Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

183results about How to "Employ less" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

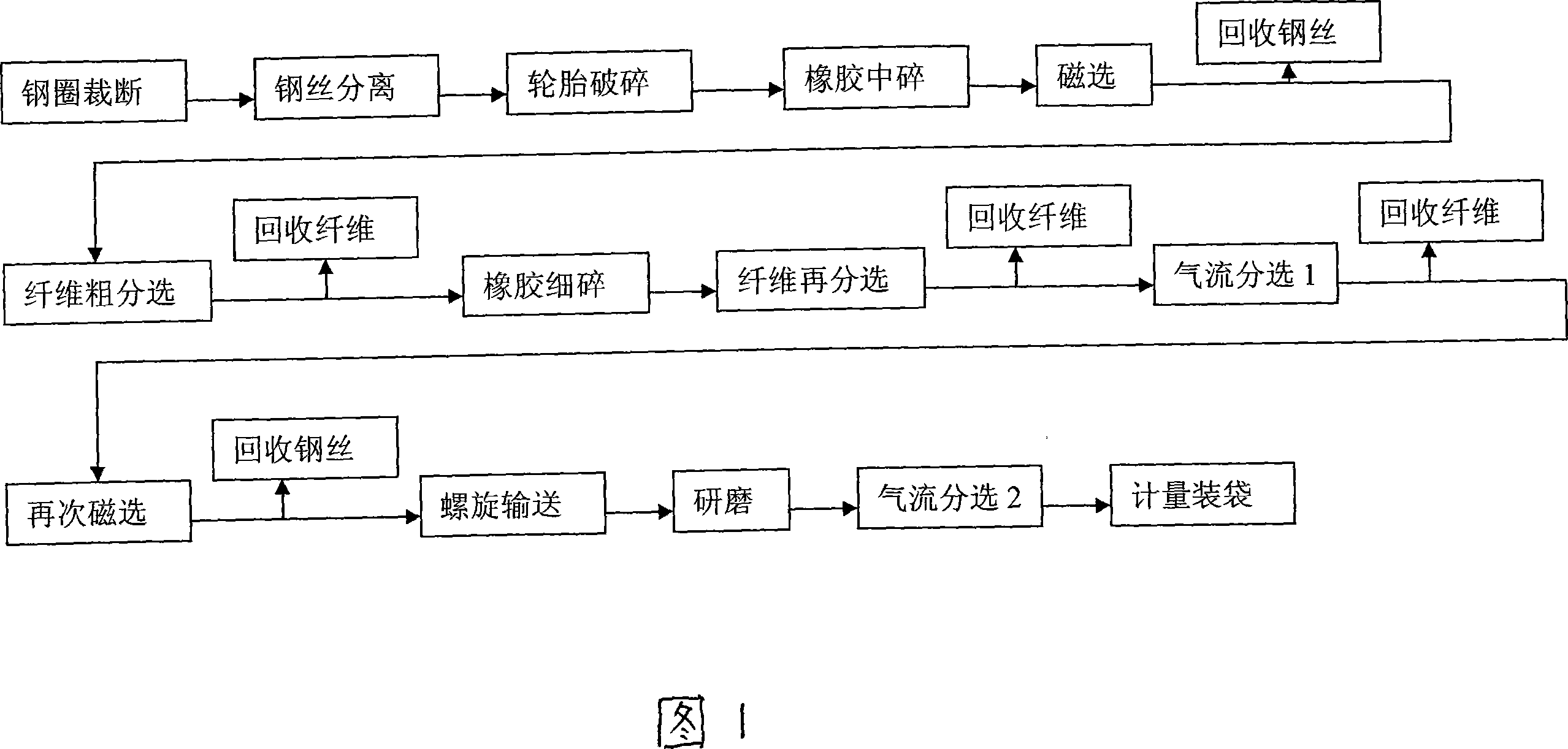

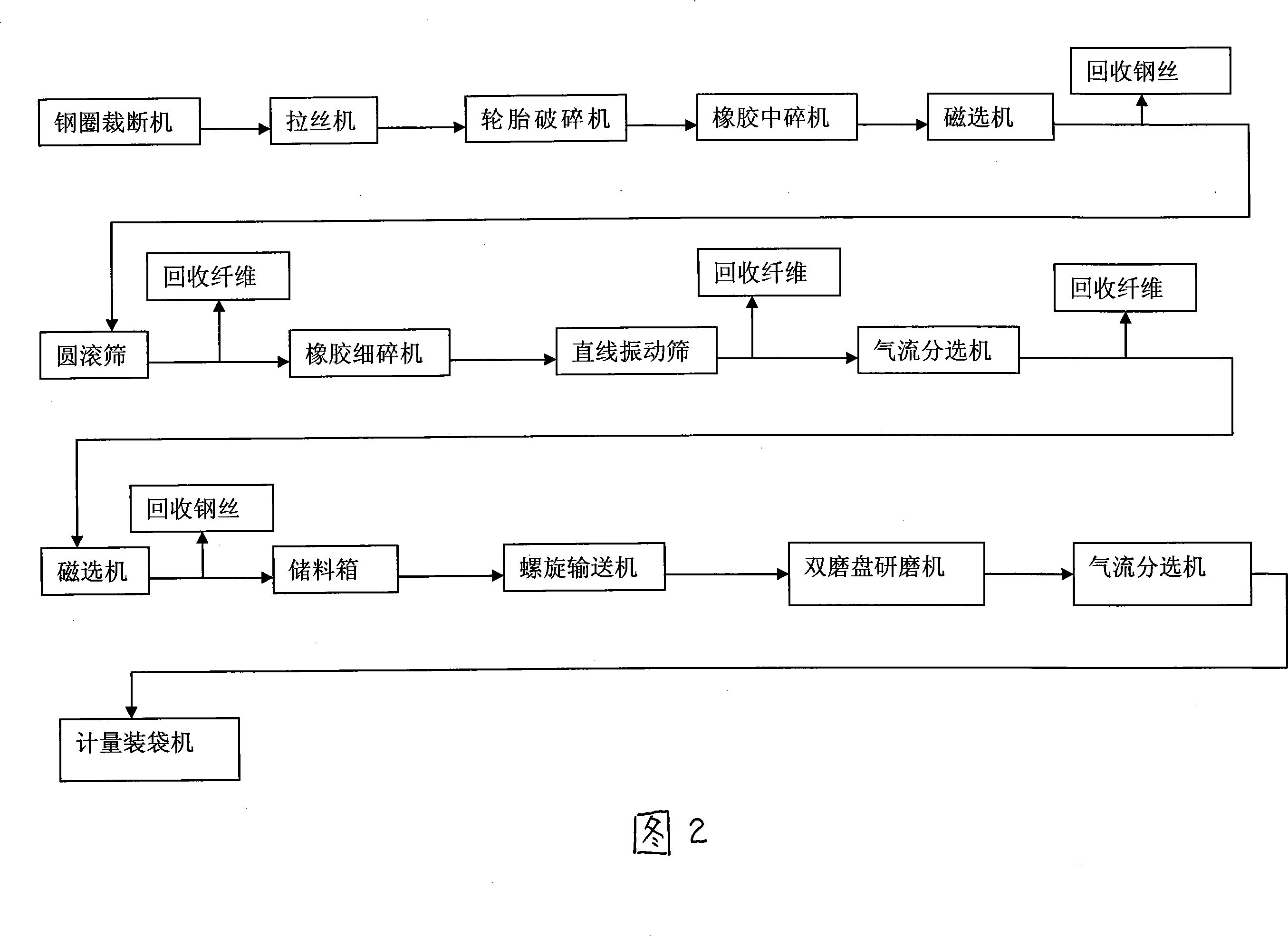

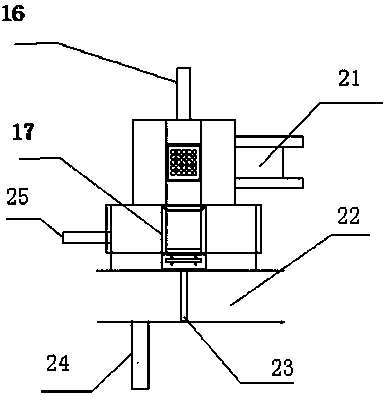

Method for crushing producing fineness rubber powder under normal temperature

InactiveCN101234517ACompact structureEasy to install and maintainSievingGas current separationProduction lineLow noise

The invention relates to a method for producing fine rubber powder by grinding under normal temperature, which adopts the following processes: trimming of steel rings, separation of steel wires, crushing of tires, grinding in the rubber, magnetic selection and separation, rough selection of fibers, finely grinding of the rubber, reselection of the fibers, magnetic reselection, spiral transportation, grinding and airflow selection. The industrial method initiates the precedent of the production of the fine rubber power in batch and the investment of equipment in a whole production line is a half investment of the traditional grinding method under the normal temperature while the investment of the equipment is one eighth of the investment of freezing grinding production line under low temperature. The industrial production line has the advantages of compact structure, convenient arrangement and maintenance of the equipment, long service, life, high rate of rubber output, low power consumption and low noise. Compared with rubber powder index of the freezing grinding production method under the low temperature, each technical index excels current the advanced technology for producing the rubber powder by expansion cooling of air turbines.

