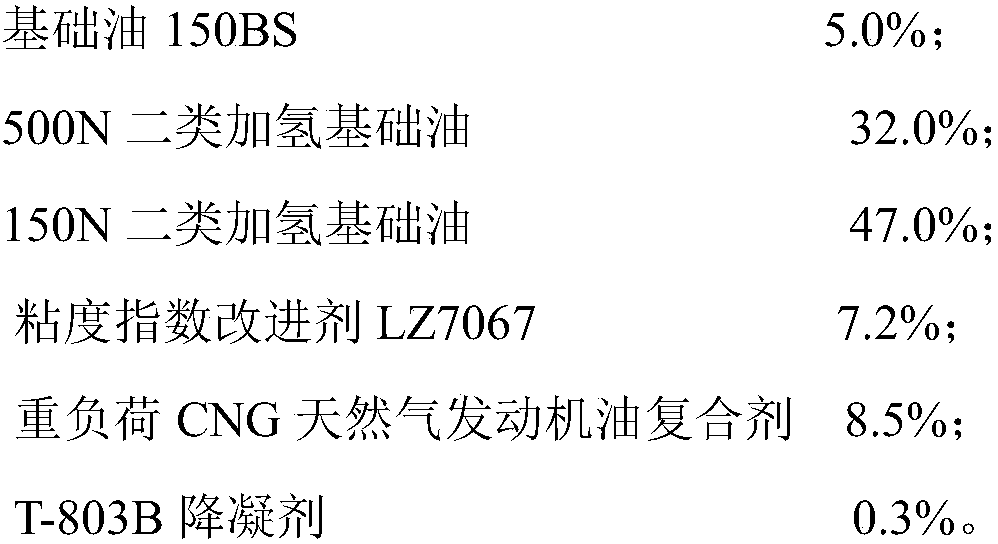

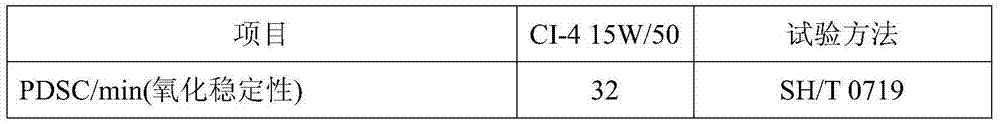

Heavy-loading CNG natural gas engine oil complexing agent and preparation method and application thereof

The invention relates to a heavy-loading CNG natural gas engine oil complexing agent and a preparation method and application thereof. The raw materials of the complexing agent comprise base zinc saltof dioctyl thiophosphate, super-alkali-value synthesis calcium sulfonate, alkylated diphenylamine, amidogen thioester, super-alkali-value synthesis magnesium sulfonate, high-molecular-weight ashlessdispersing agent and single alkenyl succinimide. The method comprises the steps that the raw materials are weighed, added to a blending kettle, heated to 60-70 DEG C, stirred for 2-3 hours at normal pressure and filtered, and the heavy-loading CNG natural gas engine oil complexing agent is obtained. The heavy-loading CNG natural gas engine oil complexing agent and the preparation method and application thereof have the advantages that the preparation method is easy to operate and the agent is easy to prepare. The complexing agent can distinctly meet the requirements in the second, third and fourth type of oil and is suitable for meeting the performance requirement of large-sized fixed and large-power mobile CNG natural gas engines.

Owner:锦州新兴石油添加剂有限责任公司

Formula and preparation method of low-carbon lubricating oil

ActiveCN103571592AImprove antioxidant capacityImprove nitrification capacityAdditivesFiltrationBase oil

