Closed internal mold suitable for small box girder

A closed, small box girder technology, applied in the direction of ceramic molding core, ceramic molding mandrel, etc., can solve the problem that the formwork cannot be demoulded at the same time, and achieve the effect of saving labor hours, ensuring the appearance and internal quality, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

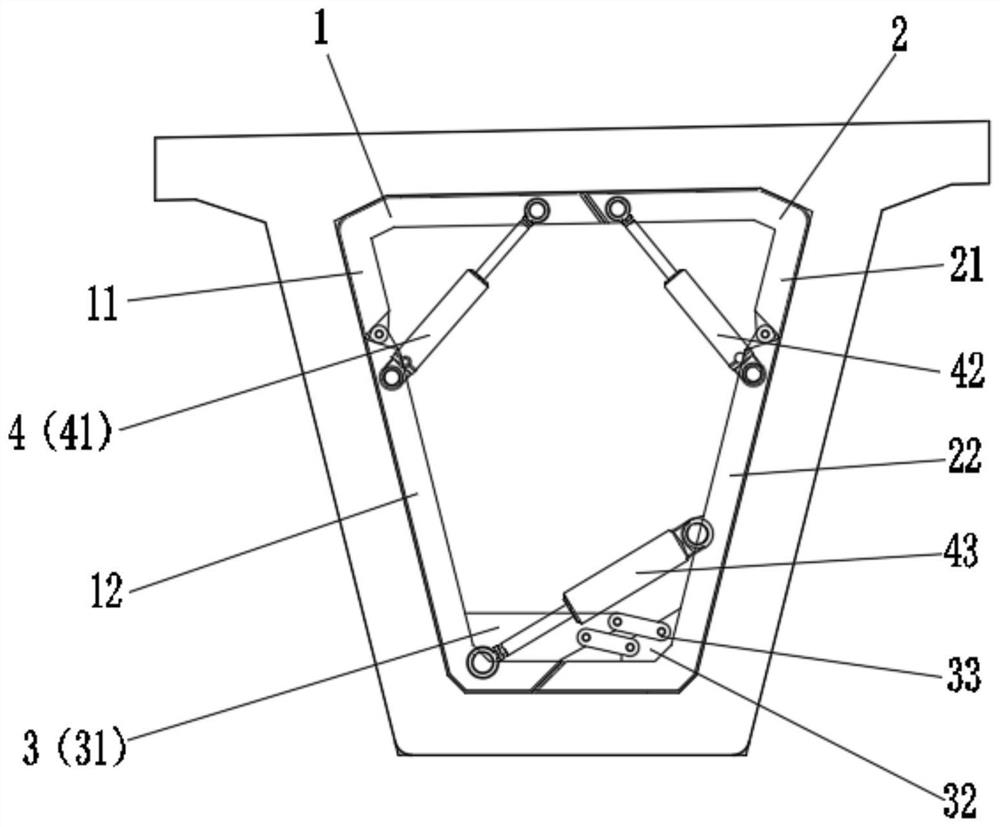

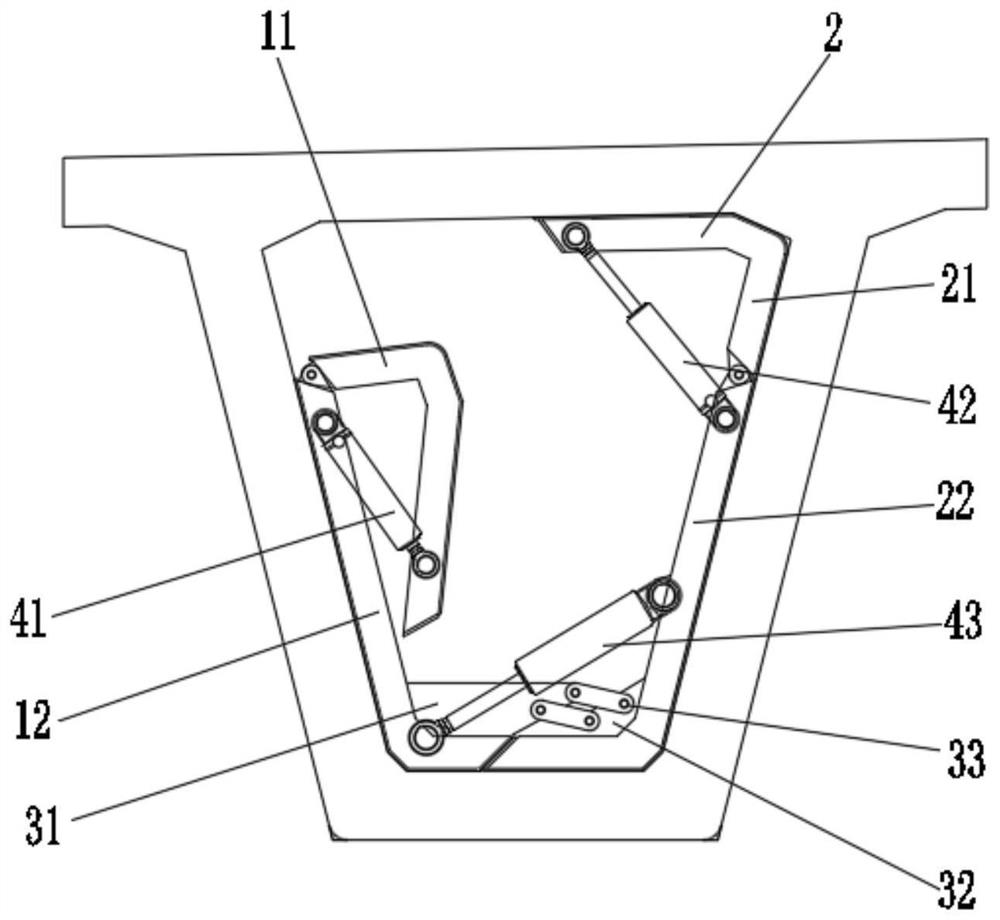

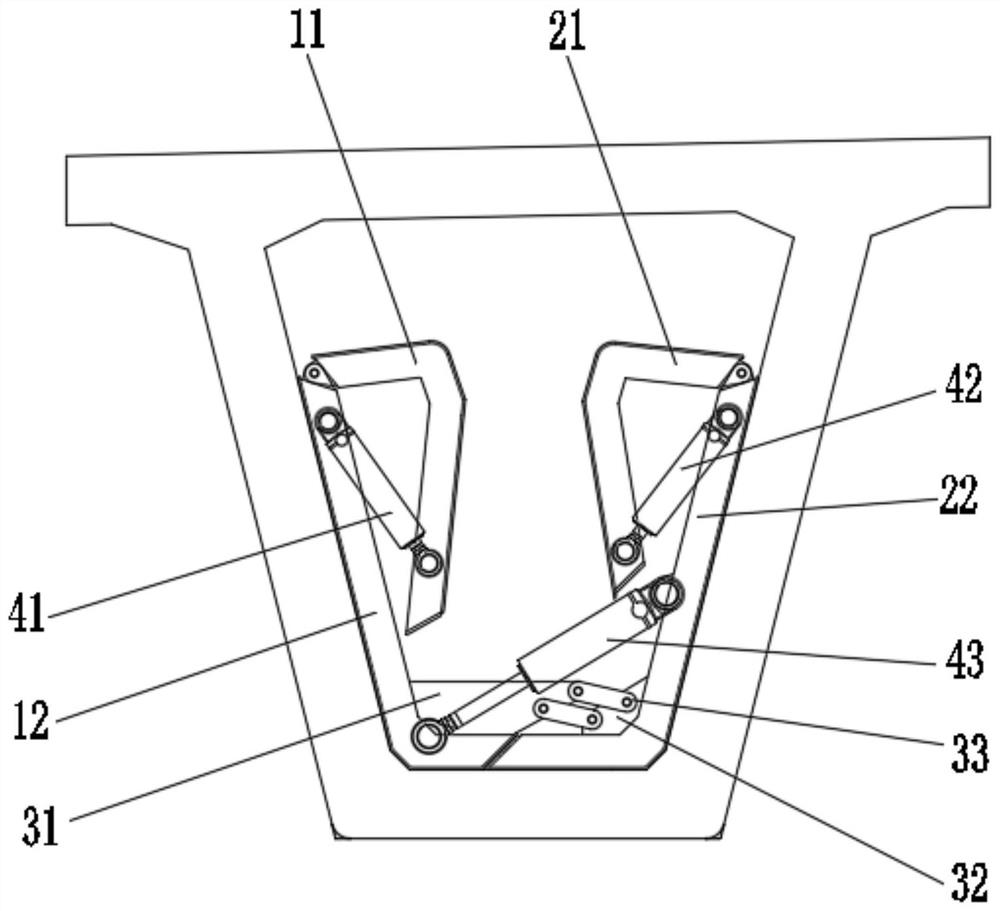

[0035] like Figure 1 to Figure 4 As shown, the present invention is suitable for a closed inner mold of a box girder with a smaller cross-sectional size, including a first side mold assembly 1 , a second side mold assembly 2 , a trajectory control mechanism 3 and a telescopic assembly 4 . The trajectory control mechanism 3 is used to connect the first side mold assembly 1 and the second side mold assembly 2 into a whole, and can make them close or open in relative translation along the set trajectory. Multiple sets of telescopic assemblies 4 are respectively arranged on the upper and lower parts of the first side mold assembly 1 and the second side mold assembly 2, and the telescopic assemblies 4 are used to drive the first side mold assembly 1 and the second side mold assembly 2. When opening and closing, the inner mold forms a closed inner mold shape when it is opened, and the whole section is smaller than the beam end outlet when it is contracted and closed. It should be ...

Embodiment 2

[0052] like Figure 5 As shown in the figure, the present invention is suitable for a closed inner mold of a box girder with a smaller cross-sectional size, and has a similar structure to that of the inner mold in Example 1. The main difference is that the second side lower mold 22 includes a side mold 221. And the bottom mold 222, the side mold 221 and the bottom mold 222 can perform relative movement. Further, the side molds 221 and the bottom mold 222 can be hinged or attached by bevel, and the bottom mold 222 and the second side lower mold 12 can be beveled. It can be understood that in other embodiments, the upper and lower molds of the first side mold assembly 1 and the upper and lower molds of the second side mold assembly 2 can be further split into a plurality of mutually connected templates, so that the inner mold after the mold is closed. The mold has a smaller volume and also provides a larger operating space for the small box girder cavity.

[0053] like Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com