Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Ensure appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction method for building concrete superface with surface modeling

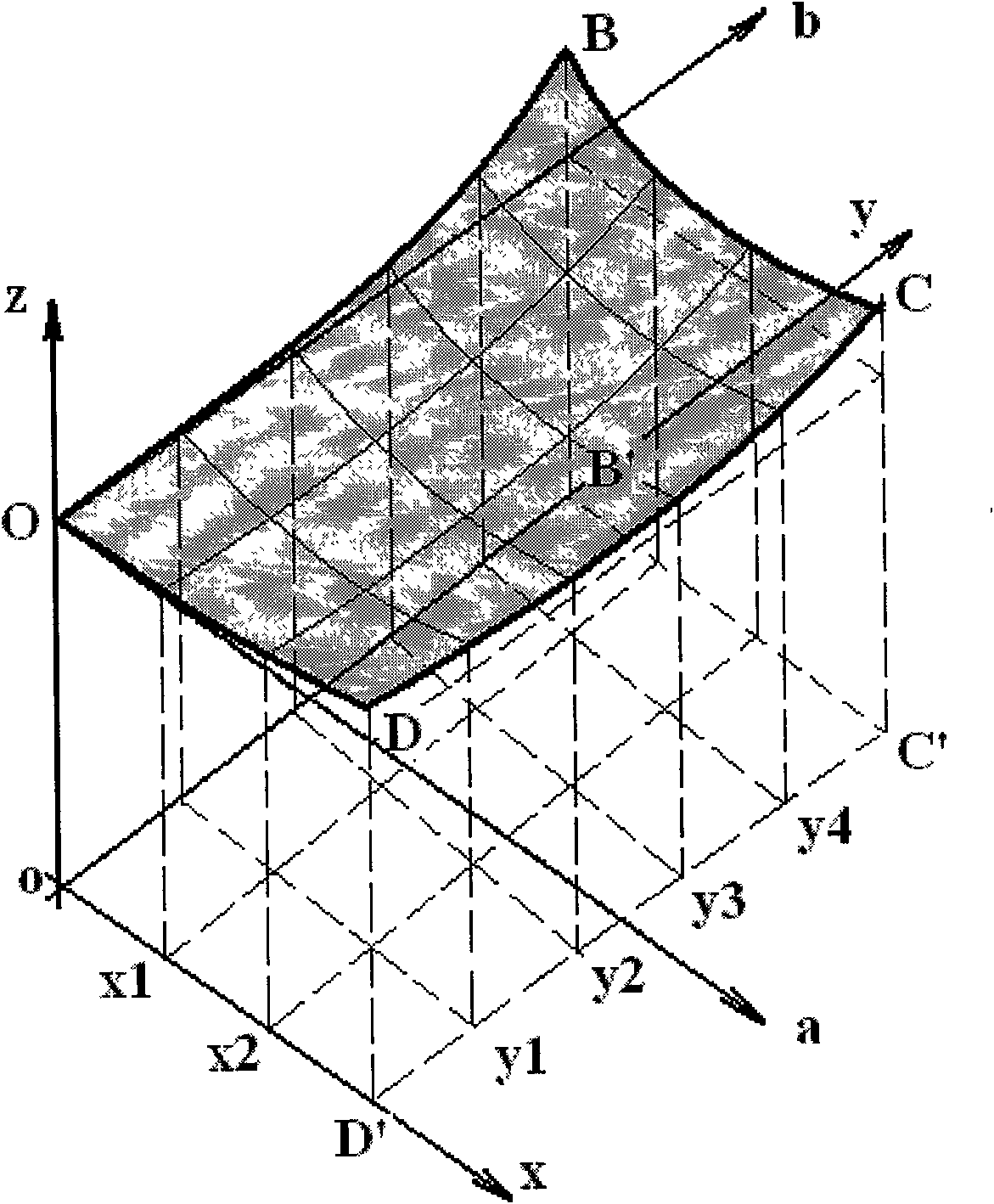

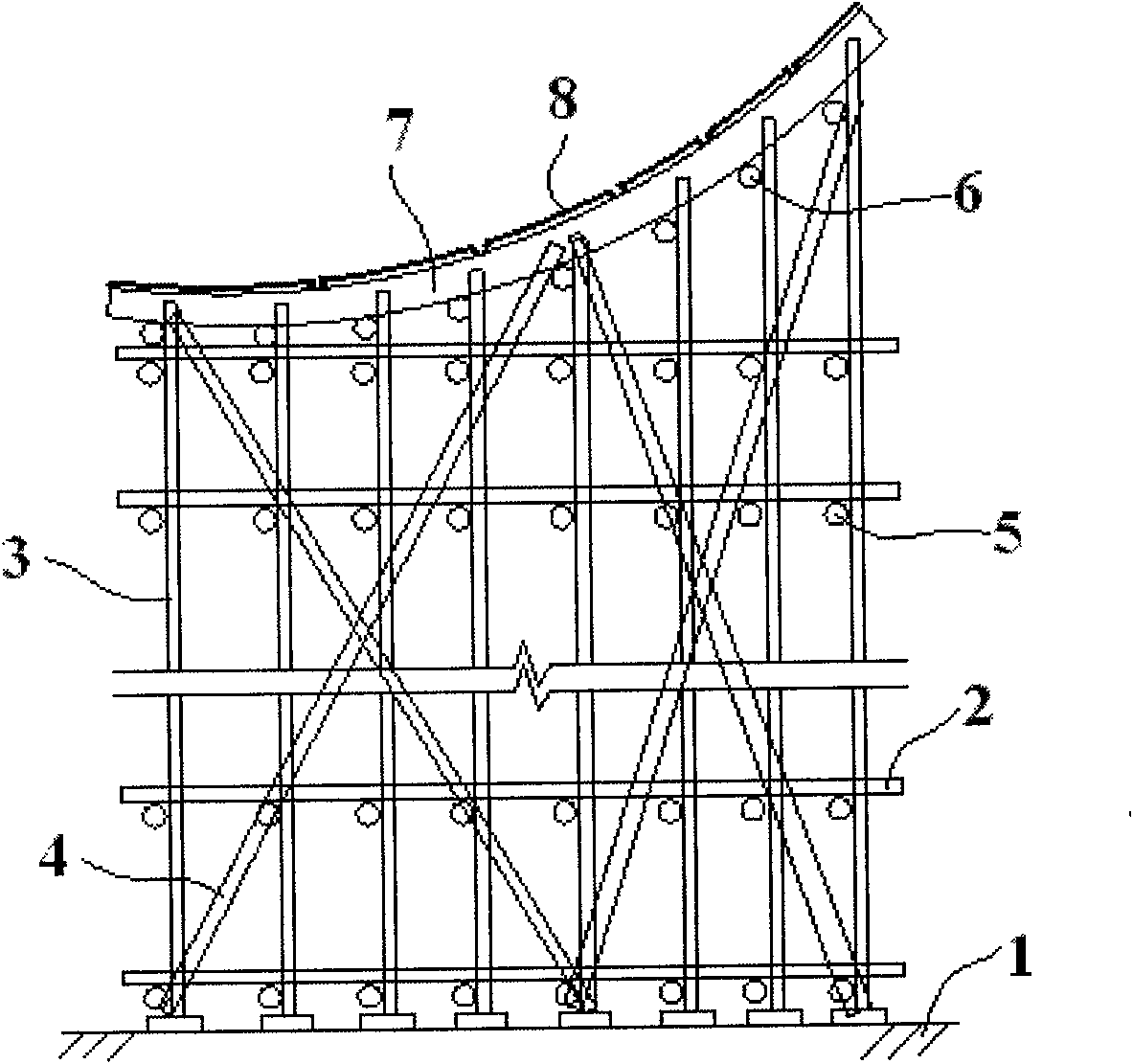

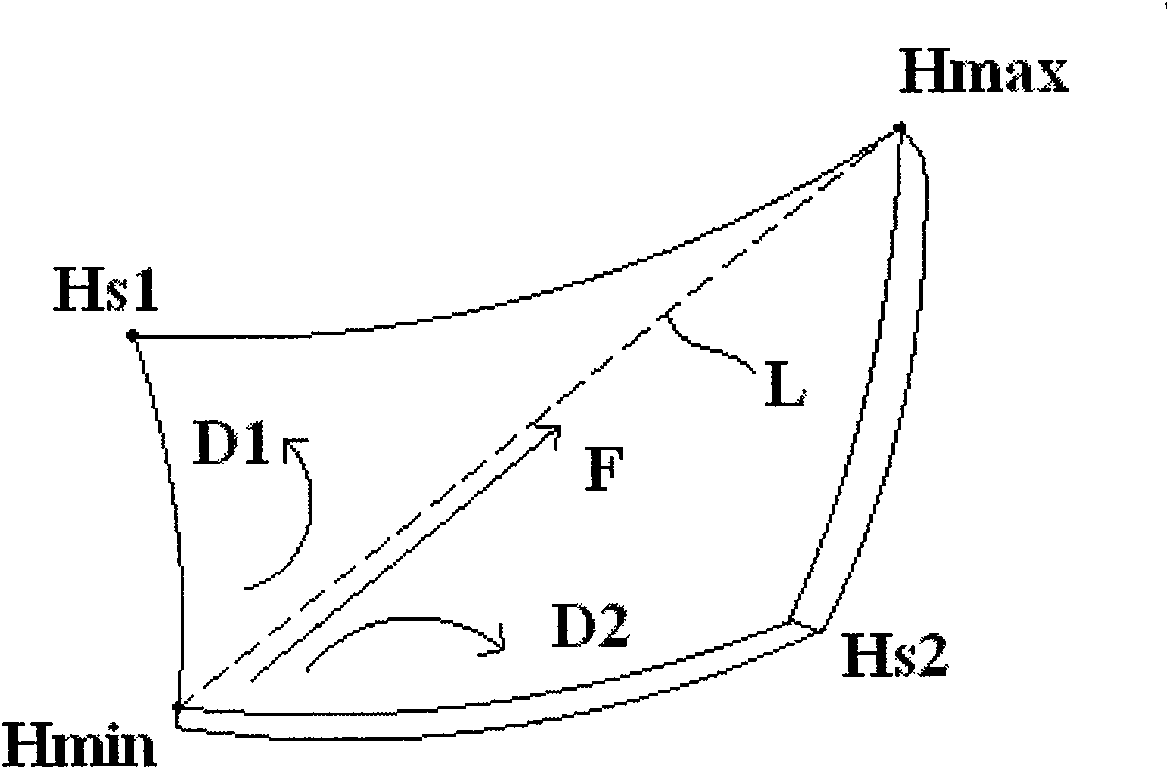

The invention relates to a construction method for building concrete superface with surface modeling, which comprises the following steps: a horizontal projection is carried out on a space curved surface structure; a horizontal projection plane is divided into a plurality of grids; by establishing a local coordinate system, the elevation on the space curved surface corresponding to each grid node in the coordinate frame of the horizontal projection plane is figured out; according to each elevation data, the position of the cross rod of each load steel tube is determined so as to finish bridging; and then according to the elevation data, a back purlin is formed, and finally the formed back purlin is fixed on the corresponding cross rod of each load steel tube; a defined of water reducing agent and fly ash with small grain diameter are doped into concrete; firstly, pump pipes are arranged in the lowest position of a double-parabolic slab, distribute materials from bottom to top along a diagonal direction, pushes toward the highest point; a pump truck alternatively cuts materials at both sides of the diagonal, builds and vibrates, which is shot by people in real time. The construction method can reduce the difficult problem and strength of the construction, has fast construction process, low construction cost and high construction quality.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU +3

Salt corrosion resistant and twisting resistant power cable for ocean wind power and manufacturing method of power cable

ActiveCN103227008AReduce tensionEliminate voidsPower cablesInsulating conductors/cablesCopper conductorElectricity

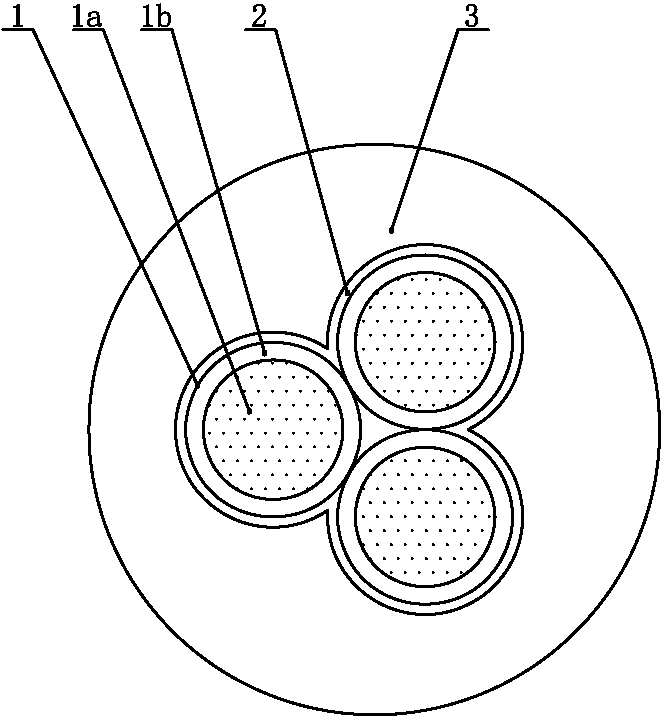

The invention relates to a salt corrosion resistant and twisting resistant power cable for ocean wind power and a manufacturing method of the power cable. A stranded copper conductor is uniformly wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form a power cable insulated core; a plurality of power cable insulated cores are mutually stranded to form a power cable core; the power cable core is wrapped in a low-strength non-woven fabric longitudinal wrap on the periphery; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The power cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the power cable insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the power cable insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

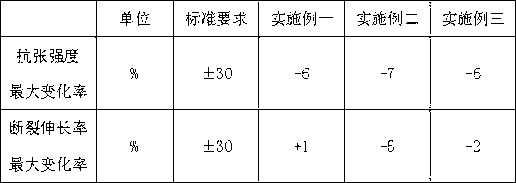

Intelligent vending system and vending method of railway station

ActiveCN106204249AQuick and easy to pick upAvoid backlogCoin-freed apparatus detailsBuying/selling/leasing transactionsInformation processingControl system

The invention relates to an intelligent vending system and vending method of a railway station. The intelligent vending system comprises a request receiving device, a shopping information generating device, a shopping information sending device for sending shopping information to a shopping information processing device, the shopping information processing device and a goods taking device, wherein the goods taking device comprises a vending cabinet body and a vending cabinet body control system, and the vending cabinet body is provided with a falling commodity buffering device. By the adoption of the intelligent vending system of the railway station, a passenger on a train chooses and purchases commodities sold at the station where the train is about to stop and can conveniently and rapidly get the purchased commodities within several minutes when the train stops at the station, the vending cabinet is provided with the falling commodity buffering device, commodities are not damaged or change in shape due to falling, the range of commodity selling is widened, and fruits, foods which are not resistant to extrusion and other vulnerable and fragile commodities can be sold. In addition, the bottom of the cabinet body is protected, the service life of the cabinet body is prolonged, and the maintenance cost is reduced.

