Preparation method for energy-saving and environment-friendly diesel engine oil

An energy-saving and environmental-friendly diesel engine technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problem of large emissions of harmful particulate matter, achieve the effects of reducing emissions, reducing friction losses, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

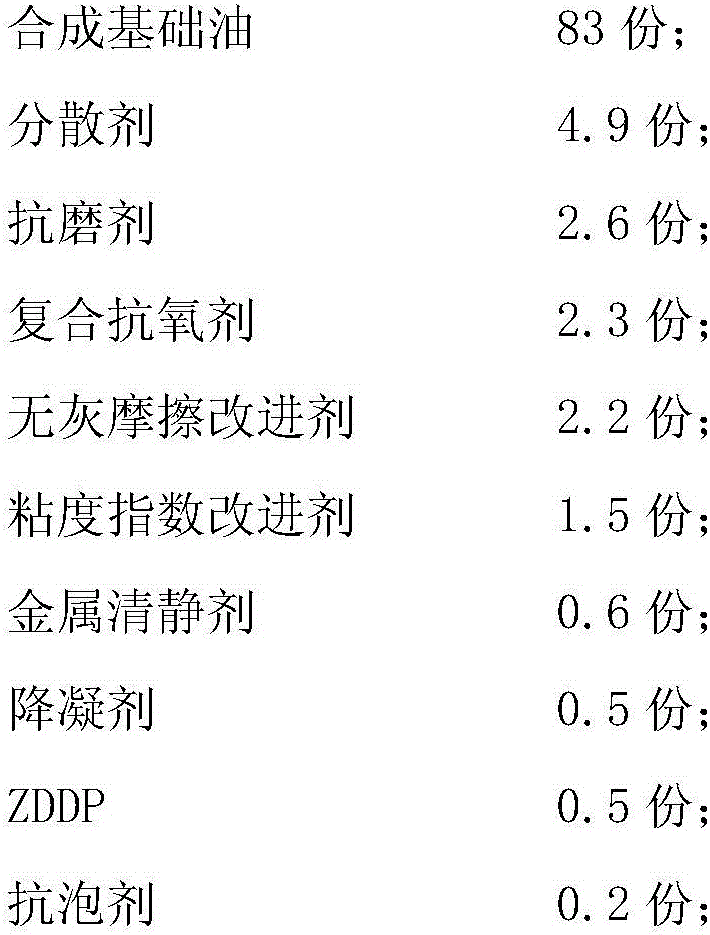

[0024] A kind of environment-friendly and energy-saving diesel engine oil, calculated in parts by mass, the composition and content of its raw materials are as follows:

[0025]

[0026] Described synthetic base oil, by 15 parts of epoxidized soybean oil, 33 parts of polyalpha-olefins, 11 parts of pentaerythritol tetramyristate, 7 parts of alkyl dibenzyl toluene, 13 parts of trimellitate and 4 parts 600N base oil is compounded; the 600N base oil is KixxLUBO 600N base oil provided by Korea GS, and its physical and chemical indicators are as follows: kinematic viscosity (40°C) 102.7mm2 / s, kinematic viscosity (100°C) 111mm2 / s , Flash point (opening) 282°C, pour point -15°C.

[0027] The dispersant is a polymer succinimide dispersant;

[0028] The anti-wear agent is N,N-di(2-ethylhexyl) molybdenum dithiotricyclic carbamate, N-cyclohexyl N-tridecyl molybdenum dithiocarbamate, amino diisopropyl A mixture of tungsten dithiophosphate, the molybdenum N,N-bis(2-ethylhexyl)dithiotri...

