Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Eliminate Calibration Errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calibration plate used for binocular camera calibration, calibration method and calibration system thereof

InactiveCN106887023AClear calibrationImprove calibration accuracyImage analysisImage resolutionDisplay device

The invention discloses a calibration plate used for binocular camera calibration and a binocular camera calibration method. In an existing camera calibration method technology, a high precision calibration reference object is difficult to make, cost is high, operation is complex and tedious, calibration precision is not high and so on. By using the calibration plate and the method, the above problems are solved. The calibration plate used for binocular camera calibration comprises an electronic equipment terminal machine and a display, wherein the electronic equipment terminal machine is used for receiving resolution information and outputting plane checkerboard image driving information according to a resolution; and the display is used for receiving the plane checkerboard image driving information and displaying a plane checkerboard image.

Owner:CHENGDU TOPPLUSVISION TECH CO LTD

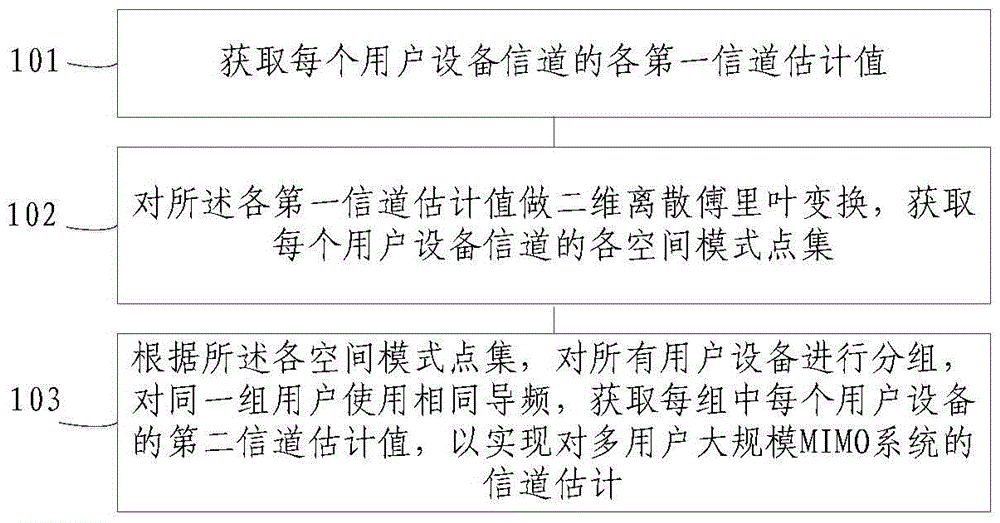

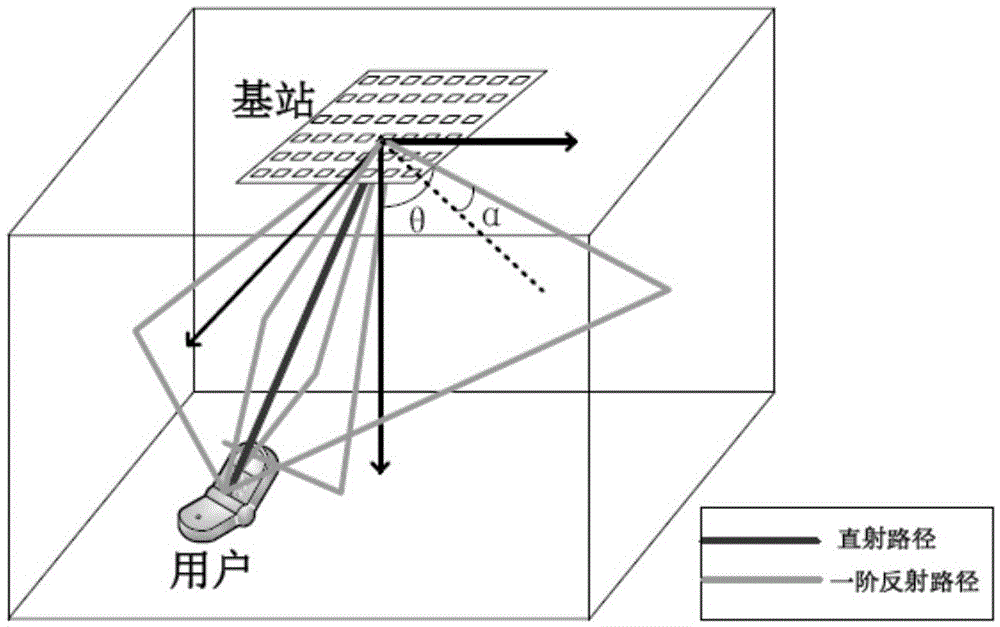

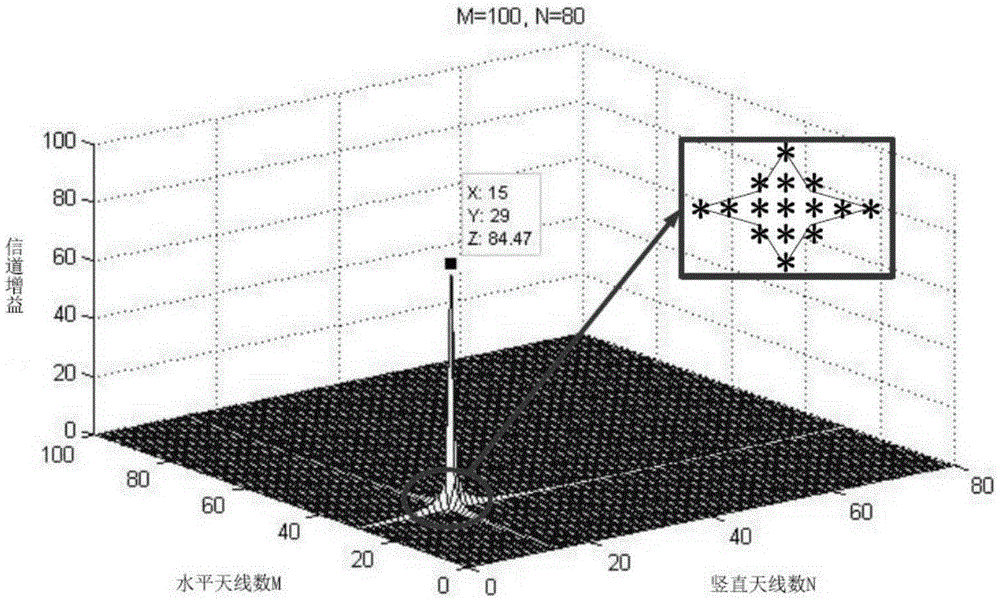

MIMO system channel estimation method and device in 60GHz indoor scene

ActiveCN105577587AReduce dimensionalityReduce pollutionChannel estimationComplex mathematical operationsEstimation methodsChannel parameter

The invention provides an MIMO system channel estimation method and device in a 60GHz indoor scene, and relates to the field of communications. The method comprises the following steps: obtaining a first channel estimation value of each user equipment; carrying out two-dimensional discrete Fourier transform on the first channel estimation value to obtain a spatial pattern point set; grouping all user equipment according to the spatial pattern point set, using the same pilot frequency on the same group of users, and obtaining a second channel estimation value of each user equipment in each group to realize the MIMO system channel estimation in the 60GHz indoor scene. According to the MIMO system channel estimation method in the 60GHz indoor scene provided by the invention, the discrete Fourier transform is used as a spatial basis expansion model of orthogonal basis to parameterize a user equipment channel, thereby reducing the dimensionality of an unknown channel parameter, reducing training and feedback costs and easing pilot frequency pollution.

Owner:TSINGHUA UNIV +1

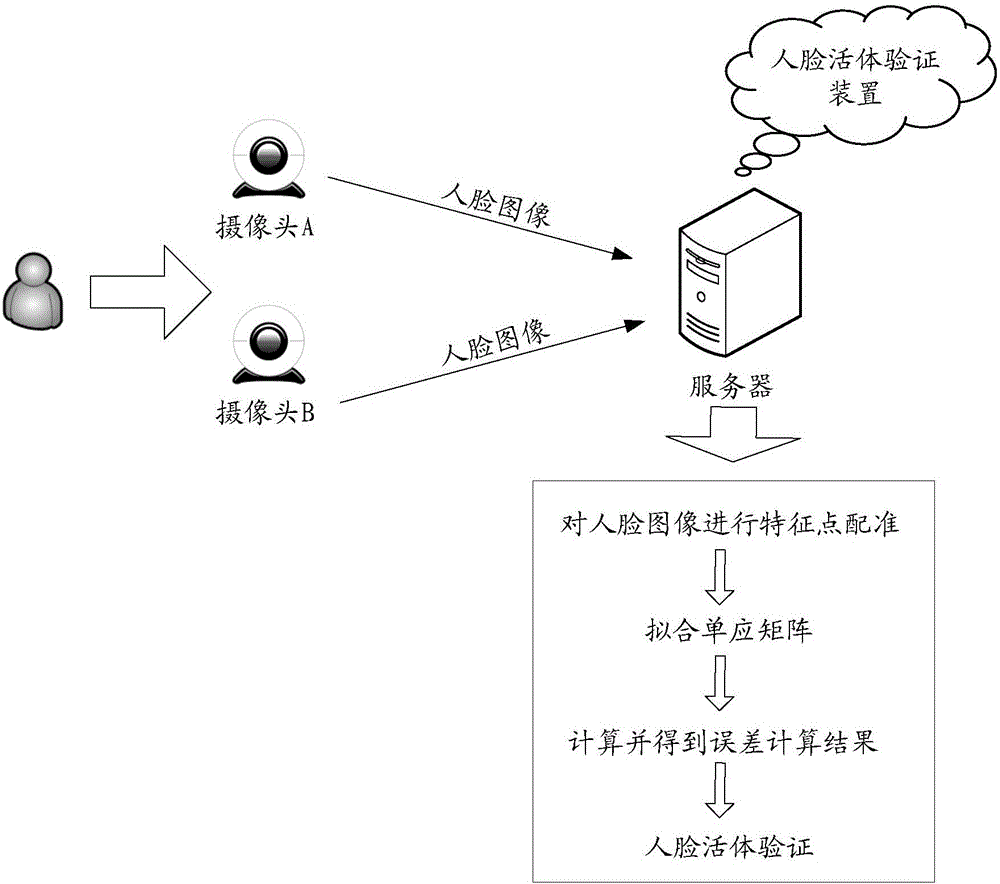

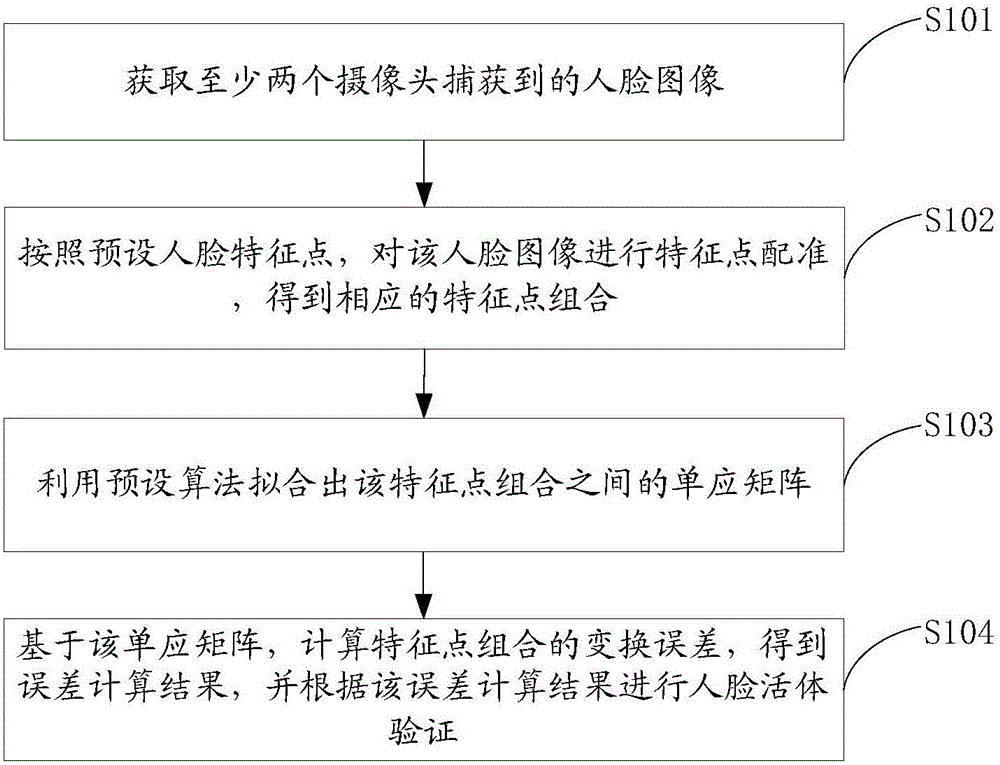

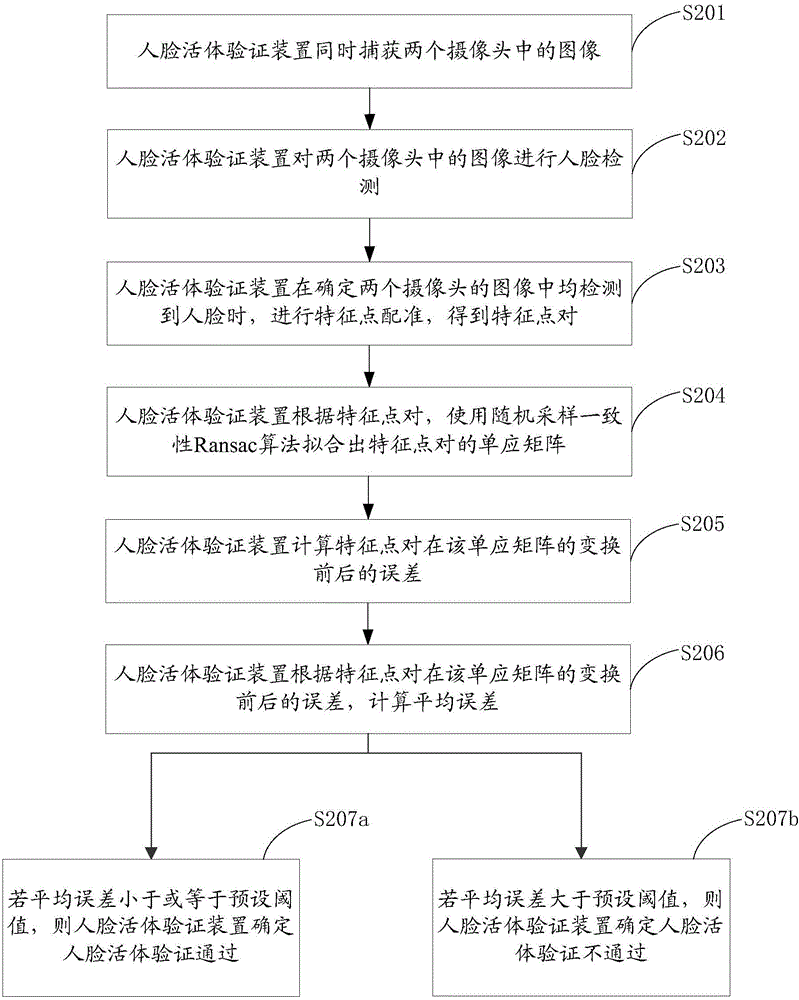

Face in-vivo validation method and device

InactiveCN105868733AFree placementIncrease flexibilityImage enhancementImage analysisPoint registrationValidation methods