Owner:山东上源网络科技有限公司

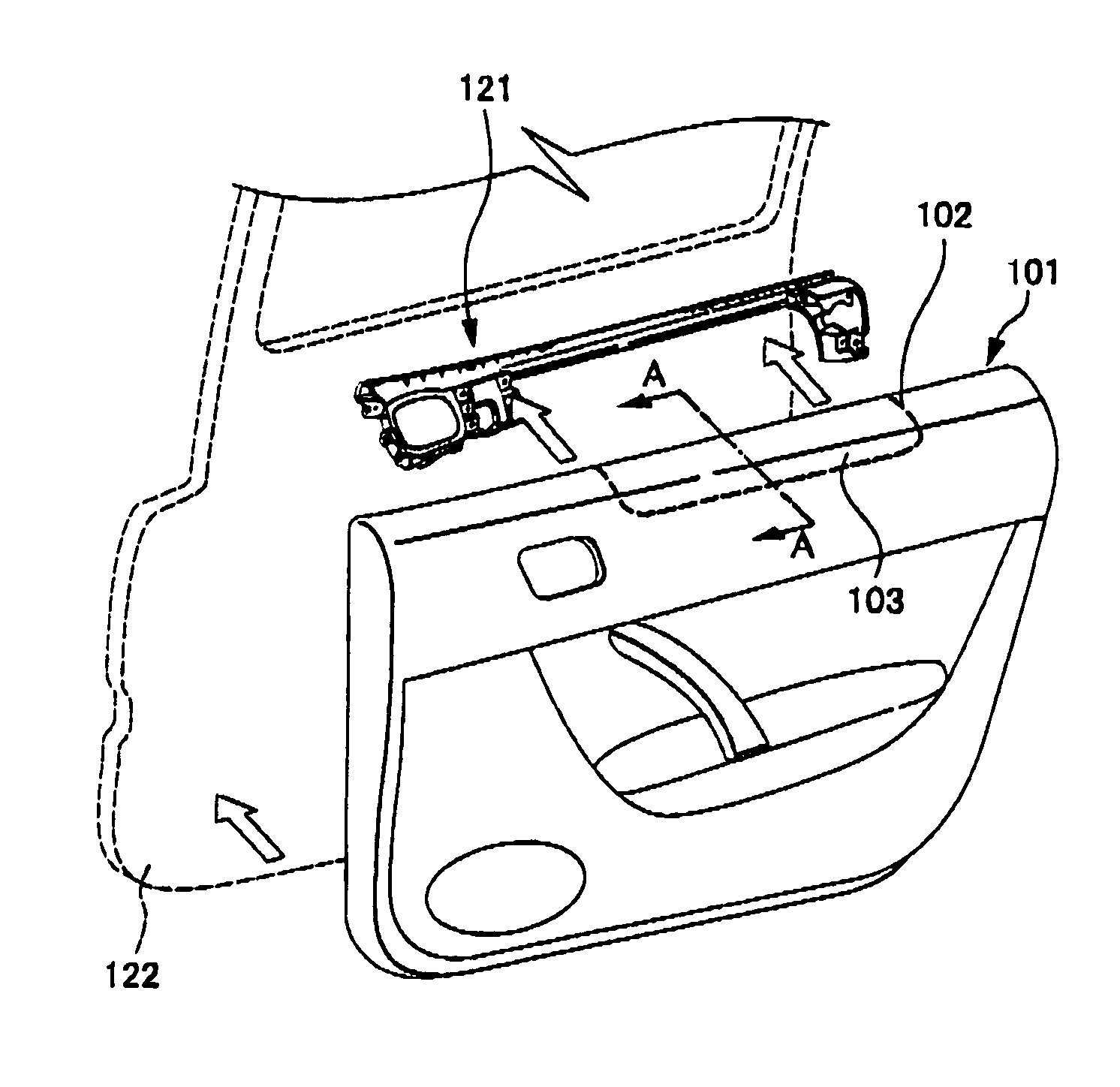

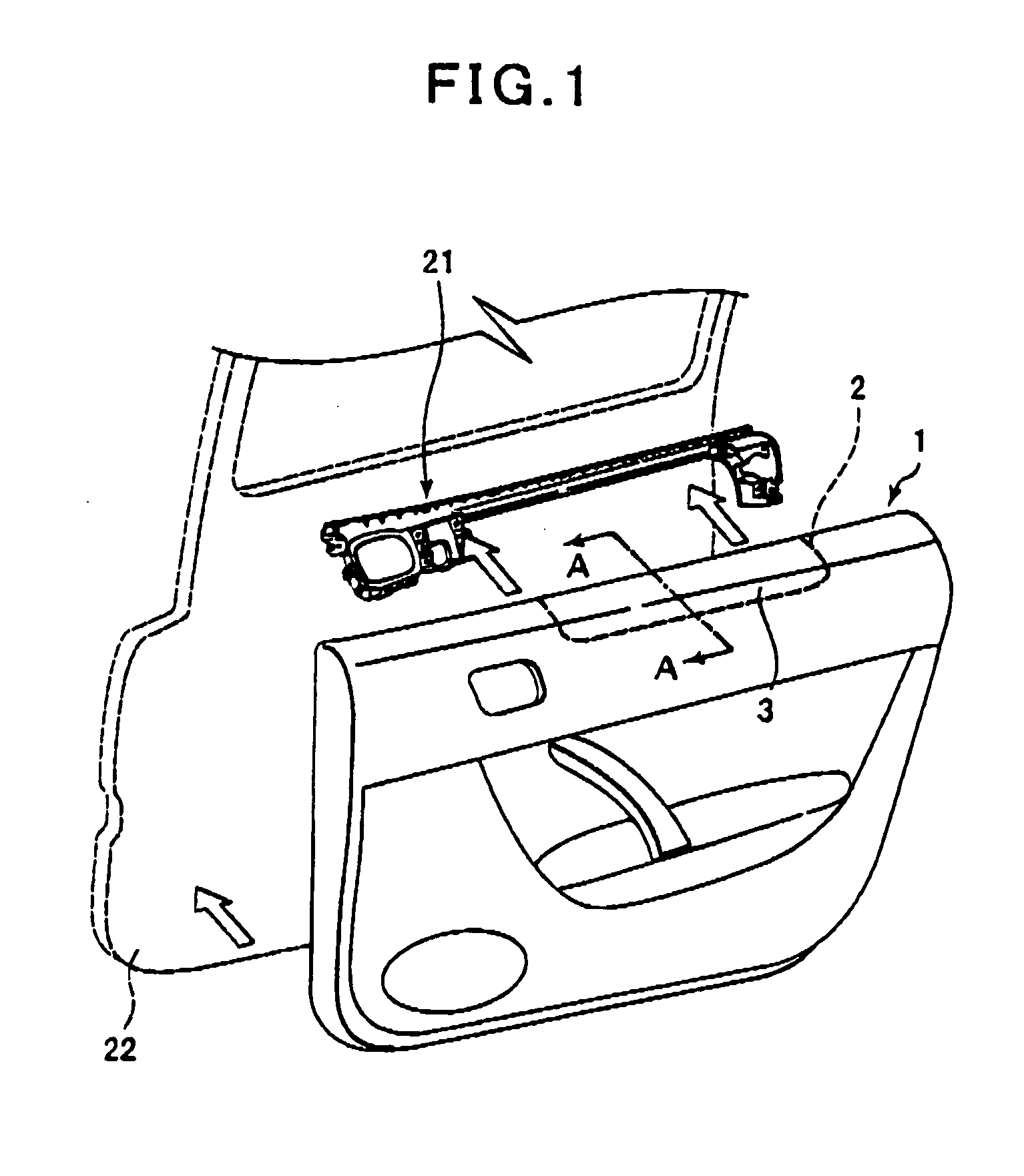

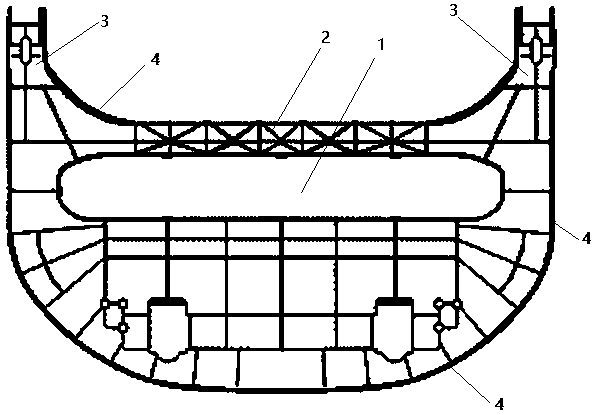

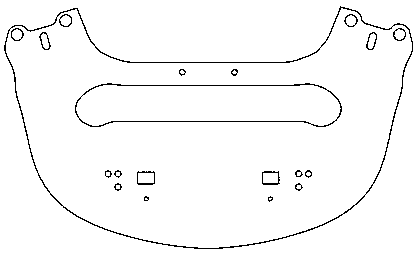

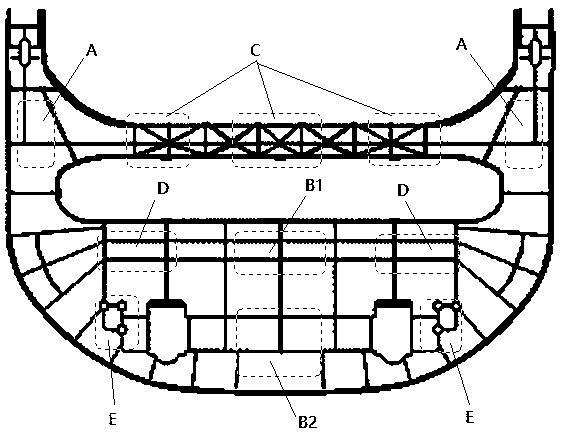

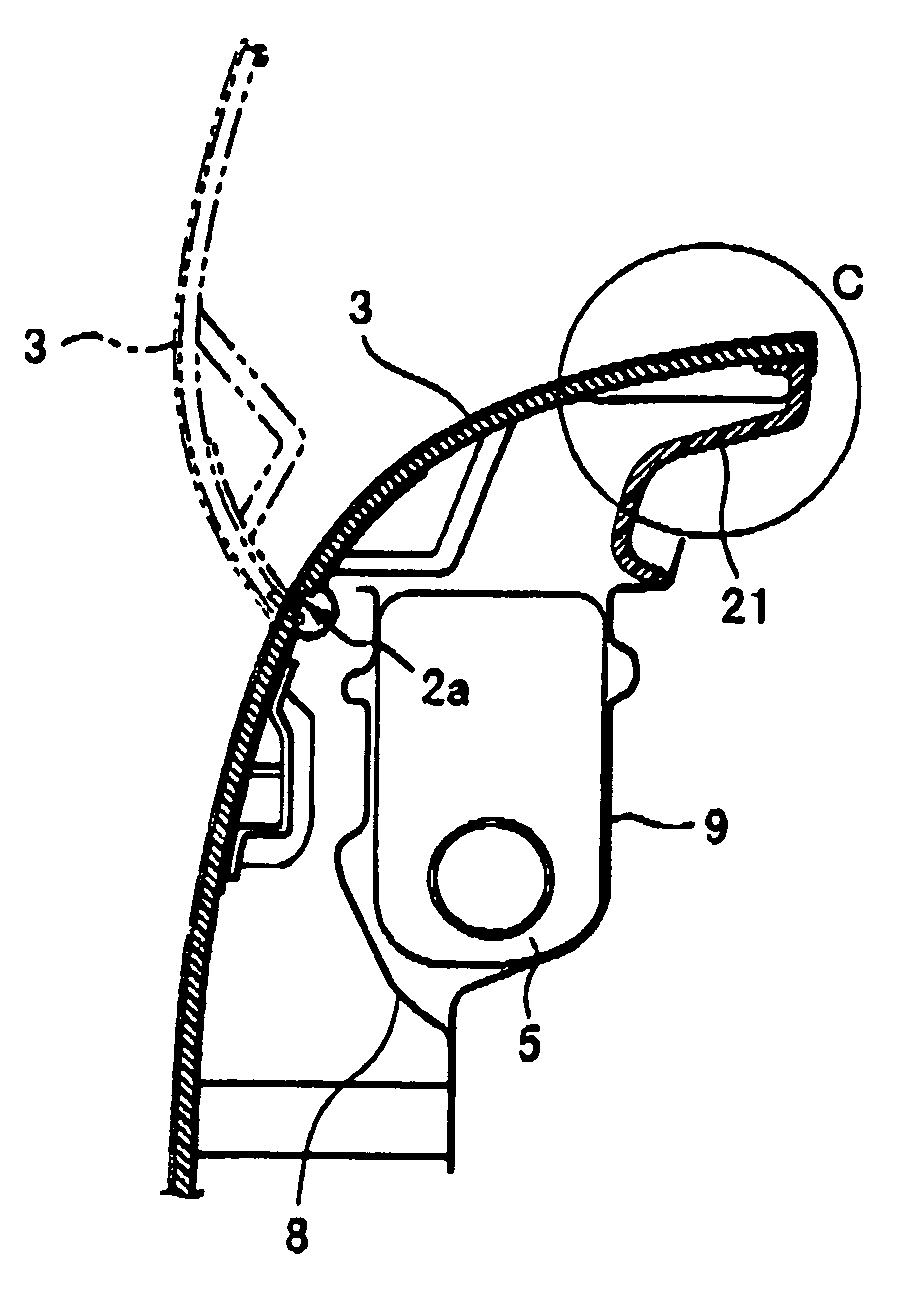

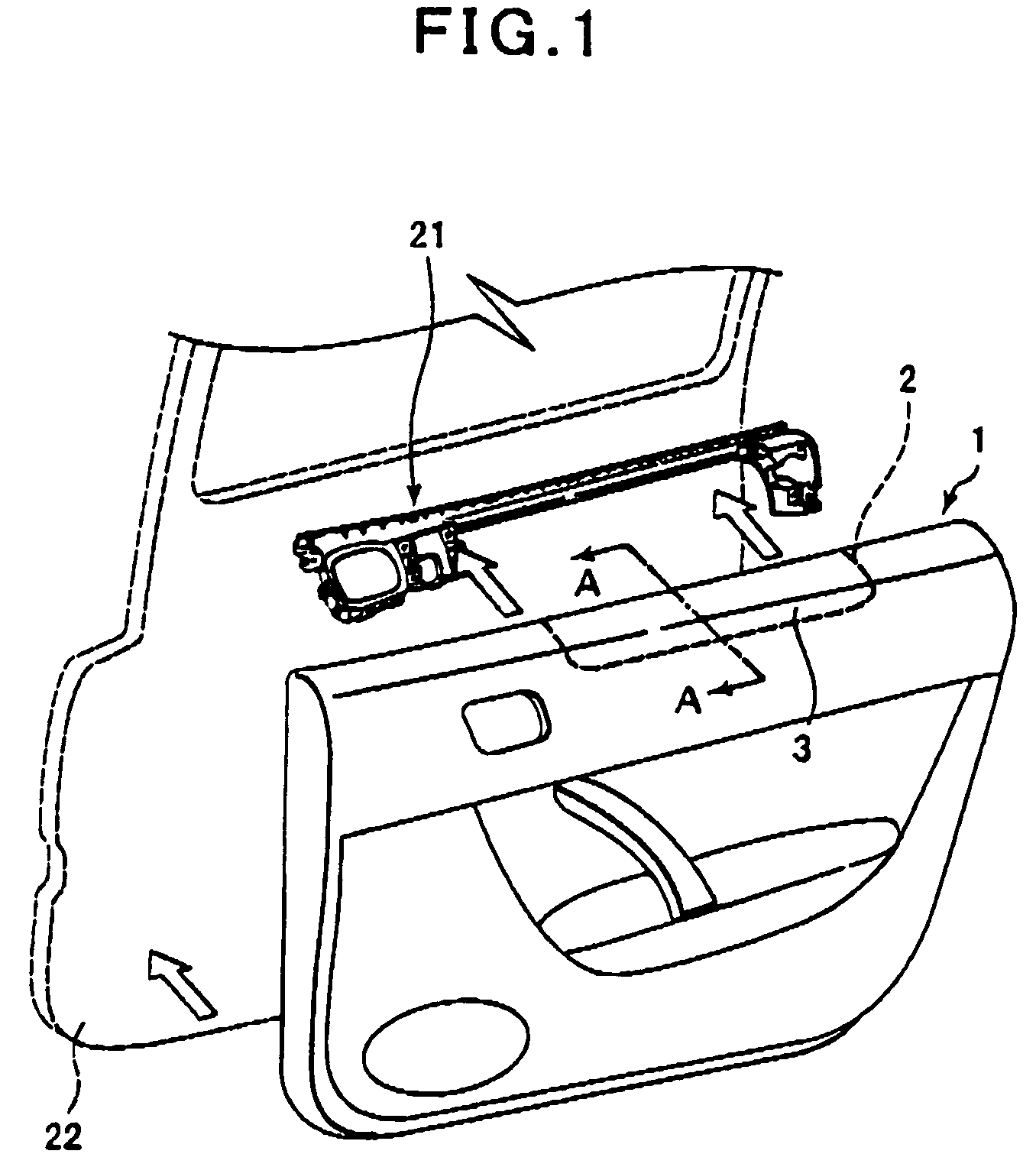

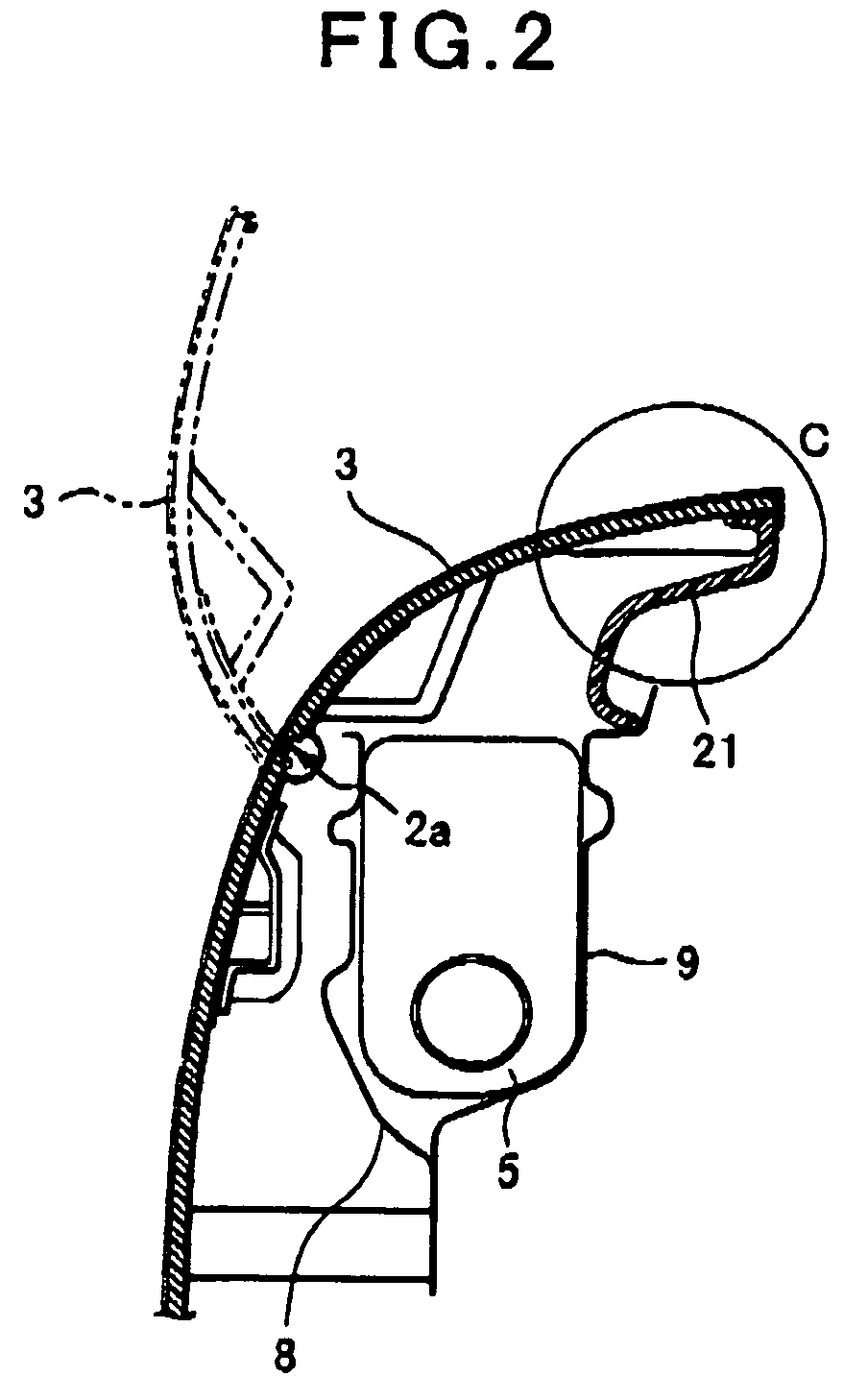

Vehicle interior parts

InactiveUS20100019474A1Restrict movementStable statePedestrian/occupant safety arrangementEngineeringAirbag

An automotive interior component according to the present invention includes: an interior component attached to a vehicle body panel at an interior side of a vehicle; an airbag installed in a gap between the vehicle body panel and the interior component; an expanding portion defined in a partial region of the interior component, the expanding portion turning in an expansion direction of the airbag to expose an opening; first locking means made up of a first locking piece provided at a rim of the expanding portion and a first engagement portion provided at a fixed portion with which the rim of the expanding portion comes into contact, receiving the first locking piece to lock movement of the expanding portion in a turning direction; and second locking means made up of a second locking piece provided at the rim of the expanding portion and a second engagement portion provided at the fixed portion with which the rim of the expanding portion comes into contact, receiving the second locking piece to lock movement of the expanding portion in a turning radial direction.

Owner:KASAI KOGYO CO LTD

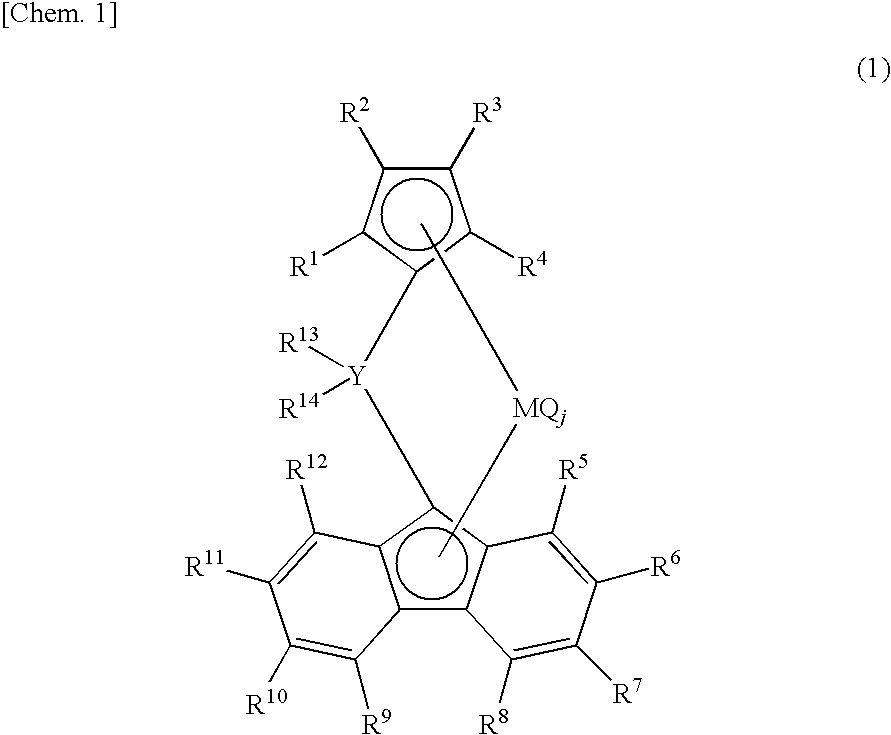

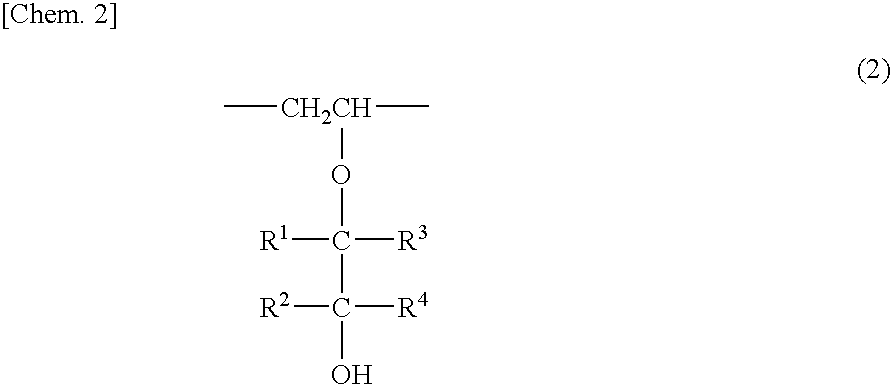

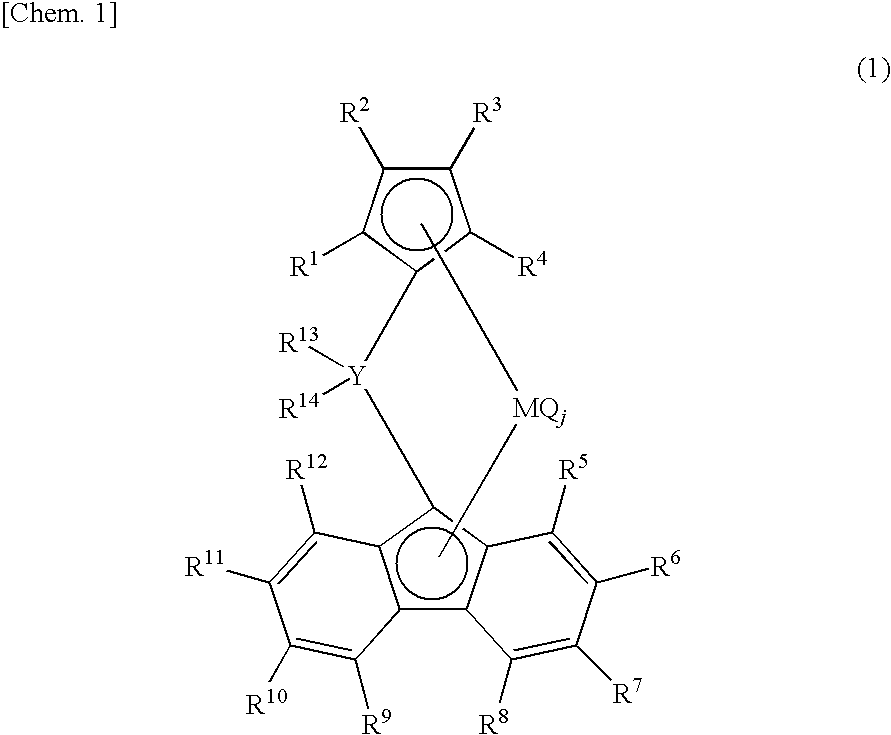

Multilayered stretched hollow material

InactiveUS20090269528A1Excellent gas barrier propertiesHigh transparencySynthetic resin layered productsDomestic containersSurface layerCrystallization temperature

The object of the present invention is to provide a multilayered stretched hollow material having excellent transparency and gas barrier properties. The multilayered stretched hollow material of the present invention is characterized in that it includes surface layers and an intermediate layer wherein the surface layers each contain a propylene polymer composition containing a propylene polymer (the weight thereof being A) and a modified propylene polymer grafted with an unsaturated carboxylic acid or a derivative thereof (the weight thereof being B) in a weight ratio of B / (A+B)≧0.15 and wherein the intermediate layer contains a modified ethylene / vinyl compound copolymer that has a melt flow rate (ASTM D 1238, 210° C., 2.16 kg load) of not less than 8 g / 10 min and a crystallization temperature (Tc) of not less than 138° C. and further wherein the multilayered stretched hollow material satisfies C / (A+B+C)≧0.05 wherein C is the weight of the ethylene / vinyl compound copolymer.