Embodiment 2

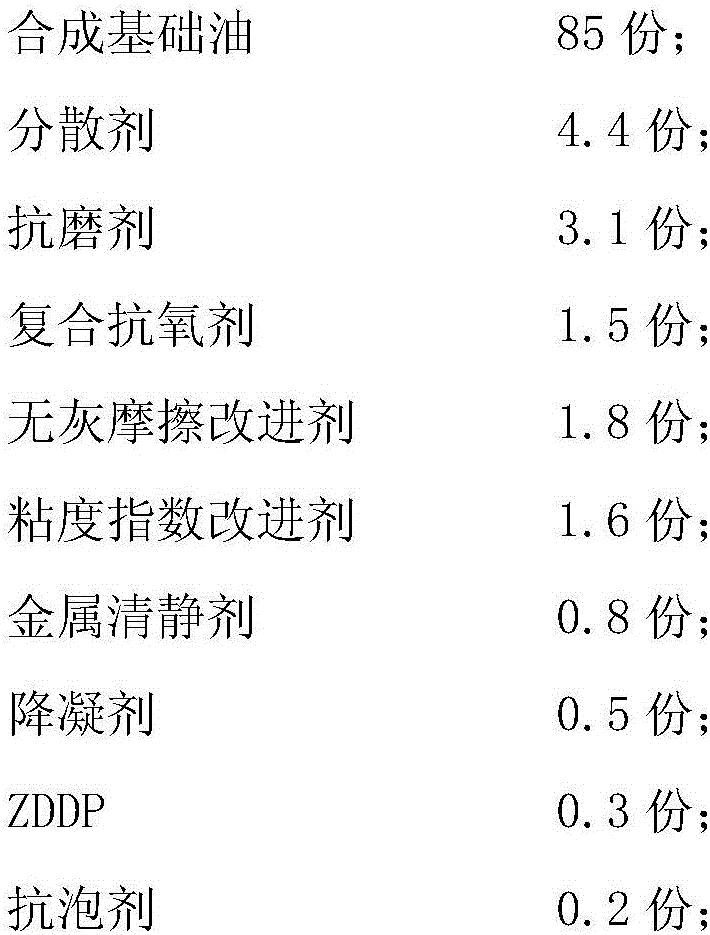

[0038] A kind of environment-friendly and energy-saving diesel engine oil, calculated in parts by mass, the composition and content of its raw materials are as follows:

[0039]

[0040] Preparation method is with embodiment 1, difference is:

[0041] Described synthetic base oil, by 17 parts of epoxidized soybean oil, 33 parts of polyalpha-olefins, 11 parts of pentaerythritol tetramyristate, 7 parts of alkyl dibenzyl toluene, 13 parts of trimellitate and 4 parts 600N base oil is compounded.

[0042] The dispersant is a combination of boronated succinimide and monopolyisobutylene succinimide, and the mass ratio of the two is 1:1.5;

[0043] The anti-wear agent is N,N-di(2-ethylhexyl) molybdenum dithiotricyclic carbamate, N-cyclohexyl N-tridecyl molybdenum dithiocarbamate, amino diisopropyl A mixture of tungsten dithiophosphate, the molybdenum N,N-bis(2-ethylhexyl)dithiotricyclic carbamate, N-cyclohexyl N-tridecylmolybdenum dithiocarbamate, amino The mass ratio of tungste...

Embodiment 3

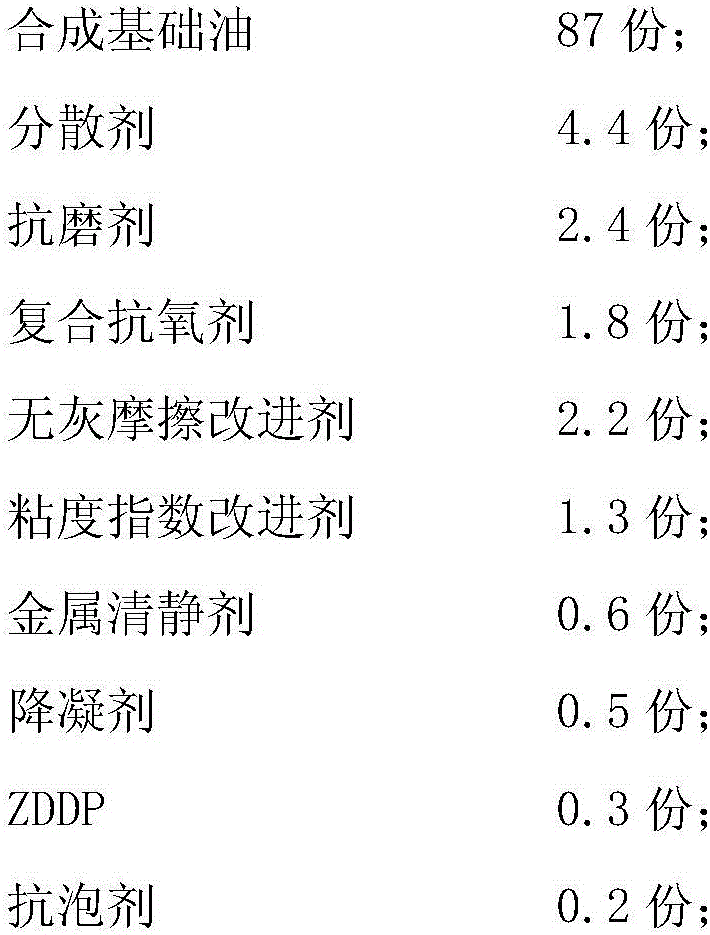

[0048] A kind of environment-friendly and energy-saving diesel engine oil, calculated in parts by mass, the composition and content of its raw materials are as follows:

[0049]

[0050] Preparation method is with embodiment 1, difference is:

[0051] Described synthetic base oil, by 17 parts of epoxidized soybean oil, 33 parts of polyalpha-olefins, 11 parts of pentaerythritol tetramyristate, 7 parts of alkyl dibenzyl toluene, 13 parts of trimellitate and 6 parts 600N base oil is compounded.

[0052] The dispersant is a combination of polymer succinimide dispersant and boronated succinimide, and the mass ratio of the two is 1:3;

[0053] The anti-wear agent is N,N-di(2-ethylhexyl) molybdenum dithiotricyclic carbamate, N-cyclohexyl N-tridecyl molybdenum dithiocarbamate, amino diisopropyl A mixture of tungsten dithiophosphate, the molybdenum N,N-bis(2-ethylhexyl)dithiotricyclic carbamate, N-cyclohexyl N-tridecylmolybdenum dithiocarbamate, amino The mass ratio of tungsten d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com