The invention discloses a face in-vivo validation method and device. The method includes the steps that face images captured by at least two cameras are acquired; feature point registration is carried out on the face images according to preset face feature points, and corresponding feature point combinations are obtained; homography matrixes between the feature point combinations are fitted according to a preset algorithm; conversion errors of the feature points are calculated based on the homography matrixes, an error calculation result is obtained, and face in-vivo validation is carried out according to the error calculation result. According to the face in-vivo validation method and device, it is unnecessary to calibrate the cameras, calibration errors are eliminated, feature point matching is carried out directly on the captured face images, the homography matrixes are fitted, and thus the calculation amount of an in-vivo discrimination algorithm can be reduced; besides, the cameras can be freely placed, and thus the flexibility and convenience of in-vivo discrimination can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

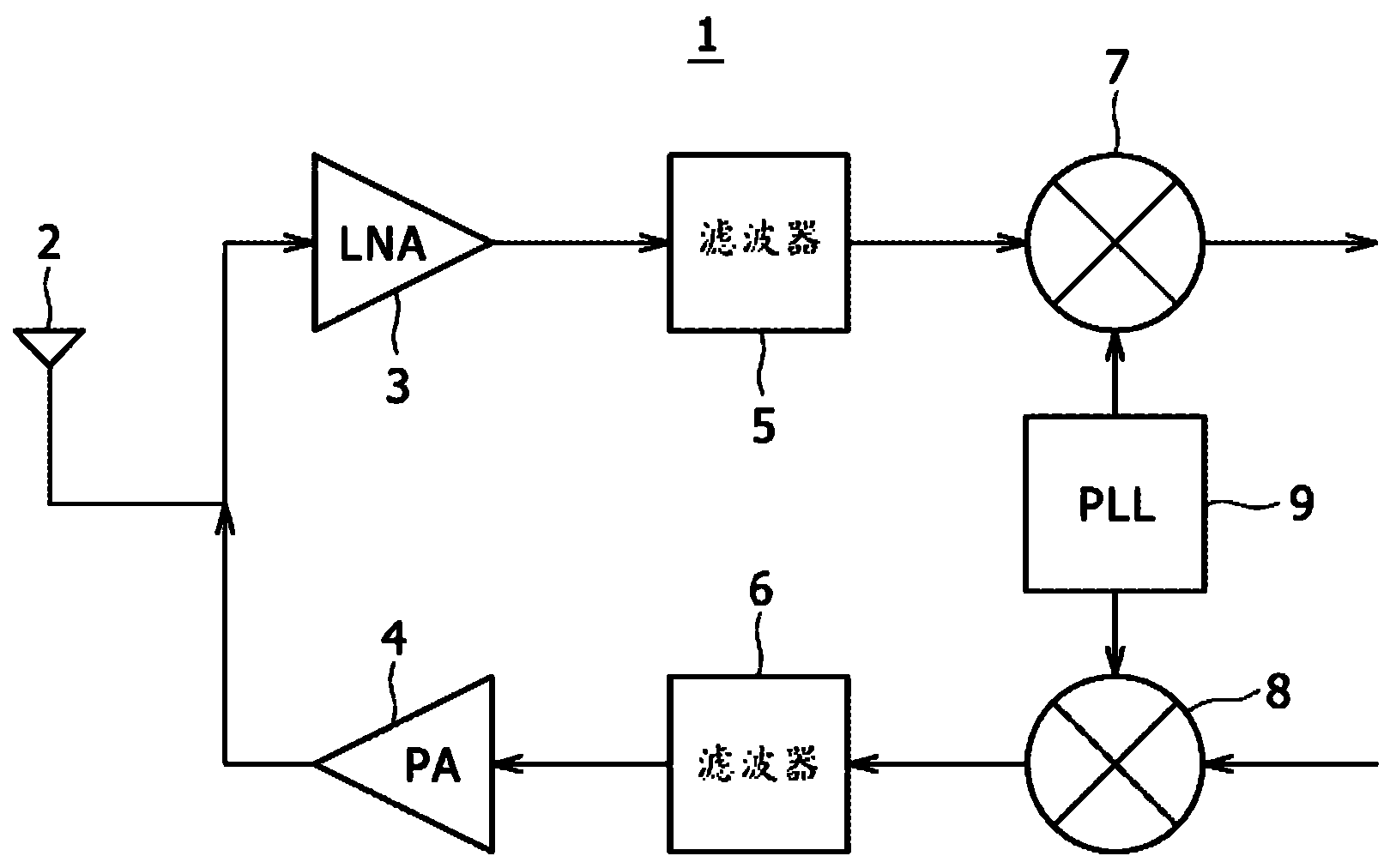

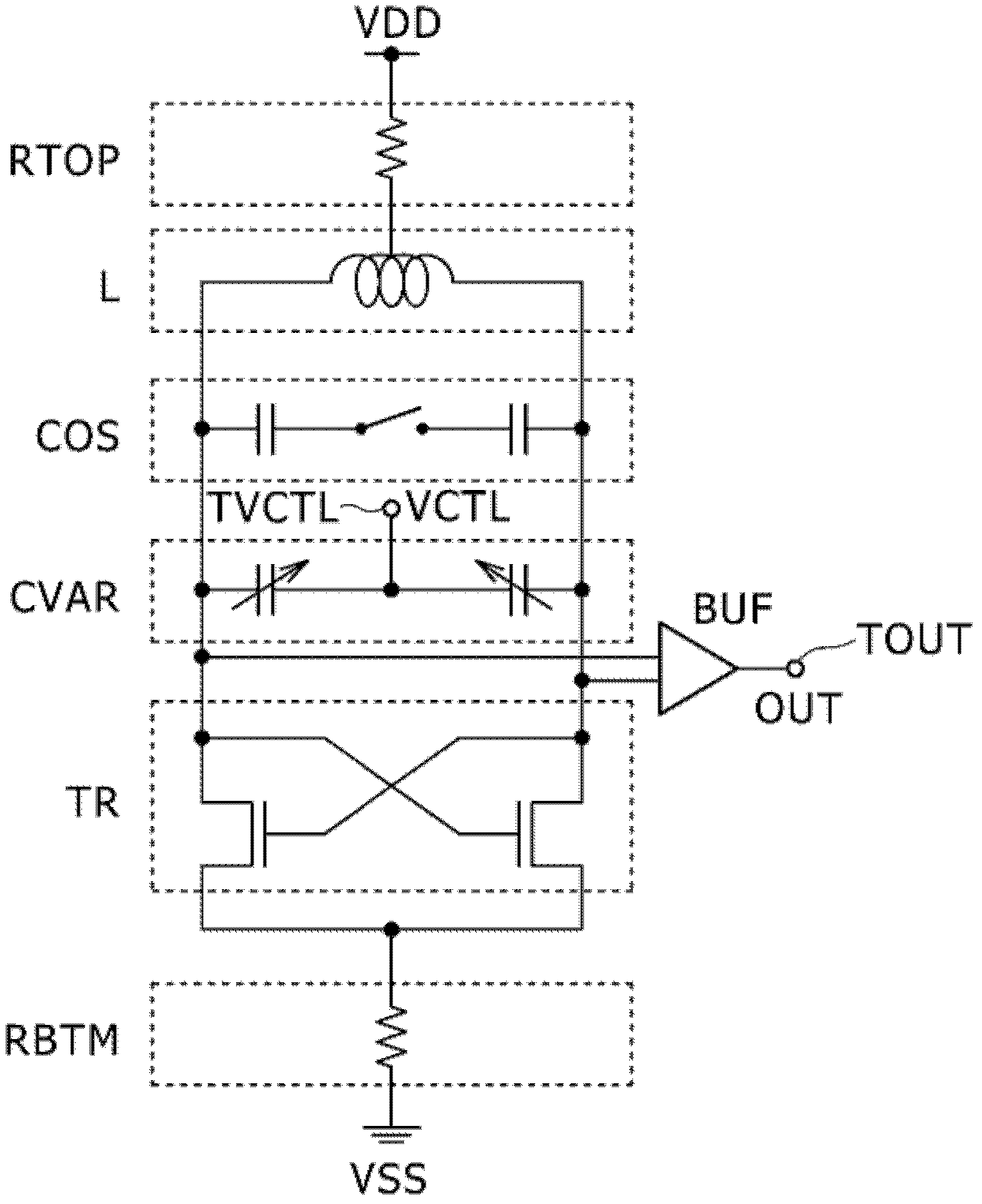

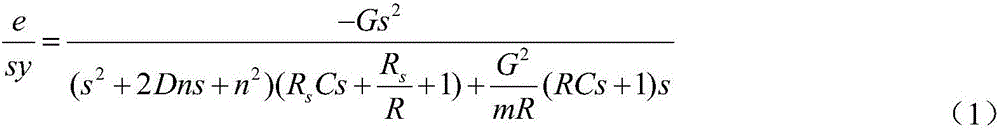

Phase-locked circuit and radio communicating device

InactiveCN102377430AEliminate Calibration ErrorsMitigate Phase Noise DesignResonant circuit tuningPulse automatic controlCapacitanceComparators circuits

Disclosed herein is a phase-locked circuit including: a phase-locked section including a voltage controlled oscillator having a capacitance bank and changing oscillation frequency according to voltage information, the phase-locked section phase-locking an oscillating signal of the voltage controlled oscillator to a reference signal; and a calibration section having a voltage correcting function for supplying an appropriate calibration voltage to the voltage controlled oscillator in performing frequency calibration for the voltage controlled oscillator; the calibration section including a counter circuit, a first storage circuit and a second storage circuit, a comparator circuit, a control circuit, a voltage generating circuit, and a processing circuit.

