Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Enough purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

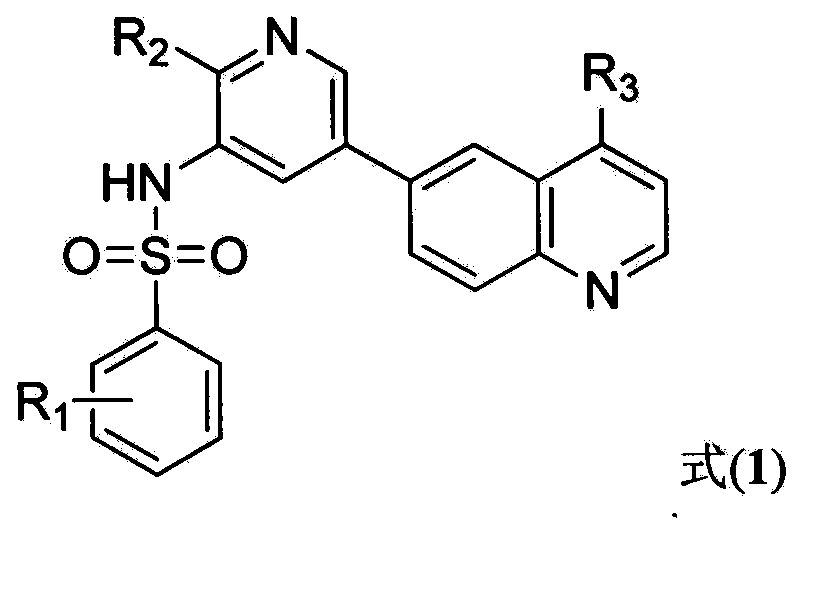

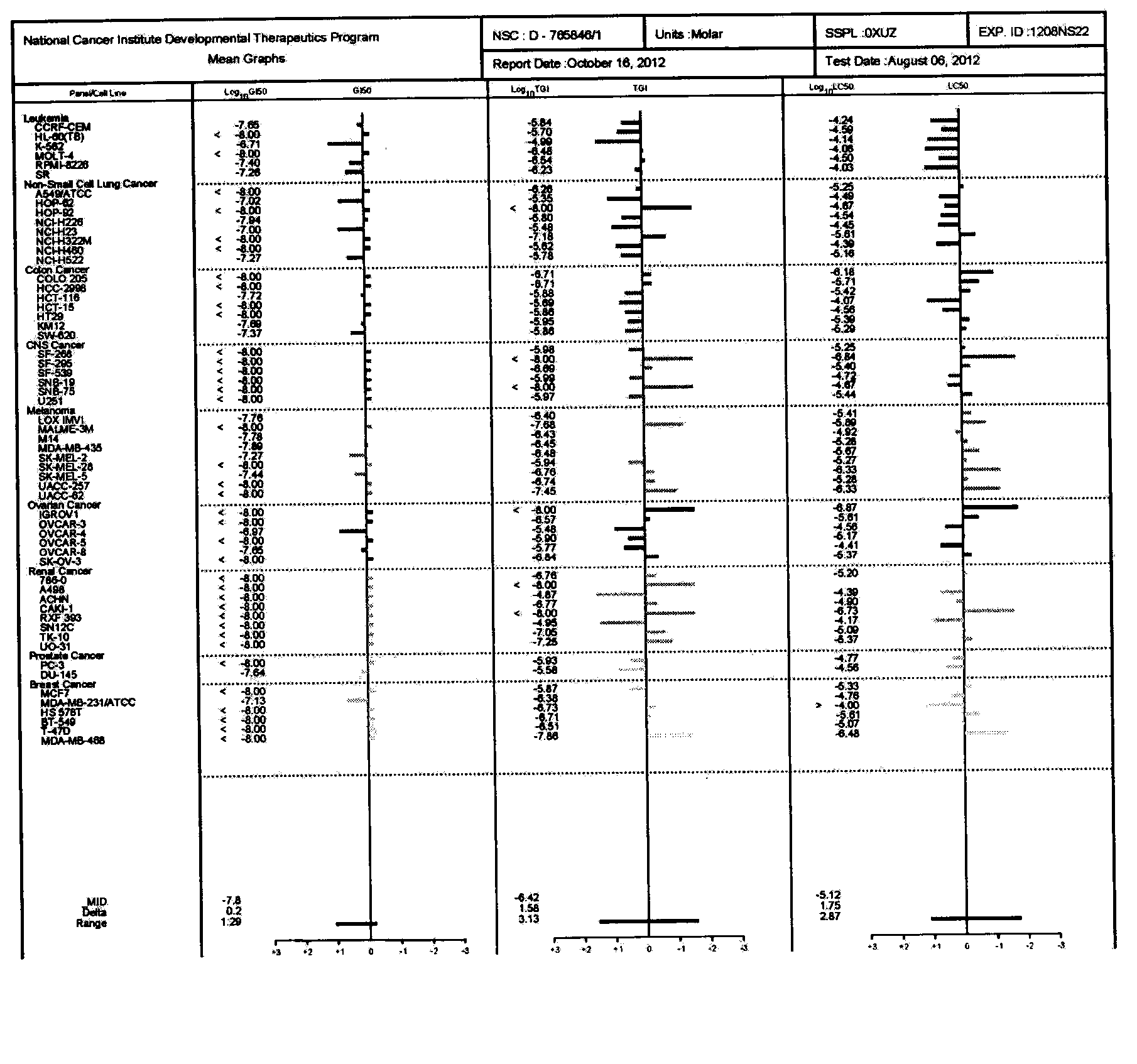

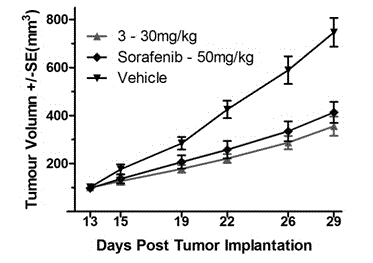

N-(5-(quinolyl-6-yl) pyridyl-3-yl)benzsulfamide derivatives, and preparation method and treatment use thereof

InactiveCN103788071AShort curative effectEnough purityOrganic active ingredientsOrganic chemistryMedicinePyridine

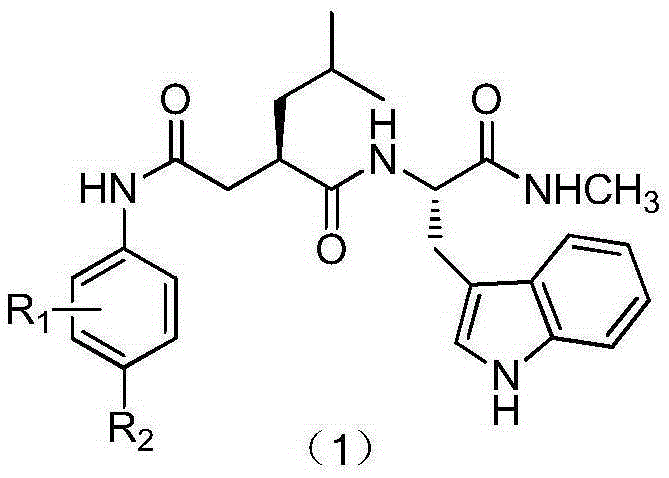

The invention relates to the technical field of medicine, and concretely relates to various different types substituted N-(5-(quinolyl-6-yl) pyridyl-3-yl)benzsulfamide derivatives represented by formula (1) (all groups in the formula (1) are defined in the specification. The above compounds have a good antitumor activity against a plurality of tumors comprising human lung cancer, colon cancer, liver cancer, breast cancer, cerebral astrocytoma and the like, lays a foundation for the development of antitumor medicines having the advantages of high efficiency, low toxicity and strong specificity, and has a very good exploitation value. The invention also relates to a composition containing the compounds, a preparation method of the composition, and a use of the composition in the preparation of the antitumor medicines.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

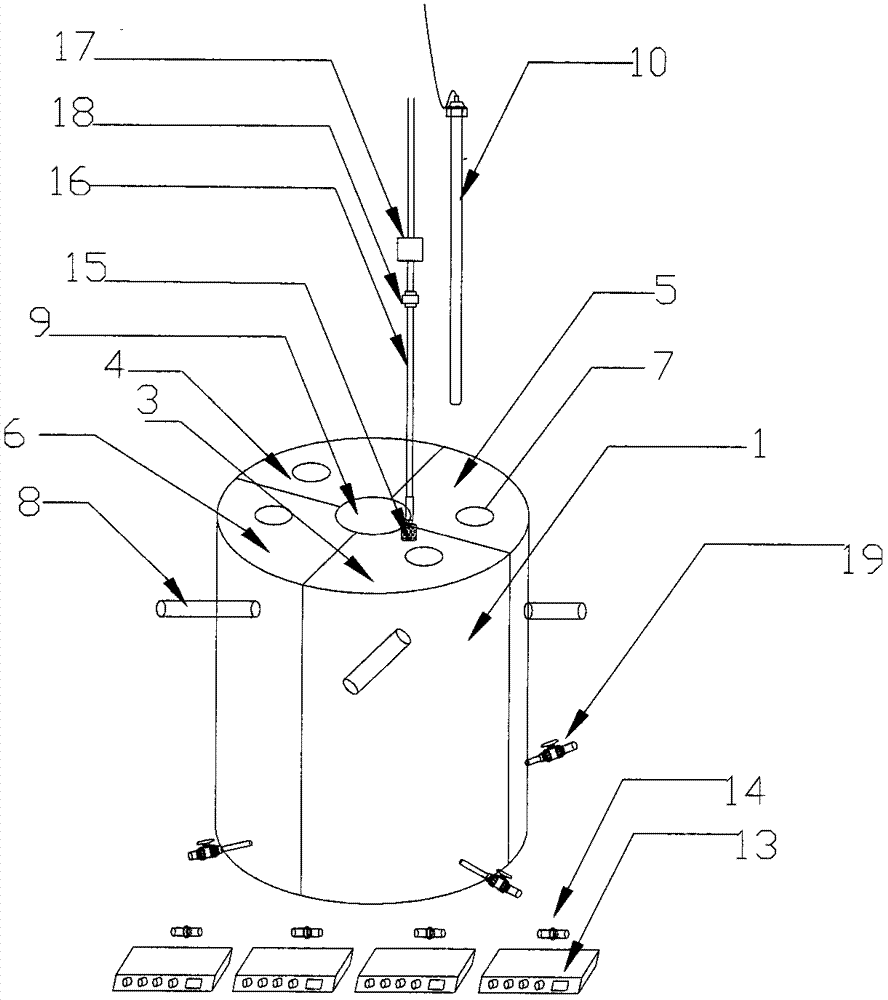

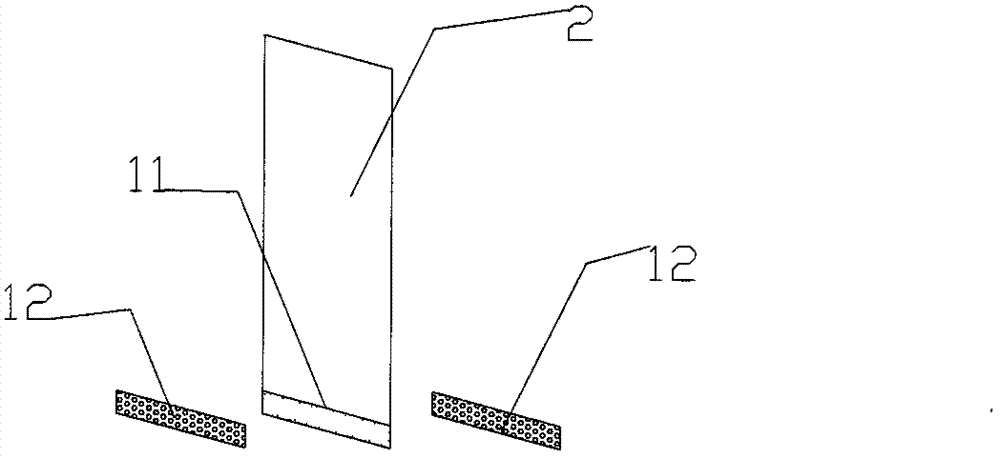

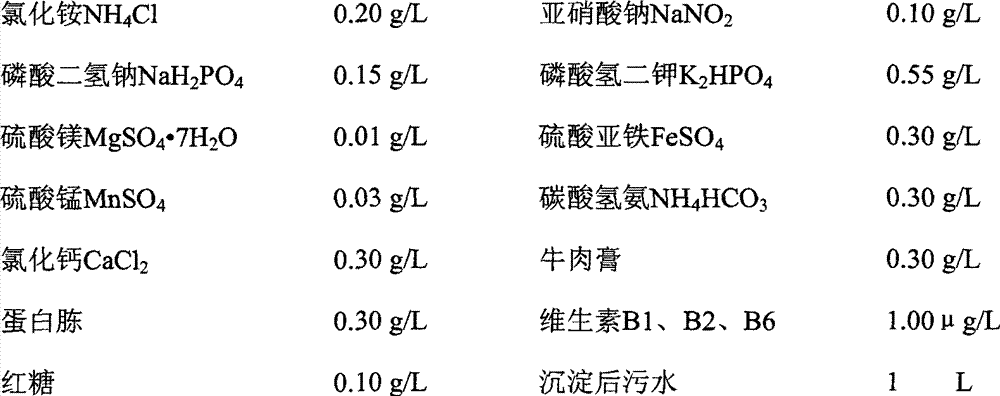

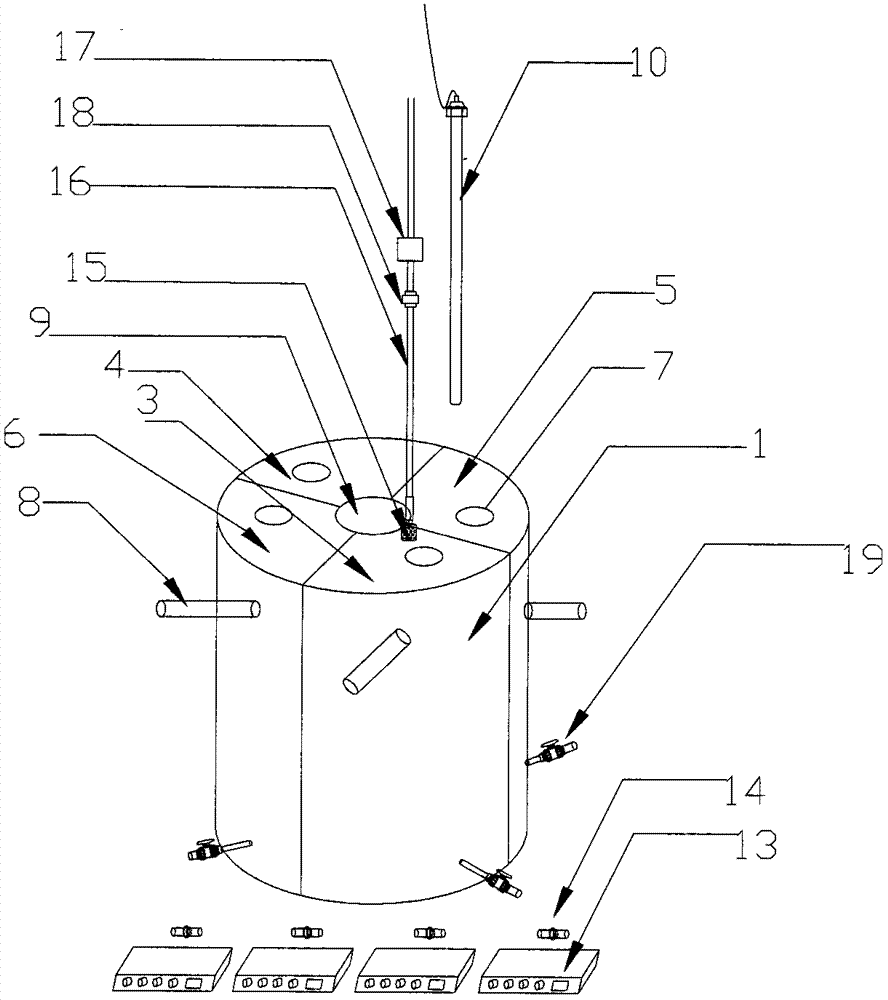

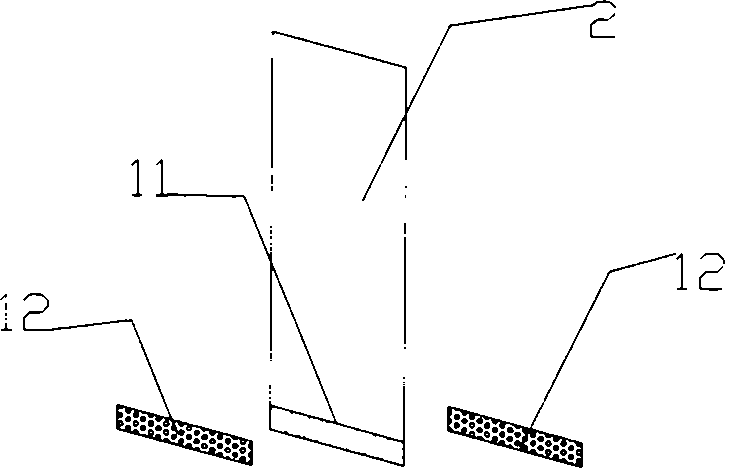

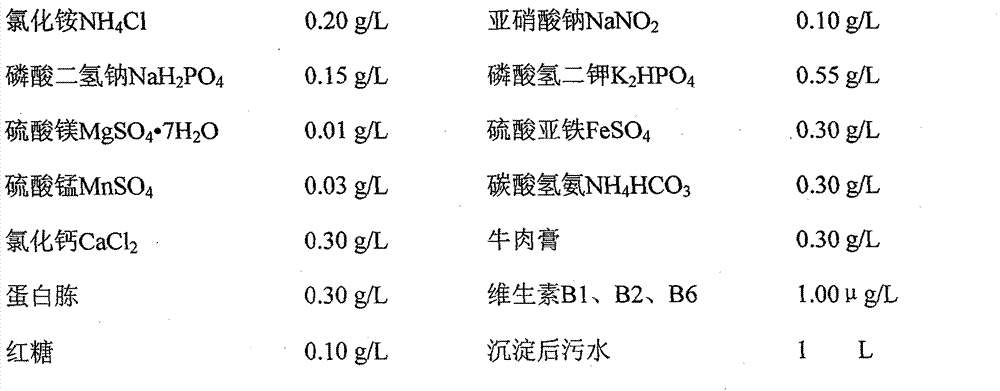

Water-treatment composite microbe continuous culture device and culture method thereof

InactiveCN103074204AImprove cultivation efficiencyAvoid Intermittent OutagesBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobiologySewage treatment

The invention discloses a water-treatment composite microbe continuous culture device and a culture method thereof. The device comprises a tank (1), the tank (1) is separated into four independent culture zones comprising an aerobic zone (3), an anaerobic zone (4), a first transition zone (5) and a second transition zone (6) by separation plates (2), the first transition zone (5) and the second transition zone (6) are positioned between the aerobic zone (3) and the anaerobic zone (4), each of the culture zones is provided with a culture medium inlet (7) and an overflow mouth (8), a culture medium is continuously charged through the culture medium inlet (7), and a cultured bacterial liquid flows to a sewage treatment zone from the overflow mouth (8). The device and the method have the advantages of realization of the simultaneous and continuous culture of a plurality of strains, automatic addition of the culture medium, automatic charging of the bacterial liquid, improvement of the culture efficiency of the bacterial liquid, substantial acceleration of the composite pollution treatment speed, and avoiding of the sewage-treatment intermittent interruption caused by intermittent culture.

