Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Ensure assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

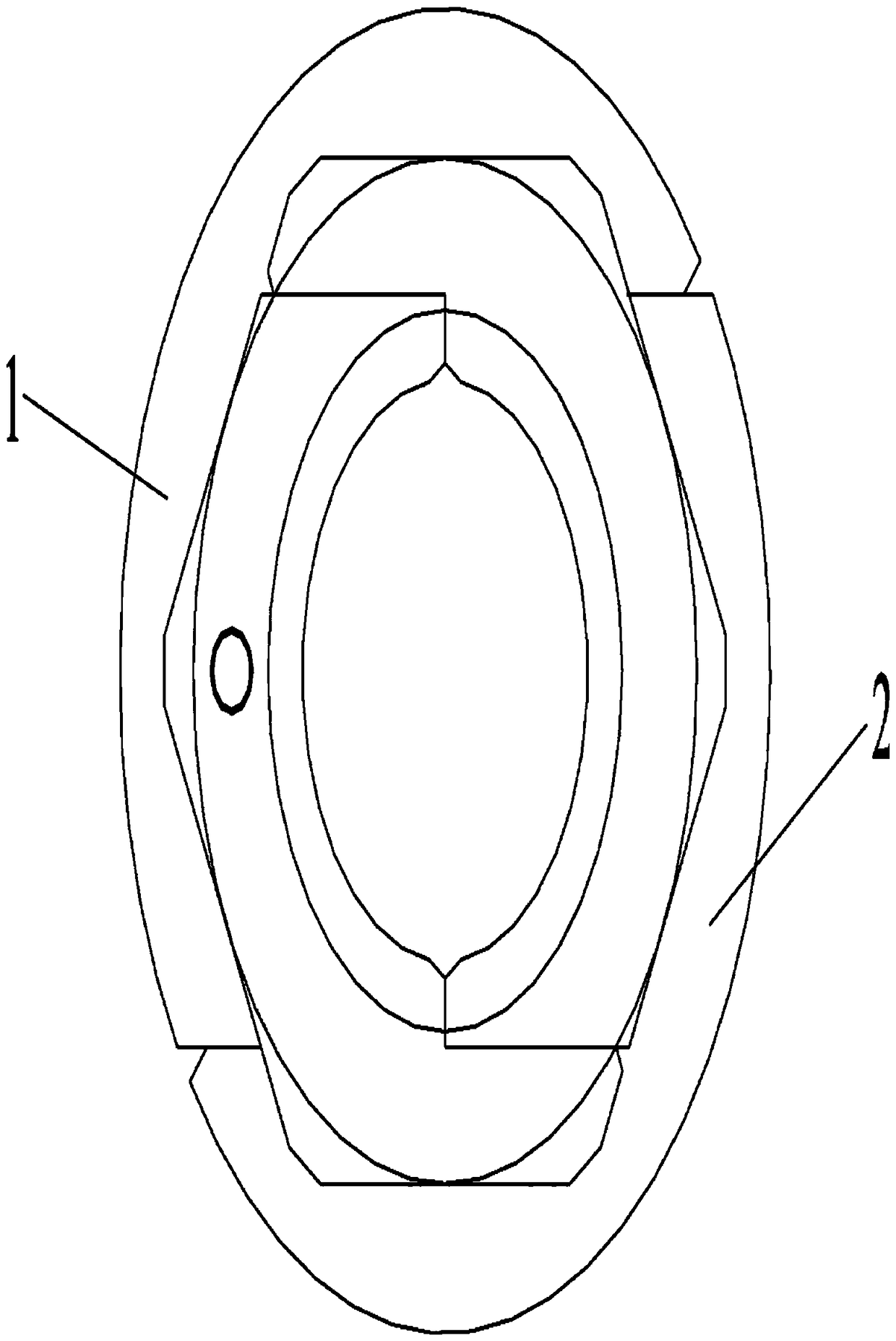

Holding/sealing material for use in catalytic converter for clarifying gaseous emission

InactiveCN1437677AEnsure assemblyCatalyst protectionInternal combustion piston enginesFiberWorking environment

An object of the invention is to provide a holding and sealing mat material of a catalytic converter for purifying an exhaust gas which can prevent inorganic fibers from flying in all directions from a surface of the holding and sealing mat material, and can keep a working environment at a time of assembling good. In the holding and sealing mat material of a catalytic converter for purifying an exhaust gas, which is arranged between a catalyst carrier and a shell covering the catalyst carrier from the outside thereof, the holding and sealing mat material includes a mat-like material consisting of inorganic fibers and being formed in a mat shape and a binder of 0.5 to 20 weight % of an organic binder or an inorganic binder, which is attached to the mat-like material, wherein a filling bulk density of the holding and sealing mat material after being assembled is within a range between 0.1 and 0.6 g / cm<3>, and wherein in the case of estimating distribution rates of solids constituents in the binder attached to the mat-like material by dividing the mat-like material into three equal parts of an upper portion, a middle portion and a lower portion in a thickness direction, the distribution rates of the upper portion and the lower portion are higher than that of the middle portion.

Owner:IBIDEN CO LTD

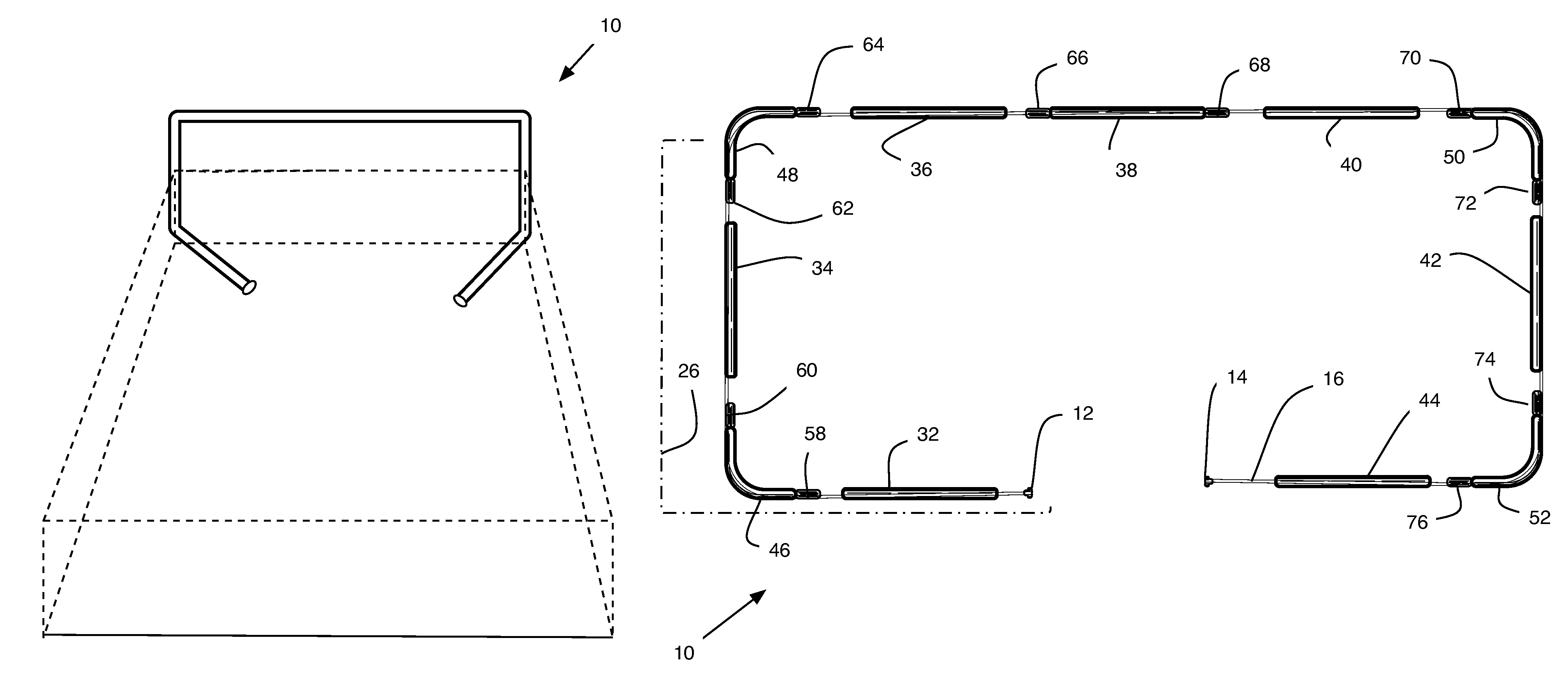

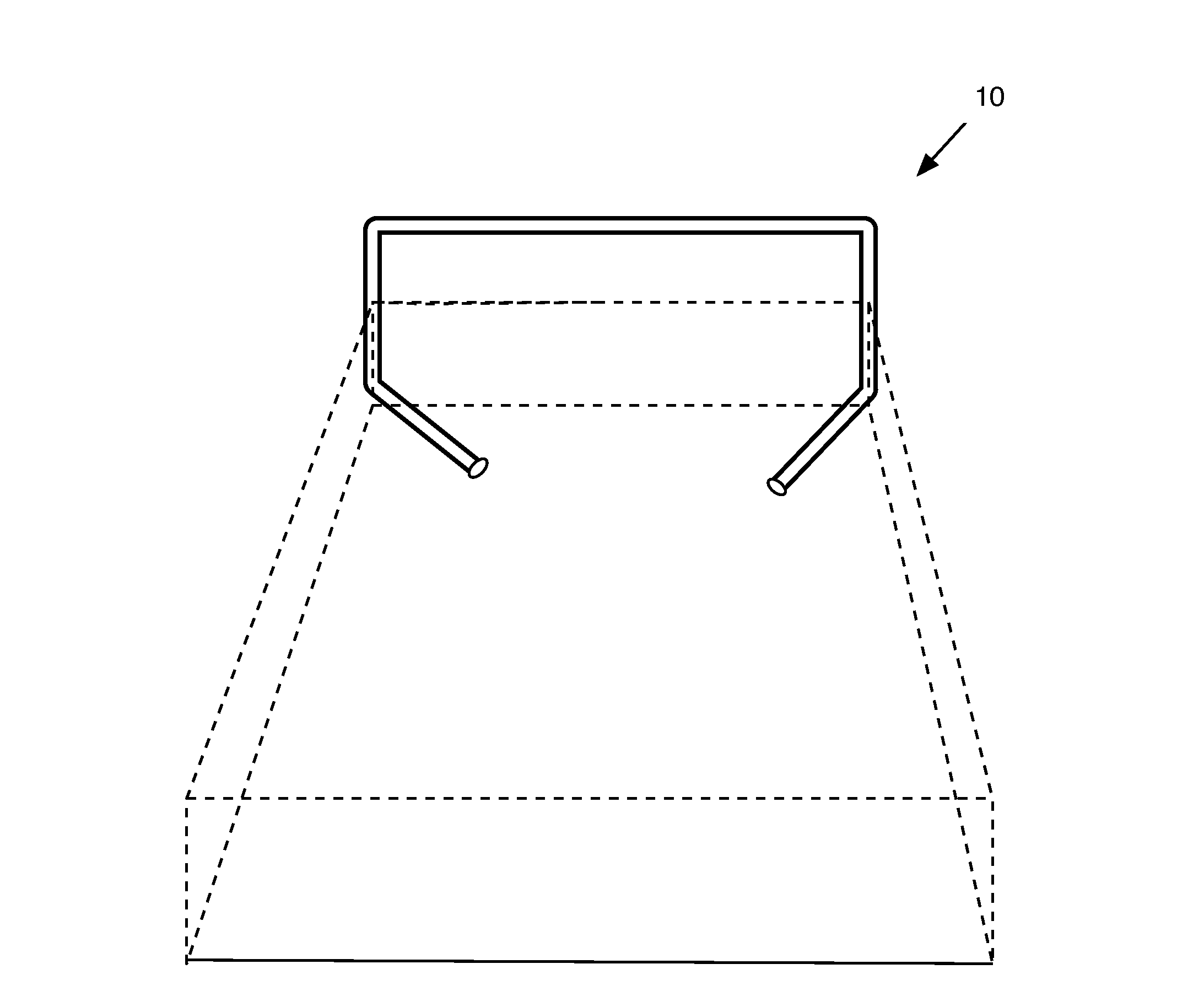

Support frame for elevating a bed covering

A plurality of hollow tubular frame members interconnected by a single internal elastic retaining member that ensures each frame member aligns relative to each remaining frame member in a manner that only one arrangement of frame members is possible when assembled. To assemble, the frame members interconnect forming a three-dimensional frame suitable for supporting a bed cover. The frame members are held in tension by the internal retaining member. The frame members interlock via an insert device between adjacent frame members. The entire assembly interlocks and selectively decouples for disassembly. When disassembled, the entire assembly lies relatively flat, which enables a compact design suitable for packaging, transport or storage.