Owner:SONY CORP

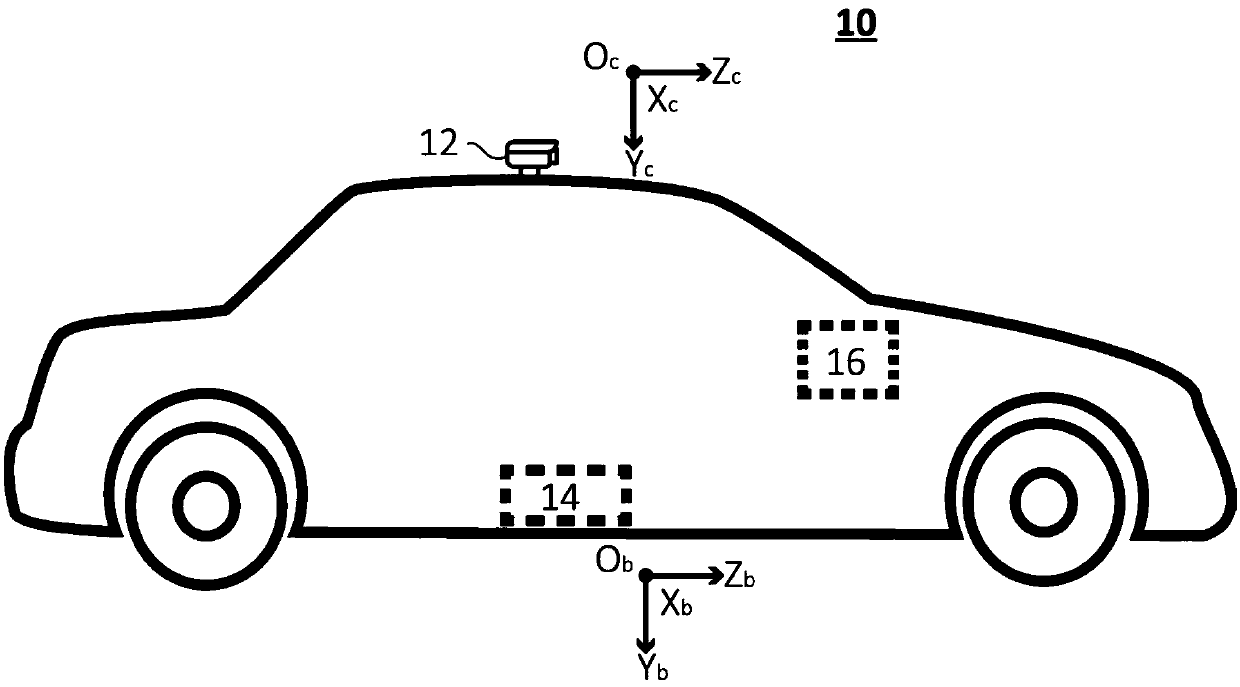

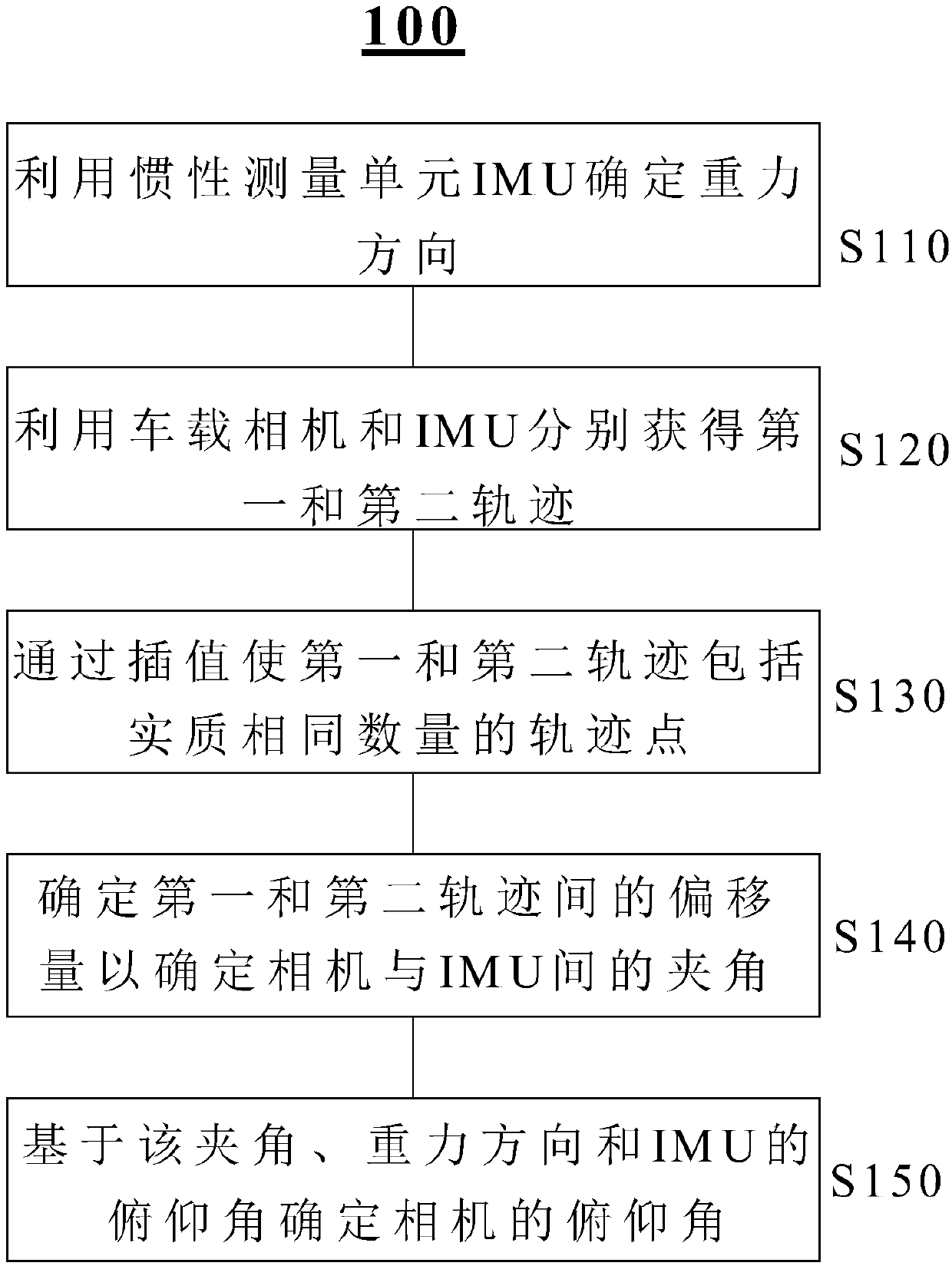

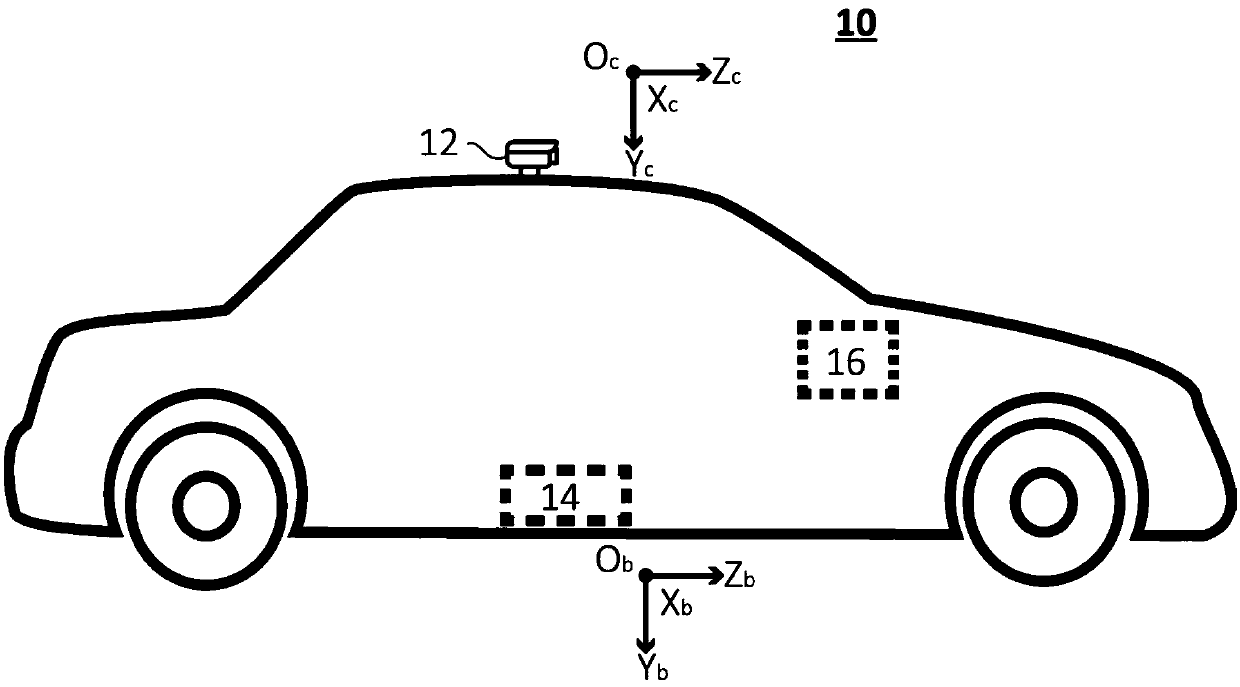

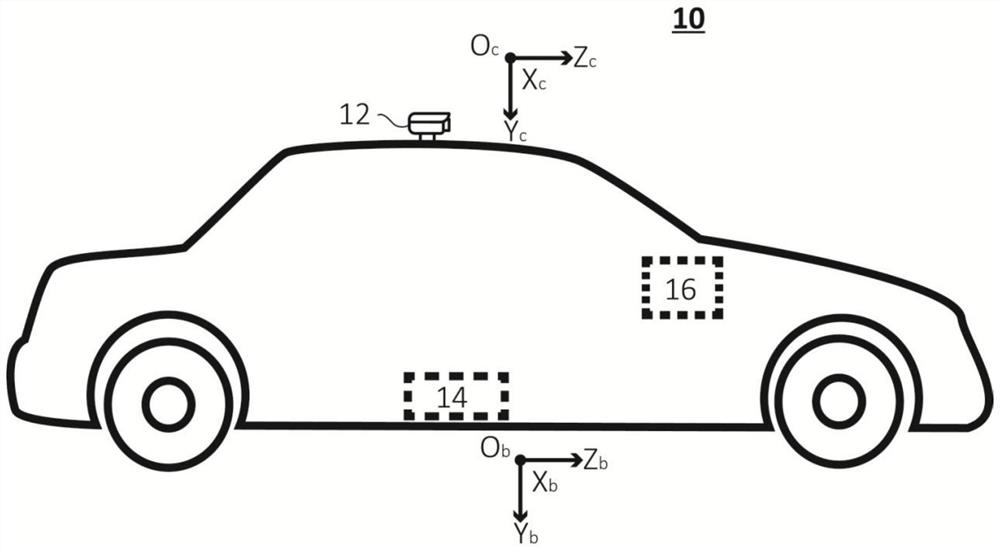

Calibration method and apparatus of pitch angle of vehicle-mounted camera, electronic device, and vehicle

ActiveCN108932737AAccurate CalibrationEliminate Calibration ErrorsImage enhancementImage analysisEngineeringElectric equipment

The application relates to a calibration method and apparatus of a pitch angle of a vehicle-mounted camera, an electronic device, and a vehicle. According to one embodiment, the calibration method comprises: an inertial measurement unit is used for determining a gravity direction; the inertial measurement unit tracks movement of a vehicle to obtain a first trajectory corresponding to a movement distance; a vehicle-mounted camera tracks the movement of the vehicle to obtain a second trajectory corresponding to the movement distance; an offset amount between the first trajectory and the second trajectory is determined and thus an included angle between the vehicle-mounted camera and the inertial measurement unit is determined; and on the basis of the gravity direction, the included angle between vehicle-mounted camera and the inertial measurement unit, and a pitch angle direction determined by the inertial measurement unit, a pitch angle of the vehicle-mounted camera is determined. According to the method provided by the application, with a full-automatic mode, real-time online calibration of the pitch angle of the vehicle-mounted camera is realized by combining the inertial measurement unit without any manual intervention, so that the calibration method and apparatus can be applied to the fields of automatic driving and the like widely.

Owner:SHENZHEN HORIZON ROBOTICS TECH CO LTD

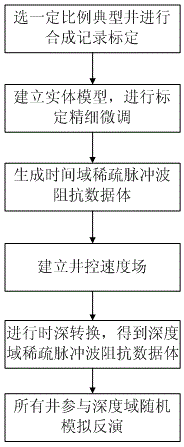

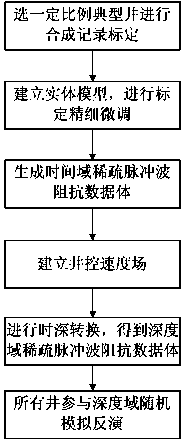

High-accuracy depth domain stochastic simulation inversion method suitable for designing track of horizontal well

ActiveCN102943669AReduce calibration errorEliminate Calibration ErrorsSurveyTime domainErrors and residuals

The invention relates to a high-accuracy depth domain stochastic simulation inversion method suitable for designing a track of a horizontal well, which comprises the following steps: firstly, selecting typical wells according to a certain proportion to carry out calibration of a synthetic record; establishing solid models for the typical wells and repeatedly carrying out calibration fine adjustment by stratigraphic correlation; generating a time domain sparse impulse wave impedance data volume and establishing a well control velocity field; carrying out time-to-depth conversion on the obtained time domain sparse impulse wave impedance data volume; and using depth domain sparse impulse wave impedance data as a restriction and ensuring all the wells to participate in the depth domain stochastic simulation inversion, so that an inversion result can be used for designing the track of the horizontal well. According to the invention, only the typical wells need to be subjected to calibration of the synthetic record; and by carrying out comparison and analysis on a logging curve and the high-accuracy solid models, carrying out fine adjustment and calibration, establishing the well control velocity field and directly utilizing absolute depth information of the wells to carry out depth domain stochastic simulation restrained inversion, a calibration error of a non-typical well is absolutely eliminated and the depth prediction accuracy of a target layer aiming at the track of the horizontal well is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

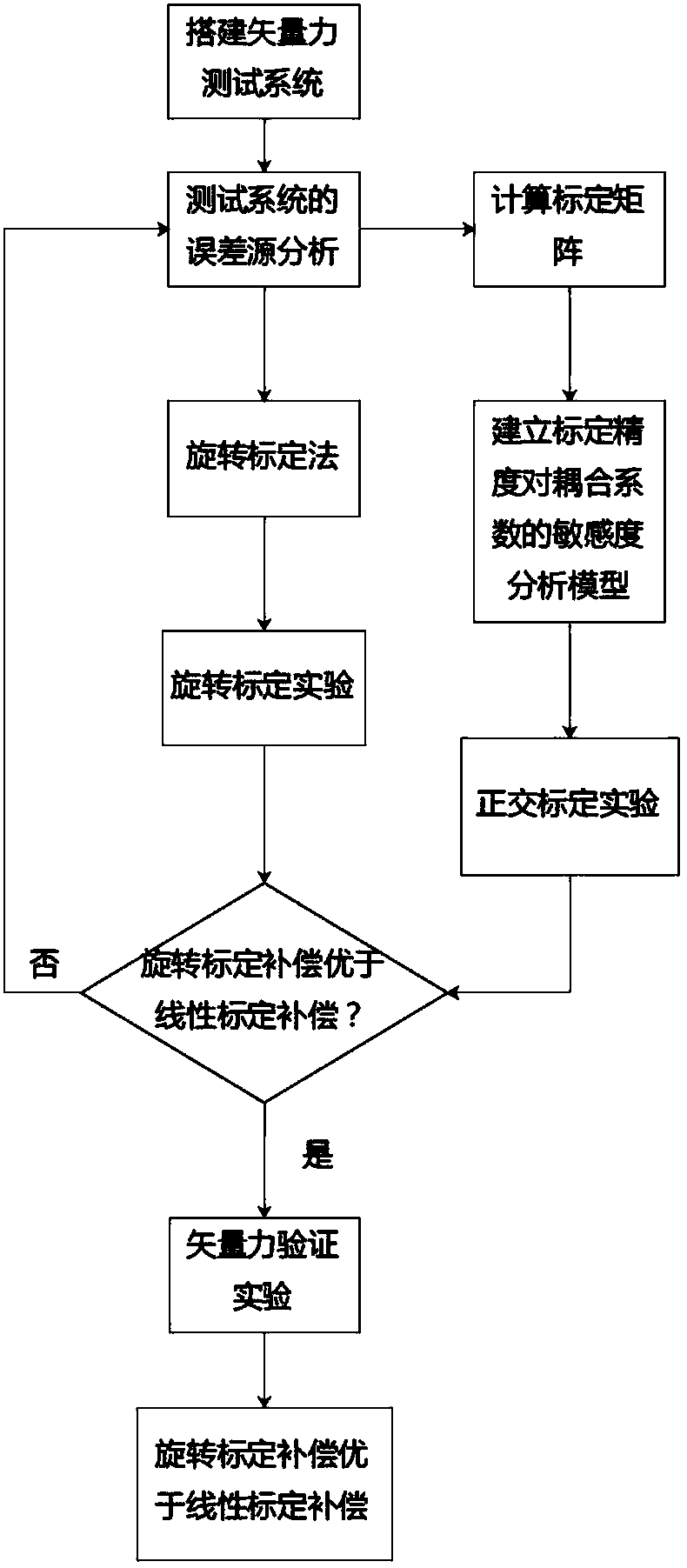

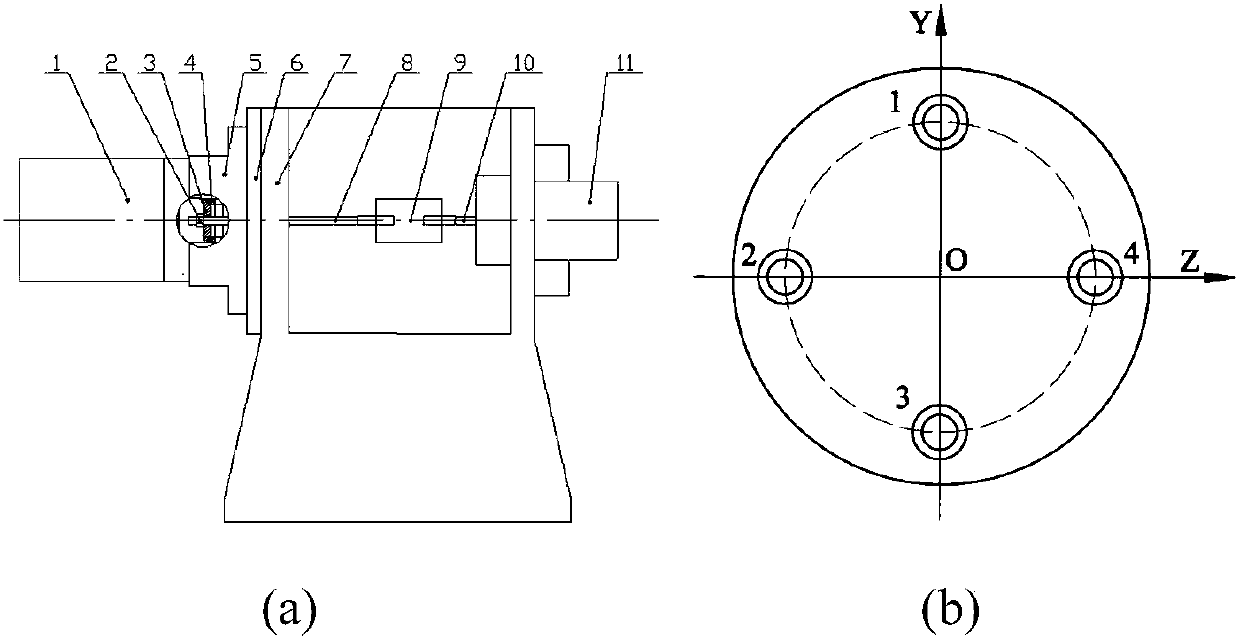

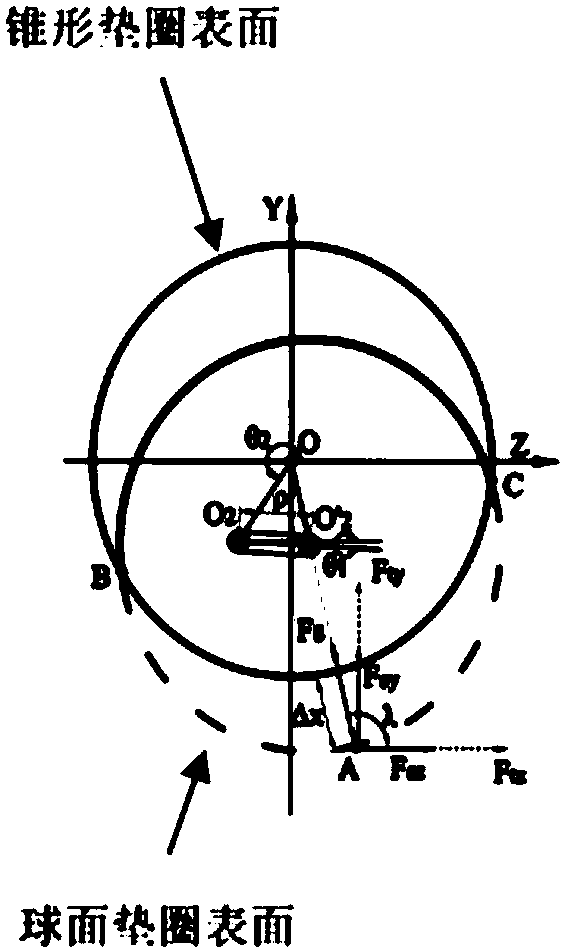

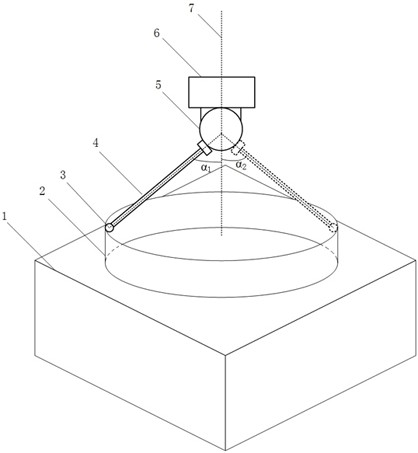

Rotary calibration method for rocket engine thrust vector calibration

ActiveCN107829843AReasonable handlingSatisfy compensatory requirementsRocket engine plantsStructural principleOffset calibration

