Micro motor capable of conveniently adjusting vibration intensity

A vibration-strength, micro-motor technology, applied in electric components, control mechanical energy, electrical components, etc., can solve problems such as complex control circuits and poor stability, and achieve the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

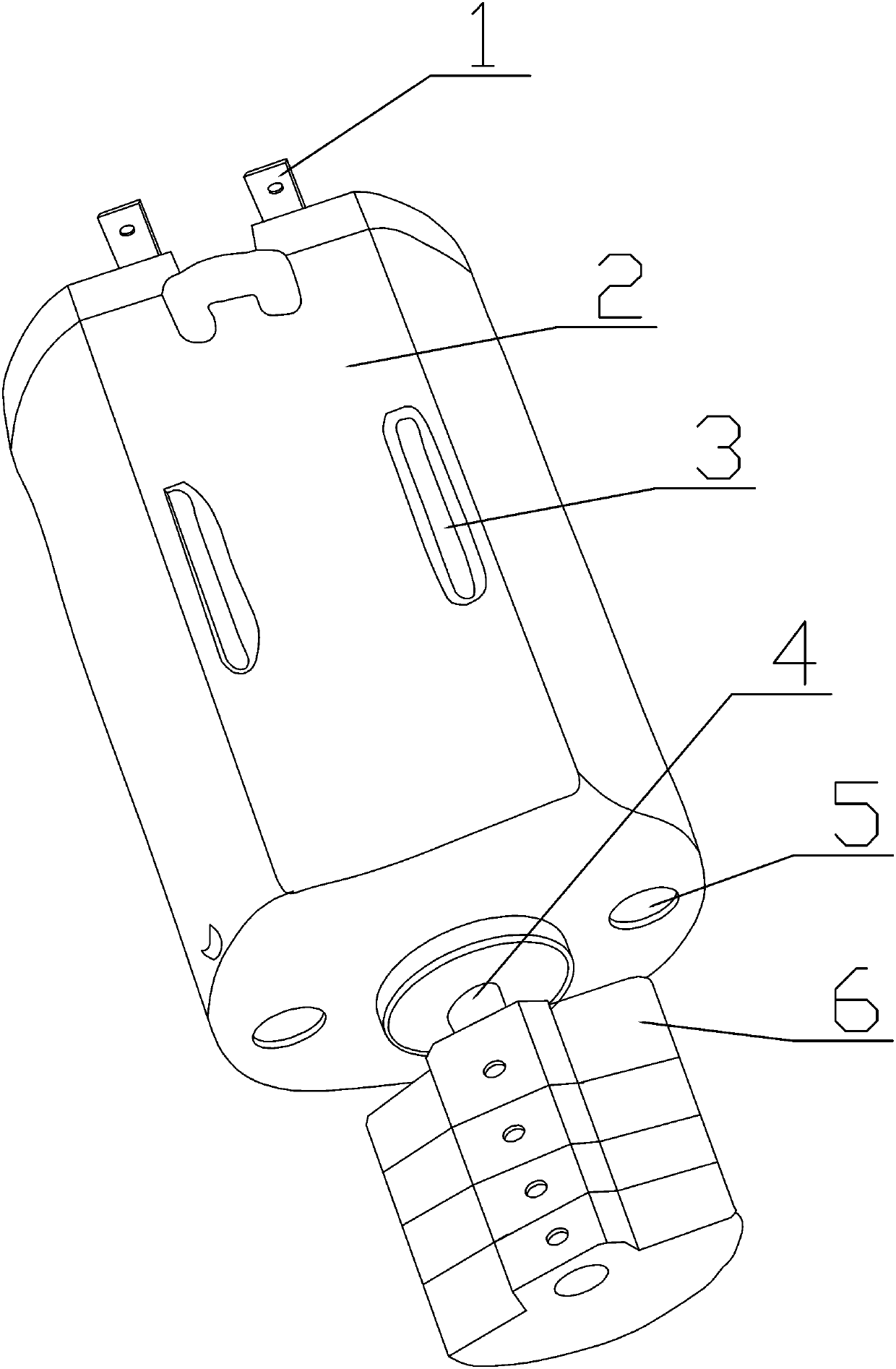

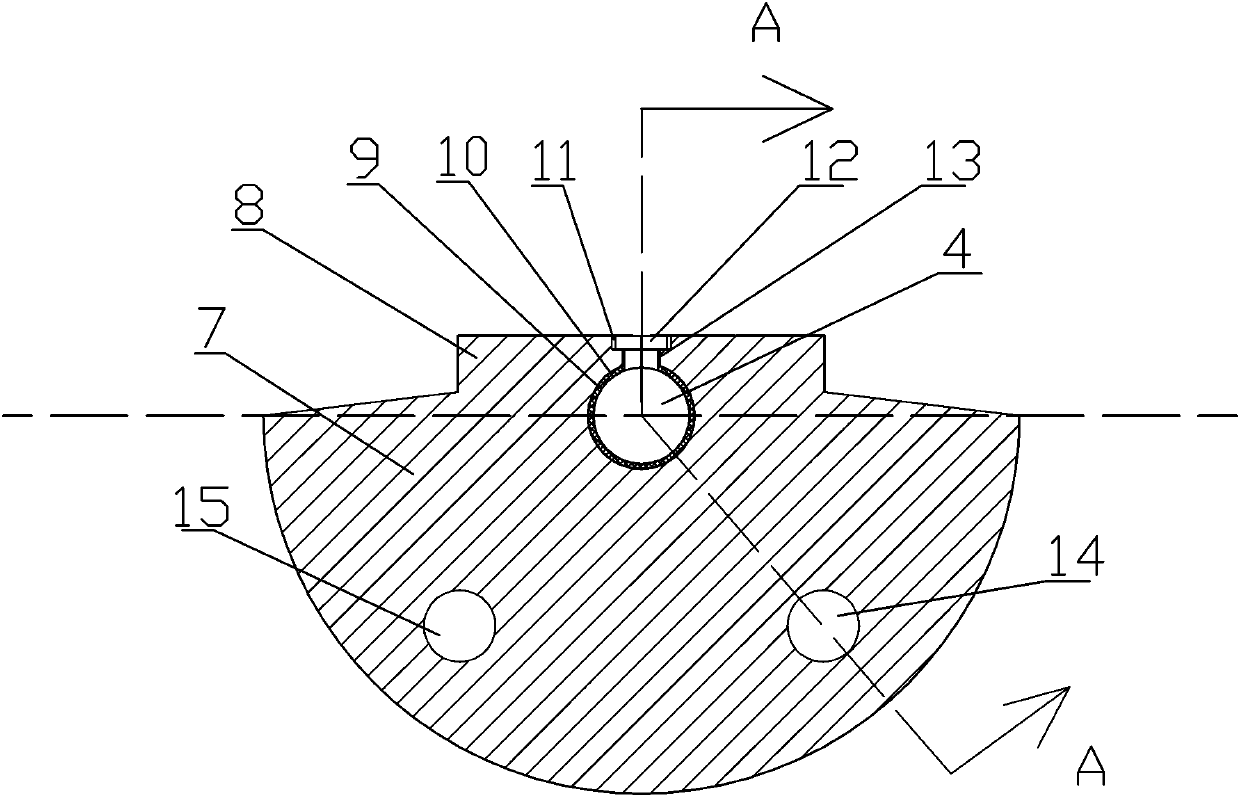

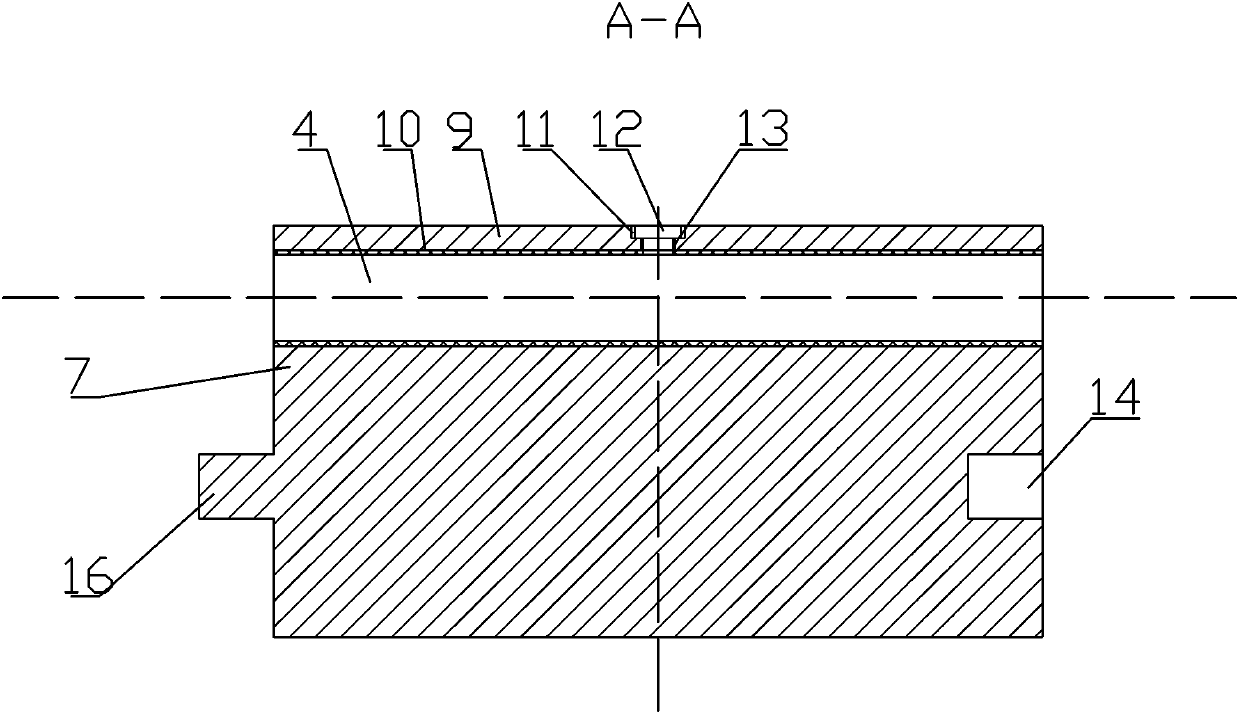

[0025] see Figure 1-5 , a micro motor capable of conveniently adjusting the vibration intensity, which includes a motor body 2, a rear cover is installed at the tail of the motor body 2, and a power plug 1 is installed on the rear cover; the front end of the motor body 2 is processed There are cooling holes 5; the main shaft 4 of the motor body 2 is equipped with a combined counterweight 6; the motor body 2 is processed with an installation groove 3. The combined counterweight 6 includes a plurality of separately assembled counterweights 7 assembled on the main shaft 4 together. Different vibration effects can be achieved by selectively installing different numbers of counterweights 7 during the working process of the above-mentioned micro motor, thereby satisfying different usage requirements.

[0026] Further, the counterweight 7 adopts a symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com