Method for improving steam turbine oil operation performances

A technology of steam turbine oil and running performance, which is applied in the direction of petroleum industry, additives, lubricating compositions, etc., can solve the problems such as the decline of anti-rust performance and the difficulty of water separation, so as to reduce the water content, extend the oil change period, and improve the anti-corrosion The effect of oxidation stability

Active Publication Date: 2013-03-20

CHINA PETROLEUM & CHEM CORP

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These additives can solve the problem of difficult water separation of steam turbine oil during operation, but for other properties of oil products, such as the decline of anti-rust performance caused by the loss of additives in steam turbine oil due to water ingress, there is no improvement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~7

[0017] Add the antirust agent and antioxidant to the base oil in proportion at 55° C., stir for 3 hours to dissolve them all, and obtain the additive composition. The types and contents of each component are shown in Table 1.

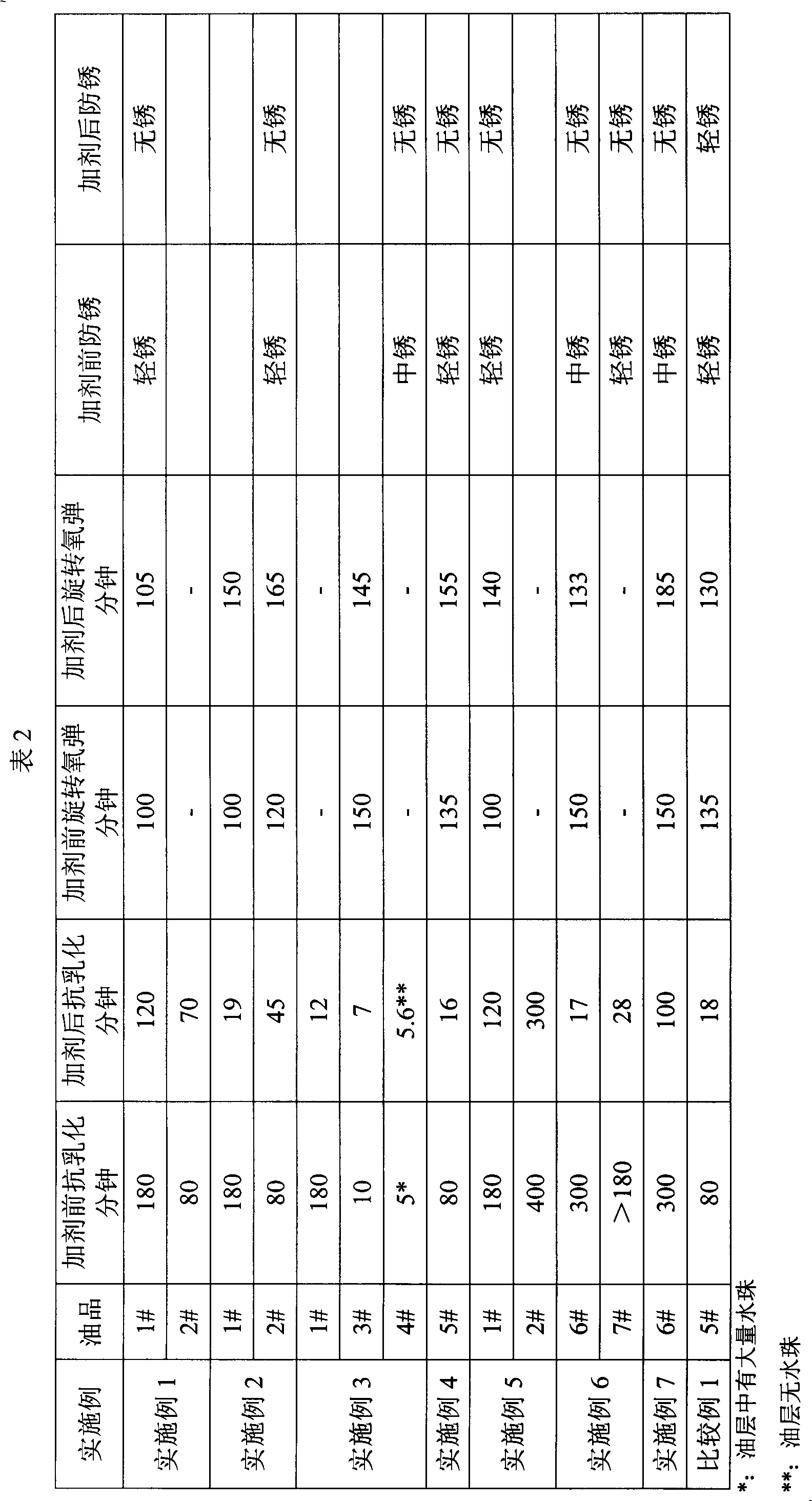

[0018] The additive composition was added into various operating oils at a rate of 3% by weight, and the effects in operating oils are shown in Table 2.

[0019] Table 1

[0020] Example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for improving steam turbine oil operation performances. The method solves the problem that based the prior art, only the de-emulsifier can improve demulsibility of steam turbine operation oil. Through utilization of 0.5 to 10wt% of an additive composition in steam turbine oil operation, the method solves the above problem and can be used for improving steam turbine oil operation performances, wherein the additive composition comprises: by weight, 0.05 to 10 parts of an antirust agent and 75 to 99.4 parts of base oil.

Description

technical field [0001] The invention relates to a method for improving the running performance of steam turbine oil. Background technique [0002] Steam turbine is also called turbine (Turbine), which is the key equipment for energy conversion in power generation equipment. A steam turbine is a rotary power machine that converts steam energy into mechanical work, and is one of the main equipment of a steam power plant. The structure and purpose of the gas turbine are similar to it. It is a thermal gas power machine that converts the thermal energy carried by the hot gas into rotating mechanical energy. The water turbine belongs to the turbo machinery in the fluid machinery, and it is a power machine that converts the energy of water flow into rotational mechanical energy. [0003] Steam turbines include drive steam turbines and industrial power generation steam turbines. According to different uses, there are power station steam turbines, industrial steam turbines and mari...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M141/08C10M141/06C10M141/02C10M135/10C10M129/28C10M129/72C10M129/93C10M129/95C10N30/12

Inventor 益梅蓉傅树琴孔吉霞何晓瑛周霞俞巧珍

Owner CHINA PETROLEUM & CHEM CORP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com