Owner:邓裕潮

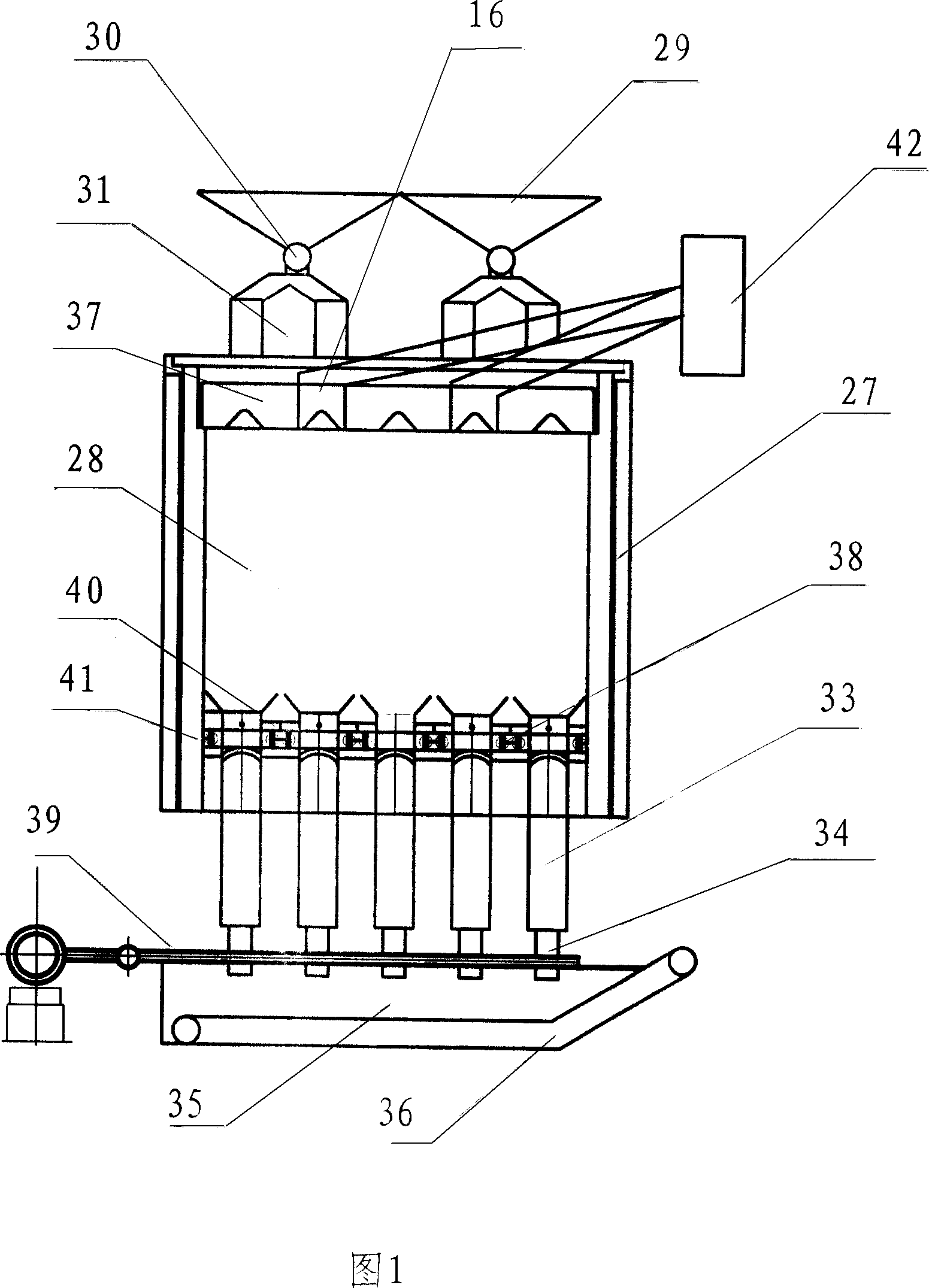

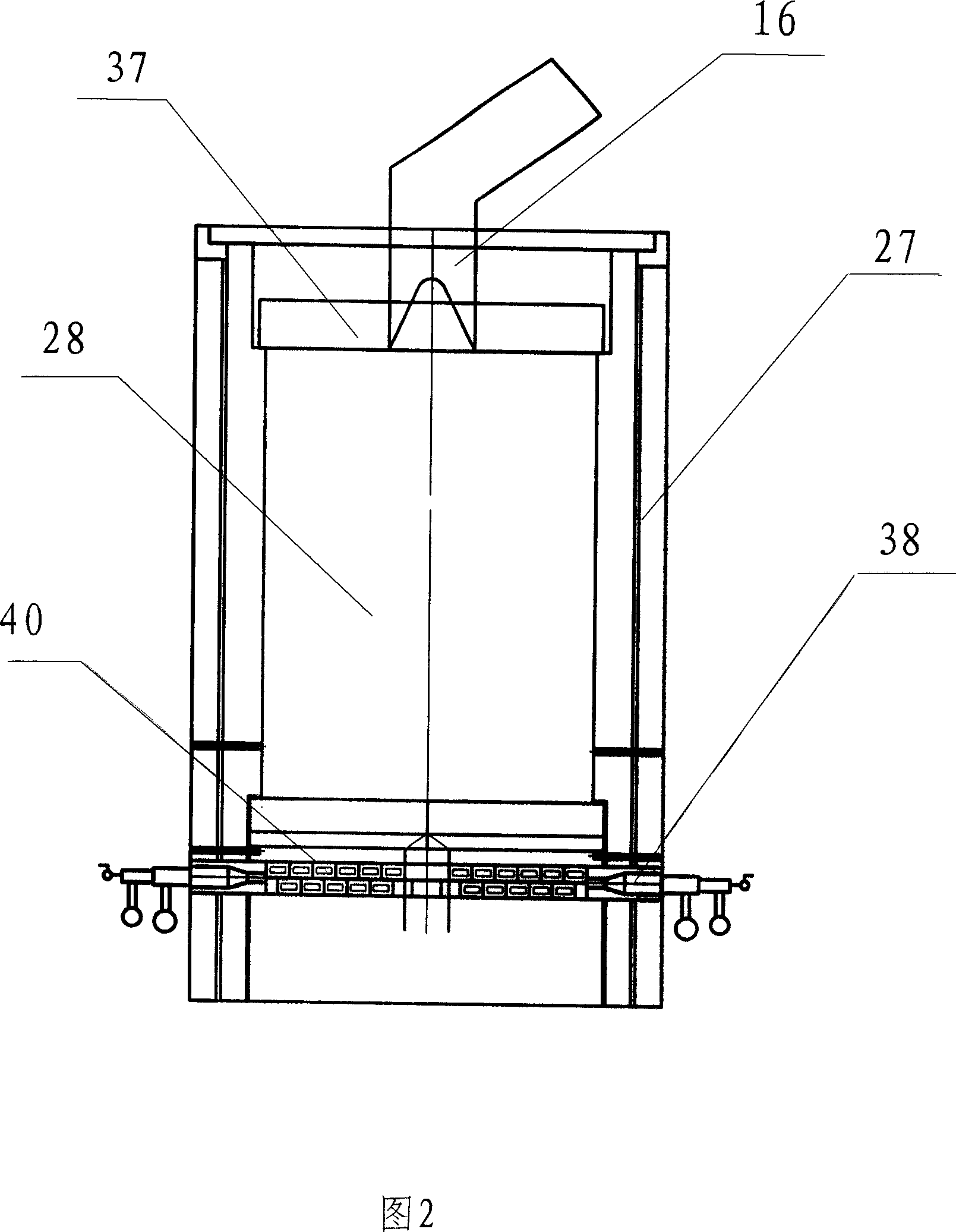

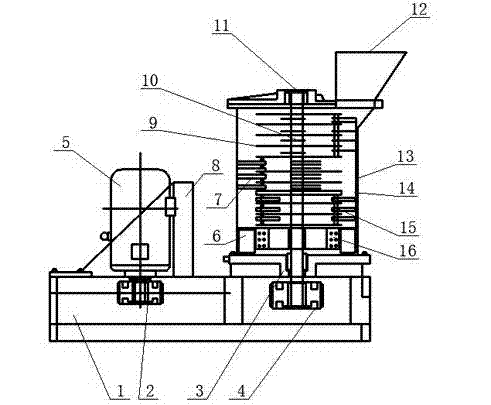

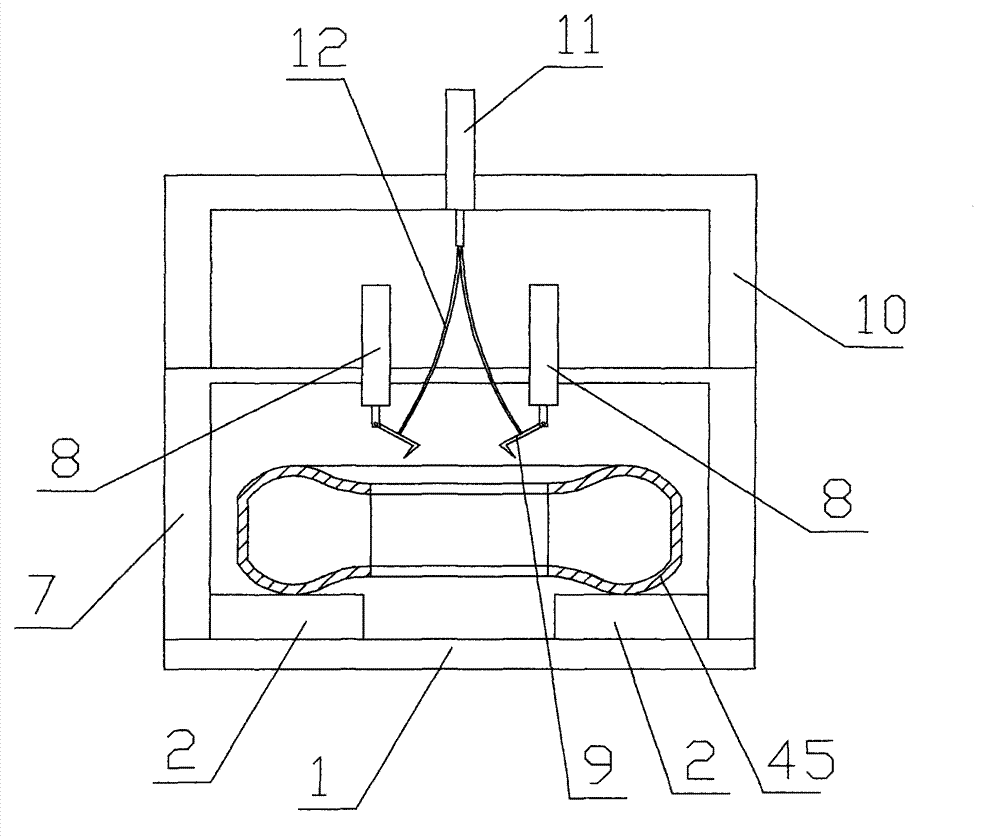

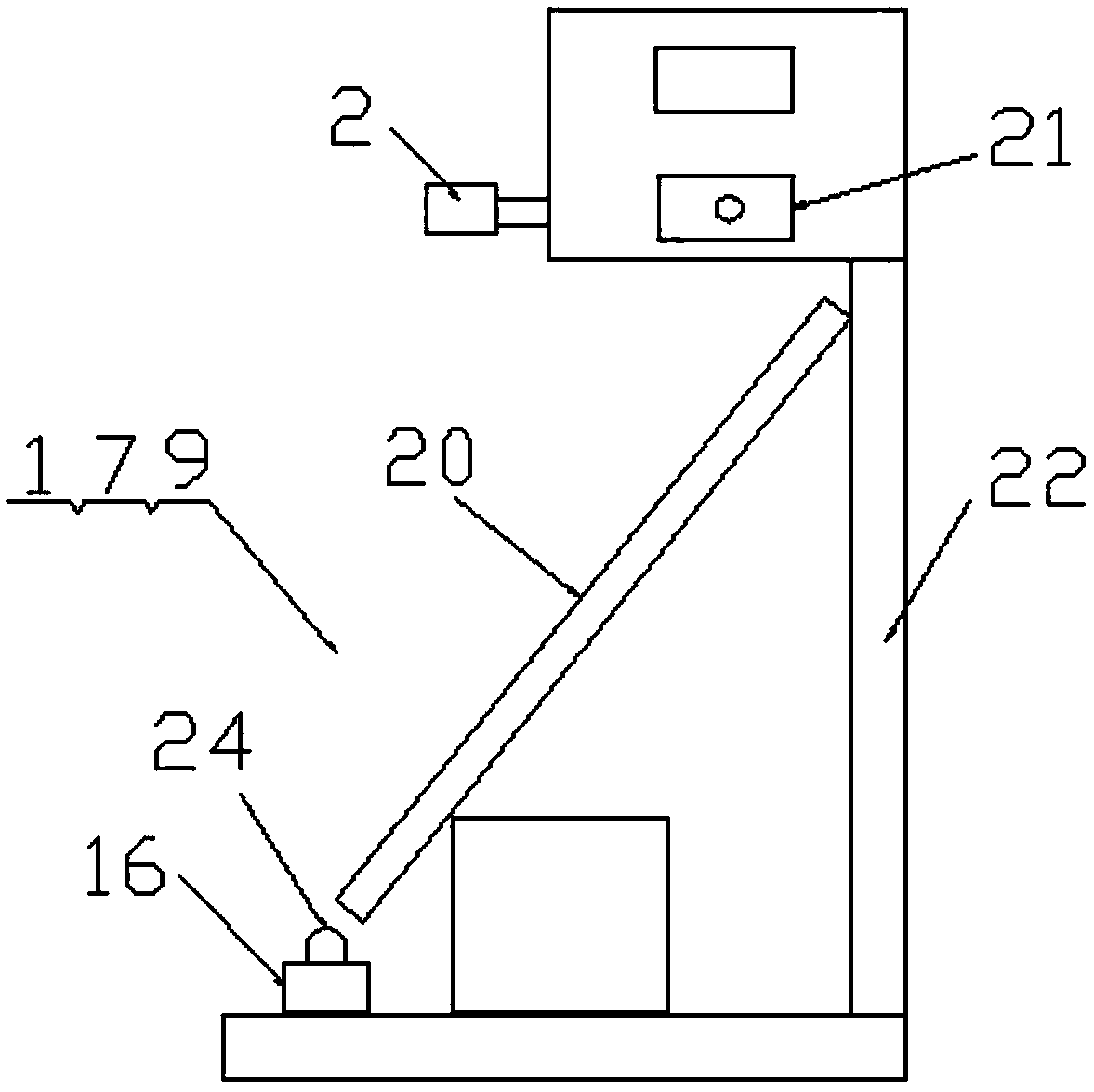

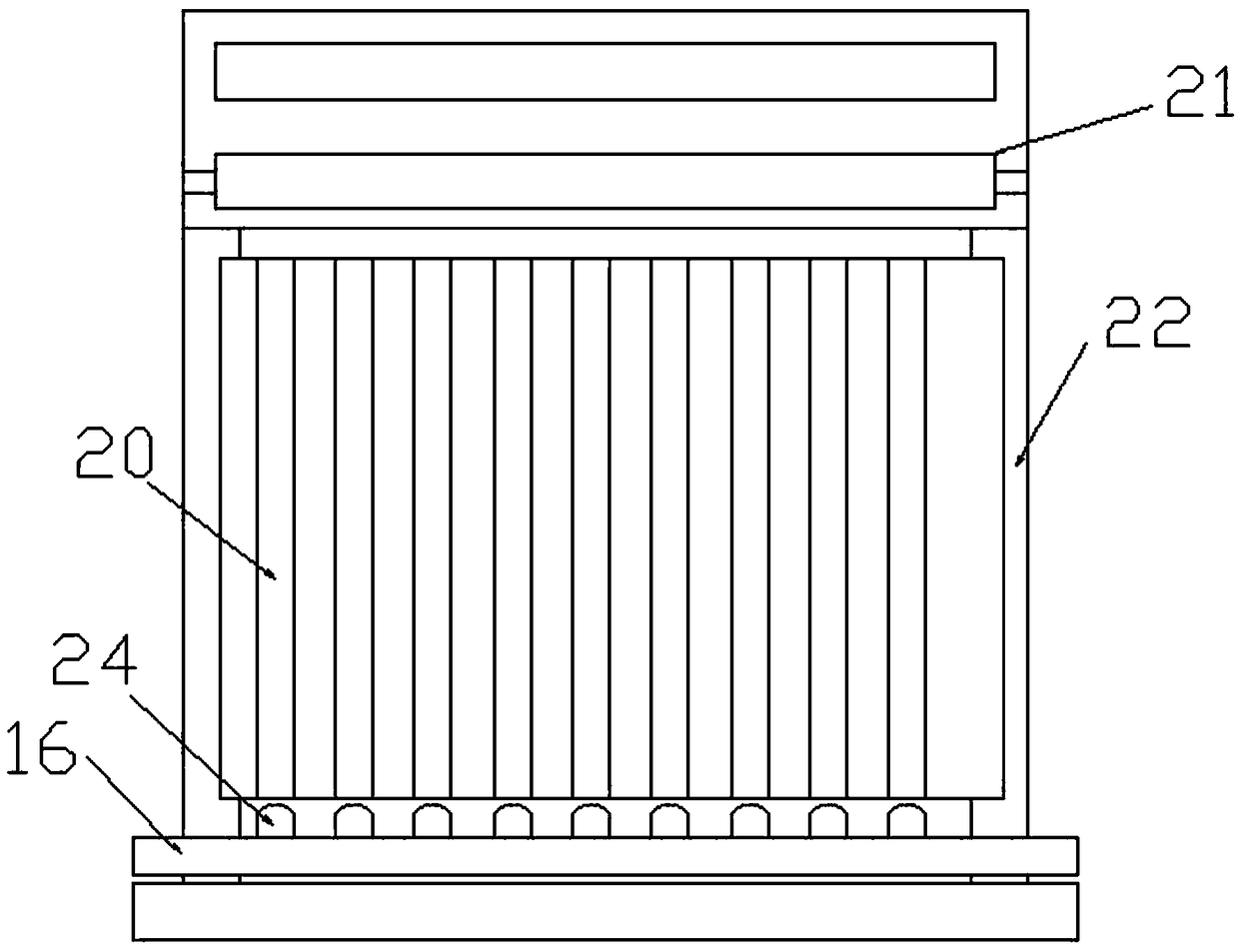

Low-temperature coal carbonization kiln

ActiveCN1966609AIncrease effective volumeHigh yieldRetortsDischarging devicesAutomatic controlCarbonization

The invention disclosed a kind of low temperature coal dry distillating square stove which includes stove body, coal cup, dant-pushing machine and branch admixer. On the top of the hearth there is installed the gas collecting umbrella, inside the stove it is cavity structure; on the bottom of the cavity there are installed several rows of emitting gas walls, every row of emitting gas wall is parallel to the interval between two side umbrella of the gas collecting umbrella; the consecutive emitting gas walls are pedestalled by arch wall; on both sides of the emitting gas walls there are two branch admixer respectively; the bottom of the stove connects the dant discharging box, the bottom of which connects the dant leading slot; the bottom of the dant leading slot is dant-pushing machine, the bottom of which is aqua sealing slot, in the slot there is scraper machine. The invention adopts the heating scheme of endo-burnning and calor internus which can heat uniformly. The gas collecting umbrella and accessory coalbox can make the material and gas-collecting uniformly while the dant-pushing machine can make the product uniform. The advantage of the invention: it can bring into full play of the producing ability and decrease the investment as well as increase the benefits; besides, it is easy to operate, it needs less people and can be controlled automatically.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

