Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Excellent plating adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroplate grade PC/ABS alloy material and preparation method thereof

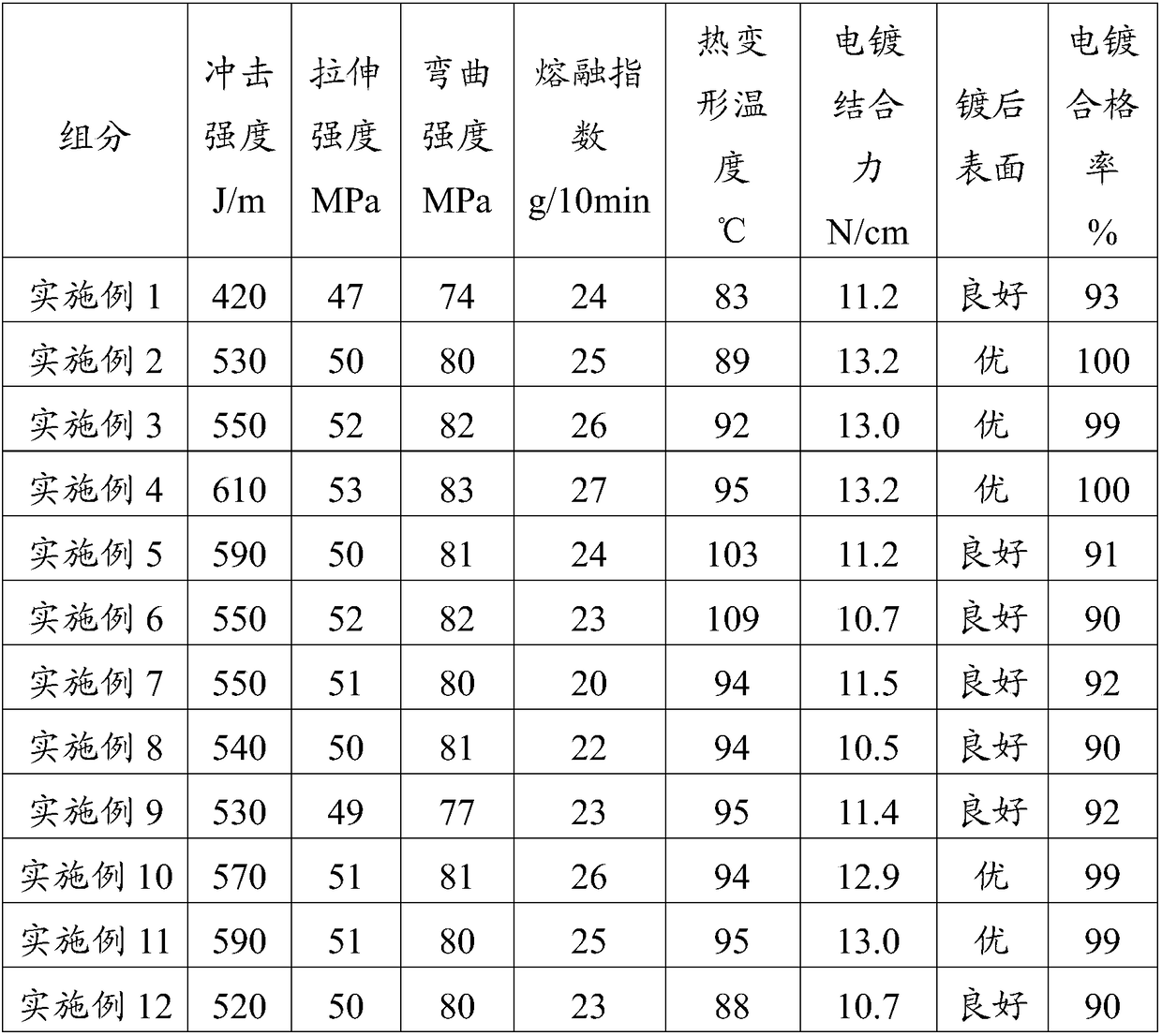

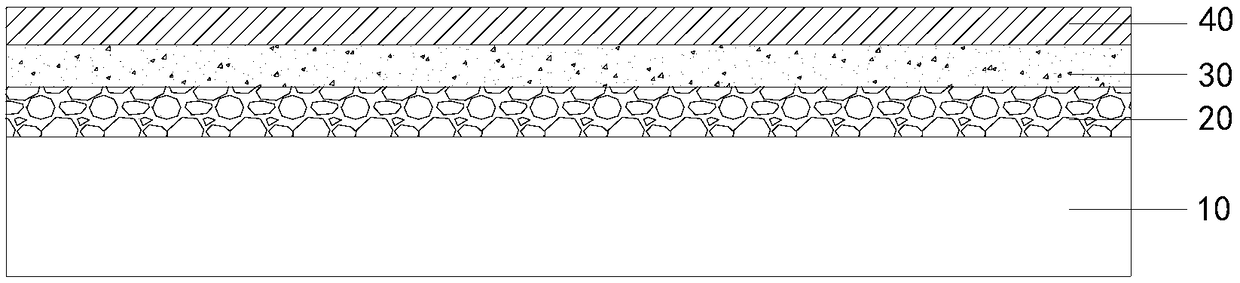

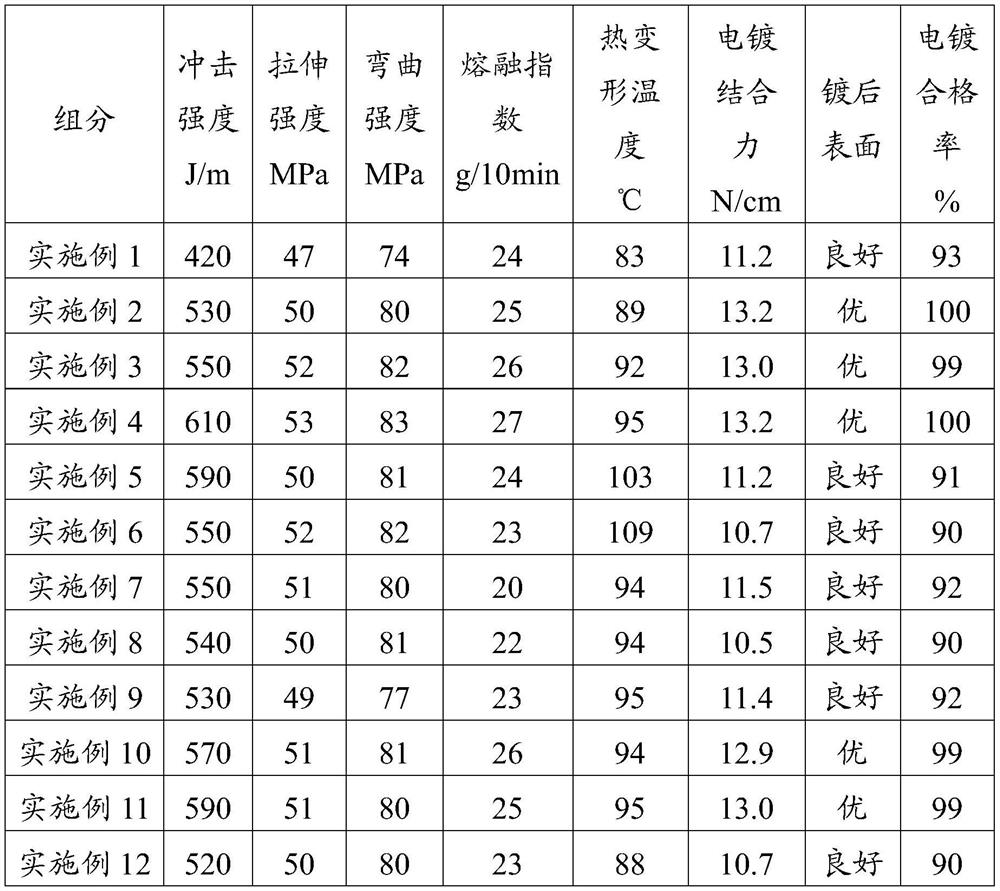

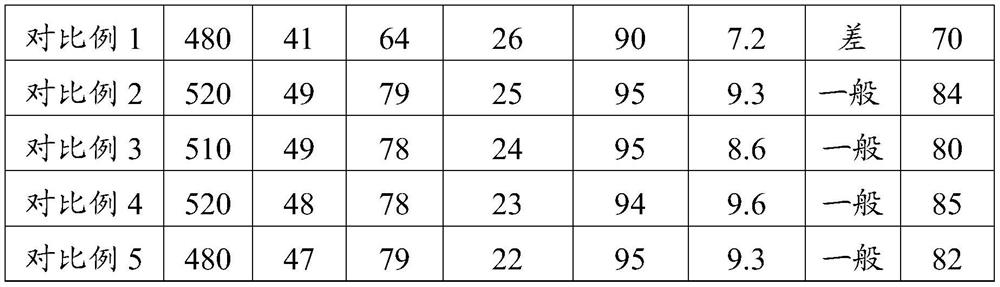

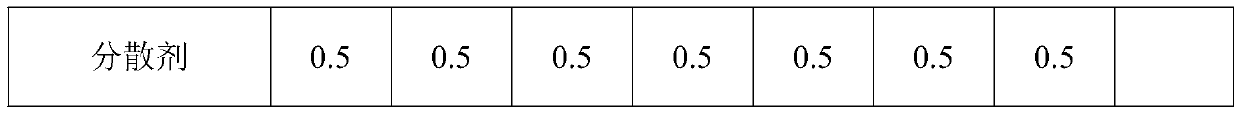

The invention provides an electroplate grade PC / ABS alloy material with high electroplate binding force and a preparation method of the electroplate grade PC / ABS alloy material. The electroplate gradePC / ABS alloy material comprises: in parts by weight, 10-70 parts of polycarbonate (PC), 10-70 parts of styrene-butadiene-acrylonitrile copolymer (ABS), 20-35 parts of terminated nitrile rubber and acertain parts of optional additives, wherein the total amount of the polycarbonate, styrene-butadiene-acrylonitrile copolymer and terminated nitrile rubber are 100 parts by weight. The injection molding process of the electroplate grade PC / ABS alloy material is further optimized, and a finished product which is made from the electroplate grade PC / ABS alloy material has the advantages of easy electroplating, high electroplate binding force, high yield and few surface defects.

Owner:WANHUA CHEM GRP CO LTD

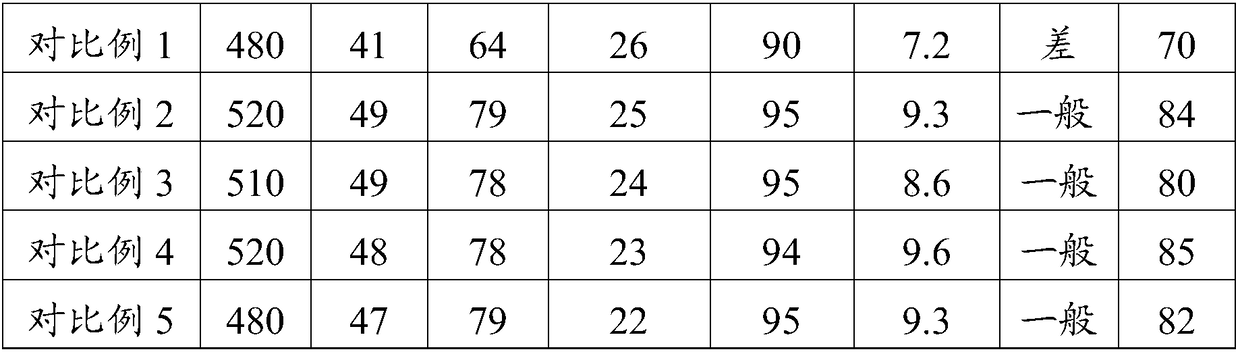

Surface mounting type electronic components and manufacturing method of the same

InactiveCN101165826AImproves plating adhesionGood installabilityMultiple fixed capacitorsFixed capacitor electrodesComposite materialSurface mounting

One inventive aspect relates to a surface mounting type electronic component excellent in a mounting property and having desired equivalent series resistance (ESR). The component has an electronic component body, and at least a pair of terminal electrodes formed on a surface of the electronic component body. The terminal electrode has a conductive resin layer formed between a substrate metal layer and a metal plating layer. The first and second layers each comprise a curable resin and metal particles. The first layer is lower in the content of metal particles than the second layer.