Owner:PRIME POLYMER CO LTD

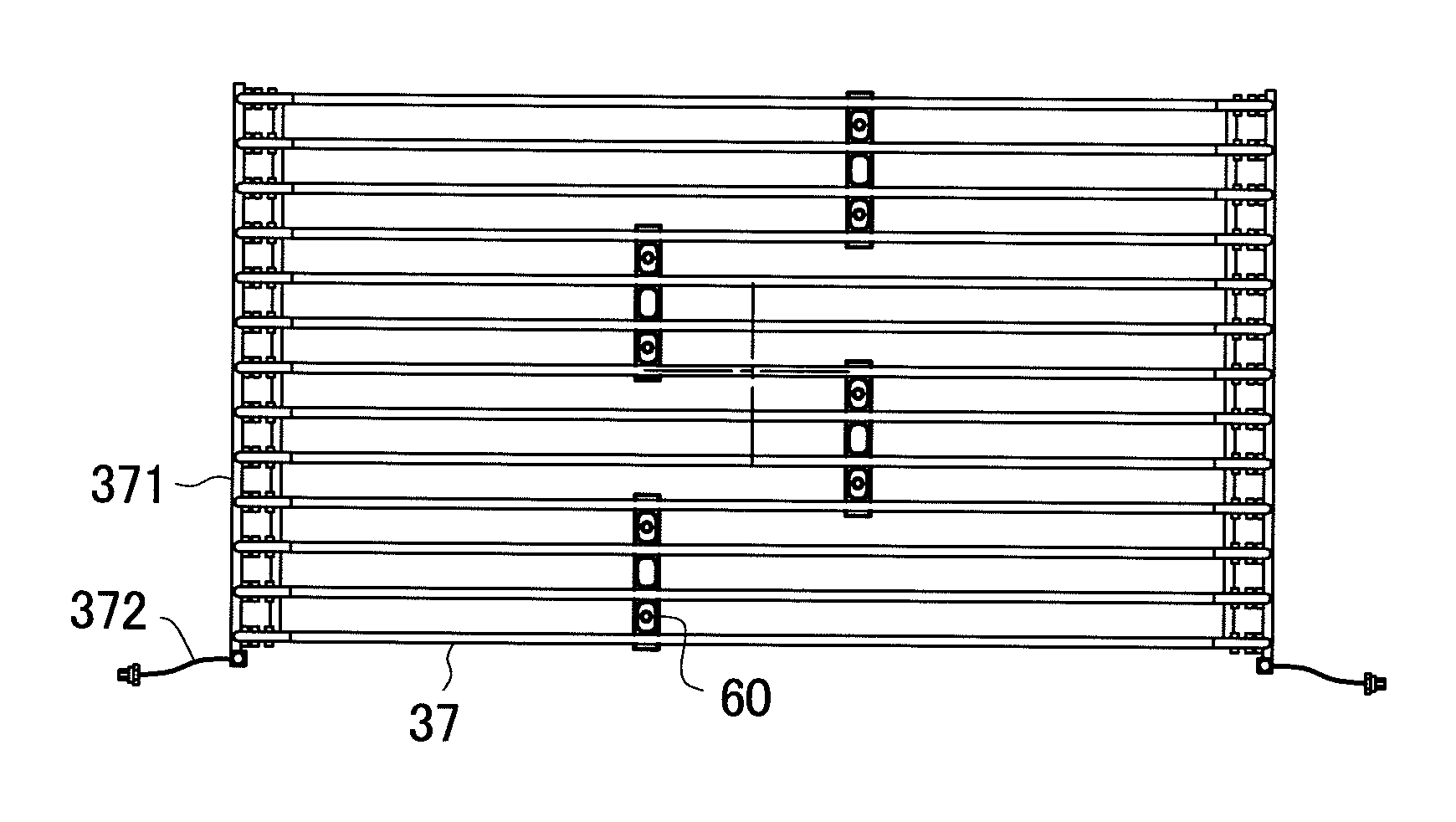

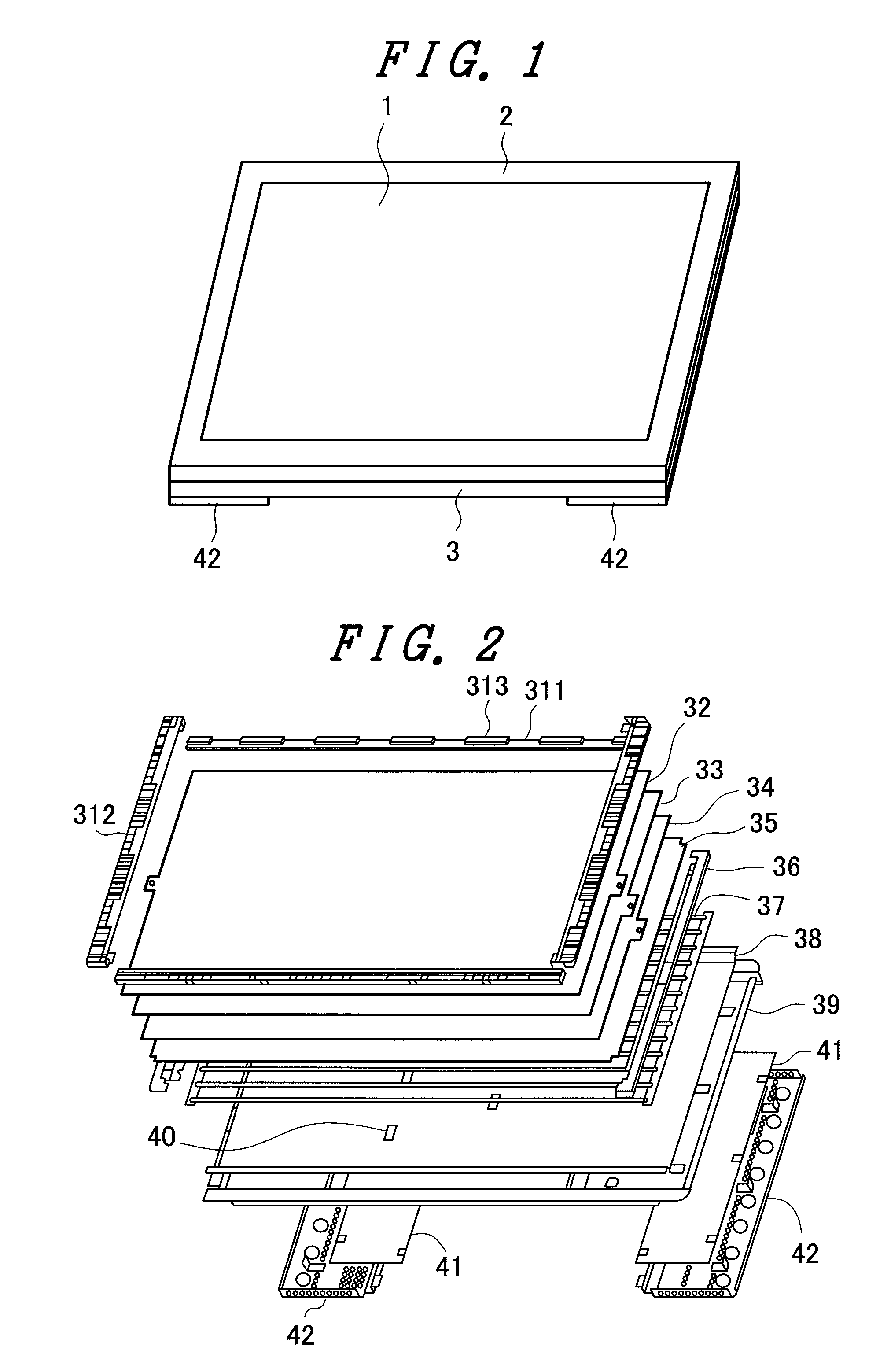

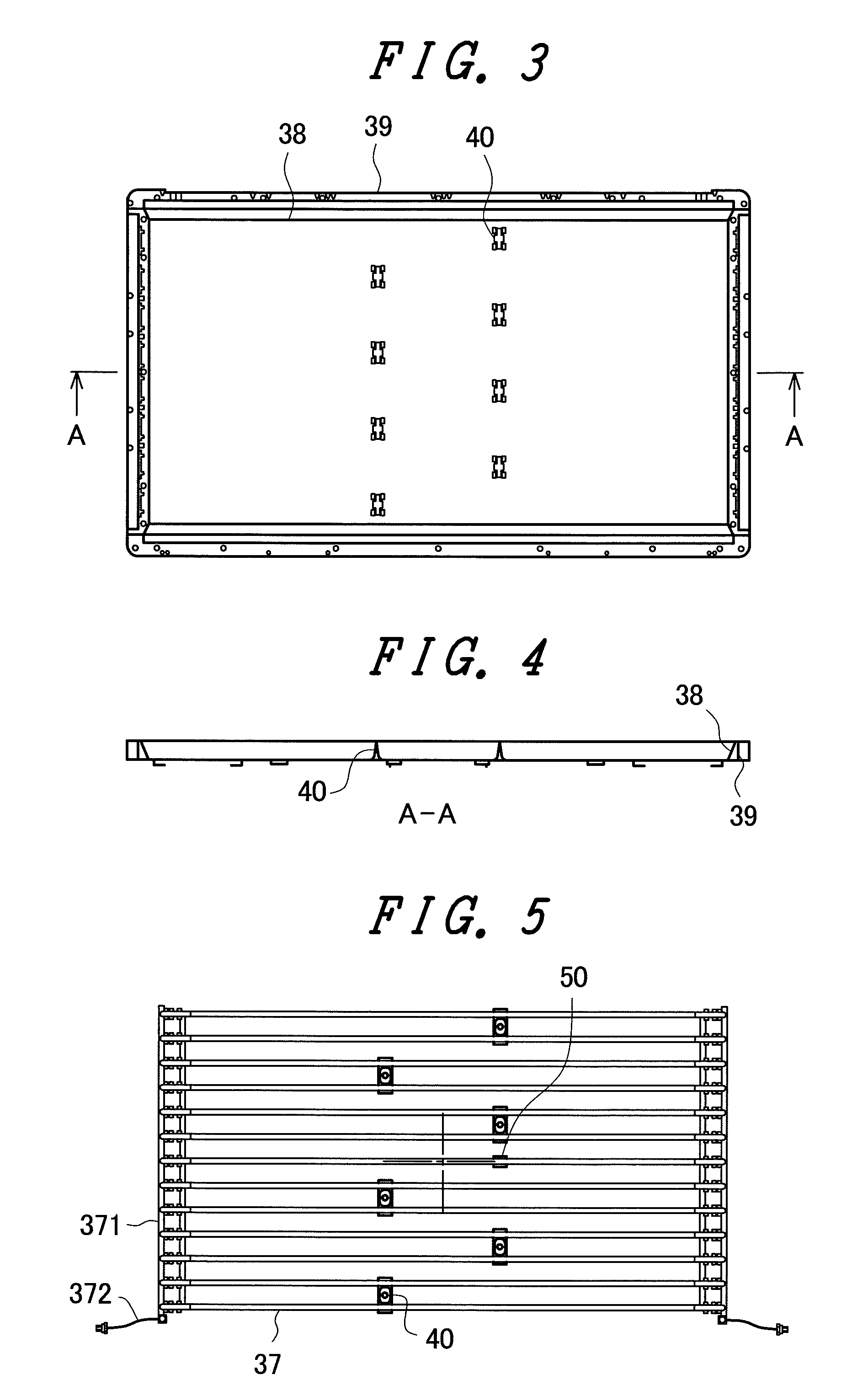

Liquid crystal display device having direct backlight with an odd number of fluorescent lamps providing enhanced brightness at center of screen

InactiveUS7826008B2Increase consumptionIncrease brightnessElectric lightingIlluminated signsLiquid-crystal displayEngineering

The present inventions enhances the brightness at a center portion of a display screen in a liquid crystal display device used in a TV set having a direct backlight. Odd-number pieces of fluorescent lamps are used in the inside of the backlight. Using external electrode fluorescent lamps as the fluorescent lamps, electrodes of the respective fluorescent lamps can be connected in common. Further, one fluorescent lamp can be arranged at the center of the display screen. Due to such a constitution, the liquid crystal display device can effectively ensure the brightness at the center of the display screen.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

