Chair counterbalanced by mortar

A mortar and seat technology, used in theaters, auditoriums or similar places for chairs, chairs, applications, etc., can solve the problems of complex surface treatment of metal ingots, affecting the overall appearance of the seat, and the color of the plastic seat cannot be unified. , to achieve the effect of small flipping force, easy flipping and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

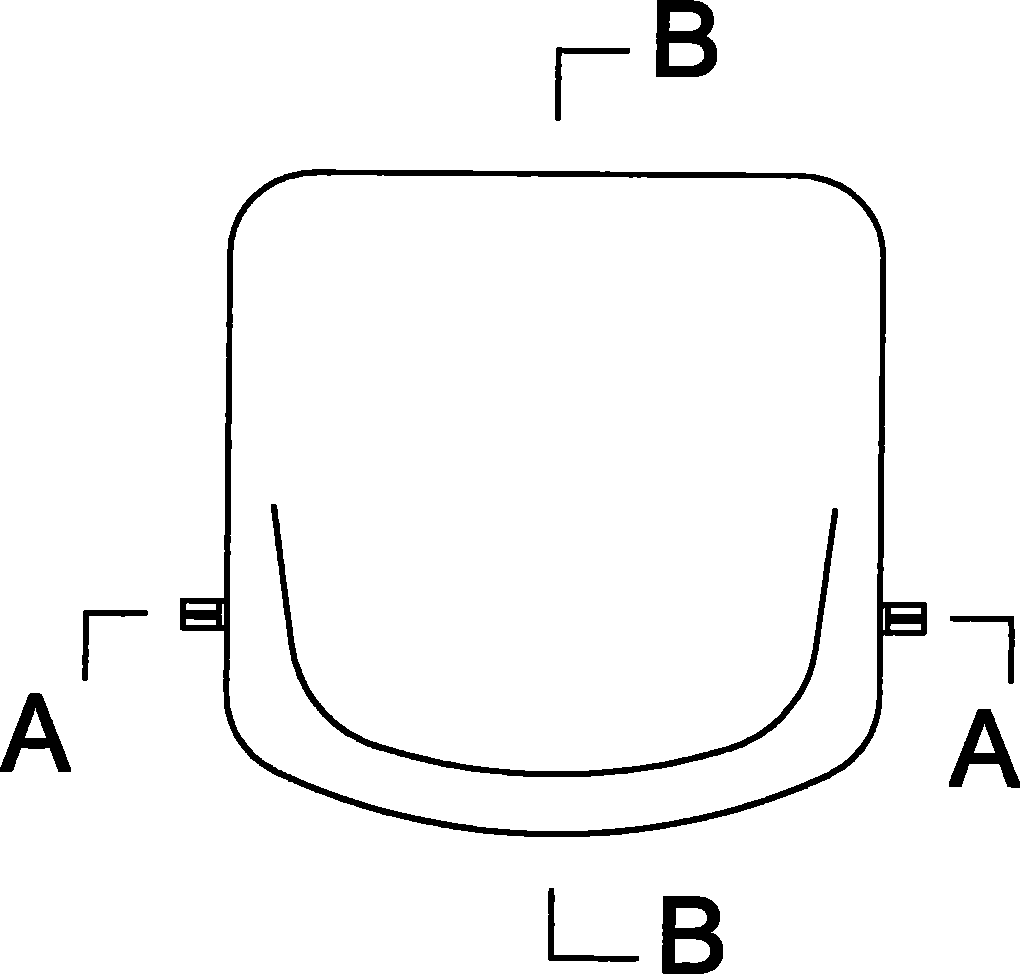

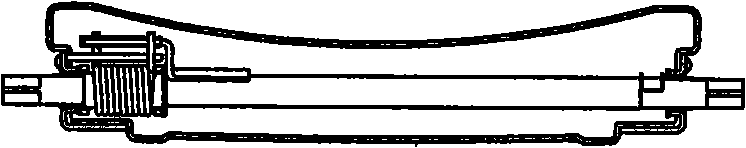

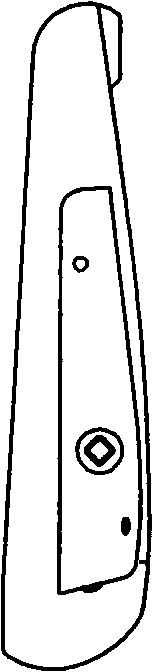

[0039] like Figure 3(A) to Figure 3(E) Shown, a kind of seat with mortar counterweight, is the seat with mortar counterweight of hollow plastic, comprises seat seat 1, rotating shaft 2, left connecting plate 3, right connecting plate 4, mortar counterweight 5, The rotating shaft 2 runs through the plastic seat transversely, at the bottom of about 1 / 3 of the length of the plastic seat, and the left connecting plate 3 and the right connecting plate 4 respectively pass through both ends of the rotating shaft 2 and are fixedly connected with both sides of the plastic seat 1 , the rotating shaft 2 is rotationally connected with the plastic seat and the left and right connecting plates, and the mortar counterweight 5 is solidified mortar, located at the bottom of the hollow plastic seat 1, accounting for about 1 / 6 of the height of the seat.

[0040] The freshly mixed wet mortar is injected into the bottom of the plastic seat through the notch of the shaft hole of the plastic seat by...

Embodiment 2

[0042] According to the seat structure of Example 1, cut out shaft holes according to the positioning on both sides of the hollow plastic seat, add 200 kg of water according to 30 kg of cement, 70 kg of coarse sand, and 1 kg of glass fiber, and take 2.1+0.1 kg of the mortar that has been stirred and put it into a measuring cup Put it into the hopper in a certain amount, inject it into the bottom of the plastic seat through an electric screw grouting machine, about 1 / 6 of the height of the plastic seat, and pre-embed the screw to connect with the plastic case, and then put it vertically in a fixed position to dry, about 20 Hours later, the mortar changes from slurry to solid, achieving the effect of counterweight.

[0043] Pass the prepared shaft through the shaft hole of the plastic seat that has been successfully counterweighted, and then pass the left and right connecting plates through the shaft to connect with the plastic seat, and the assembly of the entire seat assembly i...

Embodiment 3-11

[0050] The raw material formula of described mortar counterweight block is as follows according to weight (unit: kg); Inject the bottom of plastic seat, the ratio of the height h formed by mortar counterweight block and the height of plastic seat is shown in the table below:

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com