Owner:TAIYO YUDEN KK

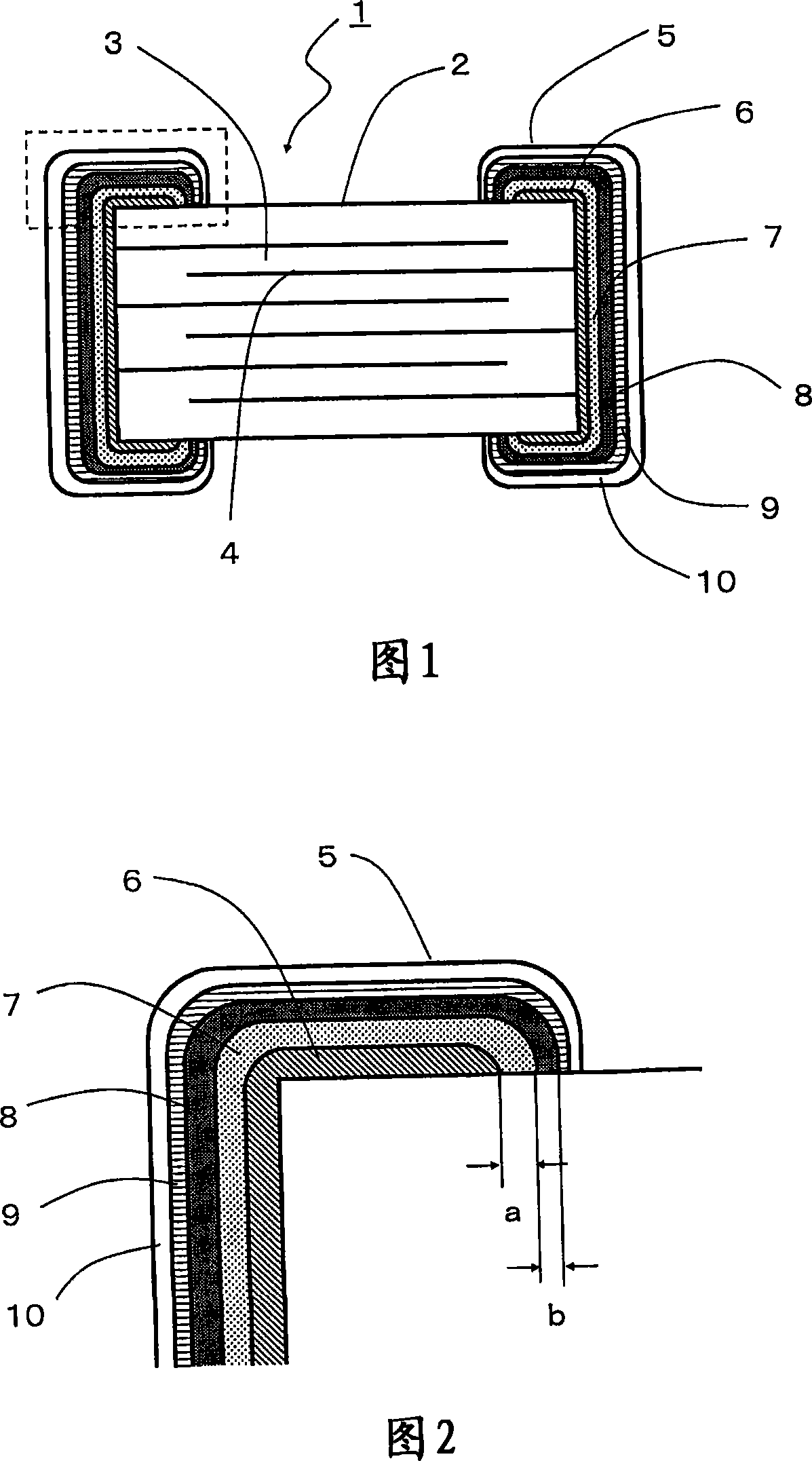

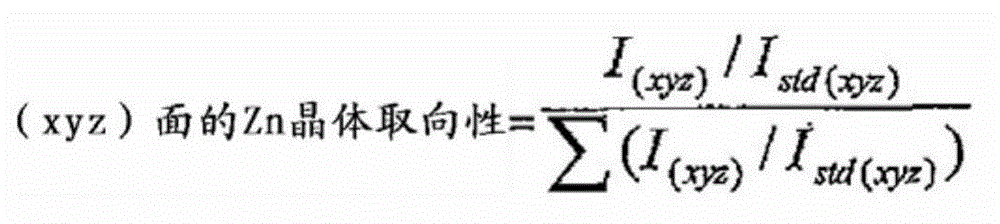

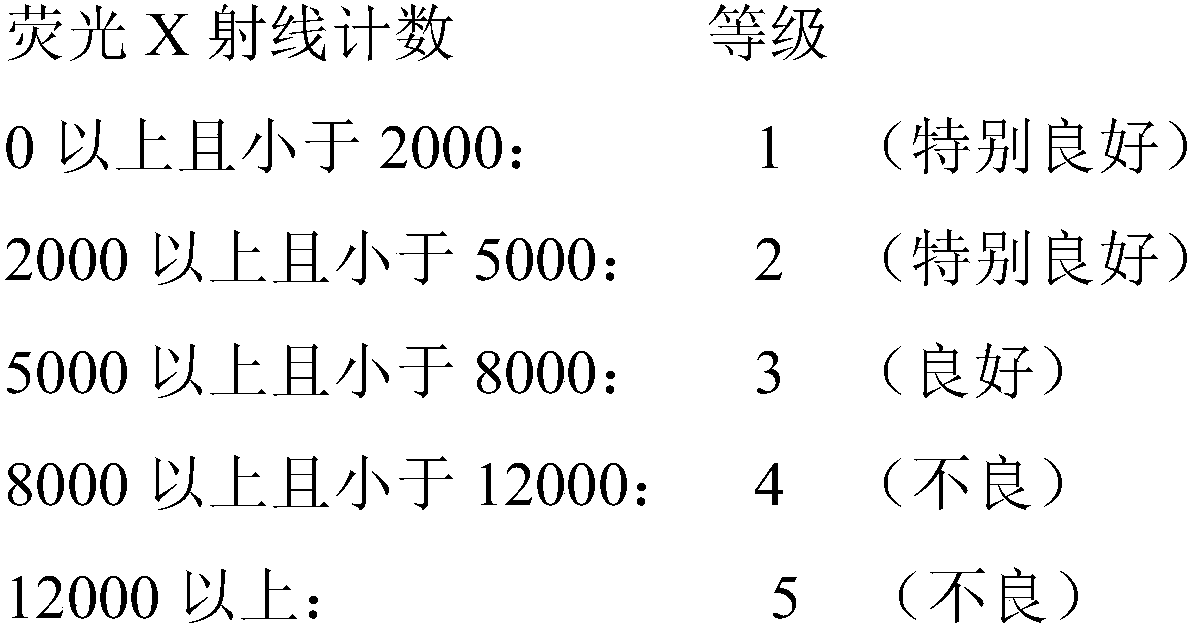

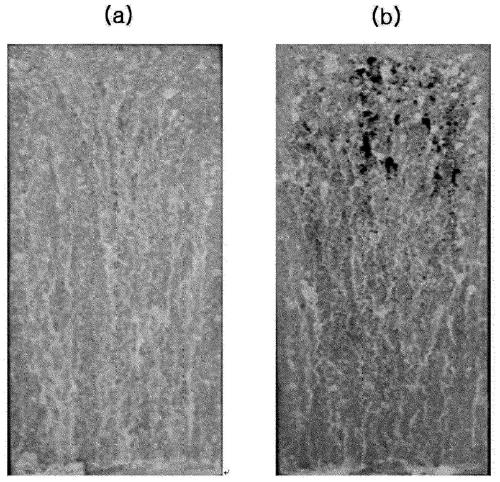

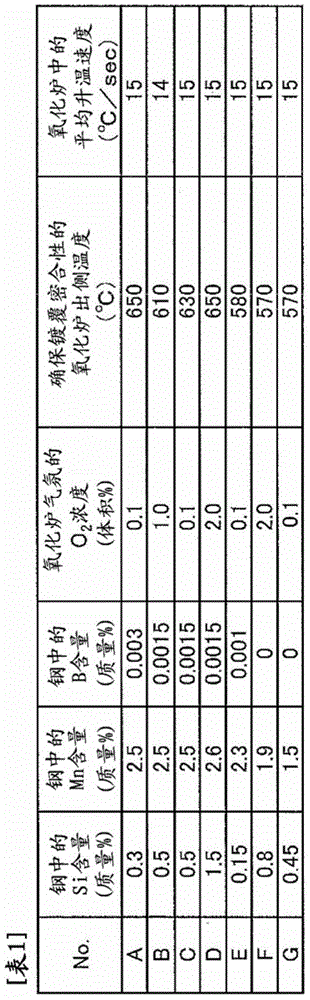

Galvanized steel sheet and manufacturing method therefor

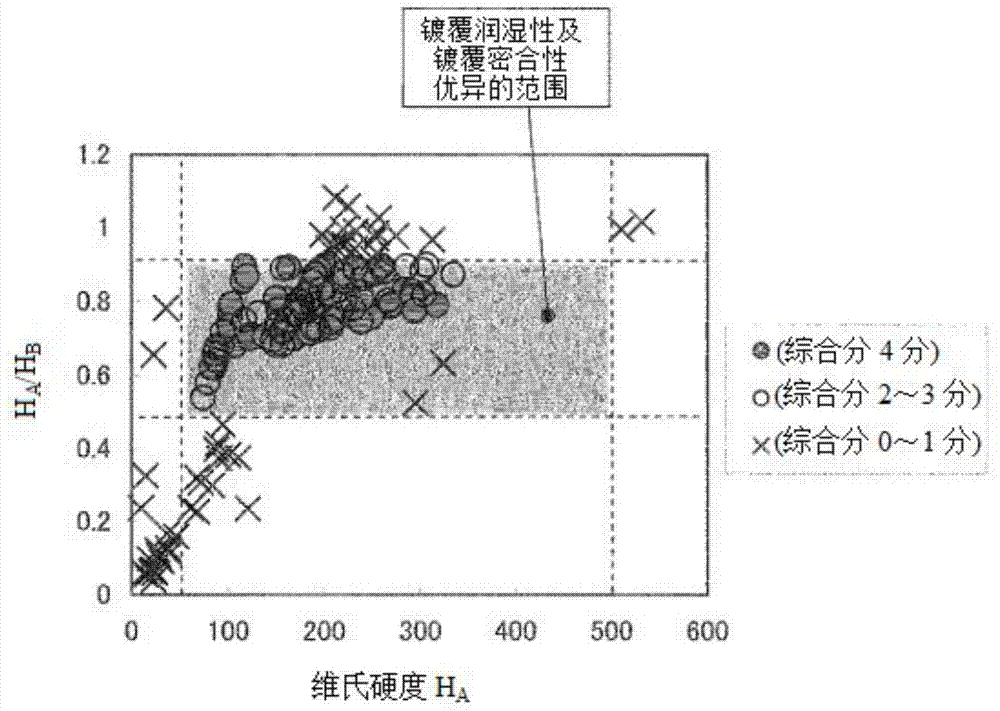

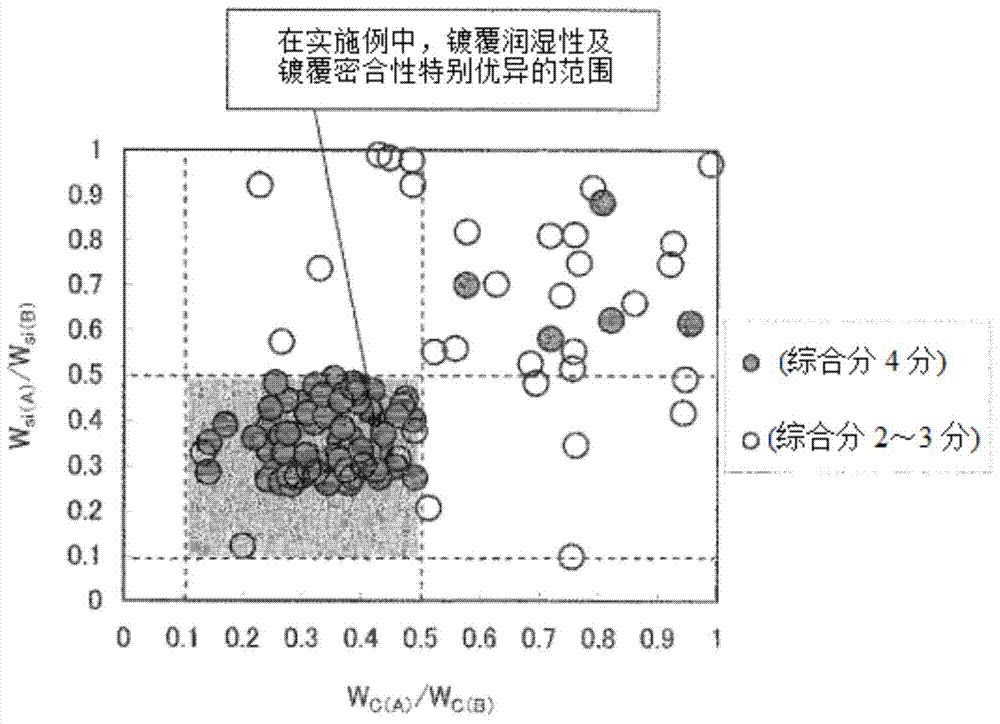

ActiveCN104508169AExcellent plating adhesionHot-dipping/immersion processesFurnace typesSurface layerSheet steel

The present invention provides a galvanized steel sheet having excellent plating wettability and plating adhesion even when the base steel sheet contains Si and Mn, and provides a manufacturing method therefor. The galvanized steel sheet pertaining to the present invention includes a base steel plate containing Si, Mn, and other predetermined components, and a galvanized layer formed on at least one surface of the base steel plate. The base steel plate has an HA value and an HB that satisfy all of the following relational expressions, wherein HA is the average hardness of the surface layer that extends to a depth of 50 mum from the interface between the base steel plate and the galvanized layer, and HB is the average hardness of deep portions in excess of 50 mum from the interface. 50 <= HA <= 500 ... (1) 50 <= HB <= 500 ... (2) 0.5 <= HA / HB <= 0.9 ... (3)

Owner:NIPPON STEEL CORP

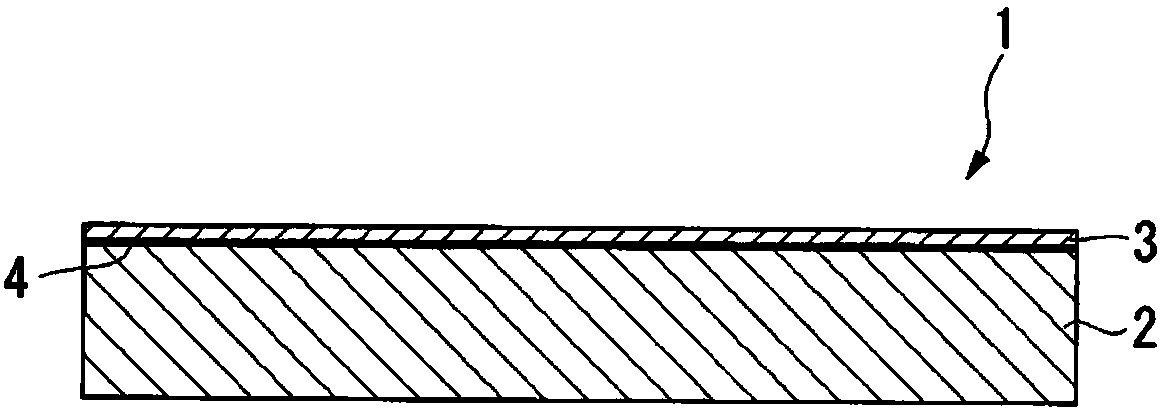

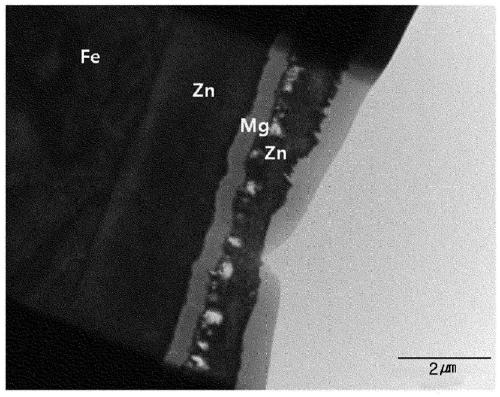

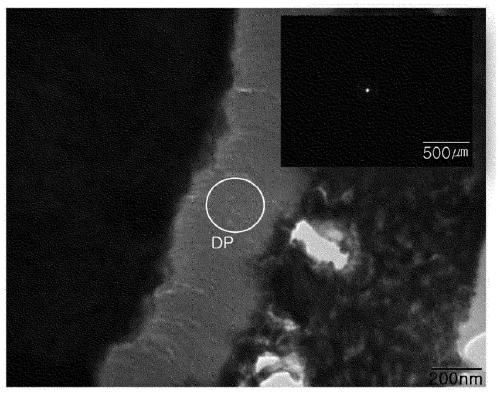

Plated steel material

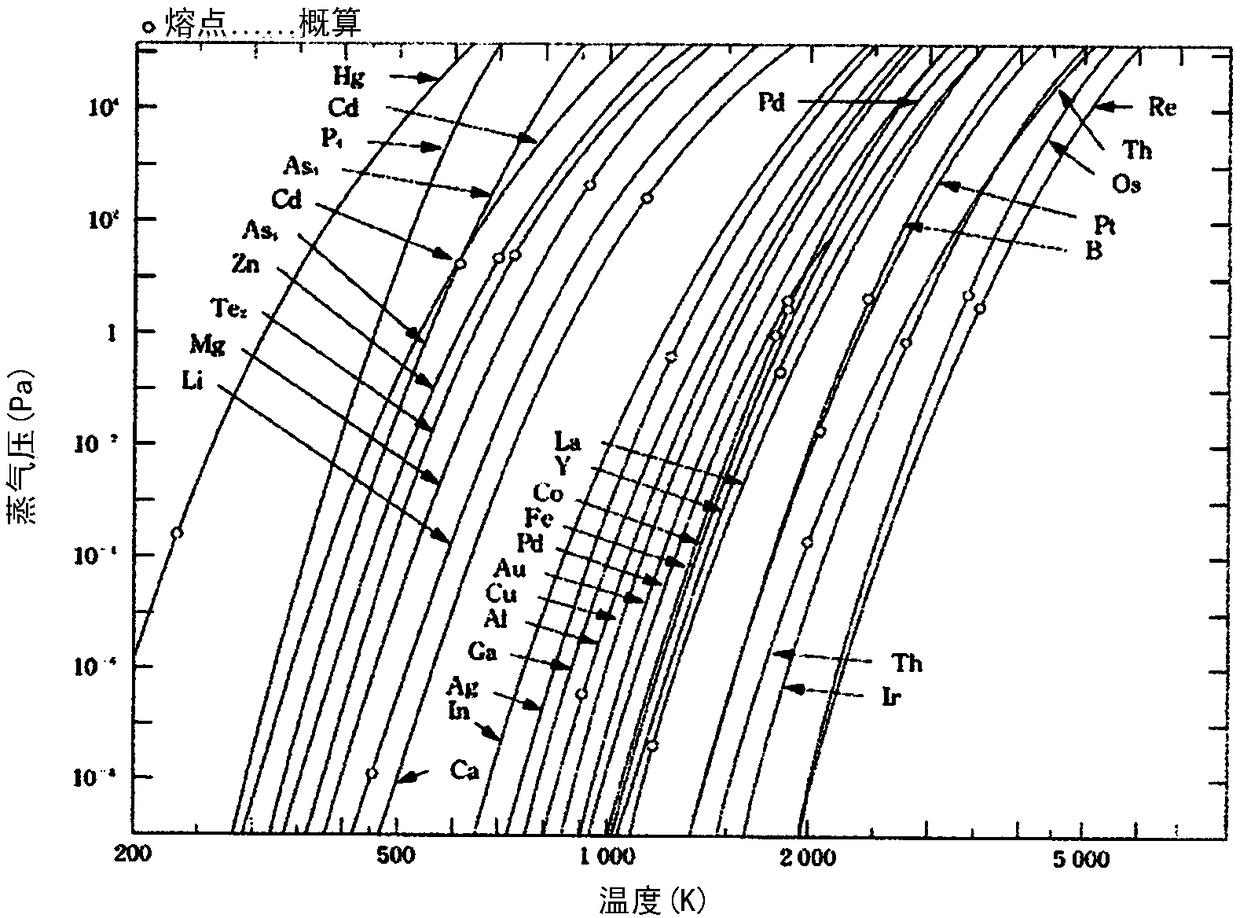

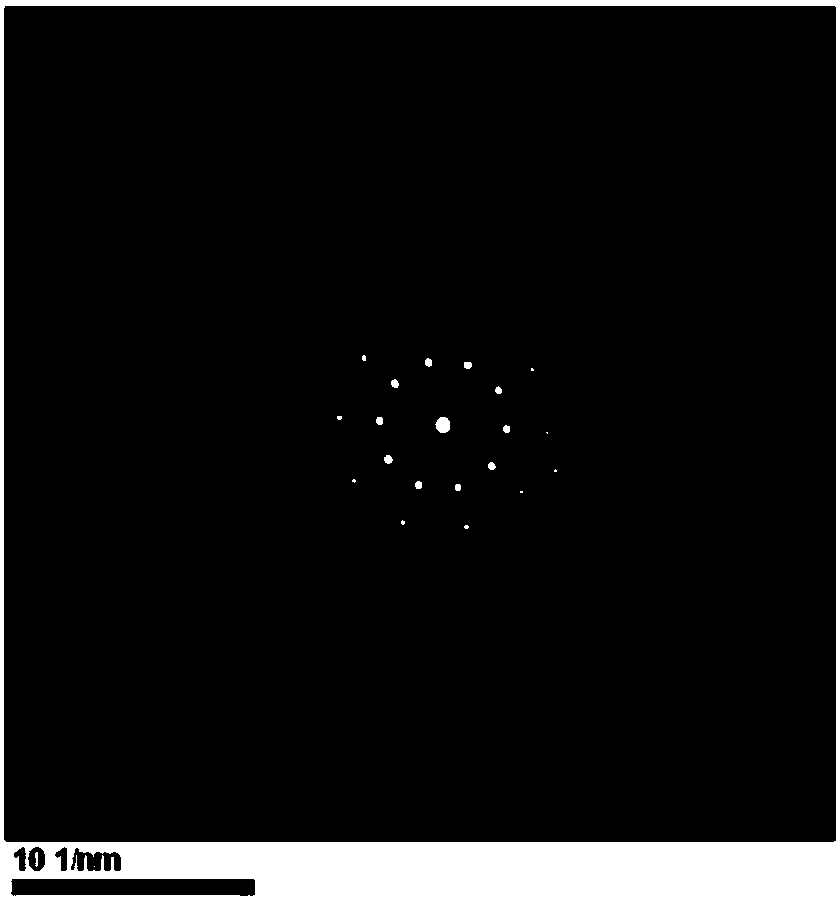

ActiveCN108138308AExcellent plating adhesionImprove corrosion resistanceHot-dipping/immersion processesVacuum evaporation coatingAlloyArea fraction

A plated steel material has a steel material, a plating layer that covers the surface of the steel material, and an interface alloy layer formed at the boundary between the steel material and the plating layer, wherein: the compositional makeup of the plating layer includes, in mass%, 20-83% of Zn and 2.5-46.5% of Al, the remaining portion being Mg and impurities, and the Mg content being not lessthan 10%. The structure of the plating layer comprises a quasicrystal phase, a MgZn2 phase, and a remaining structure; the area fraction of the quasicrystal phase is 30-60%; at least 90% by number ofthe quasicrystal phase is a quasicrystal phase of which the particle size in the longitudinal axis direction thereof is 0.05-1.0 [mu]m; the thickness of the plating layer is not less than 0.1 [mu]m;and the thickness of the interface alloy layer is not greater than 500 nm.

Owner:NIPPON STEEL CORP

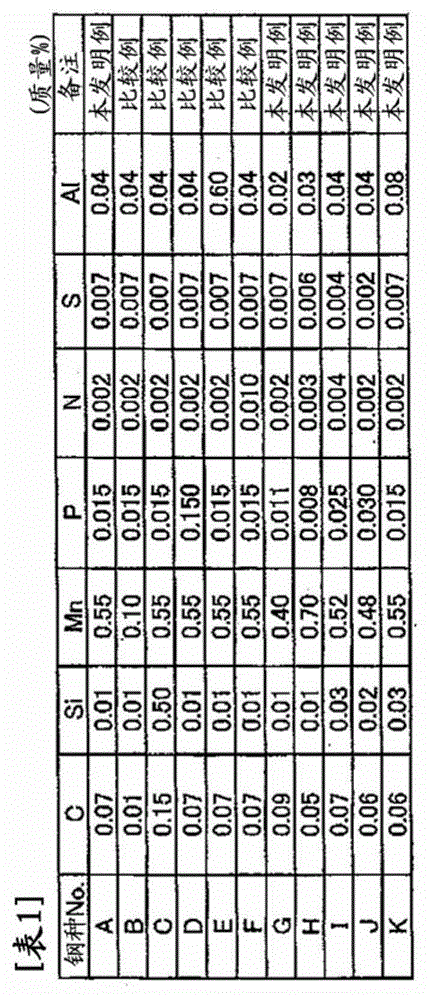

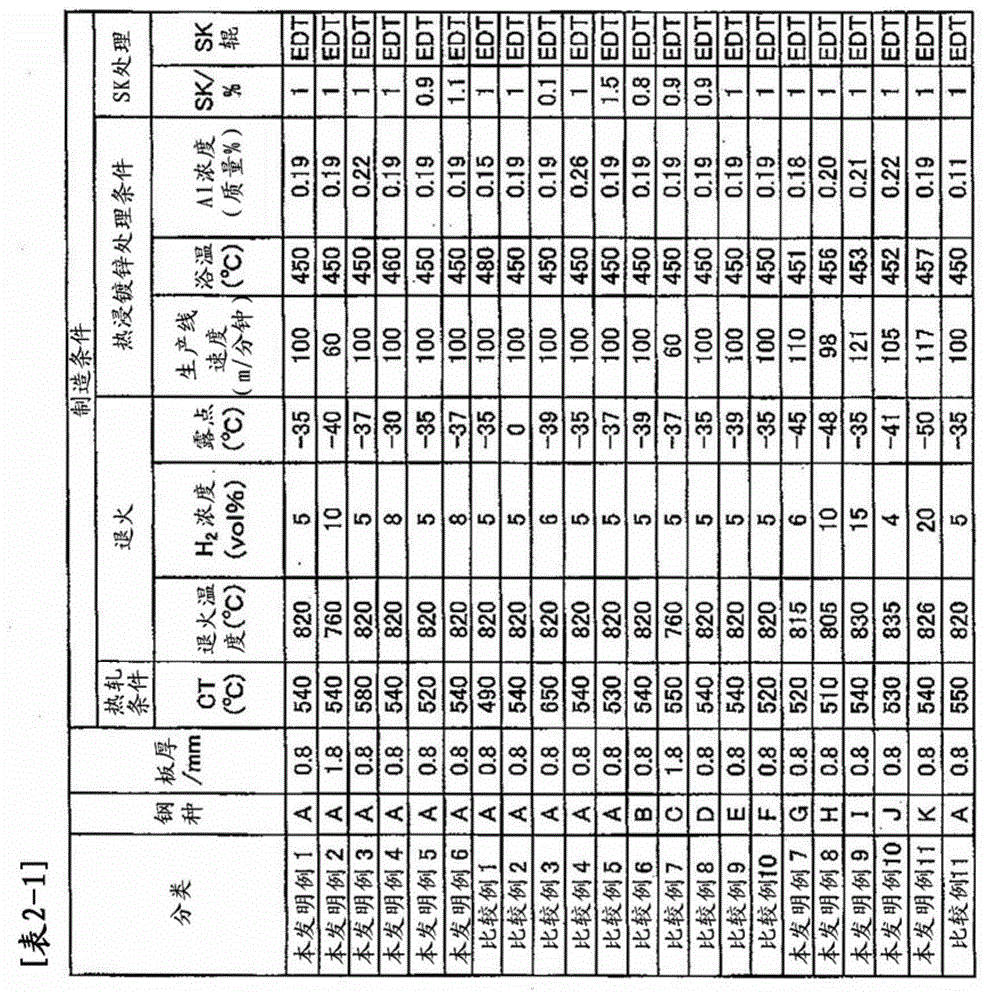

Hot-dip-galvanized steel sheet

ActiveCN104838035AExcellent plating adhesionGood spot weldabilityHot-dipping/immersion processesFurnace typesSpot weldingImpurity

Provided is a hot-dip-galvanized steel sheet which exhibits excellent appearance, post-pressing plating adhesion, spot-welding properties, and post-pressing / post-coating corrosion resistance. This hot-dip-galvanized steel sheet has a yield stress (YS) of 260-350MPa, inclusive, and has: a steel sheet comprising a composition containing, in mass%, C in the amount of 0.05-0.1%, inclusive, Si in the amount of 0.10% or less, Mn in the amount of 0.30-0.70%, inclusive, P in the amount of 0.040% or less, S in the amount of 0.010% or less, N in the amount of 0.005% or less, and Al in the amount of 0.10% or less, with Fe and inevitable impurities constituting the remainder; a hot-dip galvanized layer containing Al in the amount of 0.3-0.6 mass%, inclusive, and formed on at least part of the surface of the steel sheet; and an intermetallic compound present between the steel sheet and the hot-dip galvanized layer, and containing Al in the amount of 0.12gm-2 to 0.22gm-2, inclusive, and Fe2Al5 having an average particle diameter of 1μm or less.