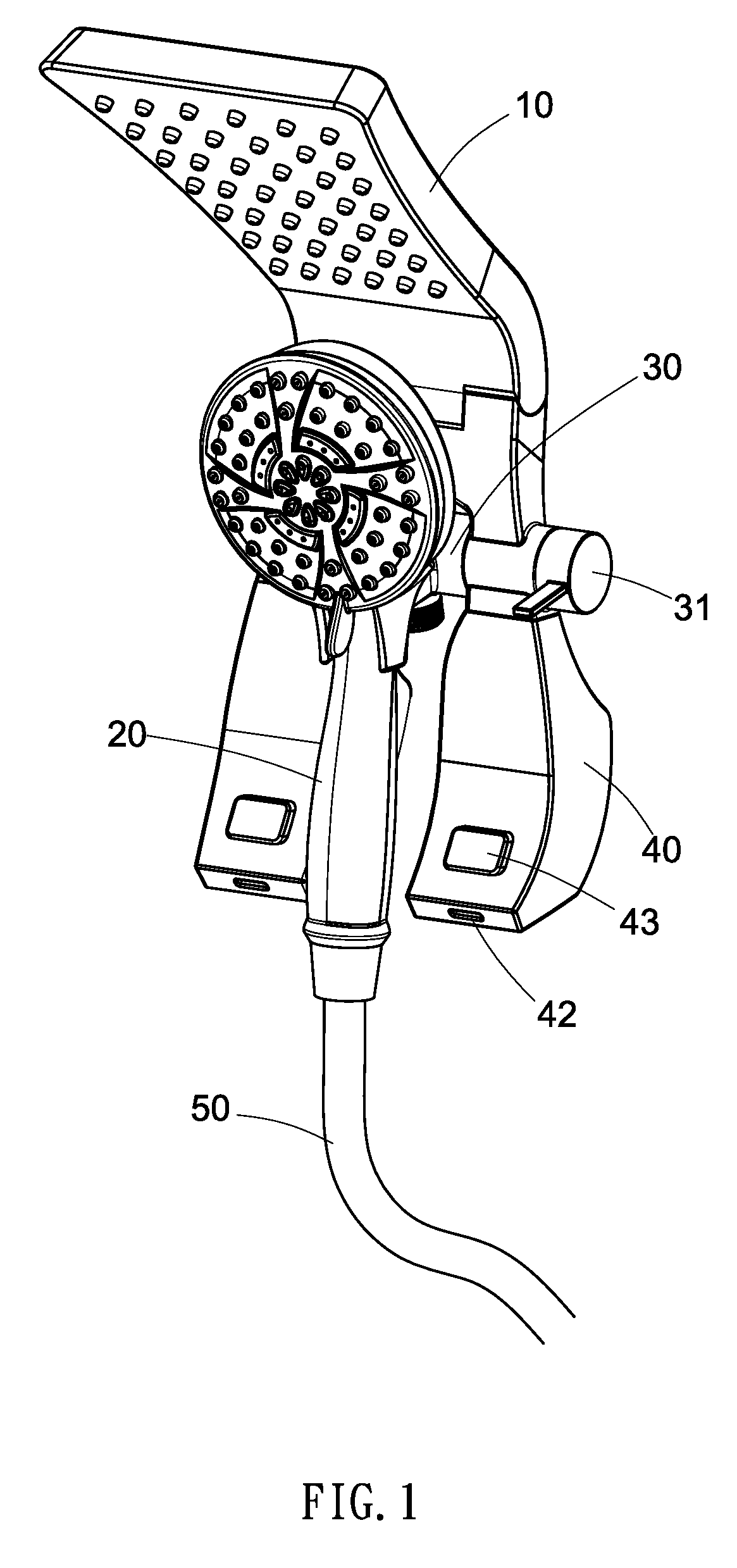

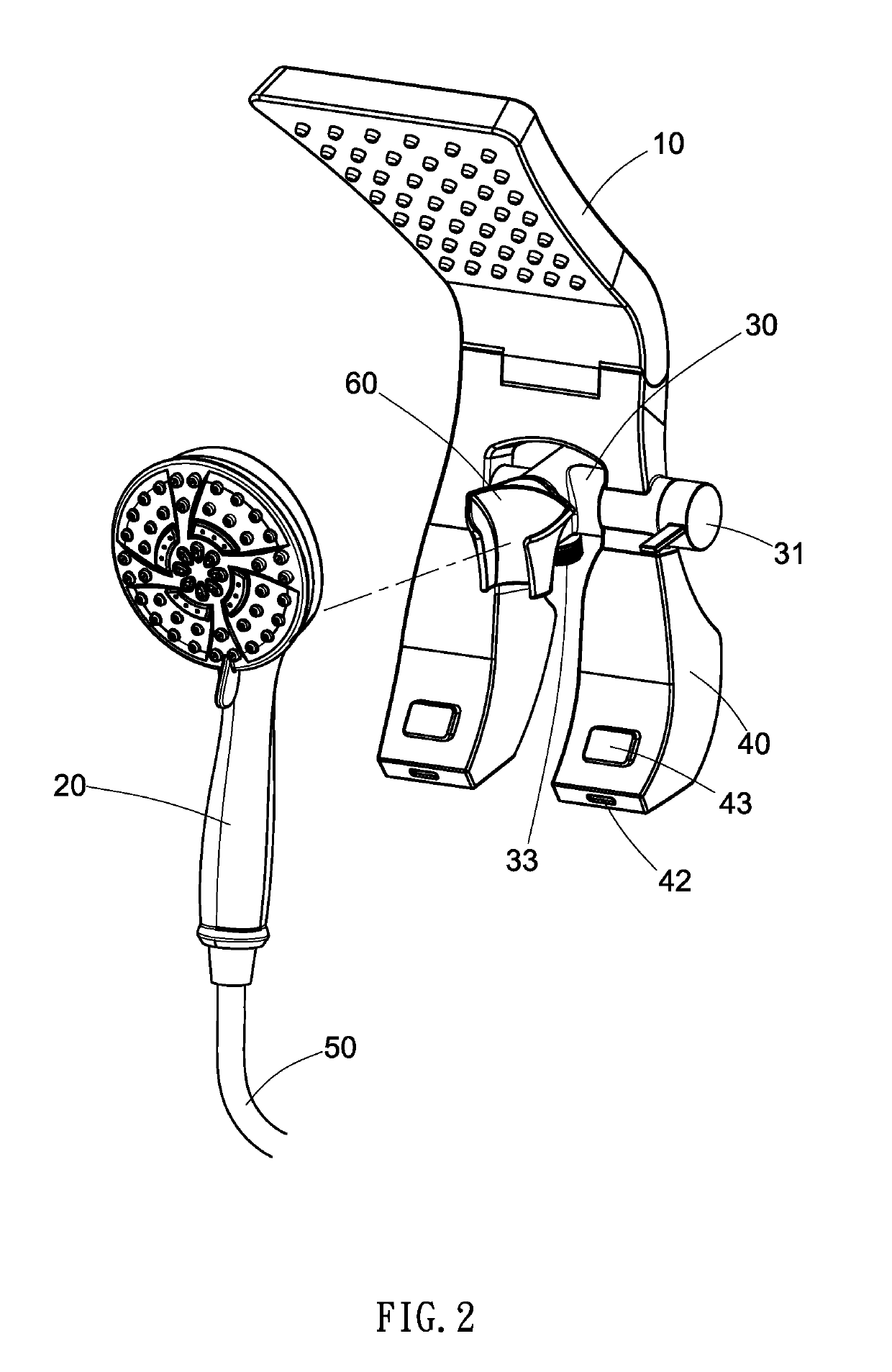

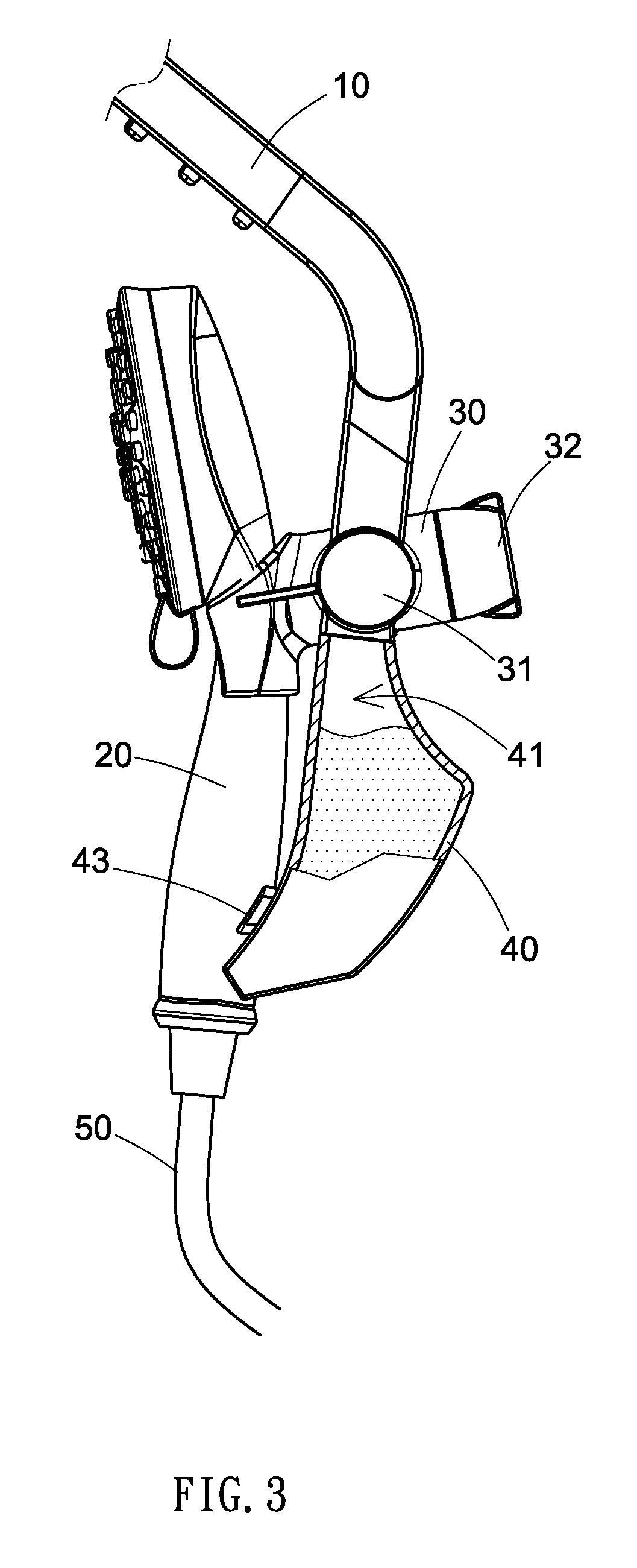

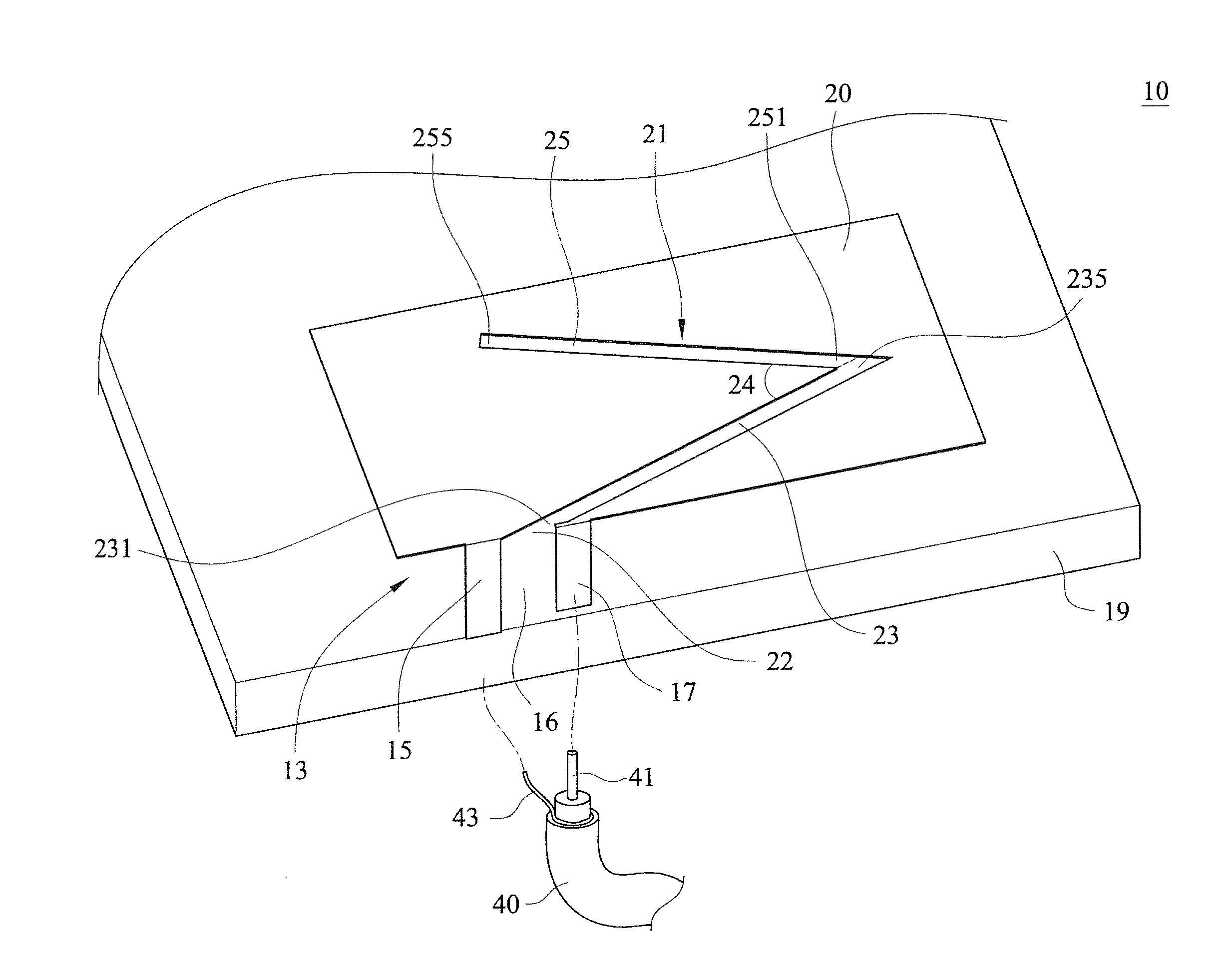

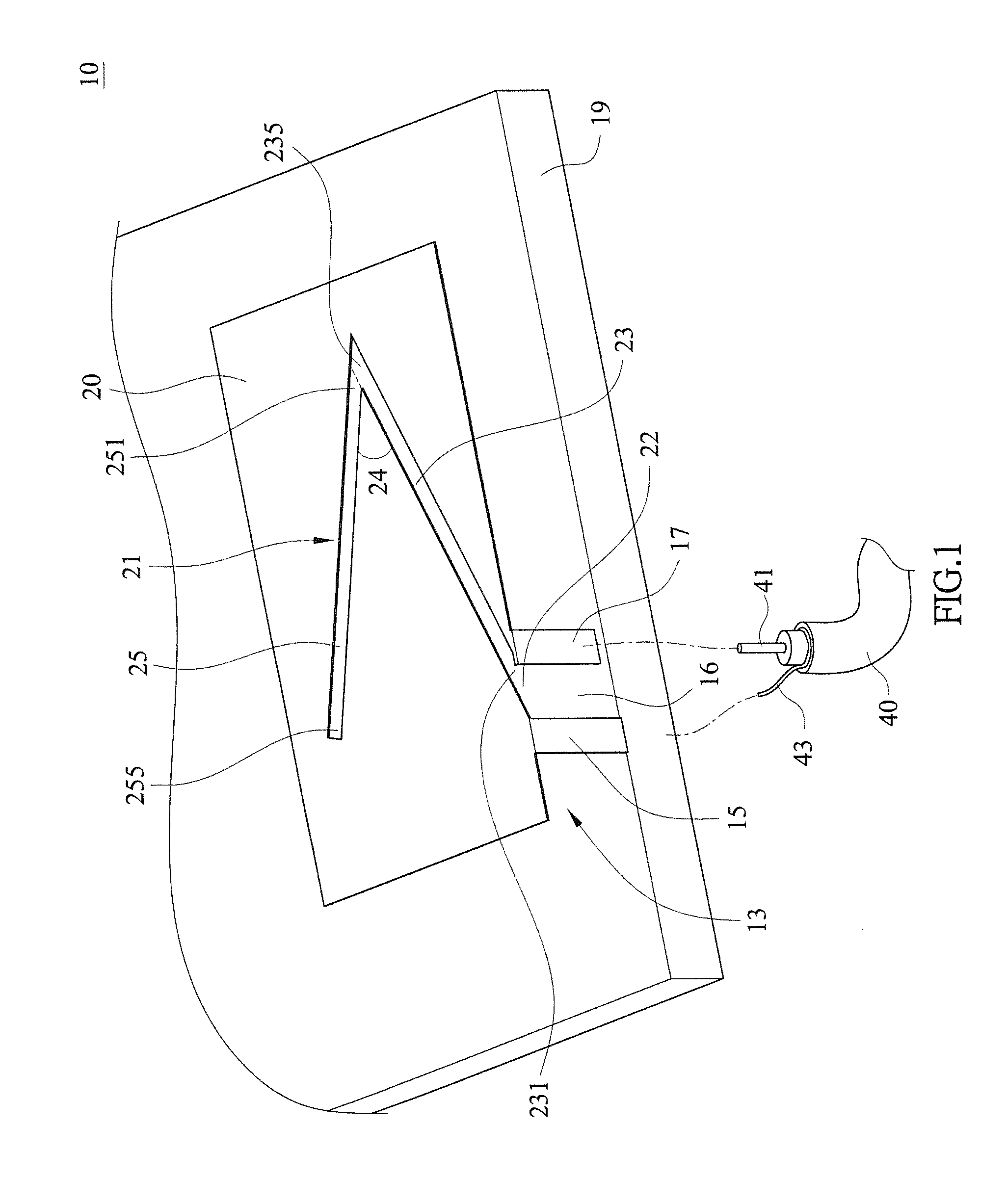

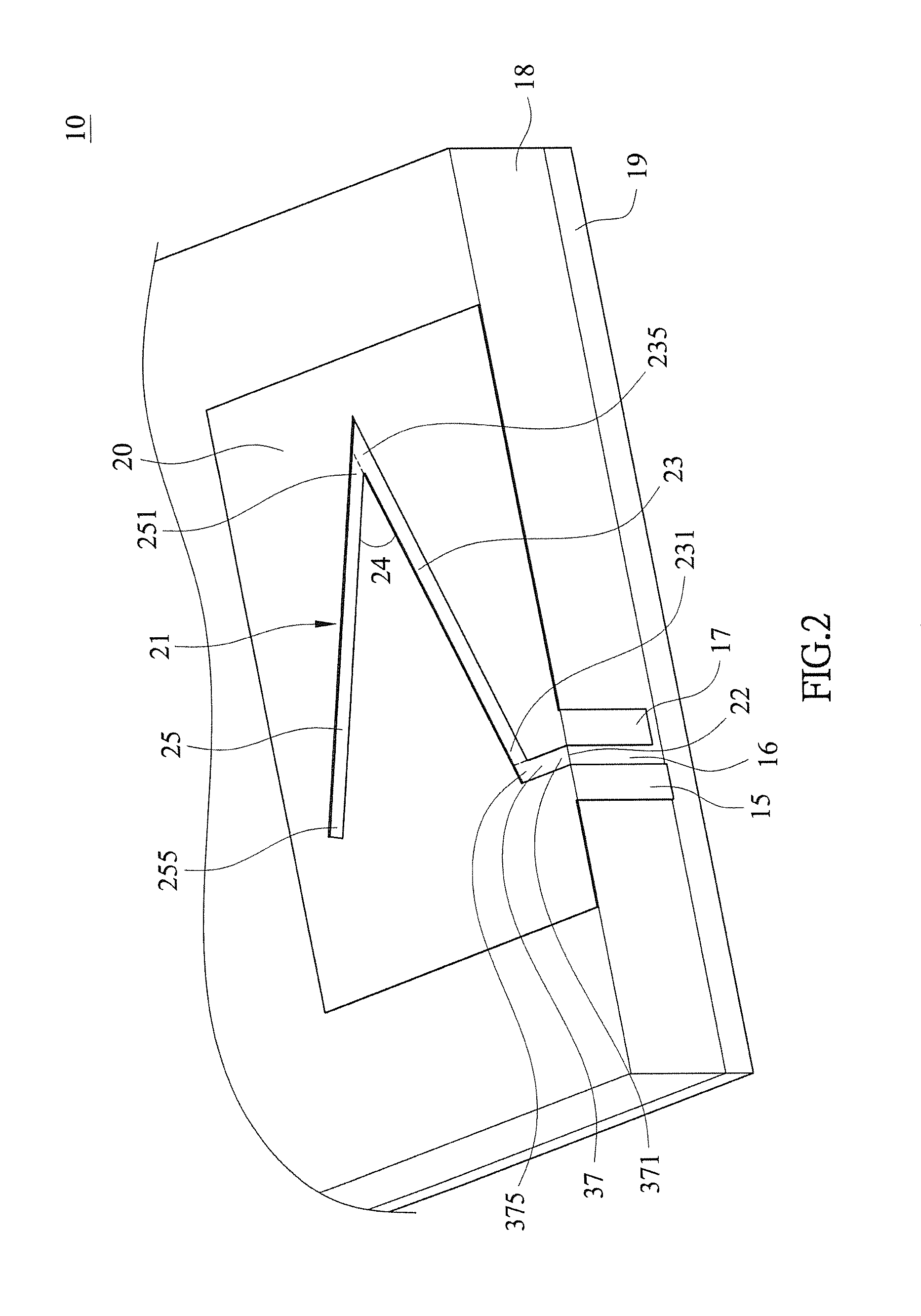

Shower structure with soap supply function

InactiveUS20190301147A1Ensure aesthetic appearanceEnsure appearanceBathsDouchesEngineeringSoap dispenser

A shower structure with a soap supply function includes a top shower head, a handheld shower head, and a water separator with a switching button. The water separator has two water outlets coupled to the top shower head and the handheld shower head respectively. A soap dispenser with at least one containing space is installed at the external periphery of the water separator, and a liquid outlet is formed on a free side, and a press button is installed on a side of the soap dispenser. The press button may be press to dispense a soap stored in the soap dispenser flows out from the liquid outlet. The shower structure not just ensures the aesthetic appearance of the shower space only, but also allows users to identify and use the soap clearly and conveniently.

Owner:WU CHIN LUNG +1

Manufacturing method of porous volcanic aggregate concrete sleeper

InactiveCN106007510AEnsure appearanceEnsure compressive strengthSolid waste managementBallastwayTemperature controlPre stress

The invention discloses a manufacturing method of a porous volcanic aggregate concrete sleeper, and belongs to the technical field of sleeper production. The manufacturing method comprises the steps of concrete raw material preparation, porous volcanic aggregate pre-treatment preparation, porous volcanic aggregate concrete preparation, pre-stressed wire frame binding, steel mould placement and tensioning, porous volcanic aggregate concrete pouring and vibration compaction forming, adoption of automatic temperature-controlled steam curing, releasing and demoulding. According to the manufacturing method of the porous volcanic aggregate concrete sleeper, disclosed by the invention, by reasonably blending the proportion of porous volcanic aggregate concrete and regulating technological parameters in a construction process, the porous volcanic aggregate concrete sleeper which can be used for the tropical zone, is light in mass and high in strength is prepared.

Owner:CCCC TUNNEL ENG +1

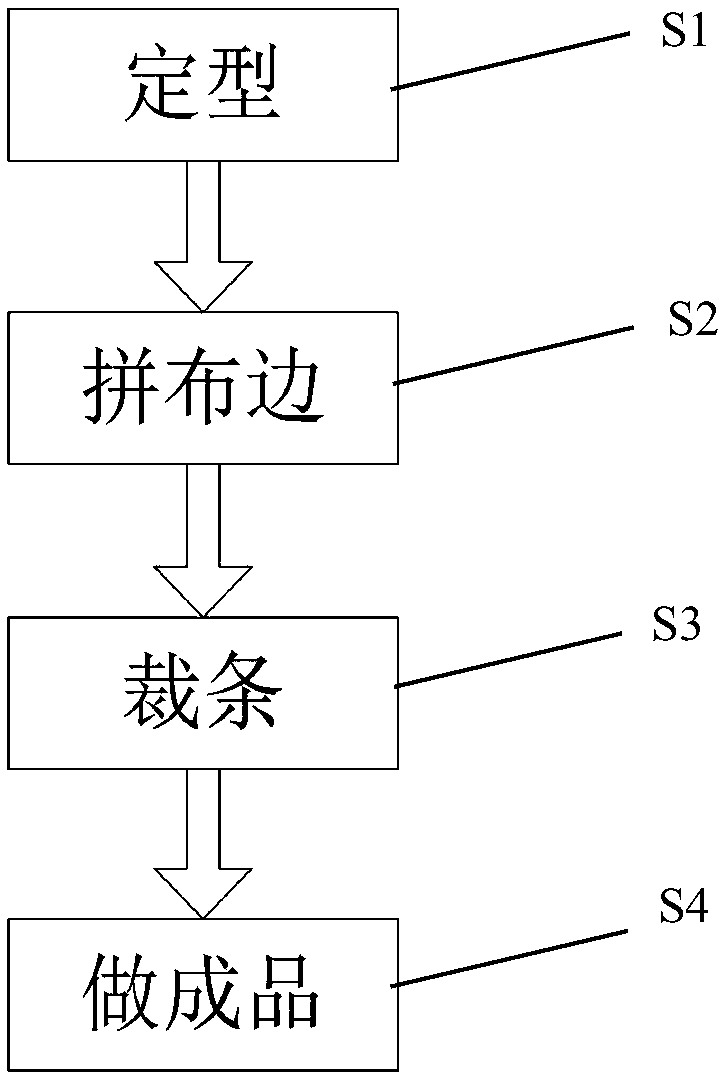

Preparation method for continuous fiber-reinforced thermoplastic composite seat base plate front end part

ActiveCN110614746AAvoid deformation damageEnsure appearanceCoatingsEngineeringThermoplastic composites

The invention discloses a preparation method for a continuous fiber-reinforced thermoplastic composite seat base plate front end part, which includes the following steps: step 1, cutting a continuousfiber-reinforced thermoplastic composite sheet; step 2, feeding the cut continuous fiber-reinforced thermoplastic composite sheet to a drying oven for heating and softening; step 3, conveying the softened continuous fiber-reinforced thermoplastic composite sheet to a fixed die of a mould pressing injection mold, wherein a moving die of the mould pressing injection mold is provided with a pluralityof top blocks to sequentially compacting parts of the continuous fiber-reinforced thermoplastic composite sheet to the fixed die; step 4, performing die assembly to the moving die and the fixed die of the mould pressing injection mold for injection molding and pressure maintaining, and opening the mould to obtain the continuous fiber-reinforced thermoplastic composite seat base plate front end part. The method provided by the invention can solve the lacking of sheets near to an elongation hole or lacking of outer side edge sheets of the seat base plate front end part, and the fact that the sheet completely covers the seat base plate front end part is guaranteed.

Owner:JIANGSU CHANGSHU AUTOMOTIVE TRIM GRP CO LTD

Vehicle interior parts

InactiveUS7874577B2Stable stateImpart stabilityPedestrian/occupant safety arrangementEngineeringAirbag

An automotive interior component according to the present invention includes: an interior component attached to a vehicle body panel at an interior side of a vehicle; an airbag installed in a gap between the vehicle body panel and the interior component; an expanding portion defined in a partial region of the interior component, the expanding portion turning in an expansion direction of the airbag to expose an opening; first locking means made up of a first locking piece provided at a rim of the expanding portion and a first engagement portion provided at a fixed portion with which the rim of the expanding portion comes into contact, receiving the first locking piece to lock movement of the expanding portion in a turning direction; and second locking means made up of a second locking piece provided at the rim of the expanding portion and a second engagement portion provided at the fixed portion with which the rim of the expanding portion comes into contact, receiving the second locking piece to lock movement of the expanding portion in a turning radial direction.

Owner:KASAI KOGYO CO LTD

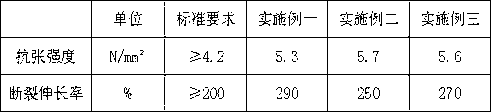

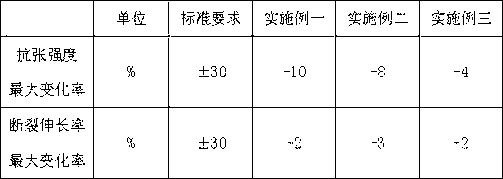

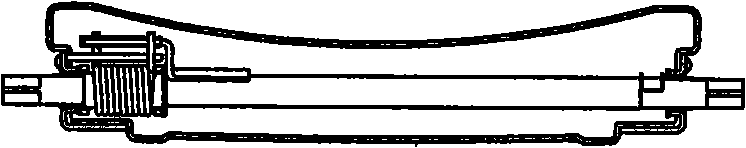

Pre-dispersing masterbatch for rubber accelerator ETU (N,N-ethylene thiourea) and preparation method of pre-dispersing masterbatch

The invention discloses pre-dispersing masterbatch for an rubber accelerator ETU (N,N-ethylene thiourea) and a preparation method of the pre-dispersing masterbatch. The pre-dispersing masterbatch comprises components in parts by weight as follows: 72-82 parts of ETU, 8-16 parts of rubber carriers, 2-4 parts of EVA (ethylene vinyl acetate copolymer) resin, 1-3 parts of epoxidized methyl acetorieinoleate, 2-4 parts of saturated fatty acid zinc, 1-8 parts of naphthenic oil and 1-3 parts of color masterbatch. The pre-dispersing masterbatch for the rubber accelerator ETU is convenient to store, transport and weigh, the preparation method of the pre-dispersing masterbatch is simple and high in operability, original activity of ETU can be guaranteed, the problems that ETU is prone to agglomeration and is non-uniform in dispersion when directly put into rubber for mixing are solved, the problem of ETU dust pollution can be solved, and the health problem of an operator caused by inhalation of ETU dust is solved; besides, the masterbatch is colored, so that material identification and management are facilitated, mistaken charging caused by the operator during feeding for follow-up rubber product mixing is avoided, and the application of the color masterbatch has no influence on colors of follow-up prepared rubber products.