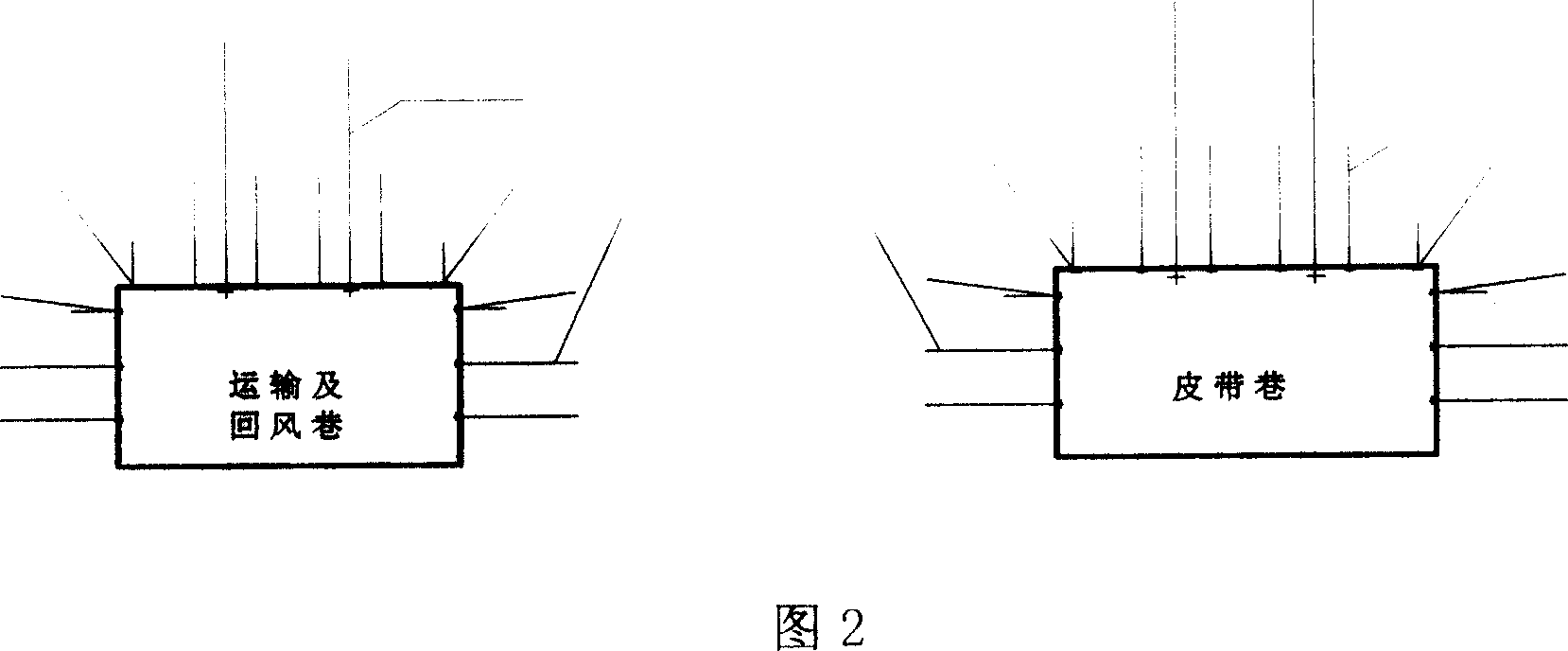

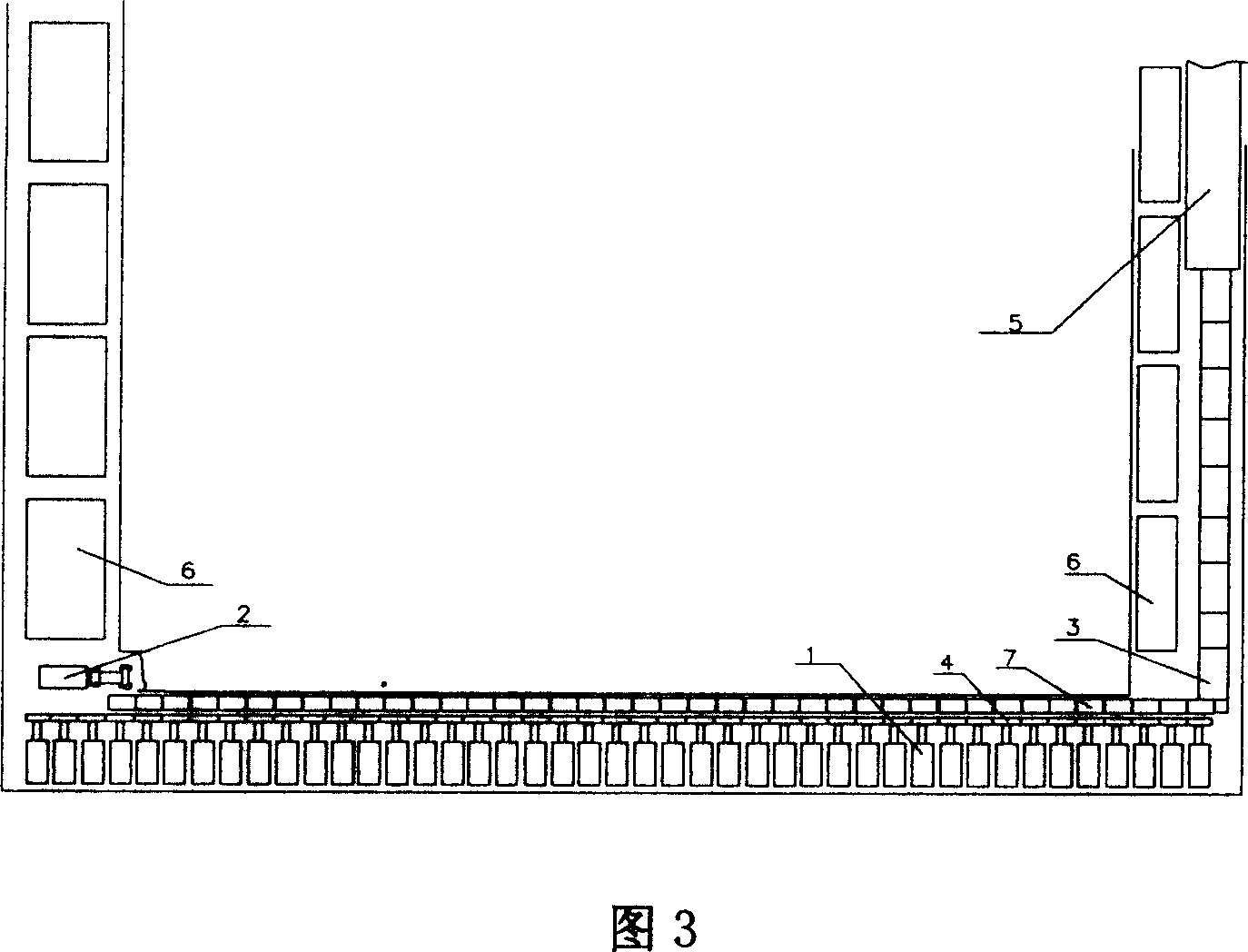

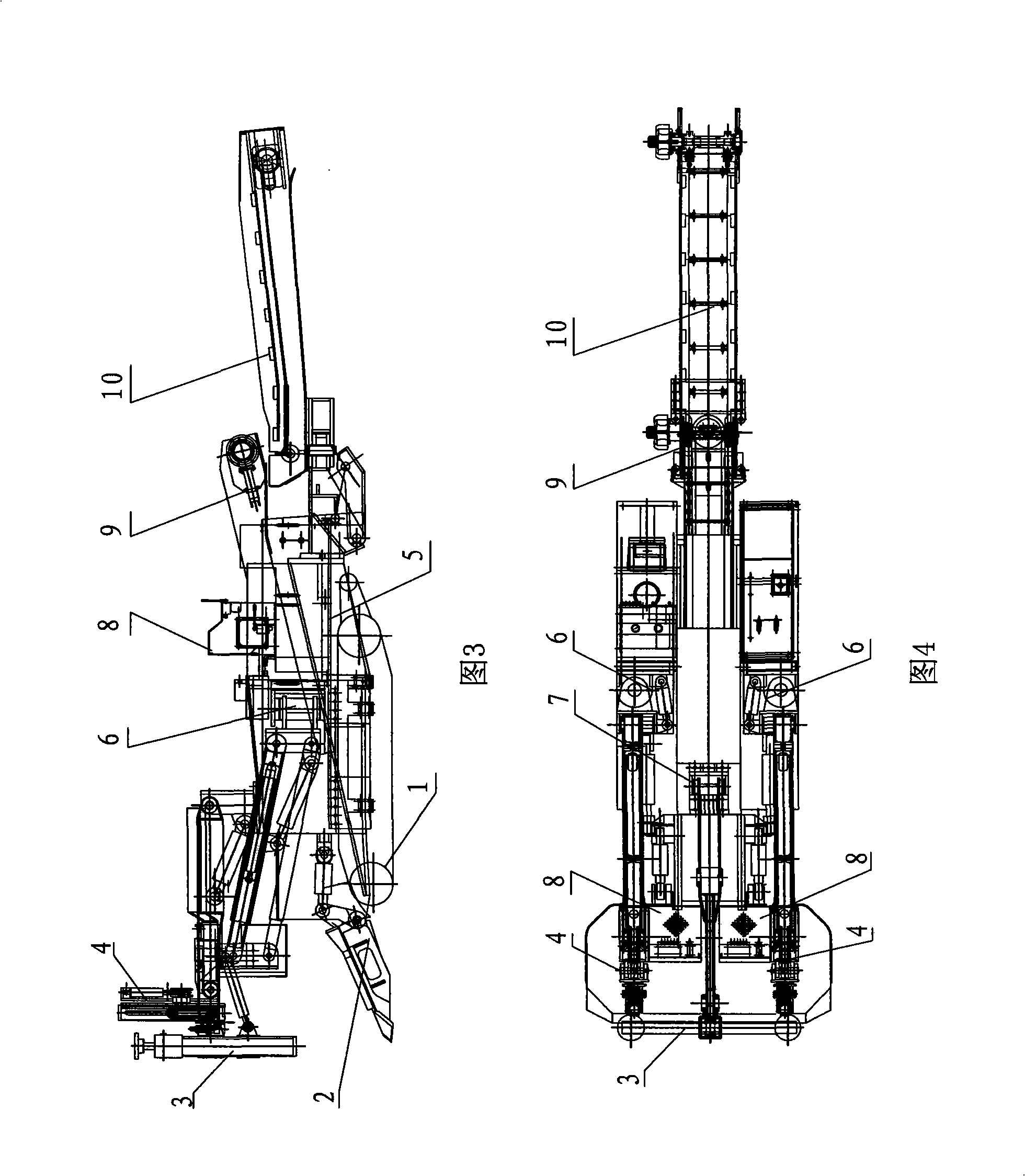

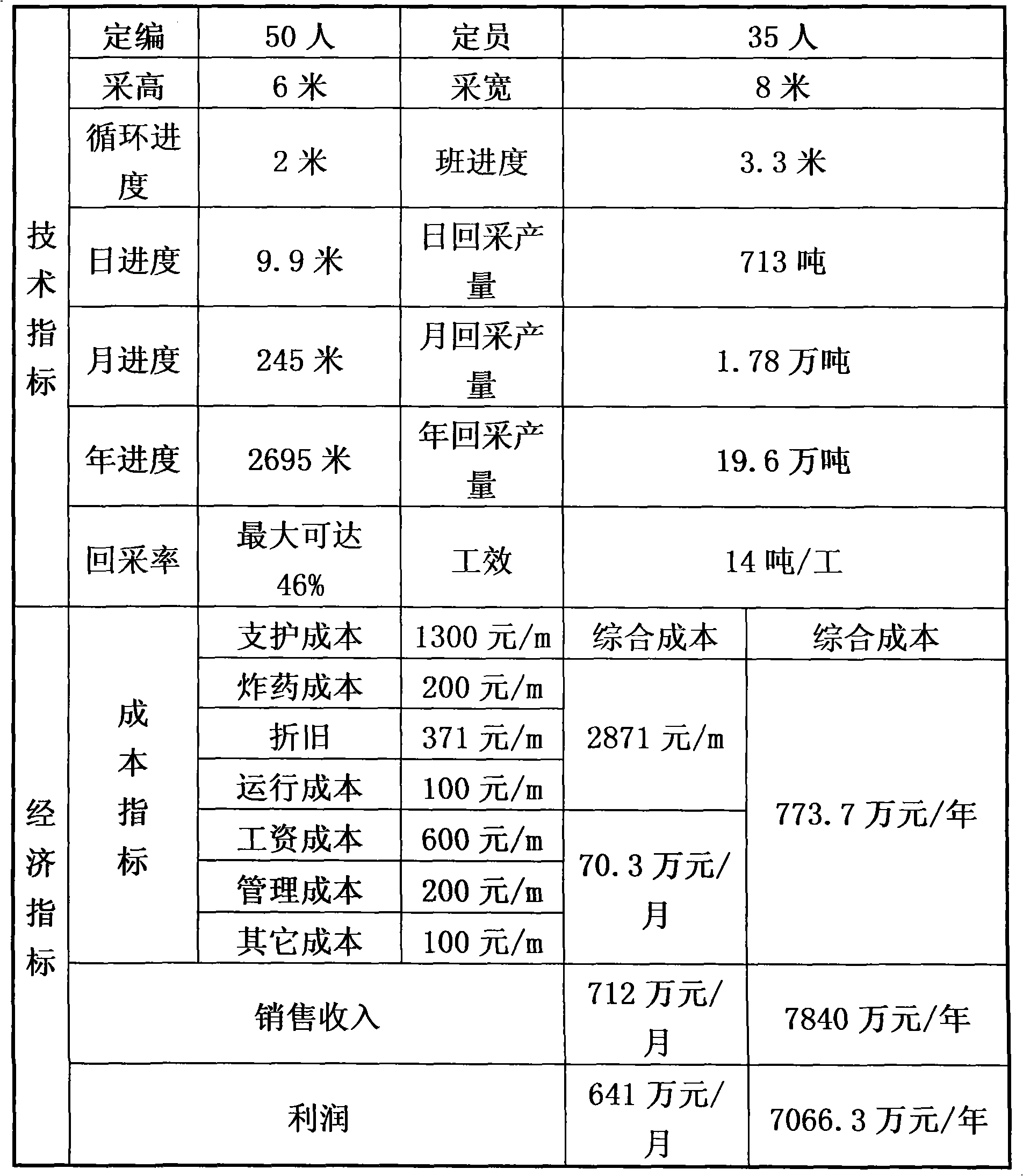

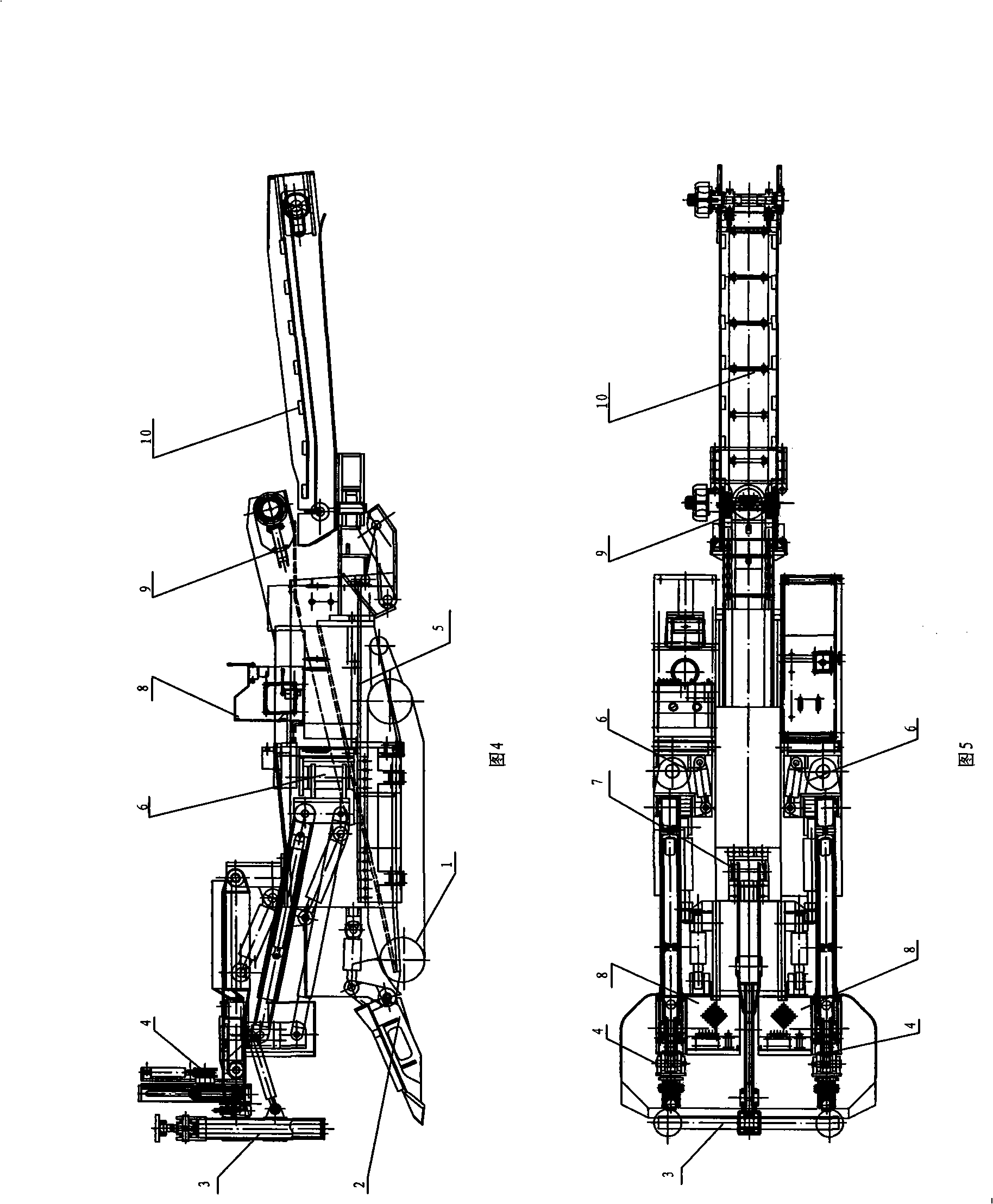

Full-seam cutting, retreating, separate moving and full-caving comprehensive mechanized coal mining method and equipment

ActiveCN1932240ALarge air volumeImprove support strengthUnderground miningSurface miningIt equipmentTransport system

The present invention provides a full-seam mining retreating separately-moving full-span comprehensive mechanized coal-cutting method and its equipment. It is mainly characterized by that it adopts full-seam mining support form, utilizes crawler-type single-drum shearer to cut coal and utilizes the separate movement of coal-cutting equipment coal-conveying equipment and supporting equipment and transporting system to implement coal-cutting operation. Besides, said invention also provides the concrete steps of said mechanized coal-cutting method.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

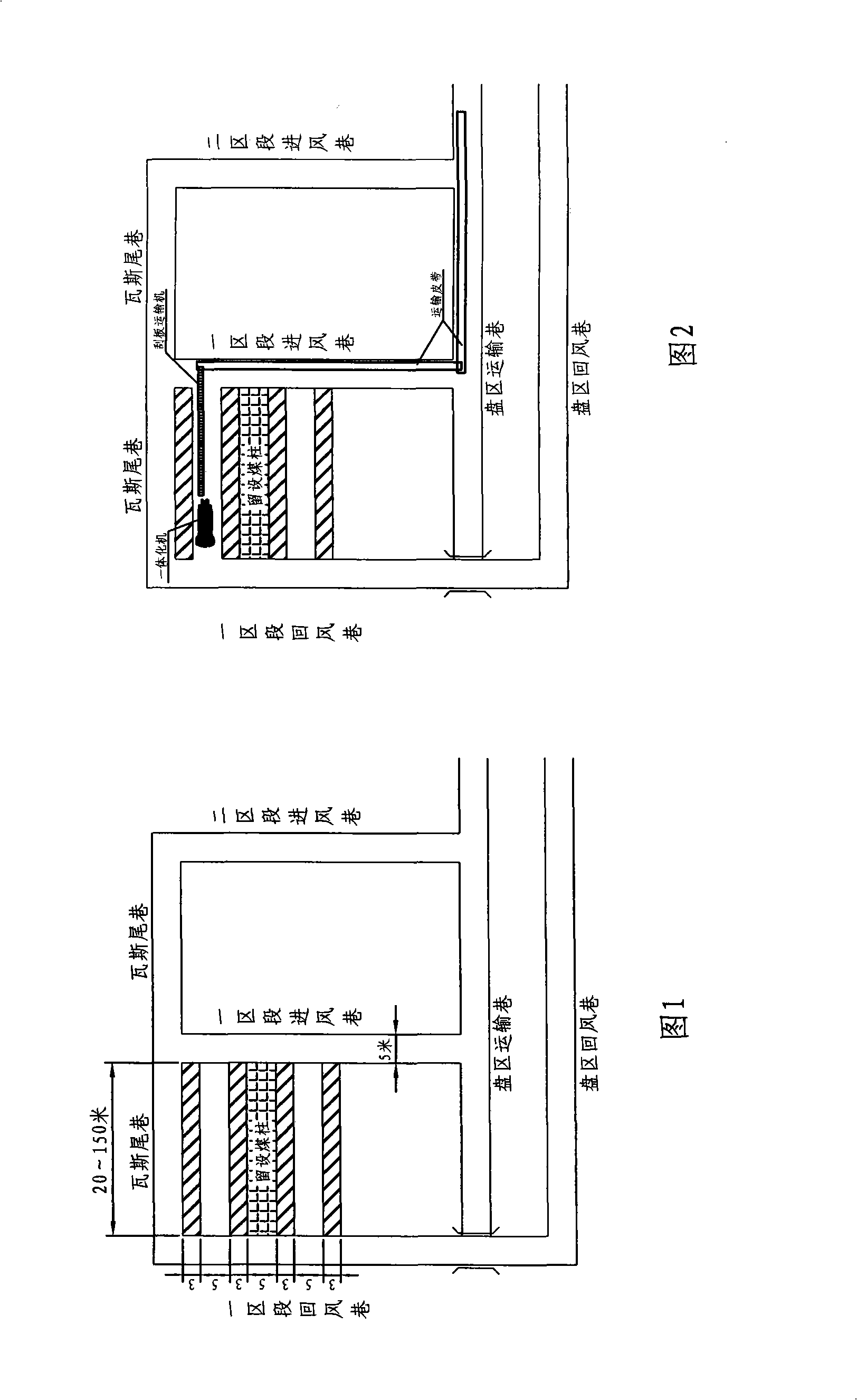

Method for extracting rim angle coal and re-extracting after warehouse coal extracting

InactiveCN101302931ASave resourcesImprove resource recoveryUnderground miningBlastingResource depletionCoal pillar

The invention relates to a method for re-mining after the coal mining in a barn and the stoping of irregular coal. The method of the invention includes the arrangement of roadways and the technologies of mining, coal blasting, coal loading, coal transporting, supporting and dual-wing recovery and is characterized in that as for the arrangement of the roadways, a plurality of sections are divided in a panel and two preparation roadways are arranged in the sections, with one preparation roadway serving as an air intake way and the other one as an air return way; after the coal mining is finished in the previous section, the air intake way of the previous section can be taken as the air return way of the next section; only one air return way needs excavating in the next section; a long strip-shaped room pillar is arranged between the two preparation roadways, which ensures that the stopping of the next room pillar can be carried out under the less pressure of a top plate; as for the technology of mining, room mining is first carried out in the strip-shaped room pillar by adopting anchor net support; the coal at two wings are recovered by bidirectional retreating after the air return way is communicated, which causes small and medium-sized coal mines with 'resource depletion' to realize the re-mining and large and medium-sized coal mines to achieve the stopping of coal pillars and the irregular coal, thus improving recovery ratio and conserving resources.

Owner:闫振东

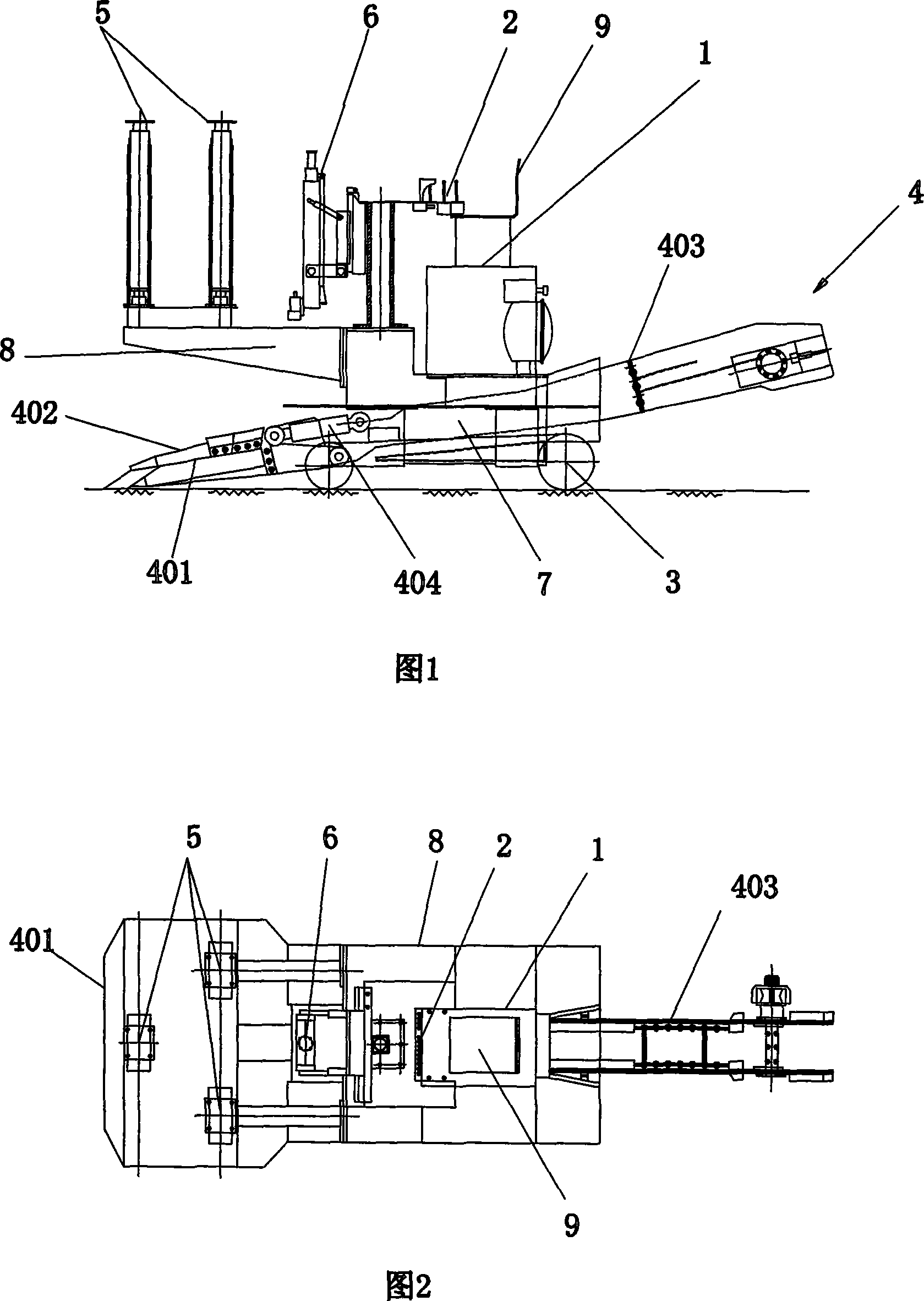

Explosion coal-falling, coal-loading, coal-conveying and anchor-rod supporting mechanism integration operation method and apparatus

InactiveCN101025086AIncrease the speed of excavationExcavation section is largeUnderground miningSurface miningResource recoveryEngineering

The invention provides a blast-winning, coal loading, coal conveying and anchor rod-timbering mechanical integrated operating method and device. And the device mainly comprises: hydraulic system, hydraulic control table, track walking part, coal loading and conveying part, timbering part, and hydraulic anchor rod machine, and the method uses integrated device, scraper conveyor and gate coal conveyor; and its drivage circulating speed is 1m to 1.5 m, blast-winning and after the fumes have settled, making the integrated device enter into the operating site, and after completing coal loading and conveying, making anchor rod timbering; after completing the anchor rod timbering operation, making the integrated device exit the operating site and over 20 meters distant from the operating site, and then making drilling and blasting operation. And it improves explosion level of blast winning and resources recovery, and reduces operators.