Owner:JFE STEEL CORP

Mold release film

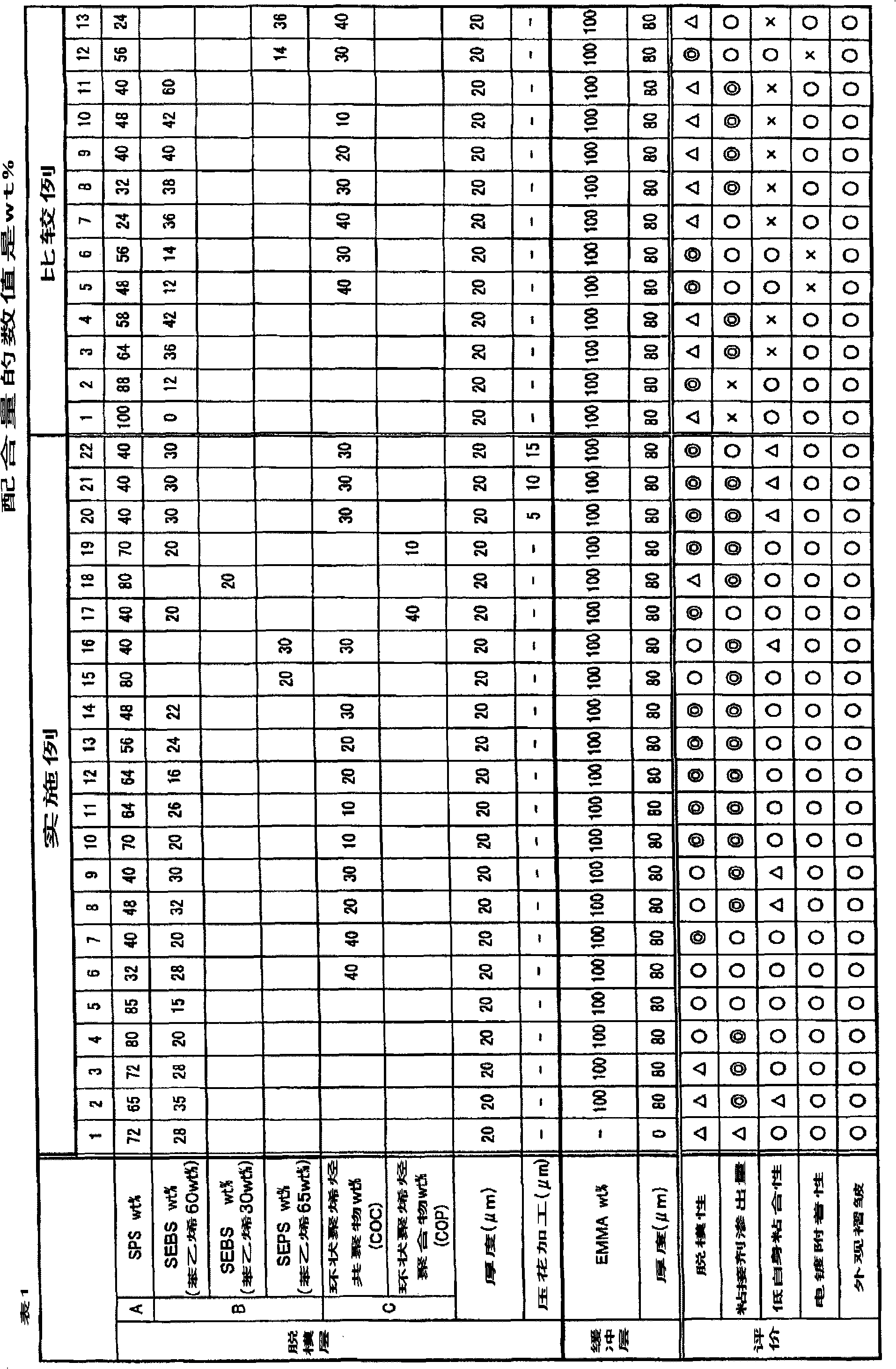

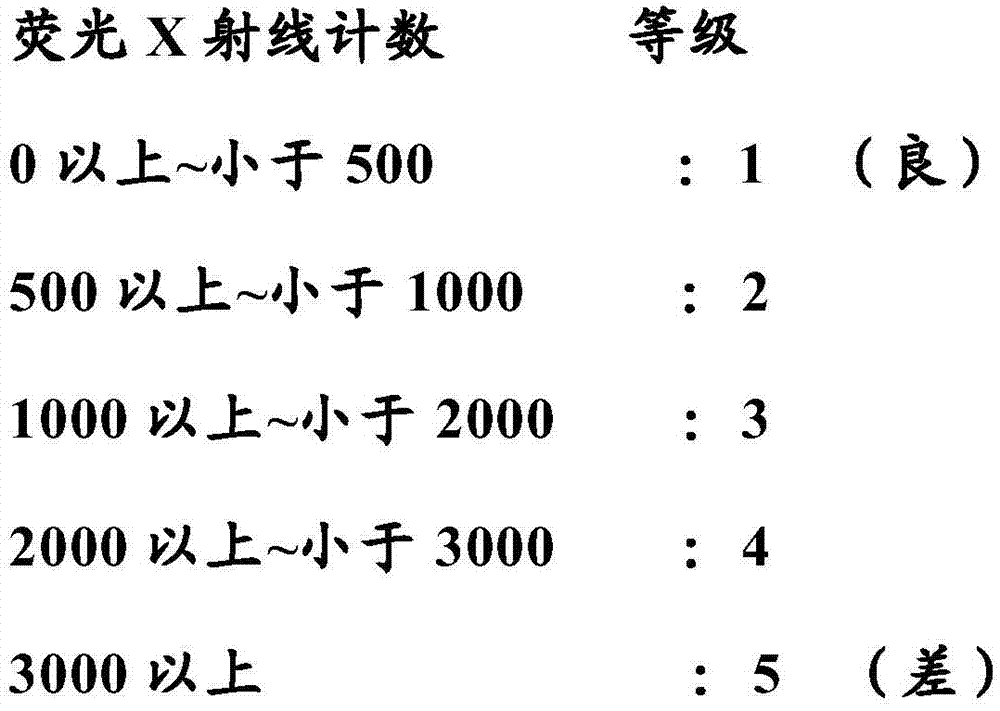

InactiveCN101778887AImprove features"Excellent landfillability" in the characteristicsFilm/foil adhesivesSynthetic resin layered productsPolyolefinThermoplastic elastomer

Disclosed is a practical mold release film which has excellent embeddability, while maintaining excellent properties of a mold release film using a syndiotactic polystyrene. Specifically disclosed is a mold release film having a mold release layer containing a syndiotactic polystyrene and a hydrogenated styrene thermoplastic elastomer. This mold release film is characterized in that the blending ratio of the hydrogenated styrene thermoplastic elastomer relative to the entire resin of the mold release layer is within the range of 15-35 wt%. The hydrogenated styrene thermoplastic elastomer is preferably (i) a styrene-ethylene-butylene-styrene block copolymer or (ii) a styrene-ethylene-propylene-styrene block copolymer. The mold release layer may further contain a cyclic polyolefin resin.