Owner:TIPPERREITER MARK R

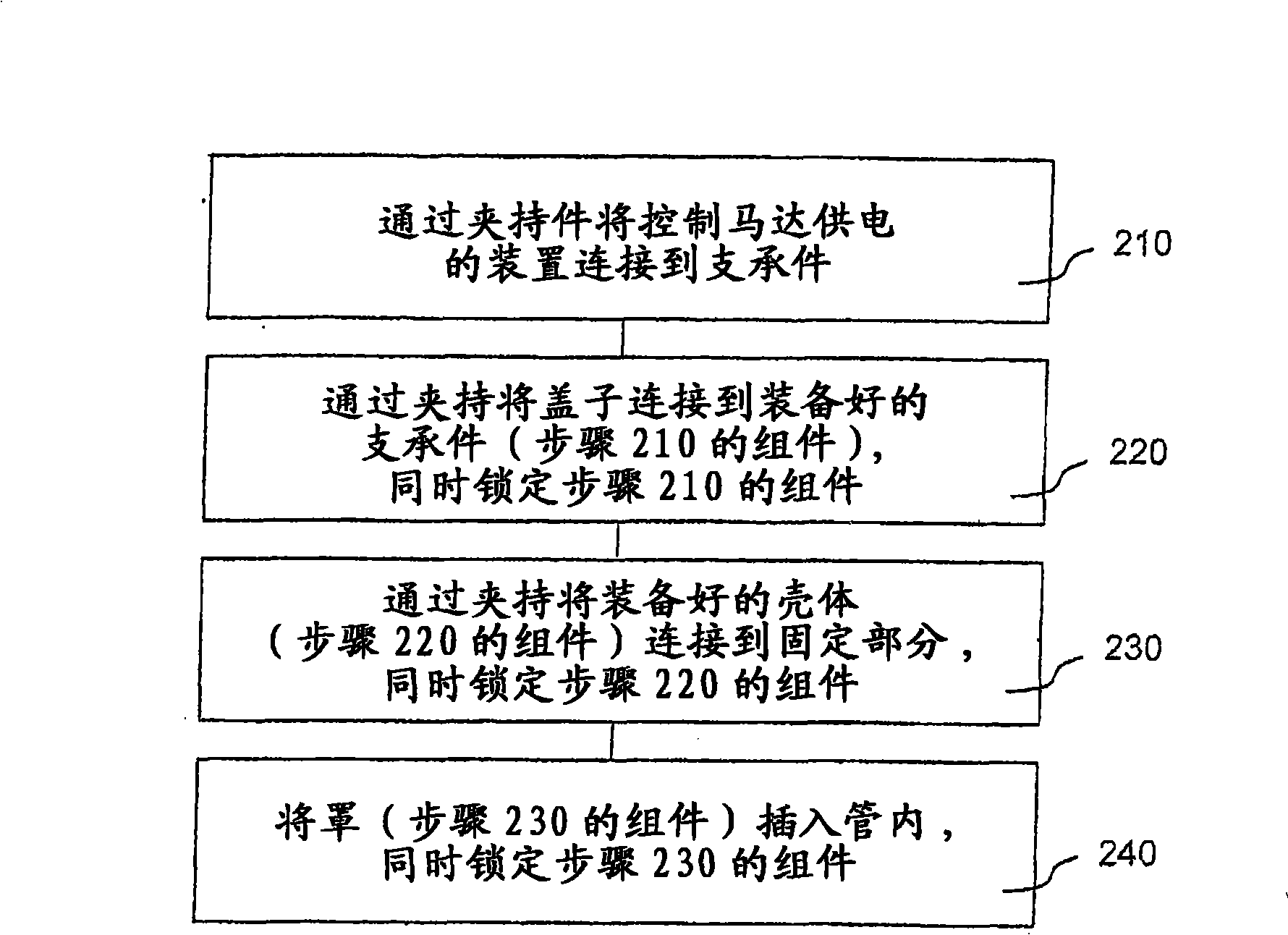

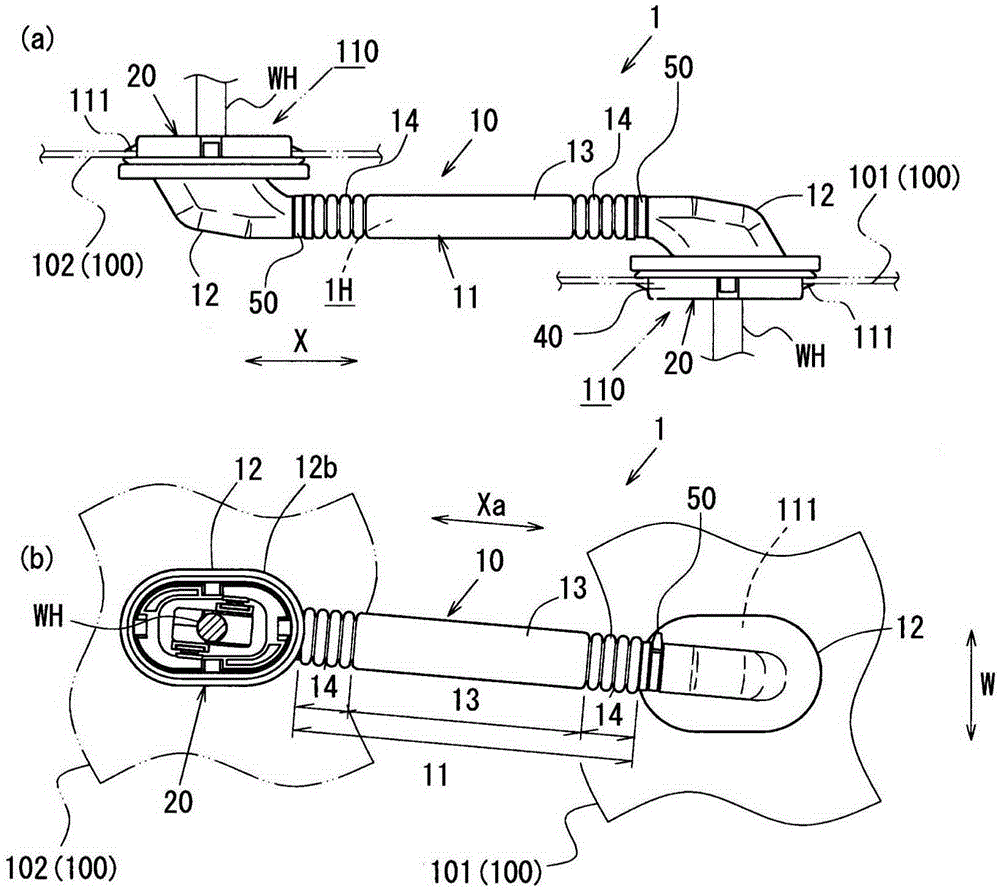

Tubular actuator for powering a screen and method for manufacturing such an actuator

ActiveCN101302919AEnsure assemblyImplement continuous lockingAssociation with control/drive circuitsDoor/window protective devicesEngineeringActuator

The actuator (100) has a fixation piece (110) integrating the actuator with a frame (5) and partially arranged inside a tube (101) of the actuator. A case (120) houses a control part i.e. electronic board (140), that controls supply of an electric motor of a gear motor (102) belonging to the actuator, where the case and the motor are arranged inside the tube. Assembling units are formed of clips (121) for assembling the piece and the case. A locking unit locks the clips between the piece and the case, when the case is placed in the tube, and is formed by an inner surface (101D) of the tube. An independent claim is also included for a method of manufacturing a tubular actuator.

Owner:SOMFY ACTIVITES SA

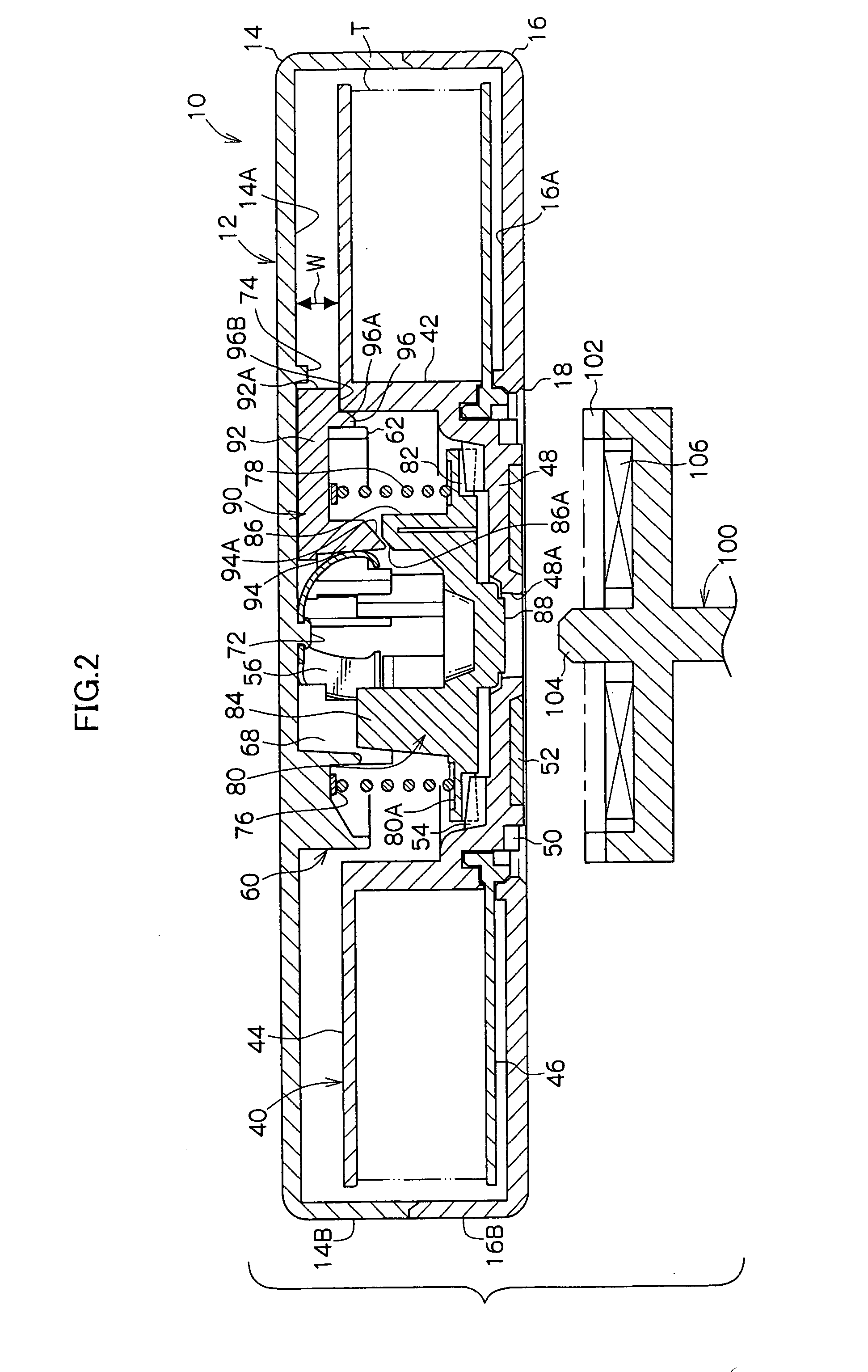

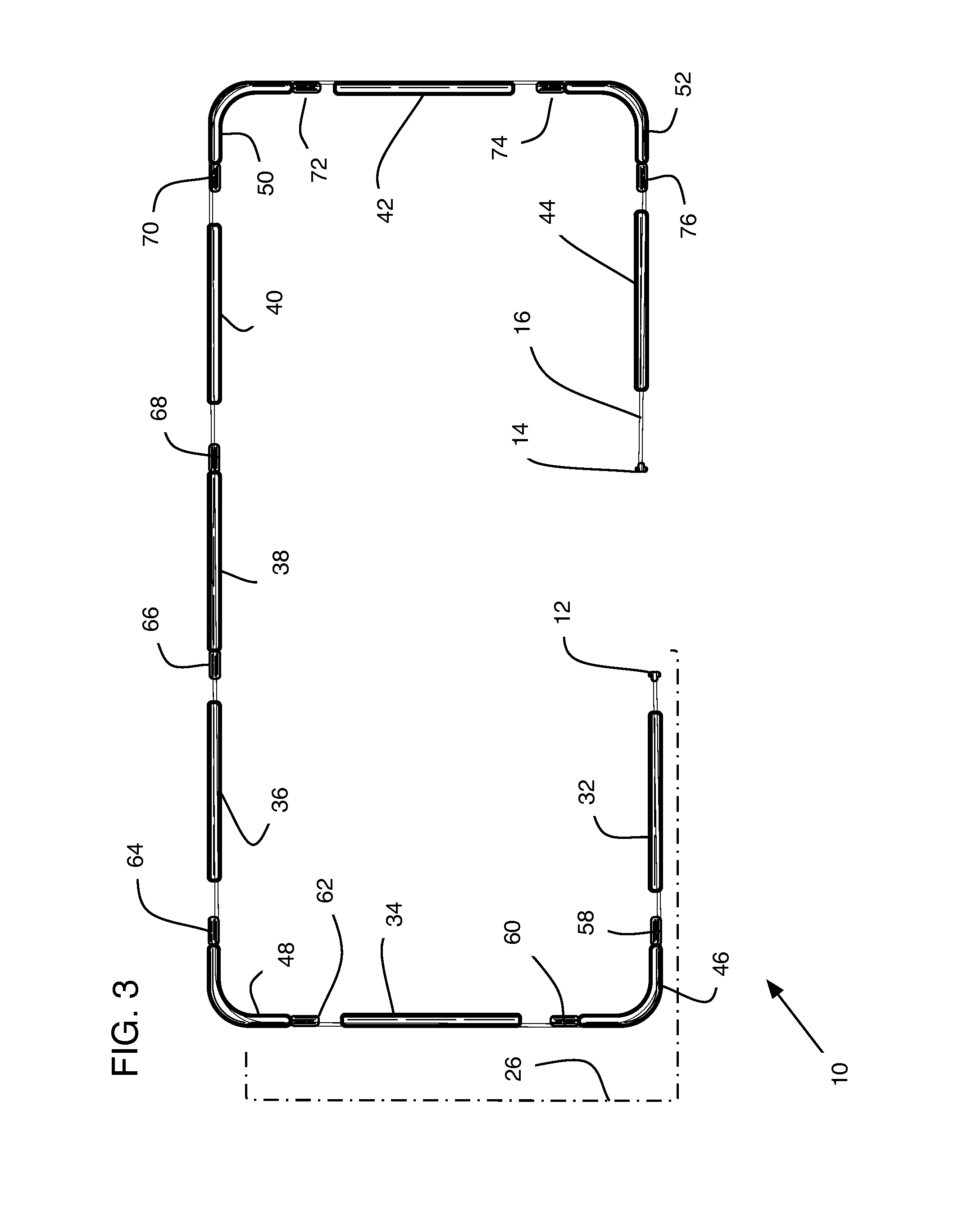

Recording tape cartridge

ActiveUS20050184179A1Ensure assemblyPicture changing apparatusAccessories for indicating/preventing prior/unwanted useBackplaneEngineering

A recording tape cartridge (10) includes: a case (12) that houses a reel (40) onto which a recording tape is wound, the case comprising an upper case (14) including a top plate (14A) and a lower case (16) including a bottom plate (16A); lock members (90) that are disposed, so as to be slidable in a radial direction of the reel, in an attachment portion (60) formed on an inner surface of the top plate, the lock members being movable between a rise / fall lock position, at which the lock members are intervened between an upper surface of the reel and the top plate to prevent movement in an axial direction of the reel, and a rise / fall allowance position, at which the lock members are retracted from between the upper surface of the reel and the top plate to allow movement in the axial direction of the reel; and projecting portions (70A) that are formed on the inner surface of the top plate and project towards the lock members so that the lock members do not fall out of the attachment portion at least when the case is assembled.

Owner:FUJIFILM CORP +1

Turbo-engine stator blading, turbo-engine comprising the blading and turbo-engine blade

A turbo-engine stator blading is disclosed. The turbo-engine stator blading includes a crown of fixed blades mounted on a ring. Each blade includes a platform and each blade is fastened to the ring. The ring includes a plurality of individual receptacles for the each of the platforms, the receptacles being machined in the thickness of the ring, the form of each receptacle being complementary to that of the corresponding platform. By means of the receptacles, the mounting of the blades within the blading is both simple and accurate.

Owner:TECHSPACE AERO

Runflat device for a motor vehicle, and a mounted assembly incorporating it

InactiveUS20060005906A1Reduce weightEnsure assemblyWithout separate inflatable insertsRimsMobile vehicleRigid wall

The present invention concerns a runflat device for a tubeless mounted assembly for a motor vehicle and an assembly incorporating said device. A device in accordance with the invention for a unit comprises a wheel rim having a plurality of pieces and a tire cover comprising beads mounted against the flanges of the rim, the device comprising: a support ring for mounting around the rim to support the tire cover following a drop in inflation pressure and divided into at least two ring sectors; and means for locking said beads against the flanges to connect the sectors to the beads. The device is such that each ring sector comprises a rigid wall which defines at least one internal volume and which defines the lateral faces of the ring sector.