The invention provides a rotary calibration method for rocket engine thrust vector calibration and belongs to the technical field of piezoelectric sensor measuring. According to the rotary calibrationmethod, on the basis of the structural principle of a measuring cell, a vector force testing system is set up firstly and subjected to error source analysis, a calibration matrix needing to be calculated is obtained through a linear calibration method, a sensitivity analysis model of the calibration accuracy to the coupling coefficient is set up, and it is concluded that the interference coefficient of the main direction to the side direction is the most important factor affecting the testing accuracy; then through a force vector offset calibration system, error analysis is conducted to search and obtain the mechanism of interference of the main direction on lateral force; a mathematical model of contact force of a calibration rod and a spherical gasket as well as the calibration rod anda tapered-face gasket is set up, and the oval geometric distribution of the lateral force in main direction calibration is obtained; and finally, aiming at the periodic characteristics of oval distribution, on the basis of the thought of error homogenization, according to the put-forward rotary calibration method, the rocket engine thrust vector is calibrated.

Owner:DALIAN UNIV OF TECH

Correcting apparatus enhancing volume measuring accuracy of small size bell jar and correcting method thereof

ActiveCN1948930AAvoid disadvantages that reduce calibration accuracyPromote inconsistencyTesting/calibration apparatusDraining tubeGraduated cylinder

The invention relates to calibrating device used to increase mini-size bell jar volumetric measurement accuracy. It includes impounding container, four exhaust valves, eight glass cock valves, globe, electric-magnetic stop valve, silicone tube, tubule needle head type drainpipe, small caliber weighing cylinder. The glass pipeline is the main structure of the whole device. The calibrating method includes the following steps: connecting the pipeline as the calibrating device; complementing water and exhausting gas; adjusting their flow quantity; elevating the ball jar; finishing the calibrating by n is not less than 6 times. The invention realize super mini-size bell jar metering volume (minimum volume reaches 10ml) high accuracy calibrating, increase flow measurement accuracy of the micro gas flow calibrating device used super mini-size bell jar as main standard.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH

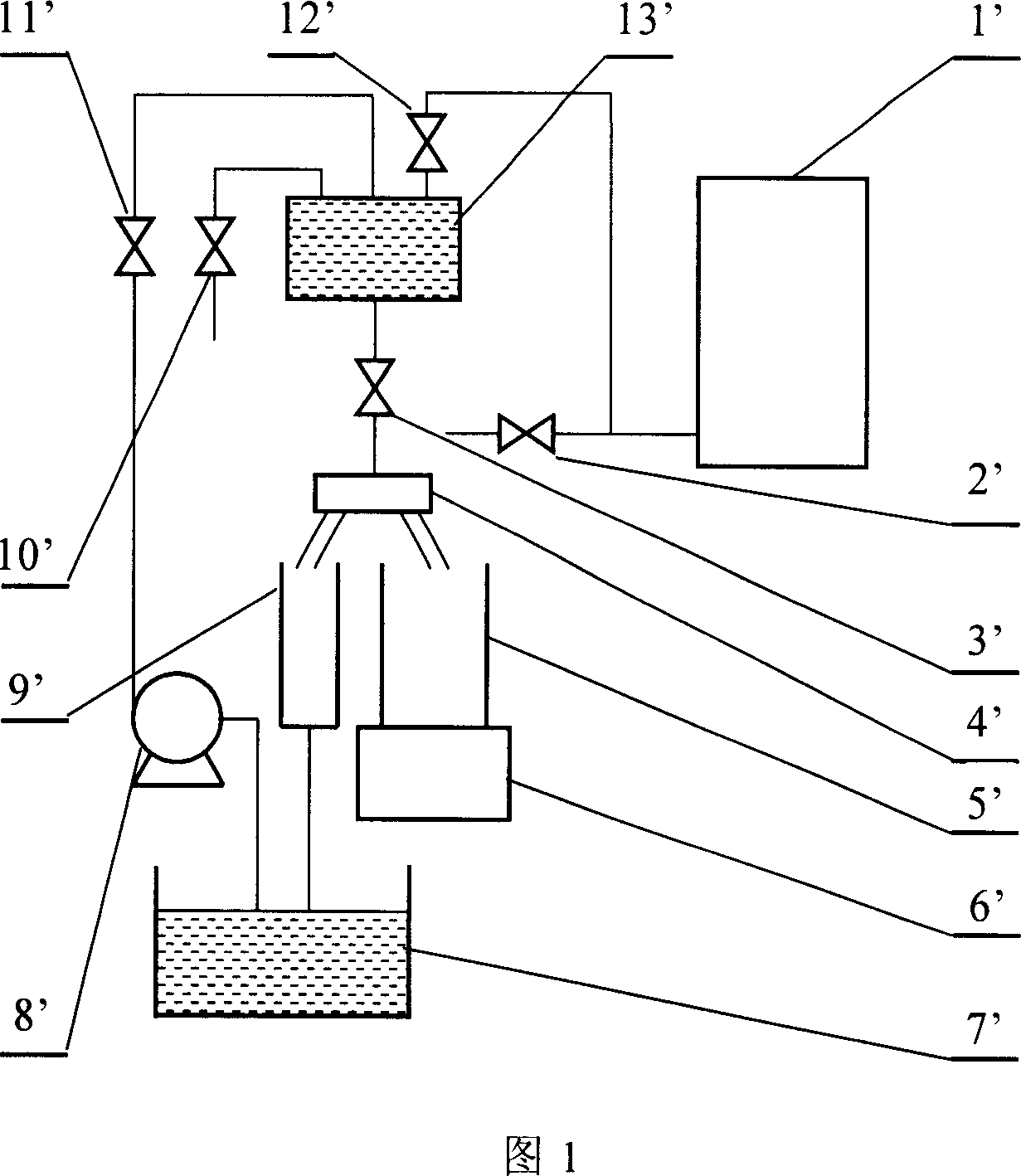

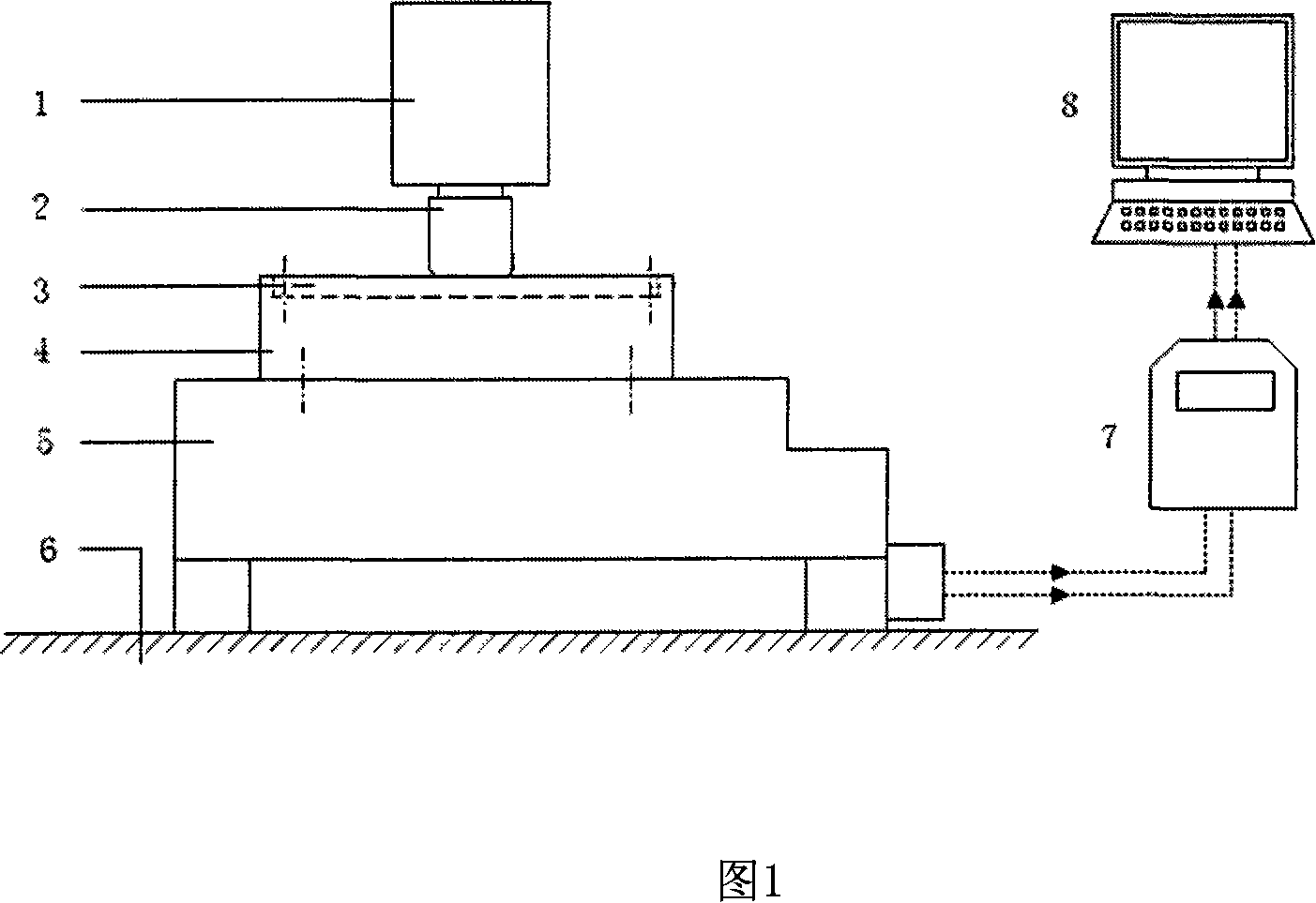

Dynamic friction coefficient measuring systems in material forming process

InactiveCN101135634AUniform relative motionEliminate Calibration ErrorsUsing mechanical meansMaterial analysisNumerical controlDynamometer

The system comprises: a shank of digital control machine tool, a friction head, a test piece fastening table, a three-phase dynamometer piezo-electrical sensor platform, a charge amplifier and a A / D collection computer. The friction head is located under the shank of digital control machine tool; the test piece fastening table is secured on the three-phase dynamometer piezo-electrical sensor platform; the three-phase dynamometer piezo-electrical sensor platform is secured on the working table of the digital control milling machine; the three-phase dynamometer piezo-electrical sensor platform is connected to the A / D collection computer via the charge amplifier.