Owner:SUMITOMO BAKELITE CO LTD

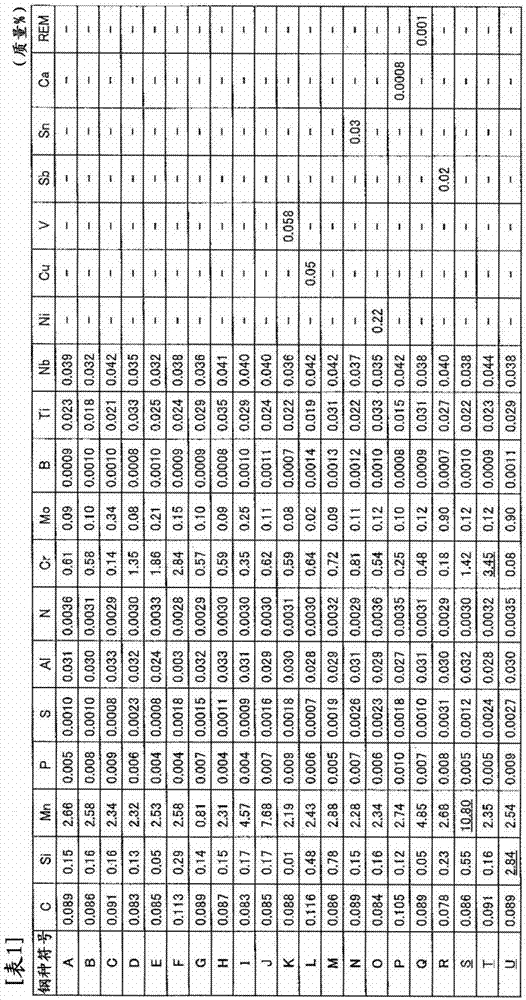

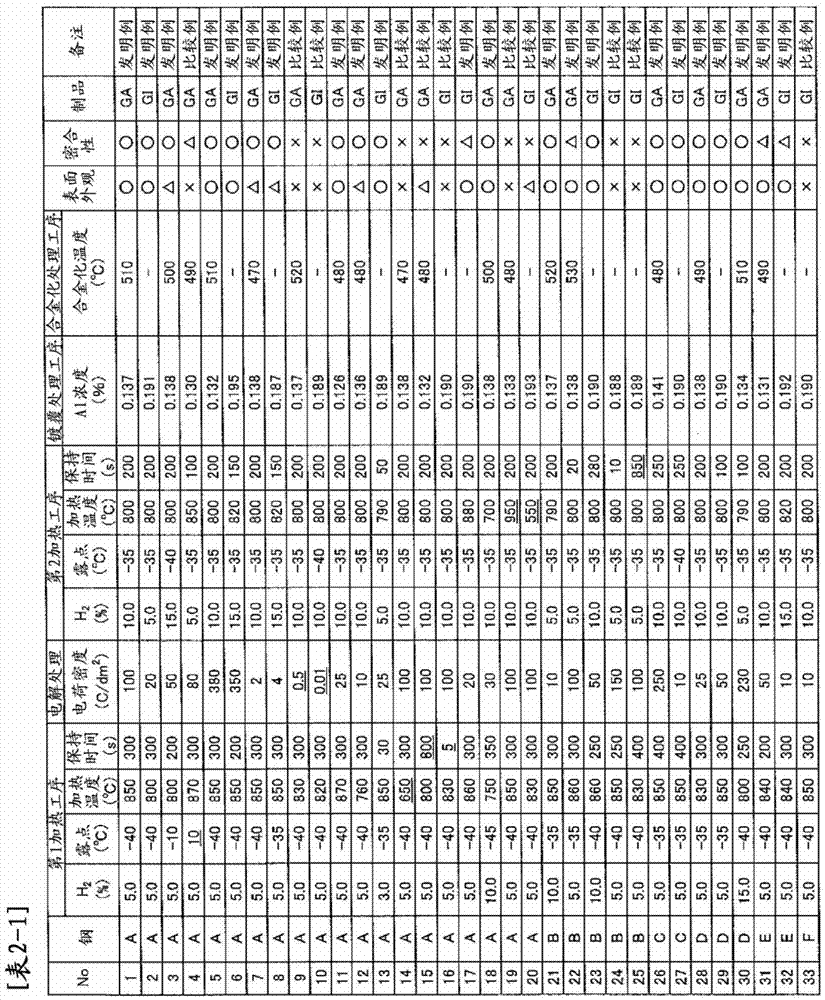

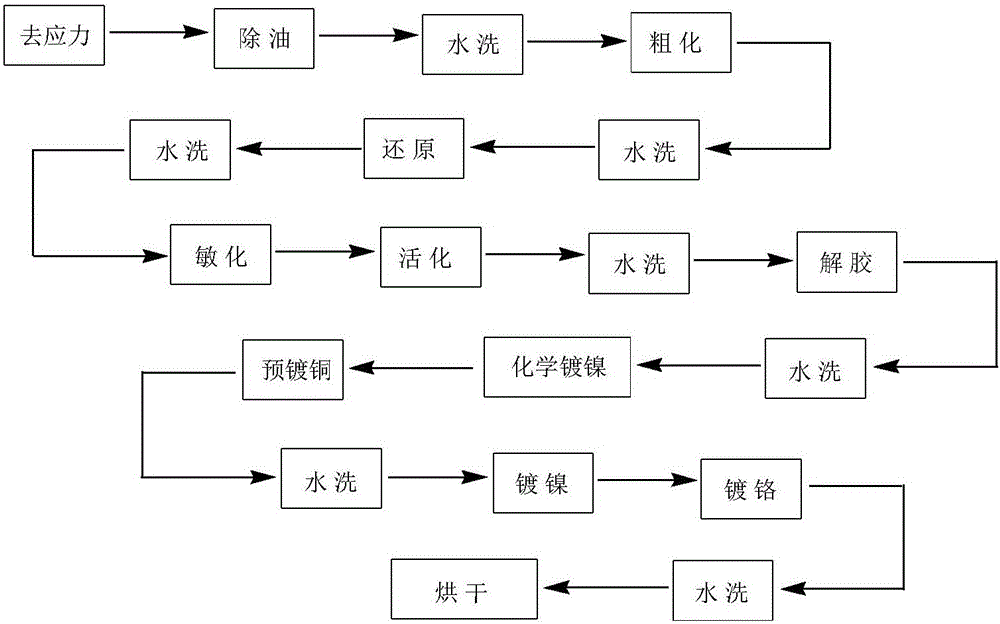

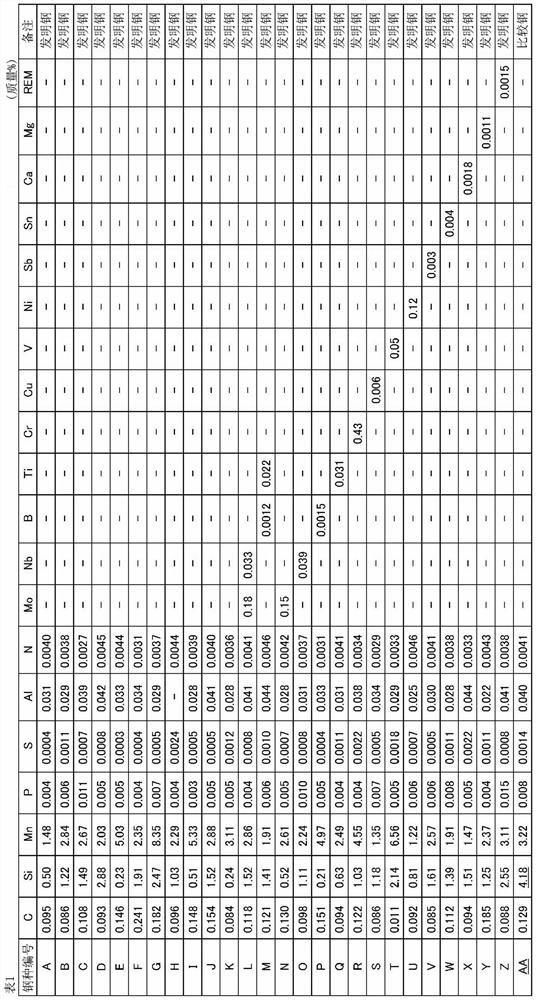

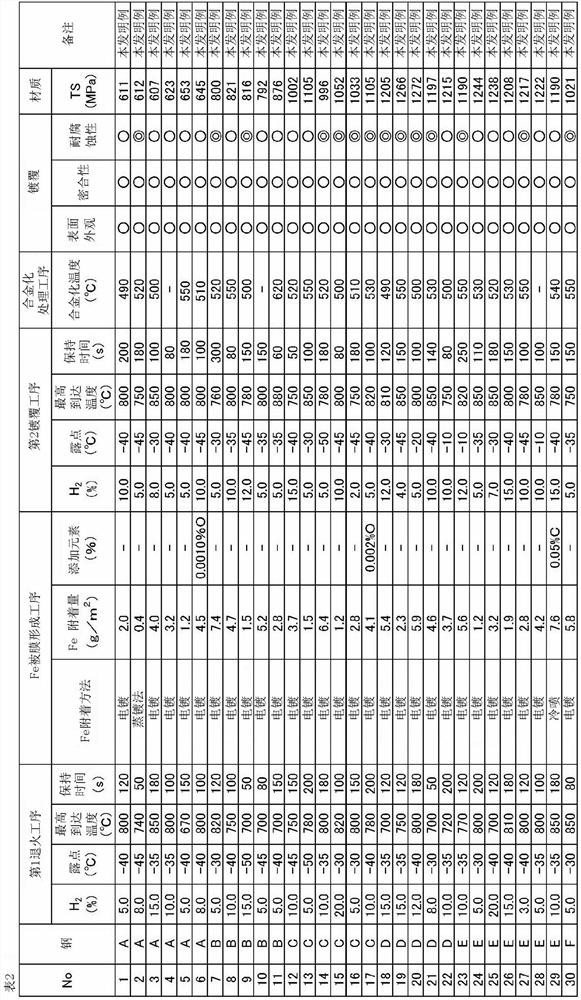

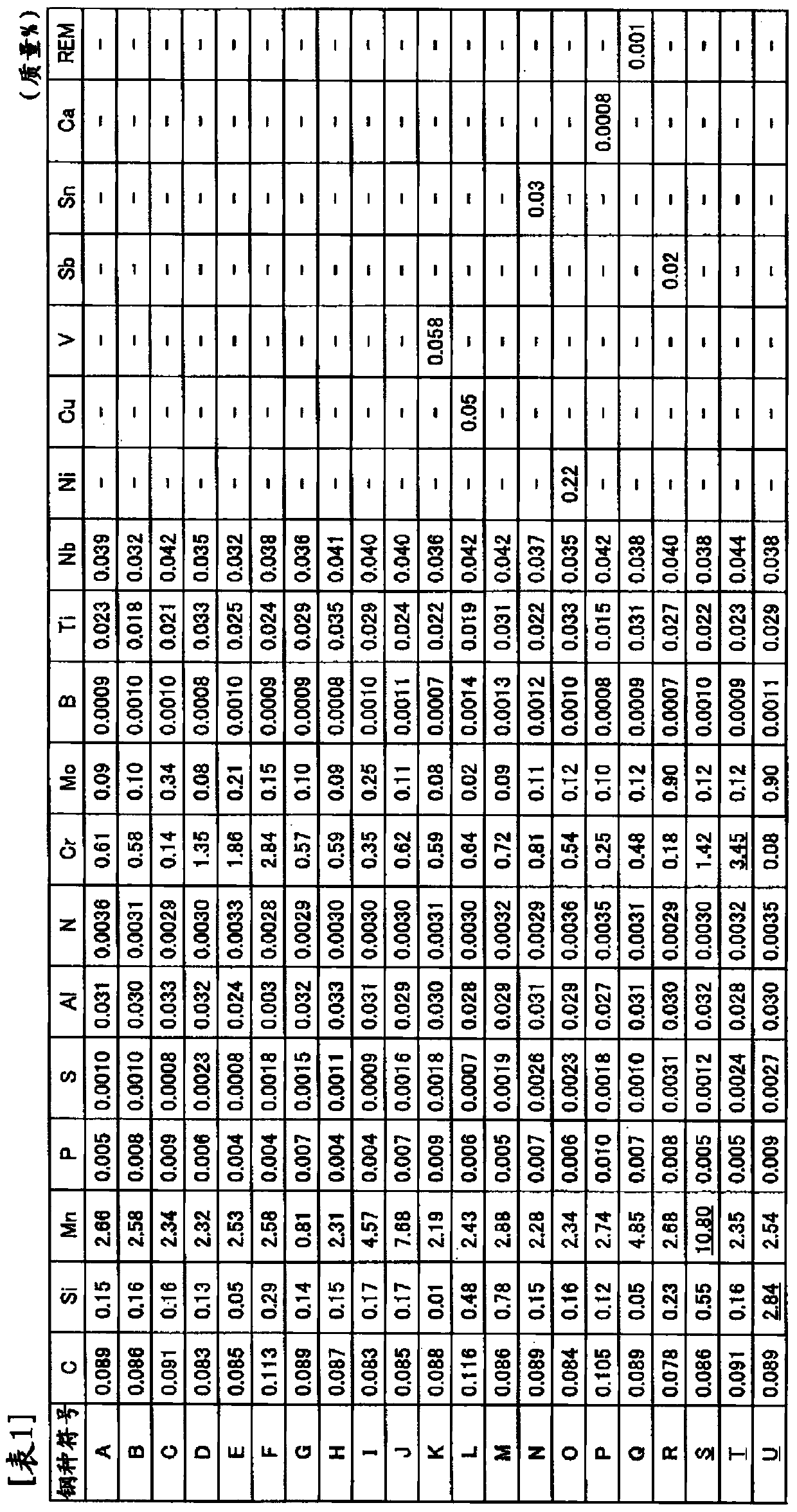

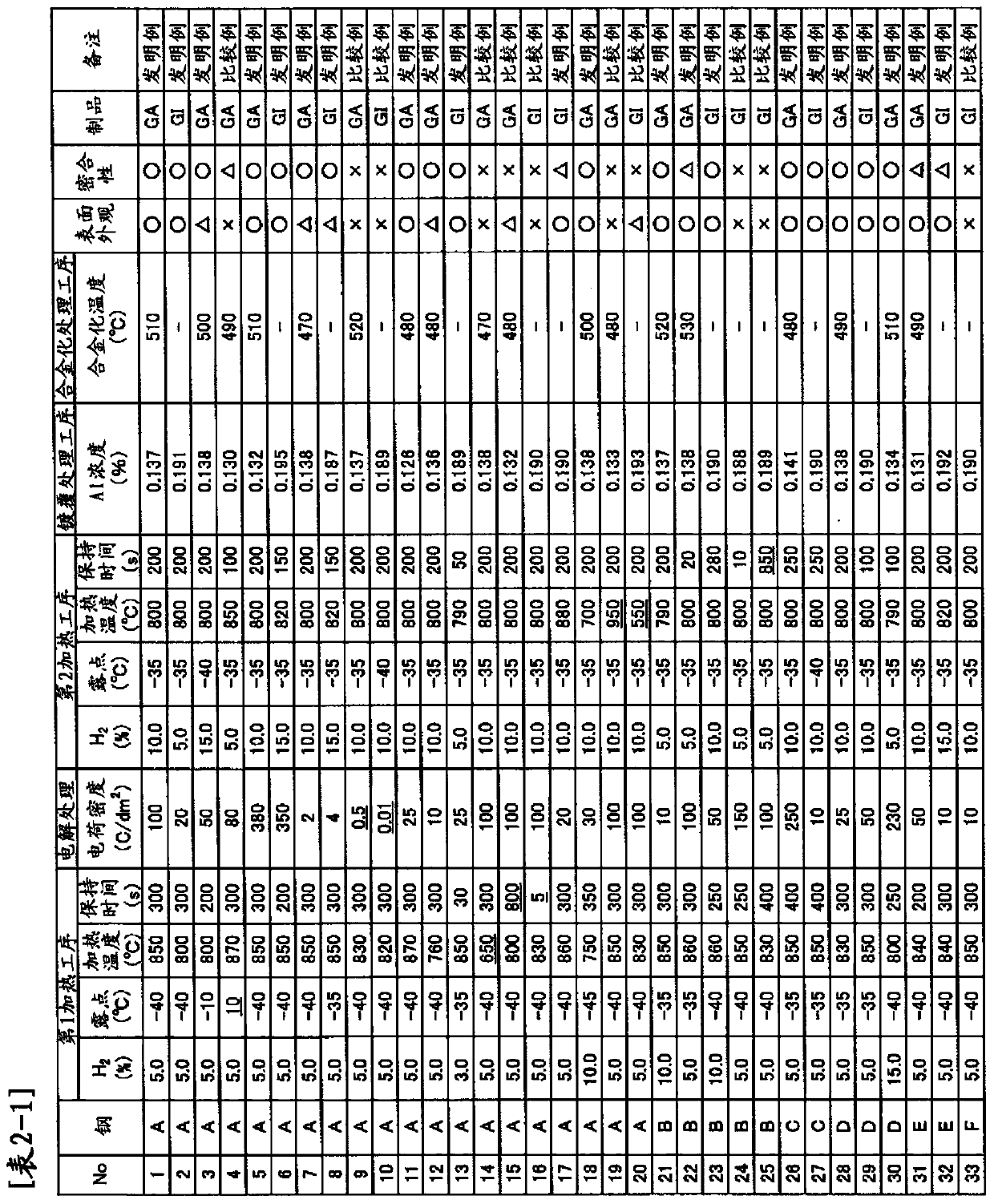

Production method for high-strength hot-dip galvanized steel sheets and production method for high-strength alloyed hot-dip galvanized steel sheets

ActiveCN105452517AHigh strengthExcellent surface appearanceHot-dipping/immersion processesSolid state diffusion coatingElectrolysisHigh intensity

Provided are a production method for producing high-strength hot-dip galvanized steel sheets and a production method for producing high-strength alloyed hot-dip galvanized steel sheets having excellent plating adhesion and surface appearance, said methods inhibiting problems caused by oxides that form on the surfaces of steel sheets containing chromium. High-strength hot-dip galvanized steel sheets are produced according to a method provided with: a first heating step in which a steel sheet composed of specific components is maintained at a specific temperature for a specific time in an atmosphere having a specific H2 concentration and a specific dew point; a cooling step in which the steel sheet, after having passed through the first heating step, is cooled; an electrolytic treatment step in which the steel sheet, after having passed through the cooling step, is subjected to electrolytic treatment under specific conditions; a second heating step in which the steel sheet, after having passed through the electrolytic treatment step, is maintained at a specific temperature for a specific time in an environment having a specific H2 concentration and a specific dew point; and a plating step in which the steel sheet, after having passed through the second heating step, is subjected to hot-dip galvanizing.

Owner:JFE STEEL CORP

Metallized ceramic substrate and preparation method thereof

The invention discloses a metallized ceramic substrate and a preparation method thereof. The metalized ceramic substrate is prepared according to the following steps: (1) preparing an aluminum nitrideceramic substrate; and (2) forming a silver layer on the surface of the aluminum nitride ceramic substrate; (3) forming an organic layer on the silver layer away from the surface of the aluminum nitride ceramic substrate; (4) forming a copper paste layer on the organic layer away from the surface of the silver layer so as to form a metallized ceramic substrate precursor; and (5) sintering the metallized ceramic substrate precursor under vacuum. When in vacuum sintering, the temperature of the vacuum sintering is relatively high, and the silver layer diffuses into the aluminum nitride ceramicsubstrate to react with aluminum nitride to form a silver nitride transition layer to improve the bonding force; during the process of the vacuum sintering, the silver layer does not react with the copper paste layer due to the isolation of the organic layer, and the silver layer is prevented from migrating to the copper paste layer; the metallized ceramic substrate prepared by the invention has high conductivity and good plating adhesion. At the same time, the metallized ceramic substrate prepared by the invention has excellent heat cycle resistance.

Owner:广东正品智慧科技股份有限公司

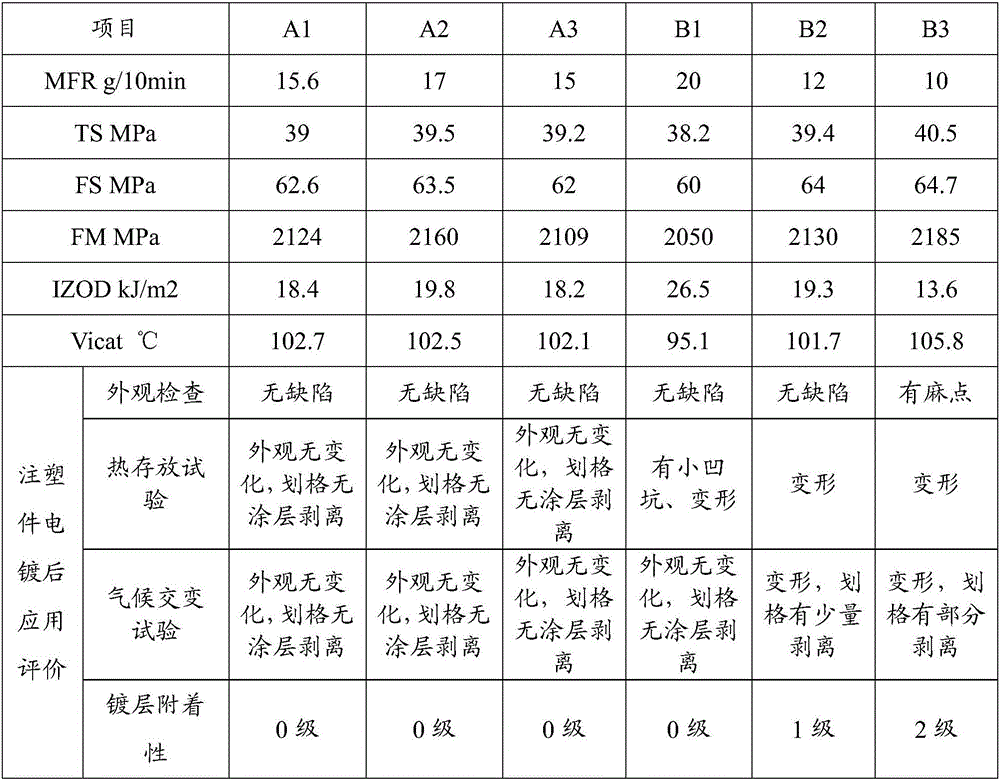

A kind of electroplating grade pc/abs alloy material and preparation method thereof

Owner:WANHUA CHEM GRP CO LTD

Thermoplastic resin composition and its product

InactiveCN1365985AExcellent plating adhesionGood coating performanceCoatingsInstrumentsCyanideMonomer

The present invention provides a thermoplastic resin composition excellent in plating adhesion to the surface of a molded product, paintability and impact resistance, and a molded product thereof. This composition is obtained by graft-polymerizing a monomer component (b) composed of an aromatic vinyl compound, a vinyl cyanide compound, and other copolymerizable monomer compounds as needed in the presence of a rubbery polymer (a). The obtained thermoplastic resin composition formed of the rubber-reinforced thermoplastic resin (A) is characterized in that the content of the rubber-like polymer (a) in the rubber-reinforced thermoplastic resin is 10 to 25% by weight, and the content of acetone in the rubber-reinforced thermoplastic resin is The content of vinyl cyanide monomer units in the soluble fraction is 15-40% by weight, the ratio Mw / Mn of the weight-average molecular weight Mw to the number-average molecular weight Mn of the acetone-soluble fraction is 2-5, and the acetone can be The ratio Mz / Mn of the Z-average molecular weight Mz and the number-average molecular weight Mn of the solution is 5-11.

Owner:大科能宇菱通株式会社

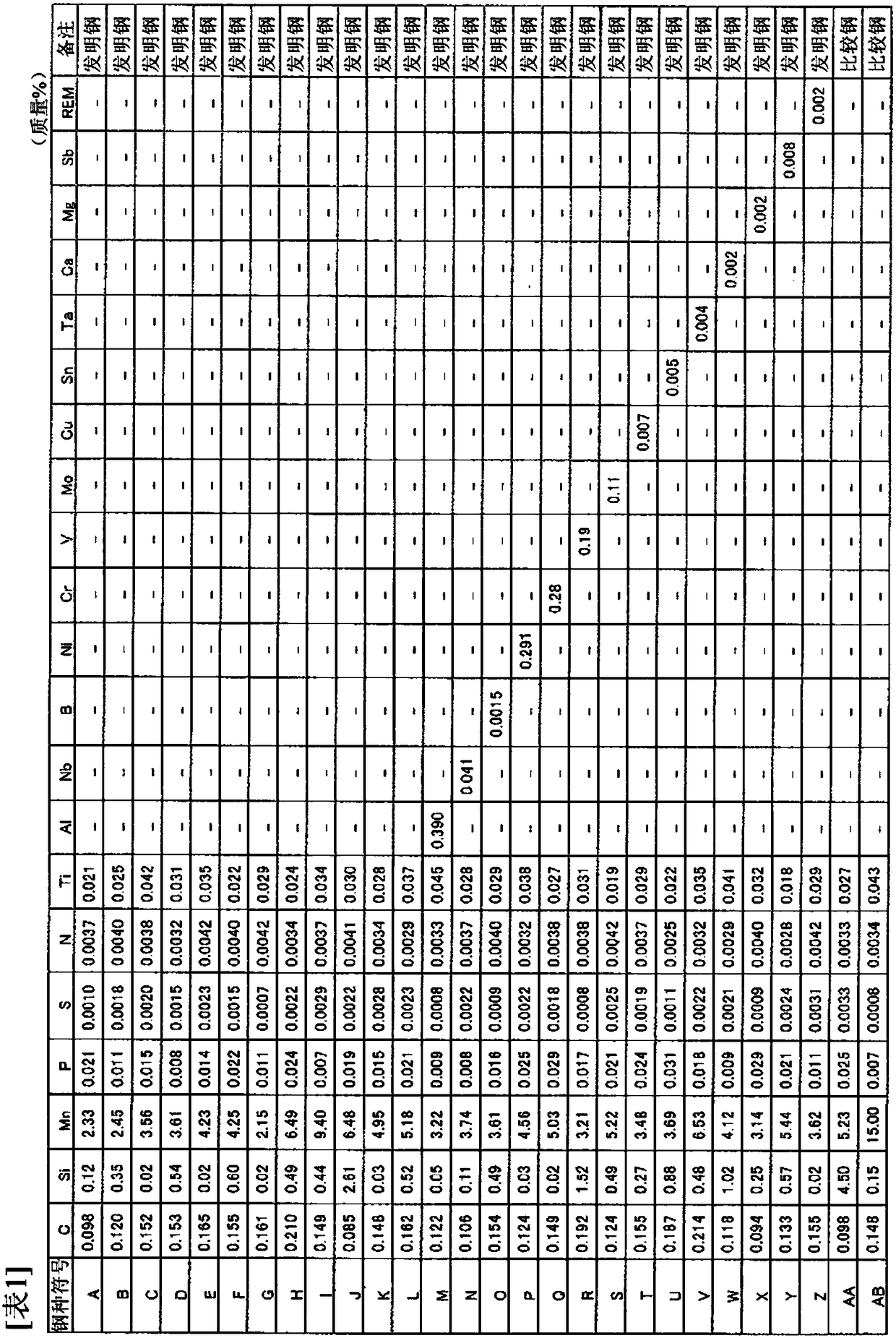

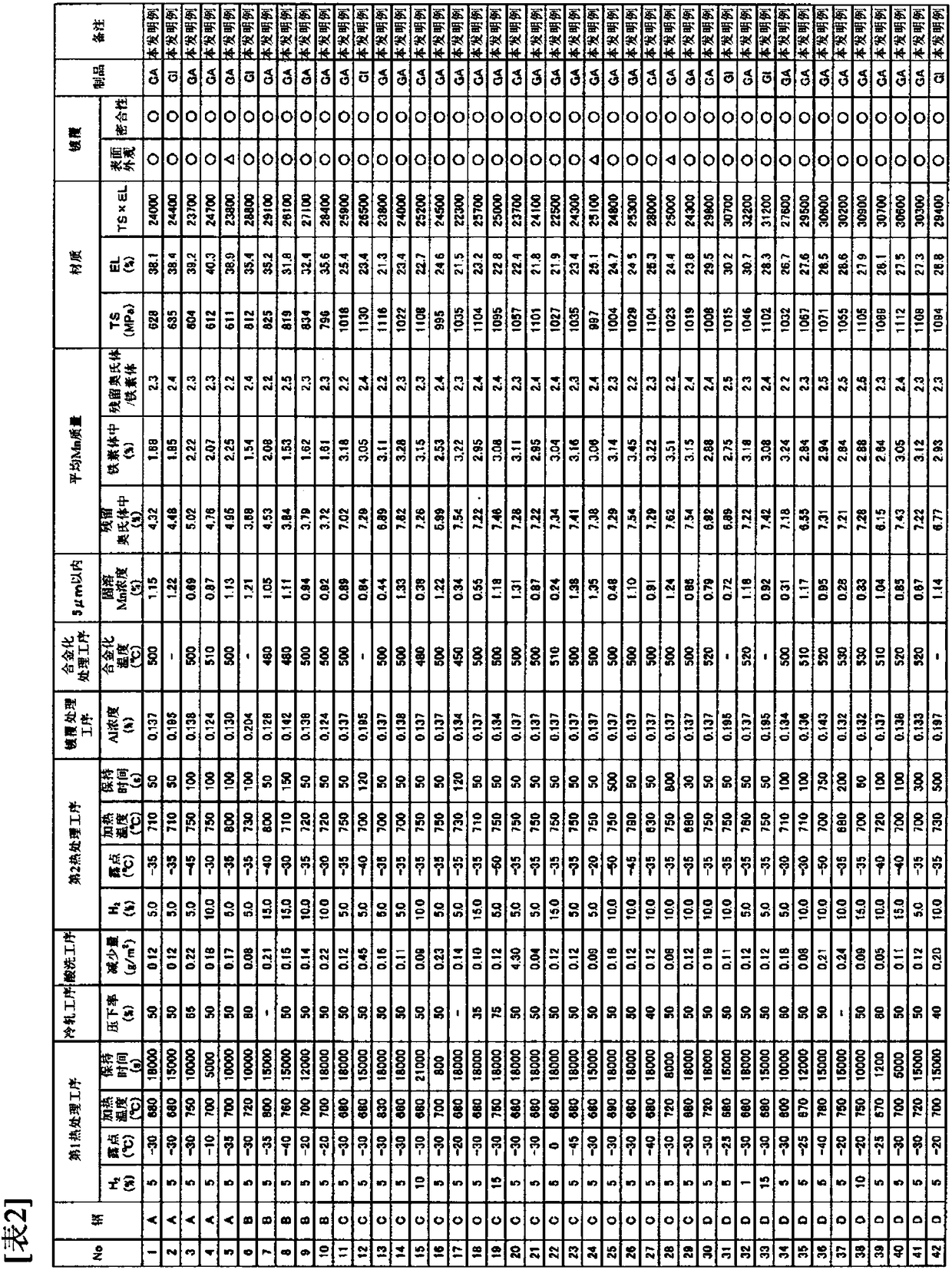

Method for manufacturing high-strength hot-dip galvanized steel sheet, method for manufacturing hot-rolled steel plate for high-strength hot-dip galvanized steel sheet, method for manufacturing cold-rolled steel plate for high-strength hot-dip galvanized steel sheet, and high-strength hot-dip galvanized steel sheet

ActiveCN108291283AGood formabilityGood lookingHot-dipping/immersion processesFurnace typesAusteniteHeat treating

Provided is a method for manufacturing a high-strength hot-dip galvanized steel sheet, a method for manufacturing a hot-rolled steel plate for a high-strength hot-dip galvanized steel sheet, a methodfor manufacturing a cold-rolled steel plate for a high-strength hot-dip galvanized steel sheet, and a high-strength hot-dip galvanized steel sheet, the high-strength hot-dip galvanized steel sheet having exceptional molding properties, outer surface appearance, and plating adhesion. The Mn content is 2.00 to 10.00%. The concentration of solid-solution Mn within a depth of 5 [mu]m from the steel plate surface is 1.50% by mass or less, and the value obtained by dividing the average Mn mass percentage in the residual austenite by the average Mn mass percentage in the ferrite is 2.0 or greater. Afirst heat treatment is performed for holding said sheet in a temperature range of 650 to 850 DEG C for 600 to 21600 s while the steel plate surface is exposed in an atmosphere having an H2 concentration of 0.1 to 25.0 vol% and a dew point of -45 to 0 DEG C, and a second heat treatment is performed for holding said sheet in a temperature range of 650 to 830 DEG C for 20 to 900 s in an atmosphere having an H2 concentration of 0.05 to 25.0 vol% and a dew point of -10 DEG C or less.