Owner:NINGHAI TIANHE ECOLOGICAL WATERSCAPE CONSTRCO

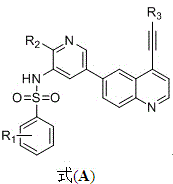

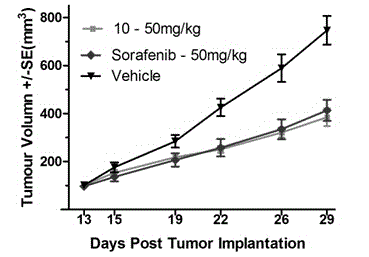

Benzene sulfonamide derivatives, preparation method, and treatment application

InactiveCN104402861AShort curative effectEnough purityOrganic active ingredientsNervous disorderOncologyHuman breast

The invention relates to the technical field of medicine, and specifically relates to benzene sulfonamide derivatives in different substitution types, wherein the derivatives are represented by the formula (A), and the definitions of each group are listed in the description. The derivatives have an excellent performance on inhibiting the activity of PI3K kinase, and moreover have high antitumor activities on tumors such as human lung cancer, human colon cancer, human liver cancer, human breast cancer, and the like. So the derivatives can be used to prepare target antitumor drugs having the advantages of high efficiency, low toxicity, and strong specificity, and thus the derivatives have very good development values. The invention further relates to a composition composed of the derivatives, a preparation method thereof, and applications of the composition in preparation of antitumor drugs.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

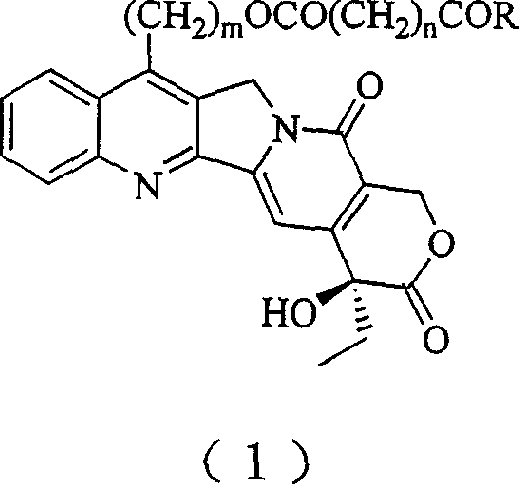

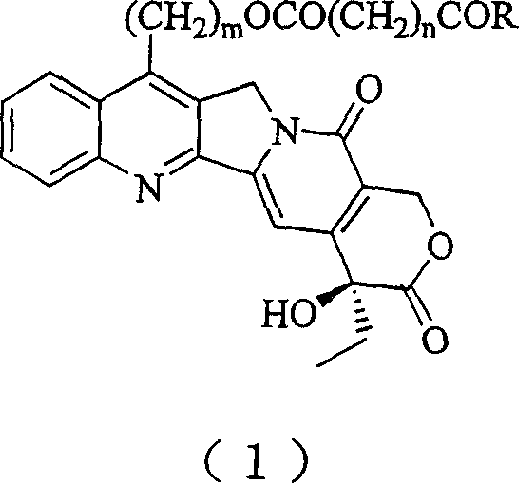

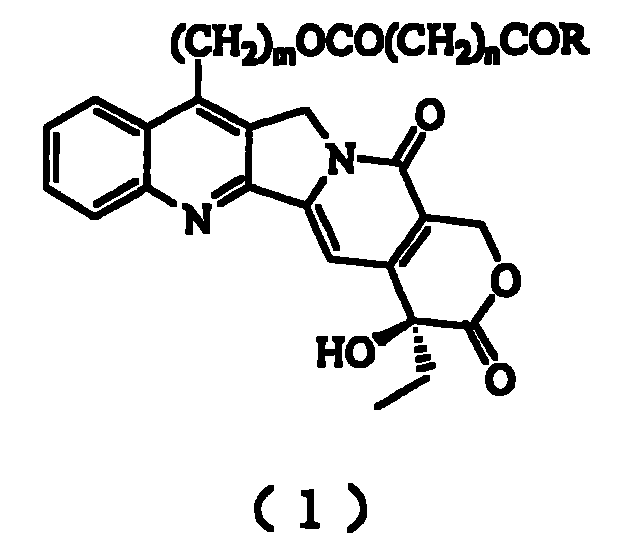

20(S) camptotheca alkaloid derivatives, their preparing methods and uses

InactiveCN1580057AReduce efficacyEnough purityOrganic active ingredientsOrganic chemistryAnti-Tumor DrugsCamptotheca

The invention provides 20(S)-camptothecin ramification demonstrated by the figure (1) or its acceptable salt in the medicine. The m in the figure is one integer between 2 and 5; R is OH, OR1 (R1 is the alkyl of C1-5), NH2, NHR1 (R1 is the alkyl of C1-5) or NR1R2 ((R1 and R2 are the alkyl of C1-5 respectively). The invention also provides the preparation method of the ramification and its use in the antineoplastic medicines.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI +1

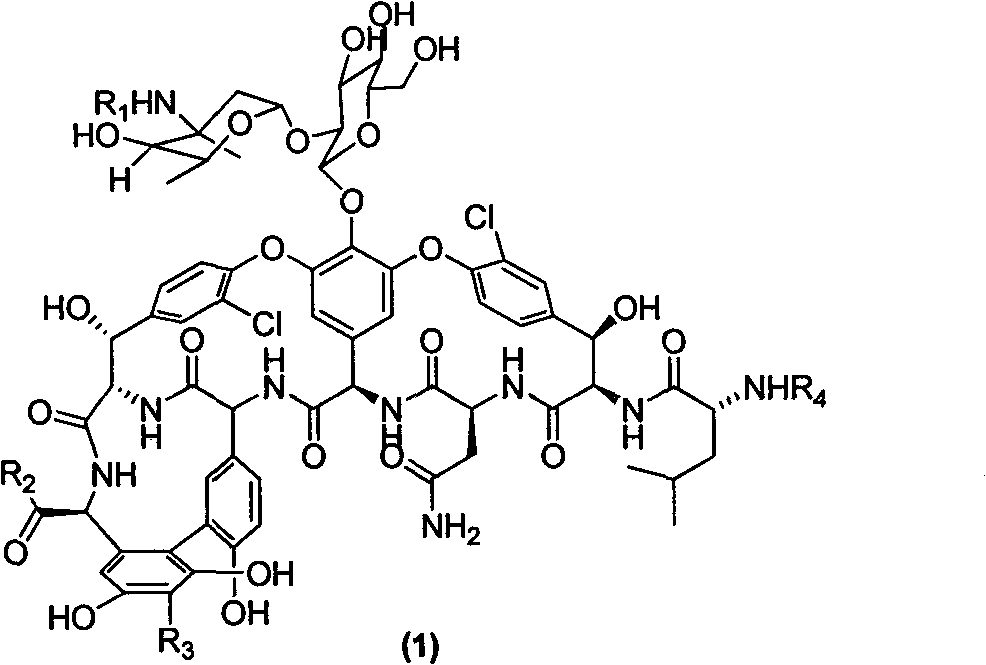

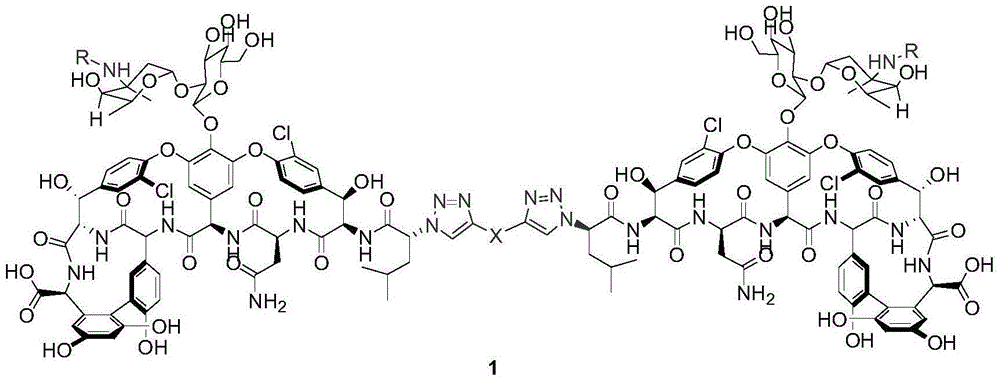

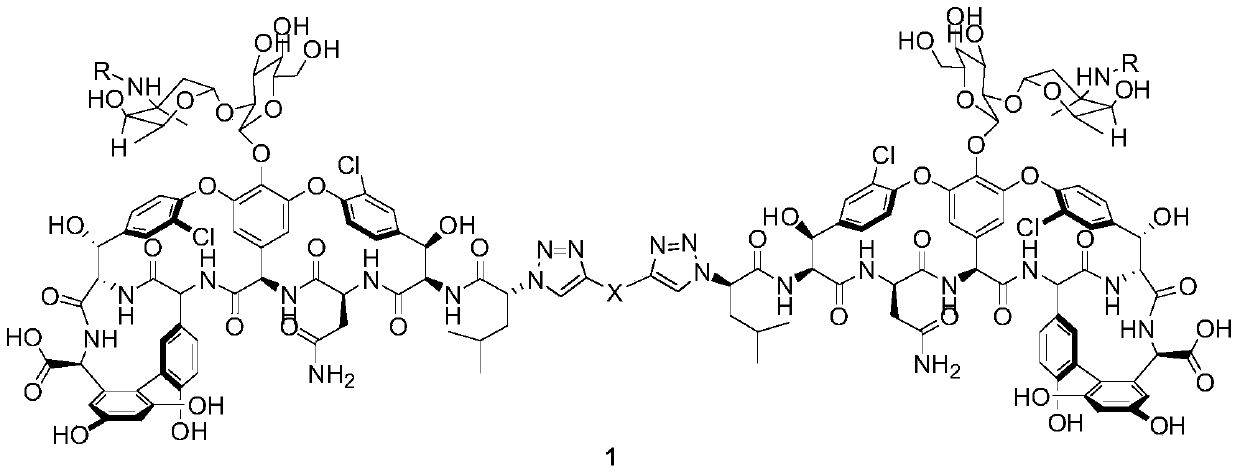

Vancomycin derivate, and preparation method and application thereof

InactiveCN102250221AEnough purityLow toxicityAntibacterial agentsSaccharide peptide ingredientsGlycopeptideVancomycin

The invention belongs to the technical fields of pharmaceutical chemistry and medicine, relates to a novel glycopeptide derivate having antibacterial activity, and particularly relates to a vancomycin derivate shown in formula (1), and a preparation method and application thereof. In-vitro antibacterial experiment shows that the compound provided by the invention has obvious antibacterial activity on multiple Gram-positive bacteria and can be used as a pharmaceutical active ingredient for preparing medicaments (especially medicaments for resisting bacterial infection).

Owner:FUDAN UNIV

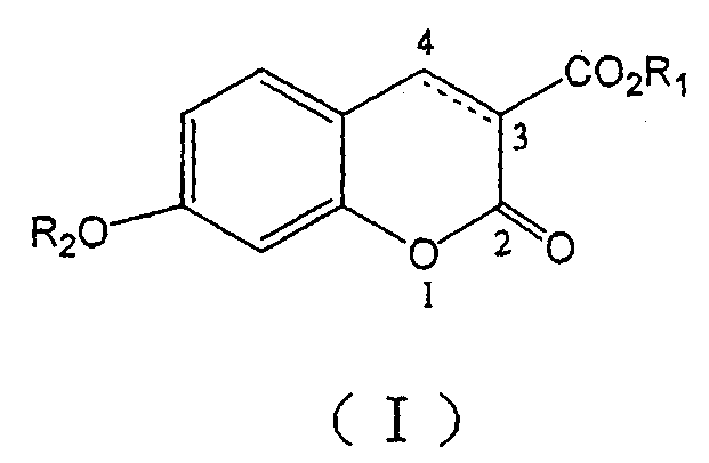

Benzofuran category compound, its preparing method and usage

InactiveCN1445222AEnough purityLow toxicityOrganic active ingredientsOrganic chemistryHydrogen atomMedicine

A benzopyran compound or its salts, their preparing process and their application in preparing medicine for treating B-type diabetes are disclosed.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