Owner:HUTCHINSON SA

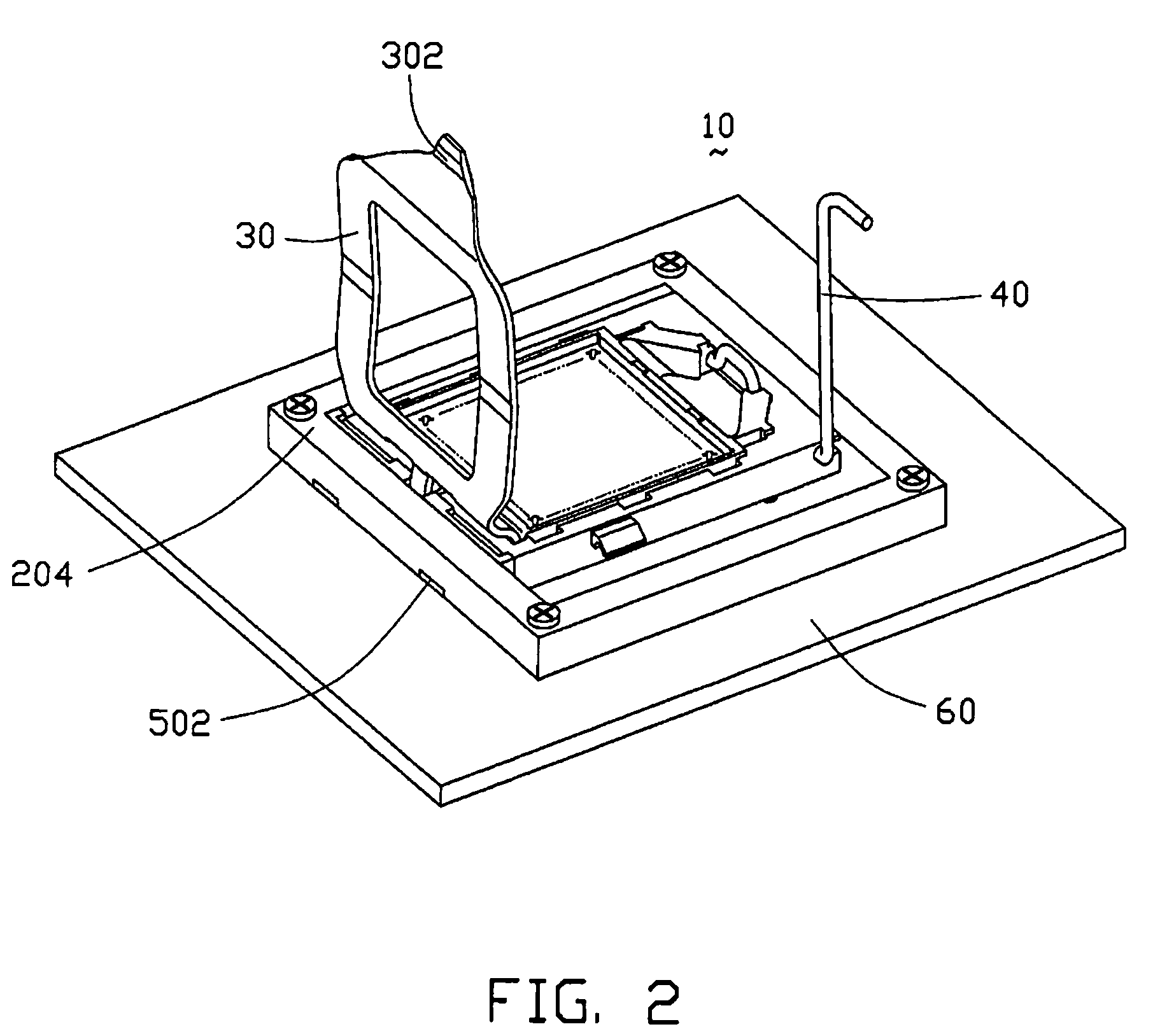

Electrical connector assembly having reinforcing mechanism

InactiveUS7070436B2Release tensionEnsure assemblyElectric discharge tubesCoupling device detailsEngineeringElectrical connector

An electrical connector assembly (10) includes a socket body (50), a frame (20) arranged around the socket body, and a socket plate (30) and a load lever (40) mounted to opposite ends of the socket body respectively. The socket body has a number of first sidewalls (505, 506). The first sidewalls form a number of protrusions (502) distant from a center of the socket body on exterior surfaces. The frame includes a number of second sidewalls (201, 202). The second sidewalls correspondingly define a number of slots (204) to mate with the respective protrusions. Via engagement between the protrusions and the corresponding slots, the frame can press down the socket body and prevent opposite ends of the socket body from bending upward, thereby reinforcing the socket body.

Owner:HON HAI PRECISION IND CO LTD

Conduit

Owner:FURUKAWA ELECTRIC CO LTD +2

Water wheel comprising a built-in generator

ActiveUS8421261B2Easy to transportEasy constructionMagnetic circuitWind motor combinationsWater wheelEngineering

In a water wheel with an integrated electrical generator, a ring element for forming a rotor is rigidly concentrically connected with the water wheel. The ring element is assembled of modular individual segments with inserted permanent magnets. At least one corresponding partial ring as a stator is allocated to the rotor, whereby each partial ring carries electrical coils in correlation to the permanent magnets of the ring element of the rotor. The partial rings of the stator are stationarily mounted by holding elements on support struts of the water wheel.

Owner:DREWS HARTMUTH

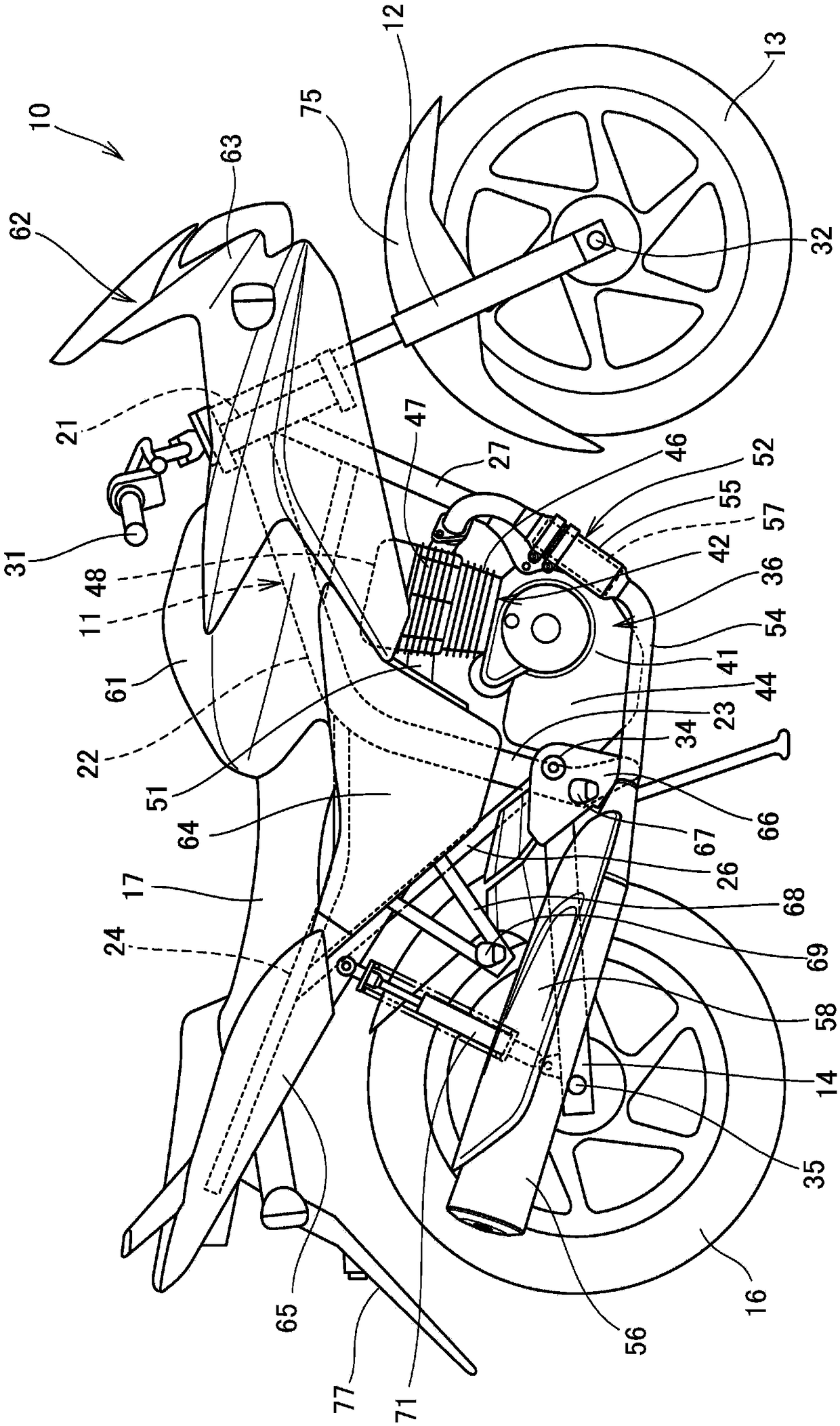

Air feeder structure of internal combustion engine

InactiveCN101509446AEnsure assemblyImprove sealingCombustion-air/fuel-air treatmentMachines/enginesAir filterInternal combustion engine

This invention provides an intake pipe structure of internal combustion engine, which may tangibly lock the connection part of the connection tube and the air filter without increasing the component number and the assembling time, and may keep the good sealability for a long time. The intake pipe (101) of internal combustion engine comprises: an air filter (54) for supplying purified air to the internal combustion engine, a connection tube (103) for connecting the air filter (54) and the internal combustion engine, a lock projection (109) mounted at a side wall (103a) of the connection tube (103). A wall part (108) is integrally mounted at the wall surface of the air filter (54) facing to the connection tube (103) along the connection tube (103). The wall part (108) is provided with a locking part (164) for locking the lock projection (109).

Owner:HONDA MOTOR CO LTD

Electrical connector assembly having reinforcing mechanism

InactiveUS20040203266A1Ensure assemblyElectric discharge tubesCoupling device detailsEngineeringElectrical connector

An electrical connector assembly (10) includes a socket body (50), a frame (20) arranged around the socket body, and a socket plate (30) and a load lever (40) mounted to opposite ends of the socket body respectively. The socket body has a number of first sidewalls (505, 506). The first sidewalls form a number of protrusions (502) distant from a center of the socket body on exterior surfaces. The frame includes a number of second sidewalls (201, 202). The second sidewalls correspondingly define a number of slots (204) to mate with the respective protrusions. Via engagement between the protrusions and the corresponding slots, the frame can press down the socket body and prevent opposite ends of the socket body from bending upward, thereby reinforcing the socket body.

Owner:HON HAI PRECISION IND CO LTD

Laser light path precollimator

This invention relates to the laser appliance field, especially the aligning device of laser path. It sets joint spider fibers at two ends of the hollow straight tube, the joint spider fibers are on the surface of the transparent glass, the glass of the input port is transparent, the output is ground glass; the connecting line of the centers of the two joint spider fibers parallel the axes of the straight tube. Or set flare stops at the two ends of the hollow straight tube, the center connecting line of the two flare stop parallel the axes of the straight tube. It mainly solves the problem that the present aligning method makes use of optics system to adjust roughly and then precisely to cause the reduction of the working efficiency. This invention can greatly reduce the difficulty of the adjustment of the optics system and improve the operational efficiency.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Scroll refrigeration compressor with anti-return device

InactiveUS9017050B2Simple and cost-effective structureImprove compressor performanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeRefrigeration compressorEngineering

The scroll refrigeration compressor includes a stationary volute and a moving volute provided with spiral wraps defining variable-volume compression chambers, a separating member sealably mounted on a plate of the stationary volute so as to allow a relative movement between the separating member and the stationary volute, a delivery chamber at least partially defined by the separating member and the sealed casing. The compressor further includes a bypass passage arranged to communicate the delivery chamber with an intermediate compression chamber, and a anti-return device comprising a closing member movable between closing and opening positions for closing and opening the bypass passage, and an enclosure, positioned between the separating member and the plate of the stationary volute, including a first portion sealably mounted in a housing defined by the separating member and oriented substantially parallel to the longitudinal axis of the compressor.

