A catalytic converter support structure for an exhaust pipe

A catalytic converter and support structure technology, applied in the field of catalytic converter support structure, can solve problems such as expansion of configuration space, existing problems, complex structure, etc., to ensure the ease of assembly and disassembly, ensure the ease of assembly, and realize the support structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

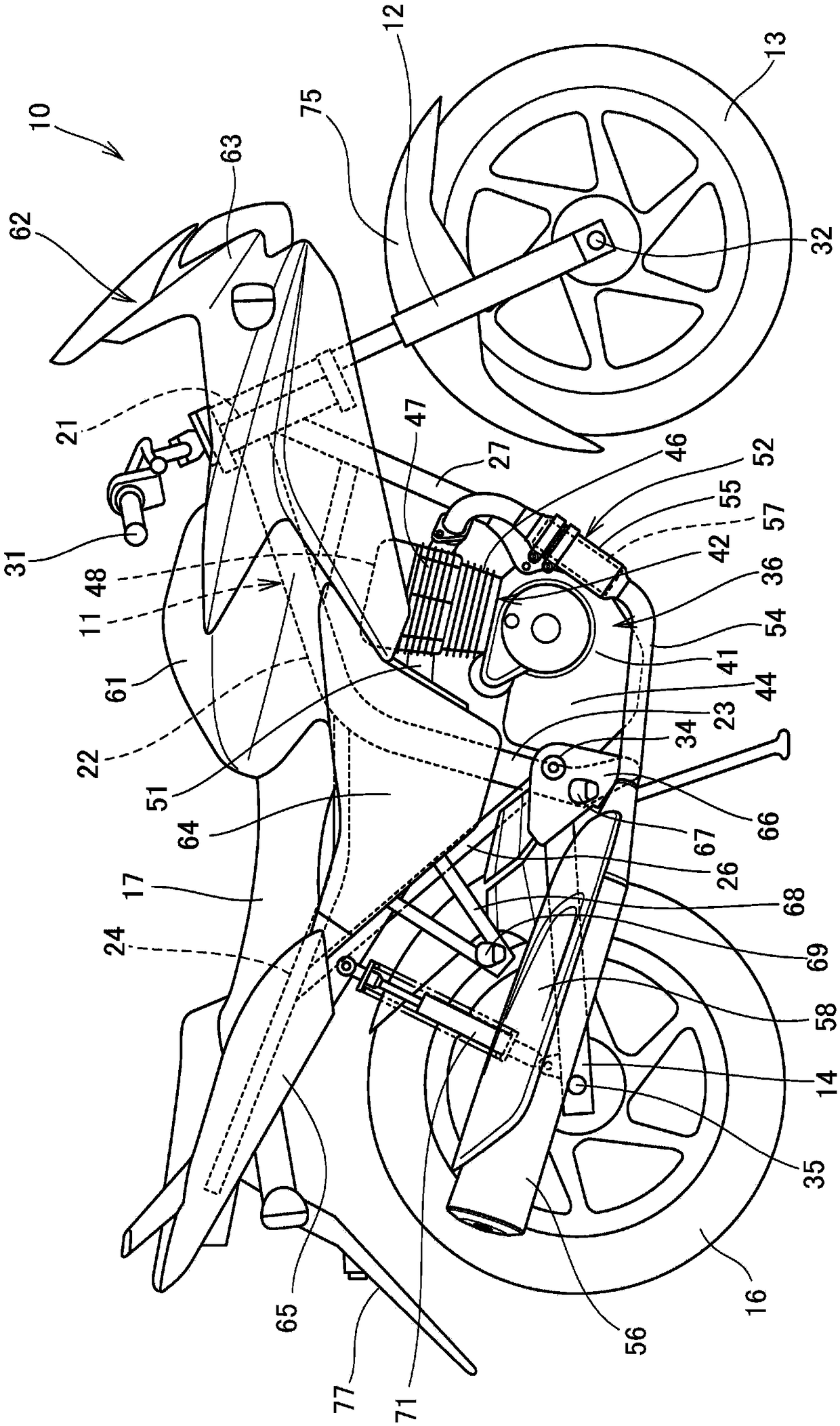

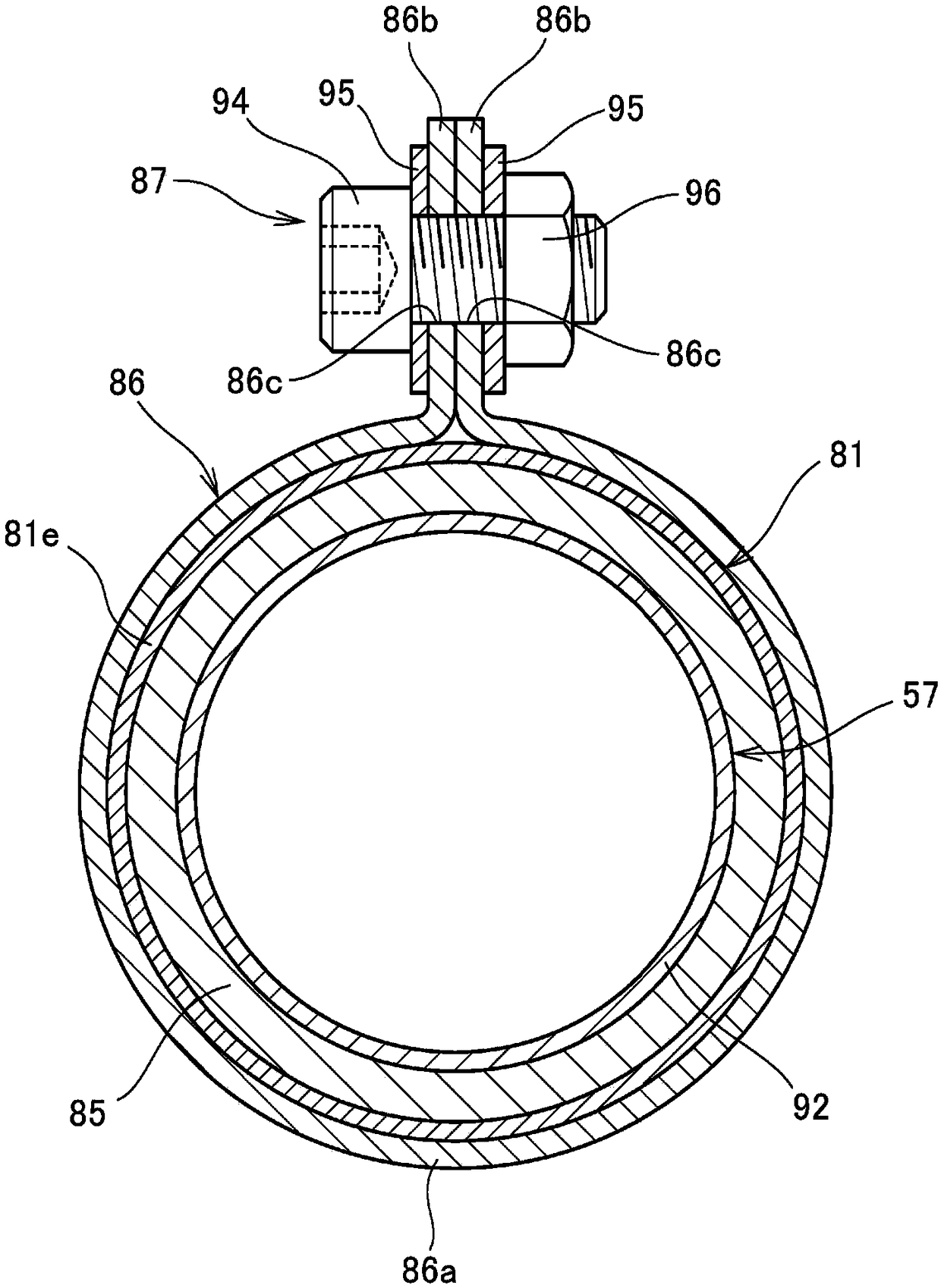

[0057] figure 1 It is a right side view of the motorcycle 10 provided with the catalytic converter supporting structure for the exhaust pipe of the first embodiment according to the present invention.

[0058] The motorcycle 10 has: a front wheel 13 supported on the front end of the vehicle body frame 11 via a front fork 12; a rear wheel 16 supported on the lower portion of the vehicle body frame 11 via a swing arm 14; Seat 17, it is installed on the top of vehicle body frame 11.

[0059] The motorcycle 10 is a saddle-ride type vehicle in which a passenger straddles a seat 17 .

[0060] The body frame 11 has a front riser 21 , a main frame 22 , a pair of left and right center frames 23 , a pair of left and right seat frames 24 , a pair of left and right sub frames 26 , and an under frame 27 .

[0061] The front stand pipe 21 constitutes a front end portion of the vehicle body frame 11 . The main frame 22 extends obliquely downward from the front stand pipe 21 rearward. The...

