Tubular actuator for powering a screen and method for manufacturing such an actuator

A technology of actuators and shields, applied in building construction, connection with control/drive circuits, electric components, etc., can solve problems such as damaged threads and non-removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

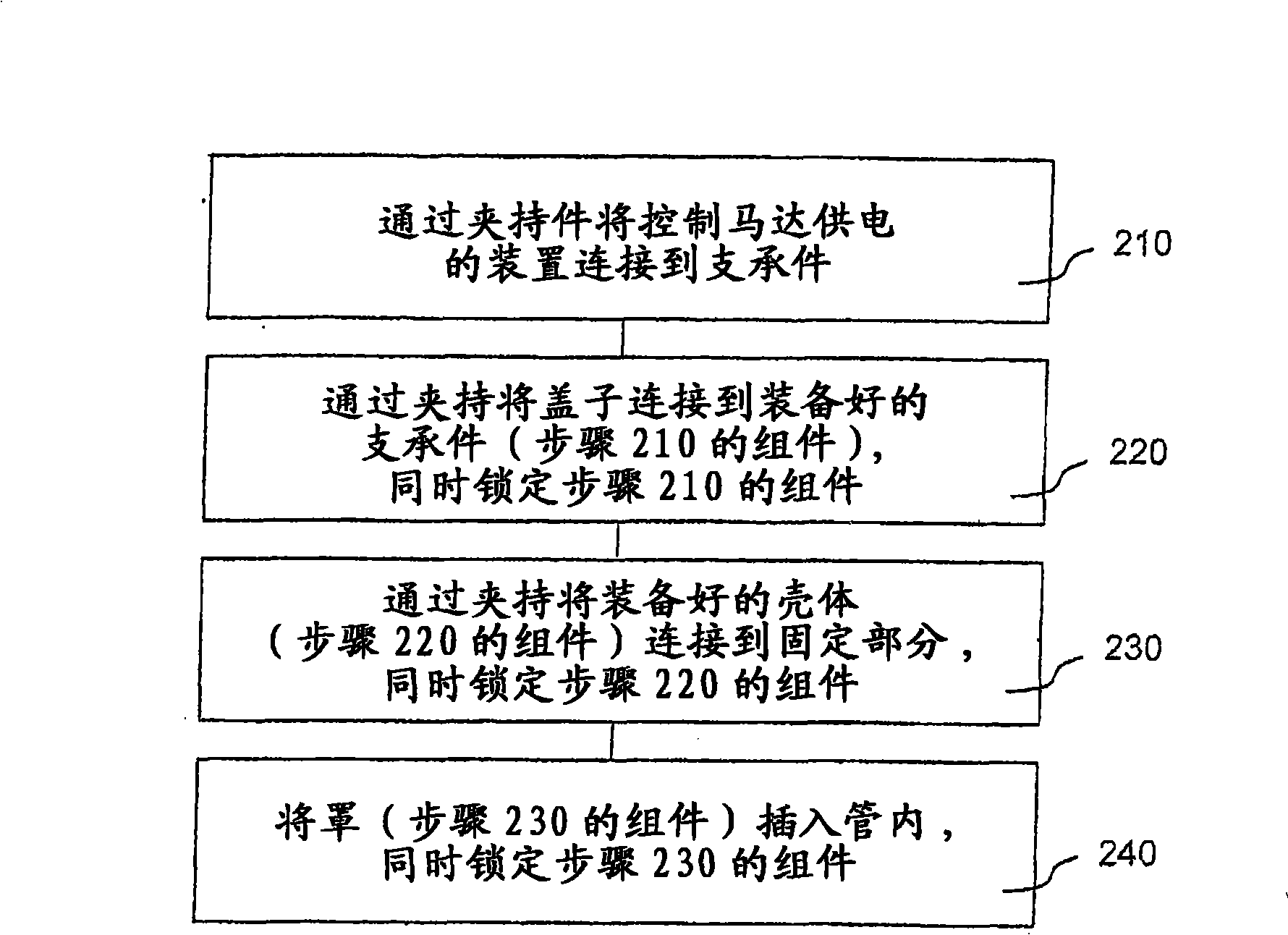

Method used

Image

Examples

Embodiment Construction

[0034] Figure 1 shows a tubular actuator 100 for driving a roller shade tube 1 on which a curtain 2 for sealing an opening O can be wound to a greater or lesser extent. The tube 1 is driven by an actuator 100 in rotation about an axis of rotation X-X lying horizontally at the top of this opening. The opening O is, for example, an opening formed in a wall of a building. Thus, the actuator 100, the tube 1 and the shade 2 form a motorized roller shade.

[0035] The actuator 100 includes a cylindrical tube 101 in which is mounted a gear motor 102 comprising an electric motor, a brake and a reduction gear, and is equipped with an output shaft 103 protruding from one end 101A of the tube 101 and driving Crown gear 3 engaged in rotation with tube 1 .

[0036] The roller shutter tube 1 rotates about the axis X-X and the fixed tube 101 thanks to two pivot joints. The ring support 4 mounted on the outer periphery of the tube 101 near the end 101B of the tube 101 opposite the end 101A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com