Automobile engine lubricating oil with effects of simultaneously reducing consumption of engine oil and fuel oil and preparation method of automobile engine lubricating oil

A technology of automobile engine and fuel consumption, which is applied in the field of lubricating oil, can solve the problem of high consumption, achieve the effects of small frictional resistance, improved scope of application and cost performance, and extended oil change mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

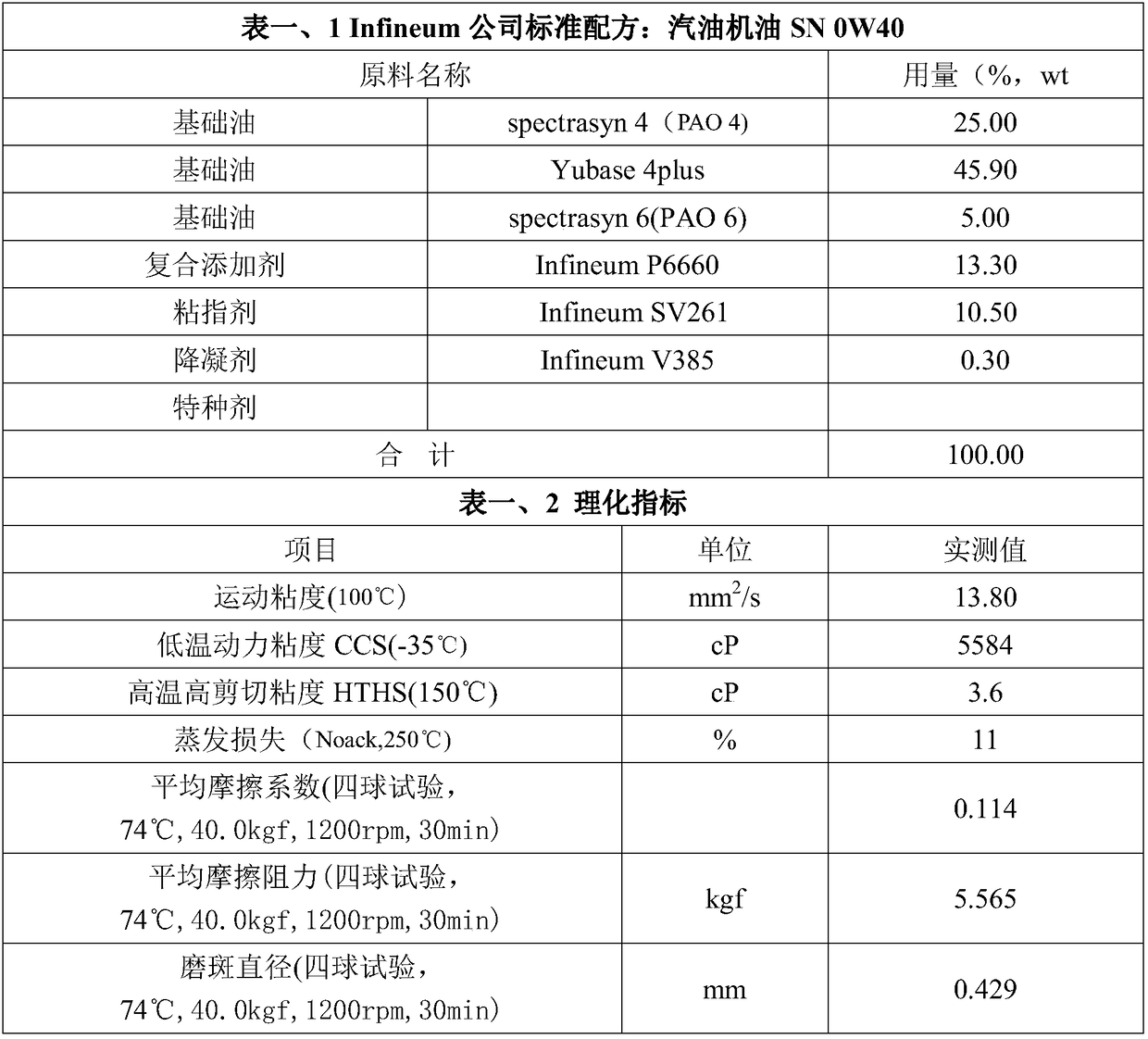

[0023] Infineum's most advanced gasoline engine oil compound additive is P6660, which has passed API SN, ACEA A5 / B5, VW501 01 / 502 00 / 505 00, BMW LL-01, MB 229.3 / 229.5, Porsche A40 certification, and its certified standards The measured indicators of the formula and blended gasoline engine oil SN0W40 are shown in Table 1:

[0024]

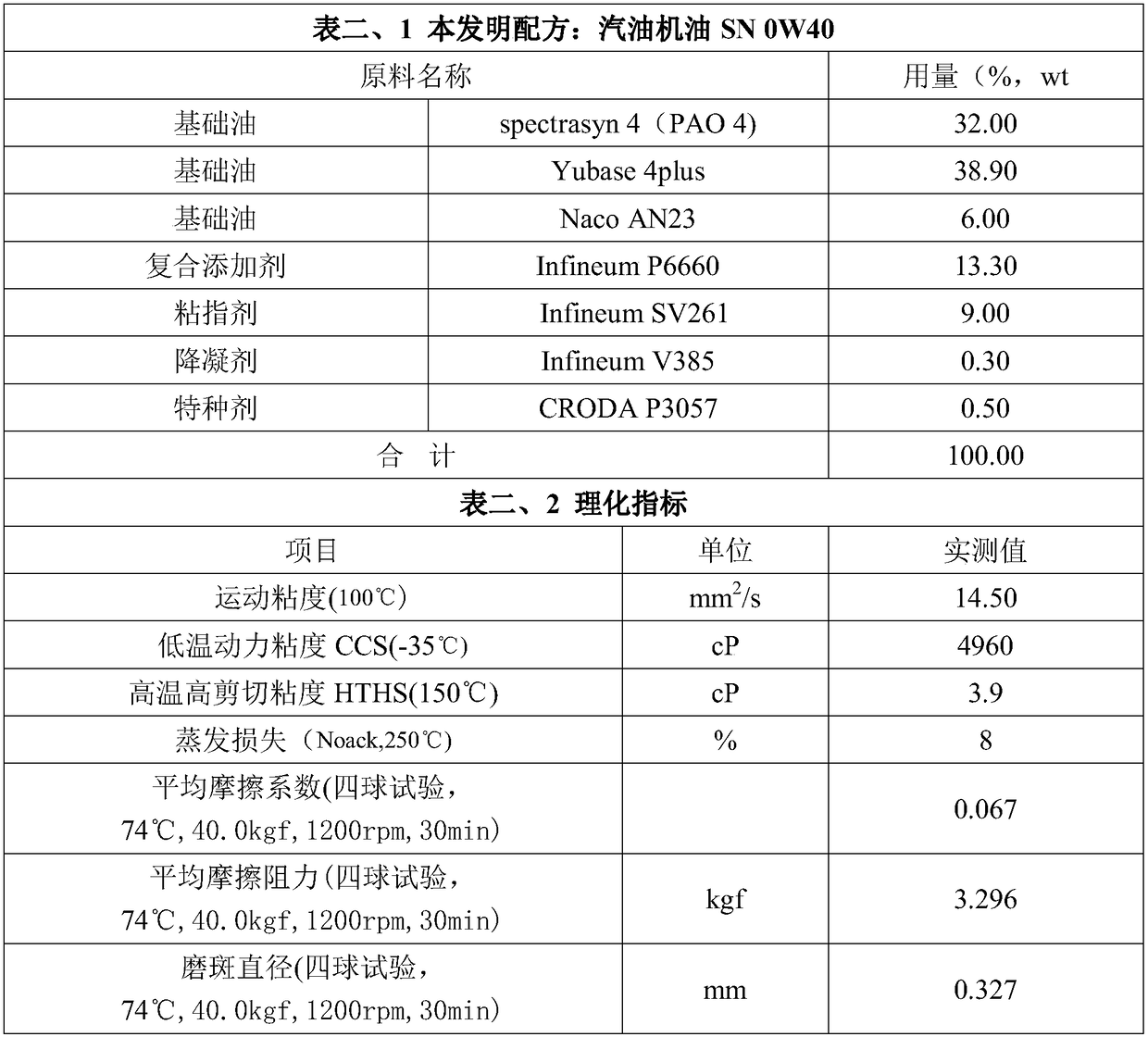

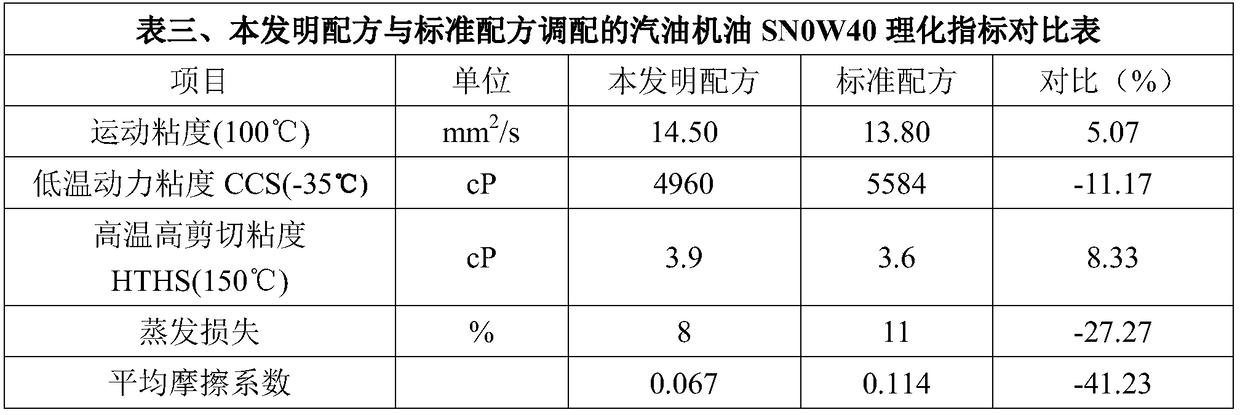

[0025] Based on the above standard formula, add a high-viscosity alkylnaphthalene synthetic base oil 6% (wt) of AN23 produced by NACO, and an organic polymer friction modifier of Perfad 3057 produced by CRODA 0.5% % (wt), the amount of composite additive P6660 and pour point depressant V385 remains unchanged, the amount of viscosity index agent is controlled not to exceed 9% (wt), the amount of base oil is adjusted until the physical and chemical indicators of the product after deployment meet the requirements of API SN0W40 standard, 100 ° C The kinematic viscosity is 14.5-15.5mm 2 / s range. According to the formula adjusted by the method descr...

Embodiment 2

[0036] Afton's gasoline engine oil composite additive HiTEC 11100 has passed API SN, GM dexos1, and ILSACGF-5 certifications. Its certified standard formula and measured indicators of gasoline engine oil SN5W30 are shown in Table 1:

[0037]

[0038]

[0039] Based on the above-mentioned standard formula, add a high-viscosity alkylnaphthalene synthetic base oil 5% (wt) of AN23 produced by NACO, and an organic polymer friction modifier of Perfad 3057 produced by CRODA 0.5% % (wt), the amount of compound additive HiTEC 11100 remains unchanged, and the pour point depressant V385 is increased by 0.2% (wt), the amount of viscosity index