Owner:DANFOSS COMML COMPRESSORS

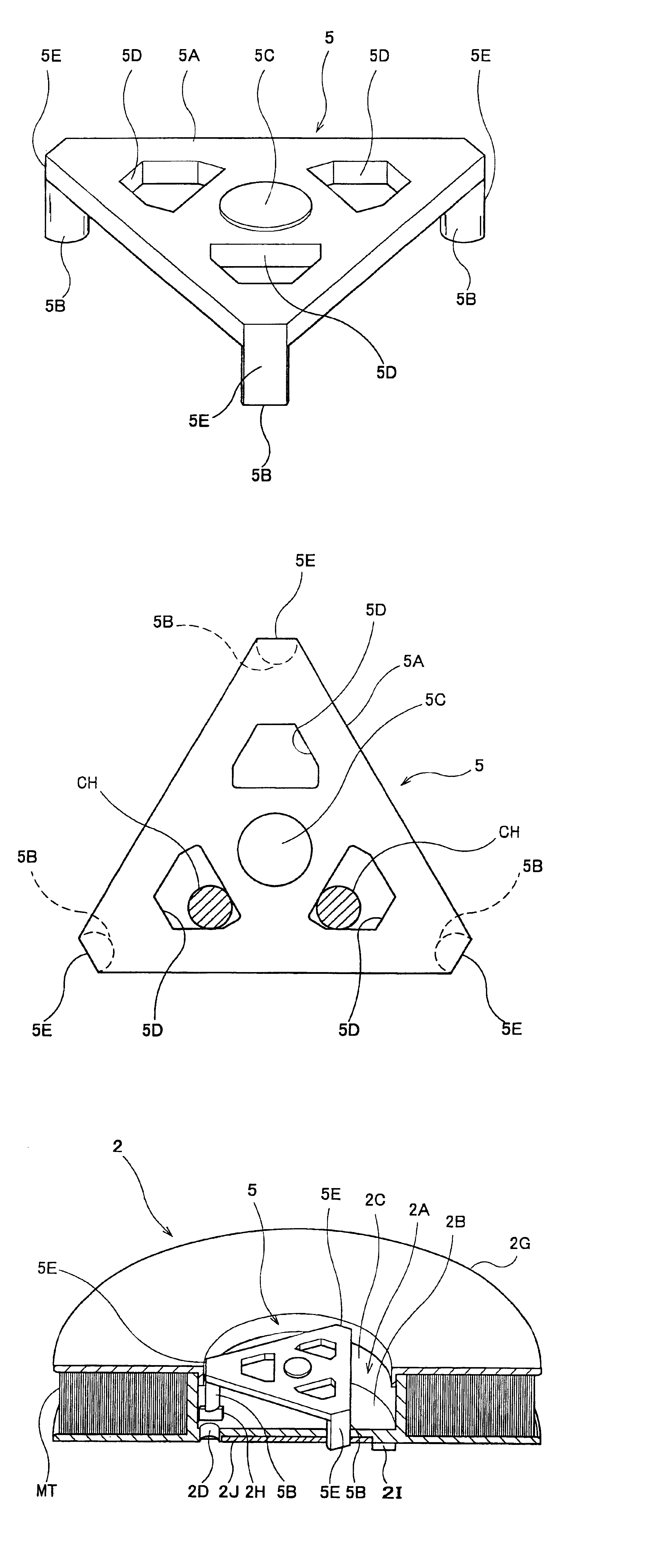

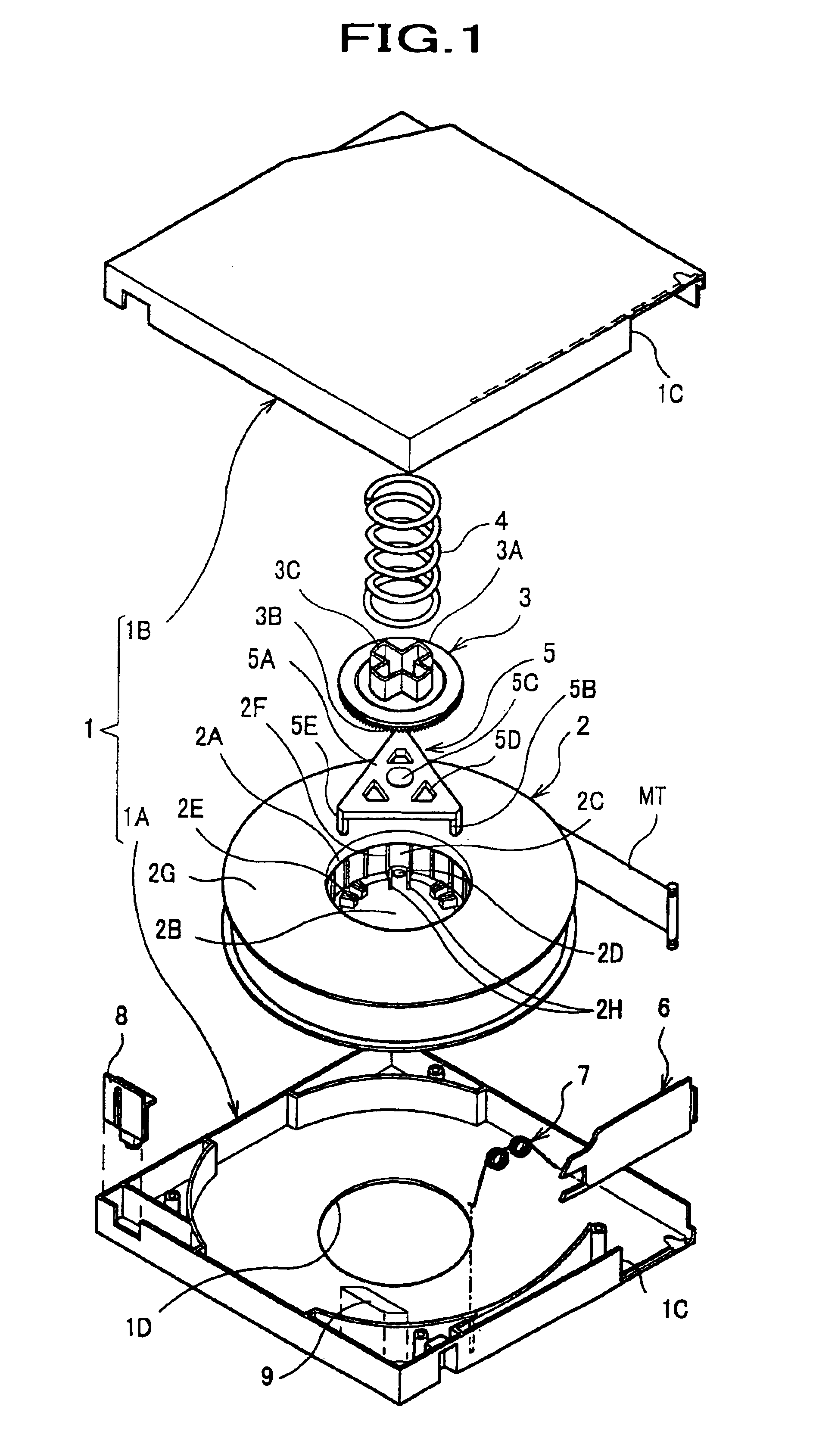

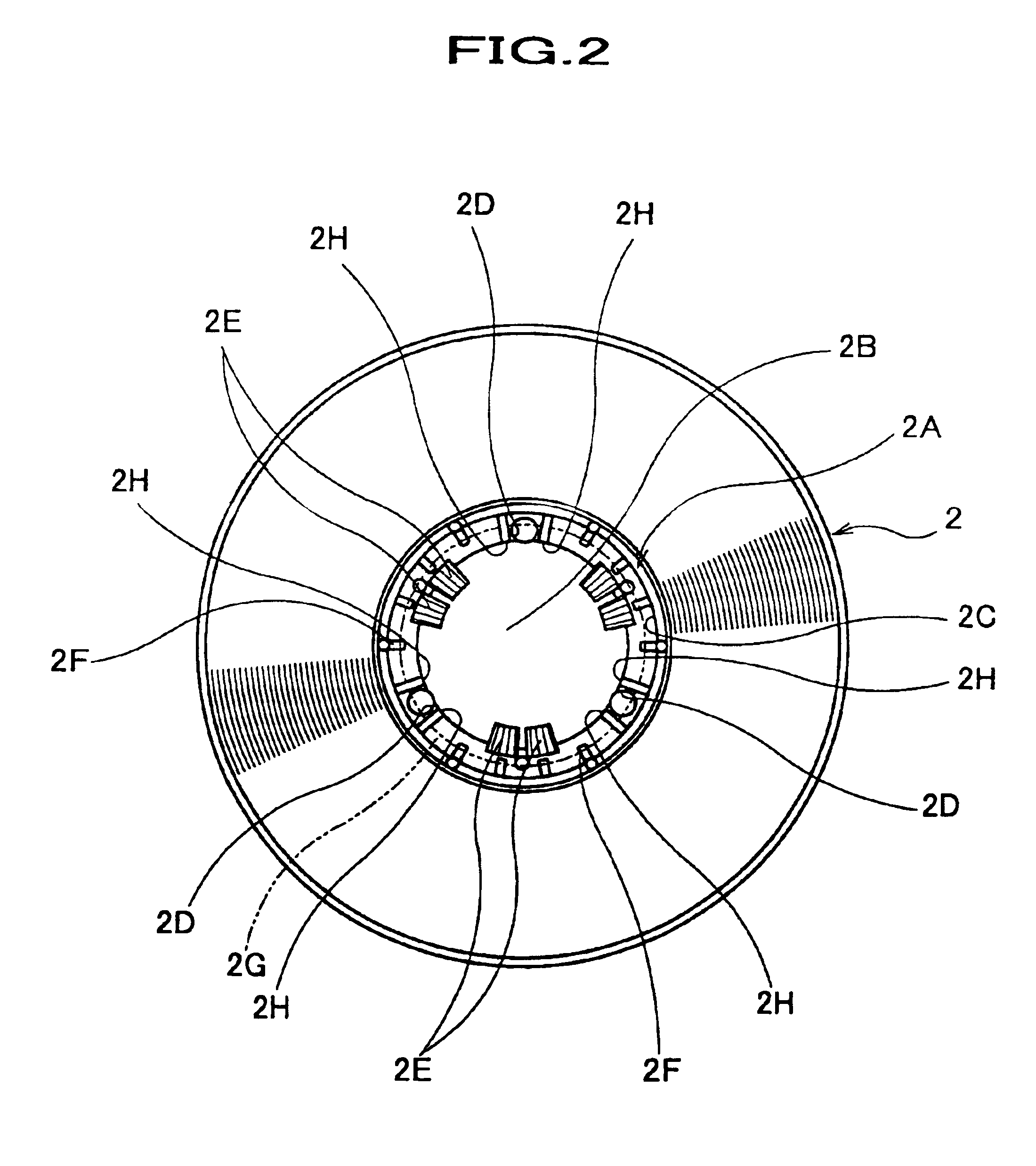

Magnetic tape cartridge

InactiveUS6954335B2Precise positioningDecrease the inclinationPicture changing apparatusRecord information storageMagnetic tapeEngineering

A magnetic tape cartridge comprises: a reel 2 around which a magnetic tape MT is wound; a cartridge case 1 for accommodating the reel 2 in a locked state; and a release pad 5 inserted into a cup-shaped hub 2A of the reel 2 in a locked state of the reel 2. The release pad 5 includes a pad body 5A having a plurality of corners to be faced proximately to the inner peripheral surface 2C of the cup-shaped hub 2A, and a plurality of lock releasing pins 5B projecting downwardly from a bottom surface of the pad body 5A at the respective corners and inserted through a bottom surface of the cup-shaped hub 2A. The release pad 5 is provided with a flank 5E extending from each corner downwardly through the respective lock release pin 5B so that an assembling clearance is formed with respect to an inner periphery of a flange 2G position in an open side of the cup-shaped hub 2A.

Owner:FUJIFILM CORP +1

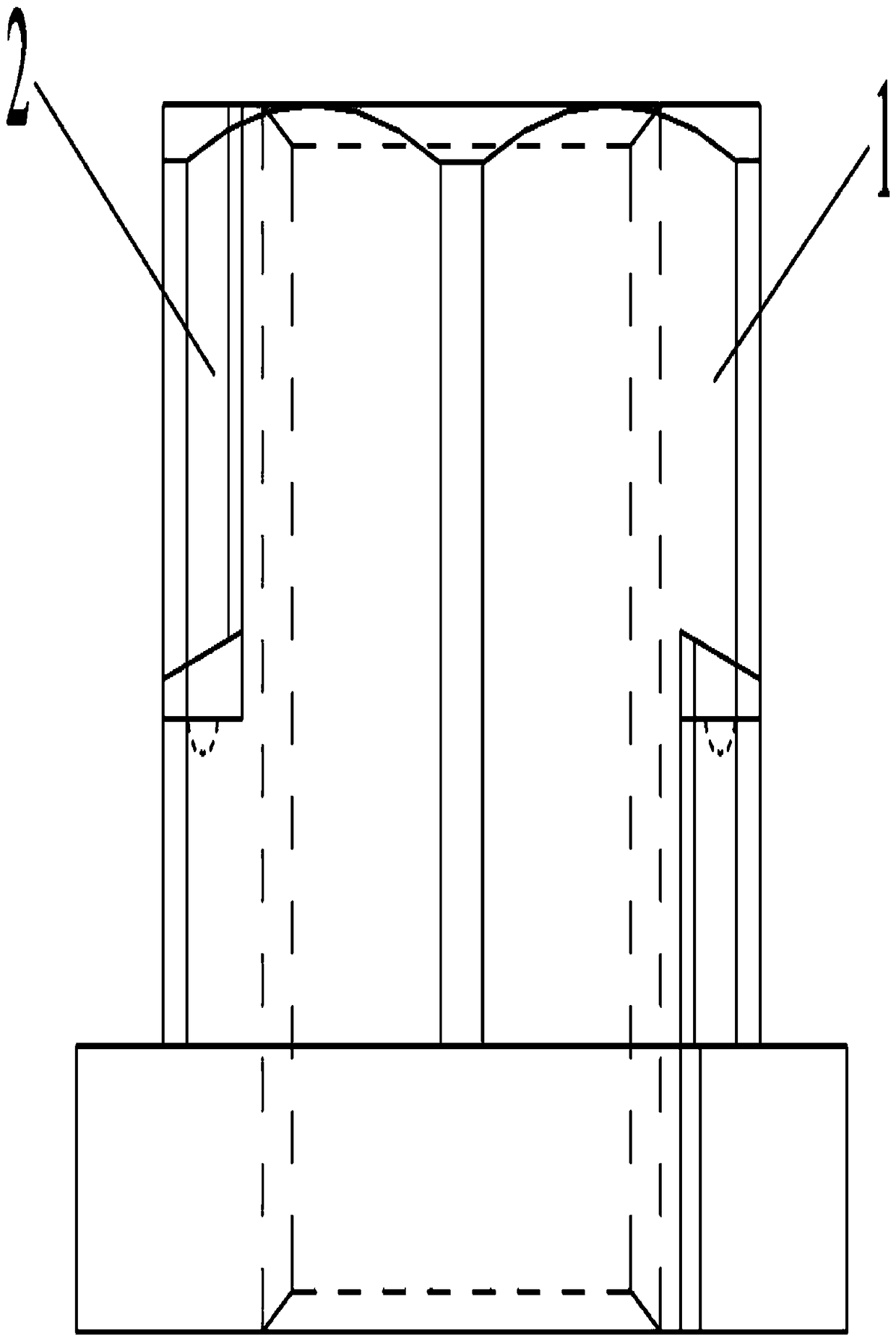

U-shaped combined type concrete prefabricated box culvert

PendingCN106869174AEasy to transportEasy loading and unloadingArtificial islandsProtective foundationArchitectural engineeringCulvert

The invention discloses a U-shaped combined type concrete prefabricated box culvert and belongs to the technical field of box culvert engineering. The U-shaped combined type concrete prefabricated box culvert aims at solving the problems that during box culvert field pouring, construction is complex, the construction period is long, an overall prefabricated box culvert is difficult to transport, and lifting is difficult. An upper box culvert and a lower box culvert are U-shaped concrete prefabricated box culverts. The height of the U-shaped side wall of the upper box culvert is smaller than that of the U-shaped side wall of the lower box culvert. Transverse installation grooves are formed in the top face of the upper box culvert and the bottom face of the lower box culvert. Multiple longitudinal installation grooves are formed in the top face of the upper box culvert and the bottom face of the lower box culvert, and the longitudinal installation groove in the upper box culvert are in one-to-one correspondence with the longitudinal installation grooves in the lower box culvert. A through hole is formed between every two corresponding longitudinal installation grooves. The through holes are located in the side walls of the upper box culvert and the lower box culvert. Longitudinal PC steel bars are arranged in the through holes. The upper box culvert and the lower box culvert are connected through the longitudinal PC steel bars. The U-shaped combined type concrete prefabricated box culvert can be prefabricated and assembled, transportation is convenient, damage brought by soil sedimentation can be resisted, and the sealing performance is high.