Owner:闫振东

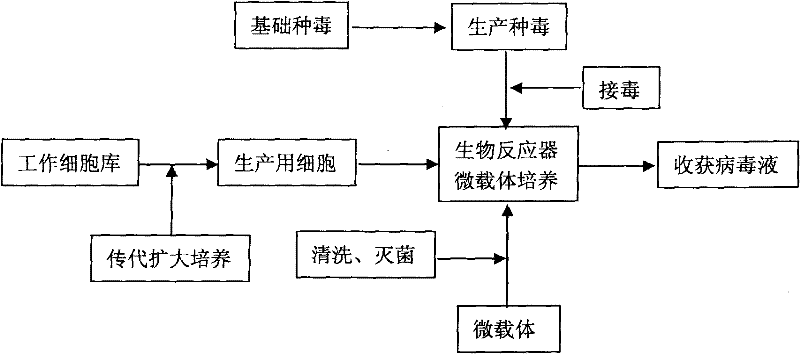

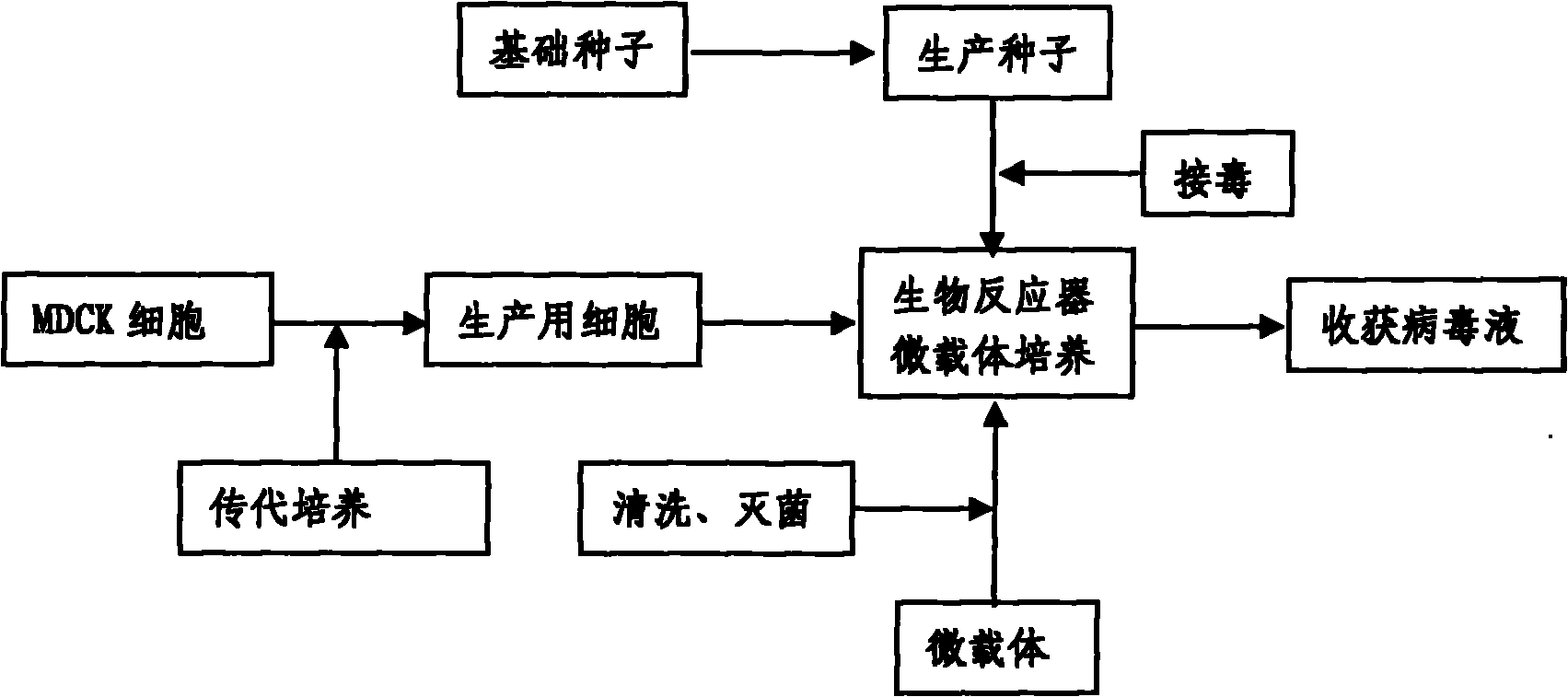

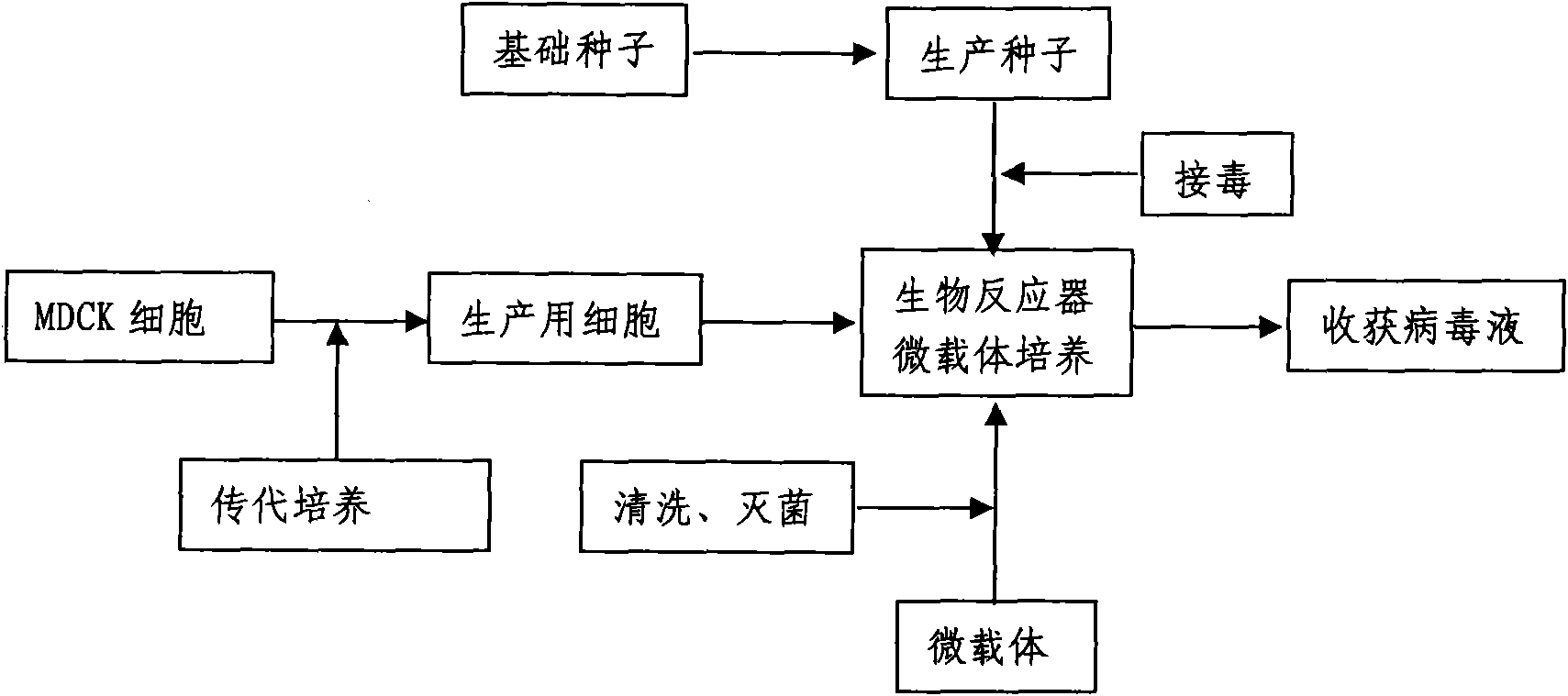

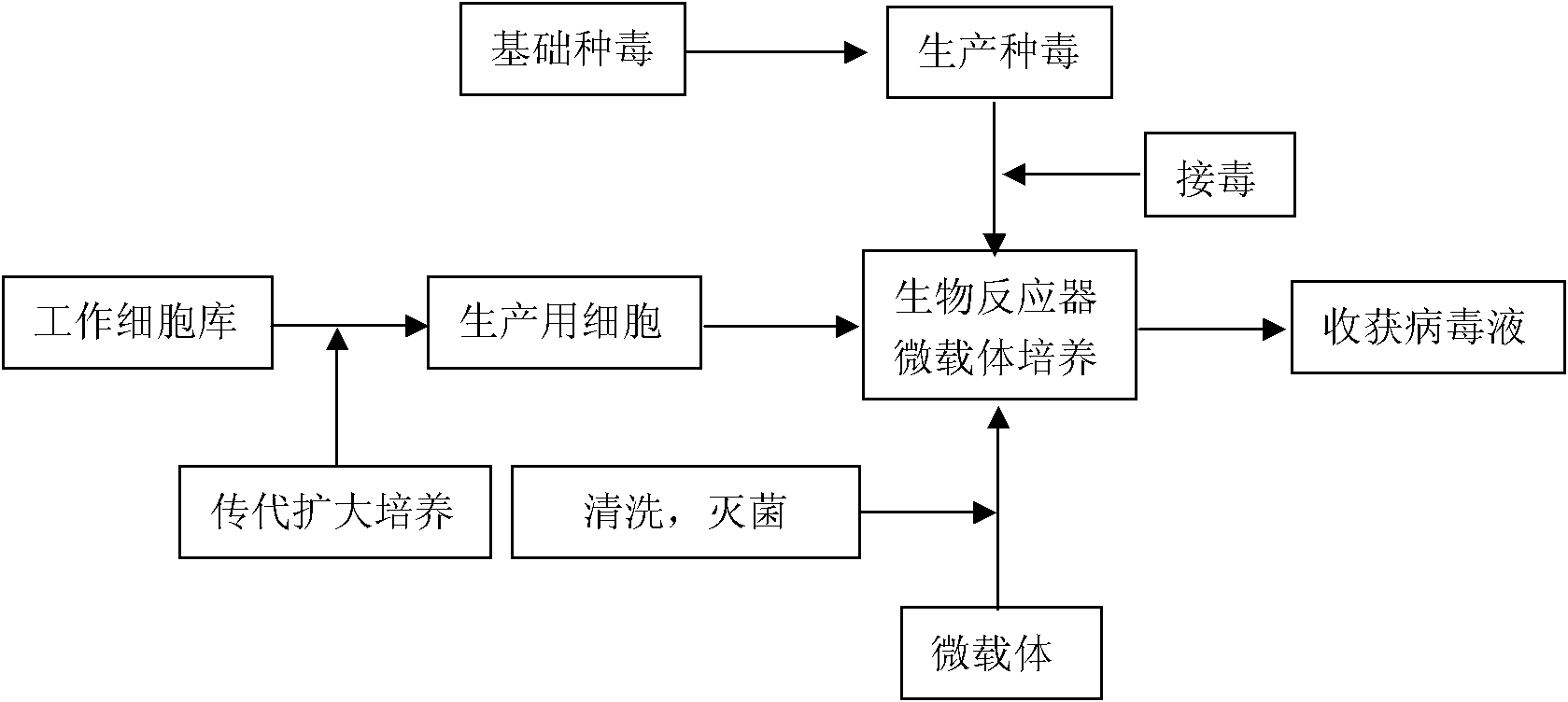

Method for production of porcine epidemic diarrhea virus

The invention discloses a technology for the production of porcine epidemic diarrhea virus by means of the microcarrier culture of VREO cells using a bioreactor, and comprises the technology for the production of different porcine epidemic diarrhea virus strains. The technology comprises the following technical steps: (1) selection of VERO cells as cell line for vaccine; (2) passage and culture of cells for vaccine; (3) propagation of seed culture of the porcine epidemic diarrhea virus; (4) microcarrier suspension culture of the VERO cells in the bioreactor; (5) propagation of porcine epidemic diarrhea virus antigen; and (6) treatment of acquired virus antigen liquid. The production method can remarkably lower production cost and enhance output-input ratio by 5 to 10 times, and has the advantages of short production period, small occupied space, great easiness for enlarging production scale rapidly, little environmental pollution, easy processing, high automation degree, a small number of staff, easy implementation of even and stable quality, obviously lowered production cost and enhanced yield and quality of vaccine.

Owner:成都史纪生物制药有限公司

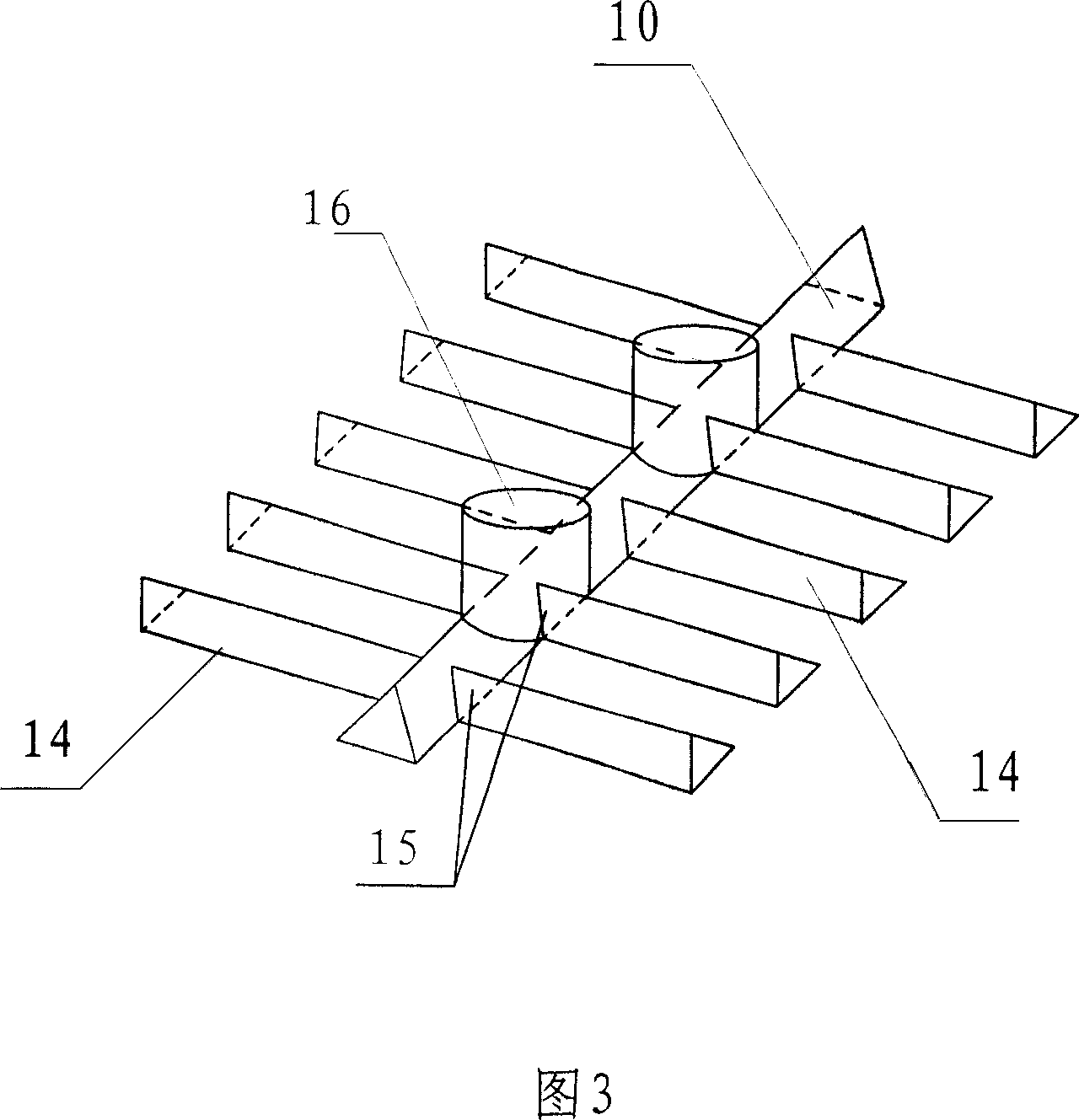

Cutting head type shortwall coal-winning machine and comprehensive mechanized coal mining technology

ActiveCN101798925AReduce cutting powerReduce electricity costsUnderground miningSlitting machinesControl systemElectrical control

The invention discloses a cutting head type shortwall coal-winning machine and comprehensive mechanized coal mining technology. A tunneller type cutting device is used, and the coal-winning machine is a hydromechatronics coal-winning machine which is in electric traction, electrically drags a cutting head, carries out hydraulic drive to change a cutting arm pitch angle and swings inside and outside the working face. The coal-winning machine mainly comprises a machine body, a cutting device, a travelling mechanism, a coal shovelling device, an auxiliary device, an auxiliary hydraulic system and an electrical control system. The coal-winning technology uses technical equipment, such as a coal-winning machine, a hydraulic support, a scraper conveyor, an elevating conveyor, a breaker, a crossheading belt, an advance support hydraulic support and the like. The technical flow is as follows: the coal-winning machine retracts to the working surface tail, a scraper-trough conveyer is pushed tocoal wall, coal is cut to the machine head, the machine is retracted, coal is cleaned, and the support is pulled. The coal-winning machine has compact structure, small volume and weight, strong adaptability and convenient installation and transportation, can solve a series of problems of four low, three high, two long and one poor in small and medium coal mining technology and provides matching coal mining technology.

Owner:闫振东

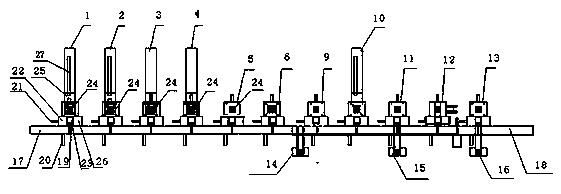

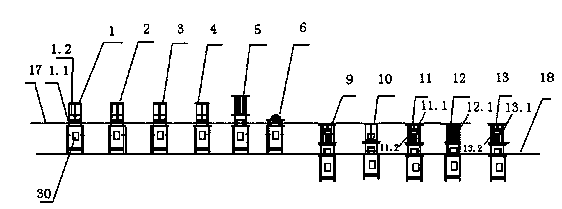

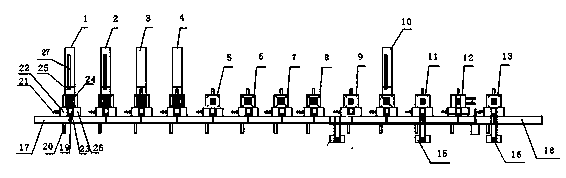

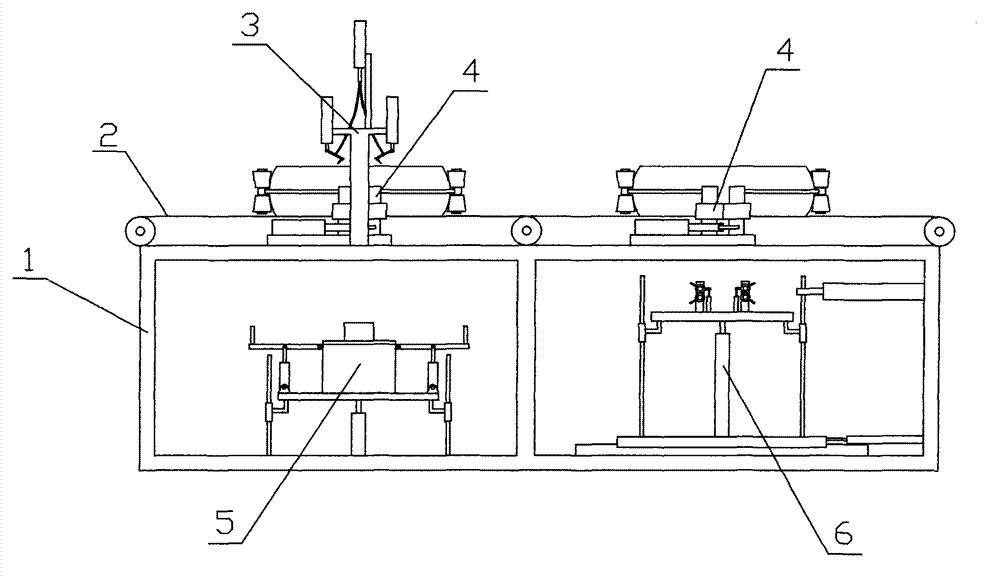

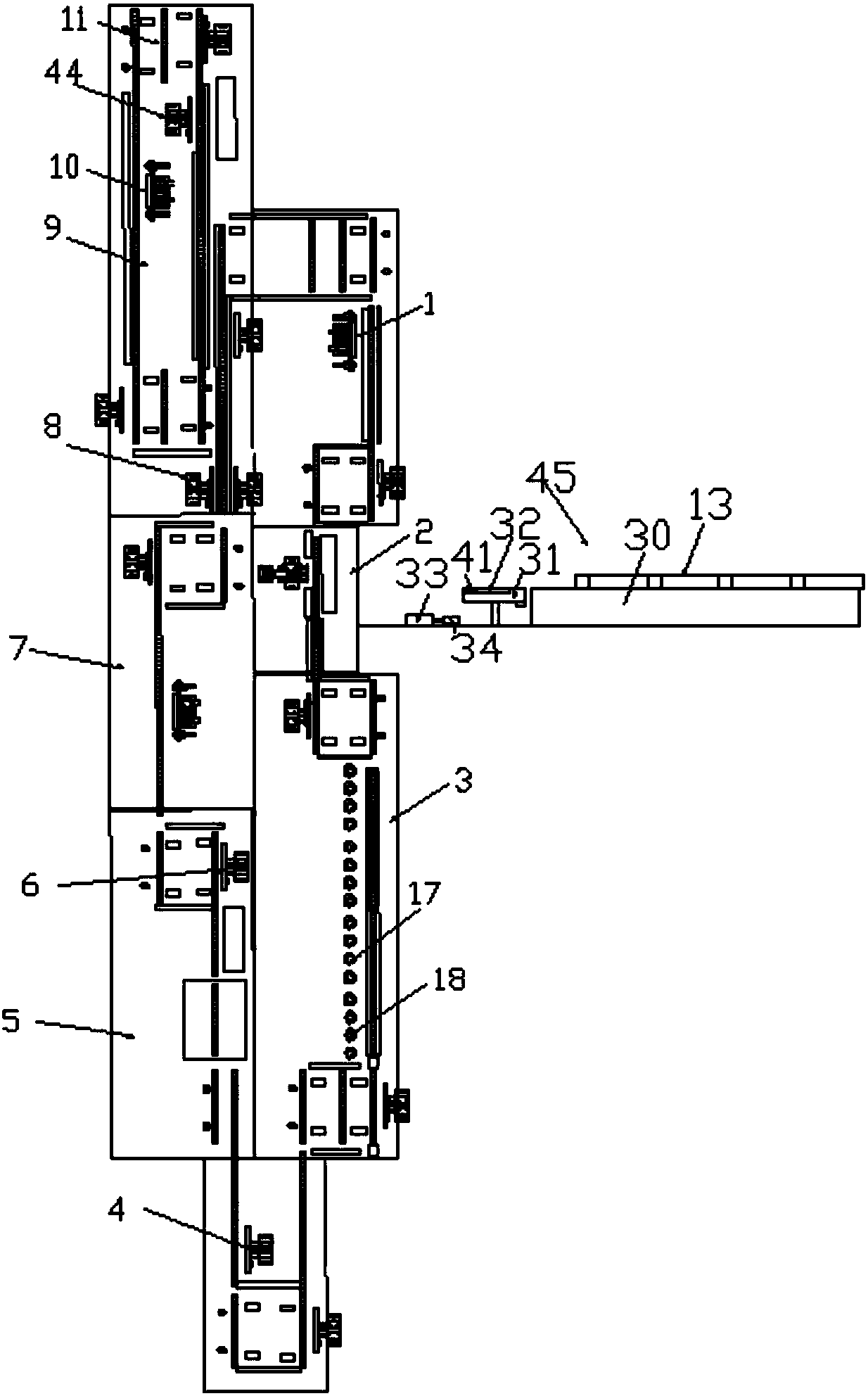

Automatic assembly production method and assembly production line of combination fireworks

InactiveCN103512435AImprove securityHigh degree of automationFireworksInformatizationTransport system

The invention relates to the technical field of firework production, and discloses an automatic assembly production method and assembly production line of combination fireworks. The assembly production line comprises a protection system, a conveying system and a firework mechanical system. The conveying system is composed of an upper conveyor belt and a lower conveyor belt, the upper conveyor belt conveys inner barrel templates filled with inner barrel tube banks, and the lower conveyor belt conveys outer barrel templates filled with outer barrel tube banks. The upper conveyor belt is arranged on the inlets of inner barrel tube bank assembly equipment which is arranged in a plurality of anti-explosion rooms of the protection system respectively. The lower conveyor belt is arranged on the outlets of the outer barrel tube bank assembly equipment which is arranged in the anti-explosion rooms of the protection system respectively. The lower conveyor belt is parallel to the upper conveyor belt. A traditional firework production process technology is improved, researched and developed, factorization, mechanization, informatization, standardization and scalization can be achieved, the automatic assembly production line has the advantages of being high in safety, small in occupied space, high in automation degree and efficiency, small in labor consumption, good in production working environment and the like, and the development mode of a firework and cracker industry can be fundamentally transformed.