Owner:SHANGHAI JIAO TONG UNIV

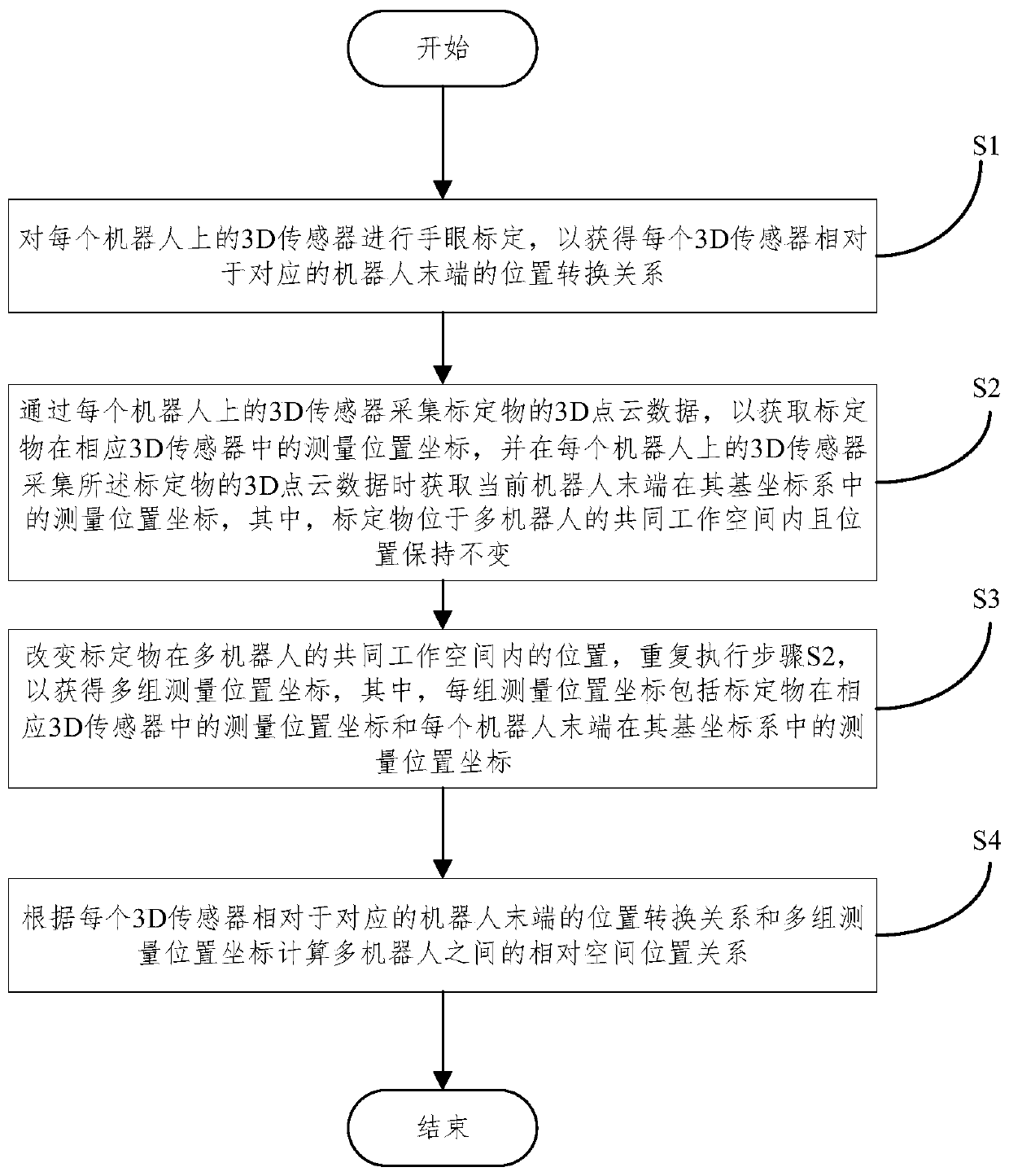

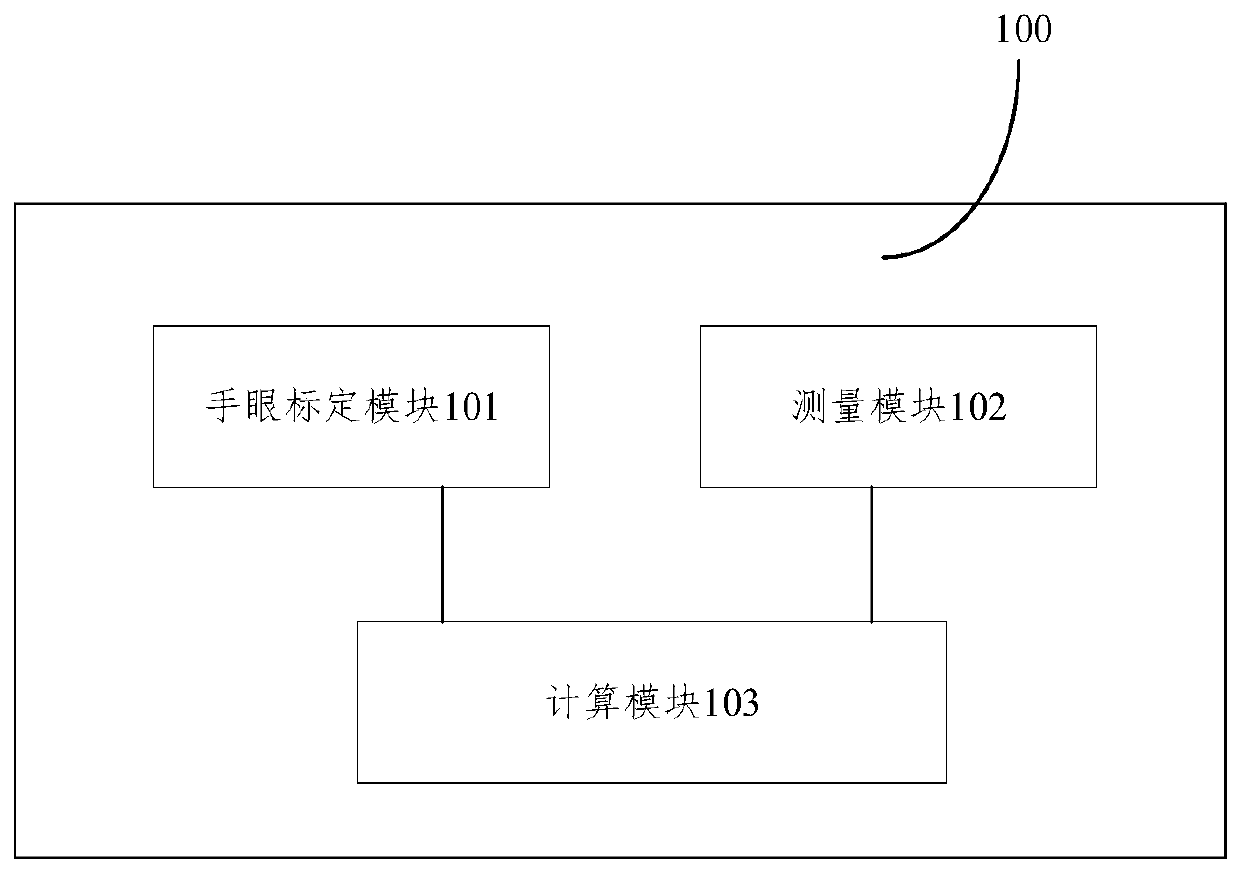

Calibration method and device for relative spatial position relation of multiple robots

PendingCN111452048AEliminate Calibration ErrorsLow costProgramme-controlled manipulatorTotal factory controlPhysicsEnvironmental geology

The invention relates to a calibration method and device for a relative spatial position relation of multiple robots. The calibration method comprises the steps that hand-eye calibration is conductedon 3D sensors on all the robots to obtain the position conversion relation of each 3D sensor relative to the tail end of the corresponding robot, 3D point cloud data of a calibration object placed ina common working space of the multiple robots are collected through the 3D sensors on all the robots to obtain measurement position coordinates of the calibration object in the corresponding 3D sensors, and meanwhile the measurement position coordinates of the tail end of the current robot in a base coordinate system of the robot are obtained when the 3D sensors on all the robots collect the 3D point cloud data of the calibration object. In the abovementioned way, by changing the position of the calibration object in the common working space of the multiple robots, multiple sets of measurementposition coordinates are obtained, the relative spatial position relation between the multiple robots is calculated according to the position conversion relation of each 3D sensor relative to the tail end of the corresponding robot and the multiple sets of measurement position coordinates, and accurate calibration of the spatial position relation of the multiple robots is achieved.

Owner:ASIMCO INT CASTING CO LTD SHANXI

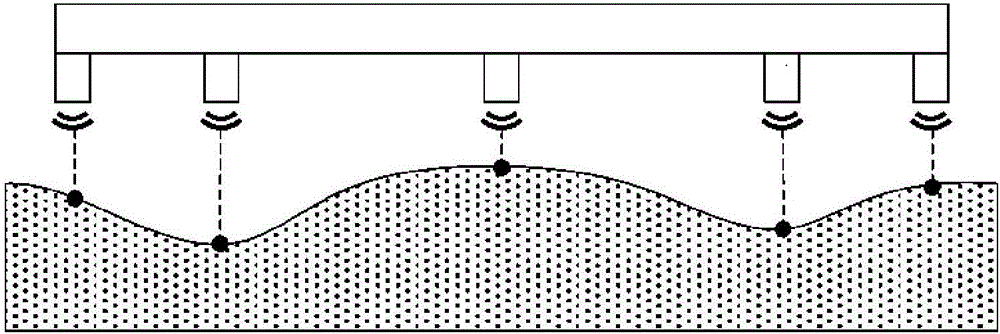

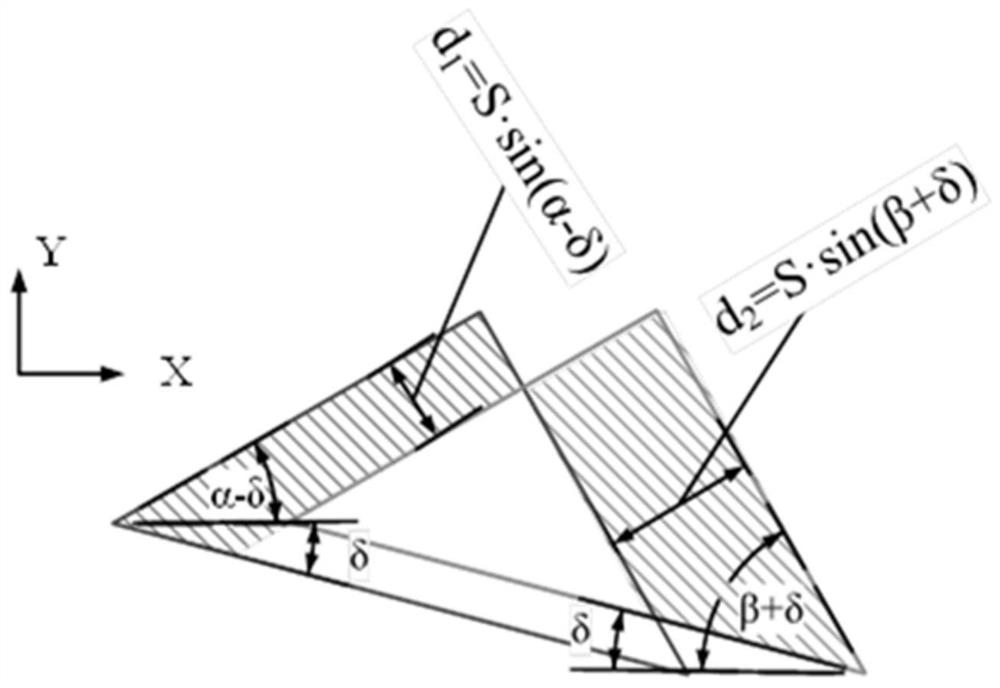

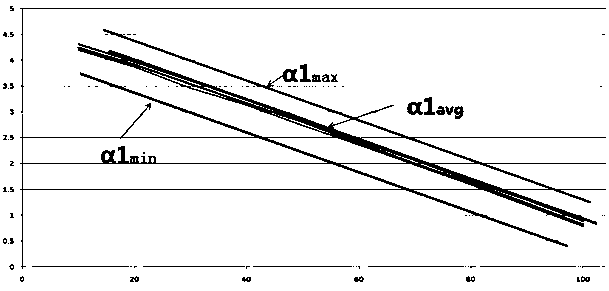

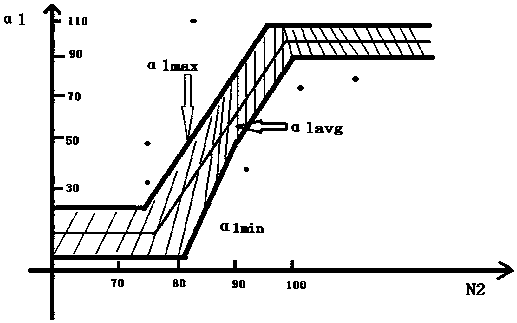

Calibration method method for multi-point co-beam rut detection device and cross-section determination

ActiveCN106758714AEliminate Calibration ErrorsHigh precisionRoads maintainenceRoad surfaceLaser light

The invention discloses a calibration method of a multi-point co-beam rut detection device and a cross-section determination method. The calibration method comprises that the installation angle ai and horizontal coordinate ai of each laser among m lasers on a rut beam are determined, wherein the horizontal coordinate ai is a horizontal coordinate value, relative to a reference laser, of the ith laser, the reference laser is the laser located at the middle position of the rut beam, the i=1-m; the reading Hi irradiating on a calibration scale or a road of the laser light of each laser is collected; among the m lasers, the n lasers installed vertically are chosen, and the horizontal dip angle beta0 is determined by the reading Hi and the horizontal coordinate ai of the n lasers; the vertical position parameter Bi of the laser i is calibrated by using the horizontal dip angle beta0, i=1-m. The method provided by the invention has the advantage that the measurement accuracy of the cross-section can be effectively improved.

Owner:ROADMAINT CO LTD

Clamp special for machining pump body of marine water-jet propulsion pump

ActiveCN105033698AReduce manufacturing costSolve the problem of concentricity of two holesPositioning apparatusMetal-working holdersLongest DiameterDiagonal

The invention discloses a clamp special for machining a pump body of a marine water-jet propulsion pump. The clamp comprises a clamp body. The clamp body is a quadrilateral plate body. A round locating pin and an annular round groove are sequentially arranged on the clamp body from the center to the outside. A diamond locating pin with the long diameter being parallel to the tangent line of the annular round groove is arranged at the position, close to the annular round groove, of the lower left corner of the clamp body. A U-shaped hinge pedestal parallel to the right end face of the clamp body is arranged at the position, away from the annular round groove, of the upper right corner on the same diagonal line with the lower left corner of the clamp body. A turnover plate which is composed of a long plate and a short plate and has an inverted-L-shaped section is arranged in a groove of the hinge pedestal and connected with the groove in a hinged mode through a pin shaft. A threaded hole is formed in the long plate of the turnover plate, and a locating screw is mounted in the threaded hole. Pressing plates are arranged on the clamp body and are in bilateral symmetry. The clamp special for machining the pump body of the marine water-jet propulsion pump is simple in structure, high in locating precision, low in manufacturing cost, capable of rapidly clamping workpieces and convenient to operate, and greatly improves the work efficiency.

Owner:镇江四洋柴油机制造有限公司

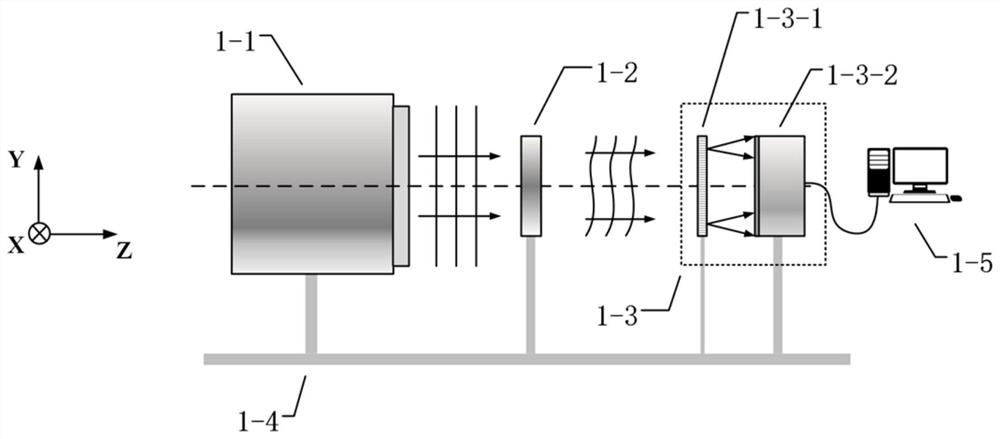

Shearing amount calibration device and method for transverse shearing interference wavefront sensor

PendingCN112013972AAvoid systematic errorsReduce complexityOptical measurementsWavefront sensorLateral shear

The invention relates to a shearing amount calibration device and method for a transverse shearing interference wavefront sensor. The calibration device comprises a collimated light source, a polygonal phase step calibration plate with a known base angle number, and a transverse shearing interference wavefront sensor to be calibrated. According to the calibration method, differential wavefront information in the shearing direction is extracted from an interference pattern acquired by a sensor to be calibrated by using a differential wavefront extraction algorithm, and the shearing amount is calculated in combination with geometrical characteristic distribution of differential wavefront, so that the calibration of the shearing amount of the wavefront sensor is realized.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Device and method for calibrating humidity switch

ActiveCN105786039AReduce labor intensityEliminate Calibration ErrorsHumidity controlControl theoryDirect current

The invention discloses a device and a method for calibrating a humidity switch. The device comprises a standard humidity sensor, a humidification part, a dehumidification part, a direct-current motor, a gearbox, a mechanical arm and a controller. When the controller detects the connection switching between the humidification part and the dehumidification part of a to-be-calibrated humidity switch, the controller acquires the current humidity value transmitted from the standard humidity sensor. After that, the direction and the angle of the rotation speed of the direct-current motor are controlled based on the positive and negative difference between the current humidity value and a preset humidity value, and the difference value between the current humidity value and the preset humidity value. Furthermore, the knob of the humidity switch can be adjusted by means of the mechanical arm. The device for calibrating the humidity switch adopts the centralized design, and all parts of the device are controlled by the controller in the unified manner. Compared with the manual calibration manner, based on the automatically acquired humidity operating value of the to-be-calibrated humidity switch, namely the value relationship between the current humidity value transmitted from the standard humidity sensor and the preset humidity value, the to-be-calibrated humidity switch is calibrated. The entire calibration process is automatically conducted.