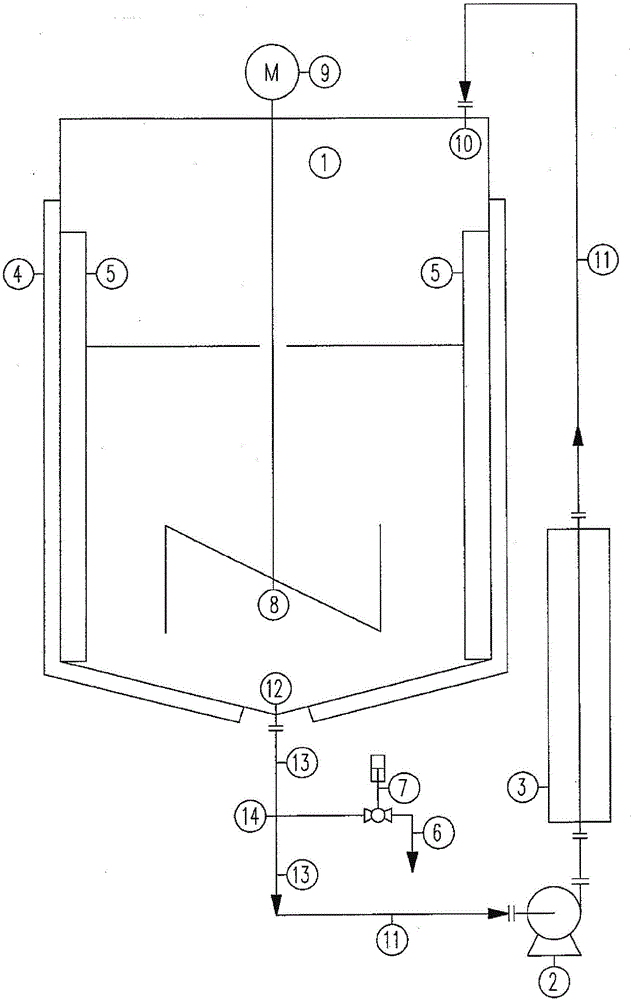

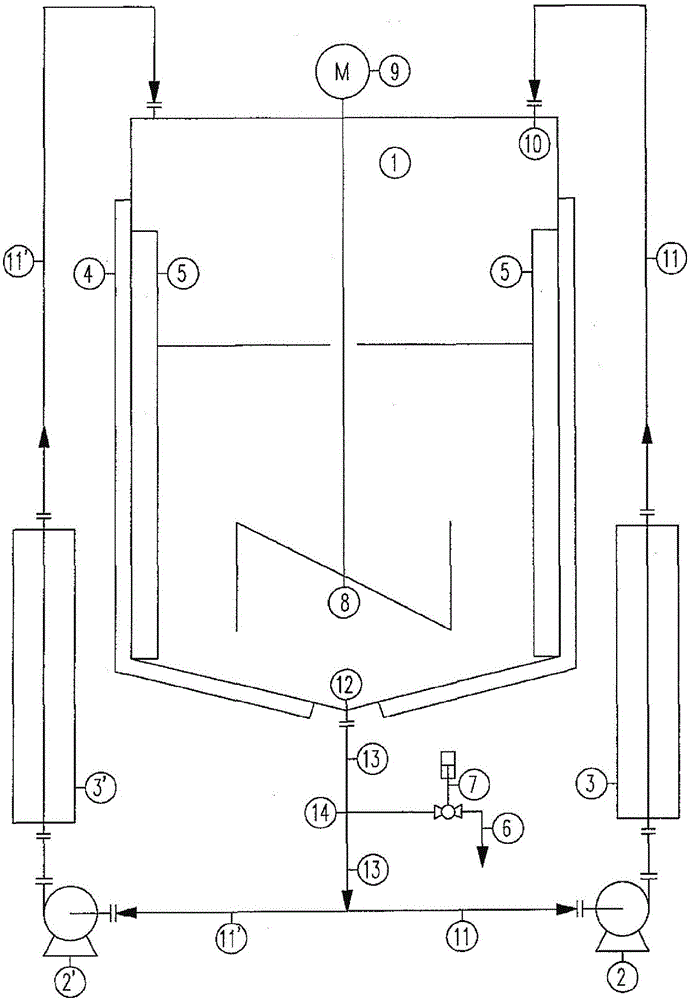

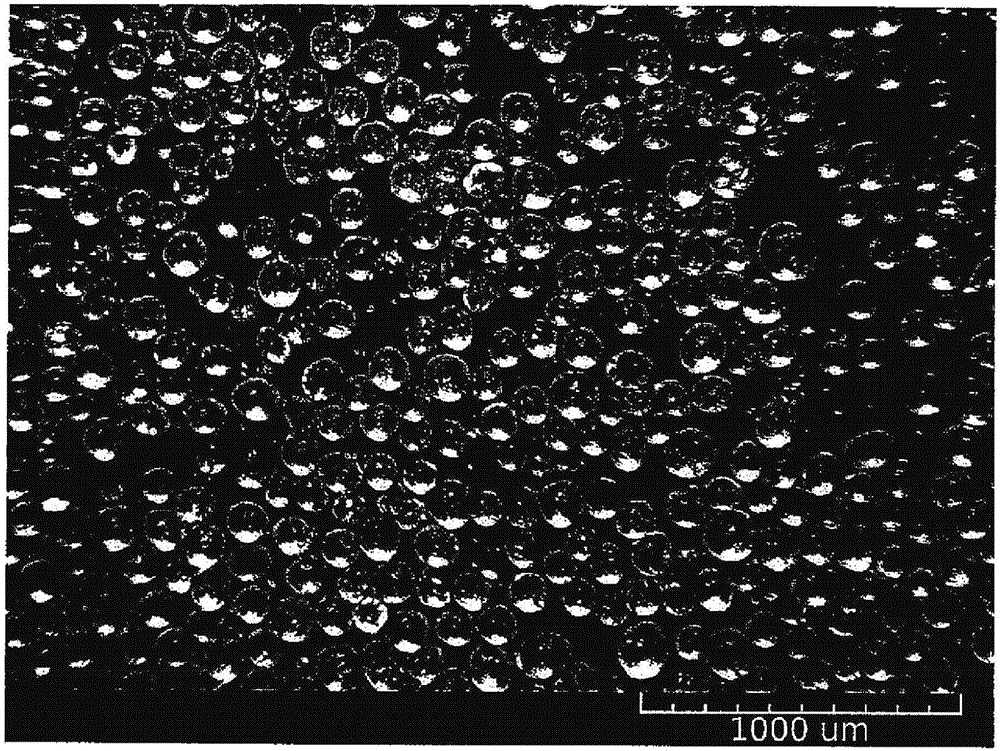

A discontinuous crystallization unit for the production of ball-shaped crystals

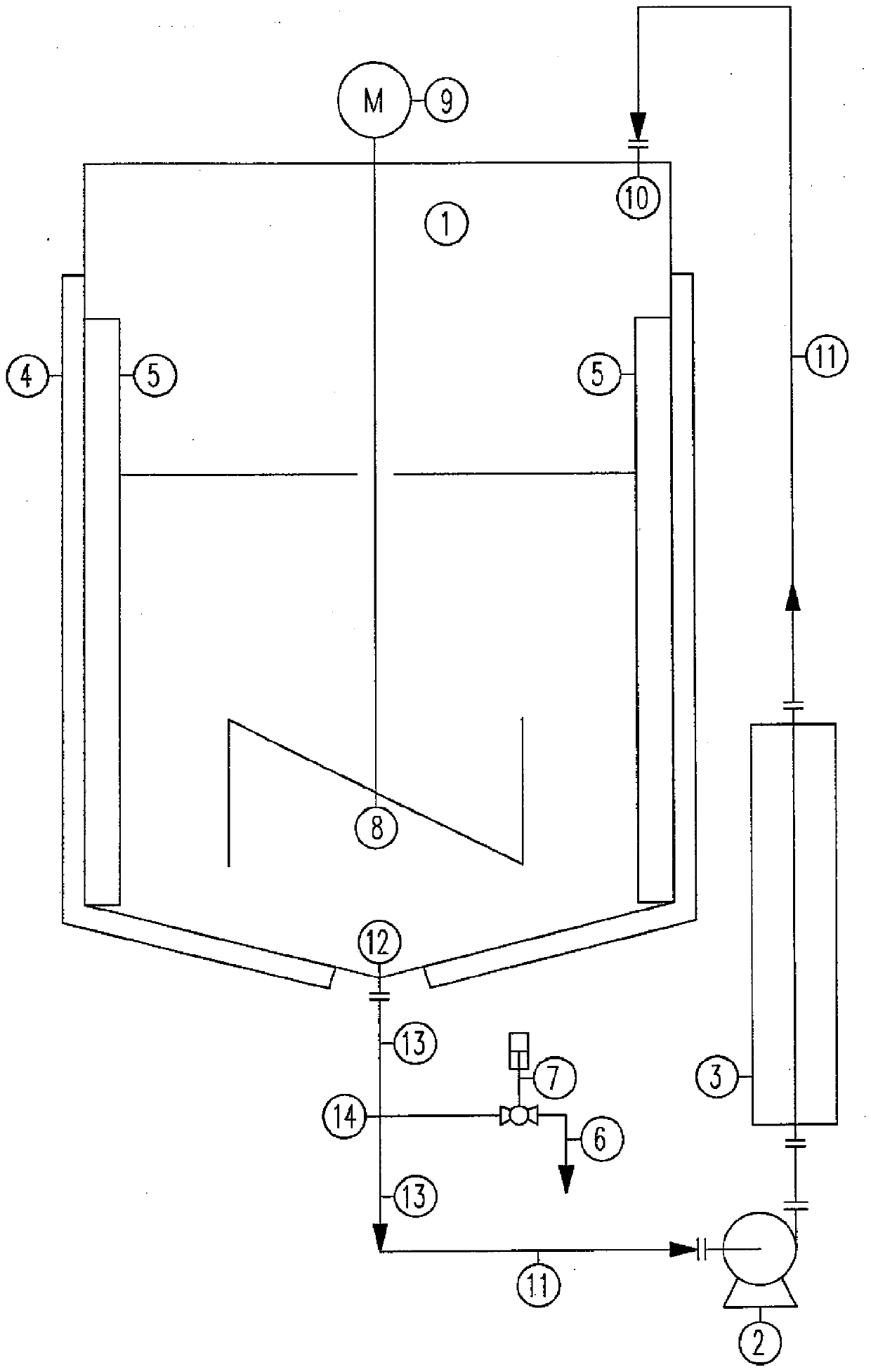

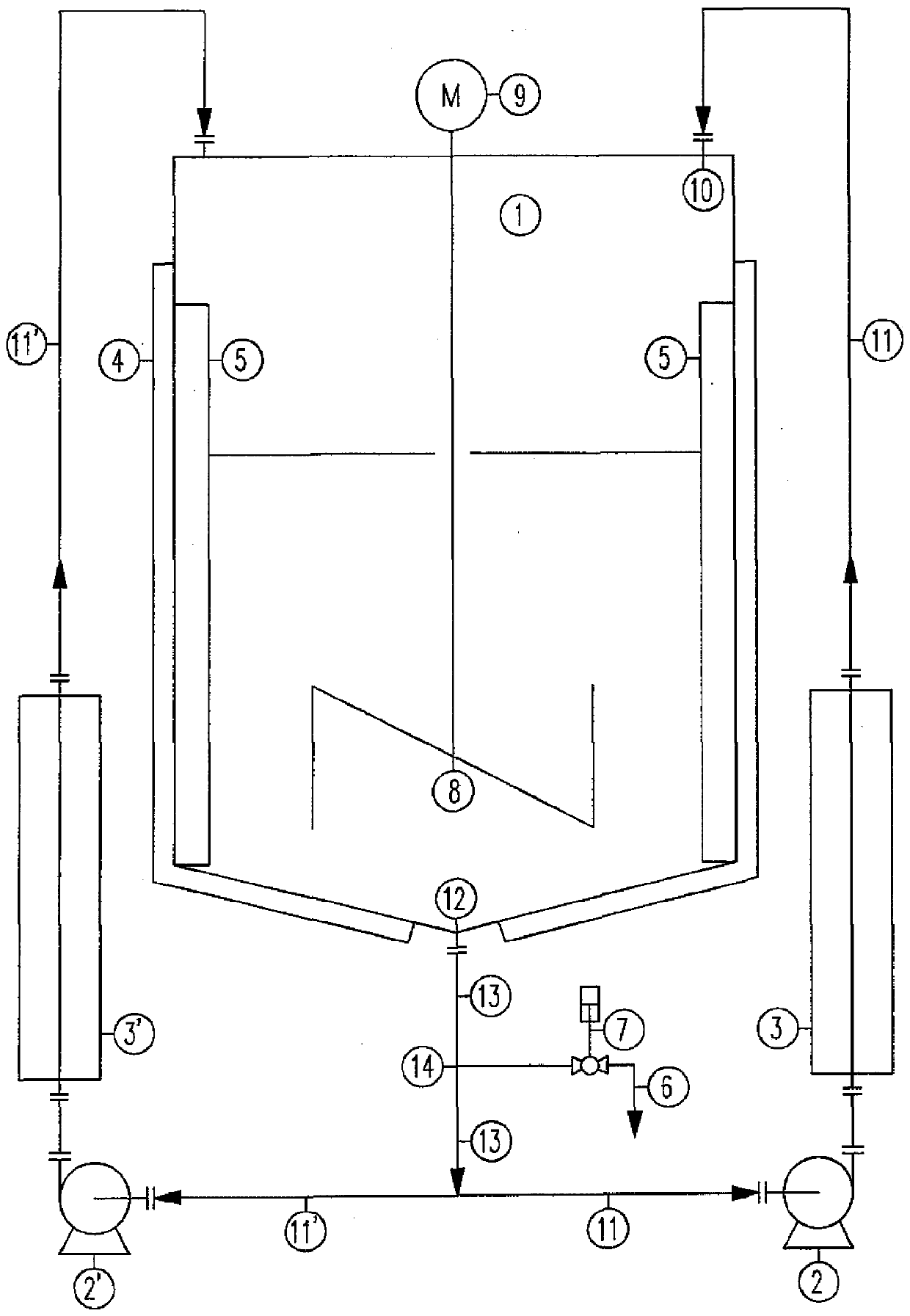

ActiveCN106457061AReduce procurement costsSimple designPolycrystalline material growthFrom normal temperature solutionsCooling curveInterconnection

The invention introduces a discontinuous crystallization unit for the production of ball- shaped crystals comprising a crystallizer (1) that consists of a metallic cylindrical vessel with its inner surface of a hard material, with an oval or circular cross-section with a conical or vaulted bottom (12), fitted along its length with a duplicator (4) for cooling of the solution and / or suspension of the solution and crystals and a high-speed agitator (8) of a hard material with a drive (9) enabling speed control and thus the rate of the impact of the mechanical action of the agitator on roundness of crystals inside the vessel together with the inner surface of the vessel containing at least 2 baffles (5) of a hard material while the vessel is fitted with at least 1 orifice (10) at the top that at least 1 independent branch of the circulation circuit (11) is connected to from the outside for the inlet of a heated solution and / or heated suspension of the solution and crystals by means of at least 1 circulation pump (2) and through at least 1 heat exchanger (3) and together with the duplicator (4) ensuring controlled periodic changes of temperatures of the crystal suspension around the cooling curve while an interconnection (13) pipeline is connected to the bottom (12) of the crystallizer (1) vessel that is connected to at least one branch of the circulation circuit (11).

Owner:ERUCA TECH SRO

Method for the production of organosiloxanes modified by a phosponic acid ester

The invention relates to a method for the producton of silicon organic compounds modified by a phosphonic acid ester by reacting at least one silane having formula [(R<3>O) fR<1>3-fSiCR<2>2P (O) (OR<4>) 2] (III) with at least one silicon compound having general formula (R2SiO2 / 2) p (R3SiO1 / 2) q [O1 / 2H] m (IV), wherein R<3> represents hydrogen or a C1-C20-hydrocarbon radical optionally substituted by -CN or a halogen atom, and m represents a whole number of 1 or 2, and R, R<1>, R<2>, R<3>, R<4>, m, p, q, f and s have the meaning cited in the description.

Owner:WACKER CHEM GMBH

Water-treatment composite microbe continuous culture device and culture method thereof

InactiveCN103074204BImprove cultivation efficiencyAvoid Intermittent OutagesBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobiologySewage treatment

The invention discloses a water-treatment composite microbe continuous culture device and a culture method thereof. The device comprises a tank (1), the tank (1) is separated into four independent culture zones comprising an aerobic zone (3), an anaerobic zone (4), a first transition zone (5) and a second transition zone (6) by separation plates (2), the first transition zone (5) and the second transition zone (6) are positioned between the aerobic zone (3) and the anaerobic zone (4), each of the culture zones is provided with a culture medium inlet (7) and an overflow mouth (8), a culture medium is continuously charged through the culture medium inlet (7), and a cultured bacterial liquid flows to a sewage treatment zone from the overflow mouth (8). The device and the method have the advantages of realization of the simultaneous and continuous culture of a plurality of strains, automatic addition of the culture medium, automatic charging of the bacterial liquid, improvement of the culture efficiency of the bacterial liquid, substantial acceleration of the composite pollution treatment speed, and avoiding of the sewage-treatment intermittent interruption caused by intermittent culture.

Owner:NINGHAI TIANHE ECOLOGICAL WATERSCAPE CONSTRCO

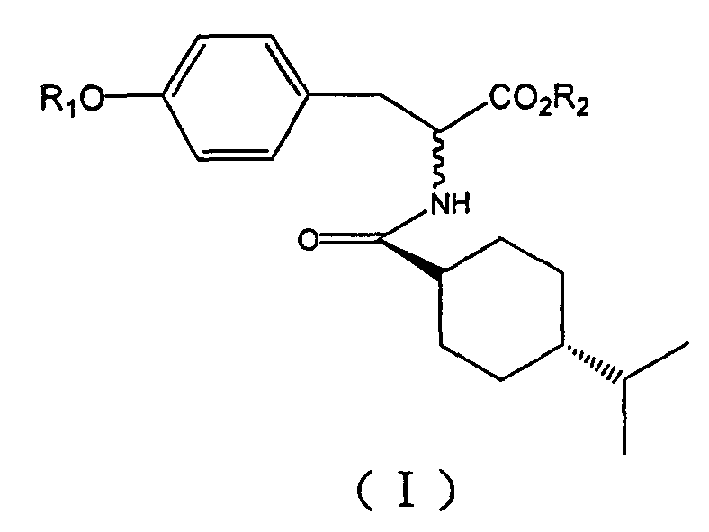

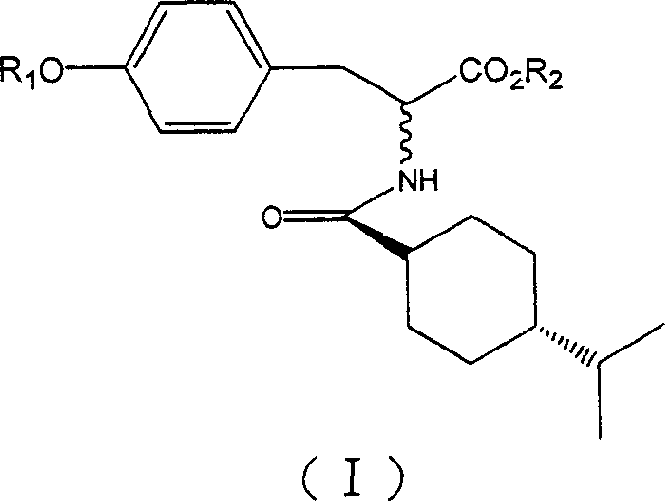

Alanine class compound, its preparing method and use

InactiveCN1431197AEnough purityLow toxicityOrganic active ingredientsPeptide/protein ingredientsHydrogen atomChemical compound

A lactamic acid compound or its salt, its two preparing processes, and its application in preparing medicine to treat diabetes B are disclosed.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

20(S) camptotheca alkaloid derivatives, their preparing methods and uses

InactiveCN100366622CReduce efficacyEnough purityOrganic active ingredientsOrganic chemistryCamptothecin derivativeAlkaloid

The invention provides 20(S)-camptothecin ramification demonstrated by the figure (1) or its acceptable salt in the medicine. The m in the figure is one integer between 2 and 5; R is OH, OR1 (R1 is the alkyl of C1-5), NH2, NHR1 (R1 is the alkyl of C1-5) or NR1R2 ((R1 and R2 are the alkyl of C1-5 respectively). The invention also provides the preparation method of the ramification and its use in the antineoplastic medicines.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI +1