The invention provides a formula and a preparation method of low-carbon lubricating oil. The formula is characterized by comprising the following components in parts by weight: 5 to 30 parts of synthetic base oil, 35 to 55 parts of III-type hydrogenated base oil, 15 to 22 parts of II-type hydrogenated base oil, 8 to 15 parts of V-type synthetic phenolic ester base oil, 5 to 15 parts of hydrogenated base oil 150BS and the balance of additives. The preparation method comprises the following steps of adding the base oil in parts by weight into blending equipment, raising temperature to 60 DEG C, and uniformly blending the base oil at constant temperature; sequentially adding various additives, raising the temperature to 70 to 75 DEG C (not more than 75 DEG C), stirring the base oil and the additives within 40 minutes at constant temperature to completely mix the base oil and the additives, and performing circulating filtration and cooling in four stages to obtain the low-carbon lubricating oil. The formula and the preparation method thereof have the beneficial effects that the limit of soot content is reduced; the low-carbon lubricating oil is energy-saving, low-phosphorus, environment-friendly, high in abrasion resistance and resistant to high temperature and high load; the high-temperature detergency is greatly improved; the carbon emission of the lubricating oil is effectively reduced.

Owner:TIANJIN LINXAN PETROCHEM

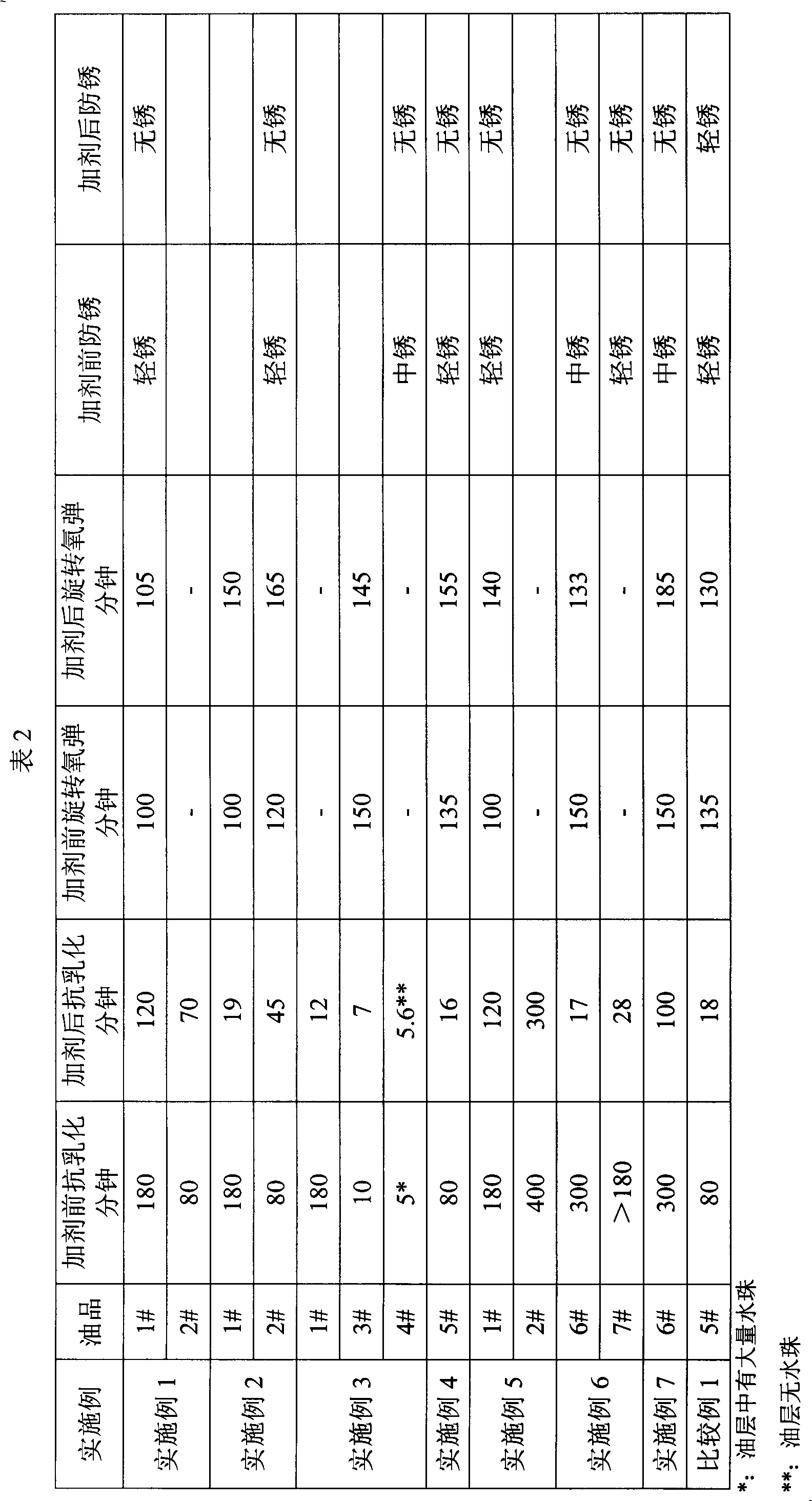

Method for improving steam turbine oil operation performances

ActiveCN102977972AImprove performanceExtended oil change intervalAdditivesBase oilPetroleum engineering

The invention relates to a method for improving steam turbine oil operation performances. The method solves the problem that based the prior art, only the de-emulsifier can improve demulsibility of steam turbine operation oil. Through utilization of 0.5 to 10wt% of an additive composition in steam turbine oil operation, the method solves the above problem and can be used for improving steam turbine oil operation performances, wherein the additive composition comprises: by weight, 0.05 to 10 parts of an antirust agent and 75 to 99.4 parts of base oil.