no. 2 approach

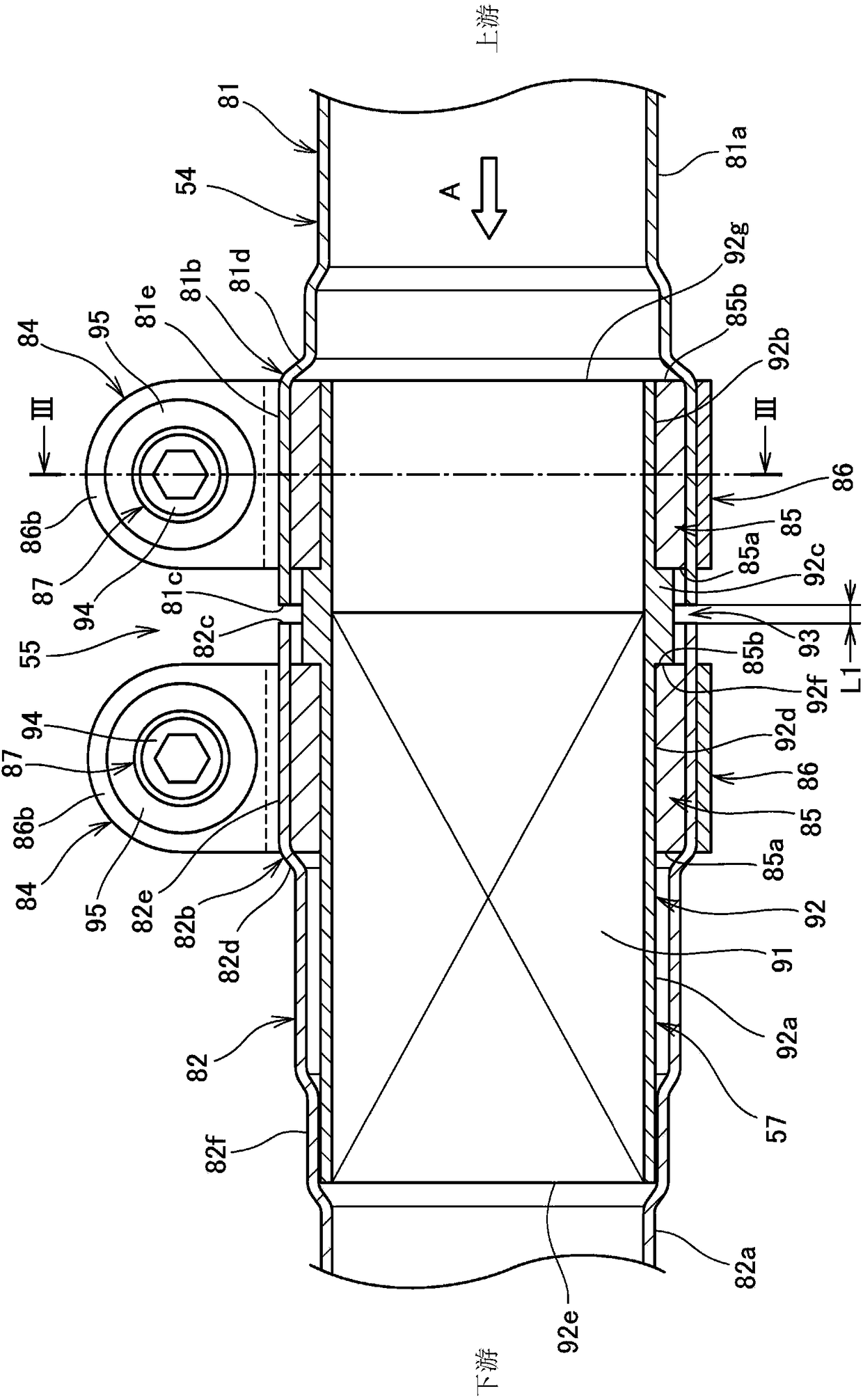

[0114] Figure 4 It is a vertical cross-sectional view showing the catalytic converter support structure of the exhaust pipe 100 according to the second embodiment. In the second embodiment, the same components as those in the first embodiment are denoted by the same reference numerals, and detailed description thereof will be omitted.

[0115] The exhaust pipe 100 is composed of a front exhaust pipe 101 and a rear exhaust pipe 102 which are divided into two parts.

[0116] The front exhaust pipe 101 has: from the cylinder head 47 (refer to figure 1 ) a front pipe portion 101a extending sideways; and a front enlarged diameter portion 101b integrally formed at the rear end portion of the front pipe portion 101a. The front enlarged diameter portion 101b is a portion enlarged in diameter from the front pipe portion 101a.

[0117] The rear exhaust pipe 102 has: from the muffler 56 (refer to figure 1 ) side extended rear pipe portion 102a; and rear enlarged diameter portion 102...

no. 3 approach

[0137] Figure 5 It is a vertical cross-sectional view showing the catalytic converter supporting structure of the exhaust pipe 110 according to the third embodiment. In the third embodiment, the same components as those in the first embodiment are denoted by the same reference numerals, and detailed description thereof will be omitted.

[0138] The exhaust pipe 110 is composed of a front exhaust pipe 111 and a rear exhaust pipe 112 which are divided into two parts.

[0139] The front exhaust pipe 111 has a flow from the cylinder head 47 (refer to figure 1 ) side extending front part pipe part 111a, and the front part enlarged diameter part 111b integrally formed in the rear end part of the front part pipe part 111a. The front enlarged diameter portion 111b is a portion enlarged in diameter from the front pipe portion 111a.

[0140] The rear exhaust pipe 112 has a slave muffler 56 (refer to figure 1 ) side extension of the rear pipe portion 112a, and the rear enlarged diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com