Owner:FUJIAN NINGDE NUCLEAR POWER

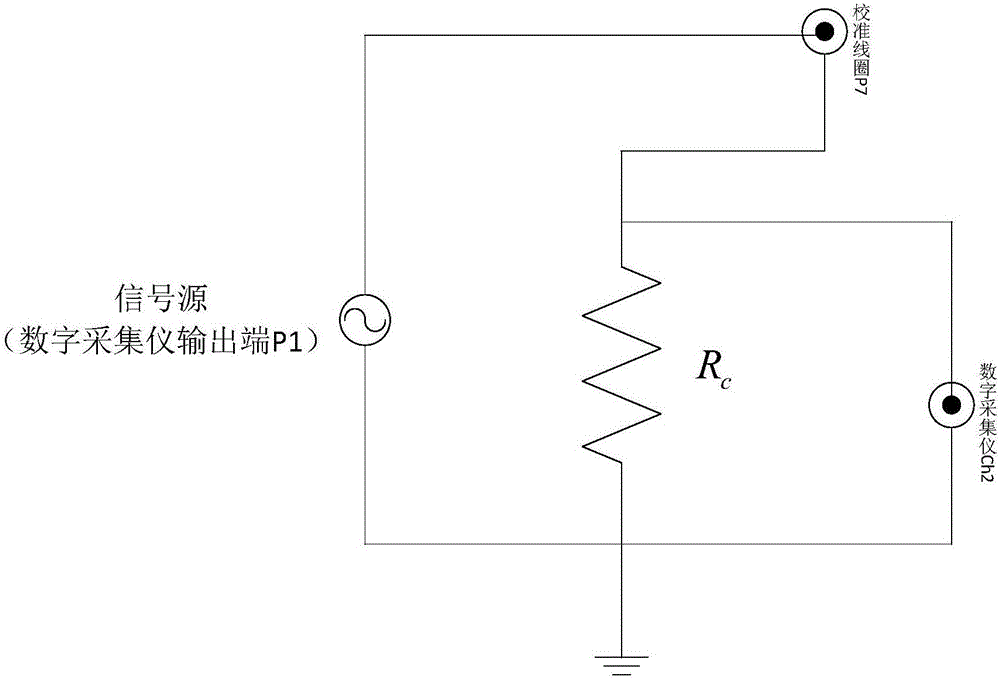

Field calibration system for magnetoelectric sensor

ActiveCN106768282ASimple structureEasy to carrySubsonic/sonic/ultrasonic wave measurementUsing electrical meansExcitation signalSignal processing

The invention provides a field calibration system for a magnetoelectric sensor. The field calibration system for the magnetoelectric sensor comprises a digital acquisition device, a calibration circuit and a signal processing device; the digital acquisition device is provided with a voltage signal output end, a first signal input end and a second signal input end; the calibration circuit is provided with an excitation signal output end and a calibration signal output end; a voltage signal output end of the digital acquisition device is used for being connected with the excitation signal output end of the calibration circuit; the excitation signal output end of the calibration circuit is used for being connected with a magnetoelectric sensor to be calibrated; the calibration signal output end of the calibration circuit is connected with a first signal input end of the digital acquisition device; a second signal input end of the digital acquisition device is used for being connected with the magnetoelectric sensor to be calibrated and receiving vibration signals of the magnetoelectric sensor; the signal processing device is connected with the digital acquisition device, and is used for receiving two paths of signals from the digital acquisition device.

Owner:匙庆磊

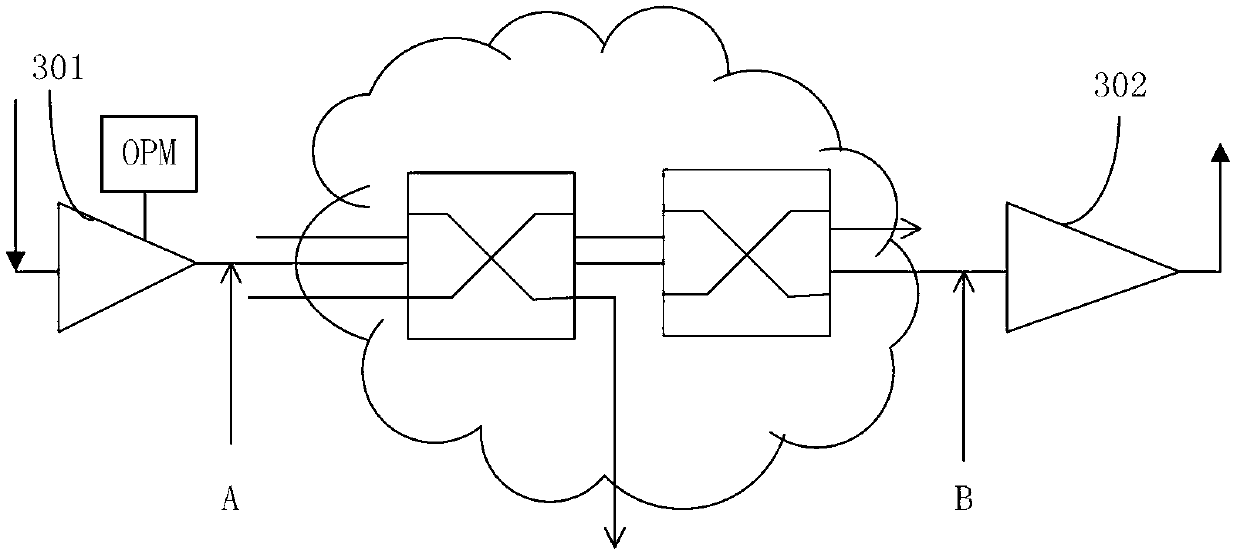

Online calibration configurable site wavelength dependent attenuation method, a device and a system

InactiveCN103004109AStrong adaptability to the sceneReliable input parametersElectromagnetic transmissionUltrasound attenuationExpansion phase

The invention is applicable to the communication field and provides on-line calibration configurable site wavelength dependent attenuation method, a device and an optical communication system. The method comprises the following steps : obtaining the transmitting end of the optical amplifier to be calibrated single wave emitted light power; the configurable site wavelength through configuration, the calibration of the wavelength of the light penetrating configurable site arrive at the receiving end of an optical amplifier, and detecting the arrive at the receiving end of the optical amplifier optical incident optical power; according to the calibration of the single wave emitted light power to arrive at the receiving end of the optical amplifier optical incident optical power, obtain calibration of wavelength dependent attenuation. In the method, the network starting stage and the expansion phase can be real-time obtaining and updating wdl, so as to timely update the network state, ensuring the quality of the communication quality.. In addition, the invention can completely based on the prior the network the environment to realize the wavelength dependent attenuation on-line calibration, does not need to add any hardware, effectively controlling the cost increase.

Owner:陆中尧

Calibration method and cross-section determination method of multi-point common beam rutting detection device

ActiveCN106758714BEliminate Calibration ErrorsHigh precisionRoads maintainenceRoad surfaceLaser light

The invention discloses a calibration method of a multi-point co-beam rut detection device and a cross-section determination method. The calibration method comprises that the installation angle ai and horizontal coordinate ai of each laser among m lasers on a rut beam are determined, wherein the horizontal coordinate ai is a horizontal coordinate value, relative to a reference laser, of the ith laser, the reference laser is the laser located at the middle position of the rut beam, the i=1-m; the reading Hi irradiating on a calibration scale or a road of the laser light of each laser is collected; among the m lasers, the n lasers installed vertically are chosen, and the horizontal dip angle beta0 is determined by the reading Hi and the horizontal coordinate ai of the n lasers; the vertical position parameter Bi of the laser i is calibrated by using the horizontal dip angle beta0, i=1-m. The method provided by the invention has the advantage that the measurement accuracy of the cross-section can be effectively improved.

Owner:ROADMAINT CO LTD

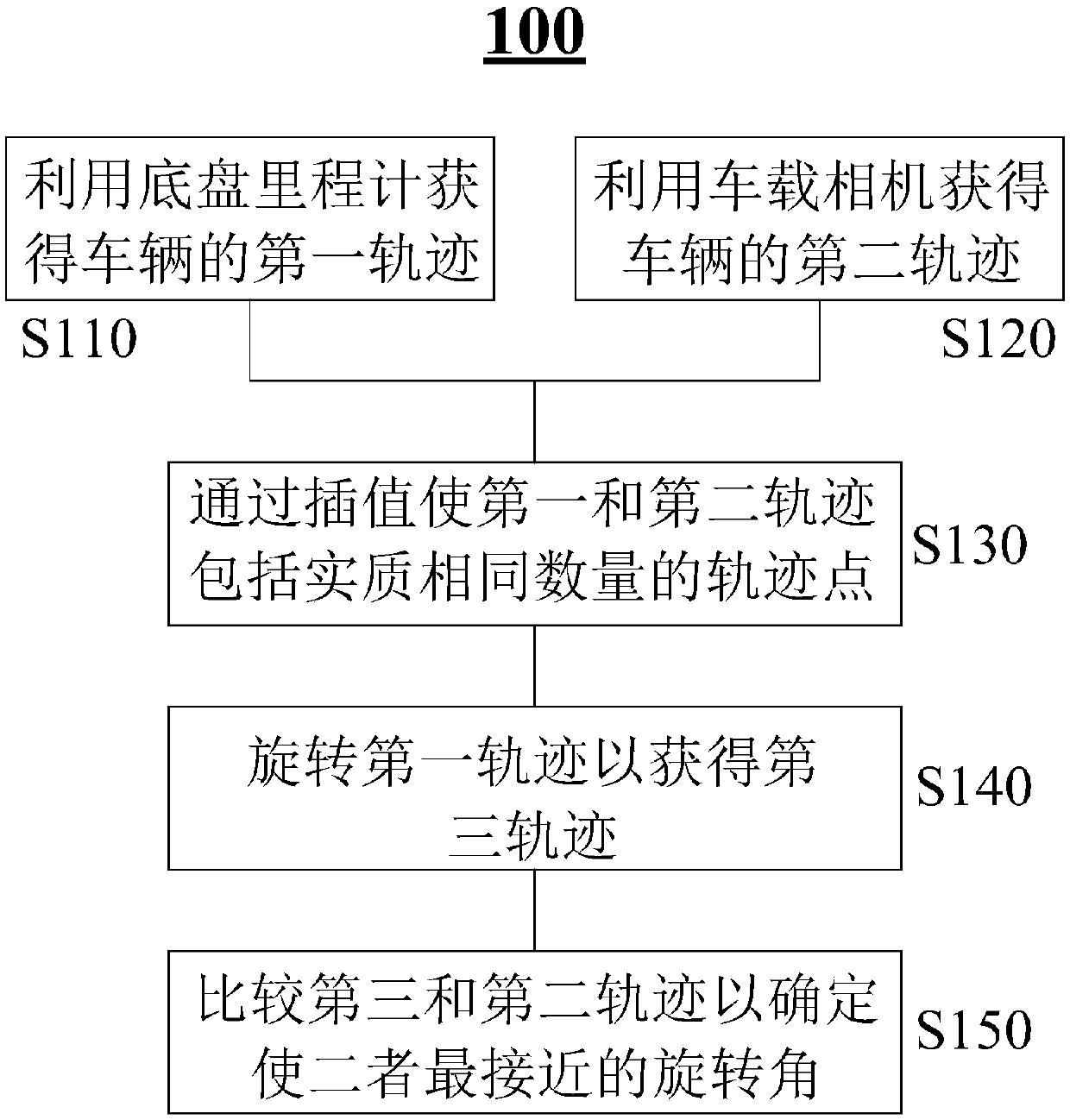

Method and device for calibrating heading angle of vehicle-mounted camera, electronic equipment and vehicle

ActiveCN108961337AEasy CalibrationAccurate CalibrationImage enhancementImage analysisComputer visionElectric equipment

The invention discloses a method and device for calibrating the heading angle of a vehicle-mounted camera, electronic equipment and a vehicle. According to one embodiment, the method for calibrating the heading angle of the vehicle-mounted camera comprises the steps of tracking the movement of the vehicle by using a chassis odometer to obtain a first trajectory corresponding to a moving distance;tracking the movement of the vehicle by using the vehicle-mounted camera to obtain a second trajectory corresponding to the moving distance; enabling the first trajectory to rotate by a heading angleto obtain a third trajectory; and comparing the third trajectory and the second trajectory to determine the heading angle which enables the third trajectory to be the closest to the second trajectory,and enabling the heading angle to serve as a heading angle of the vehicle-mounted camera. The method disclosed by the invention can perform real-time on-line calibration on the heading angle of the camera based on a visual odometer and the chassis odometer in a full-automatic mode without manual participation, so that the method can be widely applied to the fields such as automatic driving and the like.

Owner:SHENZHEN HORIZON ROBOTICS TECH CO LTD

Method for quickly calibrating zero position of straightener

ActiveCN112108537ASimple processThe basic size is accurateMetal working apparatusControl engineeringControl theory

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

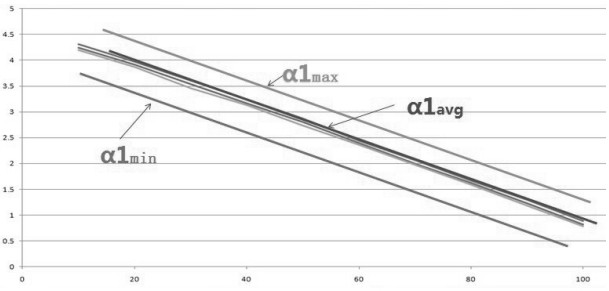

New method for aircraft engine calibration

InactiveCN111219213AReduce labor costsImprove work efficiencyGas turbine plantsSafety/regulatory devicesConvertersAirplane

The invention discloses a new method for aircraft engine calibration. The new method is characterized in that a working space of an engine parameter calibrated historically is counted, a center curveof the working space is fitted so as to serve as a standard model value curve of the same type of aircraft, and an engine parameter ground detection device is adopted to directly write the standard model value curve into an engine parameter converter. According to the new method, the engine parameter ground detection device writes the standard model value curve directly into the engine parameter converter, a traditional engine parameter calibration method is replaced, the human cost is saved, the working efficiency is improved, and the high practicability is achieved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

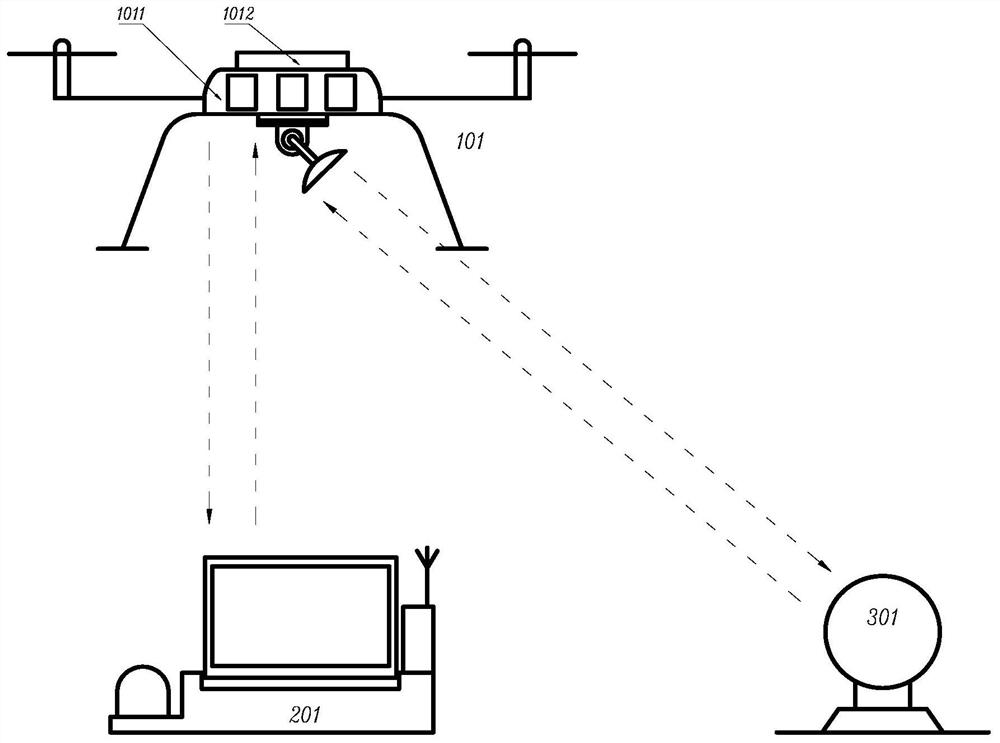

A method and system for calibrating weather radar based on UAV

ActiveCN111537965BImprove accuracyEasy to operateWave based measurement systemsRemote controlled aircraftWeather radarUncrewed vehicle

The embodiment of the present invention provides a method and system for calibrating weather radar based on UAV, which is characterized in that the method includes controlling a UAV equipped with an on-board calibration device to fly to a predetermined location by wireless communication through a ground console. Spatial position: controlling the airborne calibration device to calibrate the weather radar at the predetermined spatial position by wireless communication through the ground console. This method can solve the problems of high installation cost and inability to work under special terrain conditions in the existing signal source method, and at the same time solve the problem of inaccurate calibration results in the existing metal ball calibration method.