Owner:CHINA PETROLEUM & CHEM CORP

Internal combustion engine and oil treatment apparatus for use with the same

ActiveUS10323552B2Minimal redesignEasy to insertDrip or splash lubricationOilsumpsExternal combustion engineEngineering

An internal combustion engine having an improved oil treatment system. The internal combustion engine may be a splash lubrication engine in which oil is flowed through an oil circulation circuit by a passive pump. In another aspect, a dipstick tube may be provided that includes a portion of the oil circulation circuit. In a further aspect, the internal combustion engine comprises one or more protuberances that automatically penetrate an oil treatment apparatus upon the oil treatment apparatus being mounted to the internal combustion engine, thereby fluidly coupling the oil treatment apparatus to the oil circulation circuit.

Owner:KOHLER CO

Polyester lubricating oil and process

The invention discloses polyester lubricating oil and a blending process thereof. The polyester lubricating oil comprises the following components in percentage by mass: 18-25 percent of PAO4 base oil, 38-44 percent of PAO6 base oil, 12-16 percent of polyol ester base oil, 10-12 percent of a tackifier, 0.2-0.5 percent of a pour point reducer, 0.7-1.2 percent of a friction modifier and 11.30001-12.70003 percent of a complexing agent, wherein the complexing agent comprises 8.0-8.5 mass percent of high-alkali number petroleum calcium sulfonate, 2.0-2.5 mass percent of zinc butyl octyl dithiophosphate, 1.3-1.7 mass percent of zinc dialkyl dithiophosphate and 0.0001-0.0003 percent of methyl silicone oil ester. The polyester lubricating oil disclosed by the invention can meet the performance of the traditional lubricating oil, is high in stability, can achieve the effects of reducing pollution emission and energy consumption and automatically repairing abrasion equipment and has an environment-friendly effect.