Owner:JFE STEEL CORP

Electric-plated PC/ABS alloy and preparation method thereof

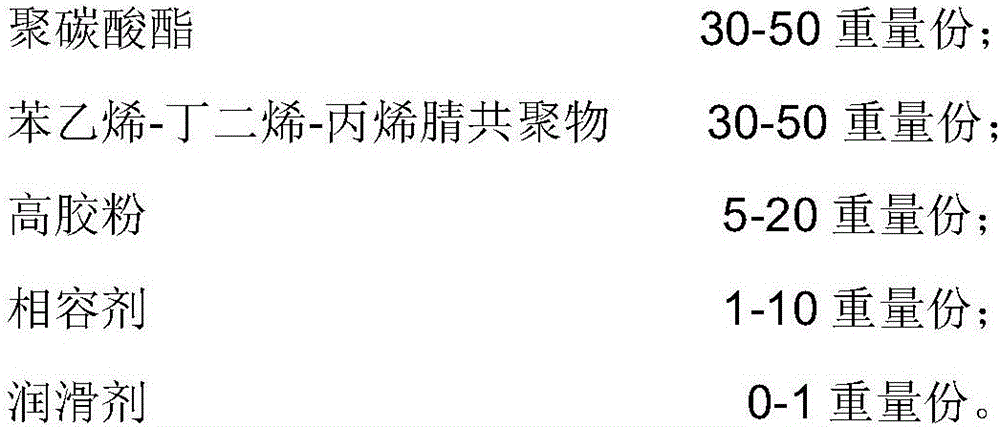

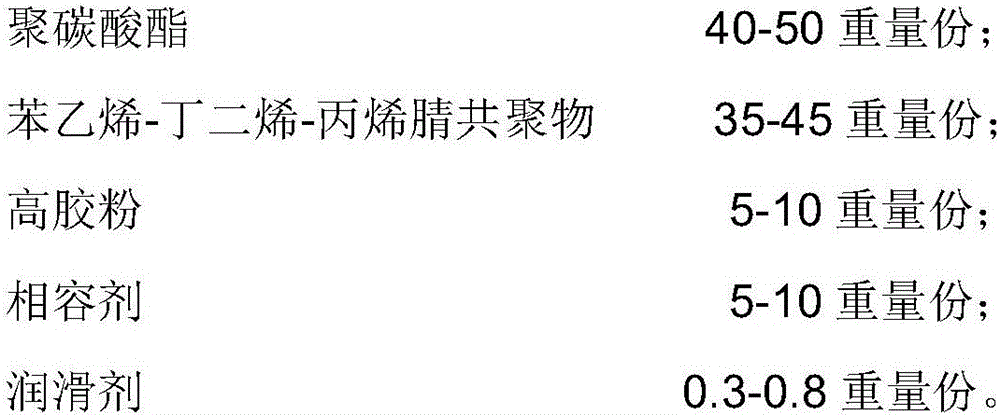

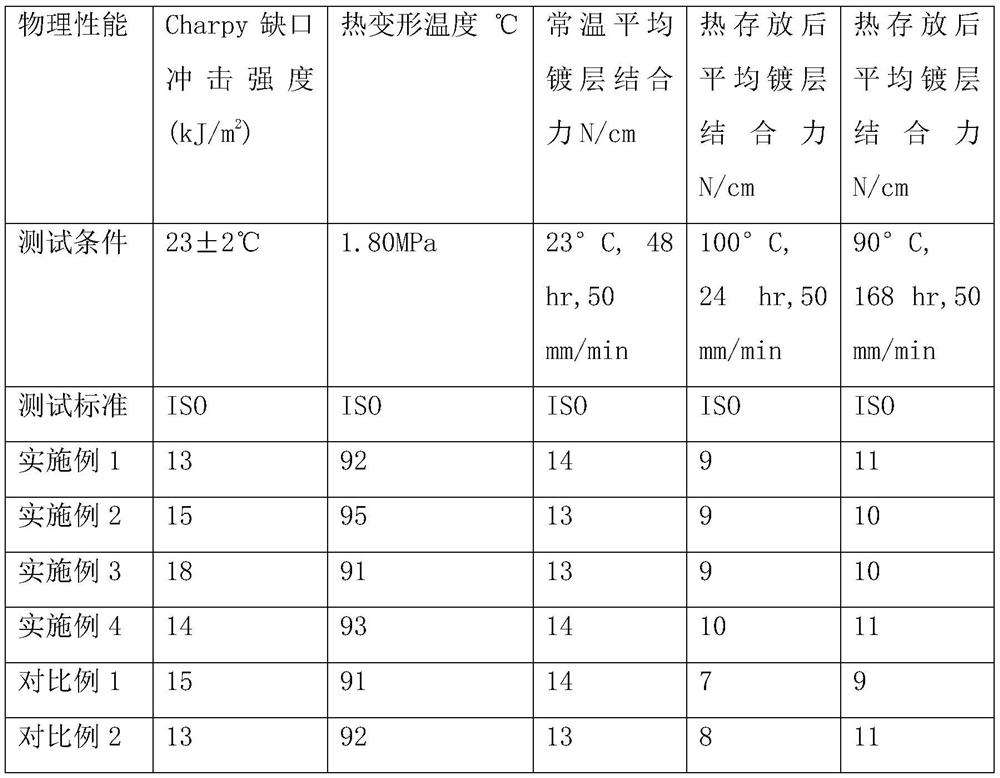

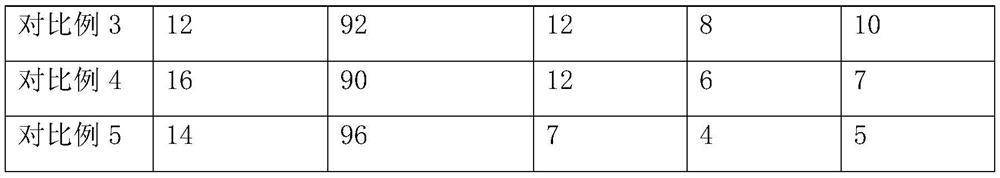

InactiveCN106380810AImprove compatibilityExcellent plating adhesionButadiene-styrene rubberMelt extrusion

The invention provides an electric-plated PC / ABS alloy and a preparation method thereof, wherein the electric-plating PC / ABS alloy includes the formula: 30-50 parts by weight of polycarbonate, 30-50 parts by weight of styrene-butadiene-acrylonitrile, 5-20 parts by weight of a high glue powder, 1-10 parts by weight of a compatilizer, 0-1 part by weight of an antioxidant and 0-1 part by weight of a lubricant. All the raw materials are stirred and mixed for 10-30 min in a mixing stirrer, the obtained mixture is sent into a double-screw extruder, the rotating speed of screws is controlled to be 160-300 rpm, melt extrusion and granulation are performed, and the electric-plated PC / ABS alloy is obtained. According to the prepared electric-plated PC / ABS alloy, by adjusting the ratio of PC and ABS, and adding a core-shell structure acrylic acid ester organic matter as the compatibilizer, the compatibility of PC and ABS is improved, and the prepared electric-plated PC / ABS alloy has more excellent tensile, bending and impact strength.

Owner:上海跃贝新材料科技股份有限公司

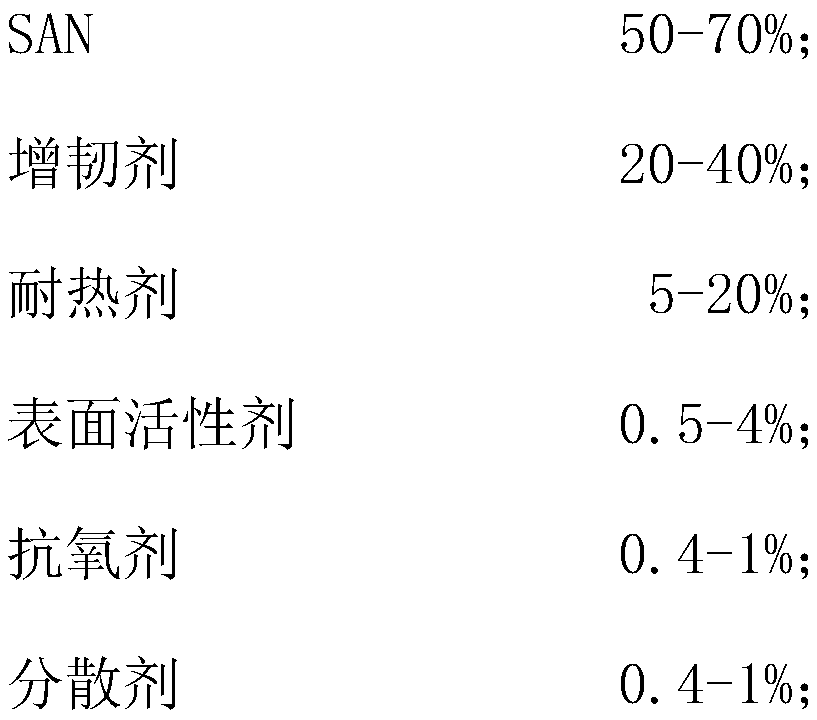

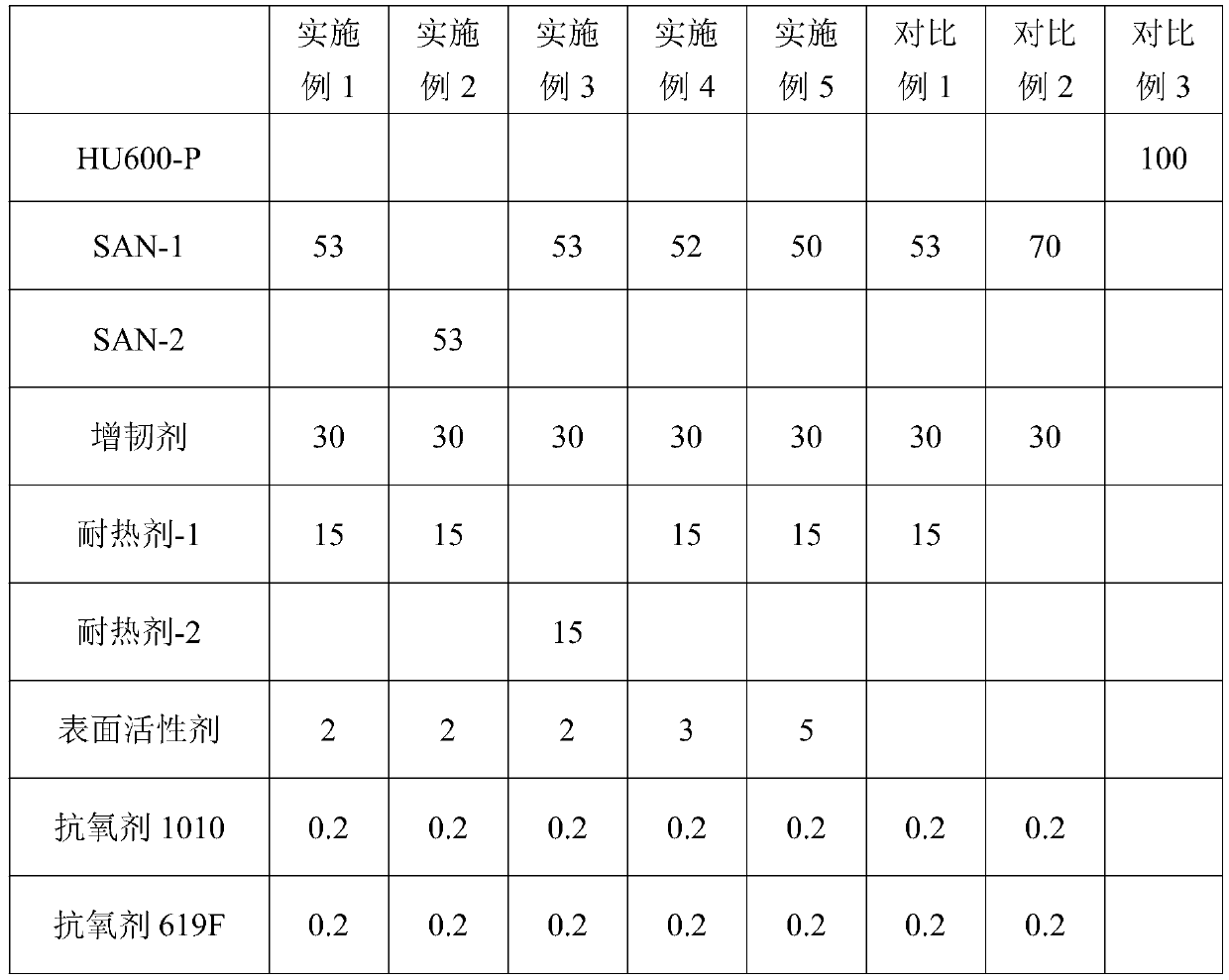

High-temperature-resistant electroplating-grade ABS resin and preparation method thereof

PendingCN111875897AGood high temperature resistanceExcellent plating adhesionComposite materialPolymer chemistry

The invention relates to high-temperature-resistant electroplating-grade ABS resin and a preparation method thereof. The high-temperature-resistant electroplating-grade ABS resin is prepared from thefollowing components in parts by weight: 10-20 parts of ABS resin, 25-35 parts of ABS high rubber powder, 40-55 parts of highly branched styrene-acrylonitrile copolymer, 10-15 parts of heat-resistantagent, 0.1-10 part of kaolin and 0.5-2 parts of other auxiliary agents. Compared with the prior art, the high-temperature-resistant electroplating-grade ABS resin is obtained by controlling the content of the ABS rubber, compounding the rubber with large and small particle sizes and introducing the kaolin filler. The high-temperature-resistant electroplating-grade ABS resin prepared by the methodhas excellent high-temperature resistance and electroplating binding force, and the failure probability of an electroplated part in a cold and hot alternating experiment is reduced, so that the use requirements of electroplating-grade ABS in the fields of automobiles, household appliances and machinery are met.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