Owner:NINGBO ACTMIX POLYMER

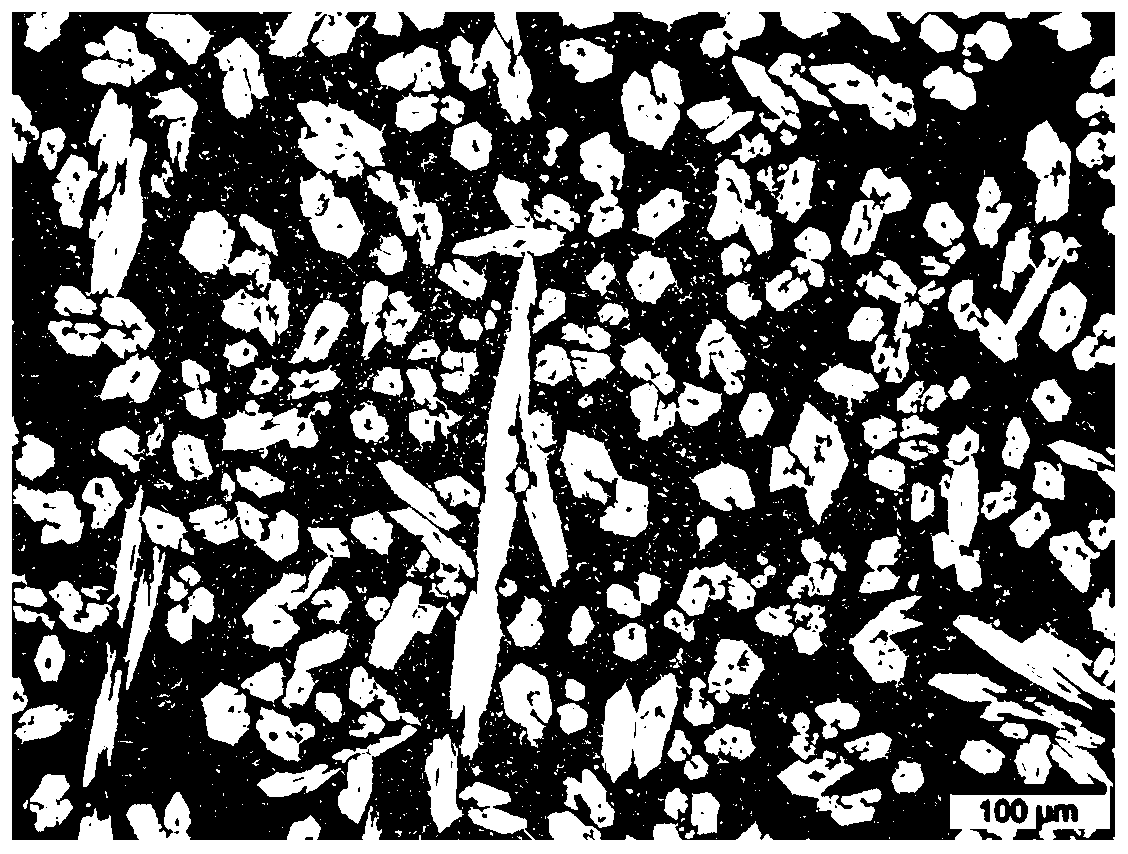

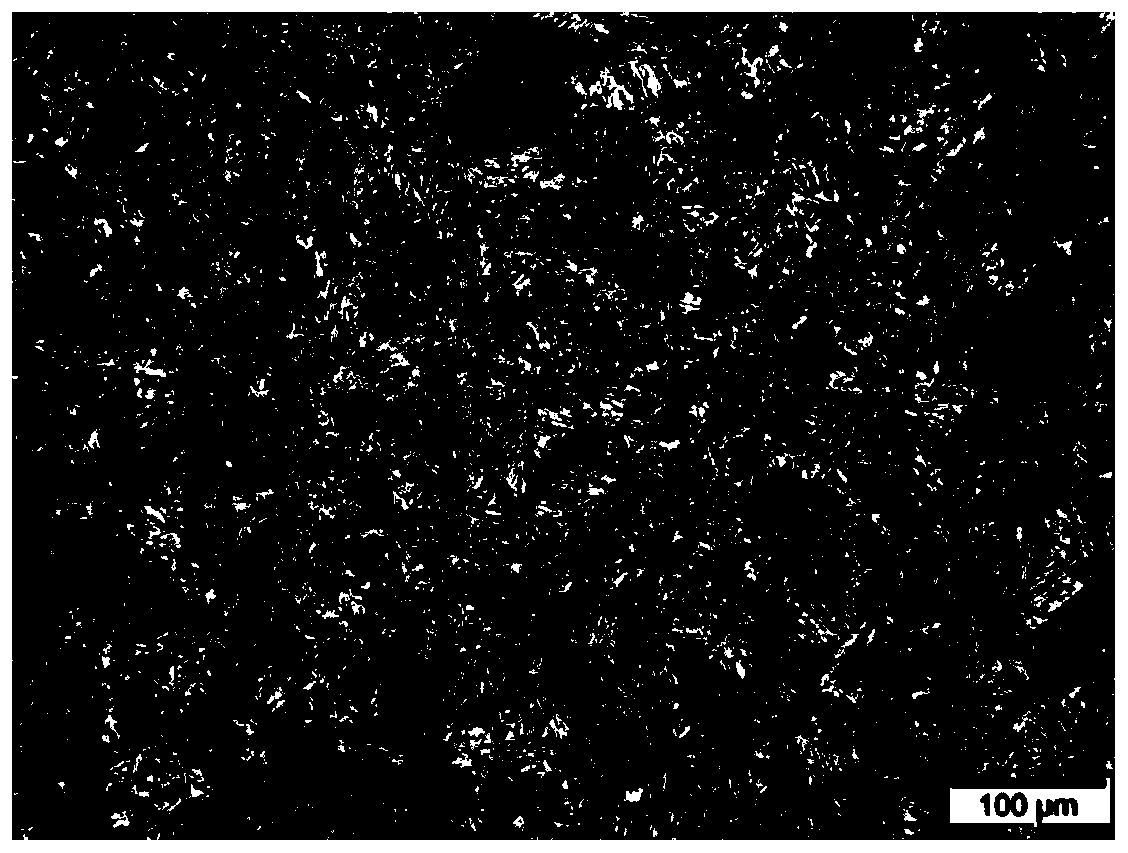

Heat treatment method of iron-based wear-resistant coating plough shovel tip

ActiveCN110592357AImprove quality stabilityShort holding timeMolten spray coatingFurnace typesWear resistantHardness

The invention relates to the field of production and processing of agricultural implements, in particular to a heat treatment method of an iron-based wear-resistant coating plough shovel tip. According to the method, a boron steel material plough shovel tip is taken as a substrate, and the plough shovel tip substrate is coated with an iron-based wear-resistant layer by adopting a plasma spray welding technology; the plough shovel tip coated with the wear-resistant layer by plasma spray welding is heated to the temperature higher than austenitizing temperature in an induction heating mode, subjected to heat preservation for a certain time, quickly transferred into a salt bath for quenching, and placed in air for cooling after being quenched, and self tempering is achieved by utilizing material characteristics. By adopting the plough shovel tip produced by the method, quenching secondary cracking of the wear-resistant layer can be basically avoided, the production cost is low, and the batch stability is good. After the heat treatment, the hardness of the wear-resistant layer is more than 63HRC, the hardness of the matrix is more than 45HRC, the impact toughness (akv) of the matrix reaches 30J / cm<2>, and the product performance and service life are greatly higher than those of similar products in China.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Salt corrosion resistant and twisting resistant control cable for ocean wind power and manufacturing method of control cable

ActiveCN103227000AReduce tensionEliminate voidsRubber insulatorsInsulated cablesCopper conductorInsulation layer

The invention relates to a salt corrosion resistant and twisting resistant control cable for ocean wind power and a manufacturing method of the control cable. A stranded copper conductor is uniformly wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form a control cable insulated core; a plurality of control cable insulated cores are mutually stranded to form a control cable core; the control cable core is wrapped in a low-strength non-woven fabric longitudinal wrap; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The control cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the control cable insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the control cable insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

Method for simply demounting copper tile from cylinder body of hydropower unit

InactiveCN108500896ALow costImprove general performanceMetal-working hand toolsThermal expansionCopper

The invention discloses a method for simply demounting a copper tile from a cylinder body of a hydropower unit. Through the difference of thermal expansion coefficients of different materials, the friction force of the copper tile and the cylinder body is reduced through liquid nitrogen; and through the structure of a container barrel, a pressure bearing plate, a jack and a pressure bearing frame,force is applied to stably press the copper tile out of the cylinder body, and the technical effect that the cylinder body and the copper tile do not suffer from any damage is achieved. According tothe method, the method for simply demounting the copper tile from the cylinder body of the hydropower unit is enriched, and the temporary repair significance on the construction site is great. The method has the beneficial effects of being easy to popularize, low in cost and obvious in effect.

Owner:HARBIN ELECTRIC MASCH CO LTD

Method for cultivating mesembryanthemum crystallinum

ActiveUS20210243974A1Ensure appearanceHigh speedFlowers cultivationMagnesium fertilisersMesembryanthemum cristallinumLight energy

The present invention relates to the field of soilless cultivation, in particular to a method for cultivating Mesembryanthemum crystallinum. The method involves the following steps: sowing; accelerating germination; growing seedlings; transplanting; separating seedlings; harvesting. In this method, Mesembryanthemum crystallinum is cultivated using a nutrient solution and under continuous indoor lighting; as a result, the Mesembryanthemum crystallinum has a shortened life cycle, no flowering period, and a long harvesting period. Edible salt is added to the nutrient solution at a specific ratio, which further promotes the growth of Mesembryanthemum crystallinum and changes its taste. Meanwhile, the nutrient solution of Mesembryanthemum crystallinum has a high EC, which promotes the growth of Mesembryanthemum crystallinum. In this method, the step of separating seedlings is carried out at a reasonable time to ensure the quality of Mesembryanthemum crystallinum growth, and to fully utilize light energy and growth space.

Owner:4D BIOS INC

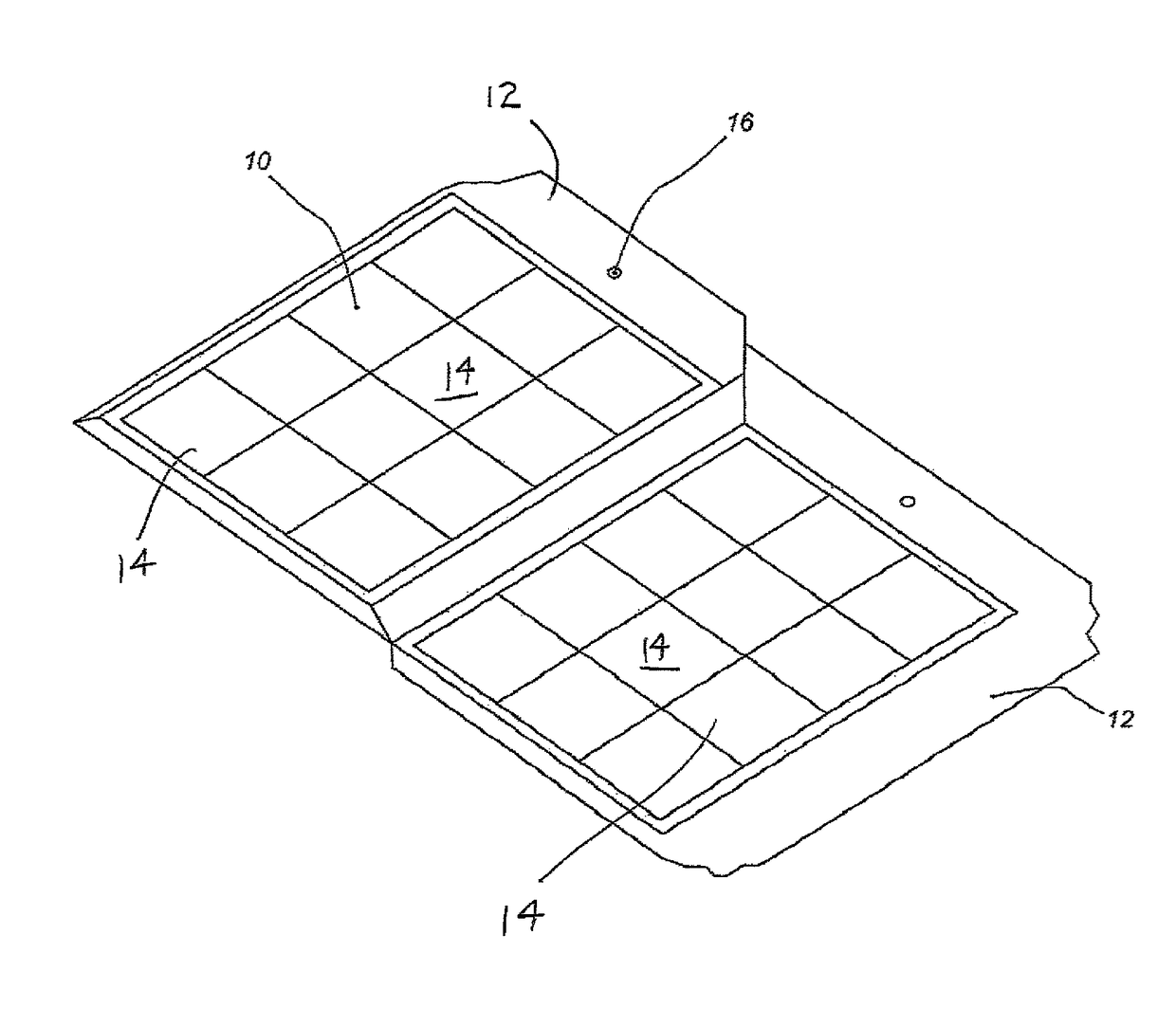

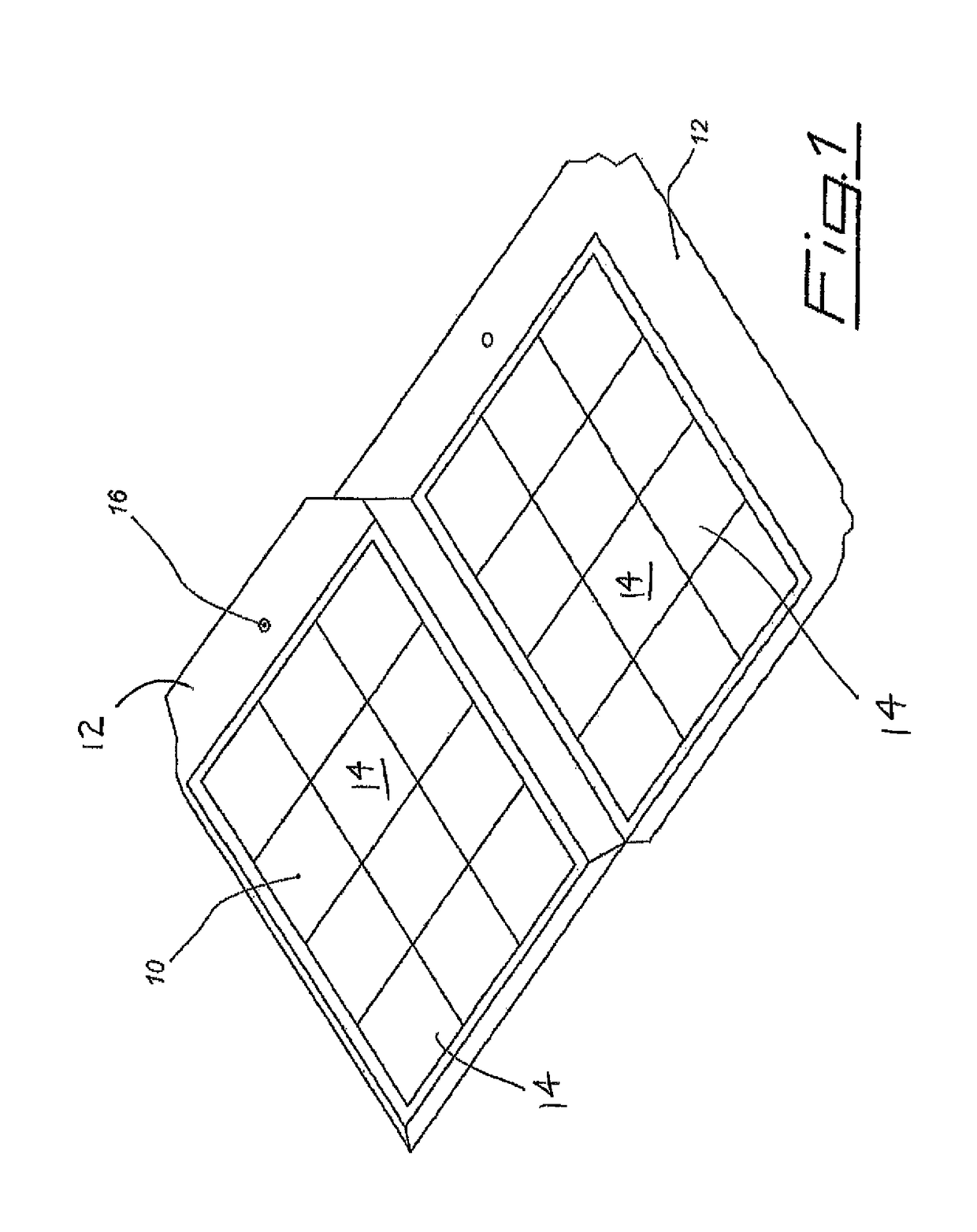

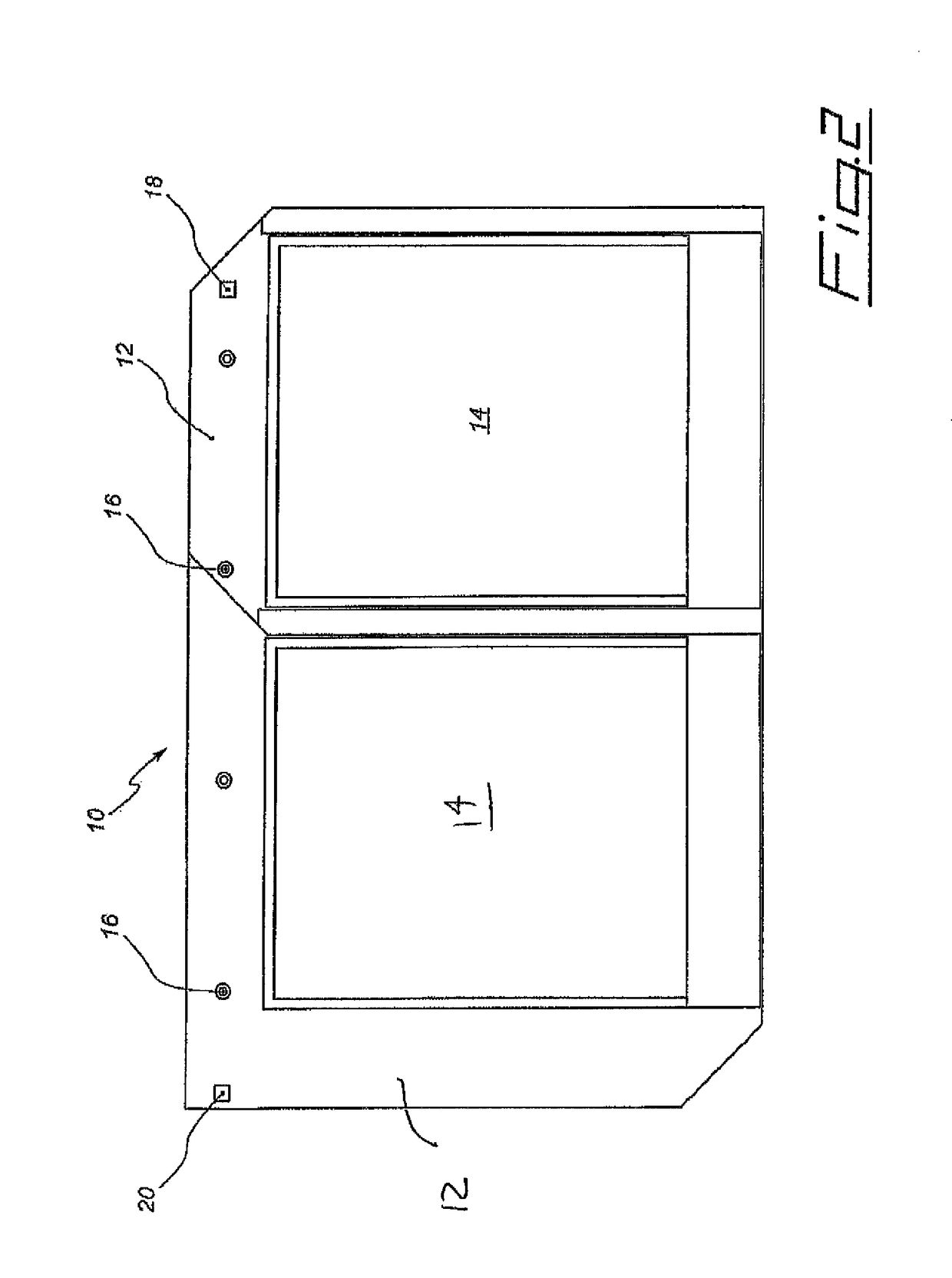

Photovoltaic tile

InactiveUS10103684B2Simply and cheaply implementedEnsure continuityPhotovoltaic supportsPhotovoltaic energy generationRafterElectrical connection

The invention concerns a photovoltaic tile free from wires and respective connectors for the electrical connections among tiles. The electrical connections are made by bushings integrated in the tiles, in the overlapping areas thereof, and electrically connected one to another by a removable pin connector. The assembly composes a roofing surface made of several equal or alike tiles, in case suitably interfaced, positioned on surfaces exposed to sun rays such as roofs, roofings or something else. The photovoltaic tile is provided with a frame made of plastic material with conventional means for fastening to the roof rafters and is characterized by means for a stable electrical and mechanical connection among adjacent tiles.