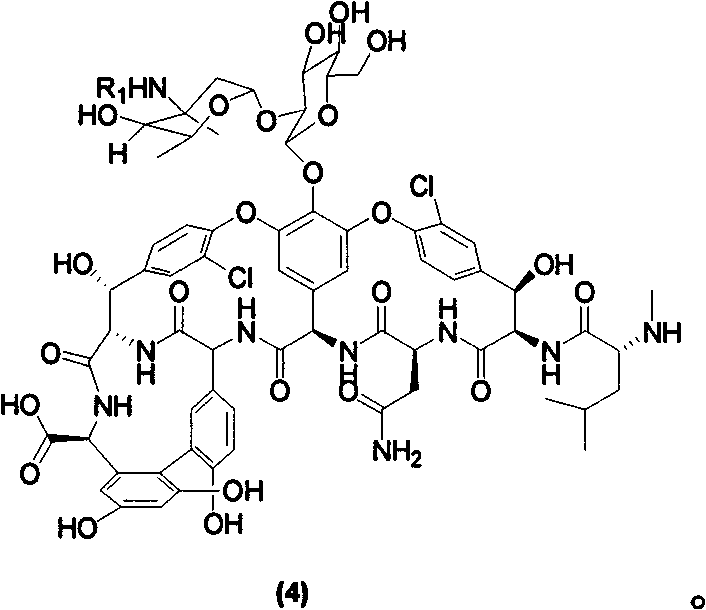

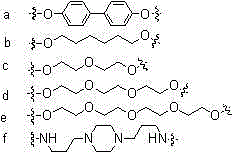

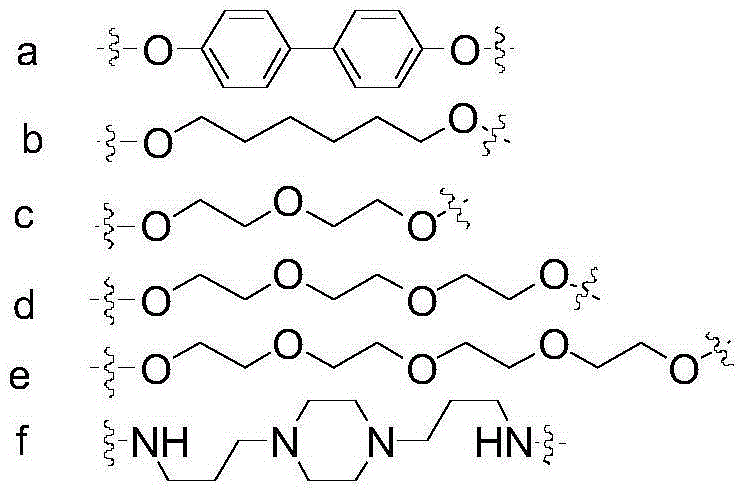

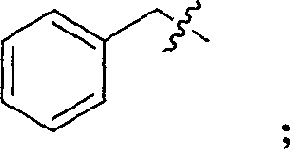

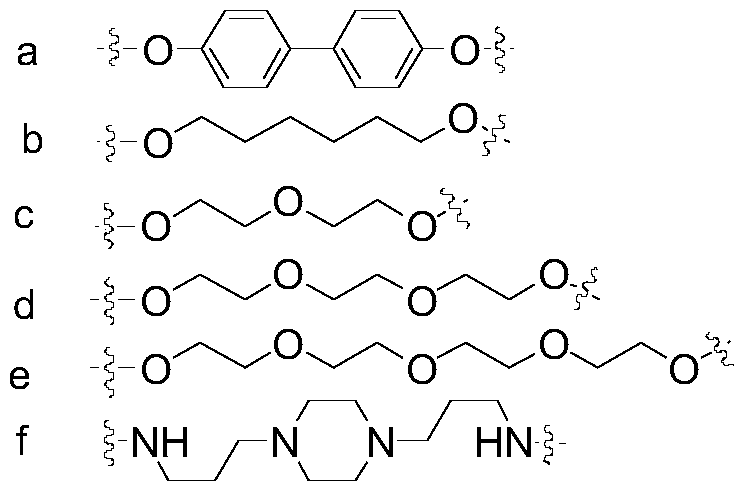

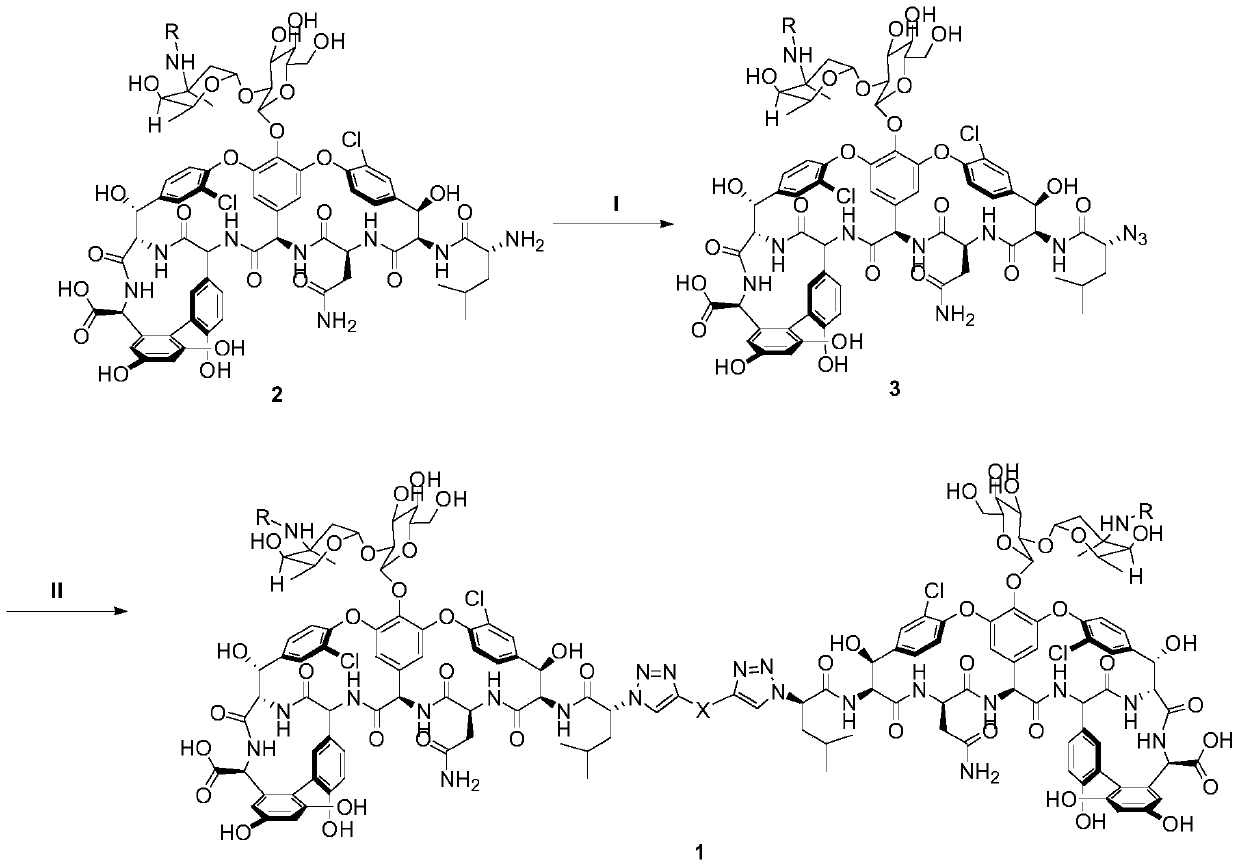

Norvancomycin-type dimer derivative, preparation method and medicinal application thereof

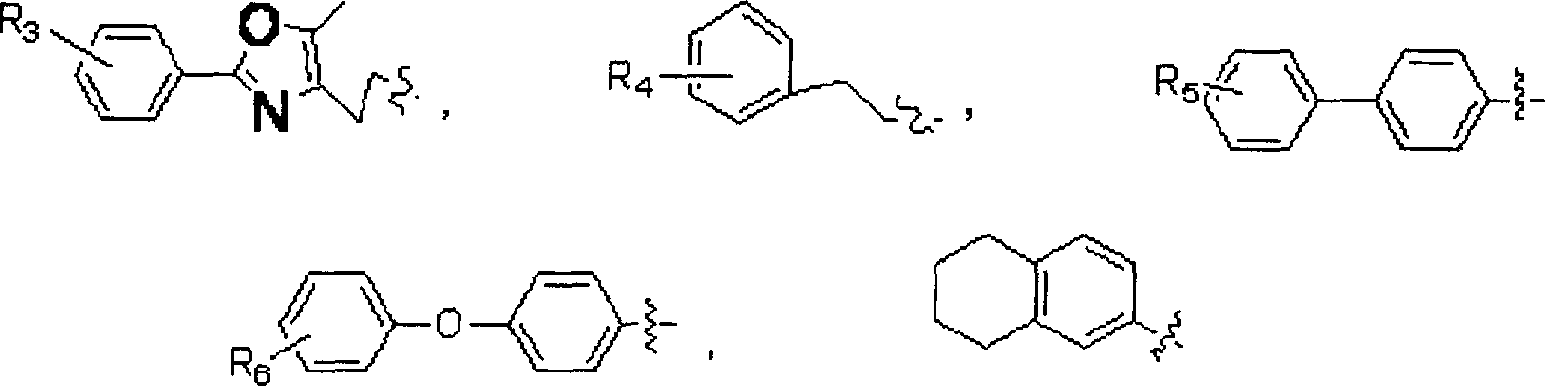

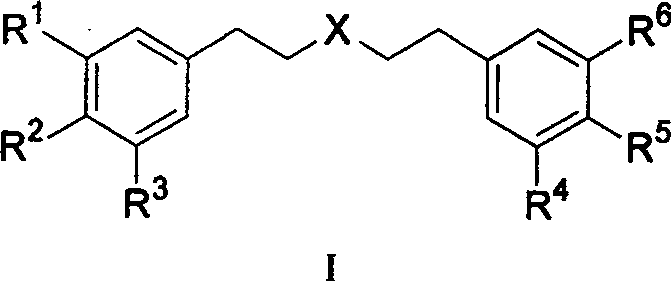

The invention belongs to the technical field of medicines and relates to novel glycopeptides antibiotics, and particularly relates to a norvancomycin-type dimer derivative represented as the formula (1), a pharmaceutically acceptable salt thereof and a preparation method thereof, and an application of the compound in preparation of medicines for treating or preventing bacterial infectious diseases. In the invention, an in-vitro antibacterial experiment is carried out and proves that the compound has significant stronger antibacterial activities on various Gram-positive bacteria than vancomycin and norvancomycin. The compound further can be used for preparing medicines, especially anti-bacterial infection medicines. The formula (1) is described as follows, wherein a bridge chain X may be the following six structures; R refers to hydrogen or substituted or non-substituted C1-C12 alkyl groups, naphthenic groups, hetero-naphthenic groups, aryl groups, hetero-aromatic substituted groups, and C1-C12 alkylacyl groups, aroyl groups, and alkylsulfonyl groups.

Owner:FUDAN UNIV

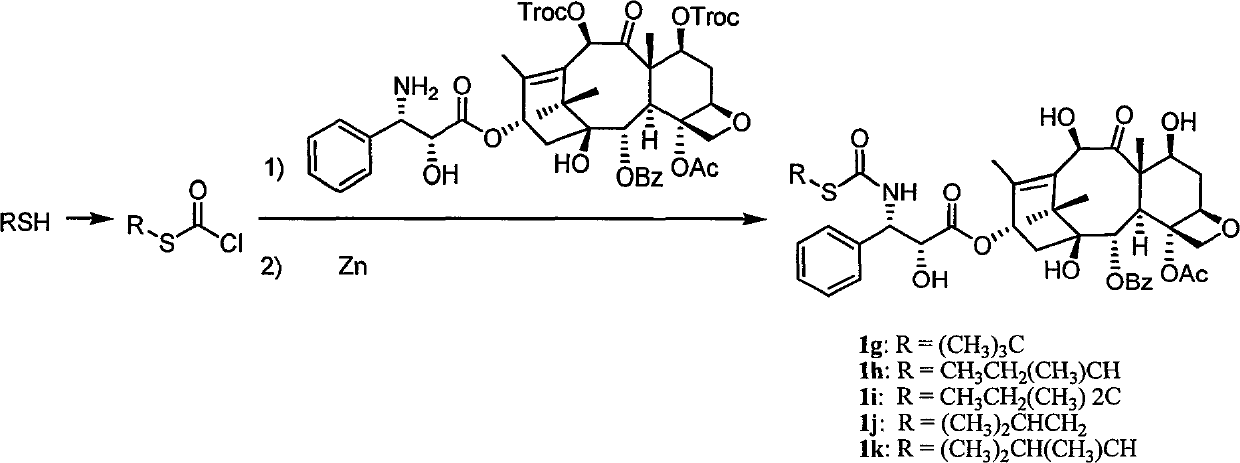

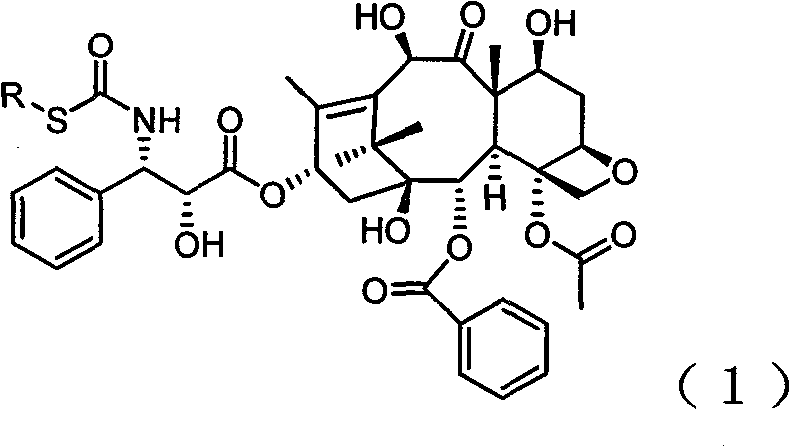

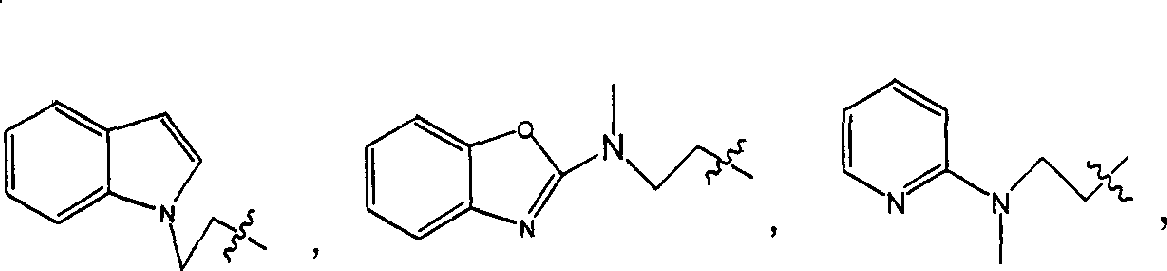

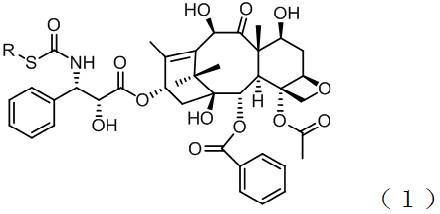

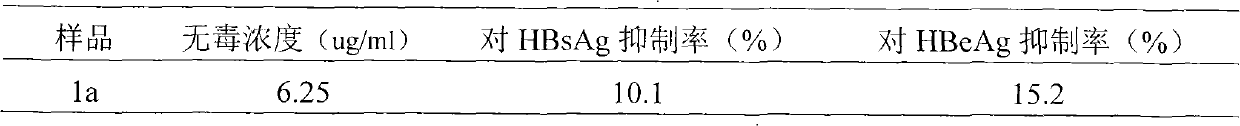

New application of thio-taxane derivatives

The invention discloses a new application of thio-taxane derivatives which have the structure shown in formula (1), wherein R is hydrogen, C1-18 are alkyl groups, C1-18 are substituted alkyl groups, C2-10 are alkenyl groups, C2-10 are alkynyl, C3-6 are naphthenic base, C4-6 are cyclenes base, aryl, substituted aryl, heterocyclic groups or substituted heterocyclic groups, and the substituent is one or several types selected from C1-8 alkyl groups, C1-8 alkoxy, C1-8 halogenated alkyl, halogen, aryl, nitryl or amino. The thio-taxane derivative can be used for preparing medicines for treating hepatitis B.

Owner:HAINAN SIMCERE PHARMA CO LTD

Discontinuous crystallization units for the preparation of spherical crystals

ActiveCN106457061BReduce procurement costsSimple designPolycrystalline material growthFrom normal temperature solutionsCooling curveEngineering

The invention relates to a discontinuous crystallization unit for the preparation of spherical crystals, comprising a crystallizer (1) consisting of a metal cylindrical container with a hard material inner surface, with an elliptical shaped or circular cross-section and tapered or arched bottom (12), along the length of said metal cylindrical vessel is mounted a replicator (4) for cooling the solution and / or suspension of solution and crystals; and hard A high-speed stirrer (8) for the material with a drive (9) that achieves speed control and is thus connected to the interior of the vessel with at least 2 hard material baffles (5) The surfaces together control the impact rate of the mechanical action of the stirrer on the crystal roundness in the container, and at the same time at least 1 orifice (10) is installed on the top of the container, and the branch of at least 1 independent circulation loop (11) is connected to the said at least 1 orifice (10) for feeding heated solution and / or heated solution and suspension of crystals via at least 1 circulation pump (2) and via at least 1 heat exchanger (3) , which together with the replicator (4) ensures a controlled periodic variation of the temperature of the crystal suspension around the cooling curve, while connecting the interconnection (13) pipeline to the crystallizer (1) vessel bottom (12), which connects At least one branch to the circulation loop (11).