Owner:HENAN LINXIAO SCI & TECH DEV

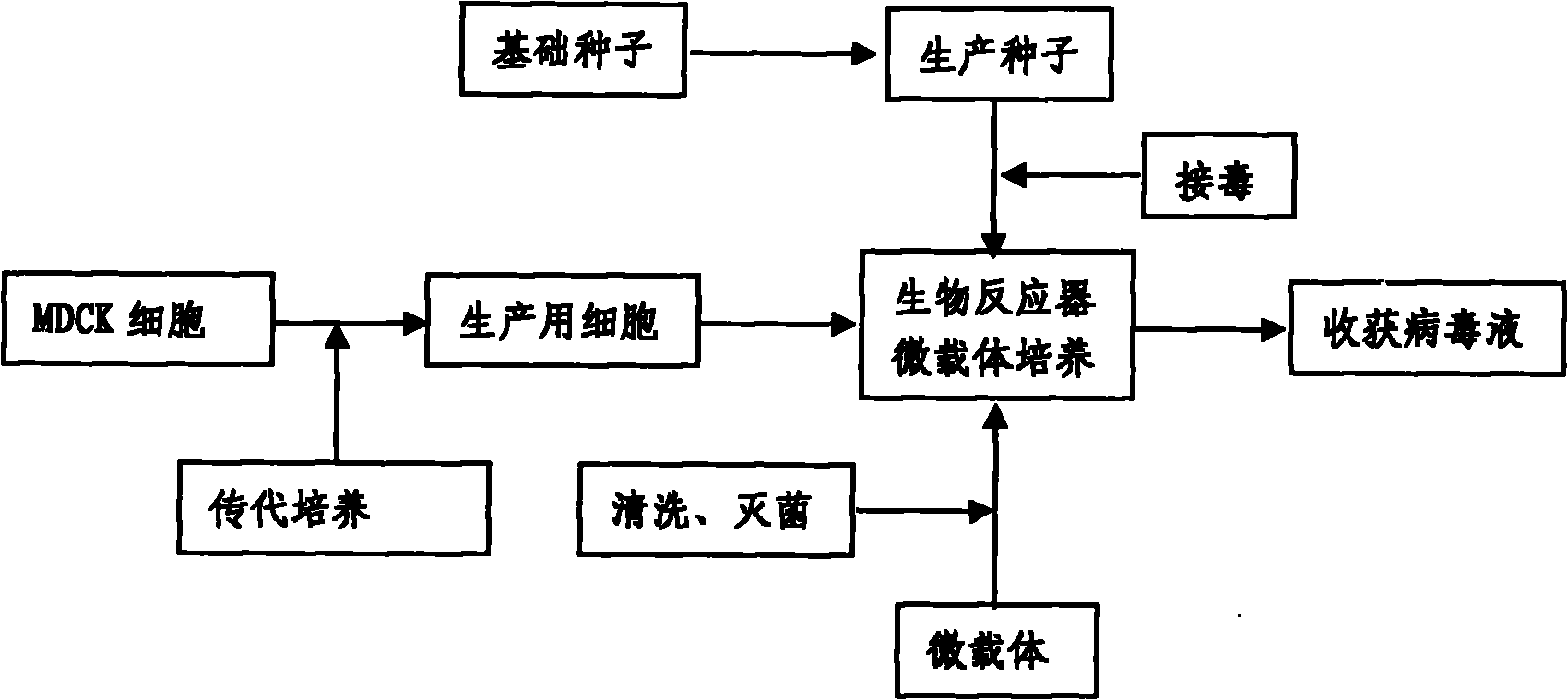

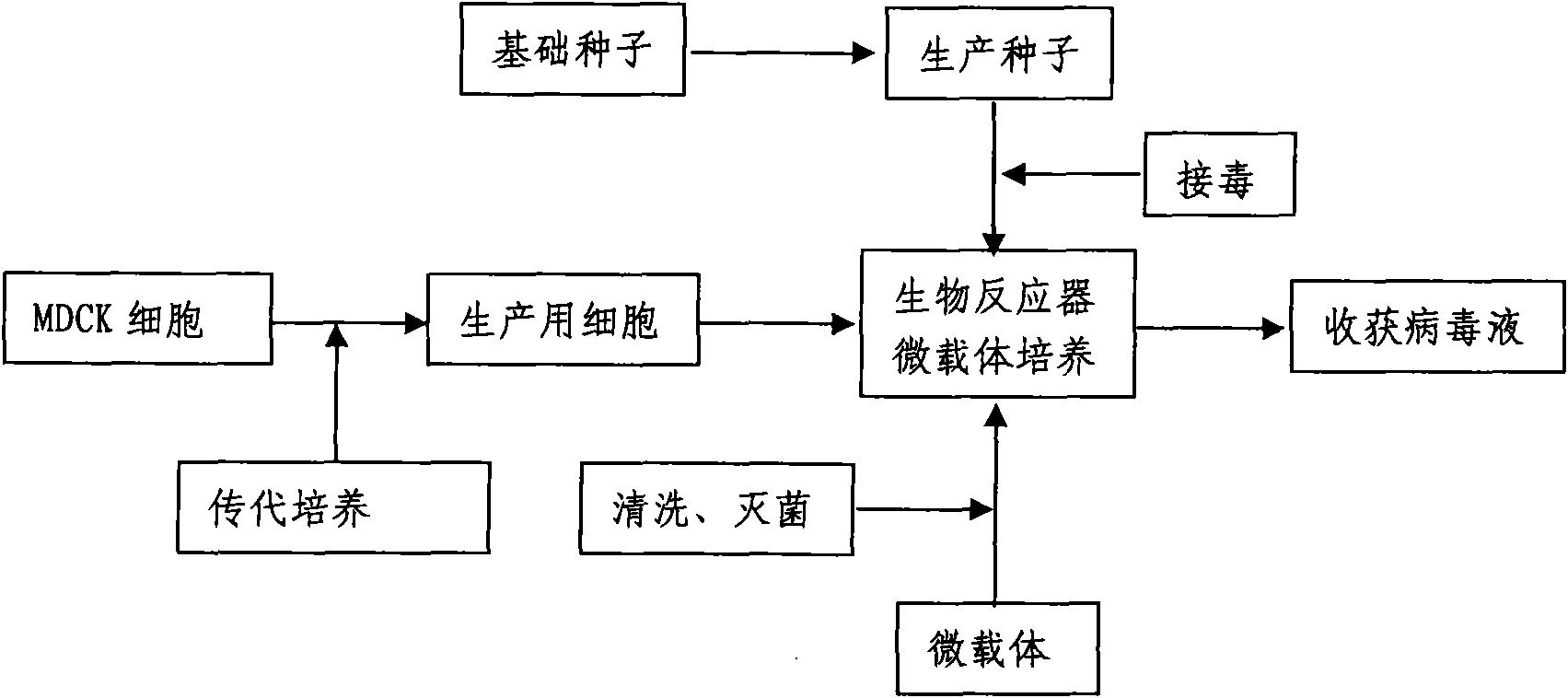

Production method for influenza virus vaccines

InactiveCN101818131ASolve yourselfSolve pollutionAntiviralsViruses/bacteriophagesEquine influenza vaccineBioreactor

The invention discloses a production method for vaccines of avian influenza virus and other influenza virus such as swine influenza, dog influenza and equine influenza, which comprises the following steps of: (1) transfer of culture and cultivation of vaccine-made cells; (2) reproduction of vaccine-made virus seeds; (3) microcarrier suspension culture of MDCK cells in a bioreactor; (4) reproduction of vaccine-made virus liquid; and (5) harvest of the virus liquid. The production method has the advantages of reducing the production cost greatly and improving the yield and quality of the vaccines obviously, along with short production period, no restriction to raw material supply, small occupied area, easy and quick expansion of production scale, light environmental pollution, easy processing, high automaticity, low employment and easy realization of balanced and stable quality.

Owner:成都史纪生物制药有限公司

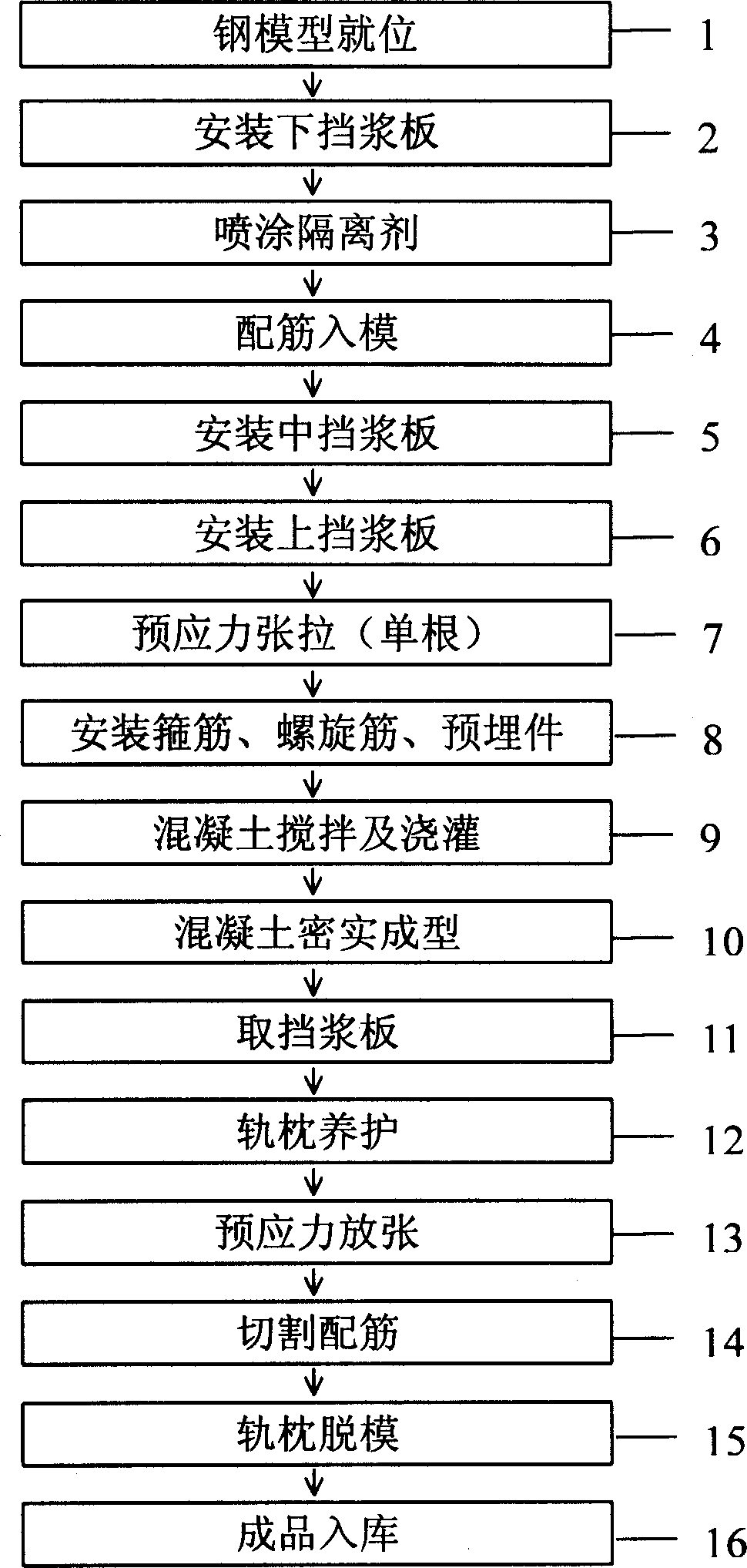

Prestressed concrete rail sleeper production process using long line pedestal method

InactiveCN1493442AEmploy lessReduce energy consumptionCeramic shaping apparatusPre stressMaterial consumption

A technology for producing prestressed concrete sleepers by long table method includes sequentially arranging steel moulds, installing bottom stopper, coating the isolating agent, locating prestressed bars, installing central and top stoppers, stretching prestressed bars, anchoring, installing hoops, spiral bars and preburied parts, stirring and pouring concrete, vibrating, removing stoppers, cutting the auxiliary bars, and demoulding. Its advantages are low energy consumption and cost, and high quality of product.

Owner:王庆昌 +2

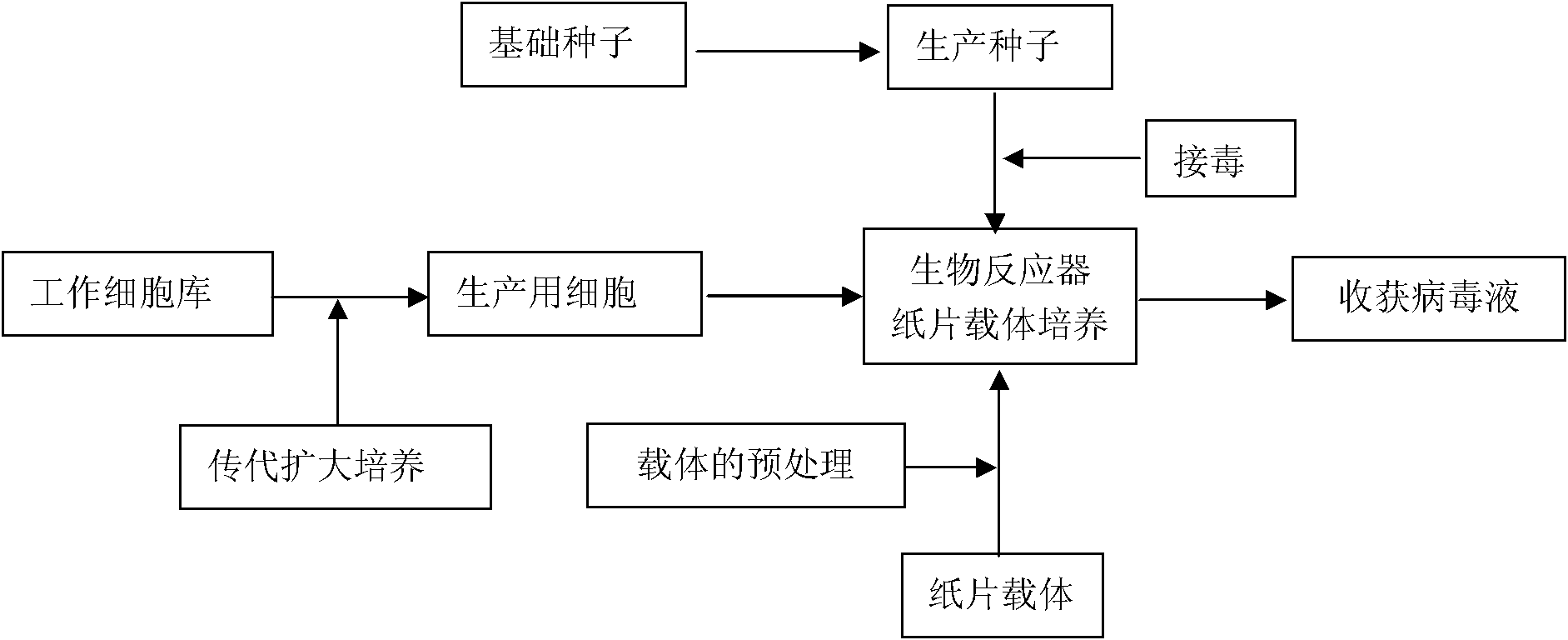

Method for producing PRRS (Porcine Reproductive and Respiratory Syndrome) viruses

ActiveCN102002482AQuality improvementIncrease productionRecovery/purificationPerfusion bioreactorPerfusion Culture

The invention discloses a method for producing PRRS (Porcine Reproductive and Respiratory Syndrome) viruses through culturing Marc-145 cells by applying a torrent-perfusion bioreactor. The method comprises the following steps of: (1) selecting Marc-145 cells as cells for culturing seedlings; (2) subculturing the Marc-145 cells; (3) reproducing virus seeds for production; (4) perfusing and culturing the Marc-145 cells on a paper carrier in the torrent-perfusion bioreactor; (5) producing the PRRS viruses in the torrent-perfusion bioreactor; and (6) treating the obtained virus antigen solution. The invention can greatly decrease the production cost, improve the input-output ratio by more than 10 times and expand the production scale easily and rapidly, has short production preparation cycle and high degree of automation, occupies less area, causes less environmental pollution which is easy to treat, consumes less labor, is easy to realize balanced and stable virus quality and can obviously improve the yield and the quality of the viruses.

Owner:成都史纪生物制药有限公司

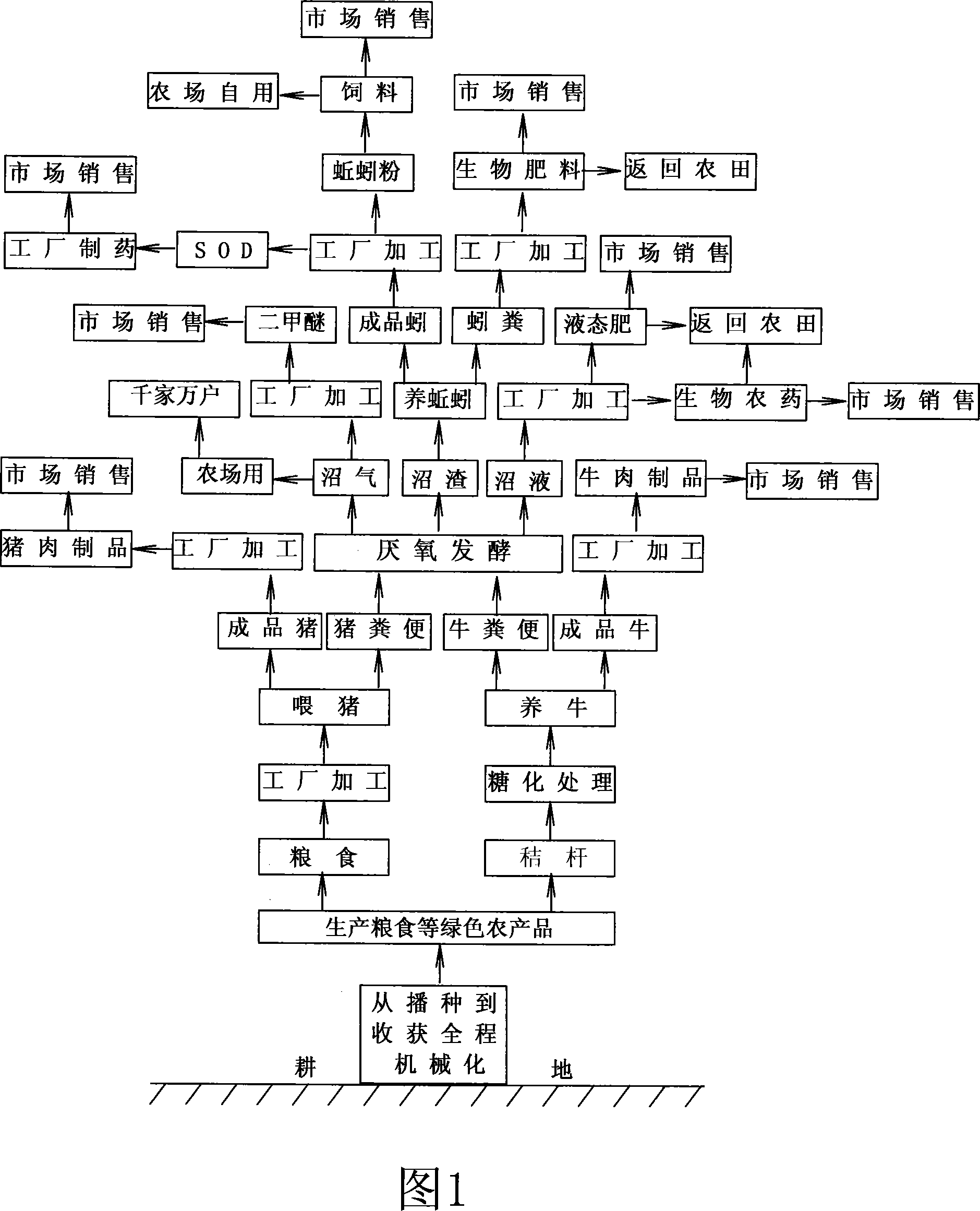

Models and methods of eco-agricultural circular economy with biogas as a link

InactiveCN101032237AAchieve growthHigh technology contentAnimal feeding stuffWaste based fuelPlant cultivationEngineering

The ecological agricultural production mode with marsh gas as the ligament has the crop and plant cultivation, raising and processing industry well combined to form one agricultural production system. Around marsh gas production, all the said production links are connected organically and compensated mutually. The present invention has high production efficiency, full utilization of resource, environment friendship and high economic efficiency.