Owner:HOBBYT

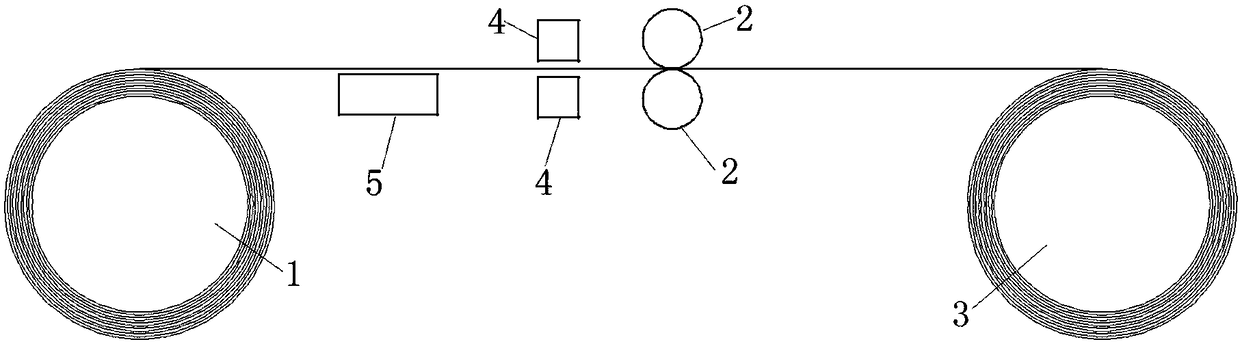

Rewinding machine for heat conduction film

The invention discloses a rewinding machine for a heat conduction film. The rewinding machine for the heat conduction film comprises at least one discharging shaft, a winding shaft and at least one suction assembly. The suction assembly is provided with at least one suction port. When the suction assembly works, the suction port faces the surface of one side of the heat conduction film located between the discharging shaft and the winding shaft. In the rewinding process, the discharging shaft is sleeved with the heat conduction film, and the heat conduction film pulled out of the discharging shaft is wound on the winding shaft; since the suction port faces the surface of one side of the heat conduction film when the suction assembly works, under the suction effect of negative pressure, scraps and solid foreign matter on the surface of the side of the heat conduction film are sucked into the suction assembly through the suction port, so that the scraps and solid foreign matter on the surface of the heat conduction film are reduced and even completely avoided, and thus, the appearance and performance of the heat conduction film meet requirements after the heat conduction film is calendered in the subsequent stage.

Owner:世星科技股份有限公司

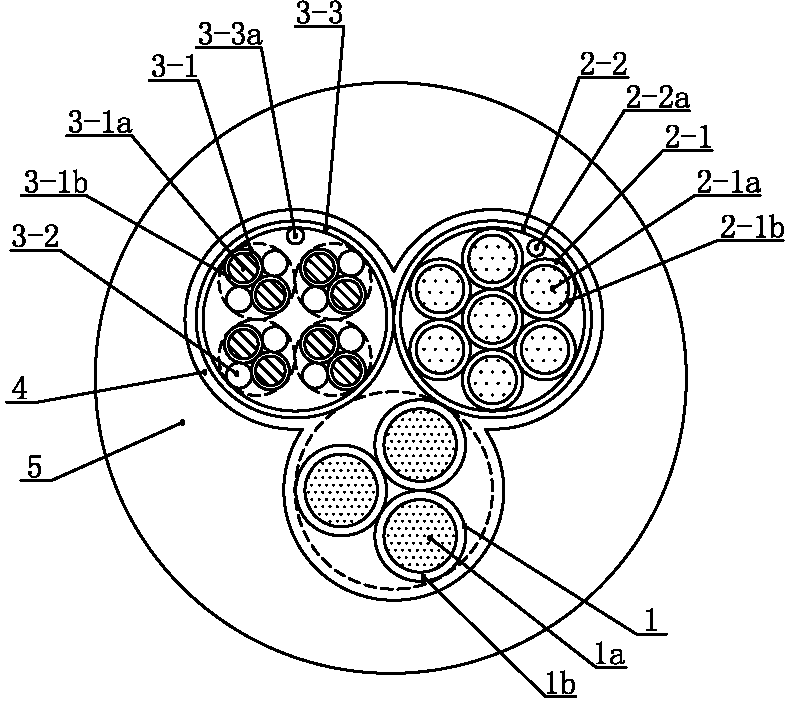

Salt corrosion resistant and twisting resistant composite cable for ocean wind power and manufacturing method of composite cable

ActiveCN103227007AReduce tensionEliminate voidsRubber insulatorsPower cables with screens/conductive layersElectricityCombustion

The invention relates to a salt corrosion resistant and twisting resistant composite cable for ocean wind power and a manufacturing method of the composite cable. Power cable insulation layers, control cable insulation layers and meter cable insulation layers are all salt corrosion resistant and twisting resistant rubber insulation layers and are mutually stranded to form a composite cable core; the composite cable core is wrapped in a low-strength non-woven fabric longitudinal wrap on the periphery; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The composite cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the insulated cores are eliminated convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

Salt corrosion-resistant and torsion-resistant telecommunication cable for offshore wind power and manufacturing method of telecommunication cable

ActiveCN103227009AEliminate voidsEase of transmissionRubber insulatorsInsulating conductors/cablesEngineeringElectrical conductor

The invention relates to a salt corrosion-resistant and torsion-resistant telecommunication cable for offshore wind power and a manufacturing method of the telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; pair-twist wire pairs adopt different stranding pitches, a plurality of groups of pair-twist wire pairs are stranded to form a cable core; the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; and a jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way. The telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the jacket is stripped during construction.

Owner:嘉兴君宏光学有限公司

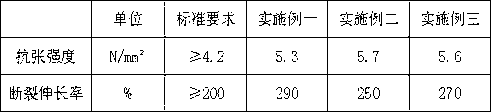

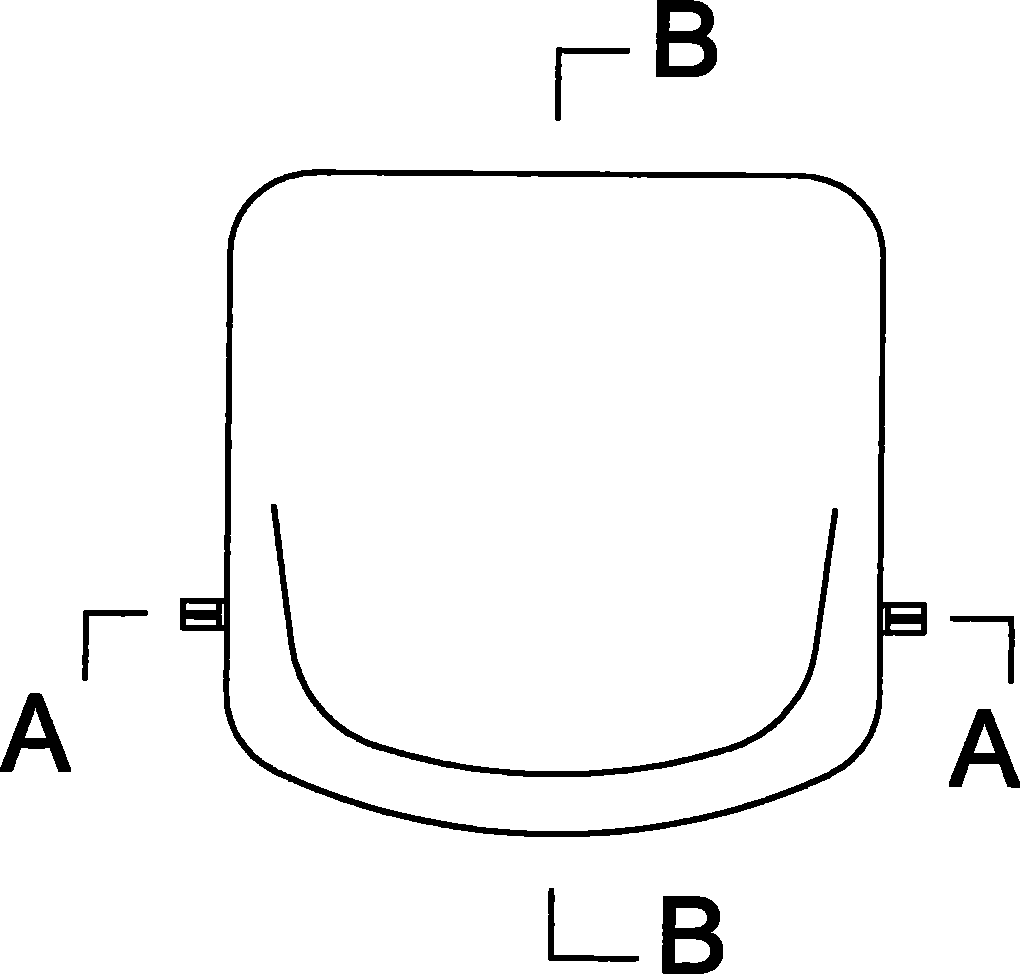

Chair counterbalanced by mortar

The invention discloses a chair counterbalanced by mortar, which is a hollow chair counterbalanced by mortar and relates to the field of chair equipment. the chair of the invention comprises a chair seat shell, a rotating shaft and 2 connecting plates, wherein the rotating shaft transversely penetrates in a position 1 / 3 of the length of a plastic seat near to the lower part of the chair seat shell; the 2 connecting plates is arranged at the two ends of the rotating shaft in a penetrated way and are positioned at two sides of the chair seat shell; the rotating shaft is rotatably connected with the chair seat shell and the 2 connecting plates, the chair seat shell comprises a bottom part of the chair seat shell; solidified mortar is in the bottom part of the chair seat shell, wherein the raw material formula of the mortar counterbalancing weight comprises the following components in mass percent: 25-35% of cement, 64-74% of coarse sand and 0.5-1.5% of glass fiber; and the height of the mortar counterbalancing weight is 1 / 5-1 / 7 of the height of the chair seat shell. Compared with the prior art, the invention has the beneficial effects of small turning and putting force, light sound, elegant appearance, simple manufacturing, durable use, fastness of surface and long service life, the material requested is the cheap mortar, the production cost is reduced, and an internal turning and putting mechanism can not be damaged due to frequent use.

Owner:ZHEJIANG DAFENG SPORTS EQUIP

Salt corrosion-resistant and torsion-resistant composite cable and manufacturing method thereof

InactiveCN106653152AReduce tensionEliminate voidsRubber insulatorsPower cables including communication wiresInsulation layerCombustion

The invention relates to a salt corrosion-resistant and torsion-resistant composite cable and a manufacturing method thereof. A power cable insulation layer, a control cable insulation layer and an instrument cable insulation layer are salt corrosion-resistant and torsion-resistant rubber insulation layers. A power cable core, a control cable core and an instrument cable core are twisted into a composite core. The periphery of the composite core is coated with a low-intensity non-woven longitudinal cladding. A sheath is arranged at the periphery of the low-intensity non-woven longitudinal cladding by means of extrusion. The low-intensity non-woven longitudinal cladding which has a shape completely consistent with the appearance of an insulated wire core is adopted, and the gap between the low-intensity non-woven longitudinal cladding and the insulated wire core is eliminated, so that flame can be prevented from spreading to the inside under the condition of combustion, and the resistance to moisture impregnation can be enhanced. Moreover, the low-intensity non-woven longitudinal cladding can ensure that the sheath and the insulated wire core are not adhered together, and the insulated wire core is not damaged when the sheath is tripped in the process of construction.

Owner:重庆三峡电线电缆科技股份有限公司

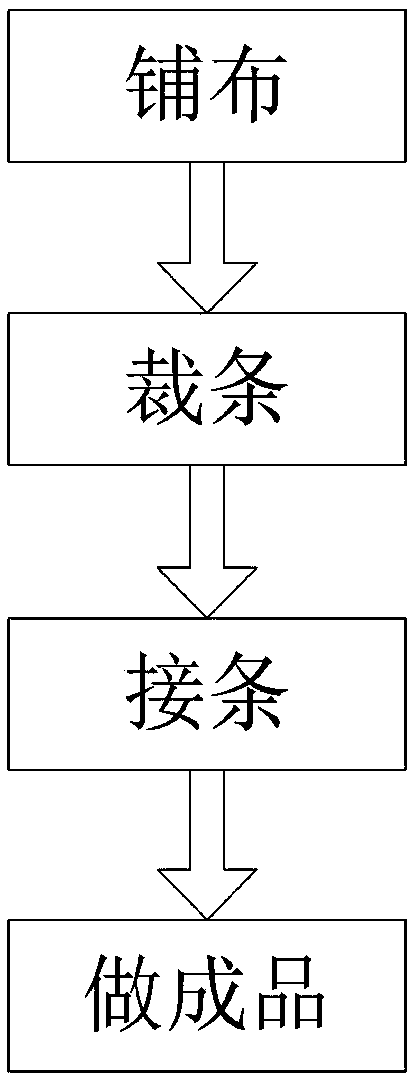

Fabric skewing improvement method

InactiveCN109695156AImprove operational reliabilityEnsure qualityFibre typesSocial benefitsEconomic benefits

The invention discloses a fabric skewing improvement method. The method comprises a step of shaping cloth with rice syrup. According to the method, material characteristics are combined with targetedselection to shape materials, so that the method is simple, environmentally friendly and high in operational reliability, and is capable of ensuring the quality and appearance of products; the selected material is slurry prepared by a plant, so that the material is low in cost, free of pollution and convenient in post-treatment. By adoption of the method, the process of binding bundles can be decreased, the material supplementation cost is decreased, the production efficiency is improved, and the integrated production cost is reduced; and the method is wide in applicability, can be applied toother fabrics needing shaping, and can produce better social benefits and greater economic benefits.

Owner:SUZHOU MEISHANZI GARMENTS CO LTD

Antenna structure

InactiveUS20160301142A1Improve antenna efficiencyImprove bandwidth efficiencyElectrically short antennasSlot antennasBroadbandMetal backed

The present invention provides an antenna structure, using a metal radiation plate having at least one bending slot and a metal grounding plate, where a starting end of the metal radiation plate is located on an edge of the metal radiation plate. A feed plate and a connecting grounding plate are separately connected to two sides of a starting end of the slot, and two ends of the connecting grounding plate may be separately connected to the metal radiation plate and the metal grounding plate. The feed plate may be connected to a core wire of a coaxial cable, and a peripheral conductor of the coaxial cable is connected to the metal grounding plate, so that different resonant modes can be controlled. The antenna can achieve a broadband effect, thereby solving the problem of the metal shielding effect in a wireless communication product using a full-metal back cover.