Owner:HEILONGJIANG ZHONGXIN ROAD & BRIDGE MATERIAL CO LTD

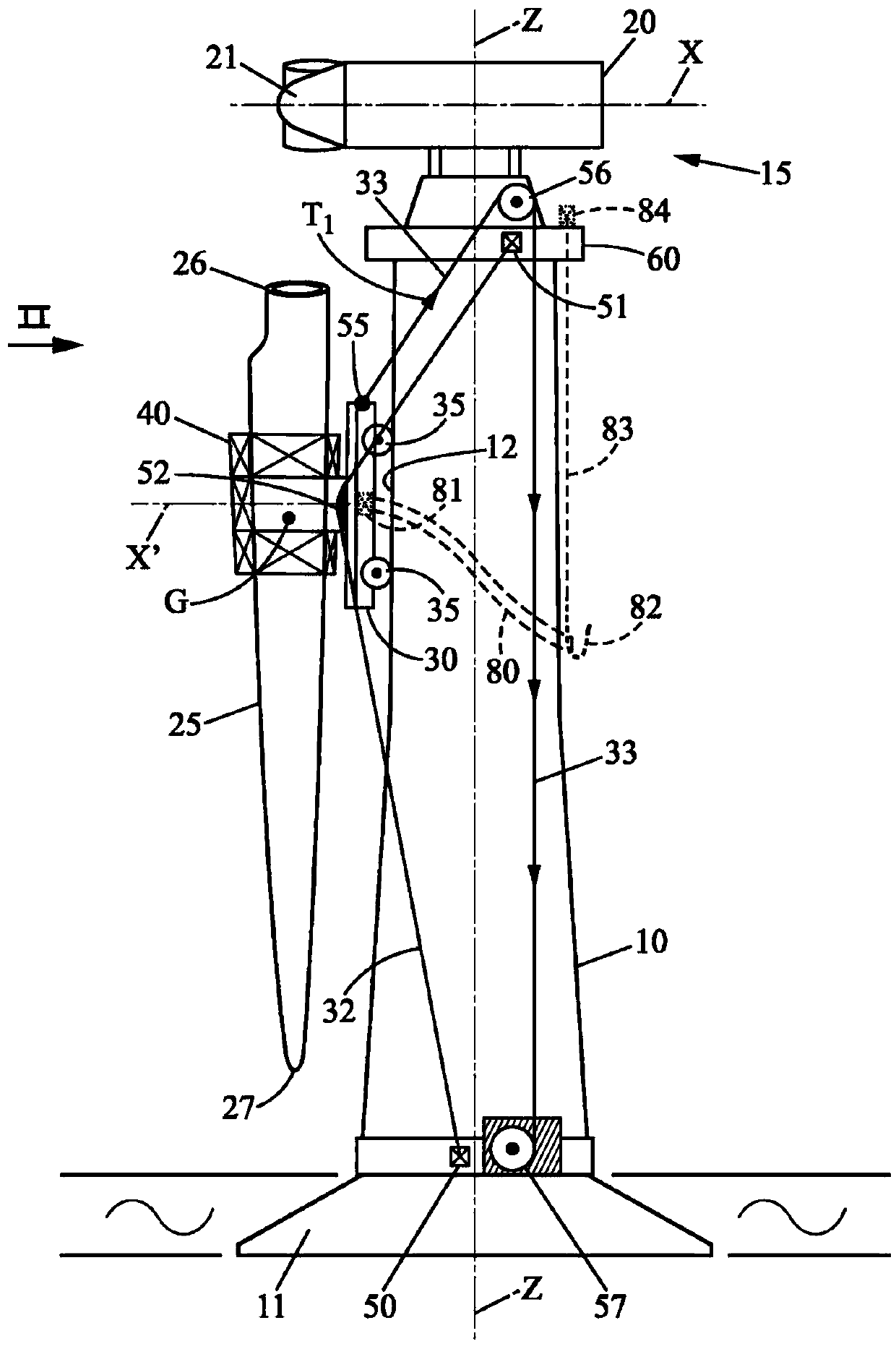

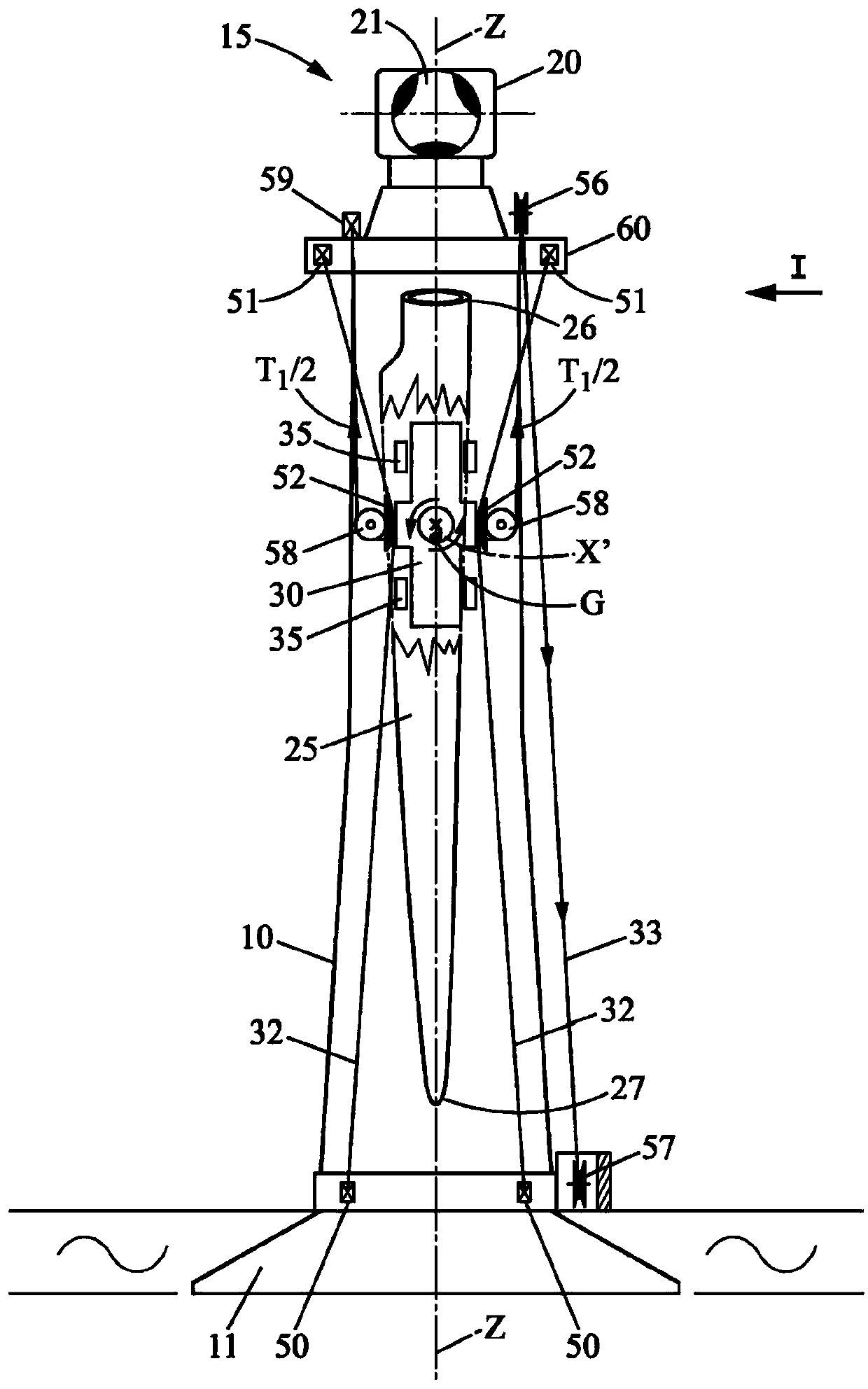

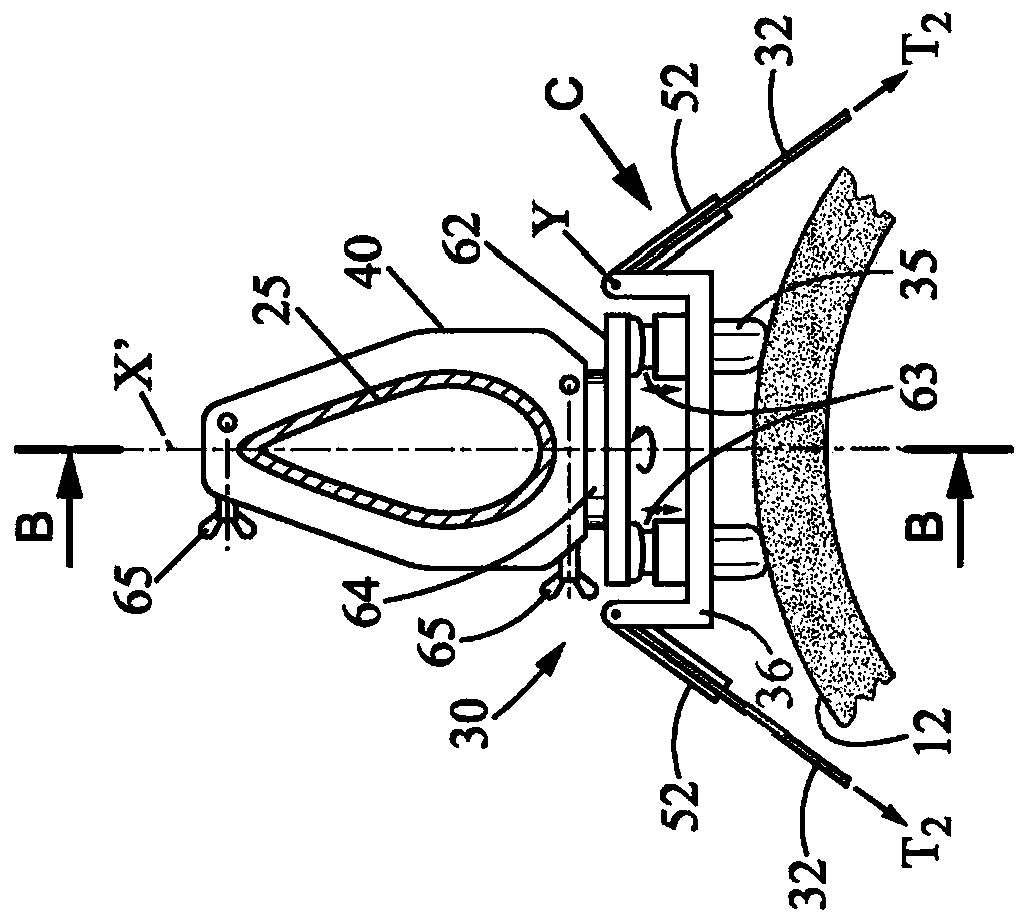

Method for handling a wind turbine blade

InactiveCN109642547AGuaranteed bearerRestraining forceEngine manufactureFinal product manufactureNacelleTurbine blade

In order to handle a wind turbine blade between the ground and a rotor of an electric generator mounted on a nacelle (15) at the top of a tower (10), the blade (25) is retained in a support (40) thatis mounted on a trolley (30) arranged against the tower. The trolley is moved and guided along the tower using at least one cable (32, 33) which is angled in such a way as to apply a force having a horizontal component in the direction of the tower to the trolley.

Owner:SOLETANCHE FREYSSINET SAS

Control panel

ActiveCN111336582AEnsure assemblyLighting and heating apparatusSpace heating and ventilation detailsEngineeringPhysics

Owner:PROTHERM PRODN SRO +1

Fastening element, arrangement comprising a fastening element, and method for installing a fastening element

ActiveUS20180172057A1Ensure assemblyBetter pressure distributionNutsBoltsMechanical engineeringEngineering

Owner:NEWFREY

Electric shaver with waterproof structure

InactiveCN1403246AEfficient assemblyEnsure assemblyMetal working apparatusReciprocating motionEngineering

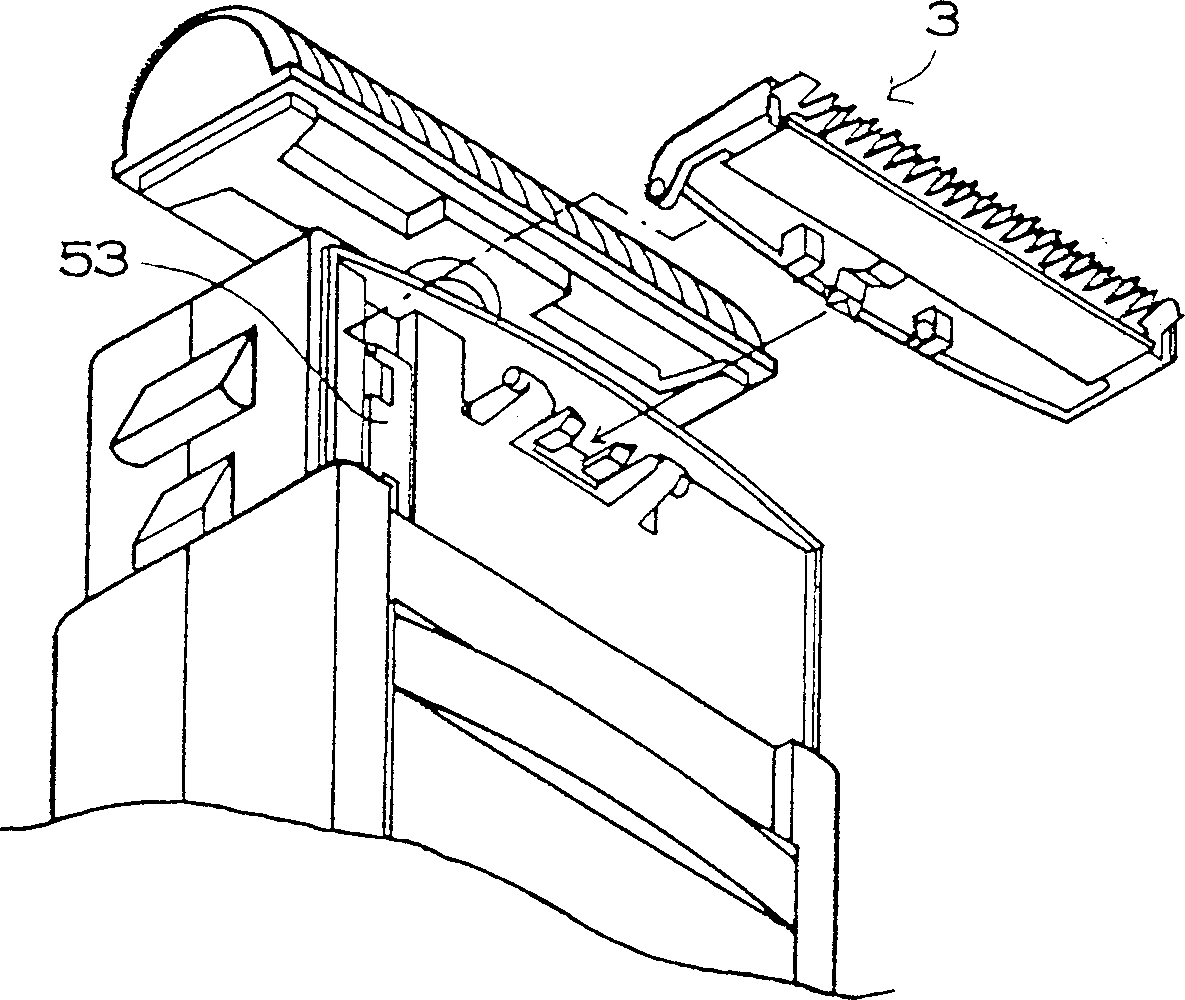

To provide a trimmer on a compact waterproof main body by simplifying the waterproof structure, and simply, easily and efficiently assemble the trimmer. This electric razor having the waterproof structure is equipped with water proof body 1, the trimmer 3, and a trimmer-driving mechanism 4. In this case, the waterproof body 1 of the waterproof structure internally contains a driving mechanism for an internal blade 8. The trimmer is provided in a manner to be movable between a housing location and a protruding location in the waterproof body 1. The trimmer-driving mechanism 4 makes the trimmer 3 move between the housing location and the protruding location. A switch cover body 5 which has a non-waterproof structure is connected with the surface of the waterproof body 1. The trimmer-driving mechanism 4 is arranged between the switch cover body 5 and the waterproof body 1. The switch cover body 5 is provided in such a manner that a knob 6 being connected with the trimmer- driving mechanism 4 can be reciprocated. The electric razor moves the trimmer 3 between the housing position and the protruding position by the trimmer- driving mechanism 4 by reciprocating the knob 6.

Owner:SANYO ELECTRIC CO LTD

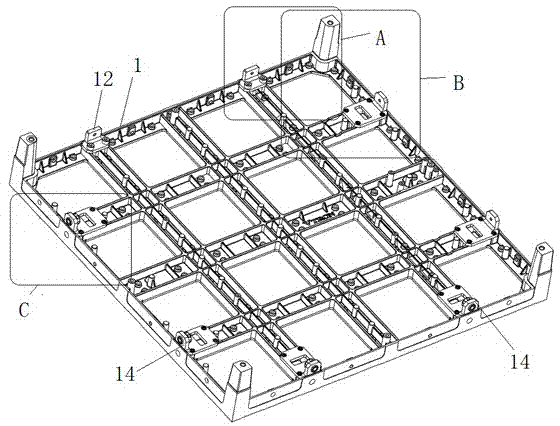

LED (Light-Emitting Diode) display screen box

InactiveCN104505001ARealize Regulatory ControlMeet specificationsIdentification meansLED displayEngineering

The invention relates to an LED (Light-Emitting Diode) display screen box which comprises a plurality of unit box bodies spliced with one another and rear covers arranged at the back surfaces of the unit box bodies, wherein four sides of each rear cover are provided with avoiding positions; four sides of the back surface of each unit box body are sequentially provided with a first locking plate, a second locking plate and two third locking plates corresponding to the avoiding positions, the first locking plate and the second locking plate are provided with a first threaded through hole and the third locking plates are provided with second threaded through holes larger than the first threaded through holes; the second threaded through holes are provided with regulating pieces; the regulating pieces are provided with three threaded through holes which have the same size with the first threaded through holes; after the third locking plates of each unit box body are aligned with the first locking plates or second locking plates of the adjacent unit box bodies, abutted seams among the box bodies are regulated by virtue of the regulating pieces; the locking pieces penetrate through the third threaded through holes of the regulating piece and the first threaded through holes of the first locking plates or the second locking plates, so that locking is realized. According to the LED display screen box, the abutted seams among the box bodies can be regulated and controlled under the condition that the rear covers are not opened.

Owner:GUANGDONG VTRON TECH CO LTD

Double-wall cofferdam structure for water conservancy and hydropower engineering

InactiveCN112323831AImprove stress resistanceImprove stabilityFoundation engineeringHydraulic cylinderCofferdam

The invention relates to the technical field of water conservancy and hydropower engineering, and discloses a double-wall cofferdam structure for water conservancy and hydropower engineering. The double-wall cofferdam structure comprises four wall bodies, a square cofferdam is formed by enclosing the four wall bodies, a main connecting block is mounted on one end surface of each wall body, and a main connecting groove is formed in the other end surface of each wall body. Outer clamping grooves are formed in the sides, close to the main connecting grooves and the main connecting blocks, of theouter side faces of the two ends of the wall bodies, and a plurality of inner supporting clamping seats are distributed on the sides, close to the main connecting grooves and the main connecting blocks, of the inner side faces of the two ends of the wall bodies from top to bottom at equal intervals. A plurality of cross-shaped inner supporting columns are distributed on the inner sides of the wallbodies from bottom to top, and two groups of hydraulic cylinders are arranged in parallel, located on the outer side surface of a steel casing, at the upper ends and the lower ends of the inner corners of the wall bodies. The multiple wall bodies are spliced in an assembled mode, transportation, mounting and splicing are easy and convenient, the safety coefficient is high, the sealing performanceand firmness of a square cofferdam are ensured, the wall body mounting accuracy is further improved, and the cofferdam deviation adjusting difficulty is reduced.