Owner:苏宏文

Harm-less fast fermented bio-organic fertilizer and preparation method thereof

InactiveCN105110833ANo pollution in the processNutritional diversityBio-organic fraction processingOrganic fertiliser preparationBiotechnologySludge

The invention provides a harm-less fast fermented bio-organic fertilizer and a preparation method thereof, belongs to the technical field of bio-organic fertilizers, and aims to solve the problems of failure in radically killing a great amount of harmful zymad and worm eggs in livestock excrement, long fermentation period, serious nutrition loss and large occupied area in the conventional livestock excrement treating method. The harm-less fast fermented bio-organic fertilizer comprises 1 weight part of strain mixture and 2500 to 3500 weight parts of organic solid waste, wherein the strain mixture comprises 1 weight part of bacillus subtilis ACCC03120 and 3 to 8 parts of one or more auxiliary materials; the auxiliary material(s) is / are one or more of rice bran, maize meal, wheat bran and crop straw powder; the organic solid waste comprises one or more of livestock excrement, carcase, industrial discharge, kitchen waste and urban sludge. The harm-less fast fermented bio-organic fertilizer and the preparation have the advantages that the fermentation period of the bio-organic fertilizer is greatly shortened; the nutrition is multiplied by 2 or more; the occupied area is greatly reduced; the use is safe and sanitary; pollution is avoided. Therefore, the bio-organic fertilizer is pure-green ecological fertilizer.

Owner:吉林省好沃施农业科技开发有限公司

Method for producing influenza virus vaccine

ActiveCN101955915ASolve pollutionGuaranteed to be pureAntiviralsViruses/bacteriophagesCanine kidneyEquine influenza vaccine

The invention discloses a method for producing a vaccine for avian influenza viruses and other influenza viruses such as a swine influenza virus, a canine influenza virus and an equine influenza virus. The method comprises the following steps of: subculturing cells for preparing the vaccine; (2) reproducing cytotoxic varieties; (3) performing microcarrier suspension culture on darby canine kidney (MDCK) cells in a bioreactor; (4) reproducing venom for preparing the vaccine; and (5) harvesting virus liquid. The method has the advantages of great reduction in production cost, short production period, no restriction to raw material supply, small occupied area, easy and quick expansion in production scale, low and readily treated environmental pollution, high degree of automation, few labors, easy equilibrium and stabilization in quality and obvious improvement on the yield and the quality of the vaccines.

Owner:成都史纪生物制药有限公司

Efficient energy-saving concrete aggregate production line and method

ActiveCN105107571ASimple processReduce the number of equipmentGrain treatmentsProduction lineAutomatic control

The invention relates to an efficient energy-saving concrete aggregate production line. A feed inlet of a crusher, a plate type feeding machine, a hammer impact crusher, an elevator and a primary vibrating screen are sequentially connected. A primary coarse material outlet, a primary medium material outlet and a primary fine material outlet are formed in the primary vibrating screen and connected with the crusher, a first stock bin and a secondary vibrating screen respectively. A secondary coarse material outlet, a secondary medium material outlet and a secondary fine material outlet are formed in the secondary vibrating screen and connected with a second stock bin, a third stock bin and a fourth stock bin respectively. According to the efficient energy-saving concrete aggregate production line, the optimized scheme that the efficient crusher is used, the elevator is used for conveying and screening machines are arranged at the tops of the stock bins is adopted, in this way, the procedure is greatly simplified, the number of pieces of equipment is greatly reduced, and the number of dust raising points is also greatly reduced; a distributed control system (DCS) centralized full-automatic control scheme is adopted, and thus the efficient energy-saving concrete aggregate production line has the advantages that the number of required workers is small, the occupied area is small, investment is low, and energy consumption is low.

Owner:坚构建材科技集团有限公司

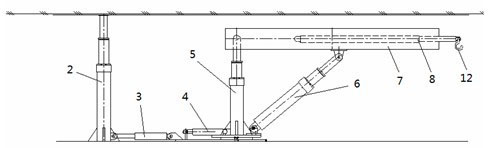

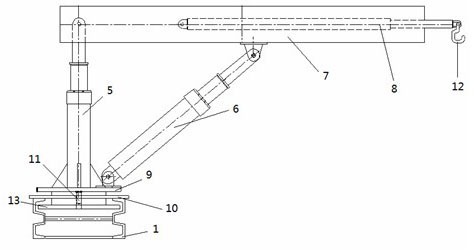

Installation and removal crane for mining devices

The invention discloses an installation and removal crane for mining devices, comprising a hoisting hook, and a support part, a rotating part, a hoisting part and a moving part, wherein the support part is installed and matched with a chute; the rotating part is hinged with the support part and drives the hoisting hook to rotate; the hoisting part is hinged with the support part and drives the hoisting hook to lift; and the moving part drives the hoisting hook to move. The installation and removal crane has the advantages that: the crane leads mechanization to be realized for both installation and removal of coal mine equipment, reduces labor intensity, improves work efficiency and reduces accidents; besides, the crane has large hoisting tonnage, can not only be used for installation of chutes but also installation of large devices such as hydraulic brackets and the like, has the advantages of strong universality, simple structure, easiness for installation and maintenance, easiness for carrying, high working efficiency when working and small workforce; and a working face chute can be installed at least 15 days in advance.

Owner:YANKUANG GRP CO LTD +1

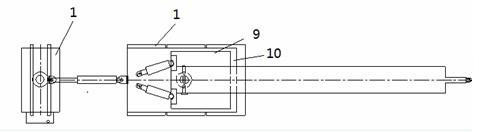

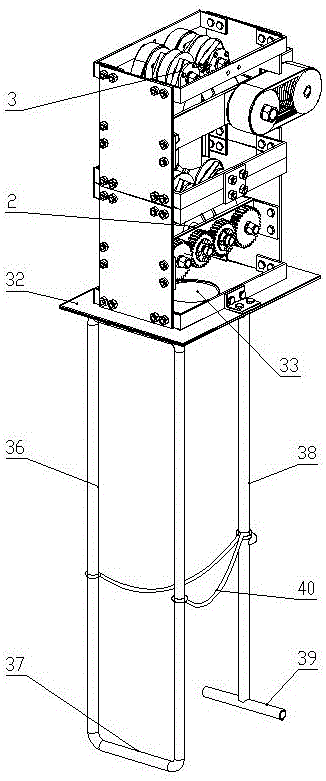

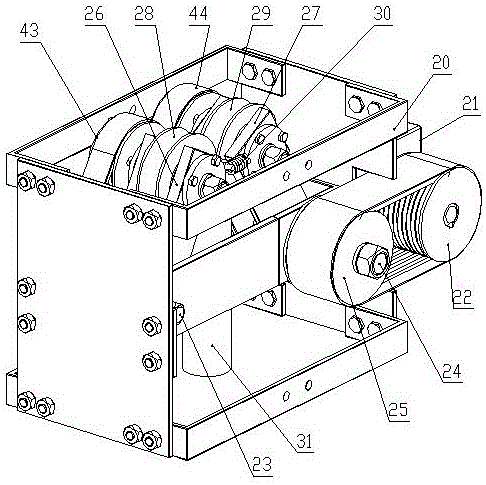

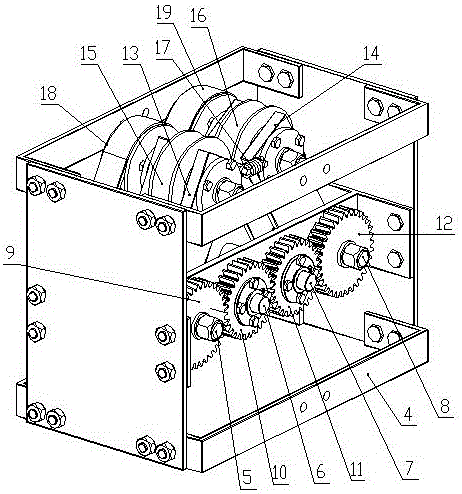

Pulverizer

The invention relates to a vertical pulverizer. The vertical pulverizer belongs to mechanical equipment. A frame of the pulverizer is provided with a main machine and a motor, a main shaft goes through the main machine and is connected to an upper end surface and a lower end surface of the main machine by a bearing, the main machine is provided with a material inlet and a material outlet, the main shaft is provided with a cutterhead, a cutter upright-bar is inserted into the cutterhead, moving blades are inserted into the cutter upright-bar, each two adjacent moving blades, and each one of the moving blades and the cutterhead are separated respectively by steel pipe sleeves, an impeller is installed at the lower end in the main machine and the impeller is connected to the main shaft. The pulverizer realizes efficient direct pulverization on a high-crude fiber content wet material, thoroughly solves the perennial problems of difficult feeding and discharging of the existing pulverizer and solves the problem that the existing pulverizer is maintained difficultly and has a low yield. The existing pulverizer can only directly pulverize hundreds jin of a wet material in one hour. The pulverizer provided by the invention can pulverize 6 tons of fresh corn straws in one hour, can pulverize 3.5 tons of high-crude fiber content fresh caragana microphylla in one hour, and can continuously work without interruption.

Owner:SIZIWANG BANNER JIAYUAN AGRI DEV

Method for underground chamber digging and laneway opening digging

InactiveCN101302932AImprove concentrationIncrease flexibilityUnderground miningBlastingEngineeringMechanical equipment

The invention relates to a method for advancing the port and the underground chamber of a roadway. The method of the invention adopts the technologies of hole drilling, coal blasting and smooth blasting, coal loading and transporting, hole drilling and supporting, etc., and is characterized in that the technologies of coal loading and transporting as well as hole drilling and supporting use a coal roadway drilling, loading and transporting integrated anchor windlass and a scraper blade transporter system to realize the single and double-roadway advancing with more flexibility, convenience, higher yield and efficiency, thus improving the mechanical equipment level of an advancing operating face; the method of the invention can be applicable to large, medium and small-sized coal mines.

Owner:闫振东

Machine for mounting inner tube and flap of tyre

InactiveCN102887041AAvoid Fatigue InjuriesEmploy lessTyre repairingUltimate tensile strengthMechanical engineering

The invention discloses a machine for mounting an inner tube and a flap of a tyre. The machine comprises a tyre conveying device, and an inner tube mounting device and a flap mounting device which are arranged on the tyre conveying device along the conveying direction. By the machine for mounting the inner tube and the flap of the tyre, the inner tube and the flap of the tyre can be automatically mounted, poor appearance phenomena such as non-uniform and irregular tyres, deflated tyres and inflated tyres caused by manual mounting are avoided, the manpower is only required to feed materials to the mounting machine, a few people is needed, the labor cost and the labor strength are low, possibility of weary injury of hands of operation workers is avoided, the operation workers can work for a long time continuously, and the production efficiency is improved.

Owner:青岛科力达机械制造有限公司

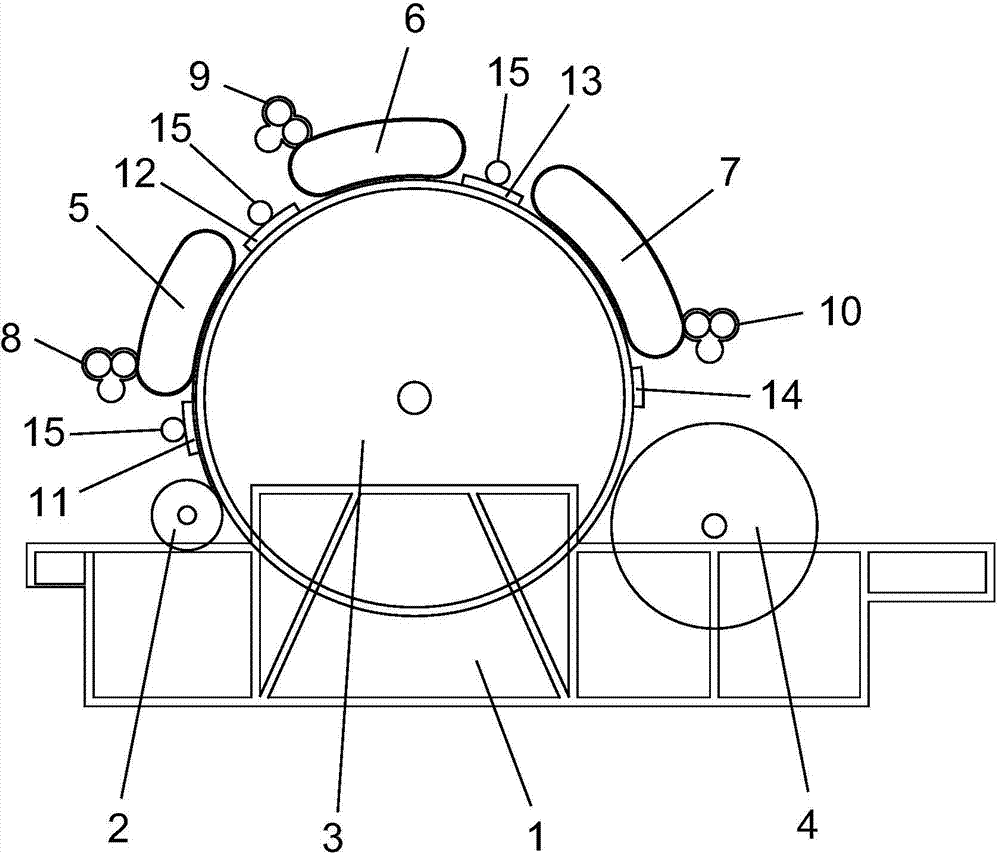

Carding machine

A carding machine comprises a rack, wherein a licker-in roller, a cylinder and a doffer are sequentially arranged on the rack from front to back; a first carding region cover plate, a second carding region cover plate and a third carding region cover plate are sequentially arranged on the top of the cylinder from front to back and correspond to the rack; partitions are respectively arranged between the first carding region cover plate and the second carding region cover plate and between the second carding region cover plate and the third carding region cover plate; the carding machine is provided with the three carding cover plates, so that three carding regions are formed; the first carding region is mainly used for clearing up and combing fibers smoothly and initially discharging impurities and short fibers; the second carding region is further used for clearing up and combing the fibers smoothly and initially discharging the impurities and the short fibers; the third carding region is mainly used for precisely combing the fibers and discharging the impurities and the short fibers further; each carding region cover plate is provided with a cover plate cleaning device; the cover plate cleaning devices can clean independently; and the cleaned carding cover plates can be used for combing operation rapidly and efficiently. The carding machine is provided with the three carding cover plates, the radian of each carding cover plate is reduced, the carding cover plates can be cleaned as soon as possible, the cleaning efficiency of the cover plates is improved further, and the carding effect is guaranteed.

Owner:QINGDAO HUANUO MACHINERY

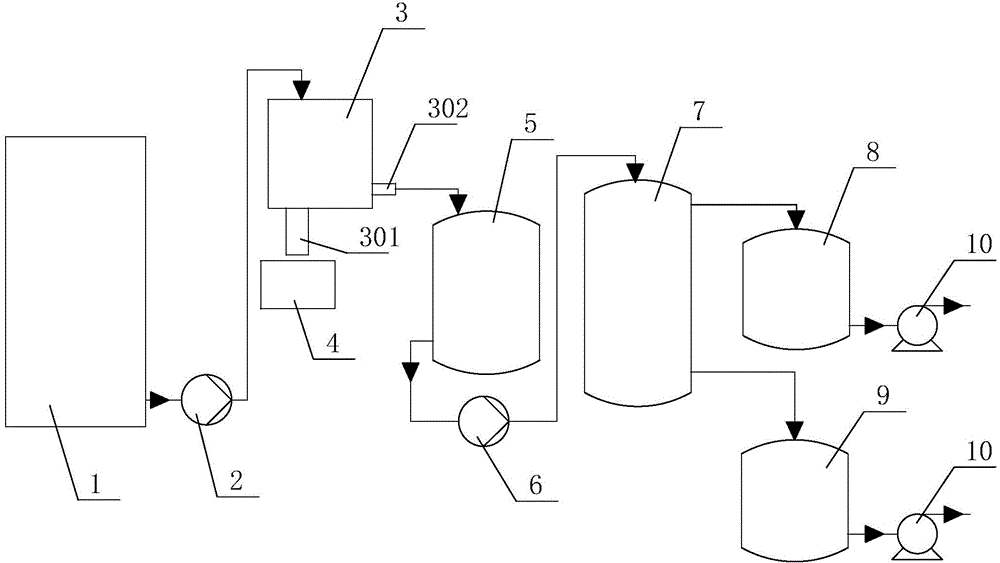

Tar slag separation recycling system

InactiveCN104888516AEasy to separateStrong solid-liquid separation abilityFiltration circuitsMoving filtering element filtersSocial benefitsSlag

The invention provides a tar slag separation recycling system which comprises a tar slag collecting groove, a first delivery pump, a centrifuge, a slag collecting groove, an oil and water collecting groove, a second delivery pump, an oil-water separator, a wastewater groove and an oil groove. Separation effect of tar slag with tar and water is improved due to high solid-liquid separation capability of the filter-type centrifuge, recycling rate of the tar slag and the tar is increased, and quality of the tar slag and the tar is improved. The tar slag and the tar which are separated can be utilized in production, and good environment-friendly benefit and social benefit are generated. The separation recycling system is automatic in feeding and discharging, simple in structure, easy to manufacture, few in personnel involved and easy to regulate and control.