agent is controlled not to exceed 9% (wt), and the amount of base oil is adjusted until the physical and chemical indicators of the product after deployment meet API SN5W30 standard requires that the kinematic viscosity at 100°C is 11.0-11.5mm 2 / s range. The formula adjusted according to the method described and the gasoline engine oil SN5W3...

Embodiment 3

[0049] Infineum's diesel engine oil compound additive D3494 has passed API CJ-4 / CI-4, ACEA E7 / E9, MB 228.31, MAN3275, Volvo VDS-4 and other certifications, and its certified standard formula and blended diesel engine oil CJ-410W40 The measured indicators are shown in Table 1:

[0050]

[0051]

[0052] Based on the above-mentioned standard formula, add a high-viscosity alkylnaphthalene synthetic base oil 9% (wt) of AN23 produced by NACO, and an organic polymer friction modifier of Perfad 3057 produced by CRODA 0.5% % (wt), the amount of compound additive D3494 remains unchanged, the amount of pour point depressant V385 is adjusted to 0.3% (wt), the amount of viscosity index agent is controlled not to exceed 9% (wt), and the amount of base oil is adjusted until the physical and chemical indicators of the product after deployment Comply with API CJ-4 10W40 standard requirements, kinematic viscosity at 100°C is 14.5-15.5mm 2 / s range. The formula adjusted according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com