Owner:ERUCA TECH SRO

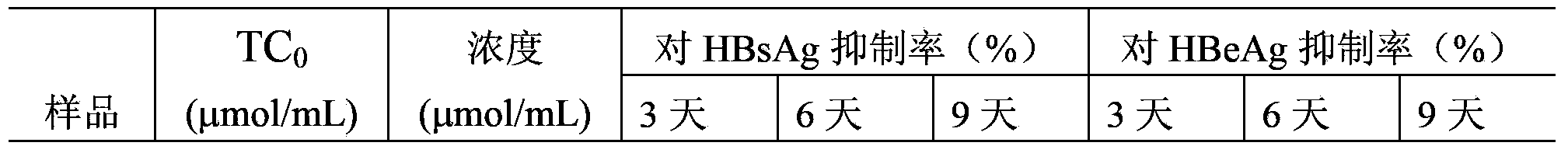

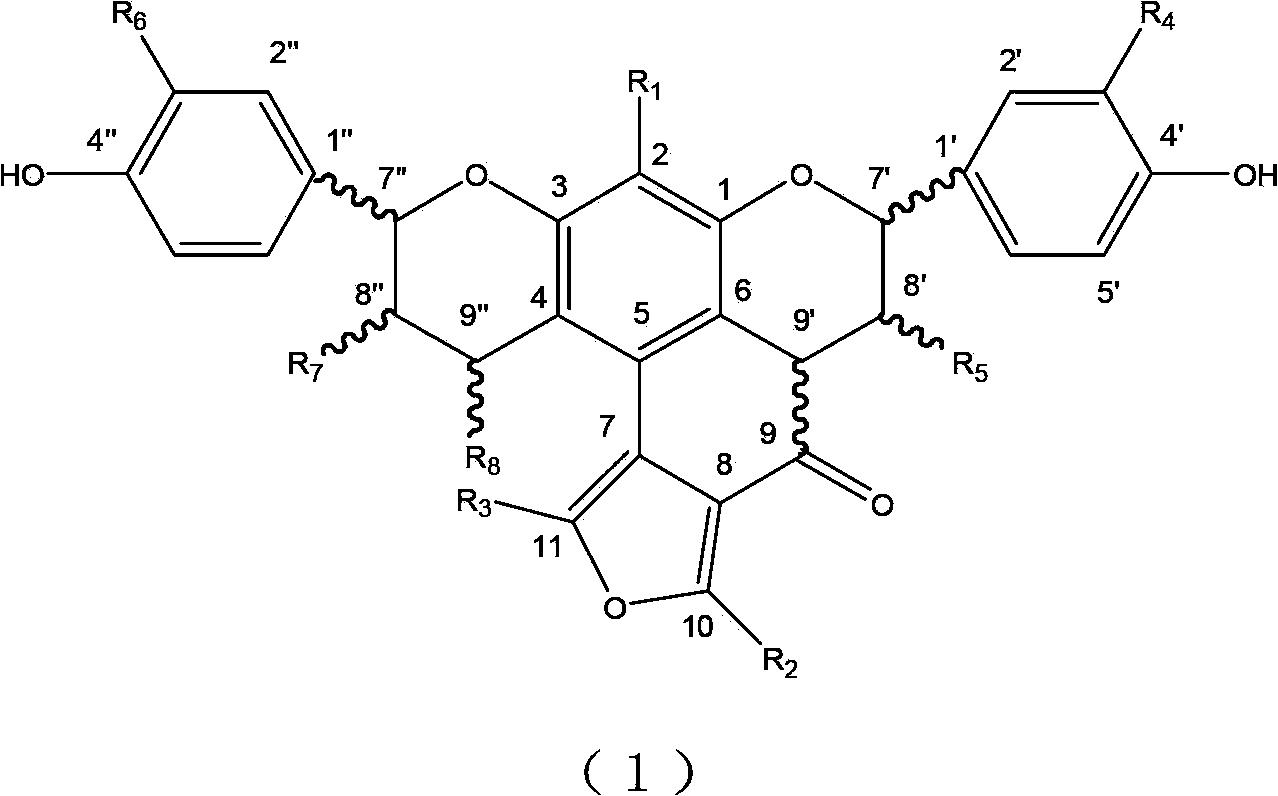

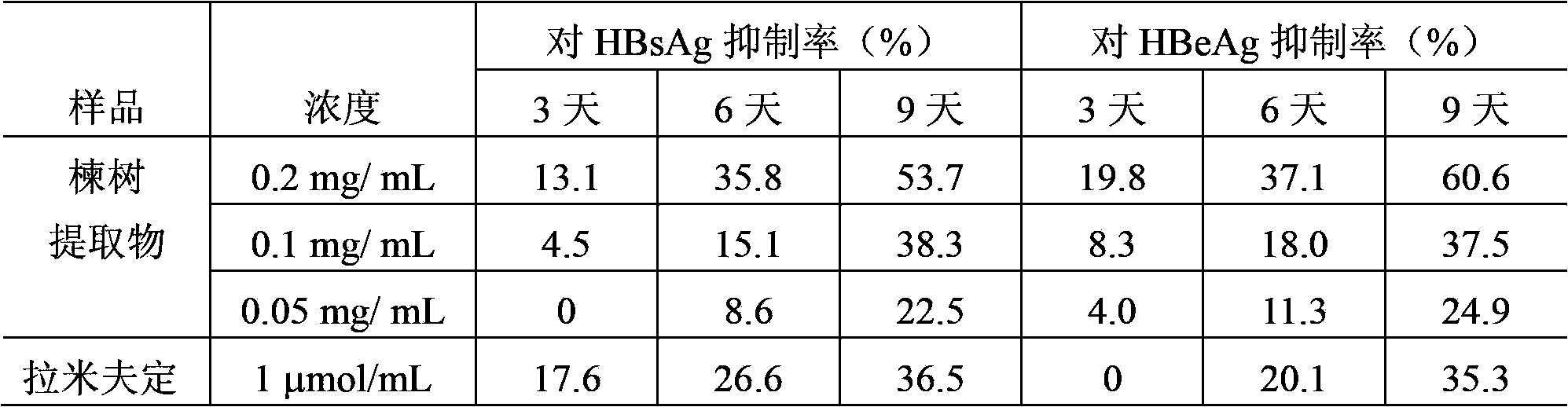

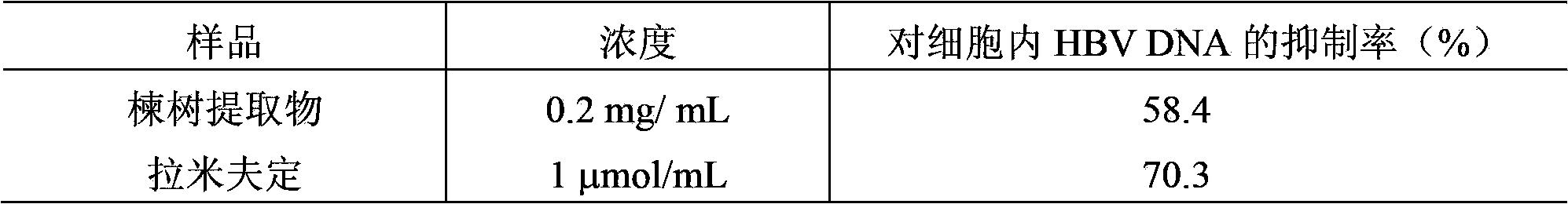

Novel phenolic compound treating hepatitis b, and preparation method and application thereof

InactiveCN104230950AInhibits HBsAg and HBeAgGood dose dependenceOrganic active ingredientsOrganic chemistrySorbentMelia azedarach

The invention discloses a novel phenolic compound treating hepatitis b, and a preparation method and application thereof. The preparation method of the novel melia phenolic compound comprises: using a hot extraction method or a cold extraction method to process a melia azedarach raw material, so as to obtain a melia azedarach crude extractive; and then using a methyl propene synthesis adsorbent or an aromatic (styrene, divinyl benzene) serial synthesis adsorbent, a gel synthesis adsorbent and a reverse-phase silica gel adsorbent to perform purification, so as to obtain the novel melia phenolic compound. The invention also discloses application of the novel melia phenolic compound to prepare medicines for treating hepatitis b.

Owner:TONGLING GINGER SCI

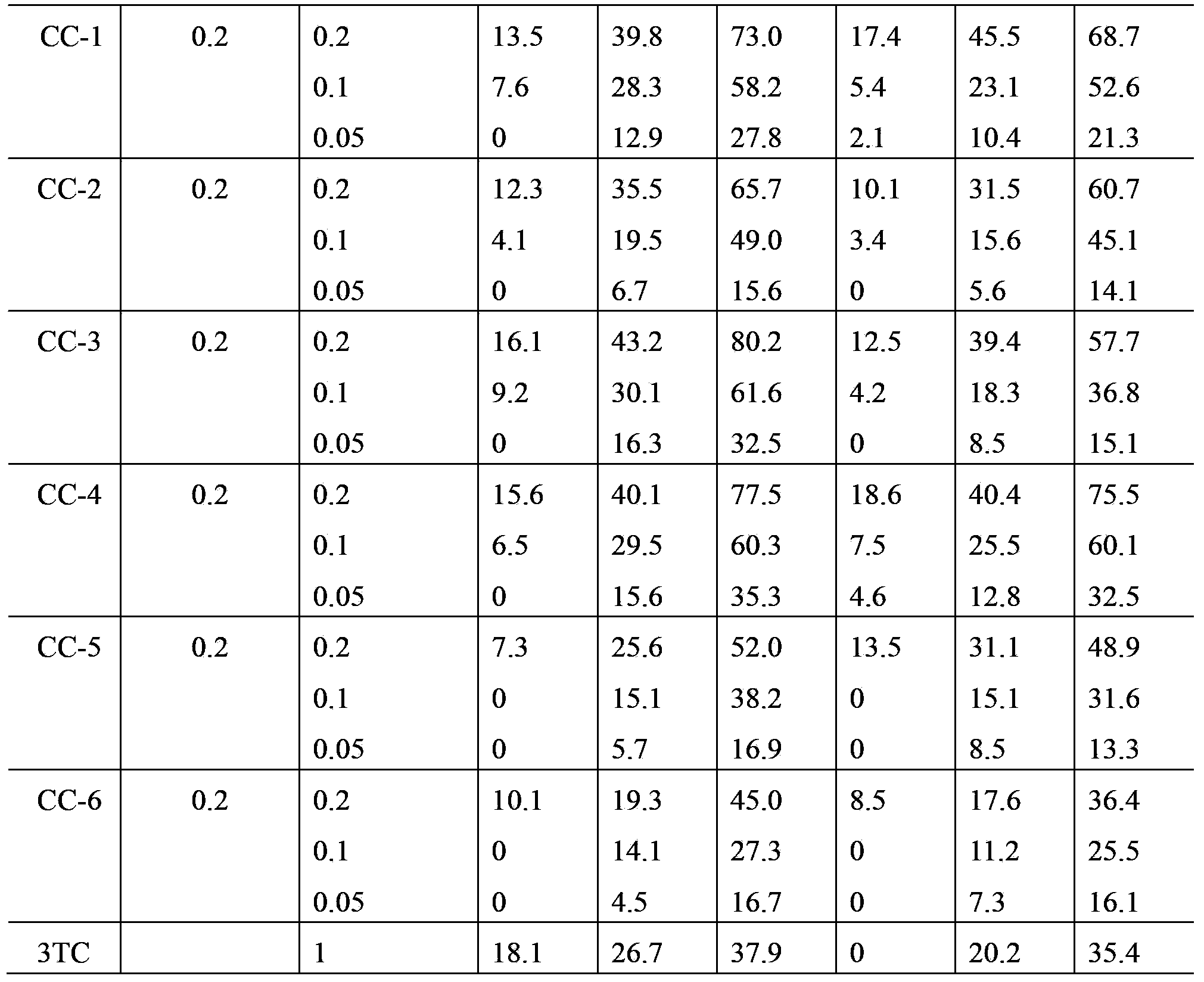

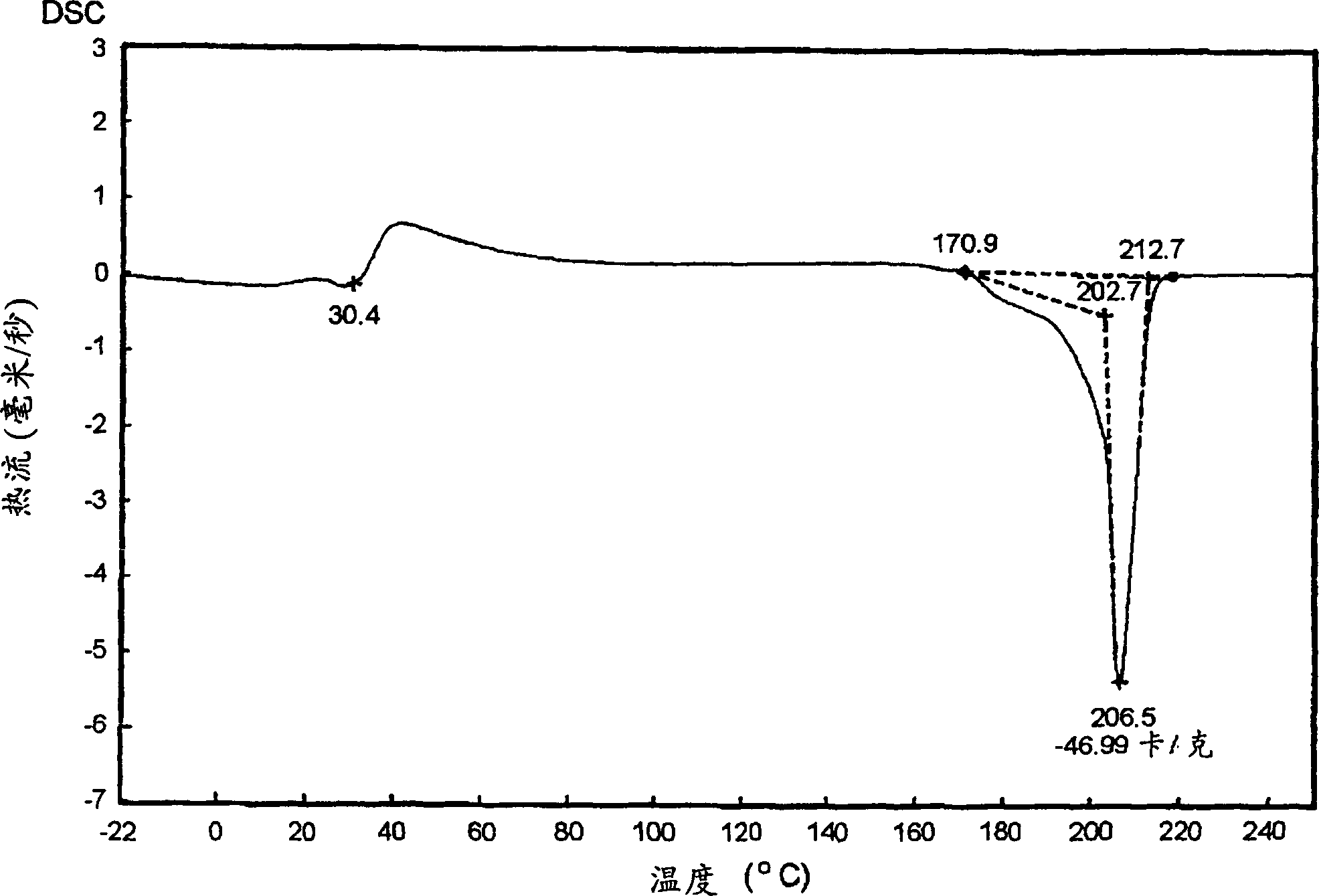

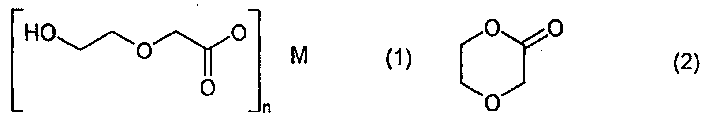

Pure beta-hydroxyethoxyacetic acid salt, pure 2-p-dioxaneone, and prodn. method thereof

InactiveCN1198782CEnough purityHigh molecular weightCarboxylic compound separation/purificationP-dioxanoneAcetic acid

A purified salt of beta-hydroxyethoxy acetic acid of formula (1) having a fusion peak-top temperature detected by differential scanning calorimetry (DSC) and a purified 2-p-dioxanone of formula (2) derived from the purified salt of beta-hydroxyethoxy acetic acid of formula (1), wherein in formula (1), n=1-2 , and if n=1, M is Na and / or K, and, if n=2, M is Ca and / or Mg.

Owner:MITSUI CHEM INC

Benzofuran category compound, its preparing method and usage

InactiveCN1244573CEnough purityLow toxicityOrganic active ingredientsOrganic chemistryMedicineDiabrezide

A benzopyran compound or its salts, their preparing process and their application in preparing medicine for treating B-type diabetes are disclosed.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

Norvancomycin dimer derivative and its preparation method and medicinal use

The invention belongs to the technical field of medicines and relates to novel glycopeptides antibiotics, and particularly relates to a norvancomycin-type dimer derivative represented as the formula (1), a pharmaceutically acceptable salt thereof and a preparation method thereof, and an application of the compound in preparation of medicines for treating or preventing bacterial infectious diseases. In the invention, an in-vitro antibacterial experiment is carried out and proves that the compound has significant stronger antibacterial activities on various Gram-positive bacteria than vancomycin and norvancomycin. The compound further can be used for preparing medicines, especially anti-bacterial infection medicines. The formula (1) is described as follows, wherein a bridge chain X may be the following six structures; R refers to hydrogen or substituted or non-substituted C1-C12 alkyl groups, naphthenic groups, hetero-naphthenic groups, aryl groups, hetero-aromatic substituted groups, and C1-C12 alkylacyl groups, aroyl groups, and alkylsulfonyl groups.