Owner:SHANDONG IRON & STEEL CO LTD

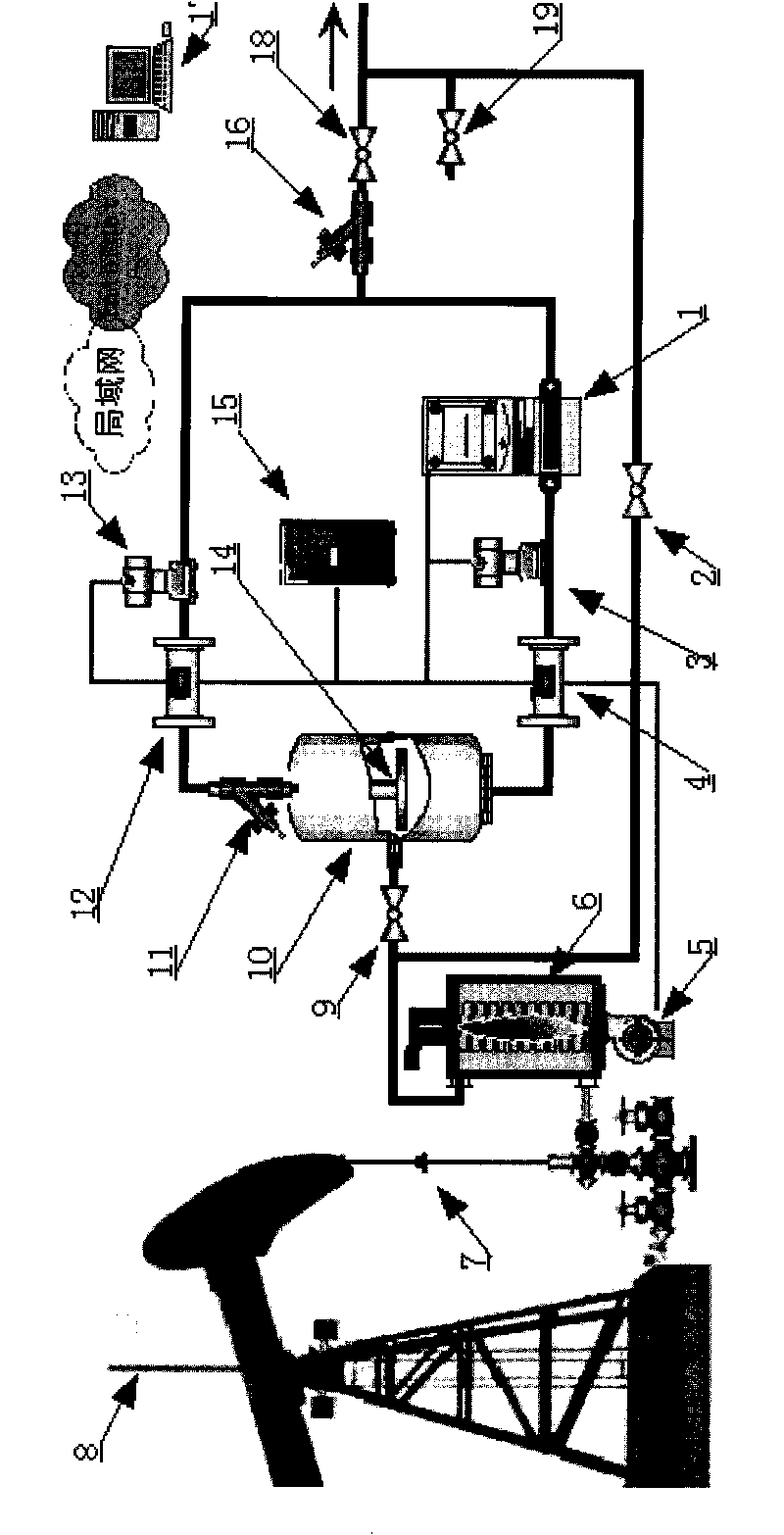

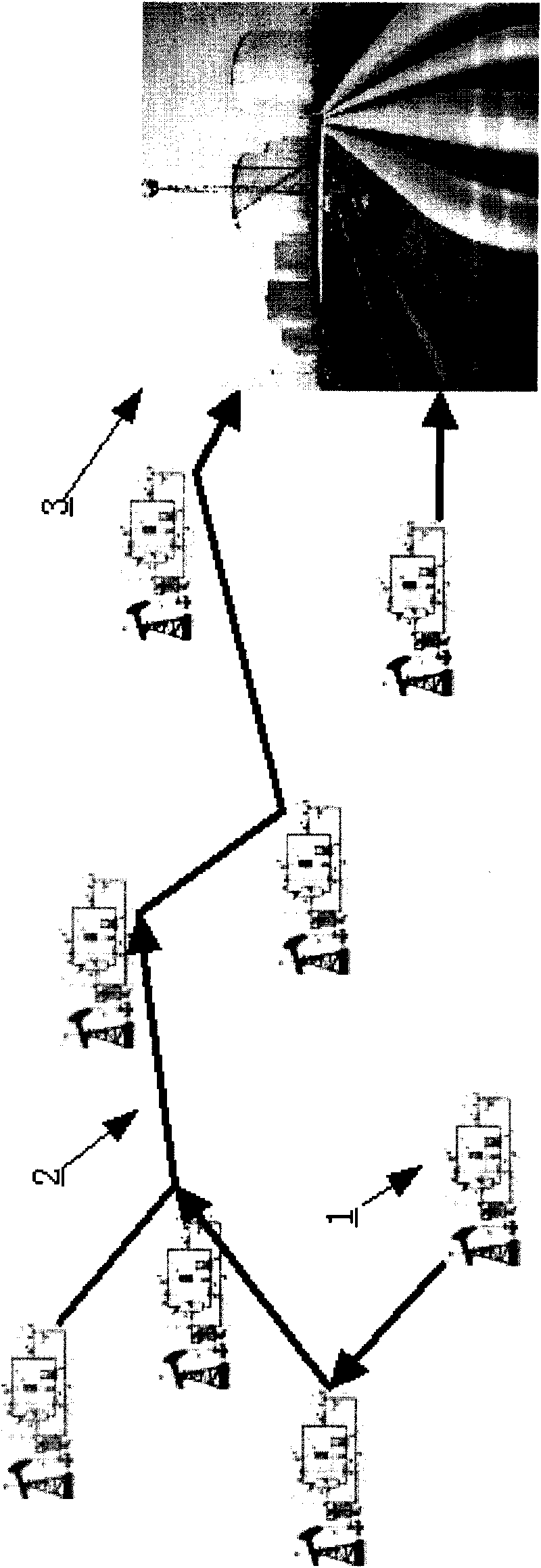

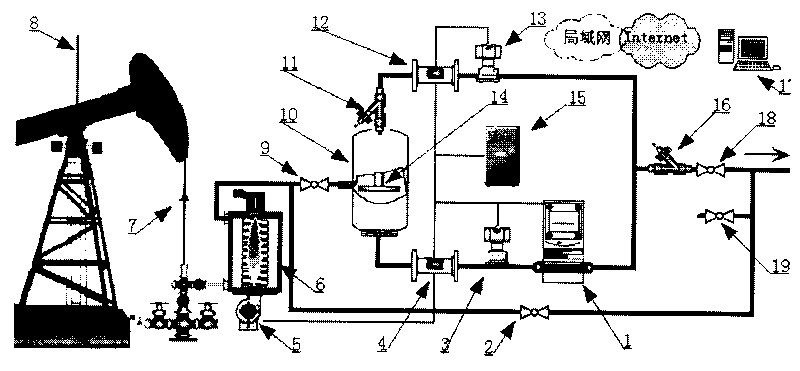

High-efficiency energy-saving oil exploitation method

The invention relates to a high-efficiency energy-saving oil exploitation method. The process for realizing the method is as follows: a multi-phase flowmeter is provided, can adapt to more oil well environments and meters the yields of oil, gas and water produced by oil wells independently at real time in the sites of production wells; and meanwhile, heating equipment of well mouths is installed at the required well mouths, the heating power is controlled by utilizing the metering data of the oil wells and parameters set manually according to the requirements of gathering and transferring, and the condition of heating as required is realized. A metering station is cancelled, the production wells are locally connected together by using pipelines, mixed fluid produced by the oil wells enters a multi-purpose station directly and is dewatered and degassed, and then the qualified crude oil is output outwards. Data processing equipment (or named as other names) of the well mouths integrally collects and processes various data of the well mouths simultaneously, automatic oil extraction, automatic metering, automatic heating, gathering and transferring and automatic accident judgment and treatment are directly realized at the well mouths, the entire oil extraction system is divided into areas according to the requirement, the data processing equipment of the oil wells is connected into a network according to the areas, and integral control is realized.

Owner:北京昊科航科技有限责任公司

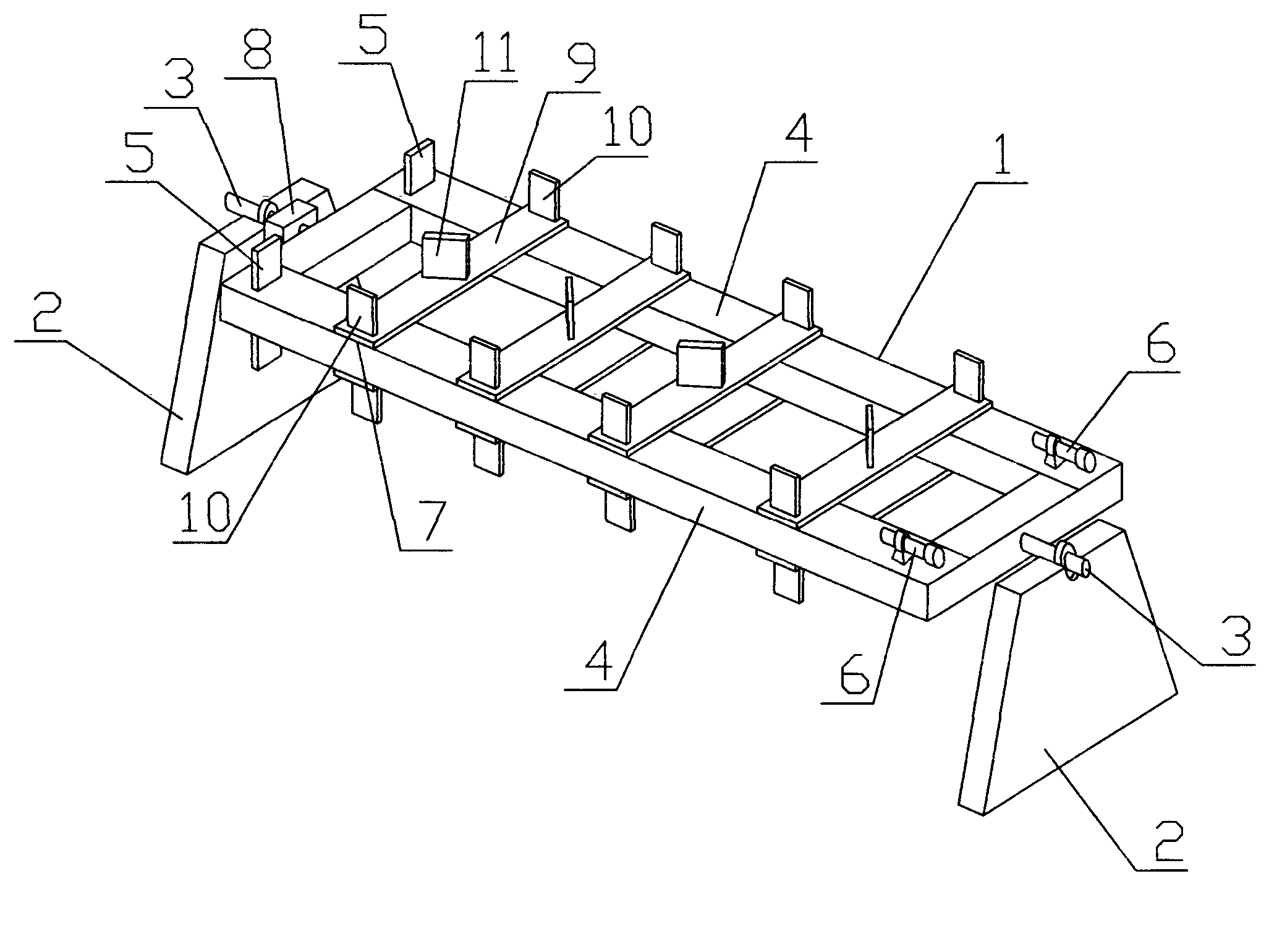

Truss assembling tool

InactiveCN103846594AAssembly positioning is accurateImprove machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention discloses a truss assembling tool which comprises a tool main body and two brackets, wherein rotating shafts are arranged at two ends of the tool main body; the two brackets are symmetrically arranged; the rotating shafts are mounted on the corresponding brackets through bearings; the tool main body comprises two parallel cross beams; a main baffle is arranged at one end of each of the cross beams; puller bolts are arranged at the other end of each of the cross beams; a plurality of fixing devices are mounted between the two cross beams. The truss assembling tool can be used for fixing and connecting an upper chord, a lower chord and a web rod of a truss; assembling and positioning are accurate; the processing precision is high; the labor is saved; the labor cost is low; components of the truss can be fixed on the upper sides and the lower sides of the cross beams; the tool main body can rotate, so that the mounted truss can be rotated to the lower side so as to be directly dismounted; the processing period is short, and the working efficiency is high; connection plates of the fixing devices are connected with the cross beams through bolts, so that the fixing devices are detachable; the fixing devices of different specifications can be arranged on the truss assembling tool according to the style of the truss to be processed, and the use expansibility is high.

Owner:QINGDAO XINGUANGZHENG STEEL STRUCTURE MATERIAL

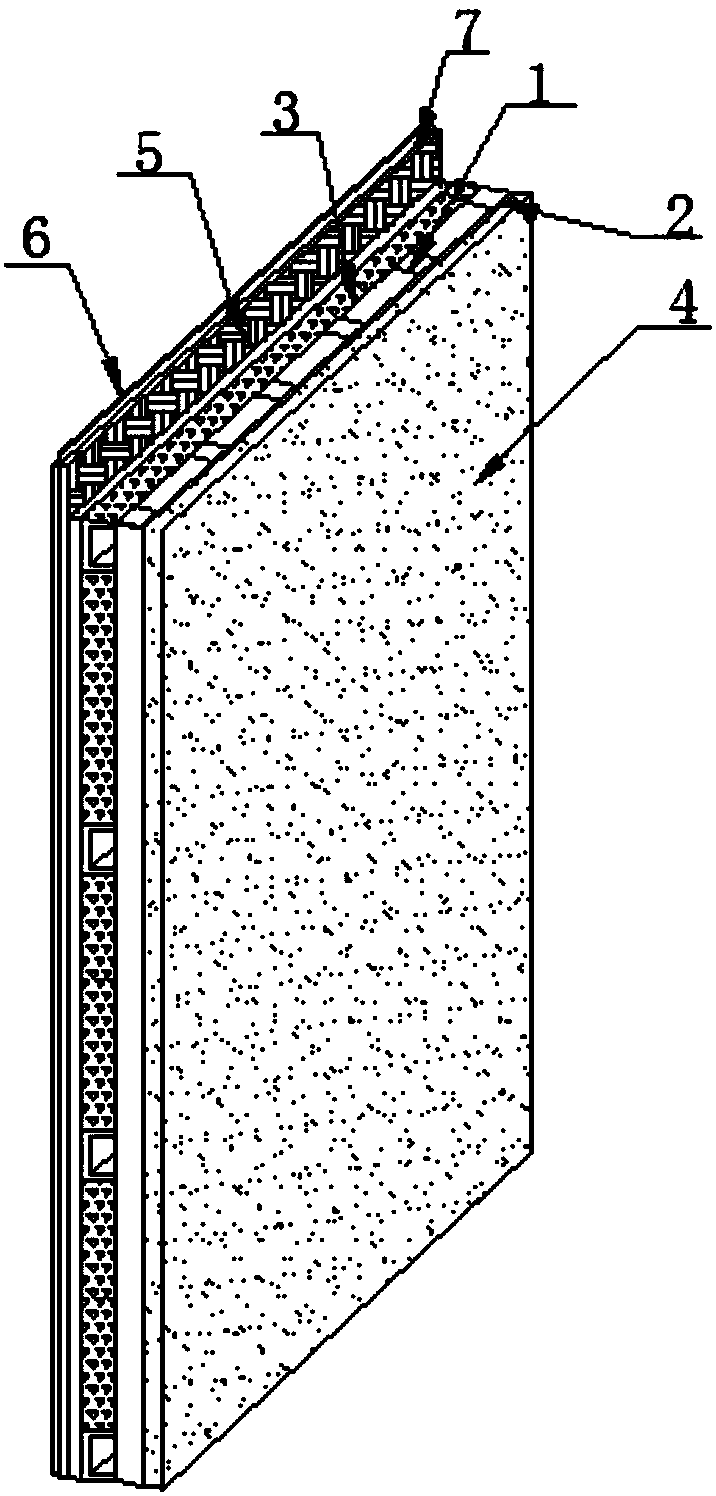

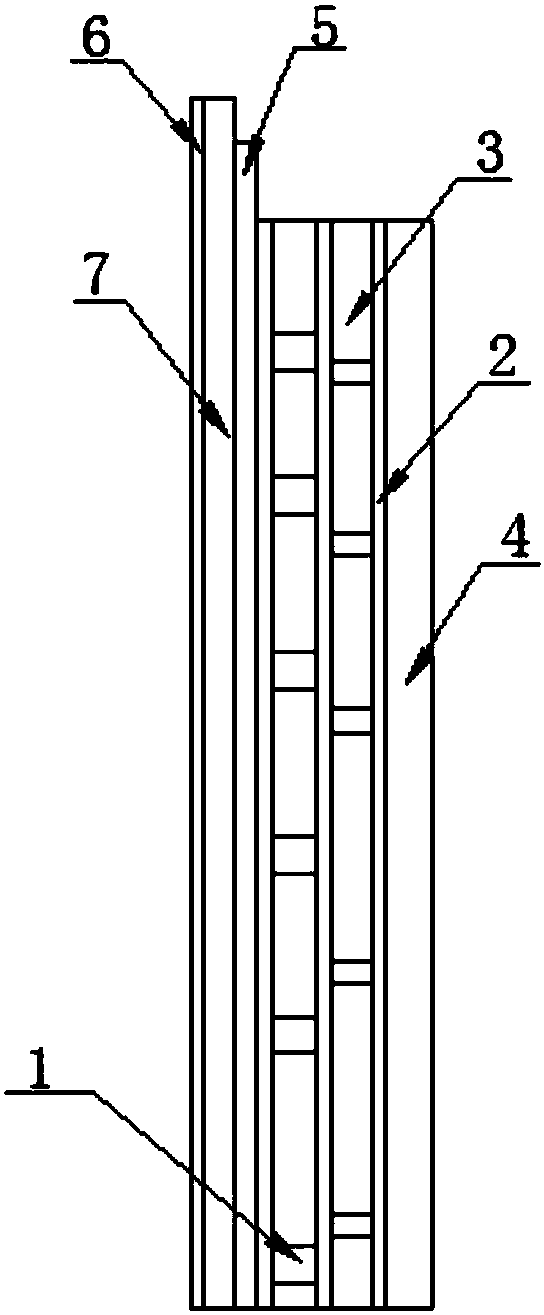

Outer wall composite wall body with gypsum thermal-insulation mortar layers and application thereof

The invention discloses an outer wall composite wall body with gypsum thermal insulation mortar layers. The outer wall composite wall body comprises structural steel, steel meshes, the gypsum thermalinsulation mortar layers, a first wall body spraying-building mortar layer, a second wall body spraying-building mortar layer, a polymer waterproof and anti-cracking mortar layer and an anti-corrosionmesh cloth. The steel meshes are mounted in the middle, on one side or the two sides of the structural steel, the structural steel is fixed to a beam-column structure and arranged in the gypsum thermal insulation mortar layers, the first wall body spraying-building mortar layer and the second wall body spraying-building mortar layer, and the structural steel, the gypsum thermal insulation mortarlayers and the wall body spraying-building mortar layers are of an integrated structure. The gypsum thermal insulation mortar layers are sprayed on the steel meshes and covered by the first wall bodyspraying-building mortar layer on the inner side and the second wall body spraying-building mortar layer on the outer side for protection. The polymer waterproof and anti-cracking mortar layer is smeared on the outer side of the second wall body spraying-building mortar layer, and the anti-corrosion mesh cloth is embedded in the polymer waterproof and anti-cracking mortar layer to form a waterproof protective layer and an anti-cracking layer on the outer side of the wall body.