Owner:CMA METEOROLOGICAL OBSERVATION CENT

A New Method of Aircraft Engine Calibration

ActiveCN110646212BReduce labor costsImprove work efficiencyGas-turbine engine testingJet-propulsion engine testingAirplaneReal-time computing

The invention discloses a new method for aircraft engine calibration, which calculates the working range of historically calibrated engine parameters, fits the central curve of the working range, and uses the engine parameter ground detection equipment to directly write the curve as the standard model value curve of the same type of aircraft. into the engine parameter converter. The invention directly writes the standard model value curve into the engine parameter converter through the engine parameter ground detection equipment, replaces the traditional engine parameter calibration method, saves labor costs, improves work efficiency, and has better practicability.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

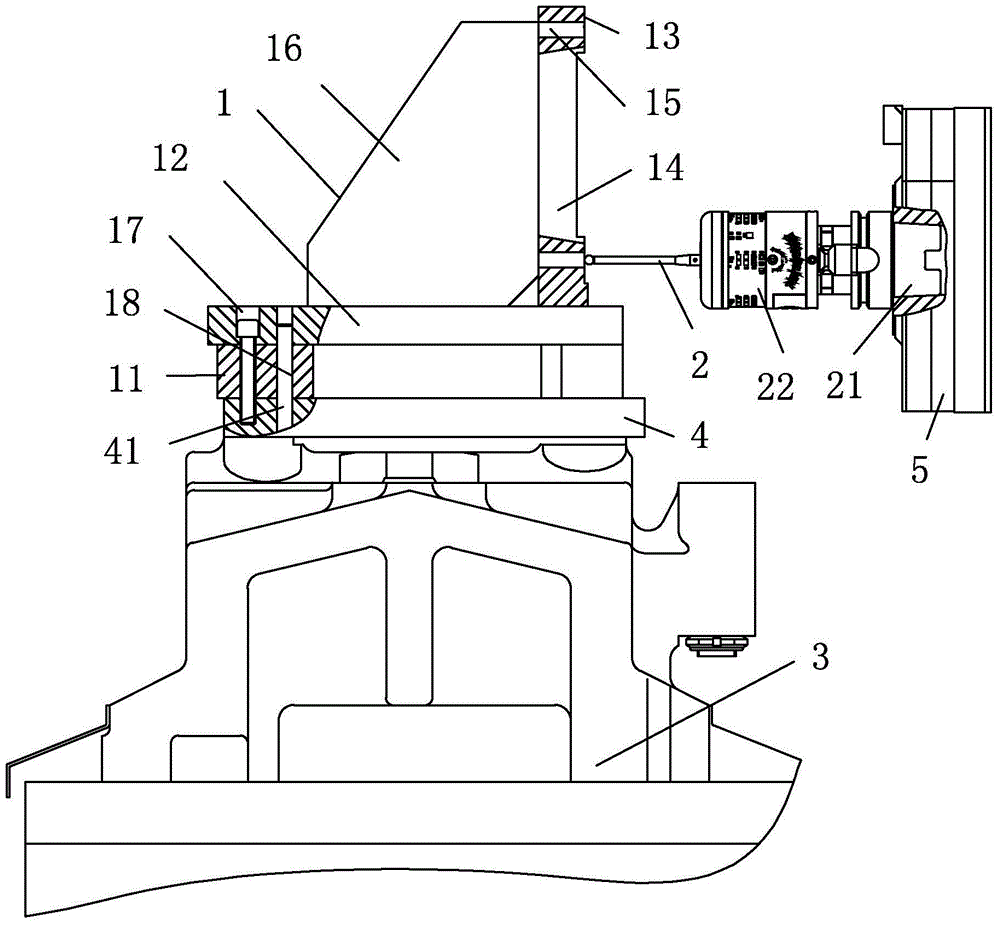

Accuracy calibration device and accuracy calibration method of fixture for box-type parts

InactiveCN104647133BDoes not affect accuracy calibration resultsSmall precision calibration errorAutomatic control devicesMeasurement/indication equipmentsElectricityEngineering

The invention relates to the field of a machining center box type part jig calibration and aims at providing a box type part jig accuracy calibration device and an accuracy calibration method. The box type part jig accuracy calibration device comprises an accuracy calibration base and an infrared probe system. The accuracy calibration base comprises a bottom plate and a vertical calibration plate, wherein the bottom plate is provided with at least two connecting blocks at the lower end surface, and the vertical calibration plate has one end surface provided with a calibration surface perpendicular to the bottom plate and is connected to the bottom plate at the lower end. The calibration surface is provided with at least a calibration hole penetrating through the other end surface of the vertical calibration plate. The lower end surface of each of the two connecting blocks is provided with a connecting through hole penetrating through the upper end surface of the bottom plate and a positioning hole. The infrared probe system comprises an infrared probe with a knife shank and a data transmission unit and a data receiver electrically connected to a controller of a machining center. The box type part jig accuracy calibration device is small in accuracy calibration errors and free of fouling and abrasion affecting calibration results.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD +3

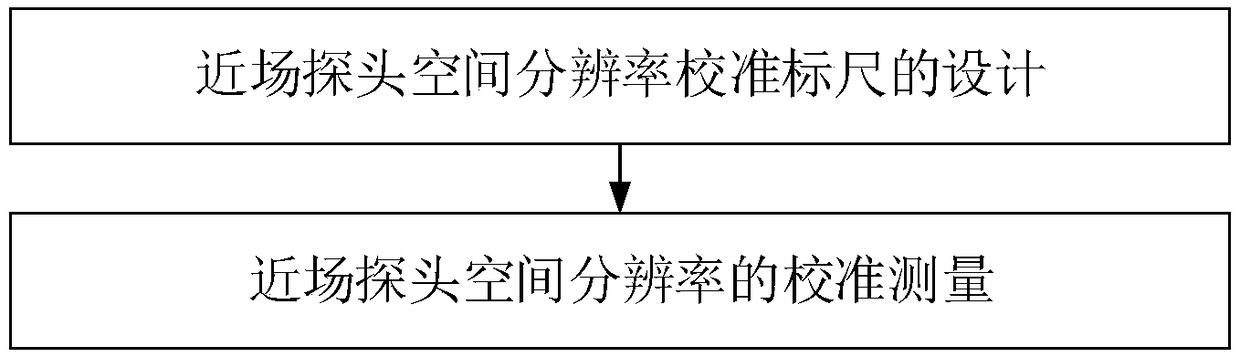

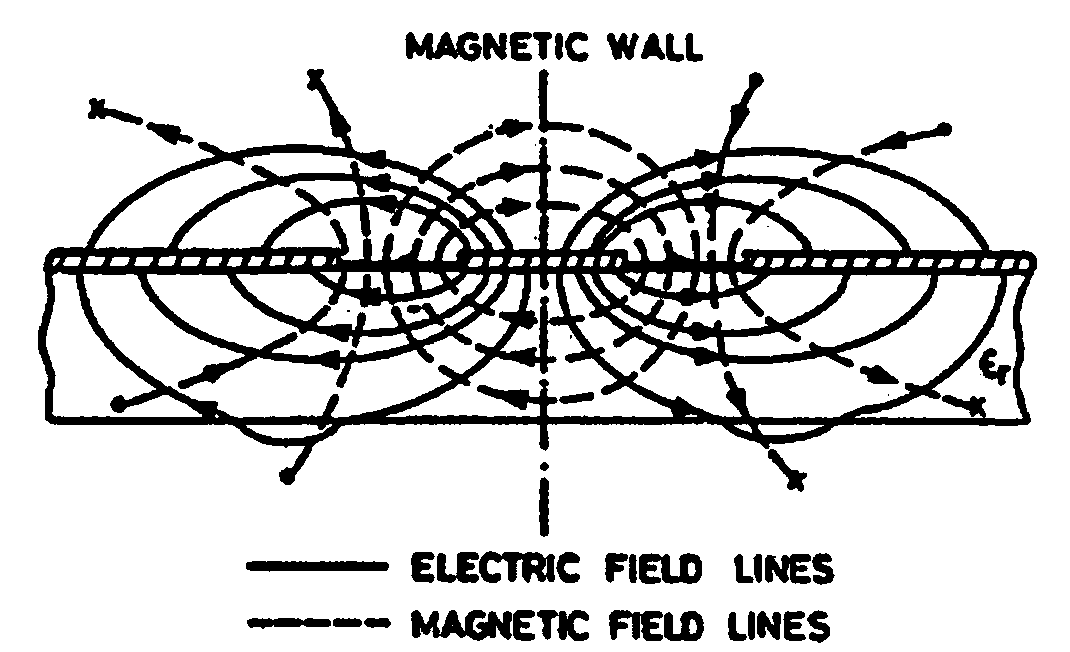

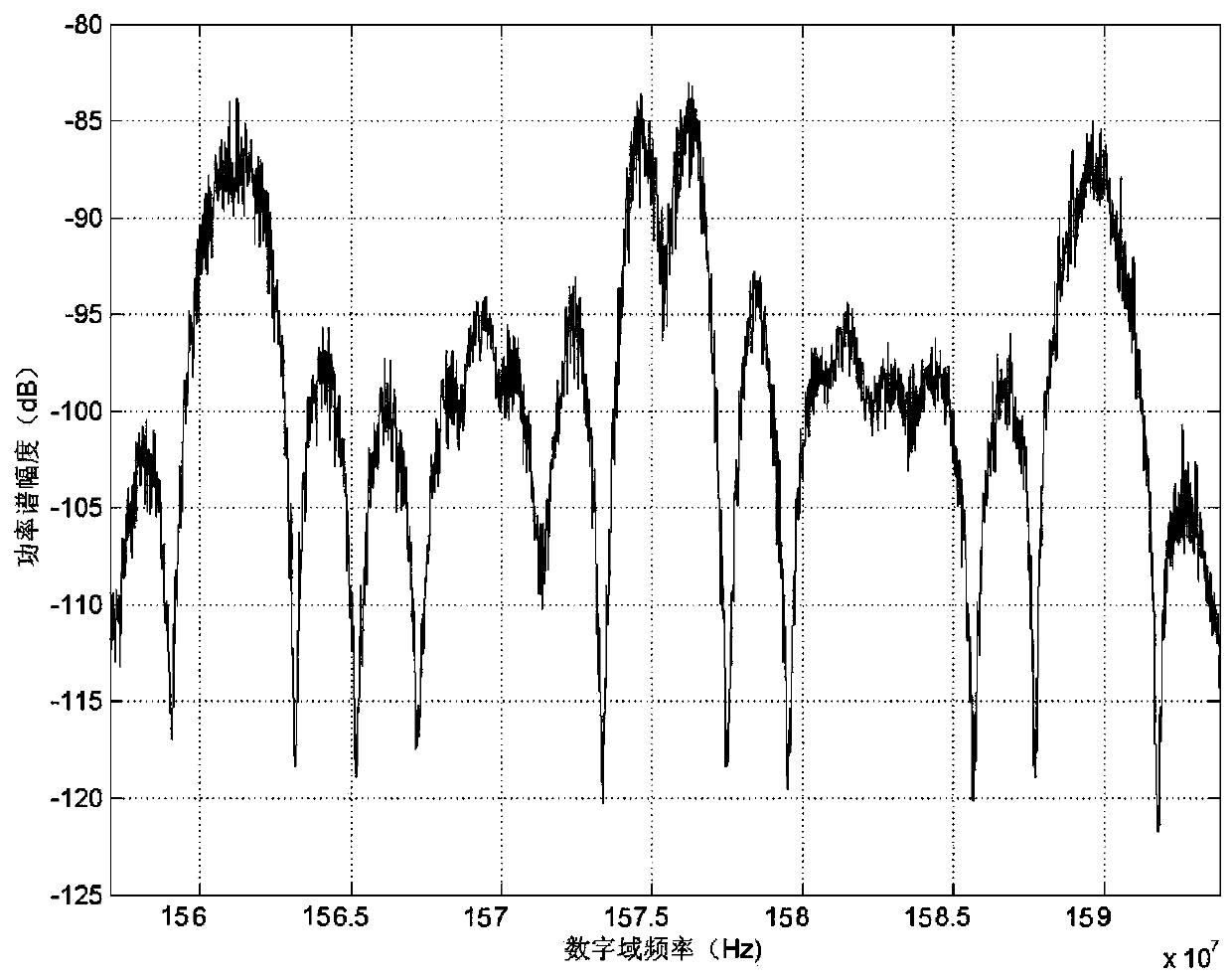

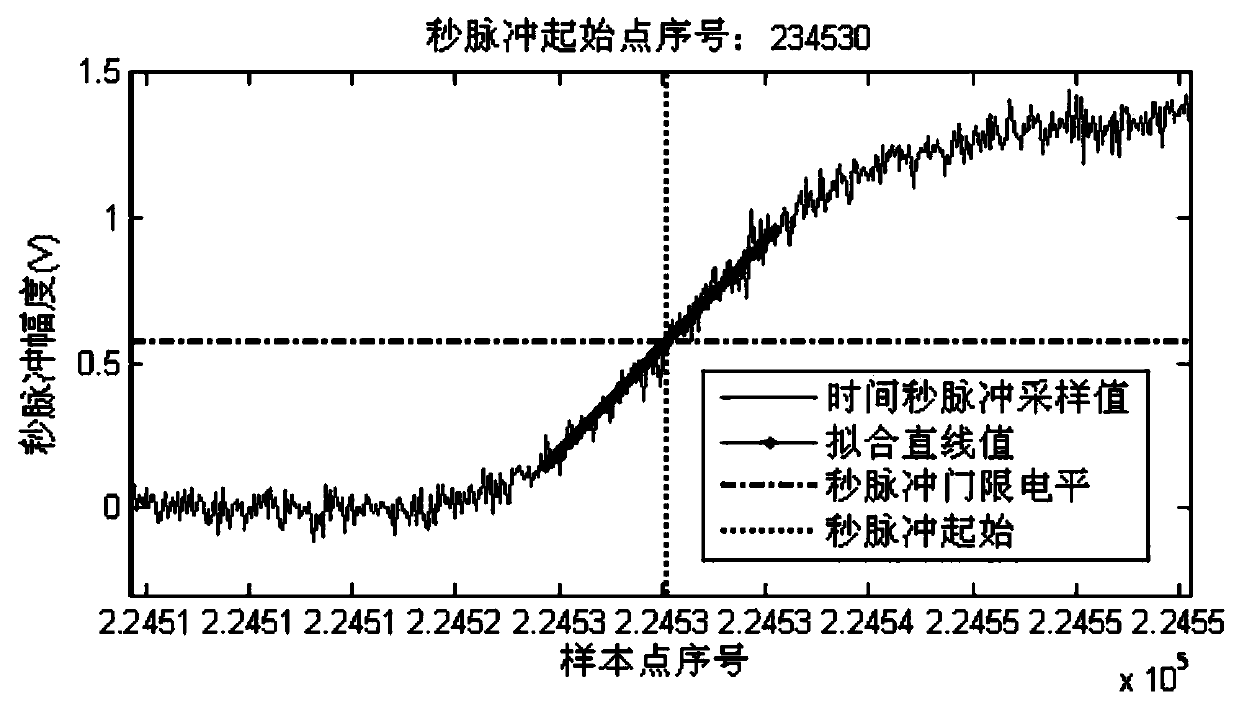

A Traveling Wave Calibration Method for Spatial Resolution of Near-field Probe Based on Transmission Line

ActiveCN106707210BSimple designImprove versatilityElectrical measurementsElectrical conductorImage resolution

The invention relates to a traveling wave calibration method based on near-field probe spatial resolution of a transmission line. The method comprises step 1, design of a near-field probe spatial resolution calibration scale; and step 2, calibration measurement of the near-field probe spatial resolution. The method constructs a spatial resolution calibration scale having resolvable field distribution features and the calibration precision adjustable within a certain range, in combination with amplitude precision given by a receiver or a spectrometer in a near-field EMI (Electro-Magnetic Interference) test system, based on the theory of the transmission line, using the multi-conductor planar transmission line as a construction platform.