Owner:FUDAN UNIV

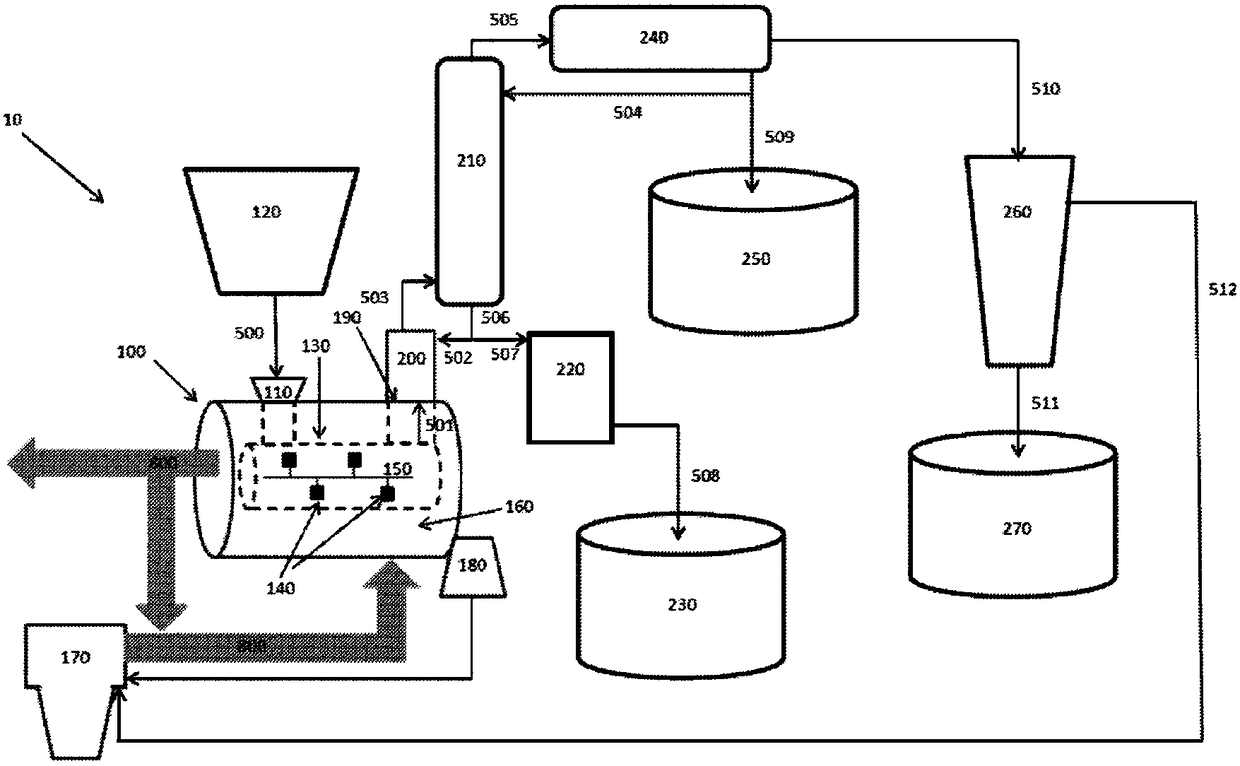

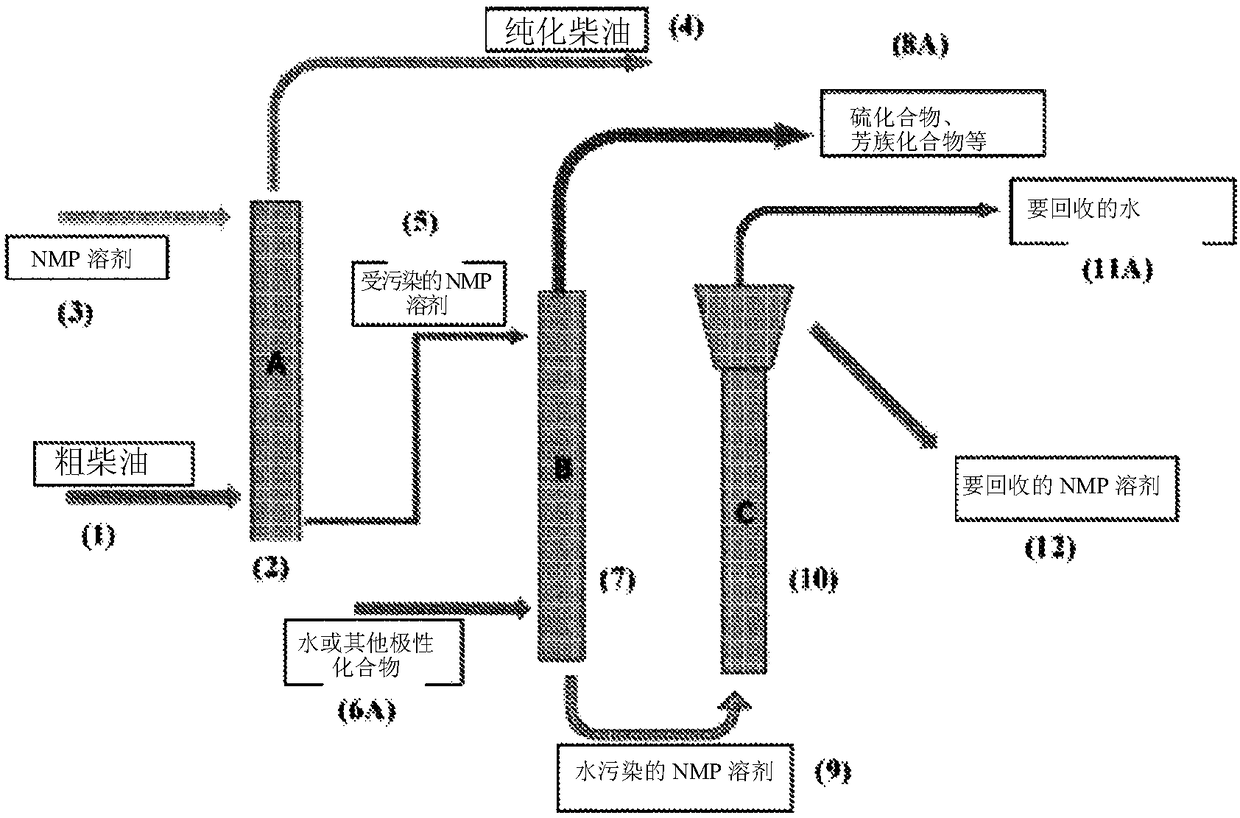

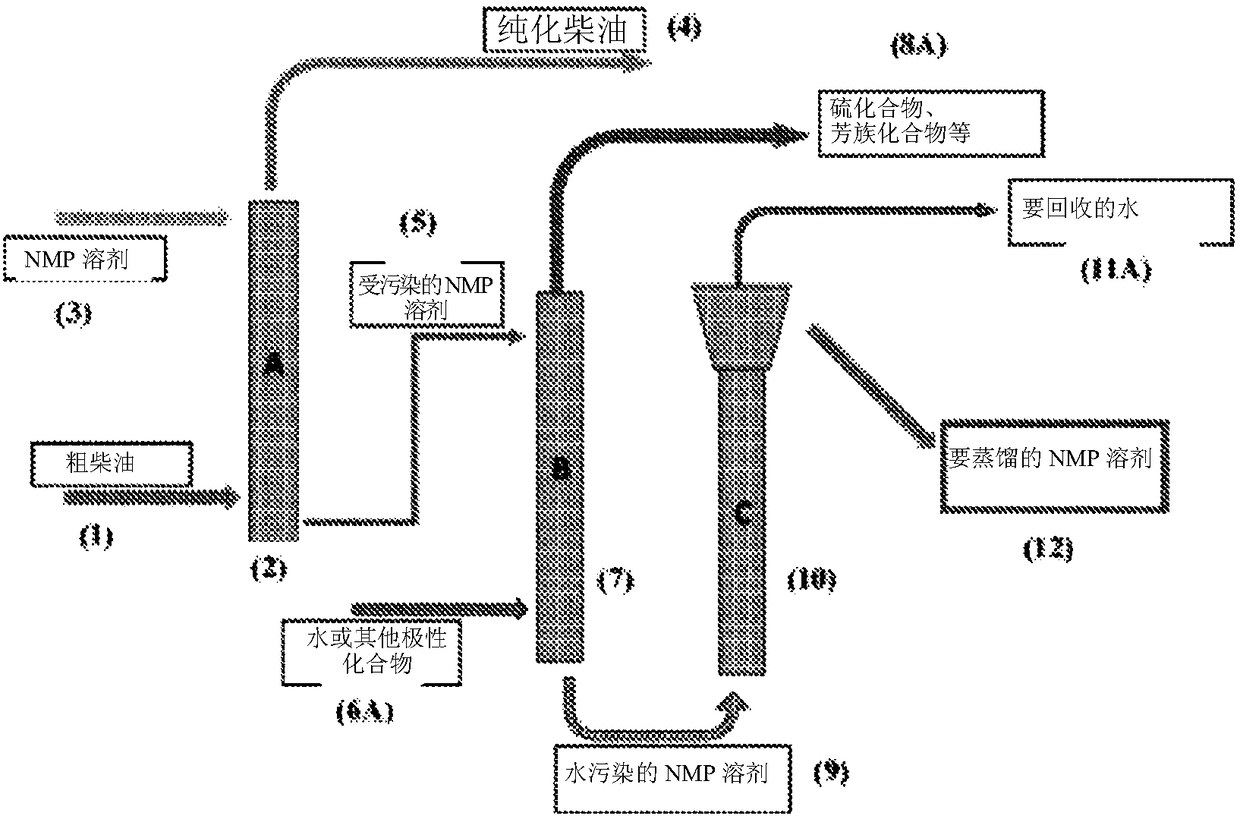

Production of hydrocarbon fuels from plastics

Disclosed herein is a kiln (100) for use in the production of hydrocarbon fuels from plastics. The kiln (100) comprises a scrubber (200) in fluid communication with a reaction chamber (130), the scrubber (200) being configured to condense hydrocarbons in the reaction chamber gas product stream (501) above a predetermined upper hydrocarbon range for returning to the reaction chamber (130) for further heating in the absence of oxygen. Also disclosed herein is a method of converting waste plastics to a commercially-useful form by way of diesel or the like. The method comprises treating a crude fuel produced from plastics in a pyrolytic process with a first extraction step comprising counterflow liquid-liquid extraction, and a second extraction step comprising counterflow extraction of solvents from the first extraction step.

Owner:INTEGRATED GREEN ENERGY SINGAPORE PTE LTD

Alanine class compound, its preparing method and use

InactiveCN1181055CEnough purityLow toxicityOrganic active ingredientsPeptide/protein ingredientsHydrogen atomChemical compound

A lactamic acid compound or its salt, its two preparing processes, and its application in preparing medicine to treat diabetes B are disclosed.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

New application of thio-taxane derivatives

ActiveCN101838250BReduce efficacyEnough purityOrganic active ingredientsOrganic chemistryArylHalogen

The invention discloses a new application of thio-taxane derivatives which have the structure shown in formula (1), wherein R is hydrogen, C1-18 are alkyl groups, C1-18 are substituted alkyl groups, C2-10 are alkenyl groups, C2-10 are alkynyl, C3-6 are naphthenic base, C4-6 are cyclenes base, aryl, substituted aryl, heterocyclic groups or substituted heterocyclic groups, and the substituent is one or several types selected from C1-8 alkyl groups, C1-8 alkoxy, C1-8 halogenated alkyl, halogen, aryl, nitryl or amino. The thio-taxane derivative can be used for preparing medicines for treating hepatitis B.

Owner:HAINAN SIMCERE PHARMA CO LTD

Process for isolating iodixanol from an aqueous solution

InactiveCN101962331AEnough puritySuitable physical propertiesCarboxylic acid amide separation/purificationIodixanolAqueous solution

This invention relates to the isolation of iodixanol (1,3-bis(acetamido)-N,N'-bis[3,5-bis(2,3-dihydroxypropylaminocarbonyl)-2,4,6-triiodophenyl]-2-hydroxypropane), more specifically to the isolation of iodixanol from an aqueous solution.