Owner:NAT TAIWAN UNIV

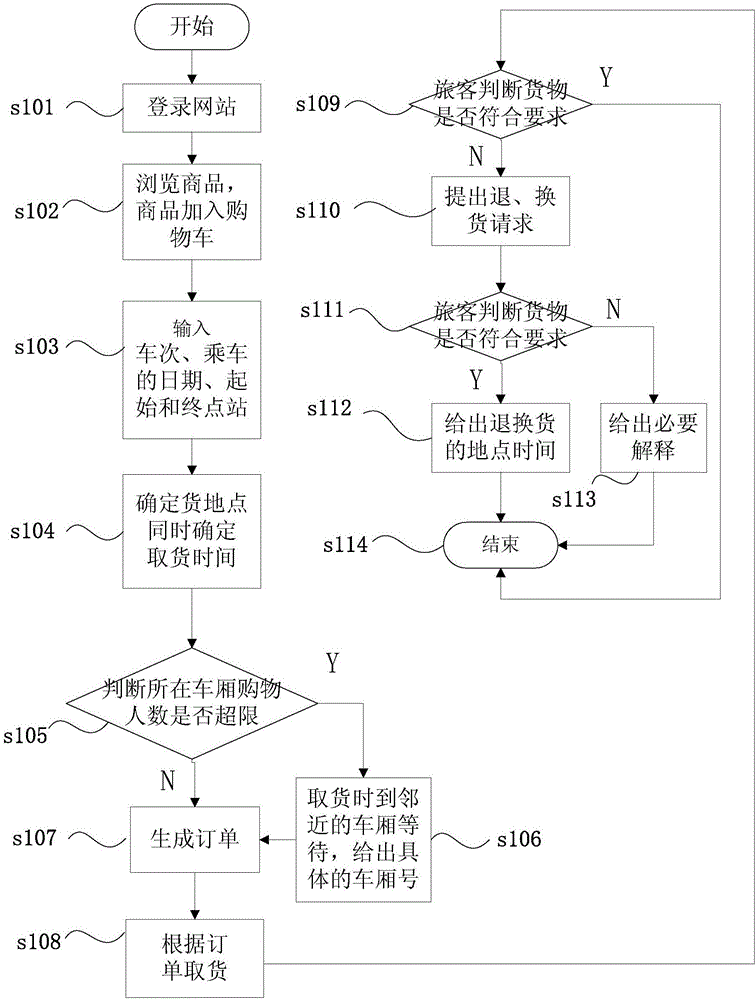

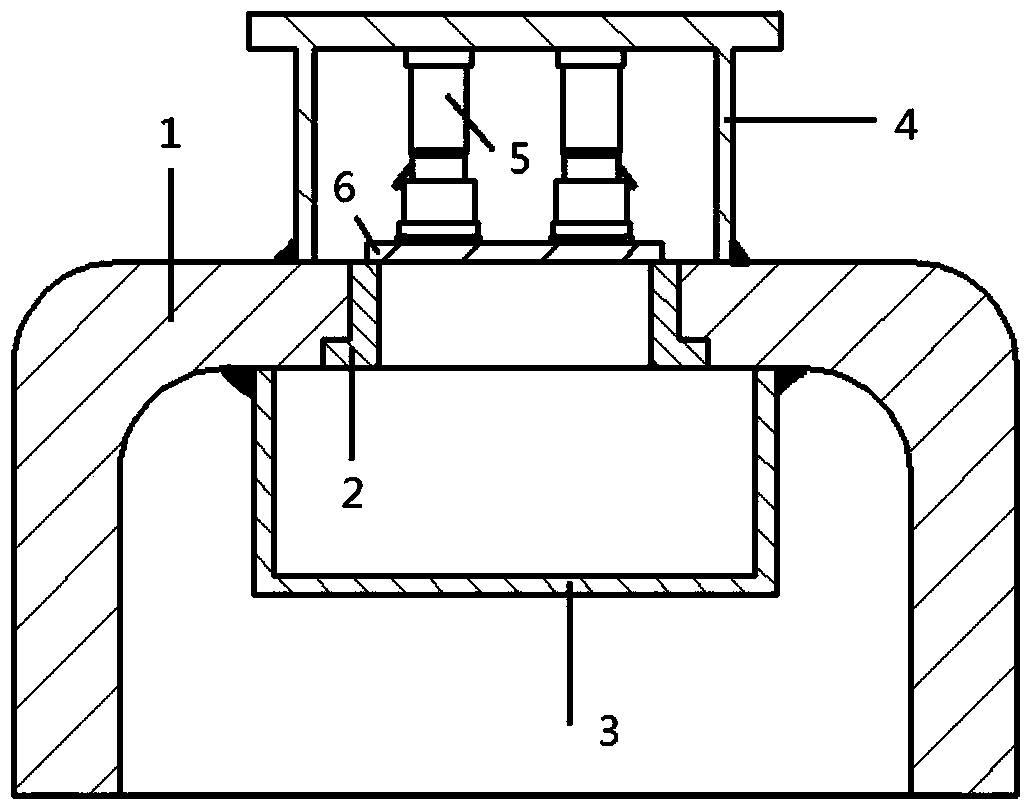

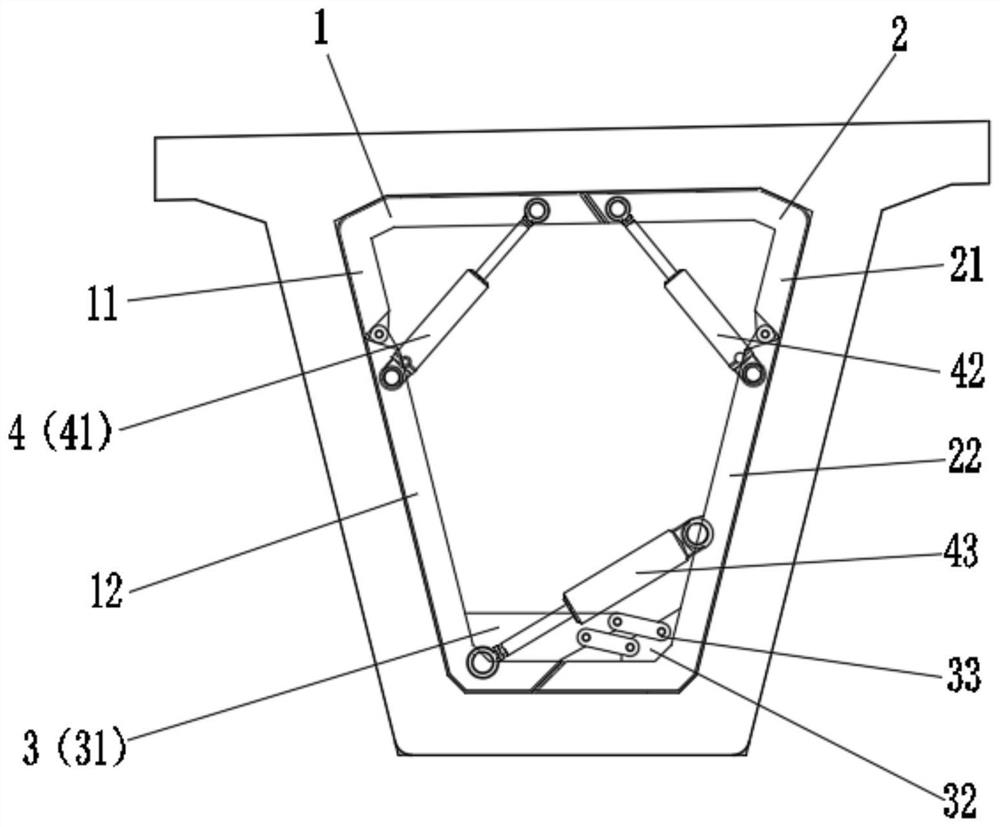

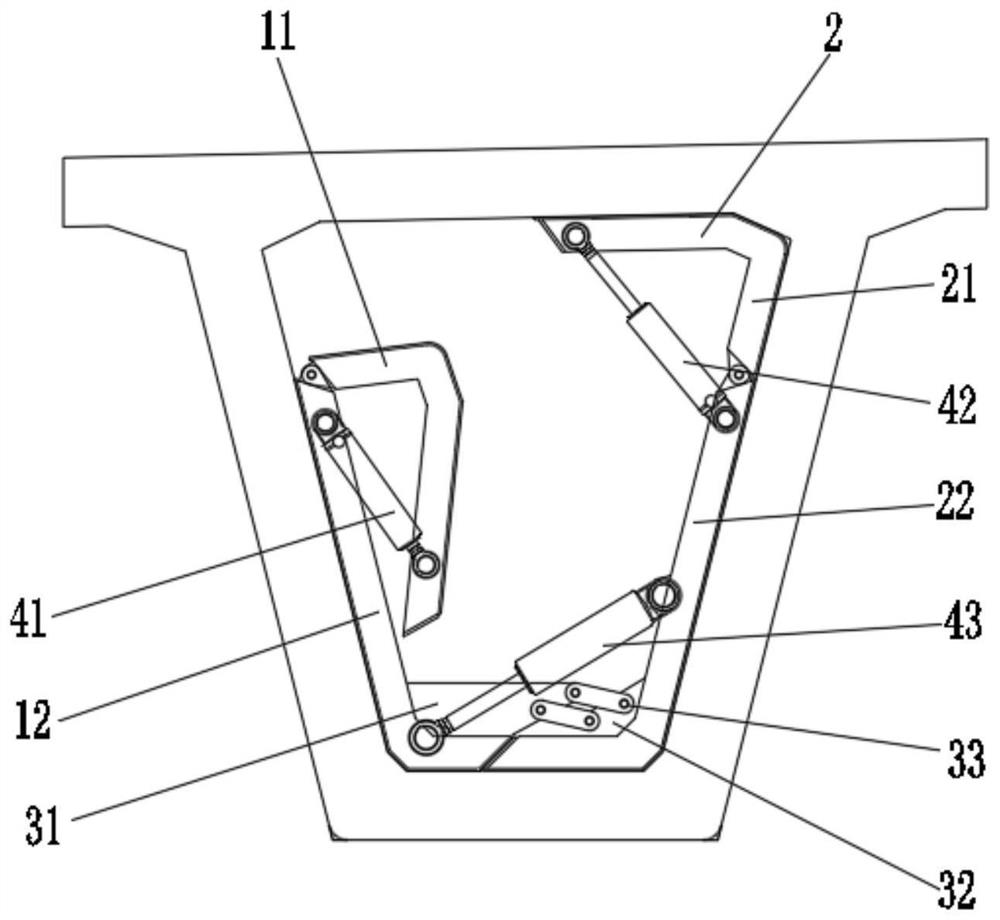

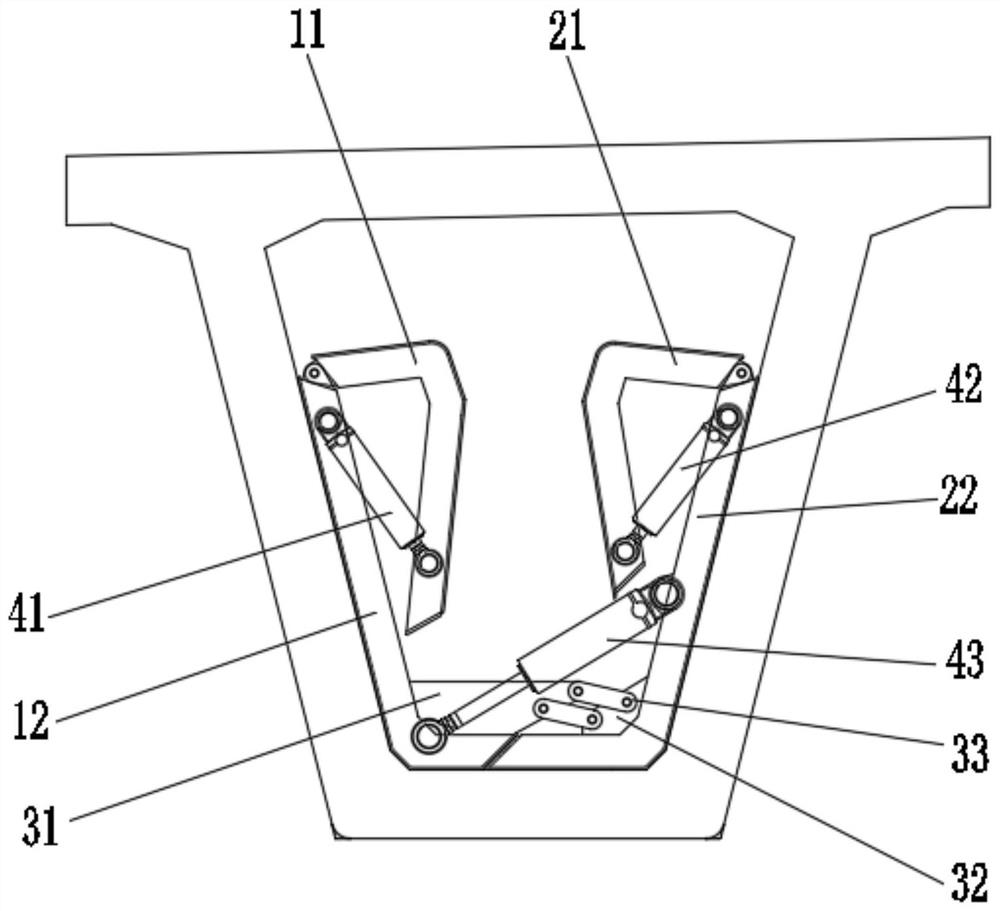

Closed internal mold suitable for small box girder

PendingCN114851364AStable structureEasy constructionCeramic shaping mandrelsCeramic shaping coresStructural engineeringMechanical engineering

The invention discloses a closed inner mold suitable for a small box girder. The closed inner mold comprises a first side mold assembly, a second side mold assembly, a track control mechanism and a telescopic assembly. The track control mechanism is used for connecting the first side mold assembly and the second side mold assembly into a whole and can enable the first side mold assembly and the second side mold assembly to be oppositely closed or opened along a set track. The telescopic assembly is used for driving the first side mold assembly and the second side mold assembly to define a closed inner mold shape when being unfolded, and the whole section is smaller than a beam end outlet when the inner mold is contracted and folded. The device has the advantages of being stable in structure, large in inner cavity operation space, easy to construct, economical, practical and the like, the problem that in the prior art, a formwork cannot be installed in a partial area of an inner formwork of a small box girder is solved, the problem that manual pouring and plastering are needed after demolding is further solved, and the construction efficiency of the box girder is remarkably improved.

Owner:湖南五新智能科技股份有限公司

Salt-corrosion-resistant torsion-resistant double-shielded communication cable for marine wind power and manufacturing method thereof

ActiveCN103227012BEasy not to hurtEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorElectricity

The invention relates to a salt corrosion resistant and twisting resistant double-shielded communication cable for ocean wind power and a manufacturing method of the communication cable. Each stranded copper conductor is wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form an insulated core; each two insulated cores are stranded to form a twisted pair of which the gaps are filled with fillers; each twisted pair is wrapped in a twisted pair copper foil shielding layer to form a twisted-pair group; the twisted-pair groups are mutually stranded to form a cable core; and the cable core is wrapped in a low-strength non-woven fabric longitudinal wrap, an inner sheath, a cable core copper foil shielding layer and an outer sheath in sequence from inside to outside. The communication cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheaths are not stuck to the insulated cores, and provides convenience for stripping the sheathes in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

Salt-corrosion-resistant torsion-resistant overall shielded communication cable for marine wind power and manufacturing method thereof

ActiveCN103227011BReduce tensionEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorTelecommunications cable

The invention relates to a salt corrosion-resistant and torsion-resistant integral shielding telecommunication cable for offshore wind power and a manufacturing method of the integral shielding telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; a plurality of groups of pair-twist wire pairs are stranded to form a cable core; and the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer, an inner jacket, a copper foil polyester composite belt shielding layer and an outer jacket sequentially from the inside out. The integral shielding telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the inner jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the inner jacket is stripped during construction.

Owner:浙江华威设备制造有限公司

Salt-corrosion-resistant torsion-resistant communication cable for offshore wind power and method for manufacturing the same

ActiveCN103227009BReduce tensionEliminate voidsRubber insulatorsInsulating conductors/cablesCopper conductorTelecommunications cable

The invention relates to a salt corrosion-resistant and torsion-resistant telecommunication cable for offshore wind power and a manufacturing method of the telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; pair-twist wire pairs adopt different stranding pitches, a plurality of groups of pair-twist wire pairs are stranded to form a cable core; the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; and a jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way. The telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the jacket is stripped during construction.

Owner:浙江华威设备制造有限公司

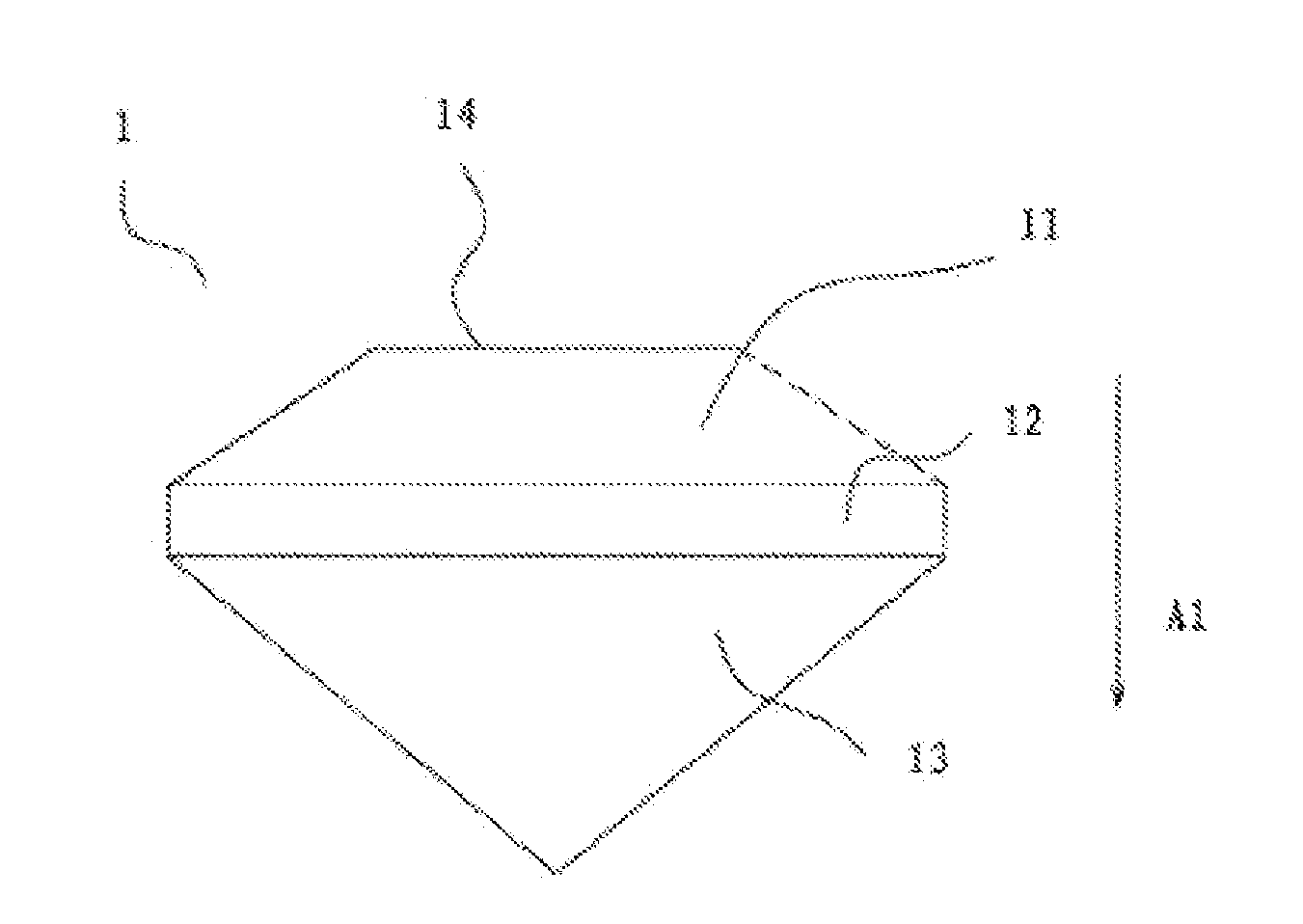

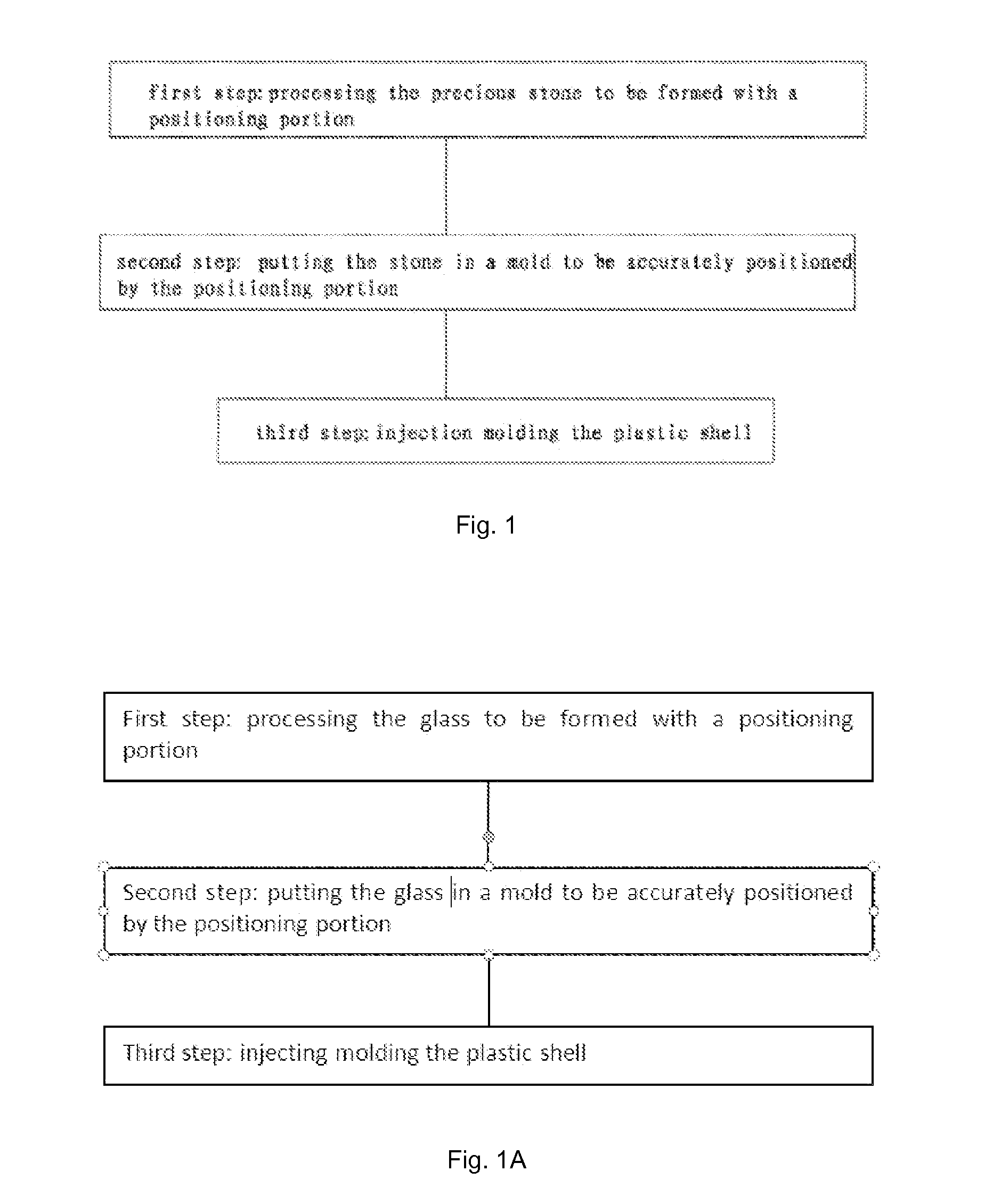

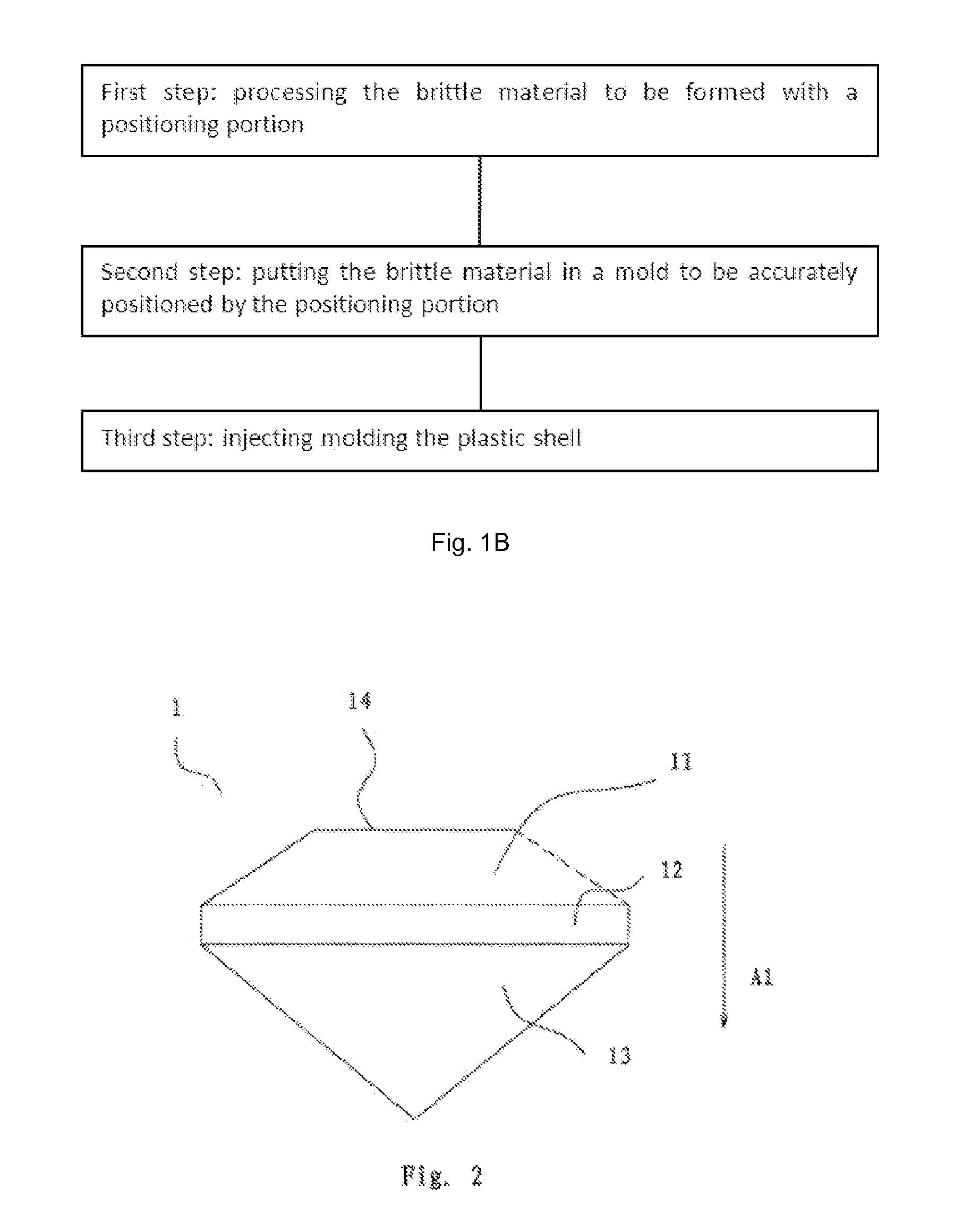

Method of inserting brittle material in plastic shell and electronic device having the plastic shell

InactiveUS20110109210A1Ensure aesthetic appearanceEnsure appearanceOrnamental structuresCasings/cabinets/drawers detailsEngineeringMechanical engineering

A method of inserting a brittle material into a plastic shell comprises: a) processing the brittle material, so that the brittle material comprises an embedded portion to be embedded into the plastic shell, an exposed portion to be exposed outside the plastic shell, and a positioning portion between the embedded portion and the exposed portion; b) putting the exposed portion and at least part of the position portion into a fixed mold core of an injection mold, with the brittle material being positioned in the fixed mold core by the positioning portion; and c) injecting molten plastic into the mold to form the plastic shell, in which the embedded portion and at least part of the positioning portion are embedded into the plastic shell with the exposed portion and the remaining or the positioning portion being exposed outside the plastic shell. An electronic device having the above plastic shell is also provided.