Owner:毛小广

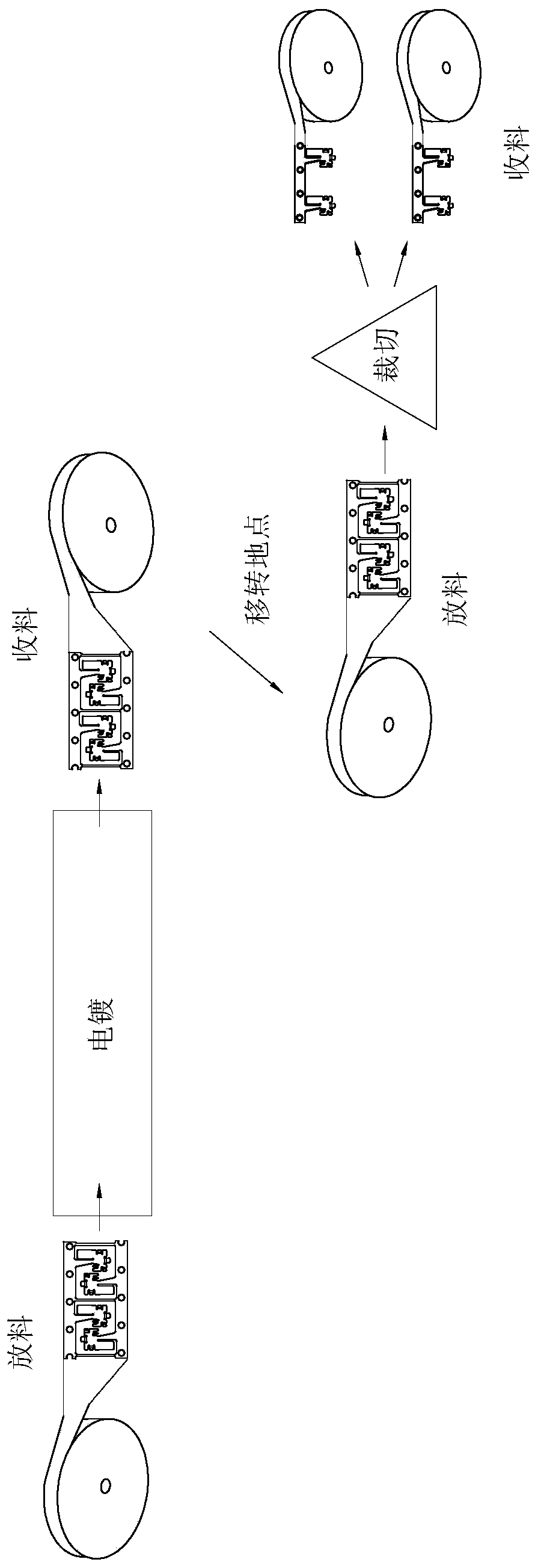

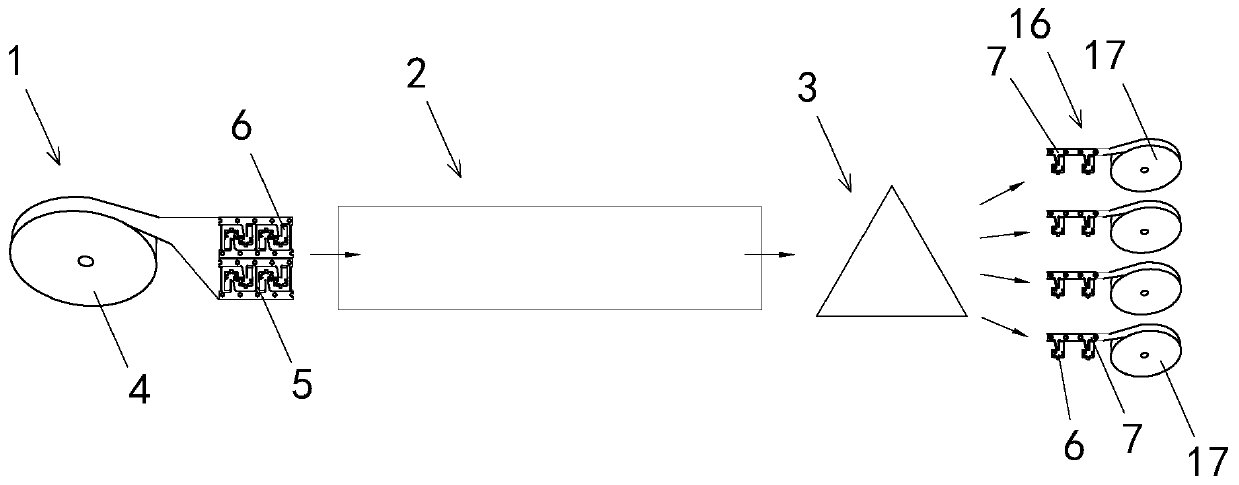

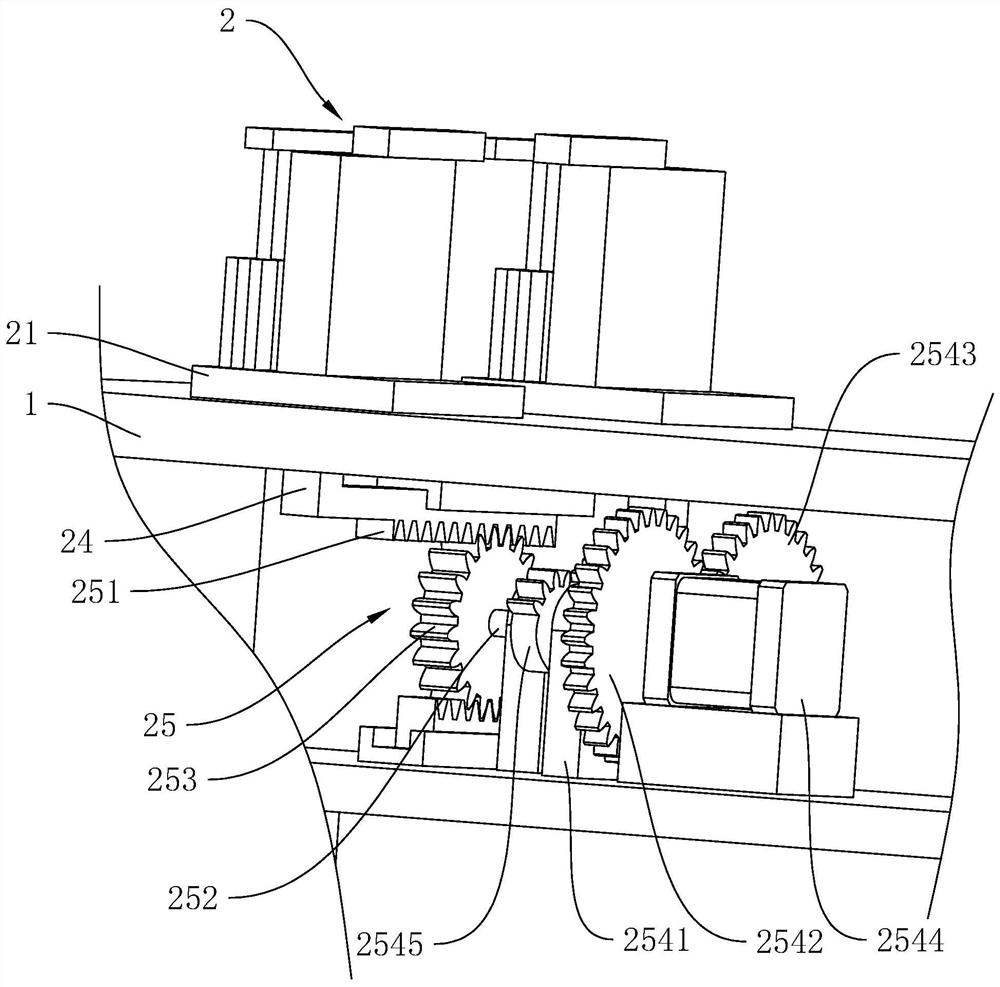

Continuous material belt type metal part efficient electroplating and cutting integrated flow line

PendingCN109968036AShorten the timeImprove processing efficiencyOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses a continuous material belt type metal part efficient electroplating and cutting integrated flow line. The continuous material belt type metal part efficient electroplating andcutting integrated flow line comprises a discharging unit, an electroplating unit and a cutting unit. The discharging unit comprises a first material roll which performs horizontal discharging in a material belt mode through rotation, and a material belt enters the electroplating unit for electroplating; the electroplating unit delivers the material belt into the cutting unit for cutting after finishing electroplating of the material belt, and thus electroplated metal parts are cut out from the material belt, or the electroplated material belt is divided into at least two branch material belts; the flow line further comprises a material belt conveying control unit which corresponds to the electroplating unit and the cutting unit; and the control unit comprises at least one pulling mechanism, and the material belt is driven by the pulling mechanisms to perform displacement from the electroplating unit into the cutting unit. The electroplating unit is connected with the cutting unit in series through the material belt conveying control unit, the conveying speed of the portions, in the electroplating unit and the cutting unit, of the material belt is balanced, and thus stable and reliable production of the flow line can be guaranteed after integration.

Owner:LEOCO SUZHOU PRECISE IND

Method for synthesizing gene with complex sequence

ActiveCN107974448AEfficient synthesisAvoid mismatchMicrobiological testing/measurementDNA preparationDouble strandedSingle stranded oligonucleotides

The invention discloses a method for synthesizing a gene with a complex sequence. The method comprises: 1) designing a series of 30-150 bp single-stranded oligonucleotide sequences containing the positive strand sequence and the negative strand sequence of a gene by using a gene segmentation and single-stranded oligonucleotide design rule; 2) selecting the single-stranded oligonucleotide fragmentsobtained in the step 1), and separately annealing each pair of the positive single-stranded oligonucleotide fragment and the negative single-stranded oligonucleotide fragment by using the annealing procedure designed by the present invention according to the complementary pairing principle of the positive strand and the negative strand to form double-stranded oligonucleotide fragments, loading onto a target vector, sequencing, and verifying; and 3) based on the double-stranded oligonucleotide fragments obtained in the step 2), by using endonuclease capable of externally digesting a recognition sequence, carrying out 1-3 cycles of in vitro linking assemblies, cloning, and verifying so as to complete the synthesis assembly of the 100bp-20kb gene with the complex sequence. With the method ofthe present invention, the complex sequence gene incapable of being synthesized or being difficultly synthesize by the traditional method can be effectively synthesized.

Owner:GENSCRIPT NANJING

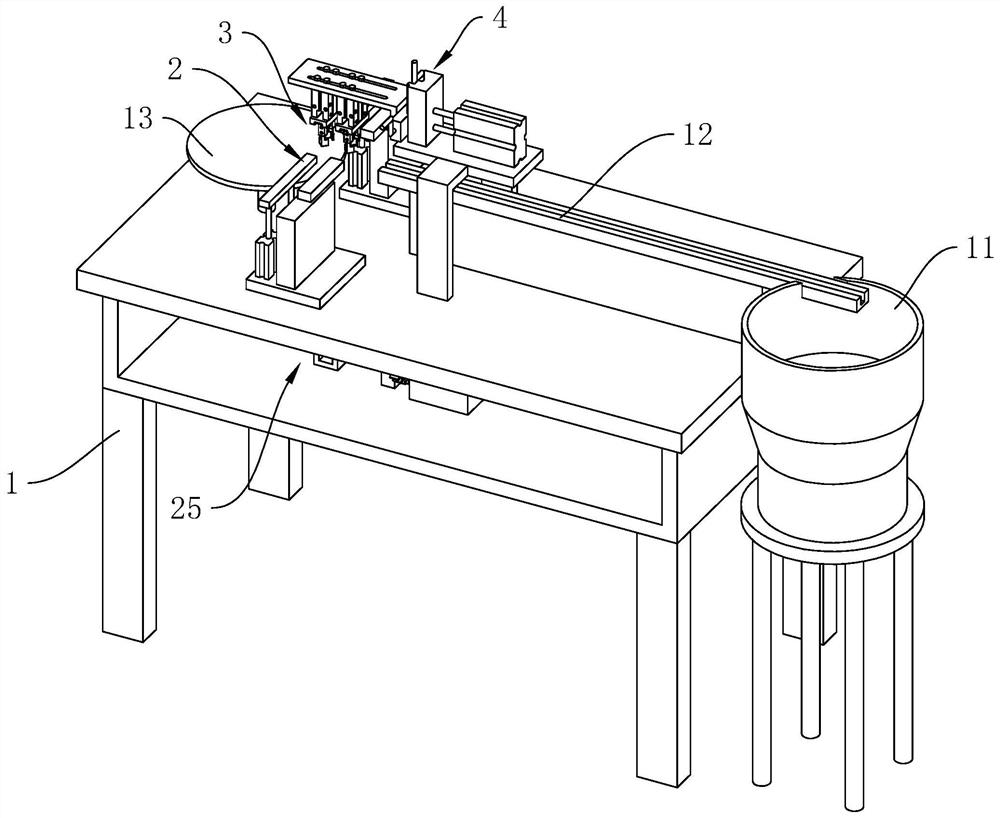

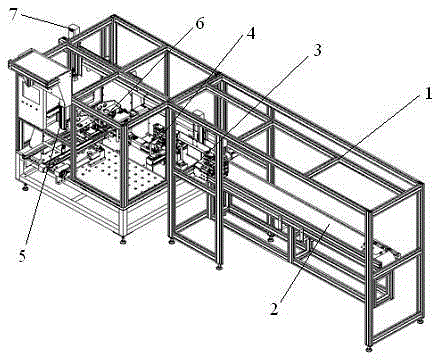

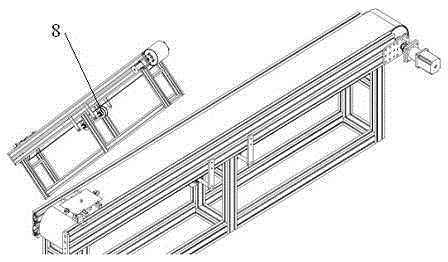

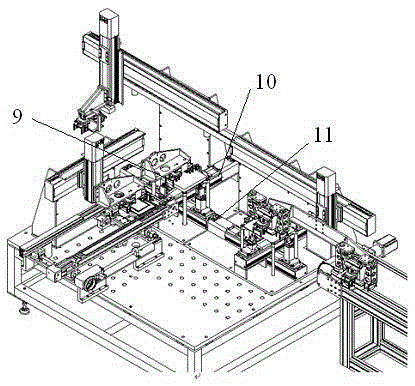

Automatic capacitor assembling device

ActiveCN112927933AImprove accuracyImprove stabilityElectrolytic capacitorsTerminal applying apparatusPhysicsEngineering

The invention relates to an automatic capacitor assembling device, which comprises a machine frame, an element vibration disc, an element conveying track and a station disc are arranged on the machine frame, the discharging end of the element conveying track faces the station disc, and the automatic capacitor assembling device is characterized in that: a clamping device is arranged at the position, between the element conveying track and the station disc, of the machine frame; the clamping device comprises two sliding plates, an element positioning clamping jaw, an element clamping assembly and a sliding plate driving assembly, the two sliding plates are slidably connected with the top face of the machine frame, the element positioning clamping jaw is fixed to the side, away from the machine frame, of each sliding plate, and the element clamping assembly is arranged on the sliding plates and located at the discharging end of the element positioning clamping jaw, the sliding plate driving assembly is arranged in the machine frame, and the machine frame is provided with a batch feeding device above the element conveying track. According to the invention, the assembly accuracy of the element and the colloidal particles can be effectively improved, the subsequent assembly of the element is further ensured, the assembly stability of the capacitor is improved, and rapid production and manufacturing of the capacitor are realized.

Owner:深圳奥凯普电容器有限公司

Support Frame for elevating a bed covering

A plurality of hollow tubular frame members interconnected by a single internal elastic retaining member that ensures each frame member aligns relative to each remaining frame member in a manner that only one arrangement of frame members is possible when assembled. To assemble, the frame members interconnect forming a three-dimensional frame suitable for supporting a bed cover. The frame members are held in tension by the internal retaining member. The frame members interlock via an insert device between adjacent frame members. The entire assembly interlocks and selectively decouples for disassembly. When disassembled, the entire assembly lies relatively flat, which enables a compact design suitable for packaging, transport or storage.