Owner:GE HEALTHCARE AS

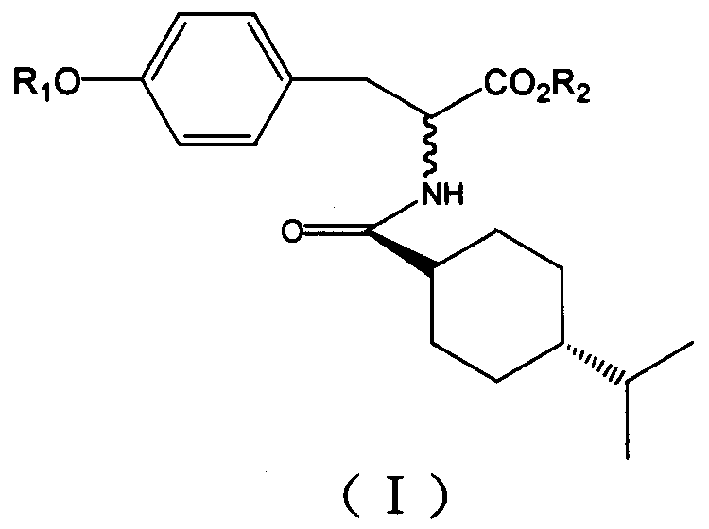

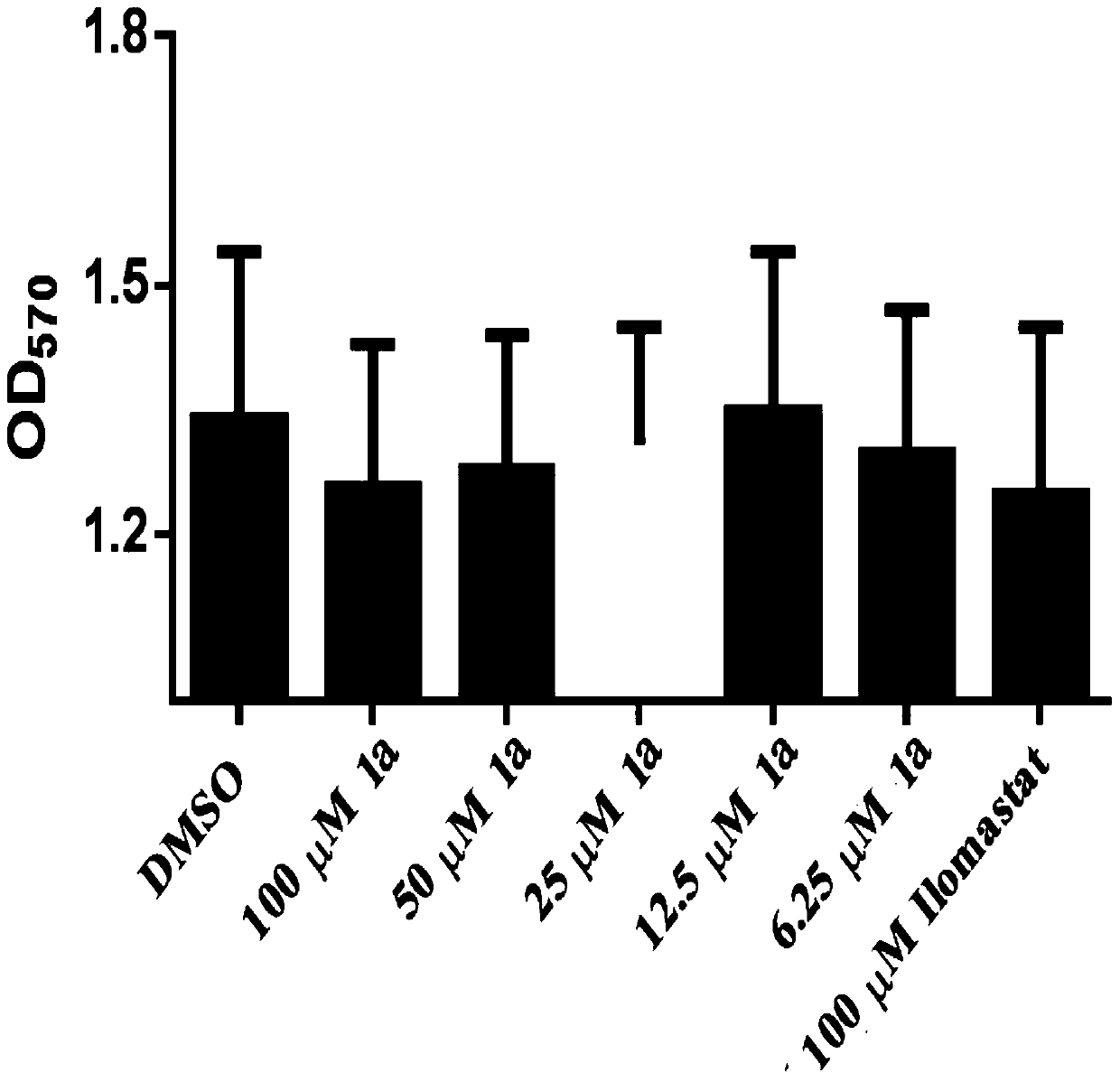

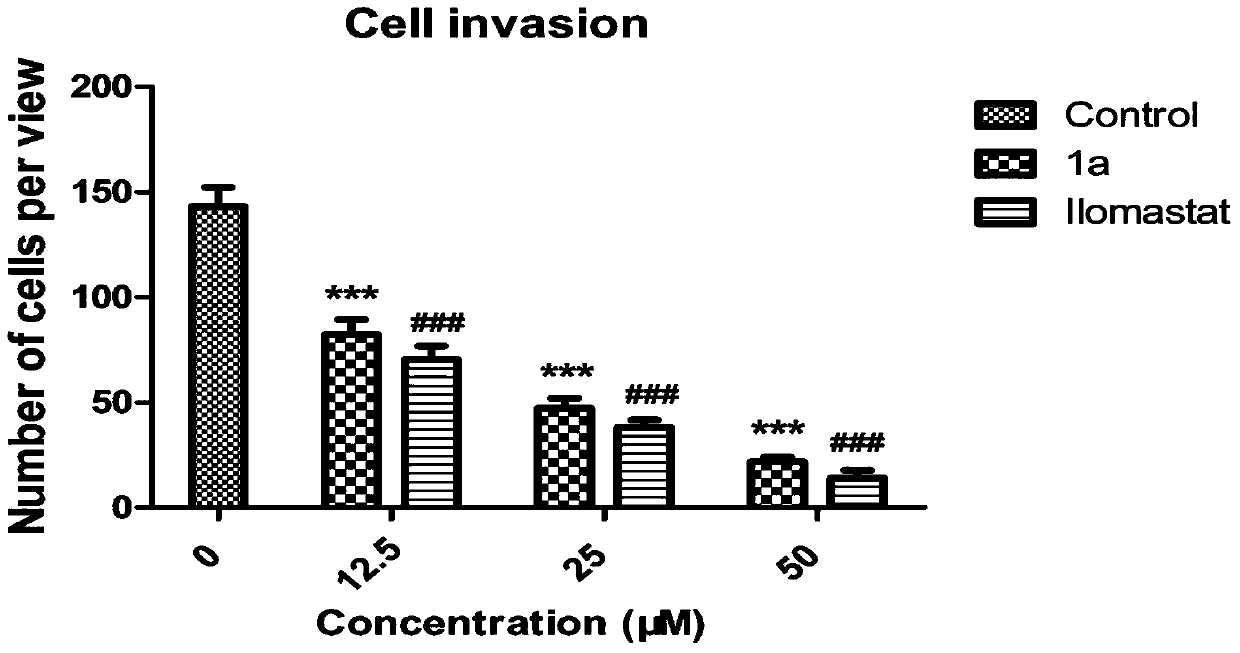

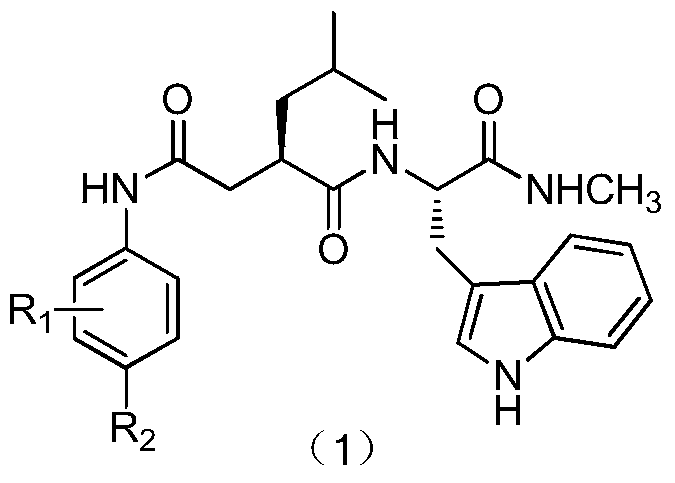

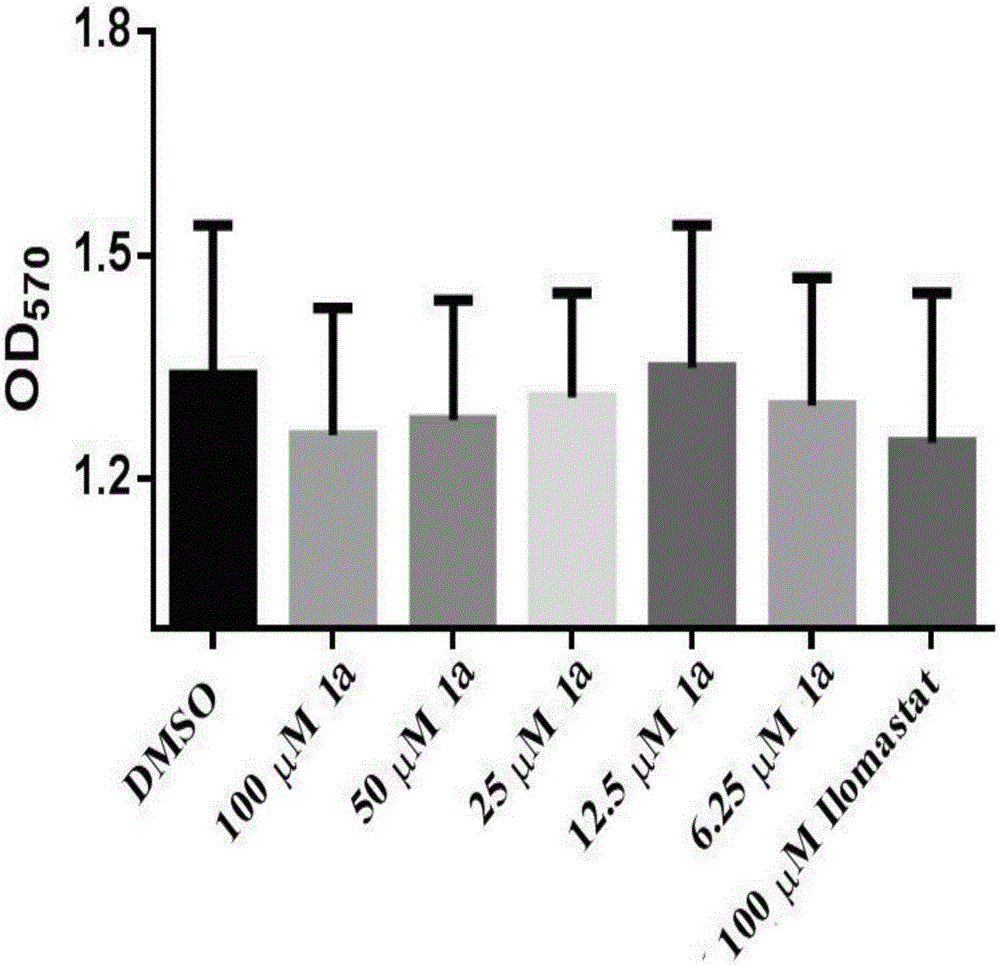

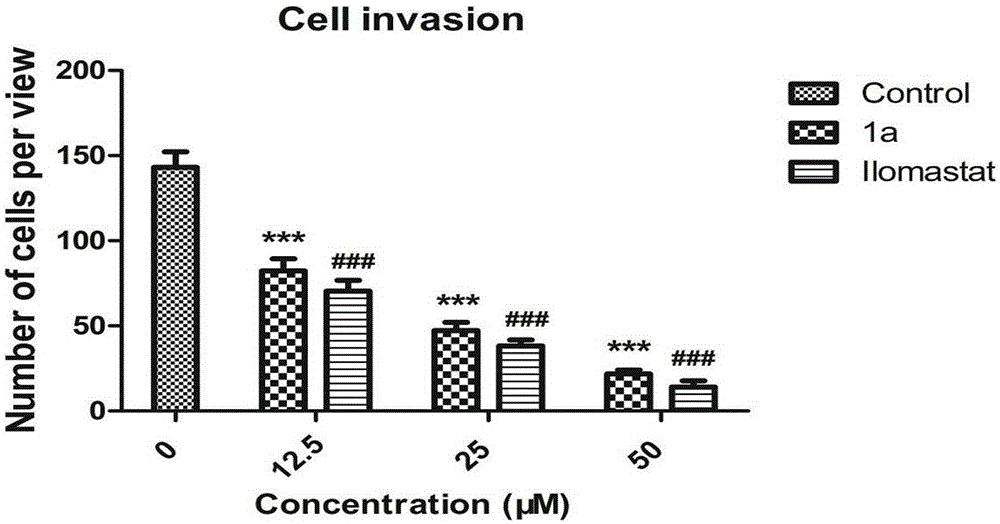

A kind of matrix metalloproteinase inhibitor and its medicinal use

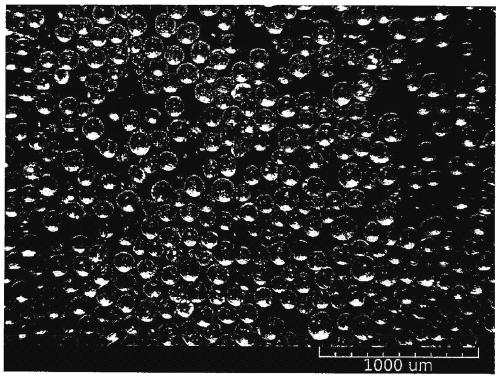

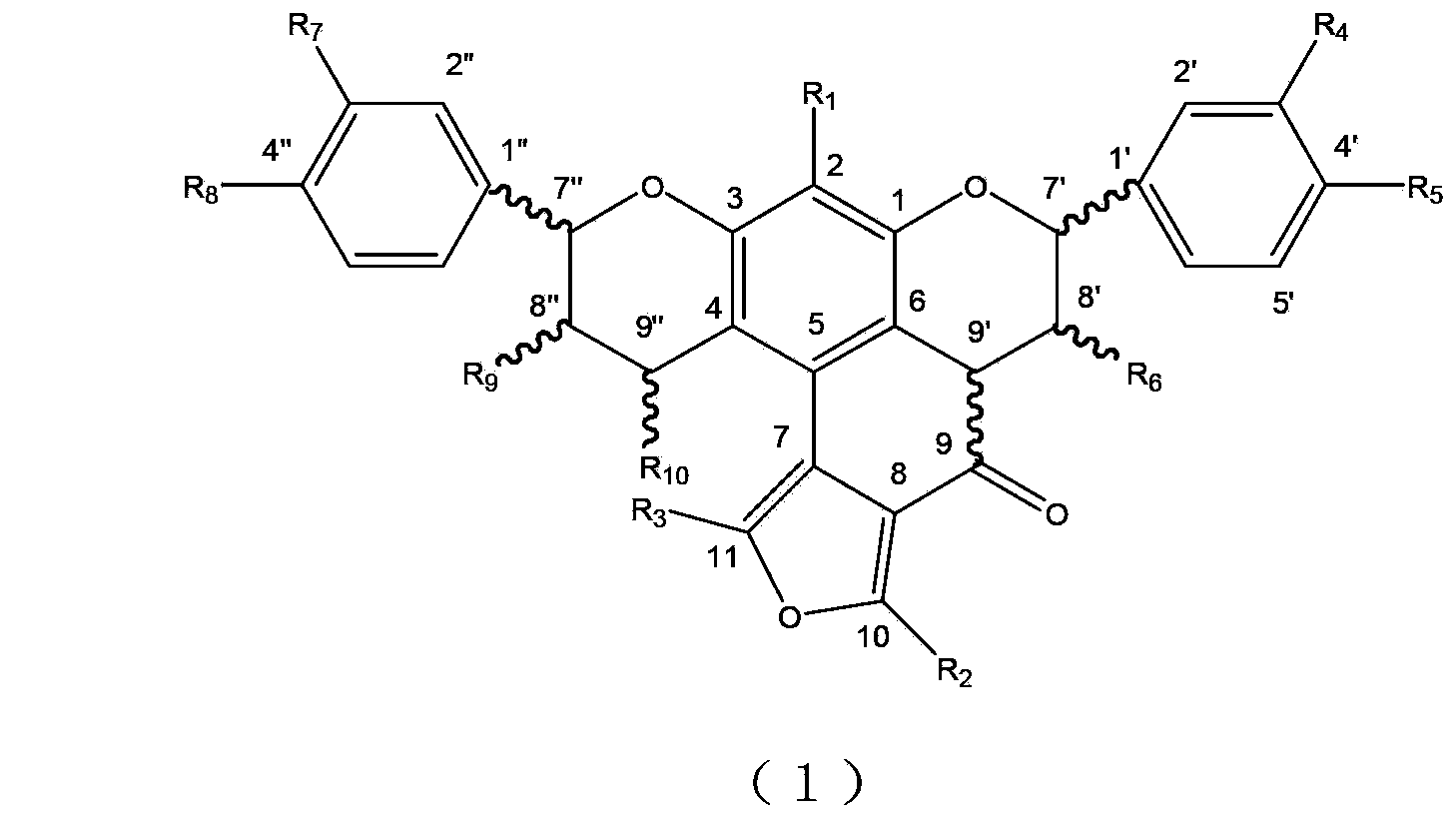

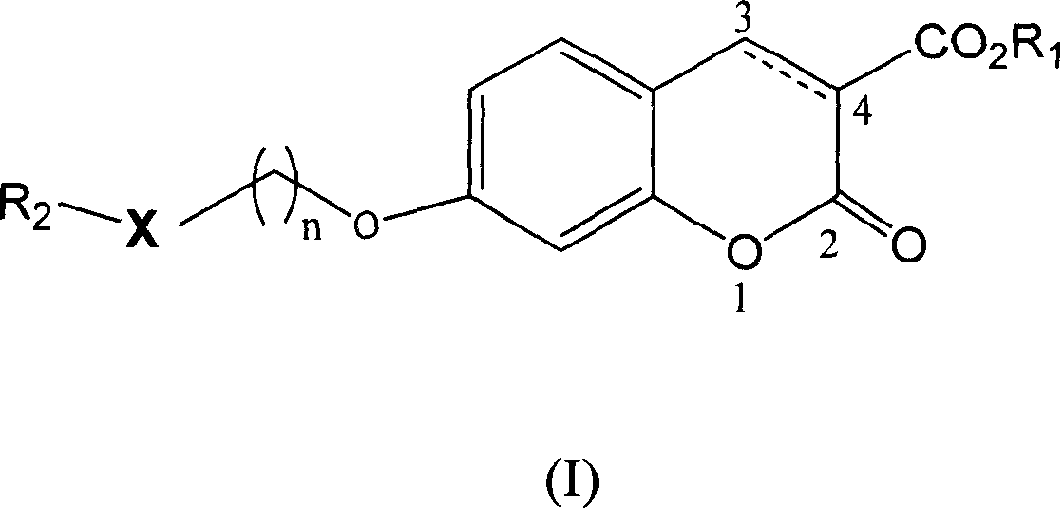

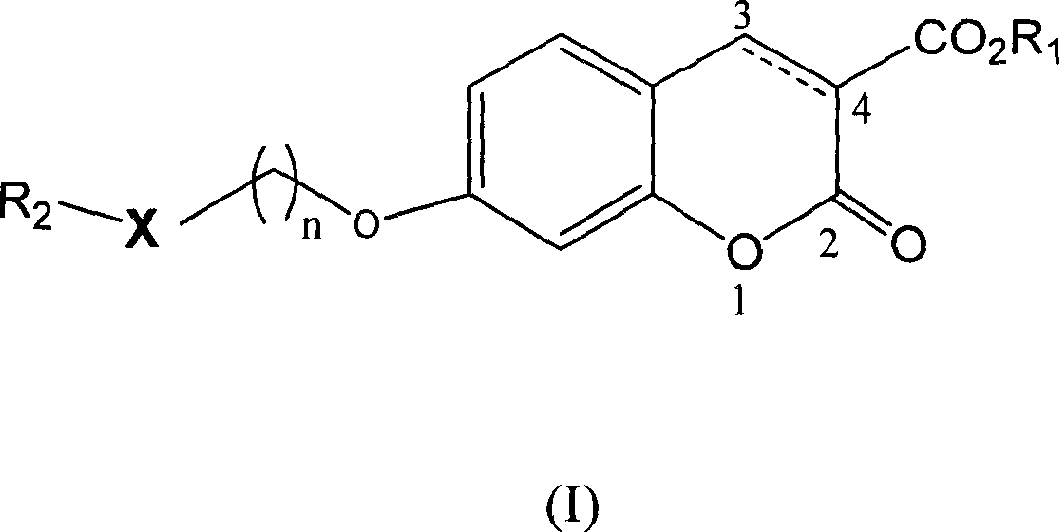

ActiveCN106588744BReduce efficacyEnough purityOrganic active ingredientsOrganic chemistryFuranEthyl group

The invention belongs to the technical field of medicinal chemistry, and relates to a novel matrix metal protease inhibitor and medicinal use thereof. The inhibitor is benzamide ilomastat derivative as shown in a formula (1) defined in the description, wherein R1 includes but is not limited to 2-NH2, an amino group is substituted with an acetyl amino group, R2 includes but is not limited to aromatic groups such as hydrogen atoms, fluorine, chlorine, bromine, a methyl group, an ethyl group, NH2, substituted amino, a methoxyl group, an ethoxy group, a trifluoromethyl group, a cyclohexyl group, a phenyl group, substituted phenyl, thiophene, pyrrole, furan, thiazole and pyridine, and the substituted phenyl of R2 includes but is not limited to radical groups such as a methyl group, an ethyl group, a methoxyl group, an ethoxy group, a trifluoromethyl group, a hydroxyl group, fluorine, chlorine, bromine, an acetyl group and benzophenone connected with 4' position of a benzene ring. Experiments show that the benzamide ilomastat derivative can be used for preparing drugs for resisting invasion and diffusion of tumors such as a liver cancer, a lung cancer, a breast cancer and an ovarian cancer.

Owner:FUDAN UNIV

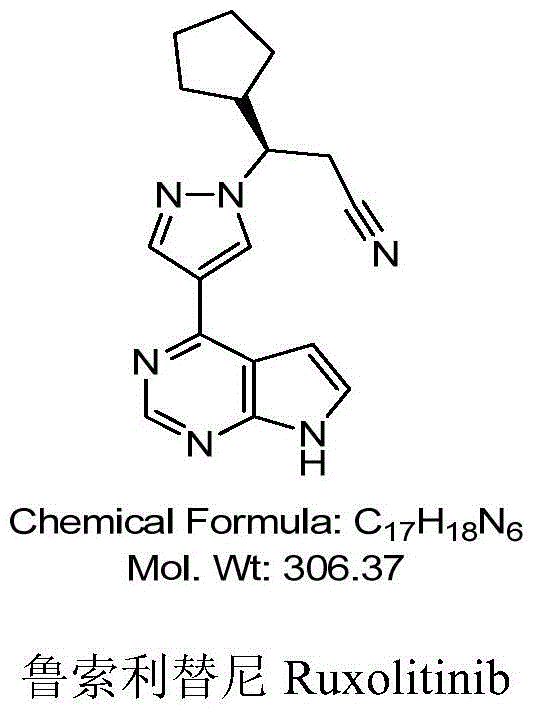

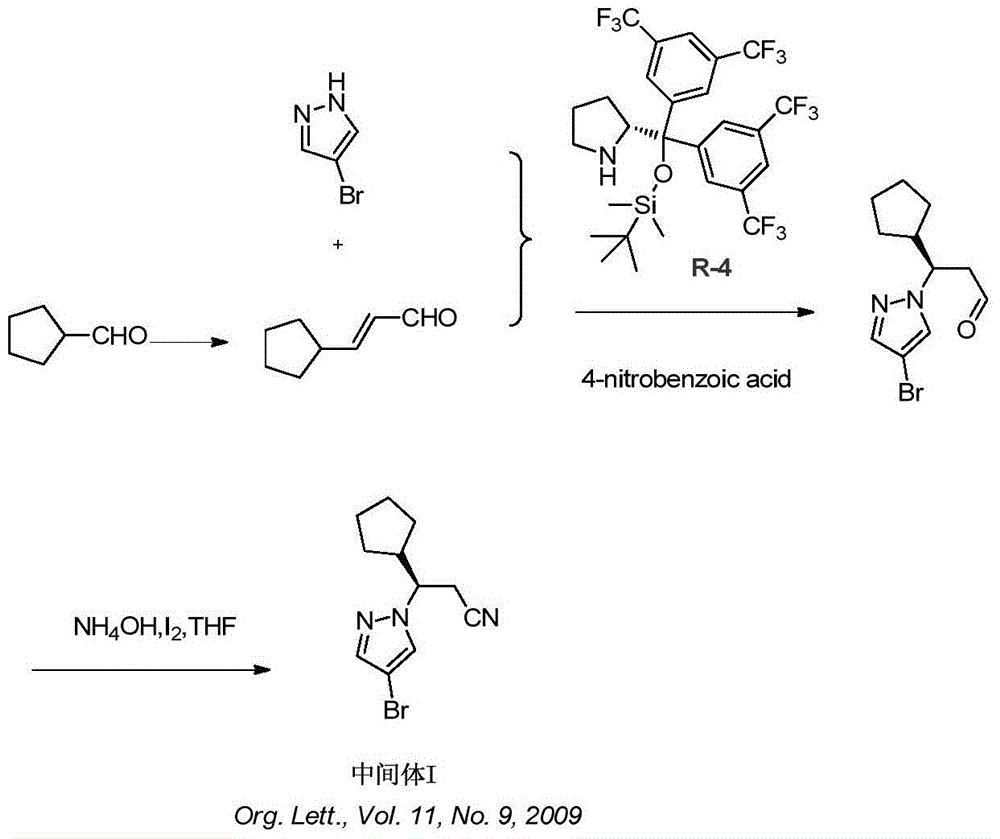

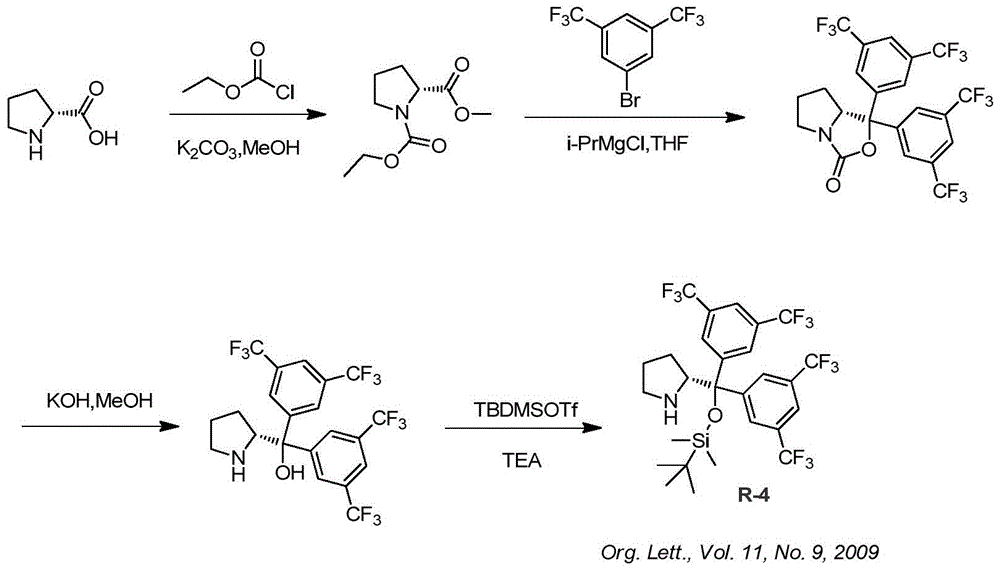

A kind of synthetic method of ruxolitinib intermediate

The invention relates to a synthesis method of a ruxolitinib intermediate. The method comprises the following steps: firstly, carrying out catalytic reaction on cyclopentane methyl formate and acetonitrile to prepare 3-cyclopentyl-3-oxypropionitrile; carrying out enzymatic asymmetric reduction on 3-cyclopentyl-3-oxypropionitrile to generate chiral alcohol (S)-3-cyclopentyl-3-oxypropionitrile; and carrying out Mitsunobu reaction and 4-bromopyrazole coupling on (S)-3-cyclopentyl-3-oxypropionitrile to obtain ruxolitinib intermediate (3R)-3-(4-bromo-1H-pyrazole-1-yl)-3-cyclopentane propionitrile. The synthesis method has the advantages of short route, low cost, mild condition and good stereoselectivity, and is suitable for industrialized mass production.

