High-manganese hot-dip aluminum-coated steel sheet having excellent coating adhesion

A hot-dip aluminum and steel plate technology, applied in hot-dip plating process, coating, layered products, etc., can solve the problems of reduced ductility and increased cost, and achieve the effect of excellent coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0076] Hereinafter, the present invention will be described more specifically through examples. However, the following examples are for illustration and concrete description of the present invention, and do not limit the scope of rights of the present invention. This is because the scope of rights of the present invention is determined by the matters described in the claims and matters reasonably derived therefrom.

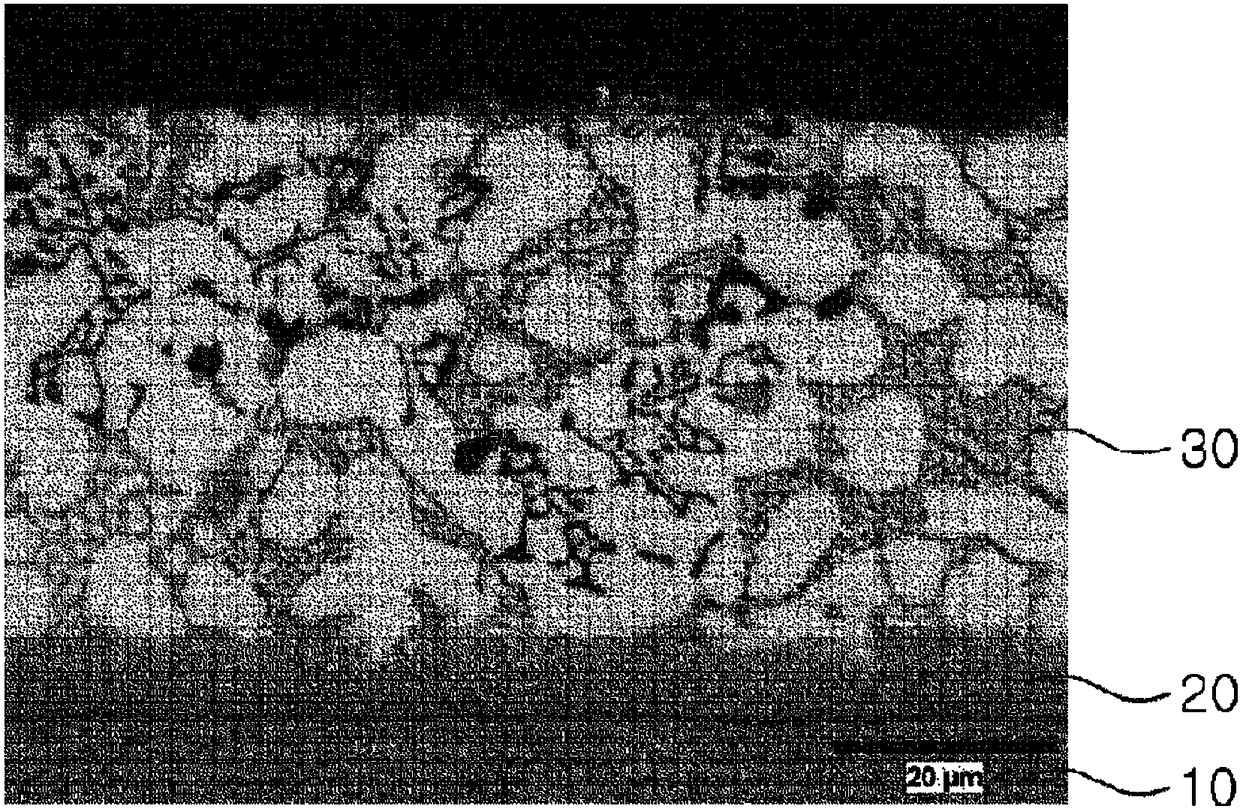

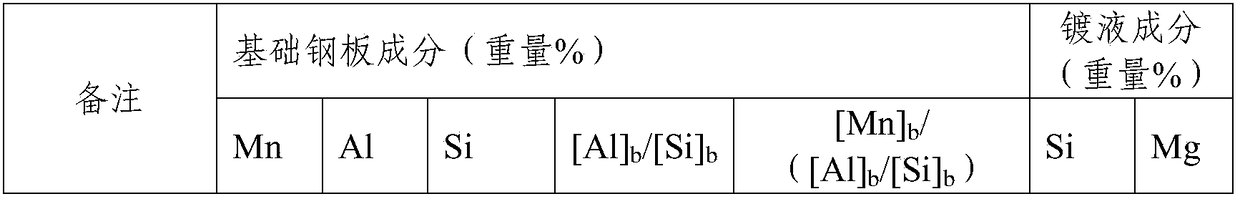

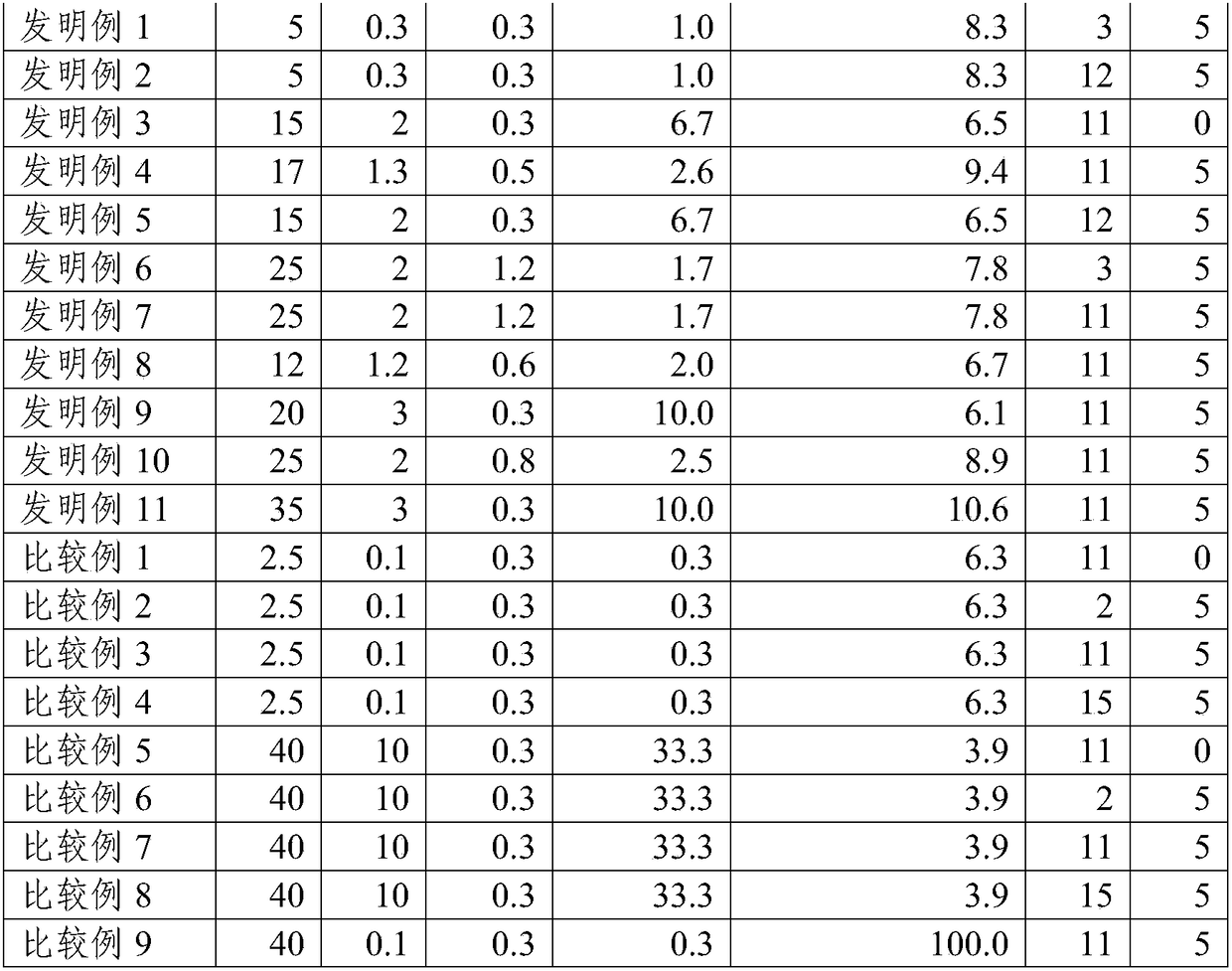

[0077] A steel slab having the composition shown in Table 1 below was heated to a temperature of 1200° C., hot-rolled at 860° C., coiled at 620° C., and then air-cooled to obtain a hot-rolled steel sheet. After that, oxides on the surface of the hot-rolled steel sheet were removed with a hydrochloric acid solution, and then cold-rolled at a cold reduction ratio of 70% to obtain a cold-rolled steel sheet of 1.2 mm. Afterwards, at 800°C in N 2 -10vol%H 2After the cold-rolled steel sheet was annealed for 90 seconds in an atmosphere, it was immersed in an aluminum-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com