An oil-soluble non-sulfur phosphorus organic molybdenum compound, its preparation method and application

A technology of organic molybdenum and compounds, which is applied in the field of oil-soluble non-sulfur phosphorus organic molybdenum compounds, can solve the problems of unfavorable tail gas emissions, and achieve the effects of favorable tail gas emissions, overall content reduction, and increased antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

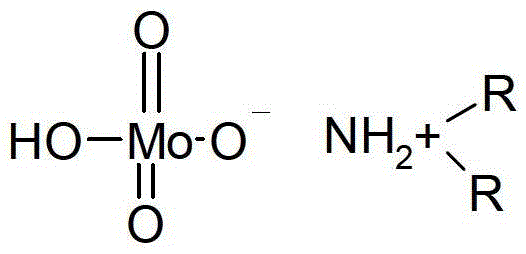

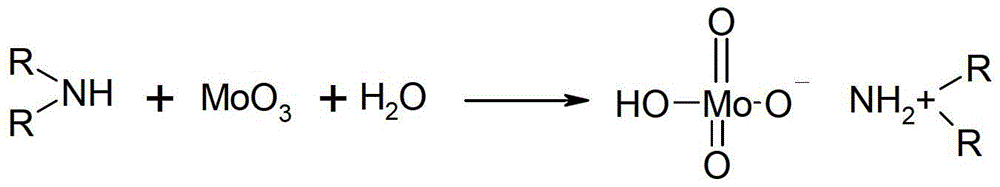

[0024] The preparation of embodiment 1 bis-isooctylamine molybdenum complex

[0025] Under the environment of nitrogen flow protection, uniformly disperse 1 mole of molybdenum trioxide solid powder in 540 ml of aqueous solution, then slowly add 0.5 mole of 60% sulfuric acid, and then slowly add 1.2 moles of bis-isooctyl secondary amine to the dispersion (recommended to complete within one hour). The temperature of the reaction system is controlled between 50° C. and 60° C., and the reaction time is about one hour. Then the upper water layer was removed to obtain a light blue crude product, which was washed, filtered and evaporated to obtain the finished product. After testing, the elemental content of the product sample: molybdenum content 22.8%, nitrogen content 3.6%. It is speculated that the product is a bis-isooctylamine molybdenum complex (R is a branched C 8 Alkyl, and has the above general structural formula).

Embodiment 2

[0026] The preparation of embodiment 2 bis-octylamine molybdenum complexes

[0027] Under the environment of nitrogen flow protection, uniformly disperse 1 mole of molybdenum trioxide solid powder in 540 ml of aqueous solution, then slowly add 0.5 mole of 60% sulfuric acid, and then slowly add 1.2 mole of bis-n-octyl secondary to the dispersion. Amines (recommended within one hour). The temperature of the reaction system is controlled between 50° C. and 60° C., and the reaction time is about 1 hour. Then the upper water layer was removed to obtain a light blue crude product, which was washed, filtered and evaporated to obtain the finished product. After testing, the elemental content of the product sample: molybdenum content 22.4%, nitrogen content 3.5%. After speculation, the product is bis-octylamine molybdenum complex (R is C 8 And has the above general structural formula).

Embodiment 3

[0028] The preparation of embodiment 3 ditridecylamine molybdenum complexes

[0029] Under the environment of nitrogen flow protection, uniformly disperse 1 mole of molybdenum trioxide solid powder in 540 ml of aqueous solution, then slowly add 0.6 mole of 60% sulfuric acid, and then slowly add 1.5 mole of ditricone to the dispersion Alkyl secondary amines (recommended within one hour). The temperature of the reaction system is controlled between 60° C. and 70° C., and the reaction time is about 1.5 hours. Then the upper water layer was removed to obtain a light blue crude product, which was washed, filtered and evaporated to obtain the finished product. After testing, the elemental content of the product sample: molybdenum content 16.4%, nitrogen content 2.3%. After guessing, this product is ditridecylamine molybdenum complex (R is C 13 And has the above general structural formula).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com