Owner:BIOCOMPOUNDS PHARMACEUTICAL INC +1

Matrix metal protease inhibitor and medicinal use thereof

ActiveCN106588744AHas pharmacological research valueReduce efficacyOrganic active ingredientsOrganic chemistryFuranEthyl group

The invention belongs to the technical field of medicinal chemistry, and relates to a novel matrix metal protease inhibitor and medicinal use thereof. The inhibitor is benzamide ilomastat derivative as shown in a formula (1) defined in the description, wherein R1 includes but is not limited to 2-NH2, an amino group is substituted with an acetyl amino group, R2 includes but is not limited to aromatic groups such as hydrogen atoms, fluorine, chlorine, bromine, a methyl group, an ethyl group, NH2, substituted amino, a methoxyl group, an ethoxy group, a trifluoromethyl group, a cyclohexyl group, a phenyl group, substituted phenyl, thiophene, pyrrole, furan, thiazole and pyridine, and the substituted phenyl of R2 includes but is not limited to radical groups such as a methyl group, an ethyl group, a methoxyl group, an ethoxy group, a trifluoromethyl group, a hydroxyl group, fluorine, chlorine, bromine, an acetyl group and benzophenone connected with 4' position of a benzene ring. Experiments show that the benzamide ilomastat derivative can be used for preparing drugs for resisting invasion and diffusion of tumors such as a liver cancer, a lung cancer, a breast cancer and an ovarian cancer.

Owner:FUDAN UNIV

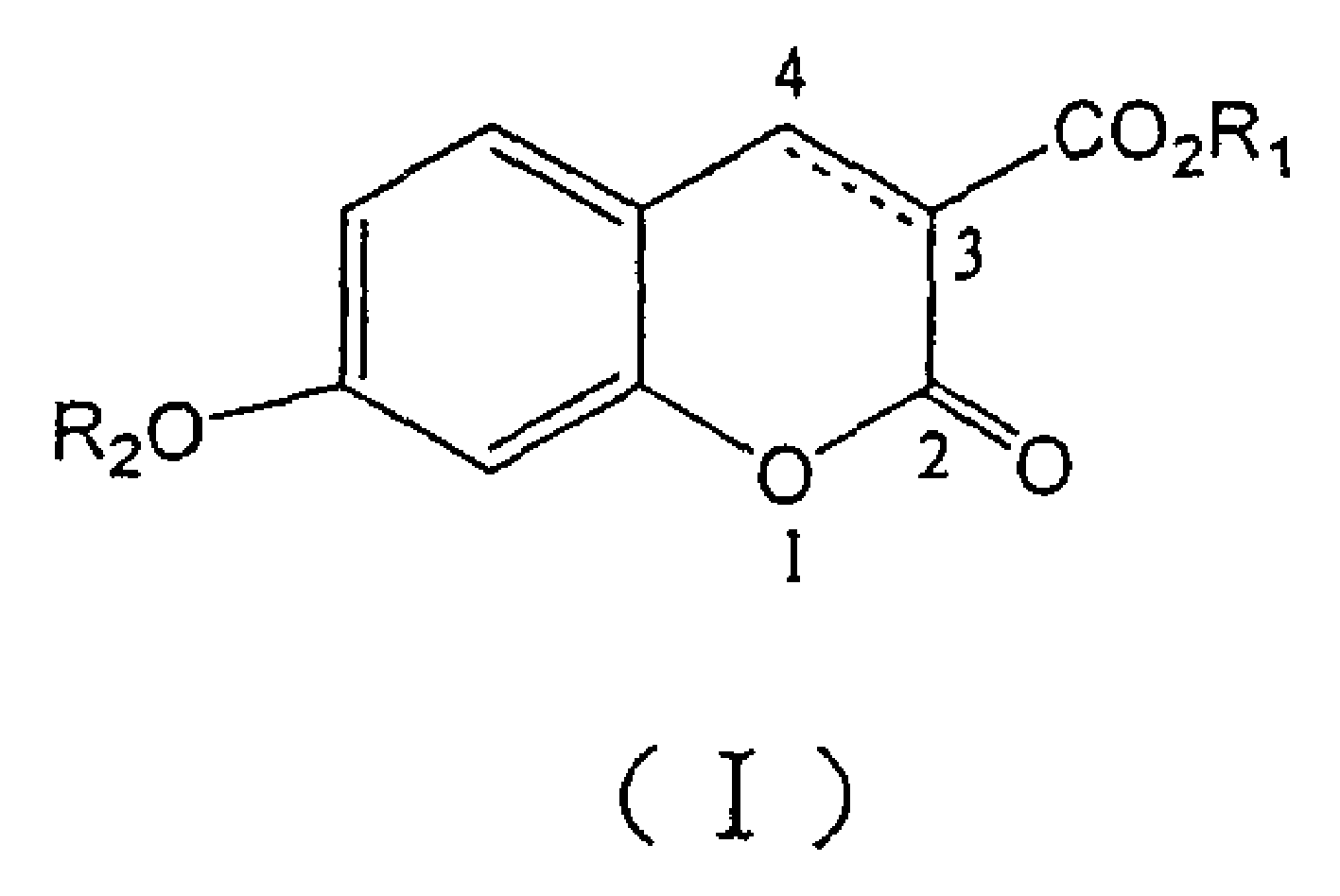

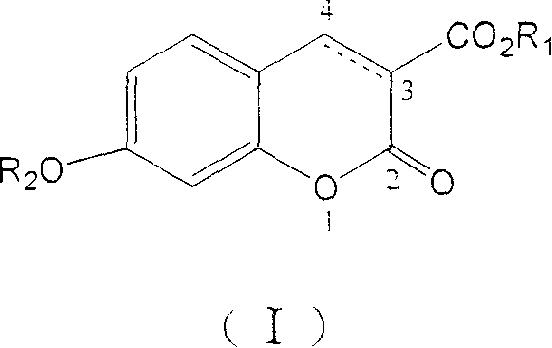

Benzopyran compound and its prepn and use

InactiveCN1810795AEnough purityLow toxicityOrganic active ingredientsOrganic chemistryDiabetes mellitusSimple aromatic ring

The present invention provides benzopyran compound as shown and its pharmaceutically acceptable inorganic and organic salts. The present invention also provides the preparation process of the compounds and medicine composite including the compounds as the active matter for treating type-II diabetes and its complications.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI +1

Traditional Chinese medicine extract for treating hepatitis B, and preparation method and application thereof

InactiveCN103623056AReduce vitalityGood dose dependenceDigestive systemAntiviralsChinese drugHepatitis B

The invention discloses an extract of the traditional Chinese medicine chinaberry for treating hepatitis B and a preparing method and application thereof. The traditional Chinese medicine chinaberry extract comprises more than 50% of total phenolic compounds and more than 20% of chinaberry phenolic compounds. The preparation method for the traditional Chinese medicine chinaberry extract comprises the following steps: subjecting a chinaberry raw material to hot extraction or cold extraction so as to obtain a crude chinaberry extract; and then carrying out purification by using a methacrylic synthetic adsorbent, an aromatic (styrene and didivinyl benzene) synthetic adsorbent or a gel synthetic absorbent so as to obtain the traditional Chinese medicine chinaberry extract. The invention also discloses application of the traditional Chinese medicine extract in preparation of medicines used for treating hepatitis B.

Owner:JINAN XINLU MEDICAL TECH

Method for extracting tungsten from tungsten-containing sodium carbonate solution and comprehensive utilization of extracted liquid

ActiveCN105293556BEmission reductionReduce precipitationCalcium/strontium/barium sulfatesIon-exchange resinBall mill

The invention provides a method for extracting tungsten from a tungsten-containing sodium carbonate solution and comprehensively utilizing an extracted solution. The method comprises the following steps of firstly, adsorbing tungsten in the tungsten-containing sodium carbonate solution by using ion exchange resin to obtain an exchanged solution and negative tungsten resin, and desorbing the negative tungsten resin under the closed condition of 40 to 60DEG C by using ammonia water; secondly, carrying out ball milling and size mixing on barium carbonate and part of exchanged solution; thirdly, slowly adding size obtained by ball milling into a stirring tank which is filled with residual exchanged solution and starts stirring, and stirring at the temperature of 60 to 90DEG C for 4 to 10 hours; fourthly, passivating barium sulfate: carrying out ball milling and size mixing on a filter cake obtained in the third step and a proper amount of water in a ball mill, then mixing with a sulfuric acid solution, stirring for 4 to 10 hours, then filtering, and washing the filter cake with deionized water to obtain a barium sulfate product. According to the method provided by the invention, the discharging amounts of waste water and waste salts in tungsten metallurgy are greatly reduced, and 50 percent or over 50 percent of sodium carbonate is recovered; meanwhile, the barium sulfate product with a higher added value is obtained, and significant comprehensive economic benefits are obtained.

Owner:CENT SOUTH UNIV +2

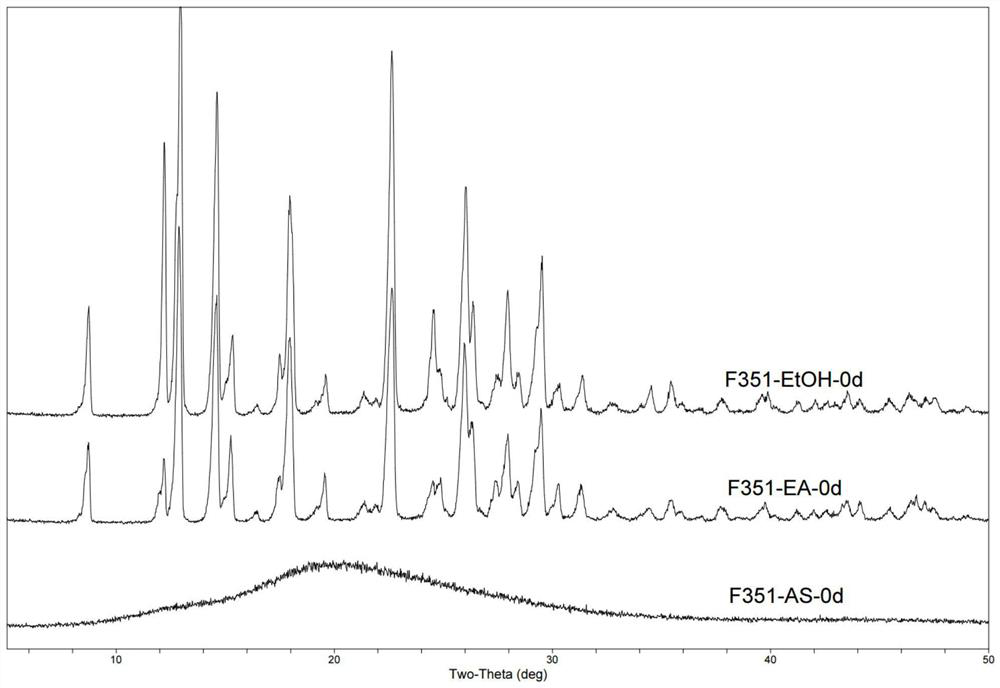

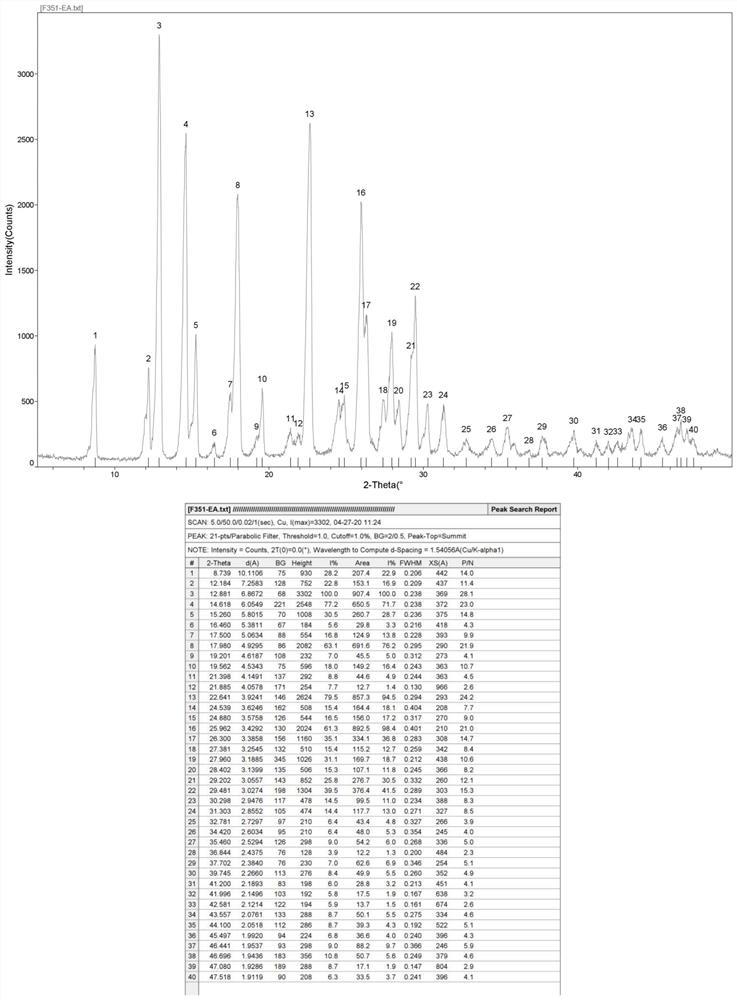

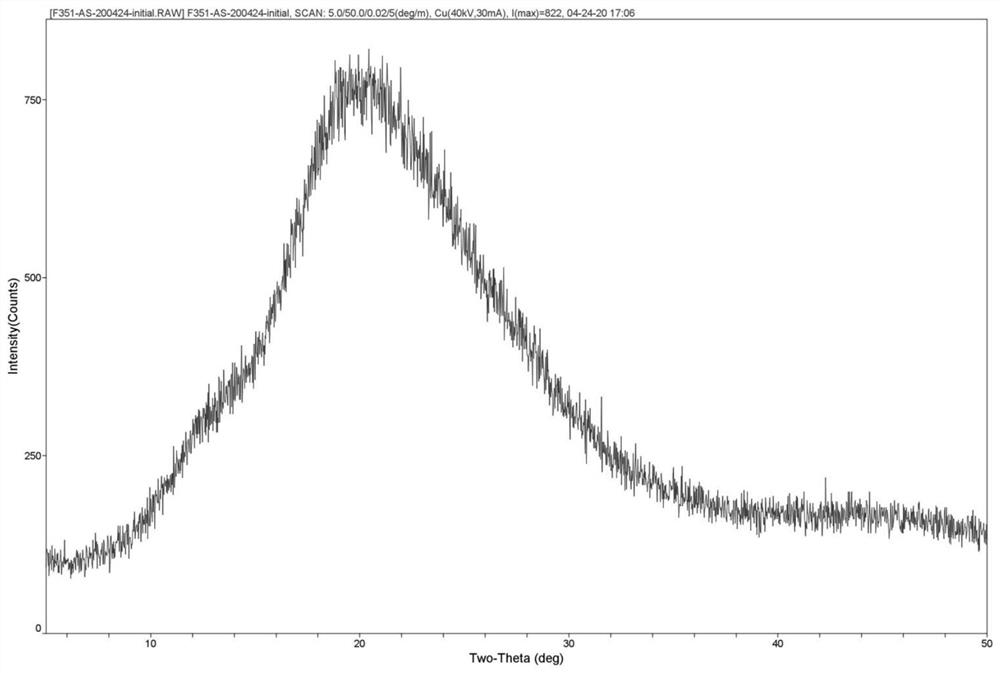

Crystal form of hydronidone, preparation method and application thereof

ActiveCN113173881AImprove stabilityGood reproducibilityOrganic active ingredientsOrganic chemistry methodsBioavailabilityMedicinal chemistry

The invention relates to a novel crystal form of hydronidone, a preparation method and application thereof, in particular to a novel hydronidone crystal form with better stability, oral exposure and bioavailability.

Owner:BEIJING CONTINENT PHARM CO LTD

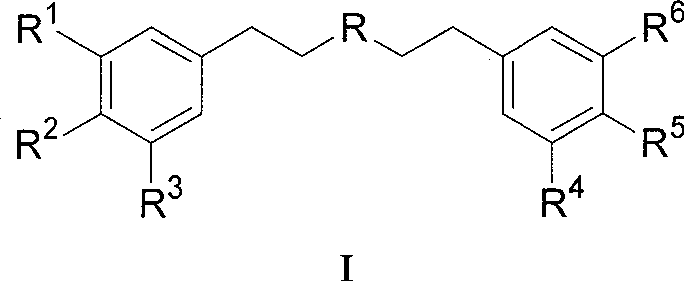

Composition of aiphenyl hepatanone compound and its use

InactiveCN100531725CInhibitory activityExcellent eradication rateAntibacterial agentsOrganic chemistryIntestinal structureHelicobacter

The present invention provides diarylheptanoids (diarylheptanoids) compounds (such as: diphenylheptanone, diphenylheptenone and diphenylheptanedione) and their pharmaceutical composition in the anti-helicobacter pylori infection or treatment of intestinal , New uses in gastric ulcer-related diseases. They have good anti-helicobacter pylori (Hp) effect, and have repairing effect on gastric mucosa damage caused by helicobacter pylori.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com