Owner:TIPPERREITER MARK R

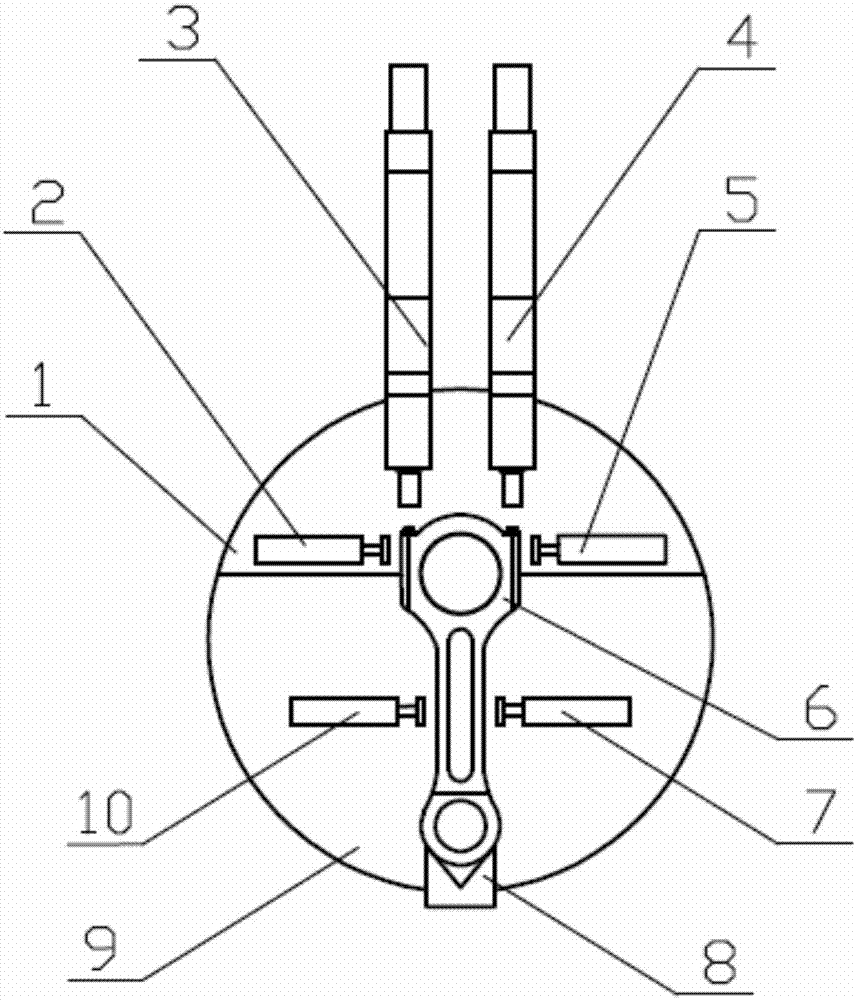

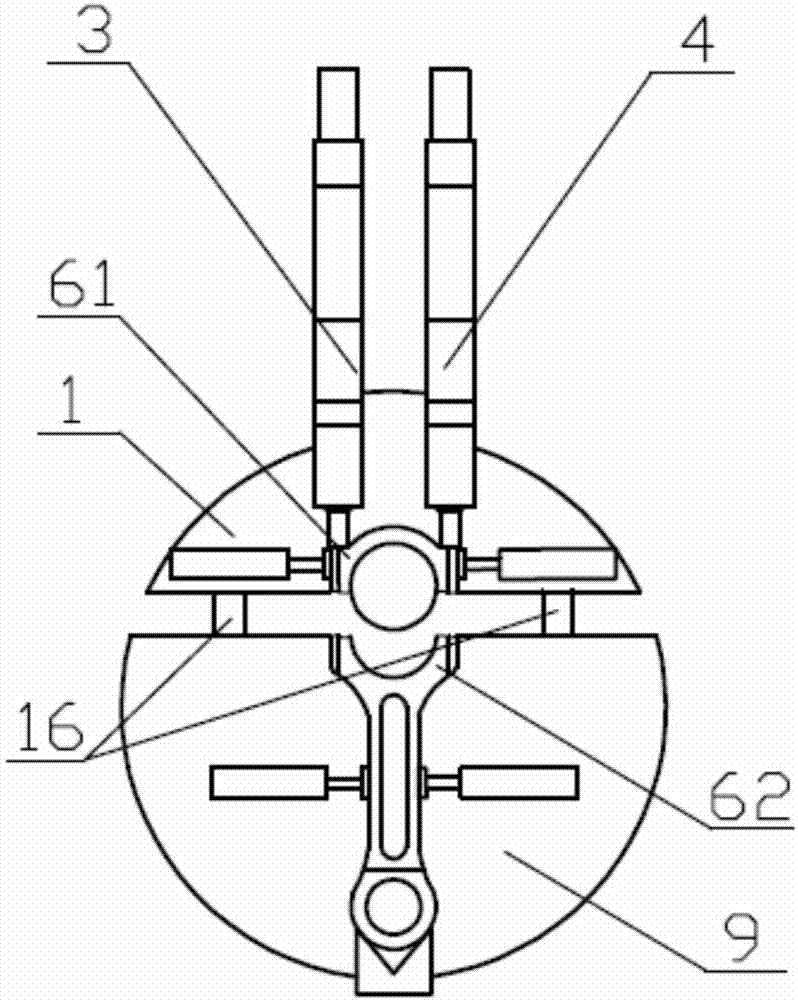

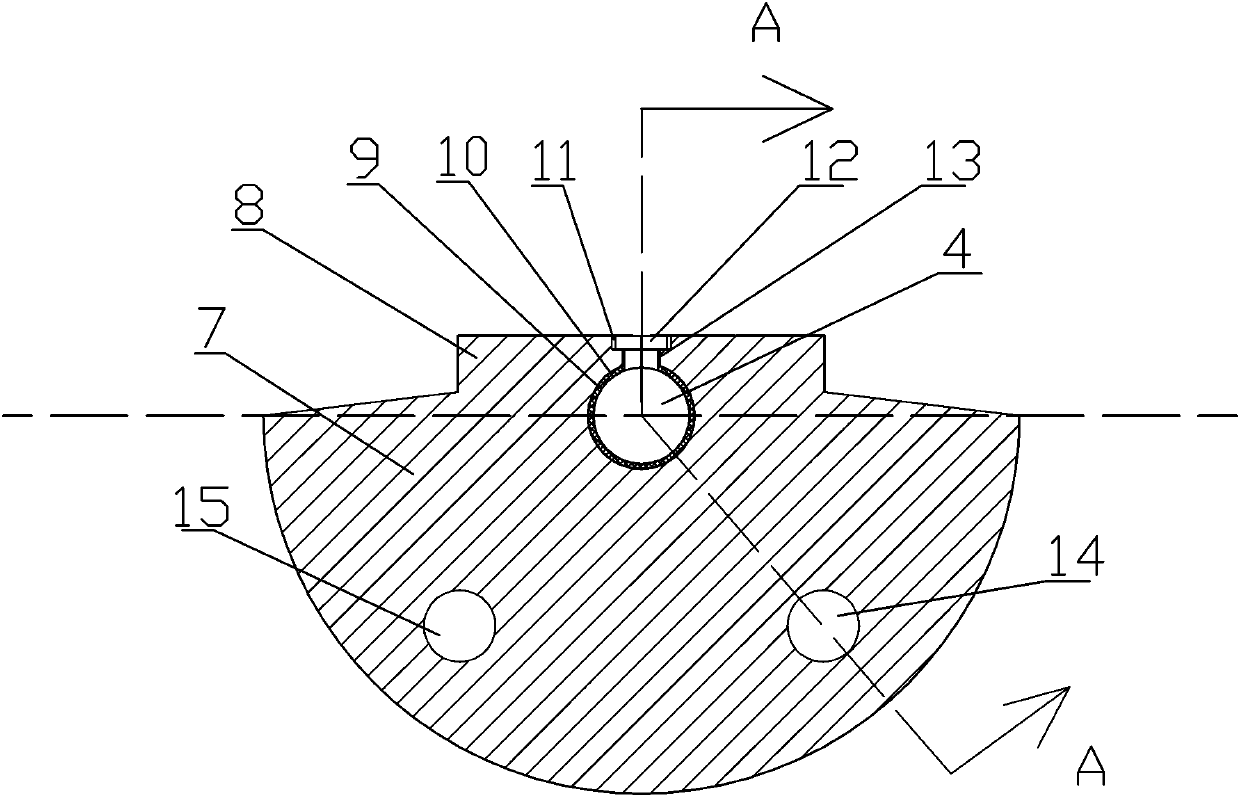

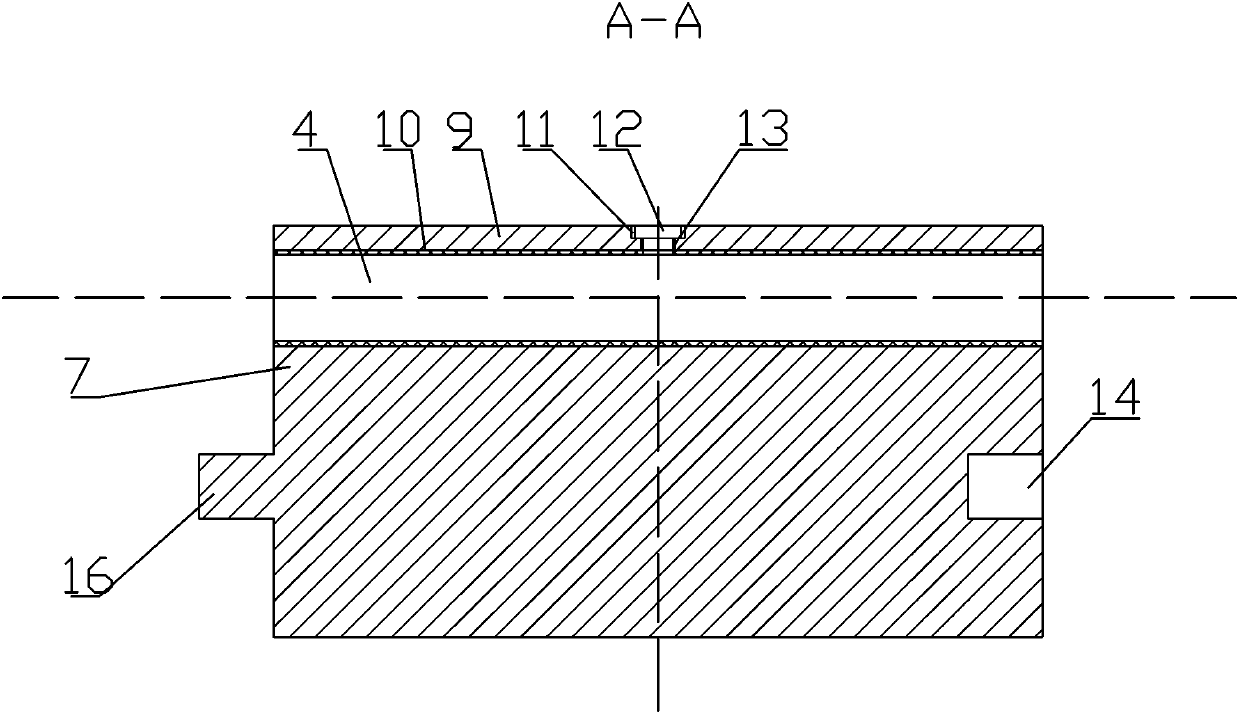

Engine connecting rod vibration deslagging device

PendingCN107243488AEnsure assemblyGuarantee the effect of implementationDirt cleaningCleaning using gasesEngineeringHigh frequency vibration

The invention discloses an engine connecting rod vibration deslagging device. An upper vibration chassis and a lower vibration chassis are connected through positioning guide rails, and a positioning spindle is arranged between the upper vibration chassis and the lower vibration chassis; the right side of the upper vibration chassis is provided with a first torque gun, a second torque gun, a first clamping cylinder of a connecting rod cap, and a second clamping cylinder of the connecting rod cap, and the back side of the upper vibration chassis is provided with a second high-frequency vibration pump; and the right side of the lower vibration chassis is provided with a first clamping cylinder of a connecting rod body, a second first clamping cylinder of the connecting rod body, and a V-shaped positioning block, and the back side of the lower vibration chassis is provided with a positioning spindle cylinder and a first high-frequency vibration pump. According to the engine connecting rod vibration deslagging device, residual particles on the cross section of a connecting rod and particles adhering to the surface of the connecting rod are removed thoroughly, and the assembly of a subsequent crankshaft connecting rod is ensured; the fault probability of an engine due to the connecting rod is reduced, and at the same time the working efficiency is improved; and the labor intensity of a working site is reduced, and the implementation effect of the connecting rod deslagging operation is ensured.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

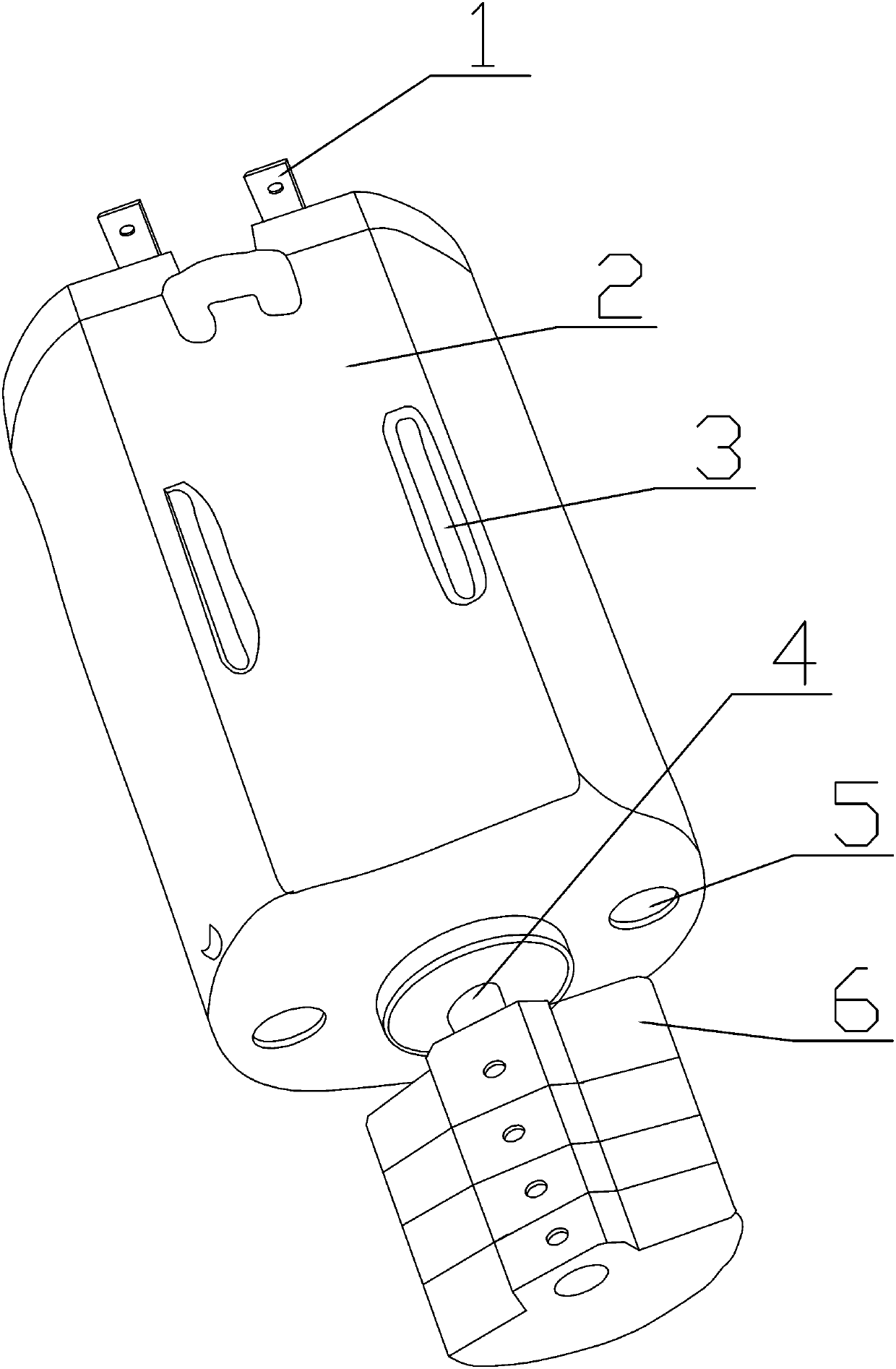

Micro motor capable of conveniently adjusting vibration intensity

InactiveCN109756064AEasy to assembleMeet different usage needsMechanical energy handlingVibration amplitudeMicro motor

The invention provides a micro motor capable of conveniently adjusting the vibration intensity. The micro motor comprises a motor body, a rear cover is installed on the tail part of the motor body, and a power plug is installed on the rear cover; a heat dissipation hole is formed in the front end of a shell of the motor body in a machined mode; a combined balance weight block is mounted on a mainshaft of the motor body; and a mounting groove is formed in the motor body in a machined mode. The combined balance weight block is formed by jointly assembling a plurality of split balance weight blocks capable of being assembled on the main shaft. The micro vibration motor uses eccentric balance weight blocks which can be assembled to finally achieve the purpose of adjusting the vibration amplitude of the micro motor, the adjustment process is simplified, and efficiency is improved.