Owner:BYD CO LTD

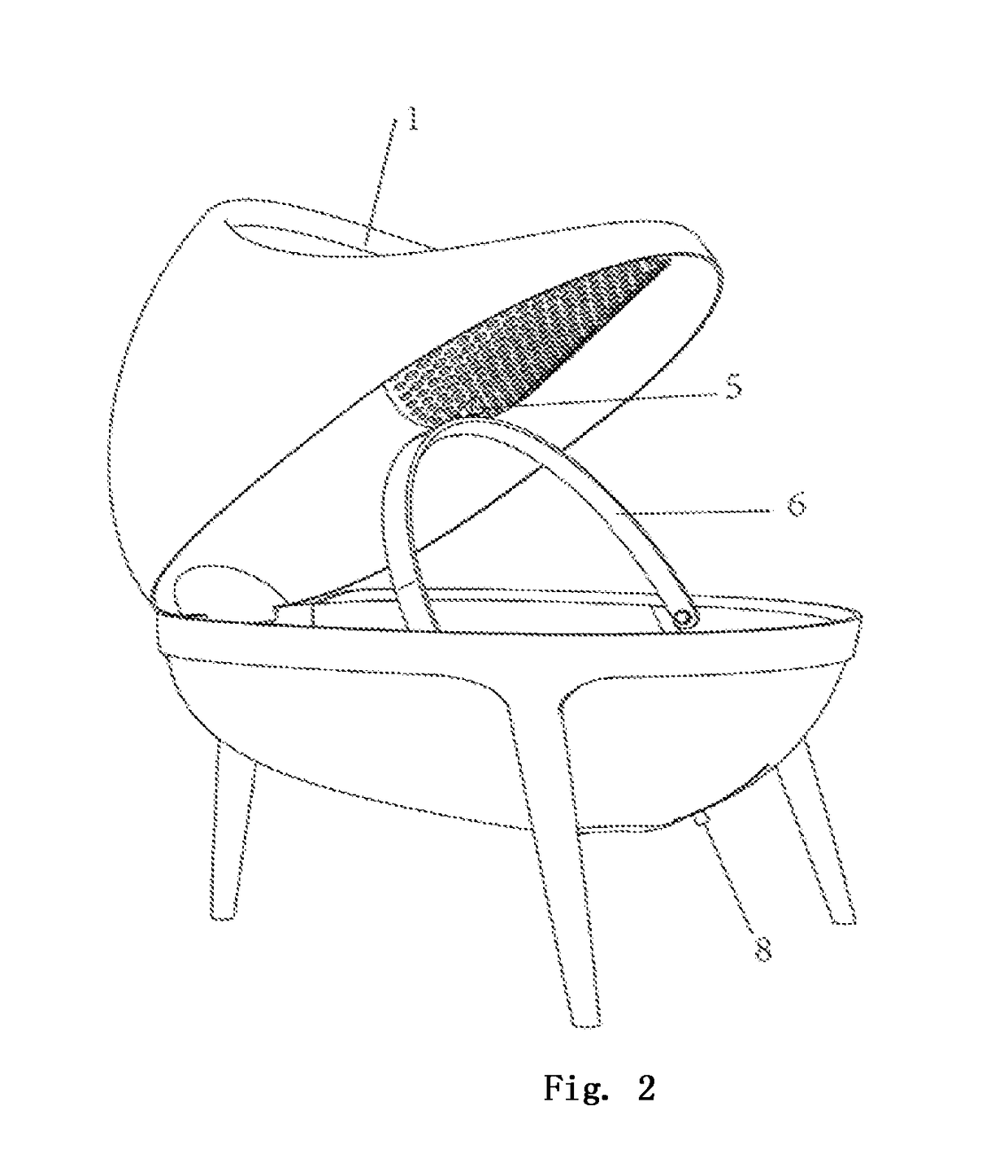

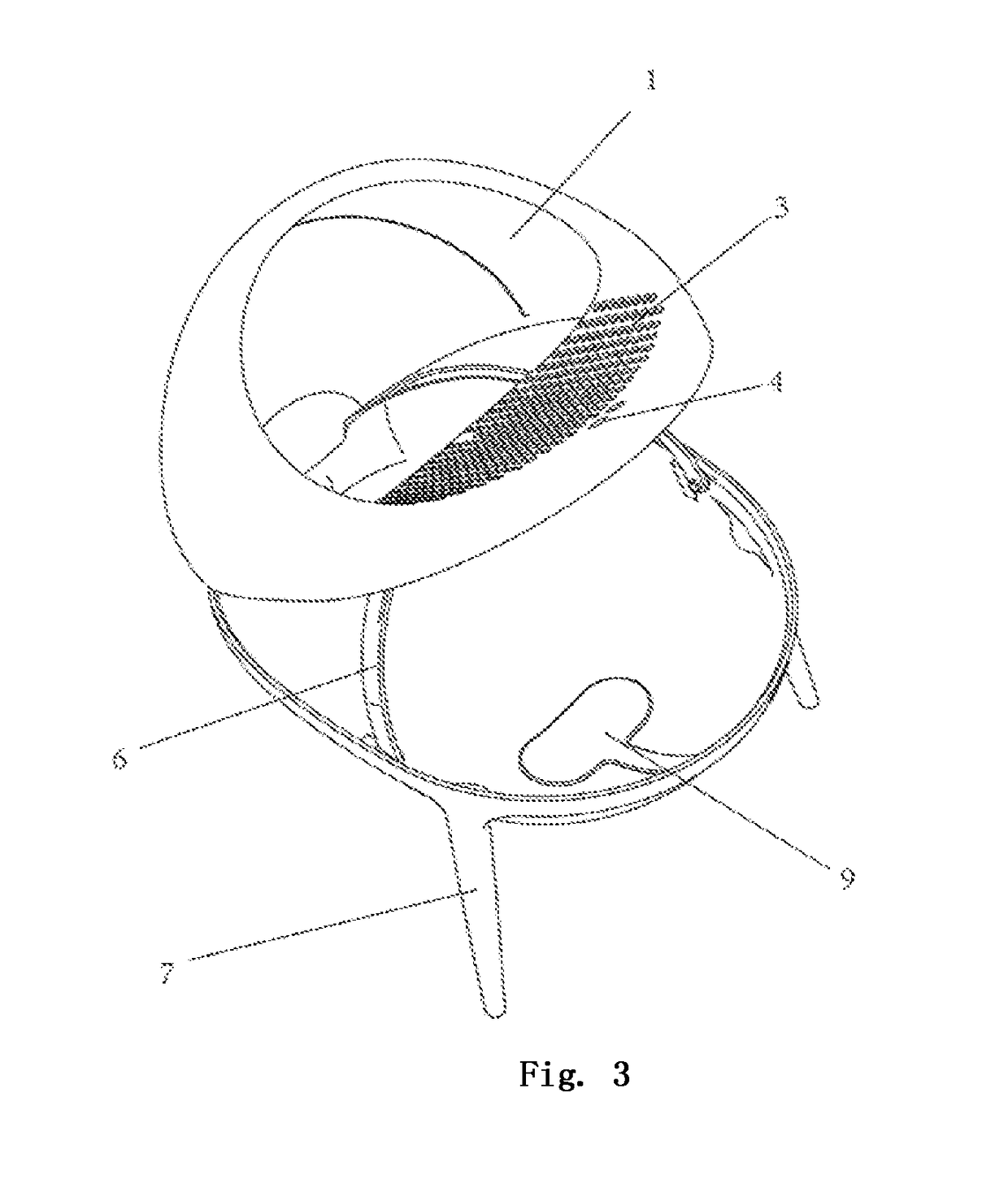

Pet toilet

The present invention provides a pet toilet including a shell. The shell includes an upper cover and a sand pot, wherein the sand pot is a semi-oval-shaped shell structure with support legs connected to the sand pot. The lowest bottom of the sand pot has an opening for leaking litters. A garbage bag may be connected the opening. The opening is provided with a baffle. The shape of the upper cover matches the shape of the sand pot. The upper cover and the sand pot are hinged together by a limit connection in back of the pet toilet. And there is an oval inlet in front of the upper cover. The pet toilet of the invention adopts the oval shape, and the overall appearance can fit with the current mainstream household style, and has both practicality and aesthetic appearance. The opening is designed at the lowest point of the semi-oval-shaped sand pot to facilitate the leakage of sand to the garbage bag on their own when the baffle opened, to reduce the manual workload and clean the overall sand pot without staying litter.

Owner:SHANGHAI BOLU PET PRODUC CO LTD

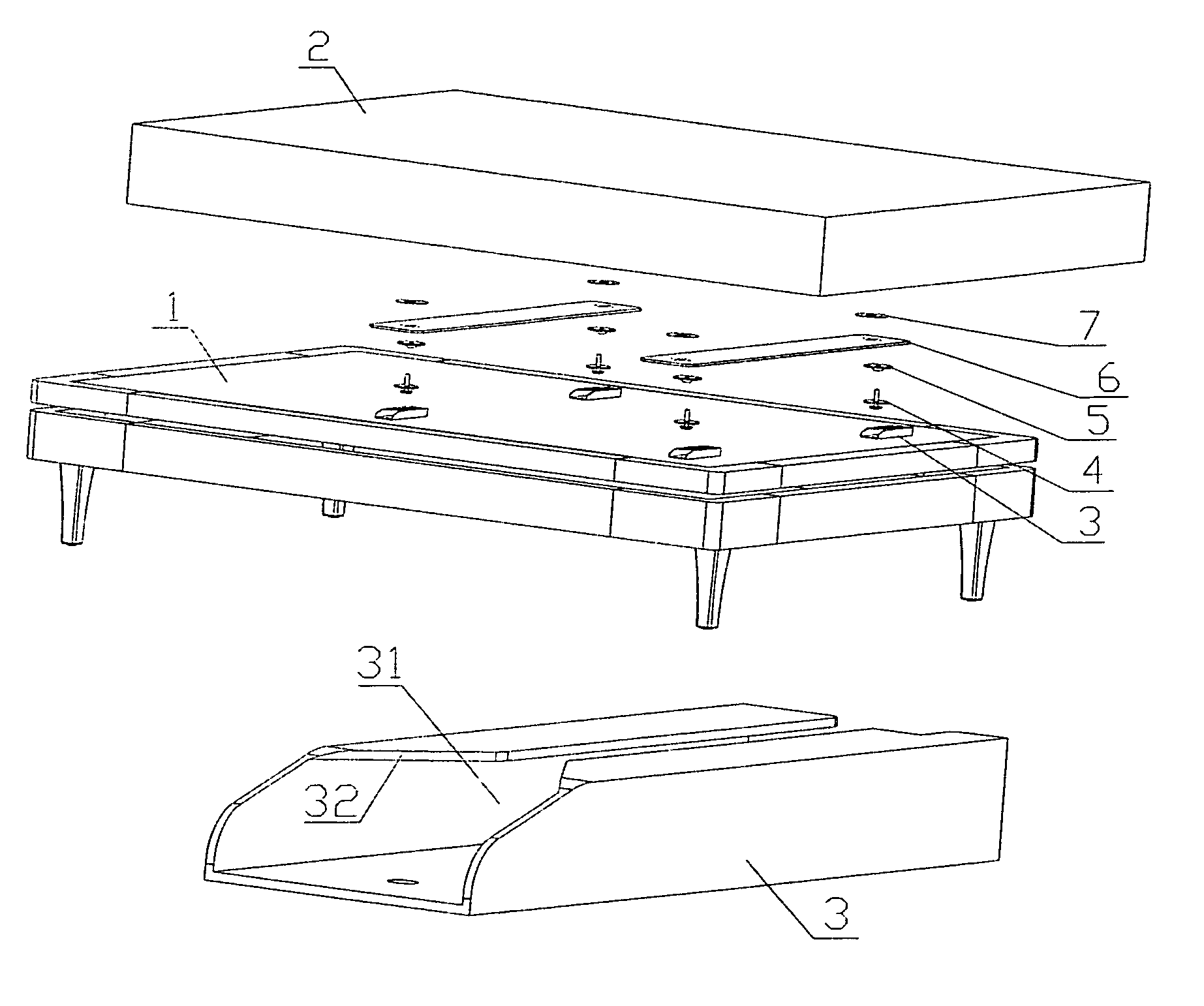

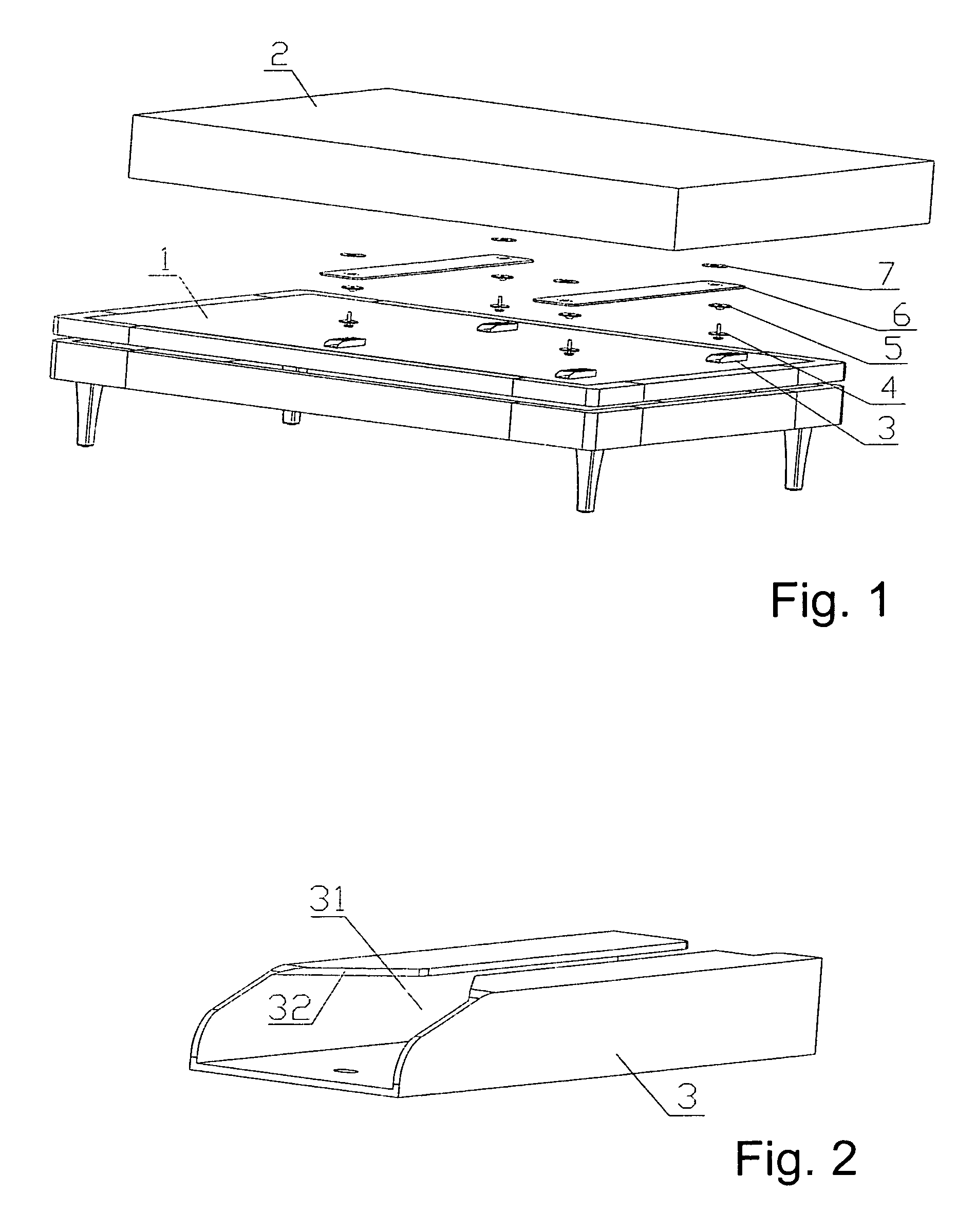

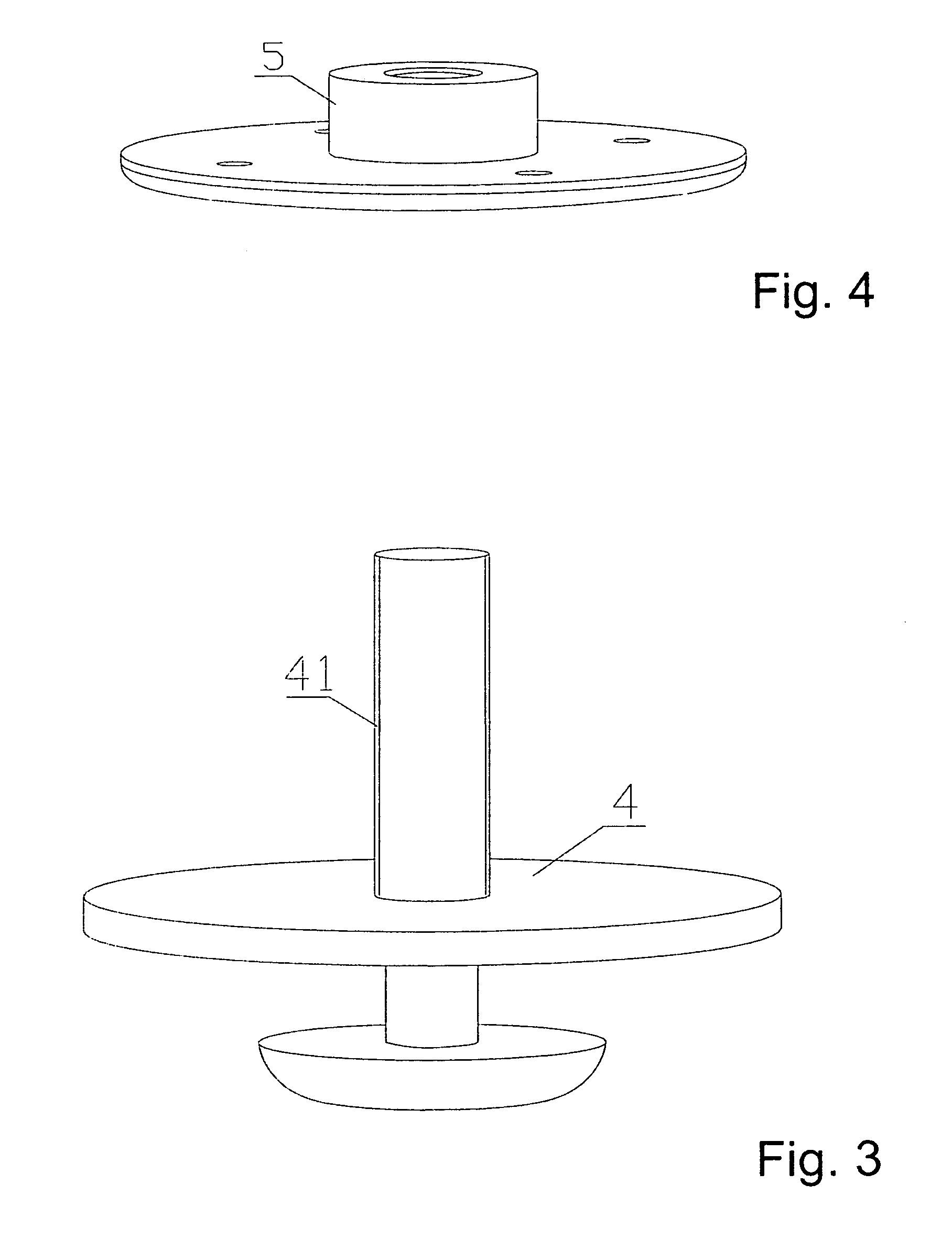

Electric bed bedboard with embedded fixed structure

This invention discloses an electric bed bedboard with embedded fixed structure. The fixed structure includes a plurality of guide pieces, multiple sliders, multiple disc sleeves and two pieces of wood, a plurality of guide pieces. Multiple guide pieces are set on top of the bedboard and also have T-shaped slots on their surface. Many disc sleeves are stacked on top of the wood pieces at intervals and there are internal threads inside the disc sleeves. Two pieces of wood are fixed into the bed support at intervals and the disc sleeves' positions matches with the guide pieces. Multiple sliders are “stem” shaped sliders and have external threads on their top. Multiple sliders are situated on top of the guide pieces inside the T-shaped grooves. Multiple sliders' tops are situated inside the multiple disc sleeves which are connected by the threads.

Owner:KEESON TECH CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com