Owner:ZHUHAI SINOCU LUBRICATING TECH CO LTD

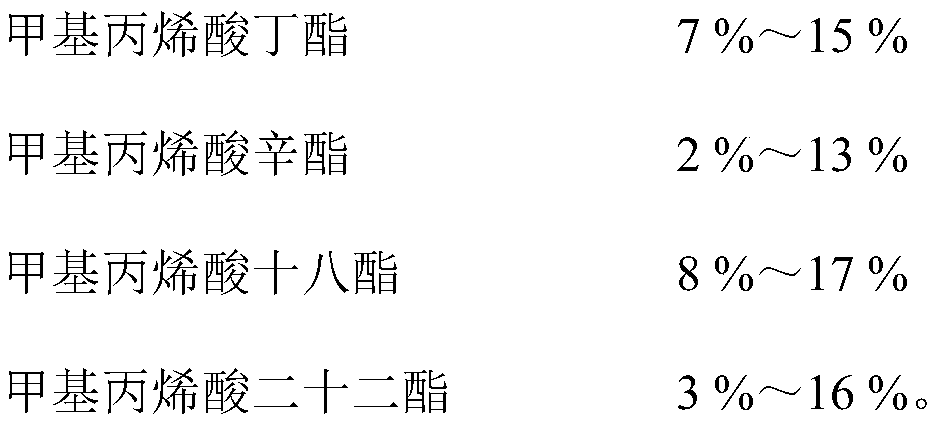

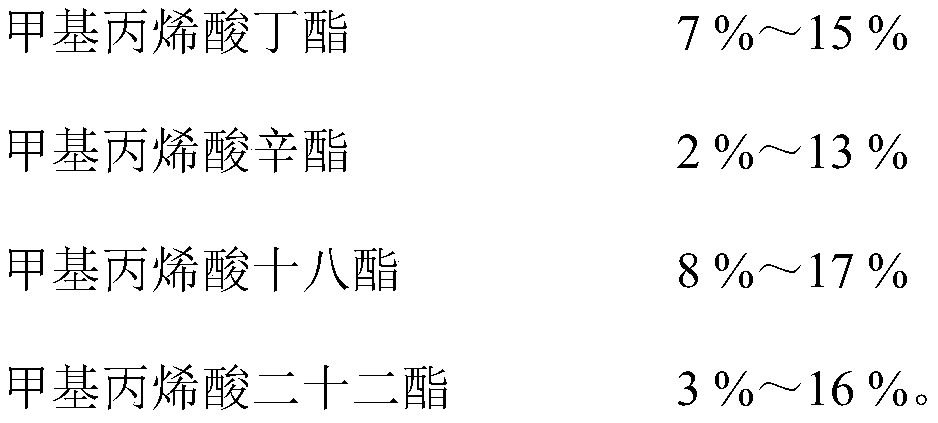

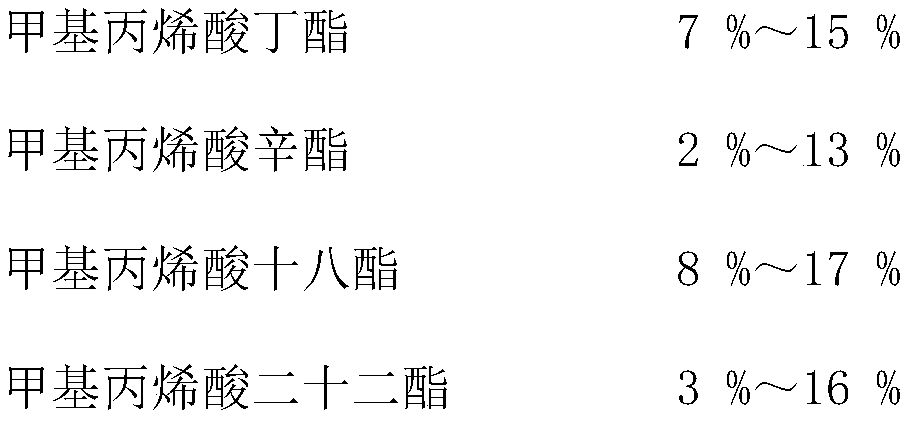

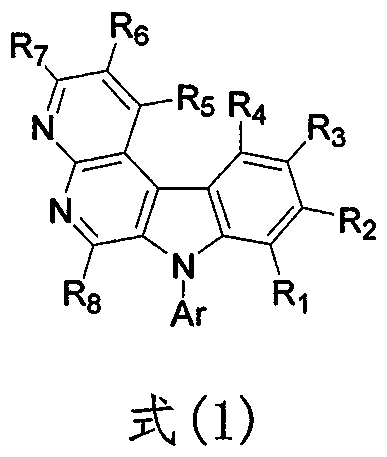

High-viscosity-index modifying agent, and preparation method and application thereof

InactiveCN109880671ALower working temperatureImprove low temperature performanceAdditivesMethacrylateViscosity index