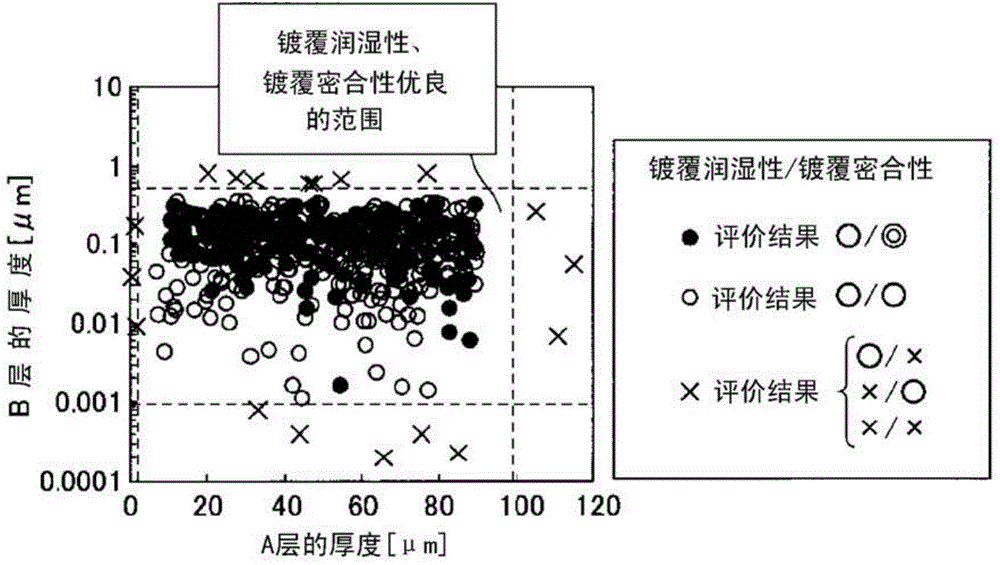

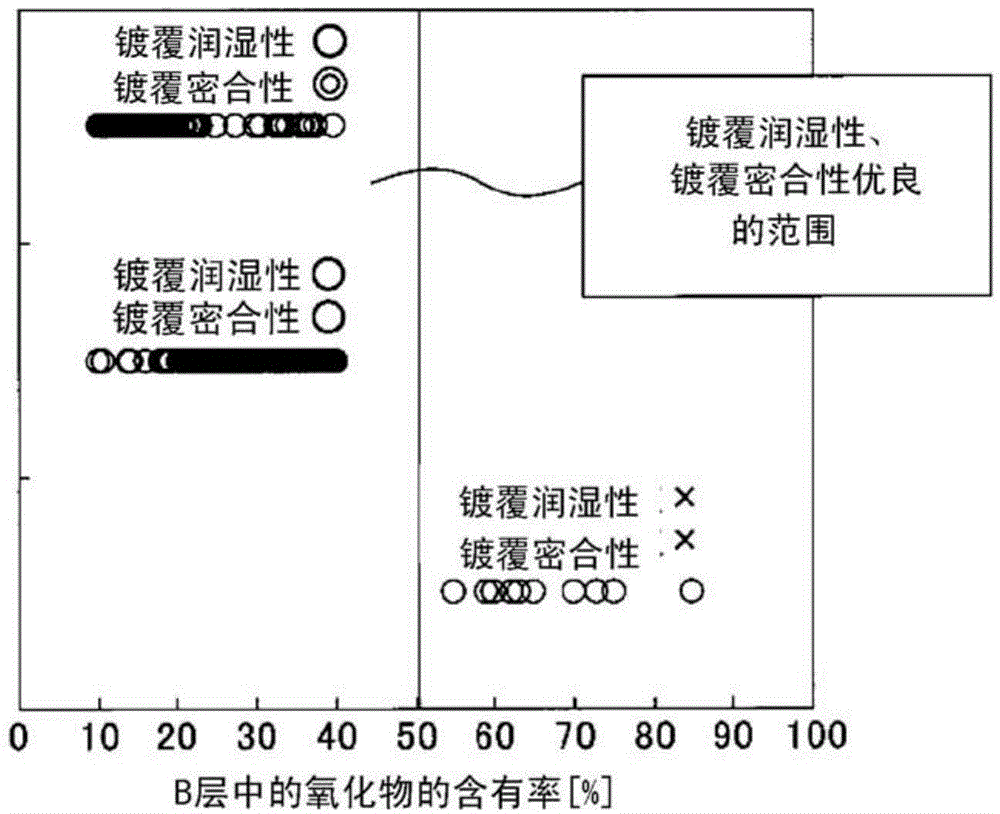

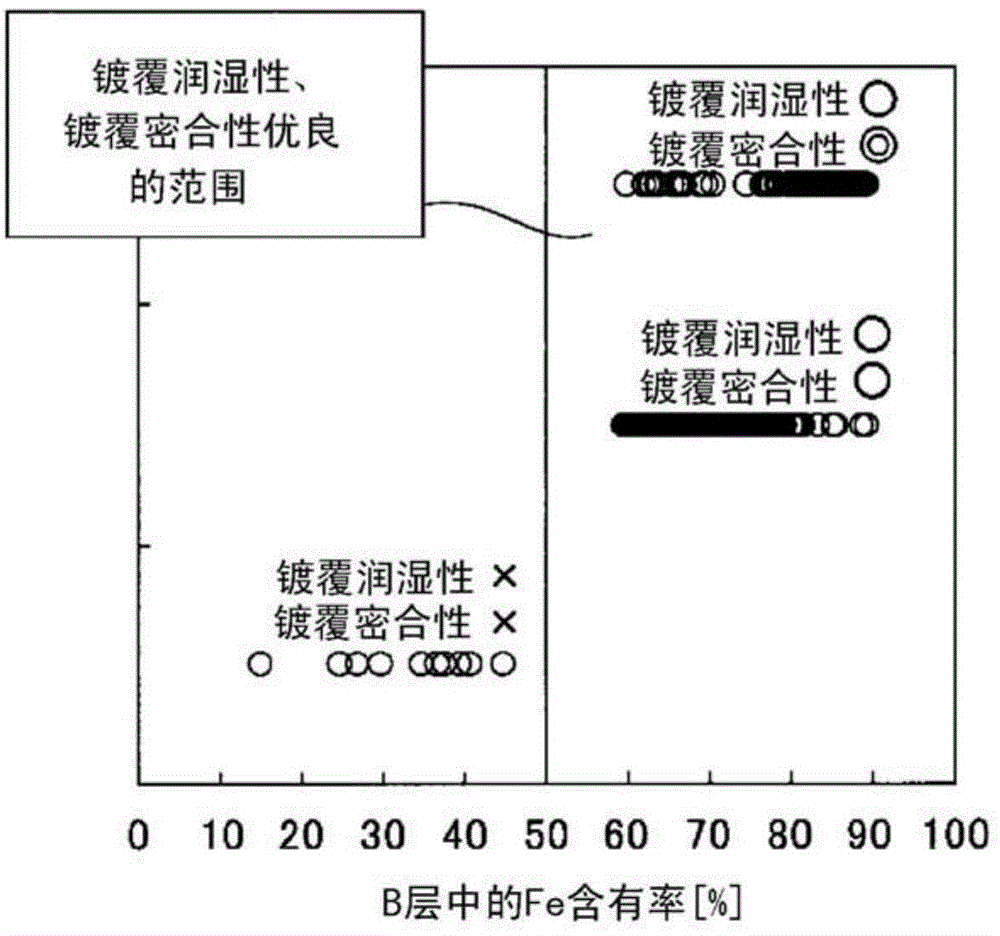

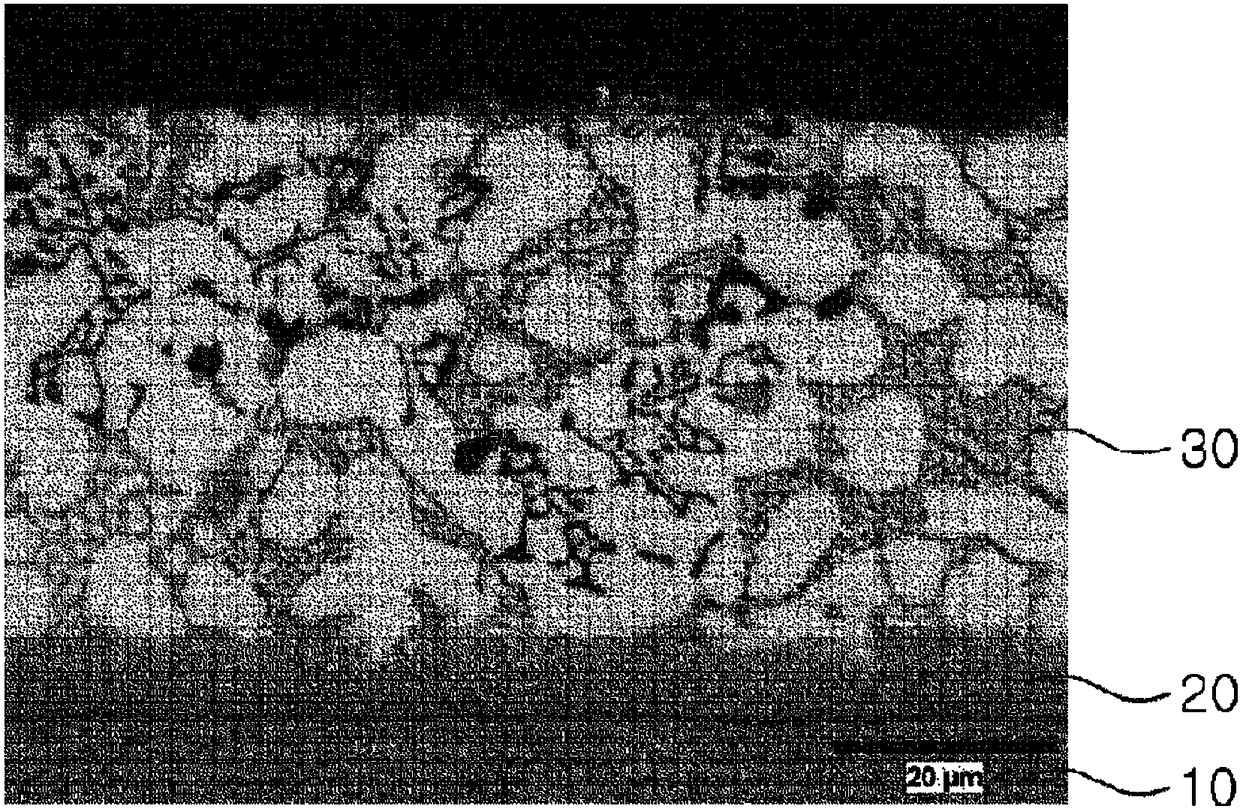

Steel sheet having hot-dip galvanized layer and exhibiting superior plating wettability and plating adhesion, and production method thereof

ActiveCN103827342AExcellent plating adhesionHot-dipping/immersion processesFurnace typesSheet steelHot-dip galvanization

Owner:NIPPON STEEL CORP

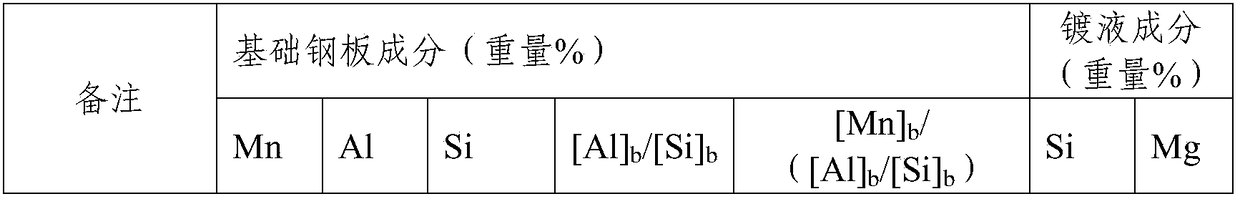

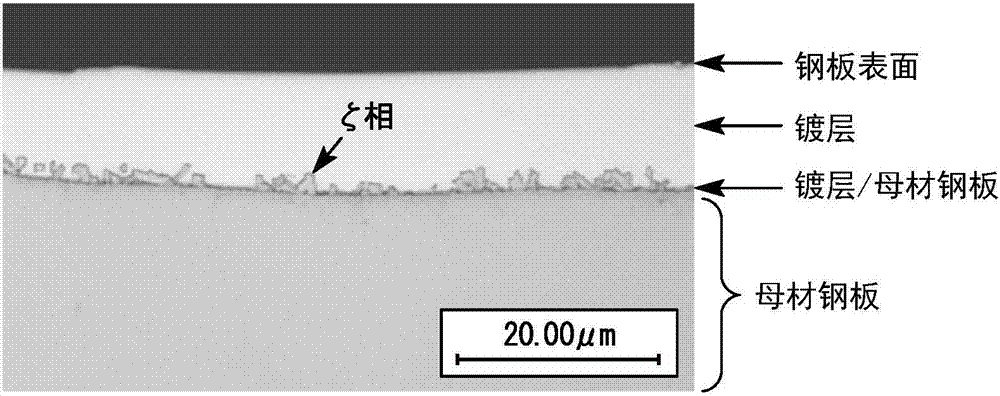

High-manganese hot-dip aluminum-coated steel sheet having excellent coating adhesion

ActiveCN108431270AExcellent plating adhesionHot-dipping/immersion processesThin material handlingManganeseCoating adhesion

Disclosed is a high-manganese hot-dip aluminum-coated steel sheet comprising: a base steel sheet containing, by weight, 5% to 35% of Mn, 0.3% to 6% of Al, 0.1% to 1.2% of Si, and the balanced amount of Fe and inevitable impurities; a hot-dip aluminum-coated layer, formed on a surface of the base steel sheet, containing, by weight, 3% to 12% of Si and the balanced amount of Al and inevitable impurities; and an alloy layer, 0.1-10 um in thickness with a Fe-Al-Si-Mn alloy phase on an interface between the base steel sheet and the hot-dip aluminum-coated layer, containing, by weight, 40% to 70% ofAl, 2% to 13% of Si, 3% to 9% of Mn, and the balanced amount of Fe and inevitable impurities.

Owner:POSCO CO LTD

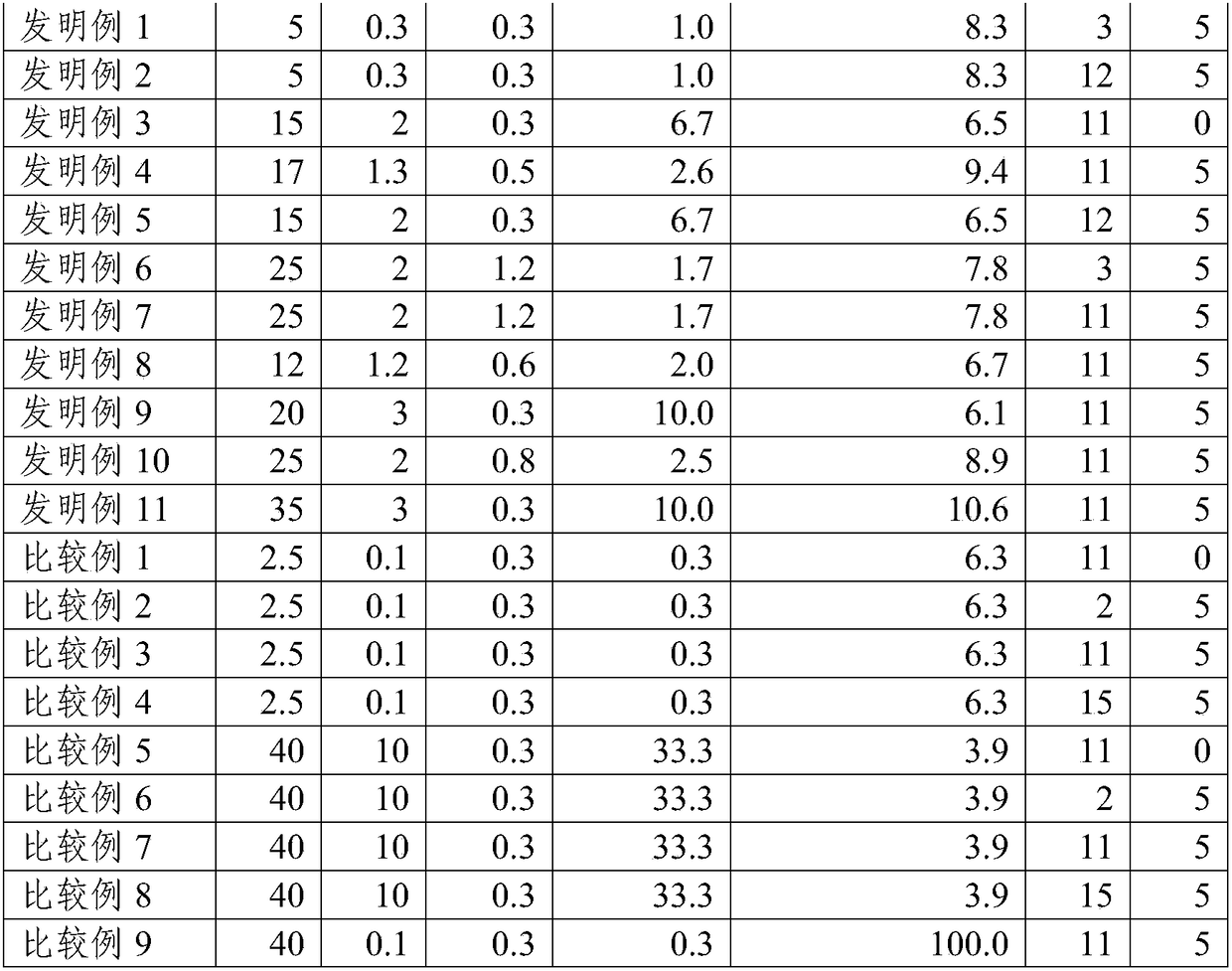

Hot-dip galvanized steel sheet

ActiveCN107109554AGood formabilityEasy to shapeHot-dipping/immersion processesFurnace typesSurface layerSheet steel

A hot-dip galvanized steel sheet comprising a base steel sheet and a hot-dip galvanizing layer, the hot-dip galvanized steel sheet having a hot-dip galvanizing layer in which columnar crystals comprising 5% or less of Fe, 1.0% or less of Al, and a Zeta phase are interposed in 20% or more of the entire interface of the plating layer and the steel sheet on the surface of a base steel sheet in which a ferrite phase constitutes 40%-97% and a hard structure constitutes a total of 3% or more in terms of volume ratio in a range of 1 / 8 thickness to 3 / 8 thickness from the surface of the base steel sheet, and the volume ratio of the hard structure in a surface layer range to a depth of 20 mum in the base steel sheet from the interface of the plating layer and the base steel sheet is 0.10-0.90 times the volume ratio of the hard structure in the range of 1 / 8 thickness to 3 / 8 thickness, the hot-dip galvanized steel sheet having a refined layer on the interface side of the base steel sheet, and the average thickness of the refined layer, the average grain size of a ferrite phase in the refined layer, and the maximum diameter of oxides included in the refined layer each being prescribed.

Owner:NIPPON STEEL CORP

Method for manufacturing hot-dip galvanized steel sheet

PendingCN113272466AExcellent surface appearanceExcellent plating adhesionHot-dipping/immersion processesFurnace typesReducing atmosphereMaterials science

Provided is a method for manufacturing a hot-dip galvanized steel sheet having excellent surface appearance, plating adhesion properties and corrosion resistance. The method for manufacturing a hot-dip galvanized steel sheet according to the present disclosure is characterized by comprising: a first annealing step of retaining a steel sheet having a component composition containing, in % by mass, 0.10 to 3.0% inclusive of Si and 1.0 to 10.0% inclusive of Mn in a temperature range from 650 to 900 deg C inclusive for 30 seconds or longer in a reducing atmosphere containing hydrogen and having a dew point of -65 to -20 deg C inclusive, and then cooling the resultant steel sheet; a step of forming a Fe coating film at an adhesion amount of 0.3 g / m2 to 10.0 g / m2 inclusive on the surface of the steel sheet; a second annealing step of retaining the steel sheet in a temperature range from 700 to 900 deg C inclusive for 30 seconds or longer in a reducing atmosphere containing hydrogen and having a dew point of 0 deg C or lower wherein the highest reachable temperature of the steel sheet is 900 deg C or lower, and then cooling the resultant steel sheet; and a step of subjecting the steel sheet to a hot-dip galvanization procedure.

Owner:JFE STEEL CORP

High-heat-resistance electroplating ABS material with anionic surface activity and preparation method thereof

The invention discloses a high-heat-resistance electroplating ABS material with anionic surface activity and a preparation method thereof. The material is prepared from the following raw materials inparts by weight: 50-70 parts of a styrene-acrylonitrile copolymer, 20-40 parts of an impact modifier, 5-20 parts of a heat-resistant modifier, 0.5-4 parts of a surface active additive, 0.4 to 1 part of an antioxidant, and 0.4-1 part of a lubricant. By adopting such a technical scheme, the high-heat-resistance electroplating ABS material with the anionic surface activity has the characteristics ofhigh heat resistance, high electroplating binding force and the like, and can be used for electroplated products with high heat resistance requirements, such as automobile air outlet decorative framesand gear decorative frames.

Owner:SHANGHAI PRET COMPOSITES +3

Plated steel sheet having multilayer structure and manufacturing method therefor

InactiveCN110168141AExcellent plating adhesionThere will be no blackening of the surfaceHot-dipping/immersion processesVacuum evaporation coatingStructural engineeringHome appliance

Owner:POHANG IRON & STEEL CO LTD

Steel sheet with excellent bake hardening properties and plating adhesion and manufacturing method therefor

ActiveUS20210071277A1Good molding effectSuitable materialHot-dipping/immersion processesFurnace typesBake hardeningHot-dip galvanization

Provided is a steel sheet used as a material for an automotive exterior panel, etc., and a method for manufacturing the same. More particularly, provided is a cold-rolled steel sheet and a hot-dip galvanized steel sheet, which have excellent bake hardening properties, plating adhesion, and anti-aging properties, and a method of manufacturing the same.

Owner:POHANG IRON & STEEL CO LTD

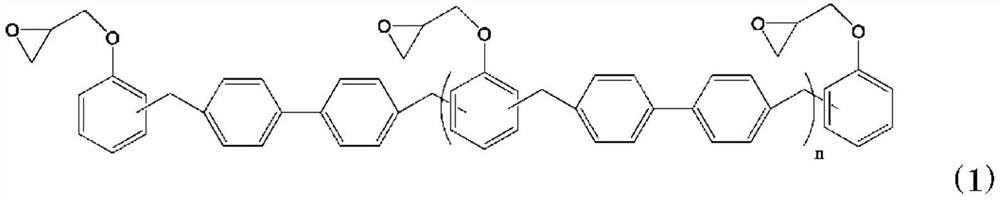

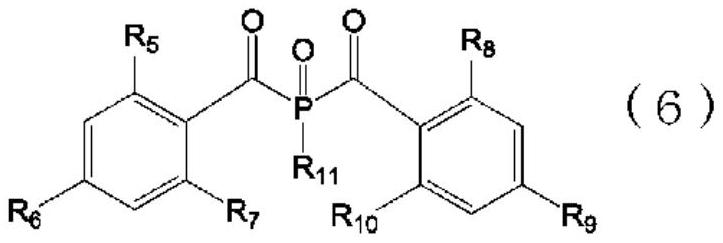

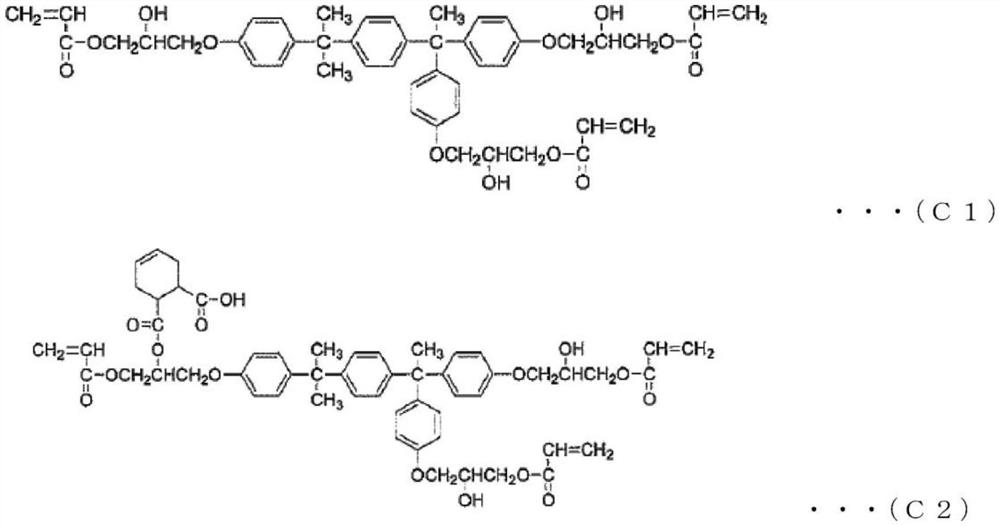

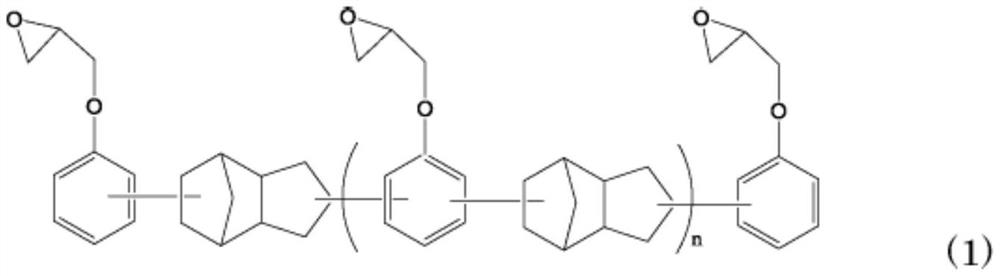

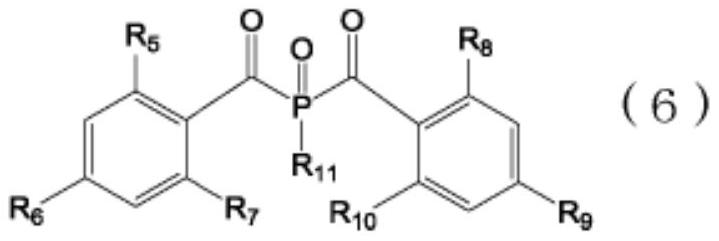

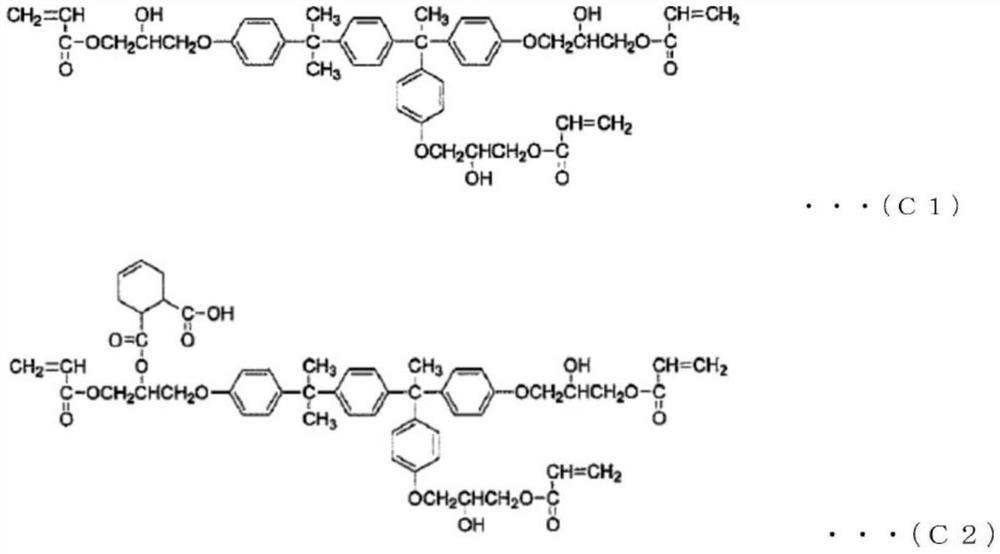

Resin composition, resin sheet, multilayer printed circuit board, and semiconductor device