Owner:宜昌博远电子有限公司

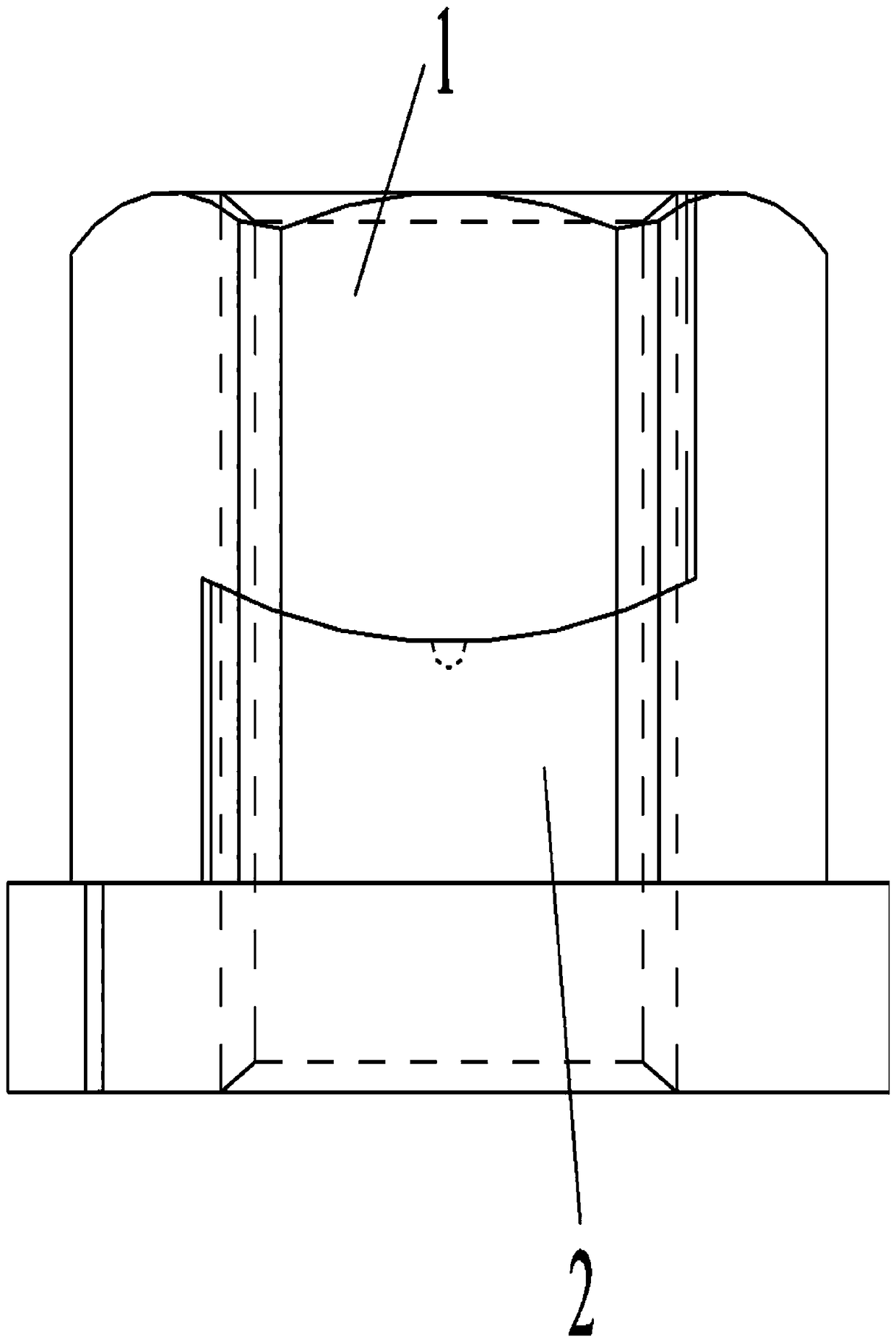

BL diaphragm assembling equipment

The invention provides BL diaphragm assembling equipment. The BL diaphragm assembling equipment comprises an equipment shell, a diaphragm conveying line, a diaphragm primary positioning and transplanting mechanism, a diaphragm secondary high-precision positioning mechanism, an OPEN BL anti-static conveying mechanism, a diaphragm and OPEN BL heart assembling mechanism and a finished product carrying-out mechanism, wherein a set of compression towing wheels are arranged in the middle part of the diaphragm conveying line, are distributed symmetrically with respect to the middle position of a conveying belt and can eliminate inertia force generated when drive of the belt conveying line stops; a positioning and centering mechanism in the diaphragm and OPEN BL heart assembling mechanism centers and positions a diaphragm, so that labor and equipment cost are reduced, and the diaphragm positioning precision is improved.

Owner:FUJIAN CHENGZHE AUTOMATION TECH

Split nut

The invention belongs to the technical field of nuts, and particularly discloses a split nut. The split nut comprises a left half nut and a right half nut. The half screw pitch difference exists between the starting positions of threads of the inner walls of the left half nut and the right half nut. The two corresponding ends of the left half nut and the right half nut are provided with bosses andnotches, wherein the bosses and the notches are matched, namely, one end of the left half nut is provided with the upper boss and the lower notch, the end, corresponding to the end of the left half nut, of the right half nut is provided with the upper notch and the lower boss, the other end of the left half nut is provided with the upper notch and the lower boss, the end, corresponding to the endof the left half nut, of the right half nut is provided with the upper boss and the lower notch, and the bottom surface of the upper boss and the top surface of the lower boss of the two corresponding ends of the left half nut and the right half nut are matched arc-shaped curved surfaces. According to the split nut, due to design of the arc-shaped curved surfaces, the left half nut and the righthalf nut can conduct one-way moving combination along the arc-shaped curved surfaces, after the left half nut and the right half nut are fastened tightly, the two half nuts are blocked in two ways andtightly clamped together, and the fastening function is quickly implemented.

Owner:龚琼

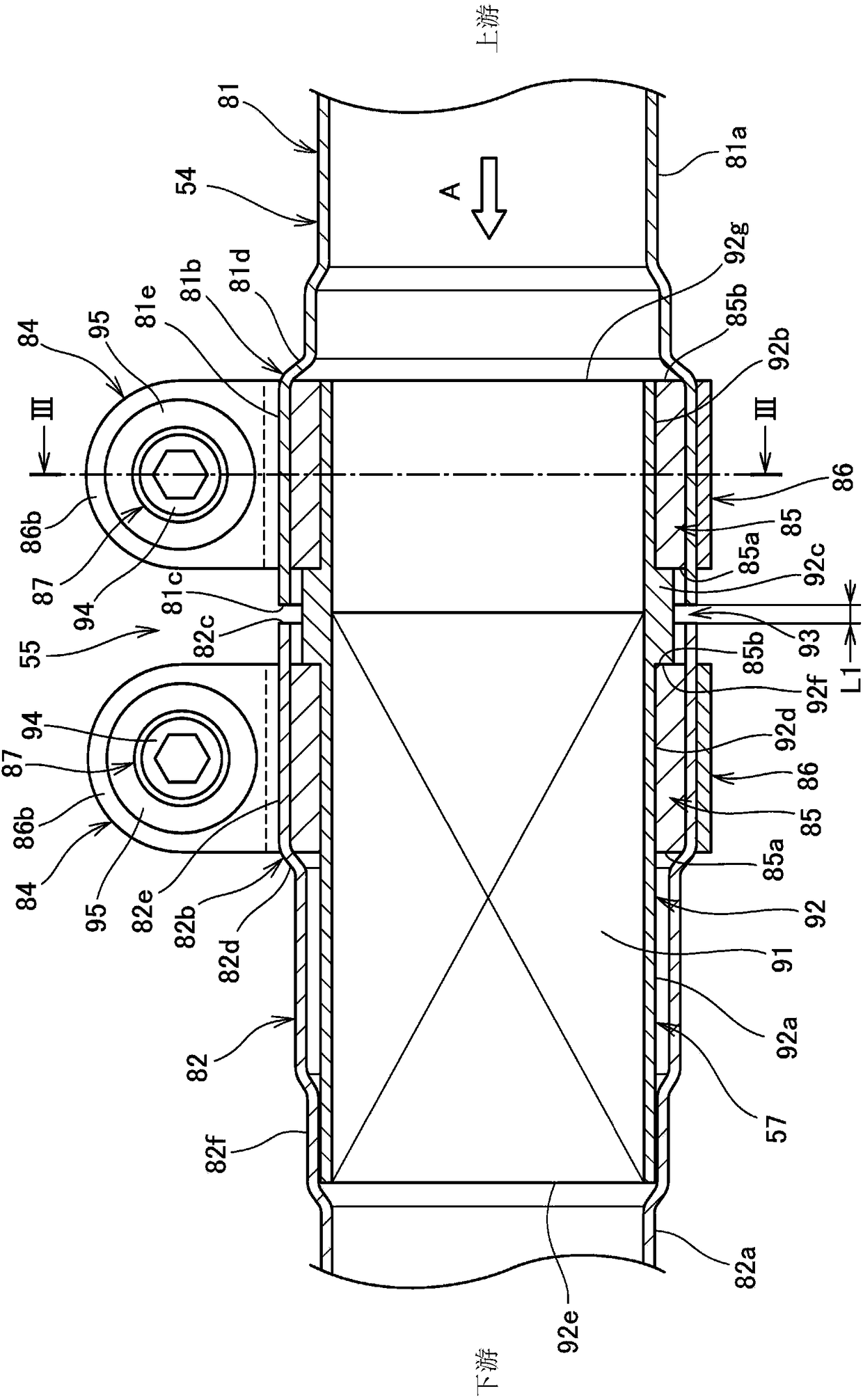

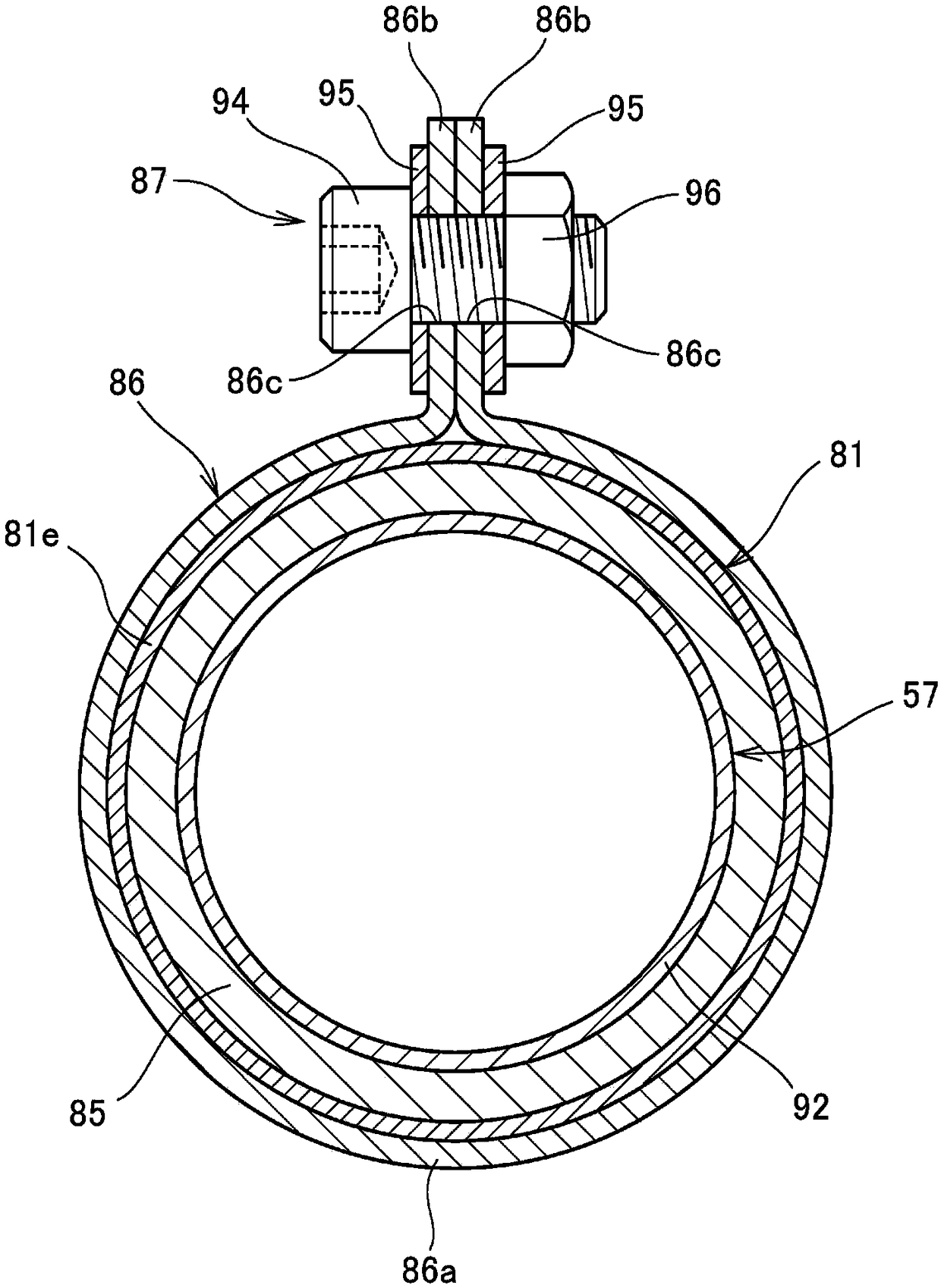

A catalytic converter support structure for an exhaust pipe

ActiveCN108661761AEnsure assemblyEffective supportExhaust apparatusSilencing apparatusCylinder headExhaust fumes

The present invention provides a catalytic converter support structure for an exhaust pipe, which is a support structure effective for vibration of a vehicle body while ensuring ease of assembly and disassembly of the catalytic converter, and is also simple in structure and miniaturized. The intermediate portion of the exhaust pipe (54) that connects a cylinder head and a muffler is divided, and an outer cylinder (92) of a catalytic converter (57) using a catalyst to purify the exhaust gas is disposed across the end faces (81c, 82c) of the exhaust pipe (54). Further, one of the front exhaust pipe (81) and the rear exhaust pipe (82) (the front exhaust pipe (81)) before and after the end faces (81c, 82c) is provided with a front enlarged diameter portion (81b) that fixes one end of the outercylinder (92). Further, the other of the front exhaust pipe (81) and the rear exhaust pipe (82) (the rear exhaust pipe 82) is held at the other end of the outer cylinder (92). The outer cylinder (92)is detachably attached to cross the exhaust pipe (54), i.e., the front exhaust pipe (81) and the other rear exhaust pipe (82).

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com