The invention relates to a high-viscosity-index modifying agent, and a preparation method and application thereof. The modifying agent is prepared from three or four kinds of low-molecular-weight metacrylic acid ester. The preparation method comprises the following steps of proportionally mixing 10 percent of low-molecular-weight metacrylic acid ester and 40 percent of solvents in percentage by mass; performing stirring for 1 to 2 h at 20 to 40 DEG C; adding 20 percent of initiators; continuously performing stirring for 0.5 h; slowly adding 30 percent of high-molecular-weight metacrylic acid ester; continuously performing stirring for 1 to 2 h; preparing the high-viscosity-index modifying agent. The invention solves the problems of great viscosity loss or poor viscosifying effect of the single metacrylic acid ester; the modifying agent can be matched with basic oil for realizing the goal that power steering oil has good anti-shearing performance, viscosifying performance and performance for reducing the oil temperature of the power steering system; the metacrylic acid ester per se also has an anti-coagulating effect, so that the compounded power steering oil has good low-temperature performance; the service life of the power steering oil is prolonged; the quality problem of inflexible steering in winter is solved; the oil changing mileage is favorably increased.

Owner:FAW JIEFANG AUTOMOTIVE CO

Lubricating oil for marine medium-speed cylindrical piston diesel engine

PendingCN113637519AImprove stabilityExtended service lifeLubricant compositionImidePhysical chemistry

The invention relates to the technical field of lubricating oil, in particular to lubricating oil for a marine medium-speed cylindrical piston diesel engine. The lubricating oil for a marine medium-speed cylindrical piston diesel engine comprises the following raw materials: 80-88% of base oil, 5-9% of a composite metal detergent, 0.2-1% of a low-nitrogen polyisobutylene succinimide dispersant, 0.1-1% of a pour point depressant, 0.5-2% of an antioxidant, 3-5% of an OCP viscosity index improver, 1-5% of a phosphorus-nitrogen anti-wear extreme pressure additive and 1-5% of zinc dialkyl dithiophosphate. According to the present invention, the product is refined from the deeply hydrogenated base oil through the scientific formula and the advanced production process, such that the oxidation resistance and the stability of the oil product are substantially improved, the oil change period of the product can be substantially prolonged, the resource consumption can be effectively reduced, the use cost can be reduced, and the high cost performance is provided.