ActiveCN109415489AGood heat resistanceExcellent developabilityCircuit susbtrate materialsConductive pattern layout detailsChemistryPrinted circuit board

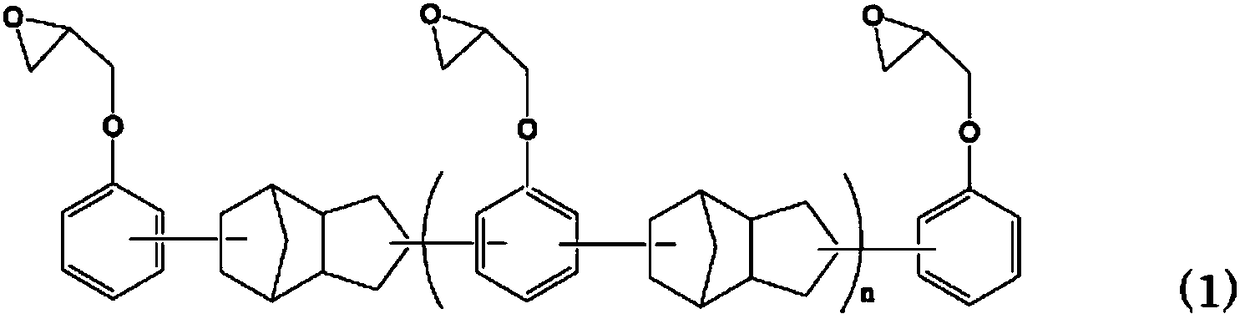

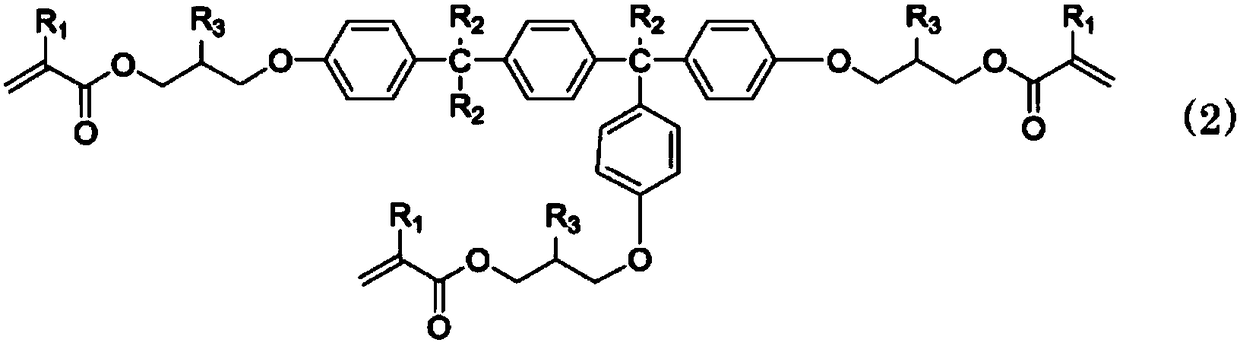

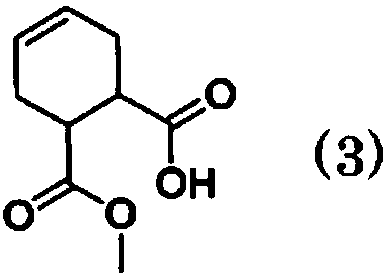

Provided is a resin composition that, when used in a multilayer printed circuit board, exhibits superior heat resistance and coating, and exhibits superior plating adhesion and developability. Also provided are a resin sheet with a support body, and a multilayer printed circuit board and a semiconductor device that use said resin composition and said resin sheet with a support body. The resin composition includes a dicyclopentadiene-type epoxy resin (A) expressed by formula (1), a photocuring initiator (B), a compound (C) expressed by formula (2), and a compound (D) that has an ethylenically unsaturated group other than the (C) component.

Owner:MITSUBISHI GAS CHEM CO INC

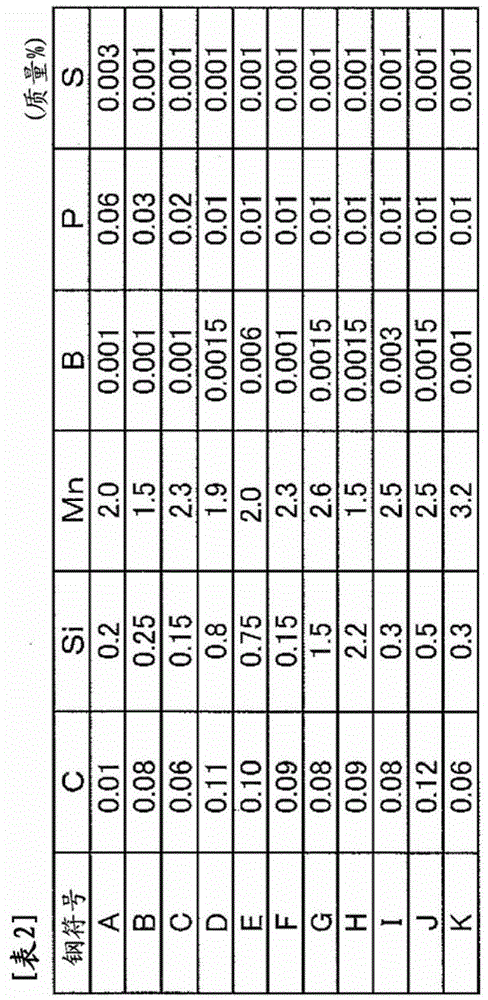

High-strength hot-dip galvanized steel sheet and process for manufacturing same

ActiveCN105026599AExcellent plating adhesionExcellent fatigue resistanceHot-dipping/immersion processesSolid state diffusion coatingSheet steelHigh intensity

A high-strength galvanized steel sheet whose base steel is a high-strength steel sheet containing Si, Mn, and B and which has good coating adhesiveness and a production method therefor are provided. A base steel sheet containing Si, Mn, and B is oxidized at a heating temperature of steel sheet T that satisfies formula below, and then subjected to reduction-annealing and galvanizing. T ‰¥ 58.65 × Si + 294400 × B - 13.59 × O 2 + 548.1 [Si]: amount of Si in the steel on a mass percent basis [B]: amount of B in the steel on a mass percent basis [O 2 ]: O 2 concentration on a volume percent basis in an atmosphere at oxidizing treatment

Owner:JFE STEEL CORP

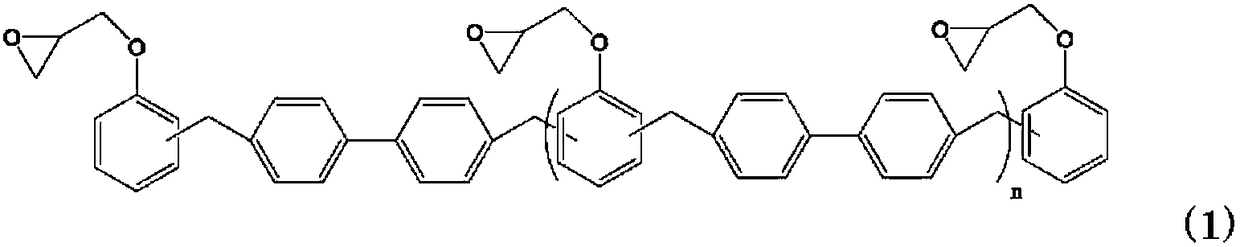

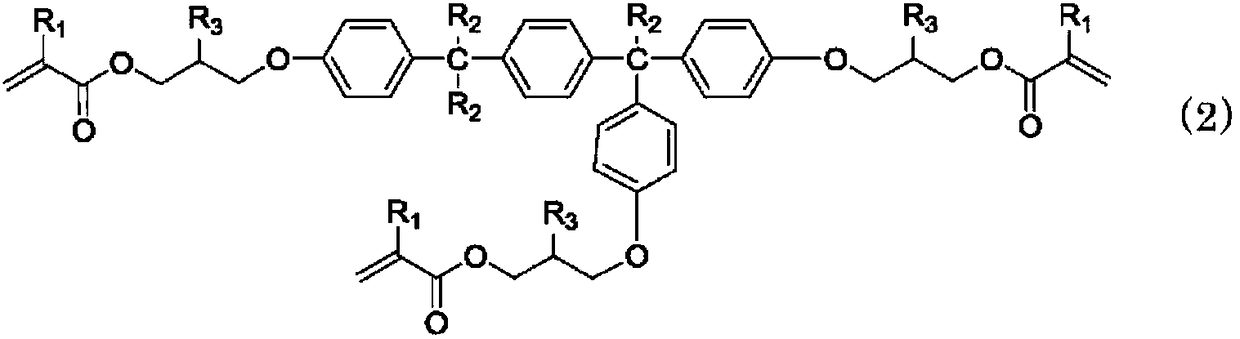

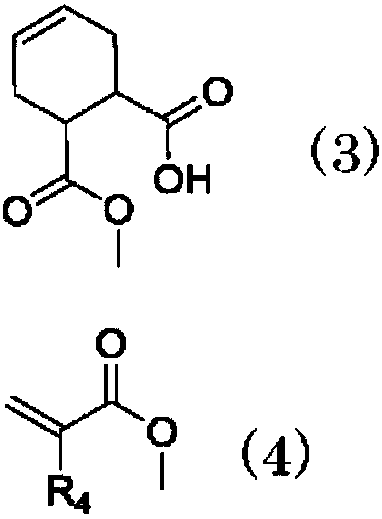

Resin composition, resin sheet, multilayer printed wiring board, and semiconductor device

ActiveCN109415491BExcellent plating adhesionExcellent film performanceCircuit susbtrate materialsEpoxyPolymer science

To provide a resin composition, a resin sheet with a support, a resin composition with excellent coating properties and heat resistance, excellent plating adhesion and developability when used in a multilayer printed wiring board, and a multilayer printed wiring board using them, semiconductor device. The resin composition contains a biphenyl aralkyl type epoxy resin (A) represented by the following formula (1), a photocuring initiator (B), a compound (C) represented by the following formula (2), and (C) The compound (D) which has an ethylenically unsaturated group other than a component.

Owner:MITSUBISHI GAS CHEM CO INC

Thermoplastic rsin composition and its product

InactiveCN100467505CExcellent plating adhesionGood coating performanceCoatingsInstrumentsCyanideMonomer

The present invention provides a thermoplastic resin composition excellent in plating adhesion to the surface of a molded product, paintability and impact resistance, and a molded product thereof. This composition is obtained by graft-polymerizing a monomer component (b) consisting of an aromatic vinyl compound, a vinyl cyanide compound, and, if necessary, other copolymerizable monomer compounds in the presence of a rubbery polymer (a). The thermoplastic resin composition formed by the obtained rubber-reinforced thermoplastic resin (A) is characterized in that the content of the rubbery polymer (a) in the rubber-reinforced thermoplastic resin is 10 to 25% by weight, and the acetone in the rubber-reinforced thermoplastic resin The content of vinyl cyanide monomer units in the soluble fraction is 15 to 40% by weight, the ratio Mw / Mn of the weight average molecular weight Mw to the number average molecular weight Mn of the acetone soluble fraction is 2 to 5, and the acetone can be The ratio Mz / Mn of the Z-average molecular weight Mz and the number-average molecular weight Mn of the solution is 5-11.

Owner:大科能宇菱通株式会社

Resin composition, resin sheet, multilayer printed wiring board, and semiconductor device

ActiveCN109415489BExcellent plating adhesionExcellent film performanceCircuit susbtrate materialsConductive pattern layout detailsEpoxyPolymer science

To provide a resin composition, a resin sheet with a support, and a multilayer printed wiring board using them, which are excellent in film coating and heat resistance, and have excellent plating adhesion and developability when used in a multilayer printed wiring board. , Semiconductor device. A resin composition comprising a dicyclopentadiene type epoxy resin (A) represented by the following formula (1), a photocuring initiator (B), a compound (C) represented by the following formula (2) and the compound (D) which has an ethylenically unsaturated group other than this (C)component.

Owner:MITSUBISHI GAS CHEM CO INC

High-strength hot-dip galvanized steel sheet excellent in coating adhesion and manufacturing method thereof

ActiveCN103582717BExcellent plating adhesionImprove corrosion resistanceHot-dipping/immersion processesFurnace typesCoating adhesionGalvanization