Owner:BEIHANG UNIV

Phase-locked circuits and radio communication equipment

InactiveCN102377430BEliminate Calibration ErrorsMitigate Phase Noise DesignResonant circuit tuningPulse automatic controlCapacitanceComparators circuits

The invention discloses a phase-locking circuit, comprising: a phase-locking part, including a voltage-controlled oscillator having a capacitor group and changing the oscillation frequency according to voltage information, and the phase-locking part locks the oscillation signal of the voltage-controlled oscillator into phase to a reference signal; and a calibration section having a voltage correction function for providing an appropriate calibration voltage to the voltage-controlled oscillator when frequency calibration is performed on the voltage-controlled oscillator; the calibration section includes a counter circuit, a first A storage circuit and a second storage circuit, a comparator circuit, a control circuit, a voltage generating circuit, and a processing circuit.

Owner:SONY CORP

A Phase Consistency Calibration Method for Multiple Long Code Composite Navigation Signals

ActiveCN106908810BResolving inconsistencies with its own zero valueEliminate Calibration ErrorsSatellite radio beaconingPoint sequenceSignal generator

The invention provides a multi-long-code composite navigation signal phase consistency calibration method, which relates to the navigation satellite system's high precision application field. The method comprises: first, picking the pilot-frequency long-code baseband sample point data in a local composite navigation signal and a complex baseband navigation signal; performing relevant processing to the two and obtaining the relevant peak point sequence P; according to the picking length, picking the long-code baseband sample and determining the number of information bits M contained in the data code sub-channel of the navigation signal in the picking length; generating 2(M-1) possible information bit samples; carrying out frequency spreading to the picked local data long-code baseband sample and processing with the picked complex baseband navigation signal to determine the peak of each processing; solving the sample point sequence D corresponding to the biggest value of the peaks; and finally, solving the difference between D and P; and based on the sampling rate, calculating and obtaining the phase consistency of two long codes using the navigation signal pilot code as reference. With the method, it is possible to realize the precise calibration of the phase consistency of various codes of a navigation signal generator under the condition of multiple long codes.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Vehicle-mounted camera pitch angle calibration method and device, electronic equipment, and vehicle

ActiveCN108932737BAccurate CalibrationEliminate Calibration ErrorsImage enhancementImage analysisIn vehicleMechanical engineering

The present application relates to a method and device for calibrating the pitch angle of a vehicle-mounted camera, electronic equipment and a vehicle. According to an embodiment, a vehicle-mounted camera pitch angle calibration method may include: using the inertial measurement unit to determine the direction of gravity; using the inertial measurement unit to track the movement of the vehicle to obtain a first trajectory corresponding to a moving distance; using the vehicle-mounted camera to track The movement of the vehicle, obtaining a second trajectory corresponding to the moving distance; determining the offset between the first trajectory and the second trajectory, so as to determine the distance between the on-board camera and the inertial measurement unit An included angle: determining the pitch angle of the on-board camera based on the gravity direction, the included angle between the on-board camera and the inertial measurement unit, and the pitch angle direction determined by the inertial measurement unit. The method of the present invention can perform real-time online calibration of the pitch angle of the vehicle-mounted camera in a fully automatic manner in combination with an inertial measurement unit without manual participation, so it can be widely used in fields such as automatic driving.

Owner:SHENZHEN HORIZON ROBOTICS TECH CO LTD

A method for calibrating the probe length of a revo measuring head

ActiveCN110030963BAvoid the impact of length calibration accuracyAvoid situations that introduce additional calibration errorMeasurement devicesMechanical engineeringPrecision testing

The invention relates to a method for calibrating the probe length of a REVO measuring head, and belongs to the field of precision testing technology and instruments. The method comprises the following steps that a ring gauge is fixed on a horizontally placed flat plate; the main axes of a measuring machine are moved so that the A axis of the measuring head is located in the zero position state, and the measuring ball center of the measuring head coincides with the central axis of the ring gauge; and the three main axes of the measuring machine are kept stationary, the measuring head A axis and the measuring head B axis are moved, two symmetrical points on the same section of the ring gauge are detected, data are returned according to the two detected points, and the probe length of the REVO measuring head is calibrated through projection calculation. According to the method, calibration is carried out in a state that the three main axes of the measuring machine are stationary, so thatprobe length calibration errors caused by movement errors of the three main axes of the measuring machine and probe length calibration errors caused by misalignment between the axis of the B axis ofthe REVO measuring head and the axis of the ring gauge can be avoided, high-precision calibration of the probe length of the REVO measuring head can be realized, and the method can be applied to measurement.

Owner:TAIYUAN UNIV OF TECH

High-accuracy depth domain stochastic simulation inversion method suitable for designing track of horizontal well

The invention relates to a high-accuracy depth domain stochastic simulation inversion method suitable for designing a track of a horizontal well, which comprises the following steps: firstly, selecting typical wells according to a certain proportion to carry out calibration of a synthetic record; establishing solid models for the typical wells and repeatedly carrying out calibration fine adjustment by stratigraphic correlation; generating a time domain sparse impulse wave impedance data volume and establishing a well control velocity field; carrying out time-to-depth conversion on the obtained time domain sparse impulse wave impedance data volume; and using depth domain sparse impulse wave impedance data as a restriction and ensuring all the wells to participate in the depth domain stochastic simulation inversion, so that an inversion result can be used for designing the track of the horizontal well. According to the invention, only the typical wells need to be subjected to calibration of the synthetic record; and by carrying out comparison and analysis on a logging curve and the high-accuracy solid models, carrying out fine adjustment and calibration, establishing the well control velocity field and directly utilizing absolute depth information of the wells to carry out depth domain stochastic simulation restrained inversion, a calibration error of a non-typical well is absolutely eliminated and the depth prediction accuracy of a target layer aiming at the track of the horizontal well is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

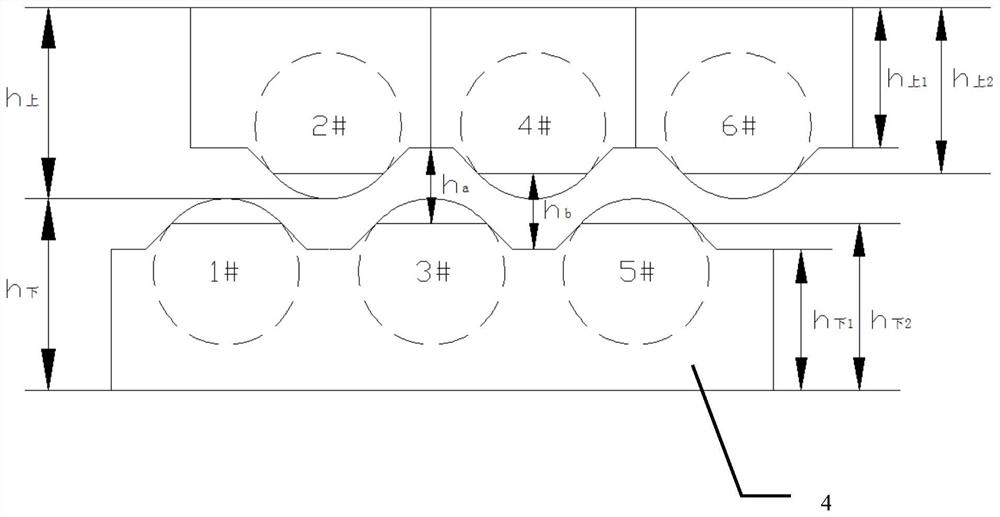

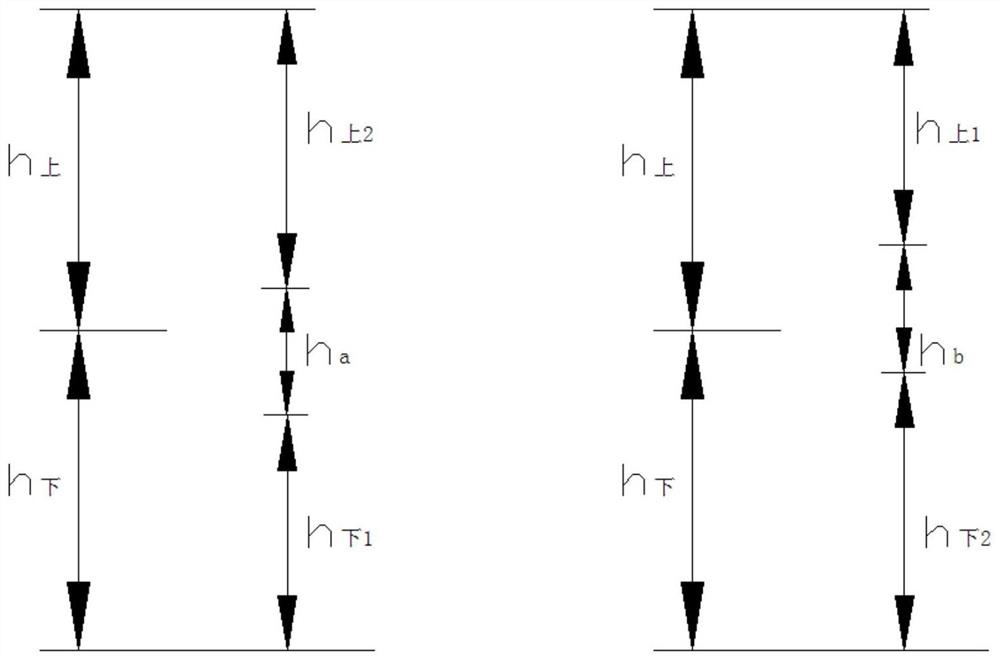

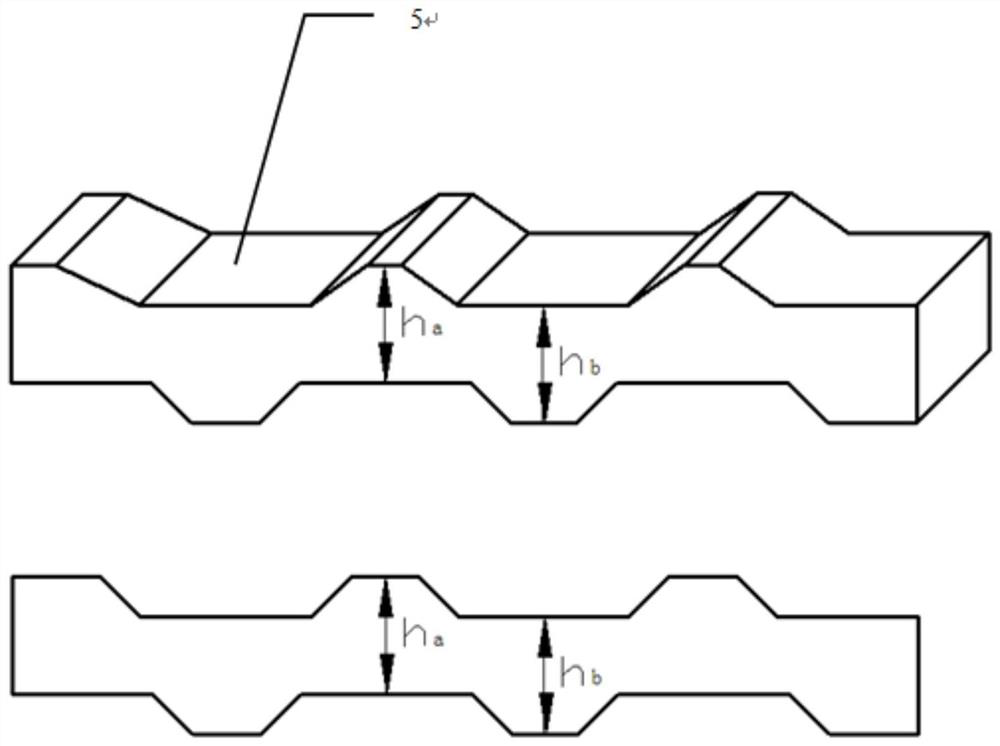

Calibration tool and method for rolling roll gap

ActiveCN109675937BEliminate Calibration ErrorsReduce labor consumptionMeasuring devicesMetal rolling arrangementsStructural engineeringMechanical engineering

The invention discloses a calibrating tool and method for spacing among rotary-expanding rollers. The tool comprises a mould base, an elastic part, a slide block mechanism and a lifting ruler, whereina slide block mounting hole and a lifting hole are separately formed in the two sides of the mould base; the elastic part is arranged in the corresponding slide block mounting hole; one end of the slide block mechanism is limited in the corresponding slide block mounting hole, and the other end of the slide block mechanism is positioned outside the slide block mounting hole and abuts against thecorresponding roller; the slide block mechanism comprises a variable-diameter section; the bottom end of the lifting hole communicates with the corresponding slide block mounting hole; and the liftingruler is positioned in the corresponding lifting hole, and the bottom end of the lifting ruler abuts against the variable-diameter section, and the lifting ruler is driven by the variable-diameter section to lift. According to the calibrating tool and method for spacing among rotary-expanding rollers disclosed by the invention, the slide block mechanism moves along with the roller, so that the lifting ruler lifts along with action of the slide block mechanism; and readings of the lifting ruler are observed, so that the practical position of the roller can be obtained; and the roller spacing is calibrated, so that consumption of labor power is reduced, and calibrating precision can be improved.

Owner:TAIYUAN HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com