Owner:SHANDONG NORTH ZITE SPECIAL OIL

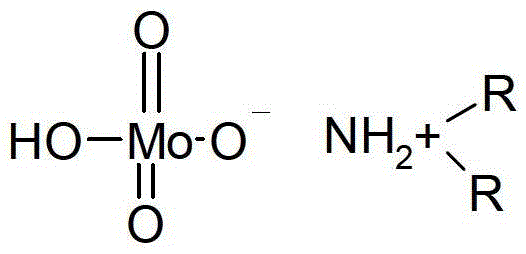

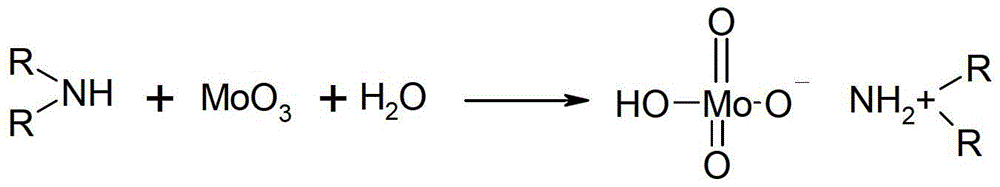

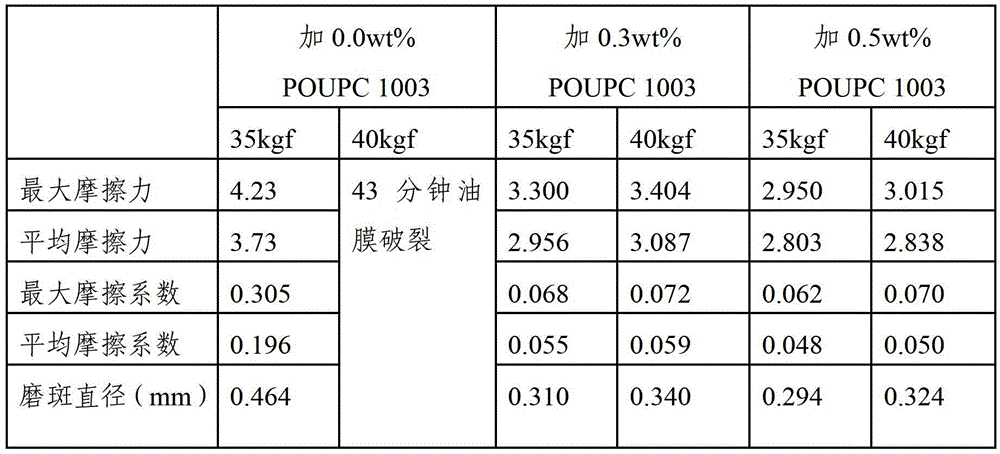

A kind of molybdenum-containing engine lubricating oil composition and preparation method thereof

Owner:BEIJING HYUNDAI LUBE PROD

Ester type flame retardant hydraulic oil and production method thereof

Owner:SHANDONG NORTH ZITE SPECIAL OIL

Polishing lubricant for automobile engine and preparation method of polishing lubricant

InactiveCN107384550ANot subject to wear and tearIncrease speedLubricant compositionSodium acetateCellulose

The invention discloses a polishing lubricant for an automobile engine and a preparation method of the polishing lubricant. The polishing lubricant is prepared from raw materials in parts by weight as follows: 10-45 parts of mineral oil, 15-25 parts of vaseline, 8-10 parts of polyisobutene, 12-25 parts of cellulose ether, 28-35 parts of trisodium phosphate, 15-20 parts of a metal corrosion inhibitor, 30-40 parts of a tackifier, 6-10 parts of sodium acetate, 7-11 parts of monopotassium phosphate, 3-7 parts of methyl silicone oil, 4-8 parts of polyvinyl alcohol, 5-9 parts of glycerol monostearate, 2-3 parts of bisphenol A polycarbonate, 7-10 parts of sulfurized calcium alkyl phenolate, 3-5 parts of magnesium alkyl benzenesulphonate, 6-8 parts of zinc dialkyl dithiophosphate, 3-6 parts of volcanic ore lava nano-powder and 5-8 parts of sodium benzoate. The polishing lubricant can protect an engine against abrasion well, increase the rotation speed of the engine, is abrasion-resistant, squeezing-resistant and high-temperature-resistant, increases oil drain interval, and increases horsepower by 20%, and engine oil does not deteriorate.

Owner:龙爱量子科技实业发展(深圳)有限公司

An oil-soluble non-sulfur phosphorus organic molybdenum compound, its preparation method and application

ActiveCN103319539BImprove antioxidant capacityImprove high temperature oxidation resistanceGroup 6/16 element organic compoundsAdditivesPhysical chemistryMolybdenum compounds

Owner:江苏现代节能科技发展有限公司

Lubricating oil containing detergent dispersant

InactiveCN109097169AImprove wear resistanceImprove thermal stabilityLubricant compositionDispersityThermal stability

The invention relates to the field of lubricating oil preparation, in particular to lubricating oil containing a detergent dispersant. The lubricating oil comprises 90-98 parts of basic oil and 2-10 parts of an additive, wherein the additive comprises 0.4-0.6 parts of the detergent dispersant which is polyisobutylene succinimide. The lubricating oil in the technical scheme has superhigh wear resistance, thermal stability, oxidation resistance, dispersity, detergency, acid neutrality, cooling performance and corrosion resistance, has functions of reducing friction, retarding wear, cooling parts, cleaning part surfaces and preventing part corrosion in use and can improve the mechanical efficiency, prolong mechanical life and oil draining period and reduce environmental pollution.

Owner:SHAANXI DONGHE NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com