Owner:SHANGHAI KENAI NEW MATERIAL TECH CO LTD

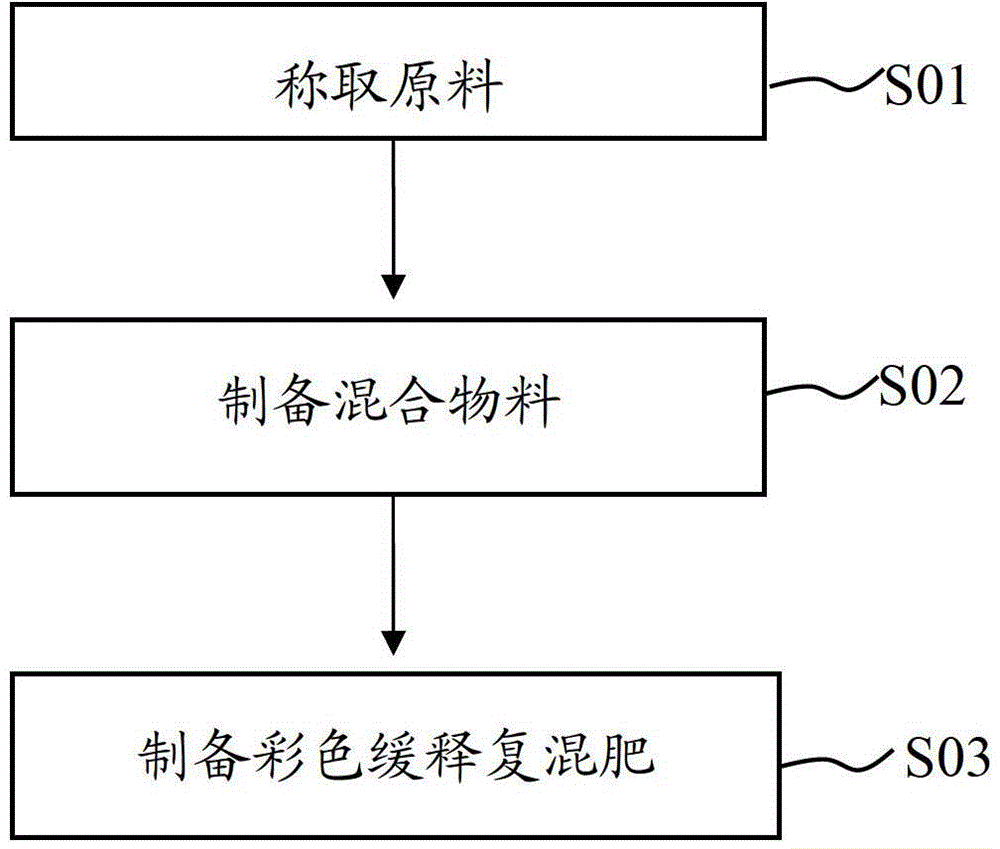

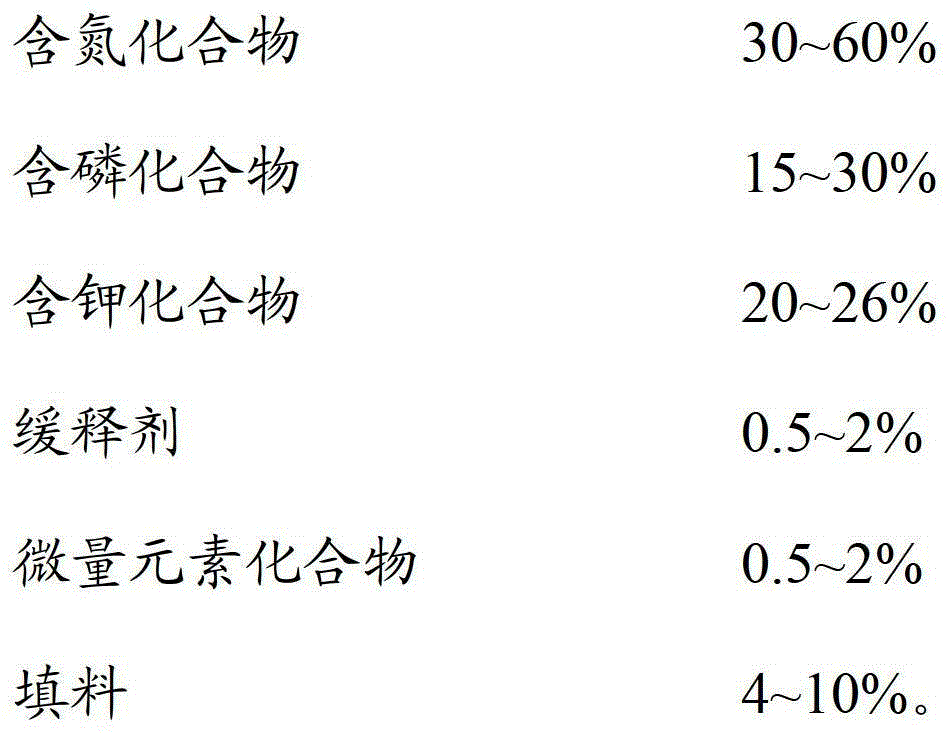

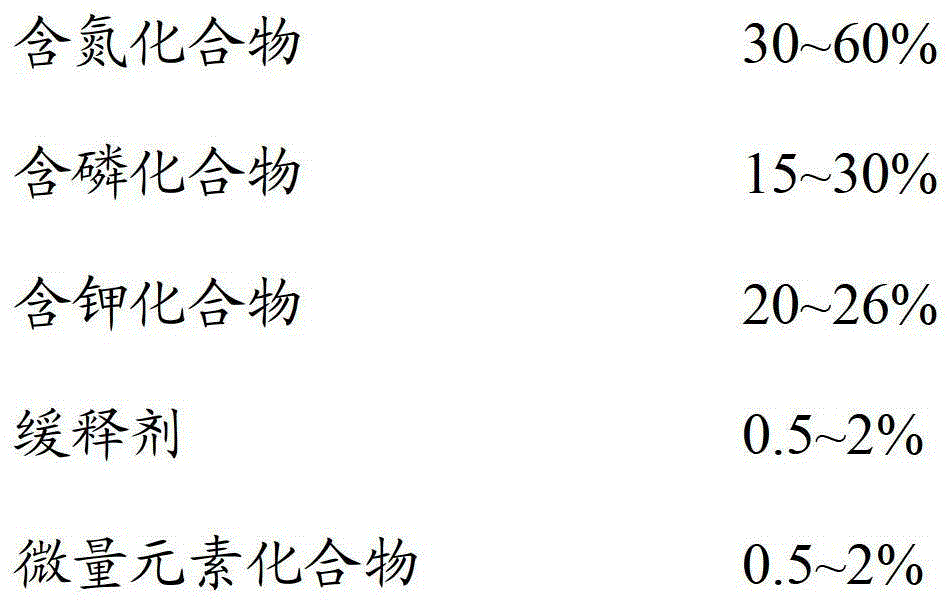

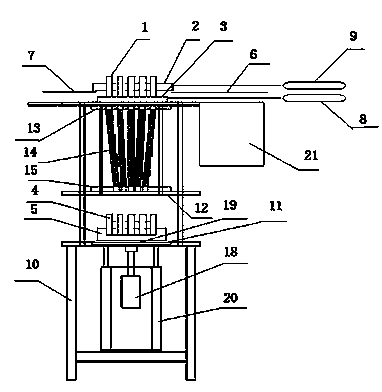

Colorful slowly-releasing compound fertilizer and preparation method thereof

ActiveCN104418637ARich in nutrientsVariety of colorsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersNitrogenRelease time

The invention is suitable for the field of agricultural chemical fertilizers and provides a colorful slowly-releasing compound fertilizer and a preparation method thereof. The colorful slowly-releasing compound fertilizer includes a nitrogen-containing compound, a phosphorous-containing compound, a potassium-containing compound, a slowly-releasing agent, a microelement compound and a filling material. In the colorful slowly-releasing compound fertilizer, the slowly-releasing agent is used as an additive, so that the releasing rate of nutrients in the compound fertilizer can be slowed down, thereby prolonging a releasing time. The slowly-releasing compound fertilizer can reduce fertilizing times and fertilizing amount and can reduce planting cost. The phosphorous-potassium granular compound fertilizer is manufactured through an extrusion technology. The compound fertilizer is simple in production technology, is increased in yield rate, is less in labor consumption, is low in energy consumption and can protect environment.

Owner:SHENZHEN BATIAN ECOTYPIC ENG +1

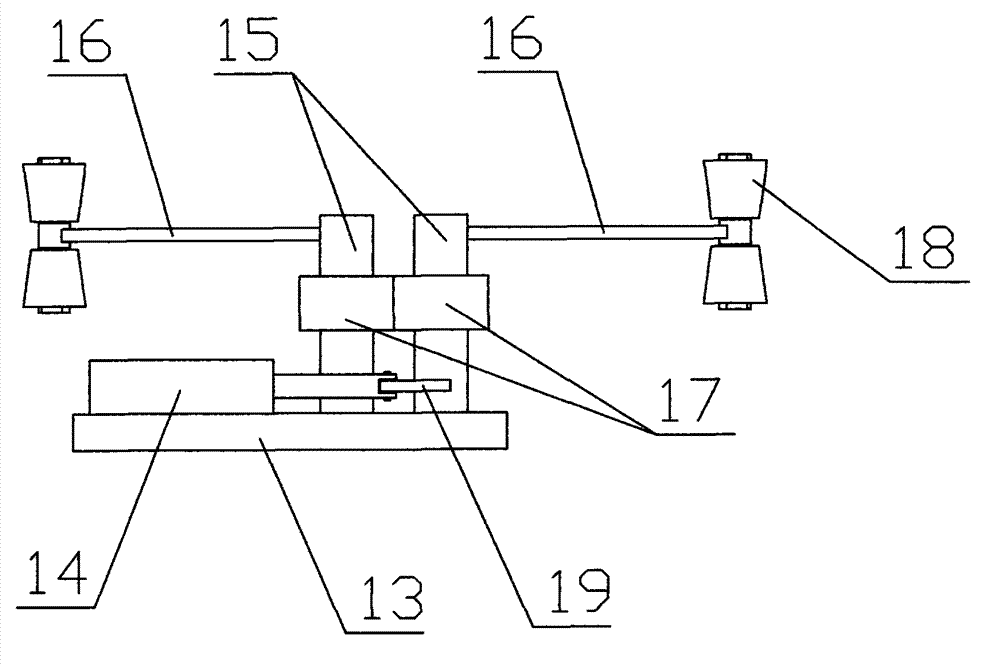

Automatic assembly method and assembly machine of inner barrels and outer barrels for producing combination fireworks

InactiveCN103512432AImprove securityHigh degree of automationFireworksInformatizationWorking environment

The invention relates to the technical field of firework production equipment, and discloses an automatic assembly method and assembly machine of inner barrels and outer barrels for producing combination fireworks. The automatic assembly machine of the inner barrels and the outer barrels comprises an inner barrel template separating mechanism and an automatic assembly mechanism. The inner barrel template separating mechanism enables inner barrel templates filled with propellant powder to enter an upper working plane for process separation. The automatic assembly mechanism enables outer barrel templates filled with propellant powder to enter a lower working plane for online assembly with the inner barrels, wherein in the outer barrel templates, base pads are pressed. The side, located on the rack, of the upper working plane is provided with an inner barrel template inlet and outlet working mechanism which enables the inner barrel templates to enter the starting separating station of the inner barrel templates. The starting separating station of the inner barrel templates is provided with the inner barrel template separating mechanism which allows the inner barrel templates to be separated from inner barrel tube banks. A traditional firework manufacturing process technology is improved, researched and developed, the automatic assembly machine has the advantages of being high in safety, small in occupied space, high in automation degree and efficiency, small in labor consumption, good in production working environment and the like, factorization, mechanization, informatization, standardization and scalization can be achieved, and the development mode of a firework and cracker industry can be fundamentally transformed.

Owner:HENAN LINXIAO SCI & TECH DEV

Automatic hypodermic needle assembling system

PendingCN108127405ARealize automatic feeding processFully automatedAssembly machinesBiomedical engineeringHypodermic needle

The invention discloses an automatic hypodermic needle assembling system. The automatic hypodermic needle assembling system comprises a needle stand feeding mechanism, a needle head feeding mechanism,a needle stand and needle head sensing and downward-pressing mechanism, an image detection mechanism, a needle head silicifying mechanism, a waste removing mechanism, a needle head protecting sleevefeeding mechanism, a needle head protecting sleeve pressing mechanism, a needle stand protective sleeve feeding mechanism, a shifting and butting mechanism, a needle stand protective sleeve pressing mechanism and a discharging and inclined pushing mechanism which are sequentially connected and fixed on a support, wherein the needle head feeding mechanism is further connected to a needle head protective cap feeding mechanism. The automatic hypodermic needle assembling system is provided with the needle head protective cap feeding mechanism, needle heads are provided with protective caps with rubber elasticity, and therefore needle stands, needle stand protective sleeves and needle head protective sleeves can be automatically fed, the needle heads can be automatically fed, and the real fullautomation is realized; and the process of feeding protective caps on the needle heads is carried out after a needle head pipe cutting mechanism works, and therefore the needles or pipes are conveyeddirectionally when pipe cutting is carried out by the needle head pipe cutting mechanism, and the protective caps can be directionally fed on the needle heads without follow-up directional change.

Owner:CAINA TECH CO LTD

Device for assisting coal mine roof timbering anchor cable feeding

InactiveCN106437835AInnovative designEasy to operateUnderground transportAnchoring boltsEngineeringUltimate tensile strength

A device for assisting coal mine roof timbering anchor cable feeding comprises a support, a lower clamping mechanism and an upper clamping mechanism. The lower clamping mechanism is arranged on the support, the upper clamping mechanism is arranged on the lower clamping mechanism and comprises an upper frame, and an air motor for providing power for the upper clamping mechanism and the lower clamping mechanism is fixedly arranged on the right side of the upper frame. The device is novel in design, easy to operate, high in automation degree, small in labor number, low in labor intensity, low in manufacturing cost, safe, reliable, good in market prospect and easy to popularize and apply.

Owner:HENAN POLYTECHNIC UNIV

Production method of porcine reproductive and respiratory syndrome virus

ActiveCN102002481AQuality improvementIncrease productionRecovery/purificationPorcine reproductive and respiratory syndrome virusVirus antigen

The invention discloses a production process of a porcine reproductive and respiratory syndrome virus (PRRSV) by using a bioreactor to culture a Marc-145 cell, which comprises the following technical steps of: (1) selecting a Marc-145 cell as a vaccine preparation cell; (2) culturing the vaccine preparation cell through passage and amplification; (3) reproducing seed virus for production; (4) culturing the microcarrier of the Marc-145 cell in the bioreactor; (5) producing an antigen of the PRRSV; and (6) treating the harvested virus antigen liquid. The invention can greatly reduce production cost and increase the input-output ratio by 5-10 times. Moreover, the invention has the advantages of short production period, small occupied land, easy and rapid expansion of production scale, less environment pollution, easy treatment, high automation degree, fewer people and easy realization of balanced and stable quality. The production cost can be obviously increased, and the yield and the quality of the vaccine can be increased.

Owner:成都史纪生物制药有限公司

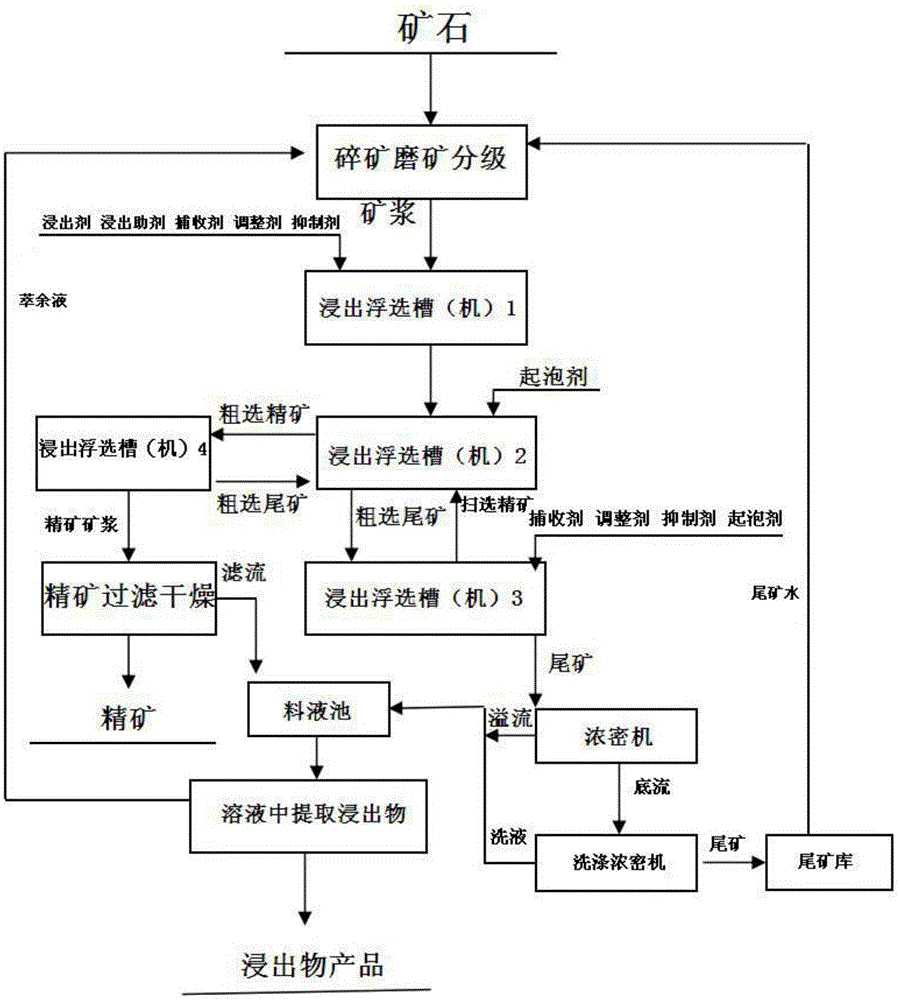

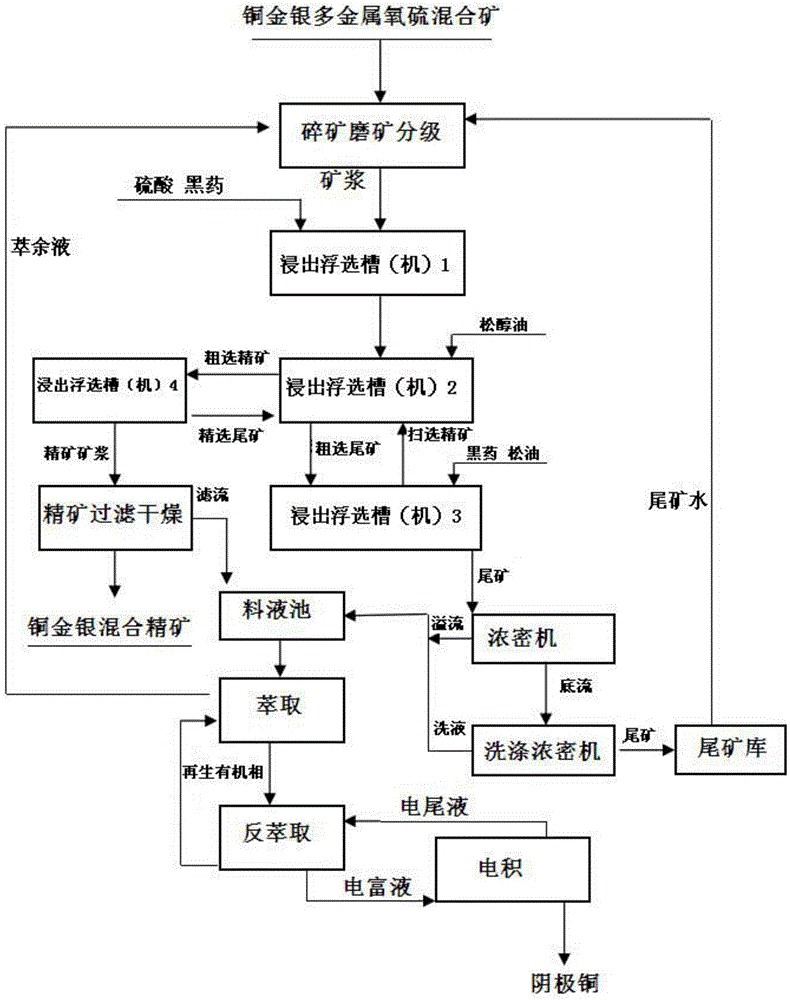

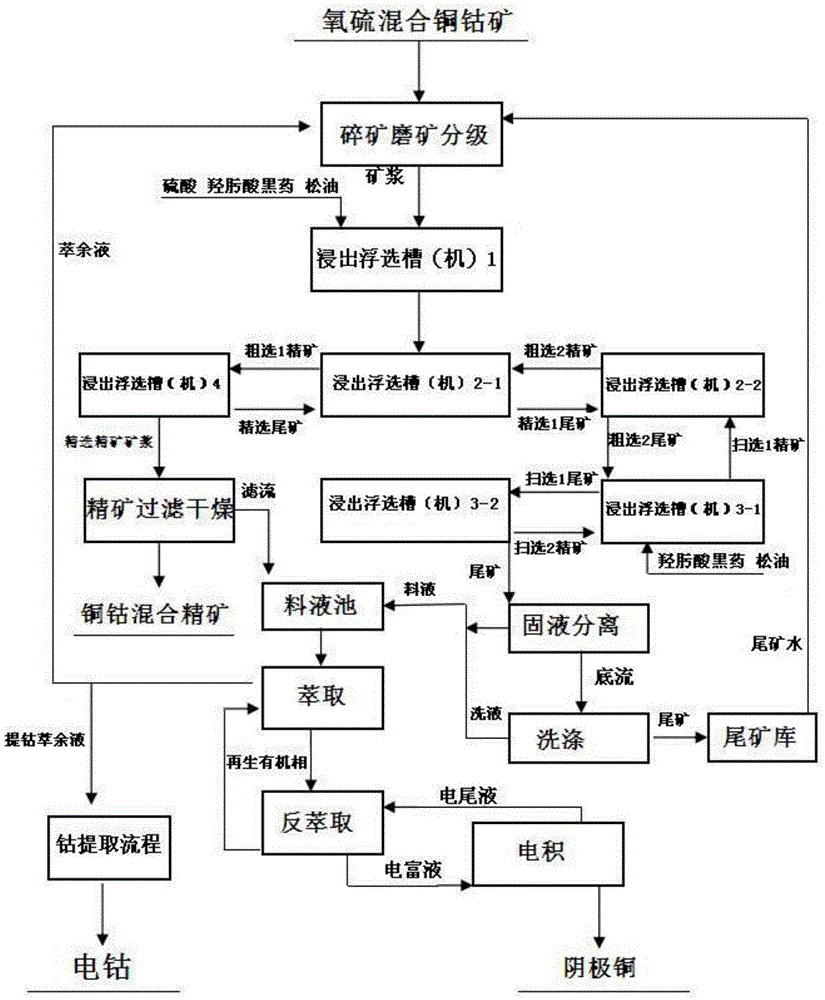

Method for conducting leaching and flotation on ores in same leaching and flotation cells

ActiveCN105483374AOptimum drug conditionSimple process conditionsFlotationEnergy consumptionMaterials science

The invention provides a method for conducting leaching and flotation on ores in the same leaching and flotation cells. The method is characterized in that the ores are leached and floated in the same leaching and flotation cells; and the leaching and flotation cells are divided into two or more sections according to the chemical mixing, roughing, scavenging and fine selecting functions required by the flotation procedure in the procedure, and each section is provided with at least one leaching and flotation cell. The method has the beneficial effects that leaching and flotation are performed in the same cells, so that the leaching process, the flotation process, a leaching system, a flotation system, a leaching agent, a floating agent and leaching liquid are coordinated, and the recovery rate index and the concentrate quality index are increased. The leaching process and the flotation process are better combined. The procedure of the method is shorter than the procedure in which the ores are leached firstly and then floated or floated firstly and then leached in the prior art, equipment investment is saved, energy consumption is low, used labor is small, and production cost is low.

Owner:罗光臣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com