Construction method for building concrete superface with surface modeling

A construction method and surface modeling technology, applied in the direction of building structure, construction, building components, etc., can solve the problem of non-standard steel form lifting, installation, debugging, disassembly, which consumes a lot of time and manpower, and cannot ensure the curvature accuracy of thin-plate structures. , the high cost of construction tooling preparation, to ensure the quality of the entity and appearance curve, saving labor and material input, saving energy consumption for hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] According to the present invention, firstly, the top surface of the building or the structure with the curved shape is thinned, so as to obtain more elevation data according to the limited elevation data marked on the drawings.

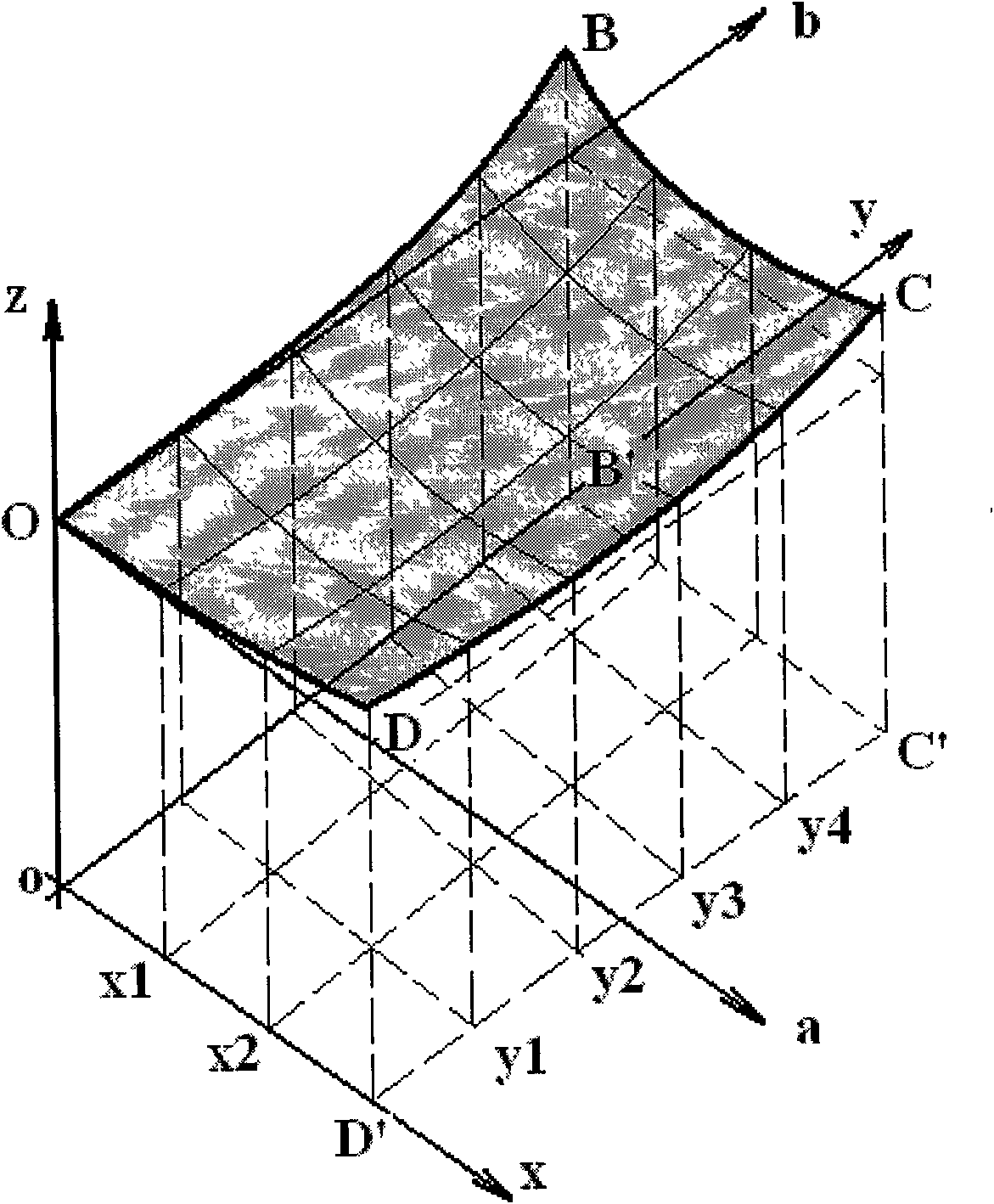

[0021] Specifically, as figure 1 As shown, if the elevation data of the four corner points of a part of the space hyperboloid OBCD are marked on the drawing, the corner point O with a lower elevation of the curved plate can be designed as the coordinate origin to establish an ab-direction coordinate system; Perform horizontal orthographic projection on the reference plane to obtain the quadrilateral oB'C'D'; then divide the quadrilateral oB'C'D' into several grids, for example, insert two points with coordinates x1 and x2 on the side of oD', Insert four points y1, y2, y3, and y4 on oB', so that the quadrilateral oB'C'D' is divided into 3x5=15 small quadrilaterals, and 4x6=24 nodes appear, thus we can find the hyperboloid in space The correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com