Full-seam cutting, retreating, separate moving and full-caving comprehensive mechanized coal mining method and equipment

A technology that integrates mechanization and coal mining methods. It is applied in mining equipment, cutting machinery, ground mining, etc. It can solve the problems of complex top coal caving process, long shutdown and moving time, and low support strength, so as to improve the recovery of coal resources. efficiency, solve the problem of energy loss, and improve the effect of resource recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

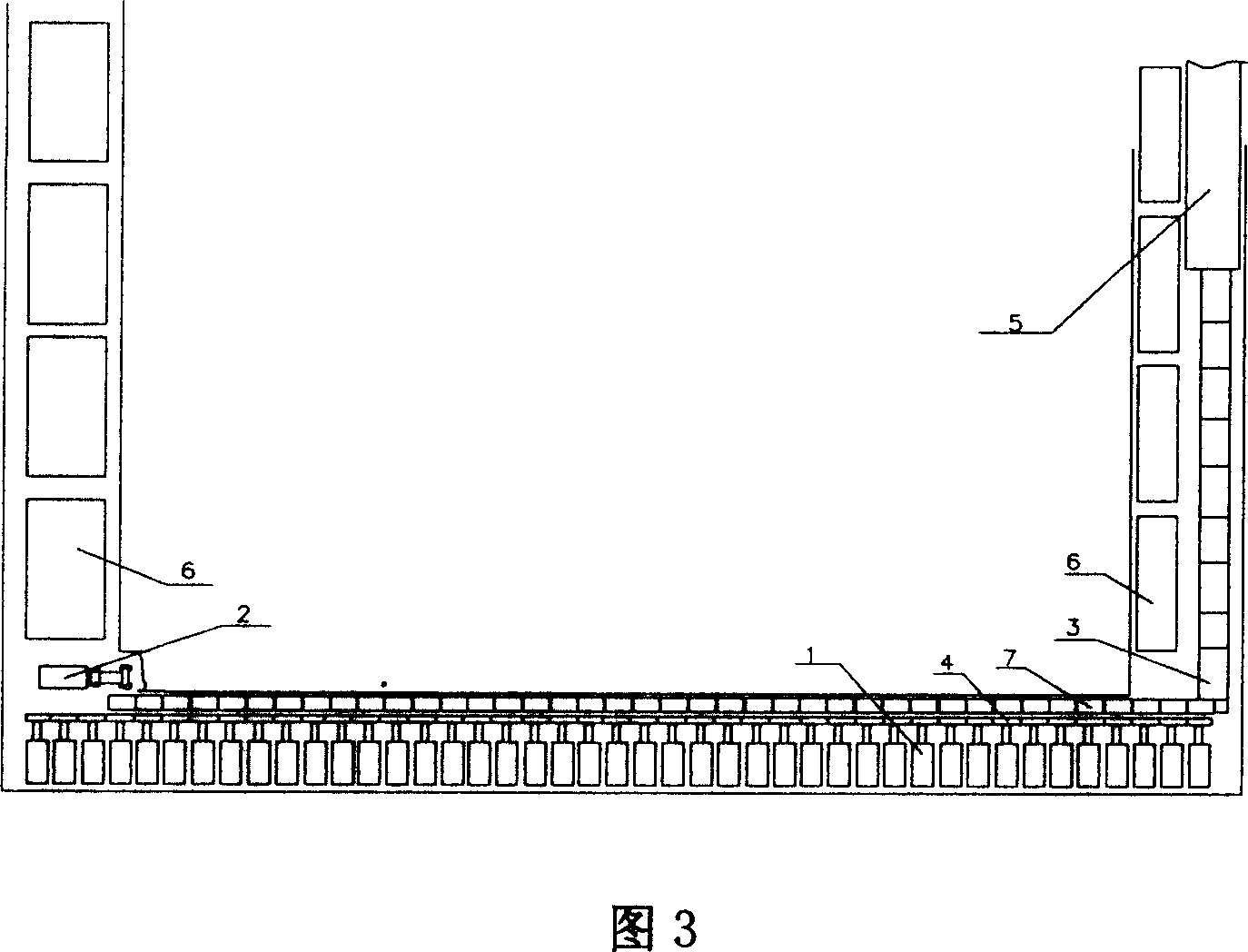

[0056] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0057] The present invention has a comprehensive mechanized coal mining method of one-time full height, retreat, split movement, and full-span fall, as shown in Figure 1. The wall-type working face adopts a double-lane layout, that is, an arrangement of one entry and one return, and one air intake lane is used as a belt for transportation. Alley, a return airway is used as an auxiliary transportation lane; the coal mining process includes support, coal cutting, coal loading, and coal discharge; among them:

[0058]●Wall-type working face: firstly arrange a wall-type working face, the inclination length of which is at least 10 meters and the longest can reach 350 meters;

[0059] ●Support: As shown in Figure 2, the air inlet lane and the air return lane are supported by anchor rods 8 and anchor cables 9. Install the hydraulic support 1 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com