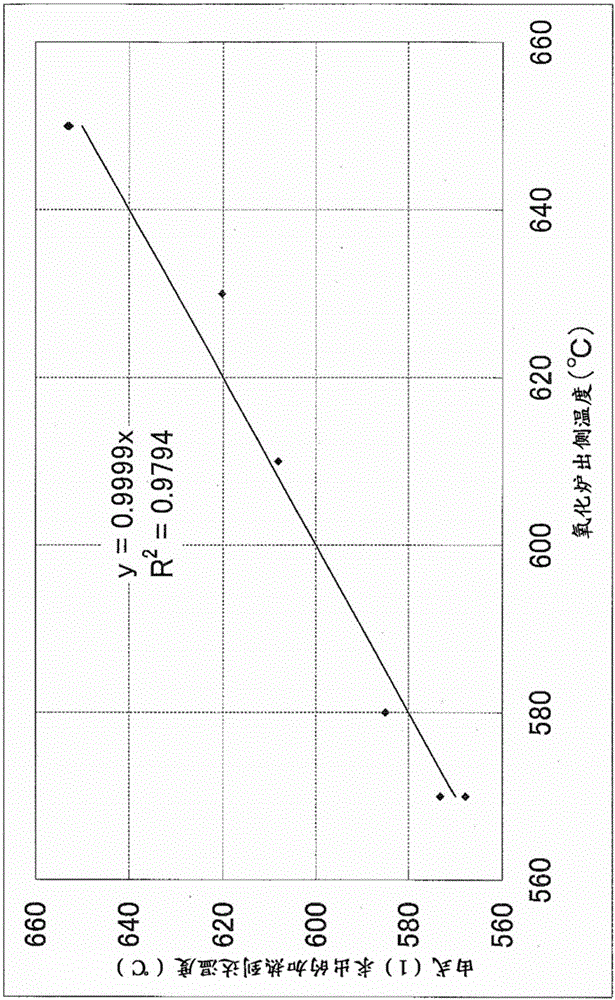

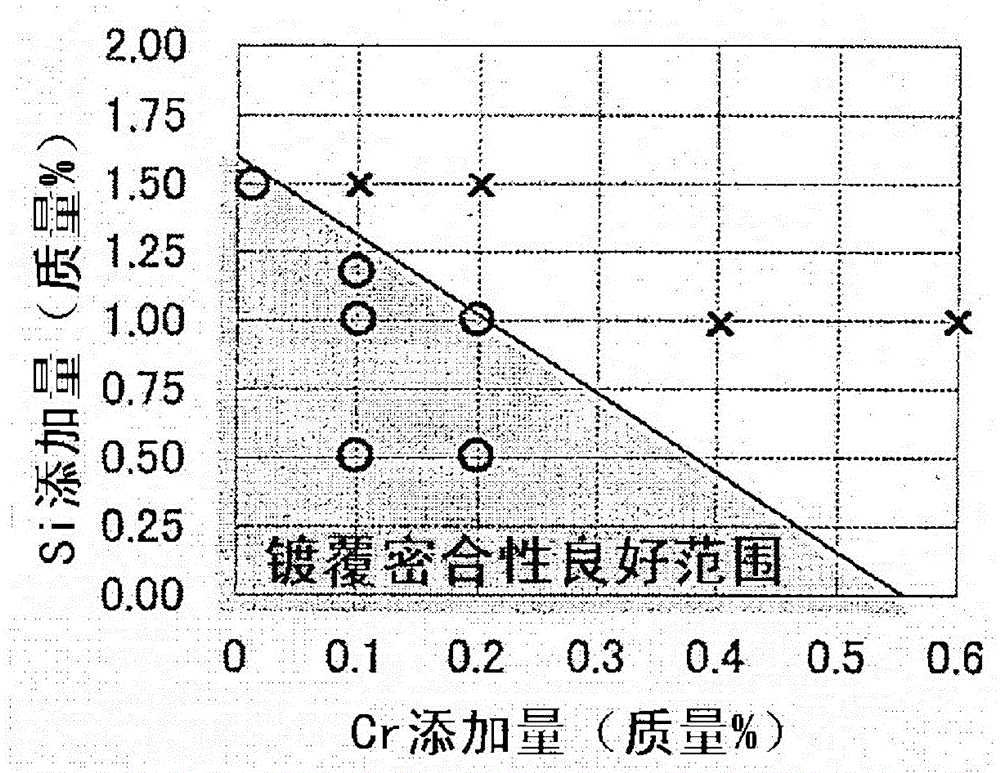

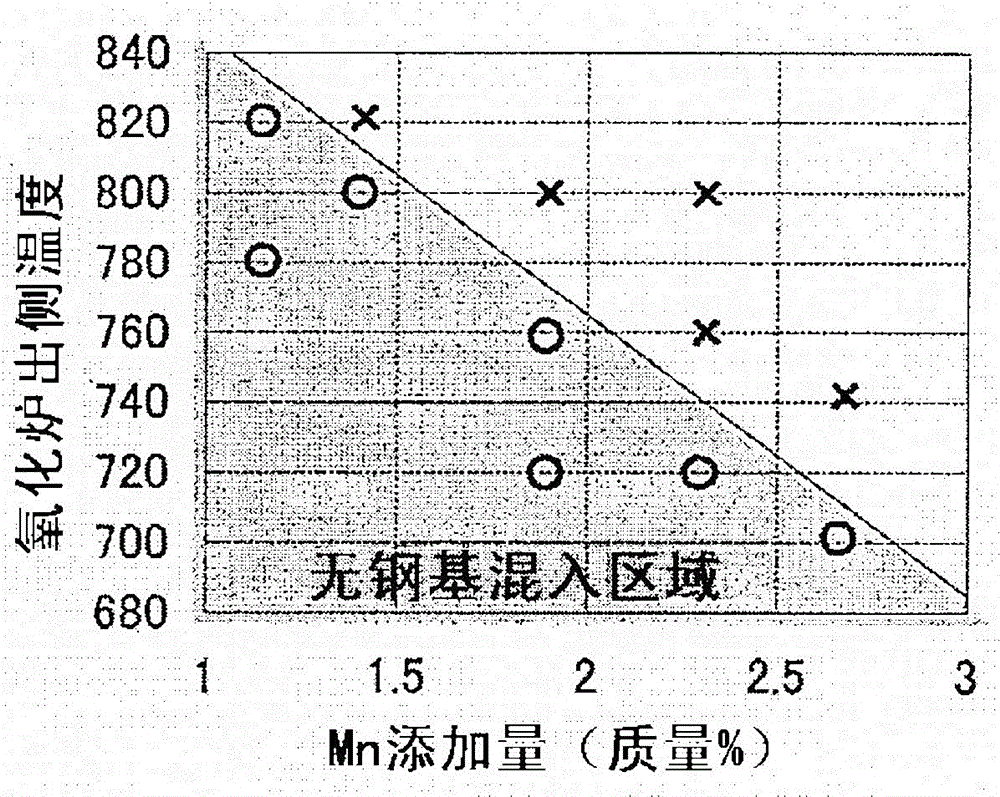

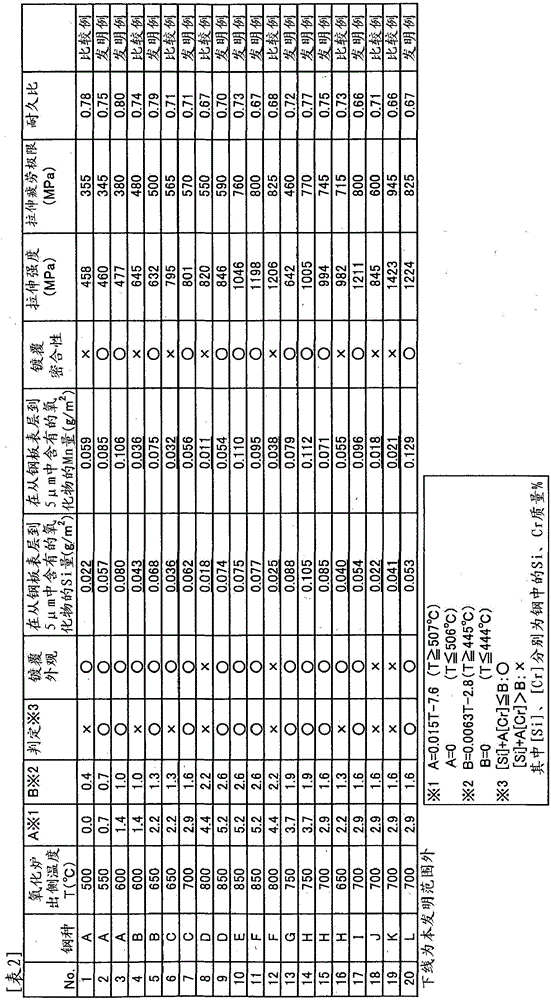

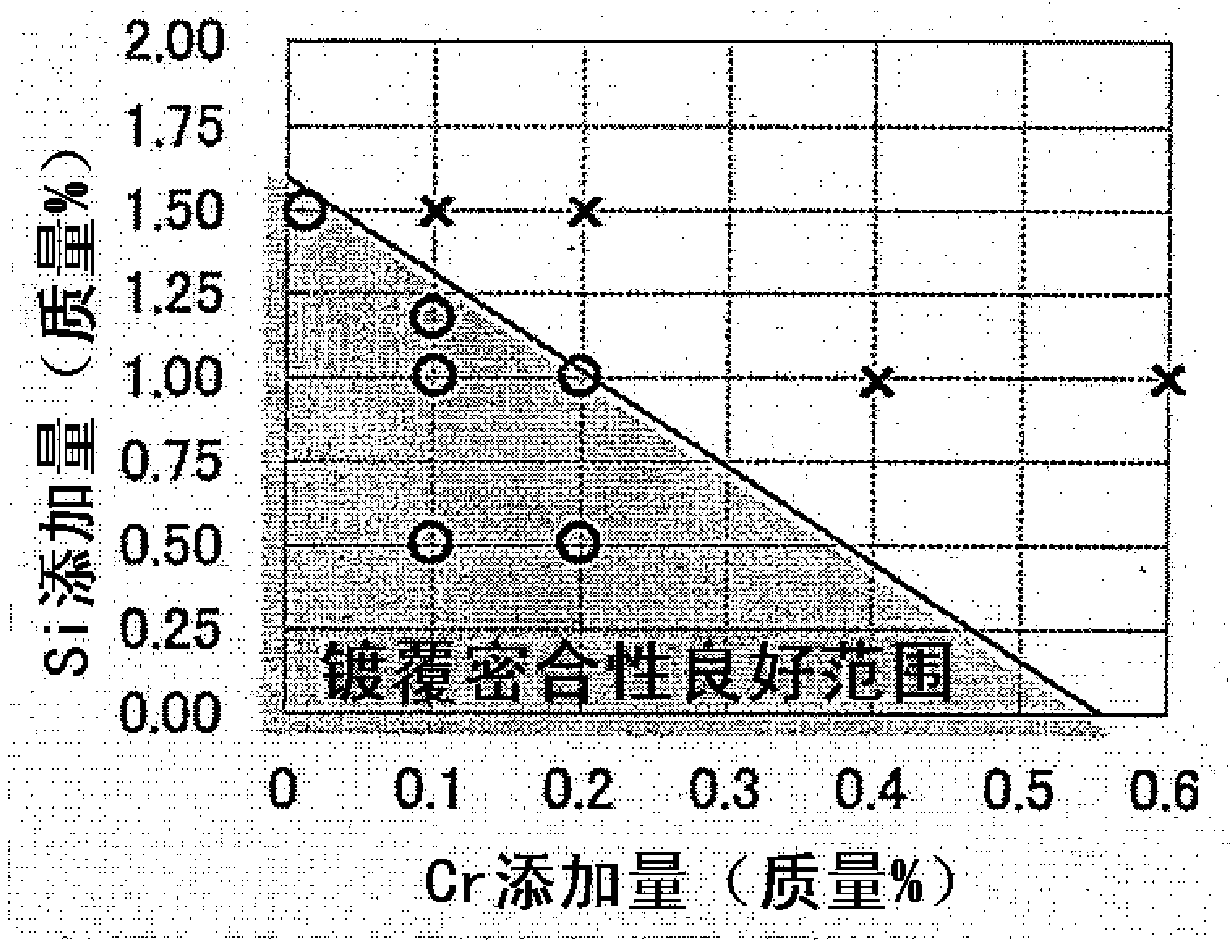

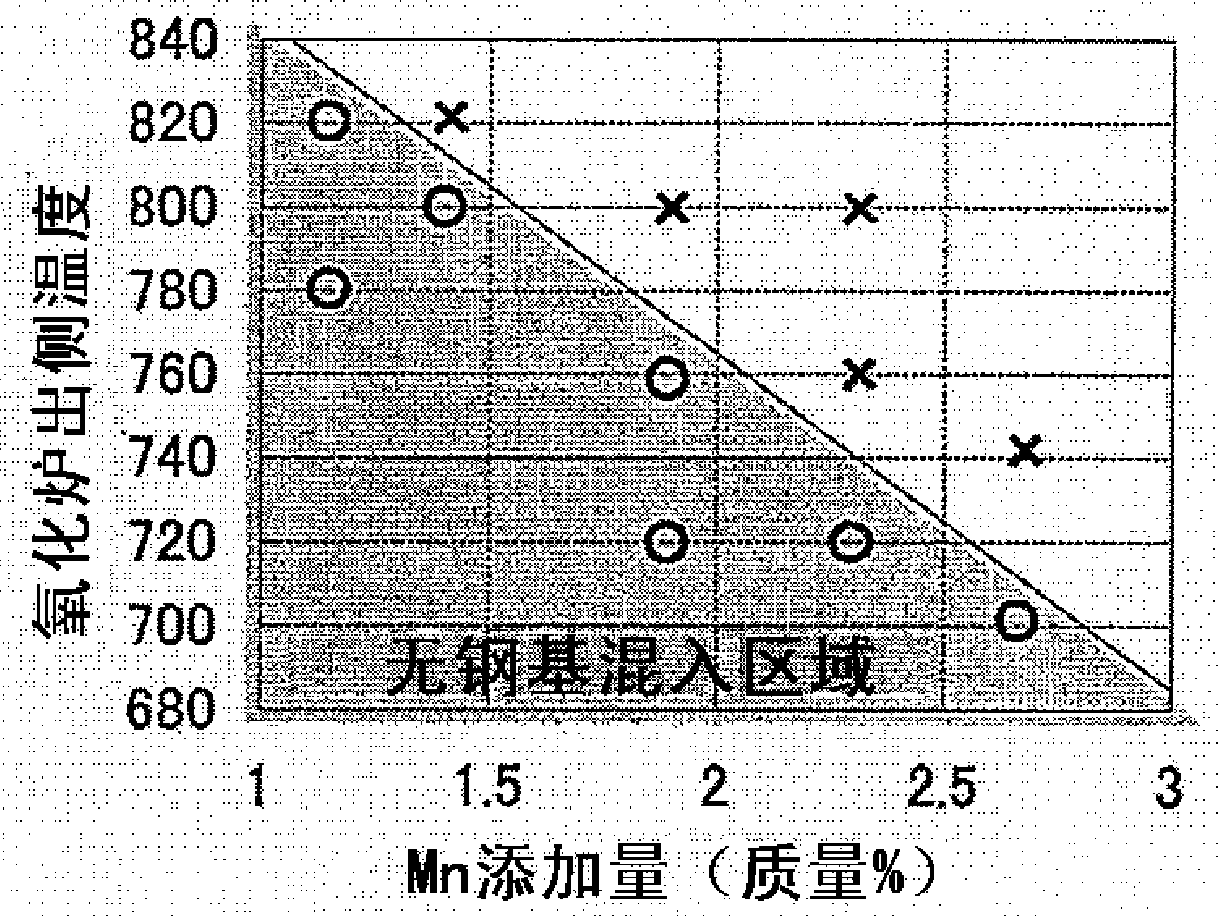

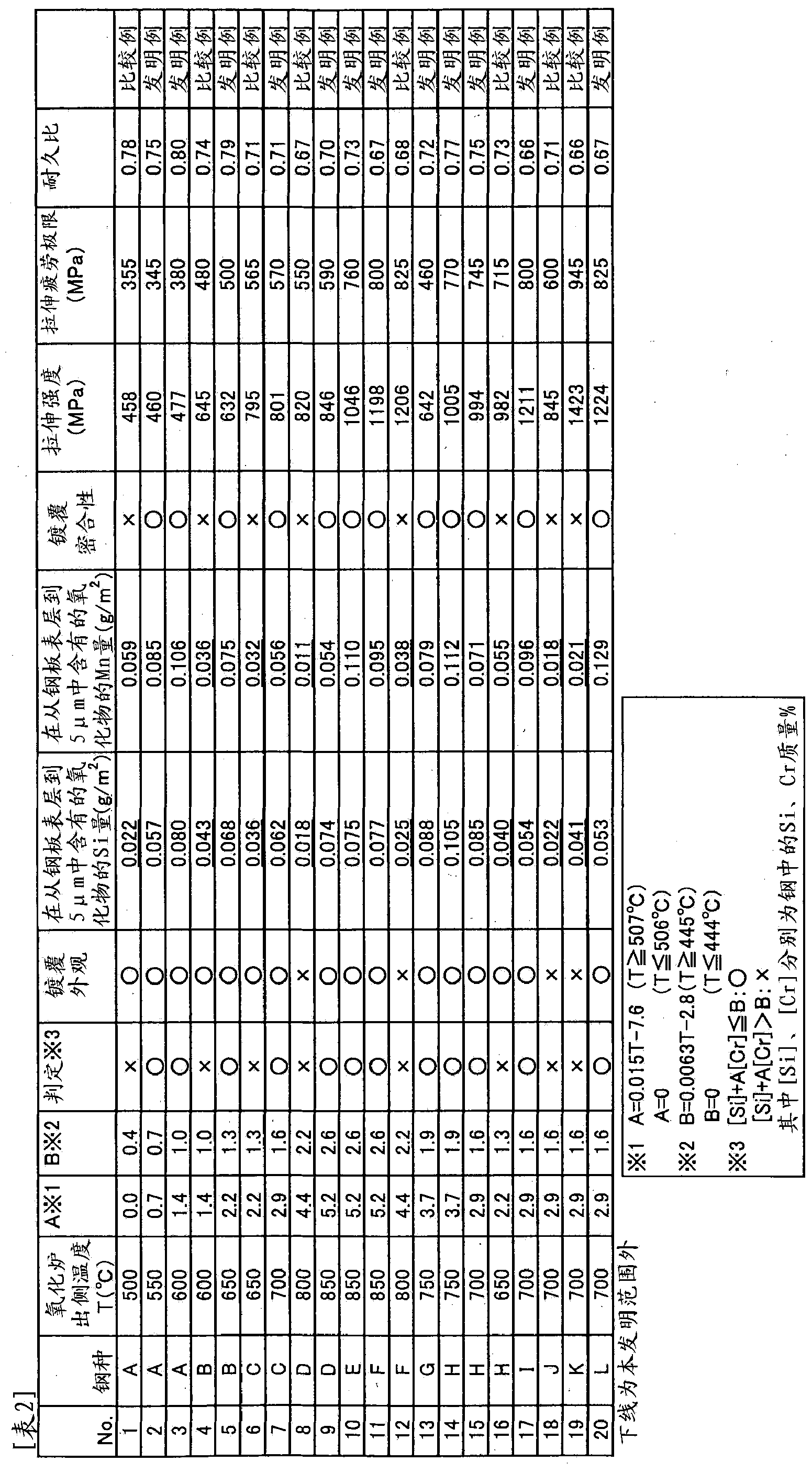

The present invention provides a high-strength hot-dip galvanized steel sheet that uses a high-strength steel sheet containing Si, Mn, and Cr as a base material and has excellent plating adhesion and a method for producing the same. Steel containing Si, Mn, and Cr is oxidized at the exit temperature T in an oxidation furnace, followed by reduction annealing and hot-dip galvanizing. Or further alloying treatment is carried out by heating at a temperature of 460-600° C. for 10-60 seconds. The above outlet temperature T satisfies the following relationship: A=0.015T‑7.6 (T≥507°C) A=0 (T<507°C) B=0.0063T‑2.8 (T≥445°C) B=0 (T<445°C) °C) [Si]+A×[Cr]≦B, where [Si]: Si mass % in steel [Cr]: Cr mass % in steel.

Owner:JFE STEEL CORP

High-strength hot-dipped galvanized steel sheet having excellent plating adhesion, and method for producing same

ActiveCN103582717AExcellent plating adhesionImprove corrosion resistanceHot-dipping/immersion processesFurnace typesHigh intensityHot-dip galvanization

Provided are: a high-strength hot-dipped galvanized steel sheet which uses, as a base material, a high-strength steel sheet containing Si, Mn and Cr and has excellent plating adhesion; and a method for producing the high-strength hot-dipped galvanized steel sheet. In an oxidation furnace, steel containing Si, Mn and Cr is subjected to an oxidation treatment at an exit side temperature (T), and then the steel is subjected to reduction annealing and hot dip galvanization. Alternatively, the steel is alloyed by being heated to a temperature of 460-600 DEG C for 10-60 seconds. In this connection, the exit side temperature (T) satisfies the following conditions: A = 0.015T-7.6 (T>=507 DEG C) A=0 (T<507 DEG C) B=0.0063T-2.8 (T>=445 DEG C) B=0 (T<445 DEG C) [Si]+A*[Cr]<=B, wherein [Si]: mass% of Si in the steel [Cr]: mass% of Cr in the steel

Owner:JFE STEEL CORP

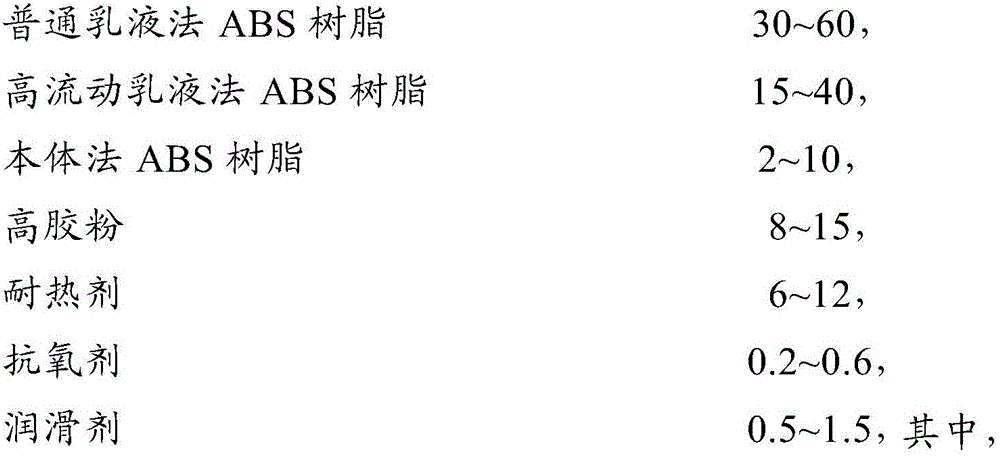

ABS material for electroplating and its preparation method and application

The invention provides an ABS (acrylonitrile-butadiene-styrene) material for electroplating, and a preparation method and application thereof. The ABS material for electroplating comprises the following components in parts by weight: 30-60 parts of common-emulsion-process ABS resin, 15-40 parts of high-flow-emulsion-process ABS resin, 2-10 parts of body-process ABS resin, 8-15 parts of high rubber powder, 6-12 parts of heat-resisting agent, 0.2-0.6 part of antioxidant and 0.5-1.5 parts of lubricant. The high-flow-emulsion-process ABS resin and body-process ABS resin are added to the ABS material for electroplating, thereby enhancing the flowability of the material, improving the processibility of the material, lowering the internal stress of the injection molding component, obtaining favorable electroplating binding force and enhancing the electroplating yield.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Resin composition, resin sheet, multilayer printed circuit board, and semiconductor device

ActiveCN109415491AExcellent plating adhesionExcellent film performanceCircuit susbtrate materialsEpoxyHeat resistance

Provided is a resin composition that, when used in a multilayer printed circuit board, exhibits superior heat resistance and coating, and exhibits superior plating adhesion and developability. Also provided are a resin sheet with a support body, and a multilayer printed circuit board and a semiconductor device that use said resin composition and said resin sheet with a support body. The resin composition includes a biphenyl aralkyl-type epoxy resin (A) expressed by formula (1), a photocuring initiator (B), a compound (C) expressed by formula (2), and a compound (D) that has an ethylenically unsaturated group other than the (C) component.

Owner:MITSUBISHI GAS CHEM CO INC

Manufacturing method of high-strength hot-dip galvanized steel sheet and manufacturing method of high-strength alloyed hot-dip galvanized steel sheet

ActiveCN105452517BHigh strengthExcellent surface appearanceHot-dipping/immersion processesSolid state diffusion coatingElectrolysisSheet steel

The present invention provides a method for producing a high-strength hot-dip galvanized steel sheet that can suppress problems caused by oxides formed on the surface of the steel sheet in a Cr-containing steel sheet, and is excellent in plating adhesion and surface appearance. A method for manufacturing high-strength alloyed hot-dip galvanized steel sheets. It is to manufacture high-strength hot-dip galvanized steel sheets by a method with the following steps, which includes: a first heating step, in a specific H 2 Concentration, a specific dew point atmosphere, the steel plate with a specific composition is kept at a specific temperature for a specific time; the cooling process is to cool the steel plate after the first heating process; the electrolytic treatment process is to cool the steel plate under specific conditions. After the steel plate is electrolytically treated; the second heating process, in a specific H 2 Concentration, specific dew point atmosphere, the steel plate after the electrolytic treatment process is kept at a specific temperature for a specific time; the plating treatment process is to perform hot-dip galvanizing treatment on the steel plate after the second heating process.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com