Rotary calibration method for rocket engine thrust vector calibration

A rocket engine, thrust vectoring technology, applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

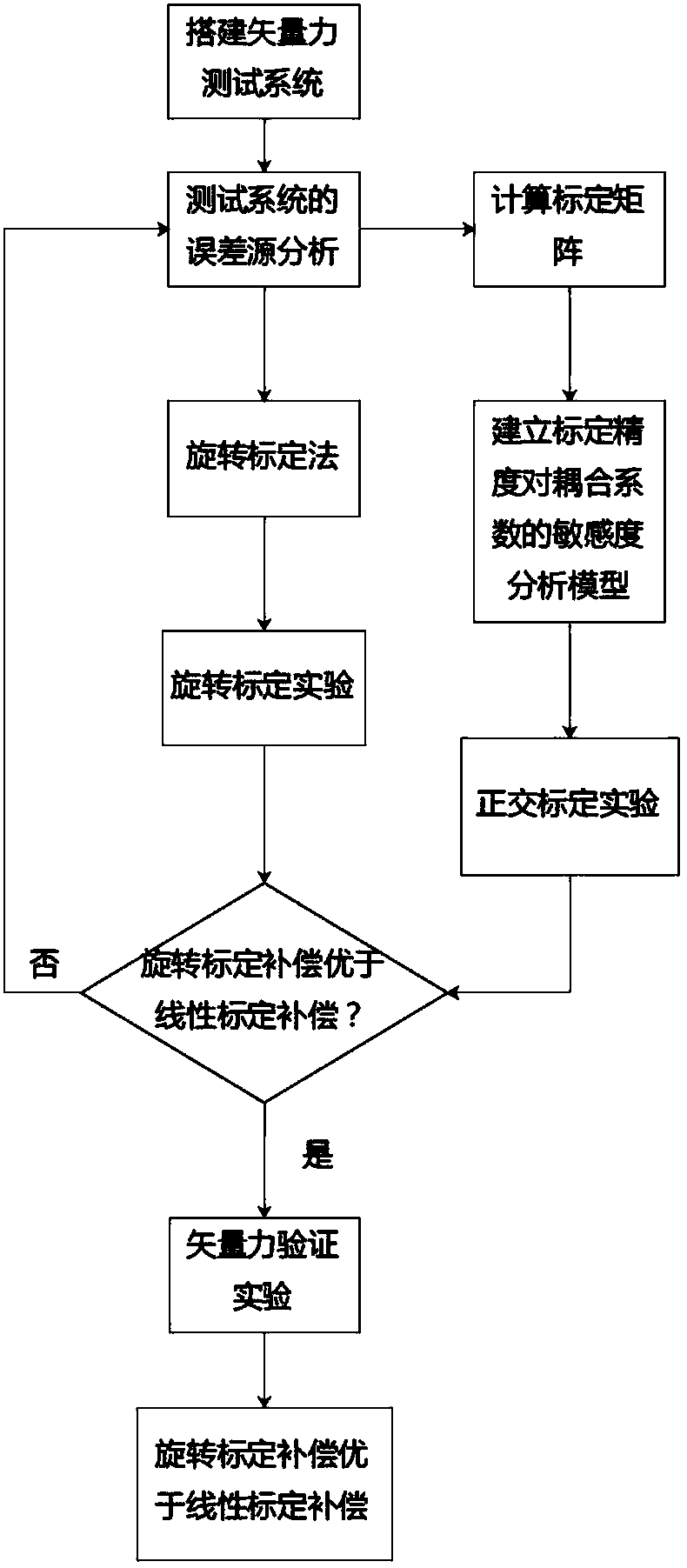

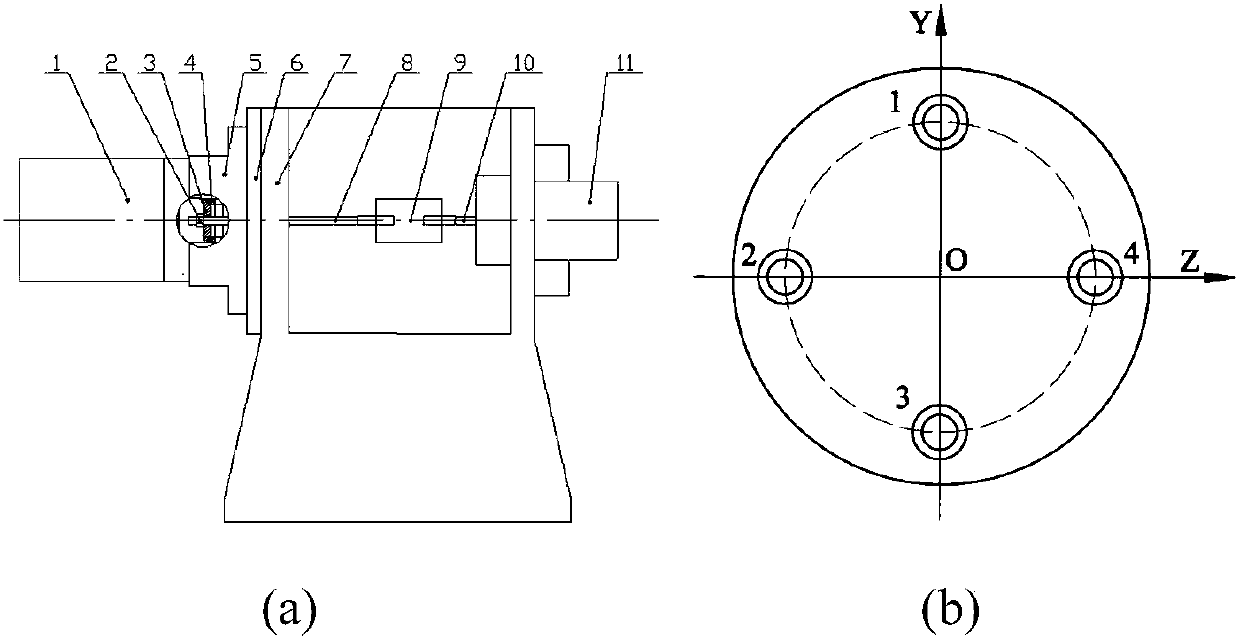

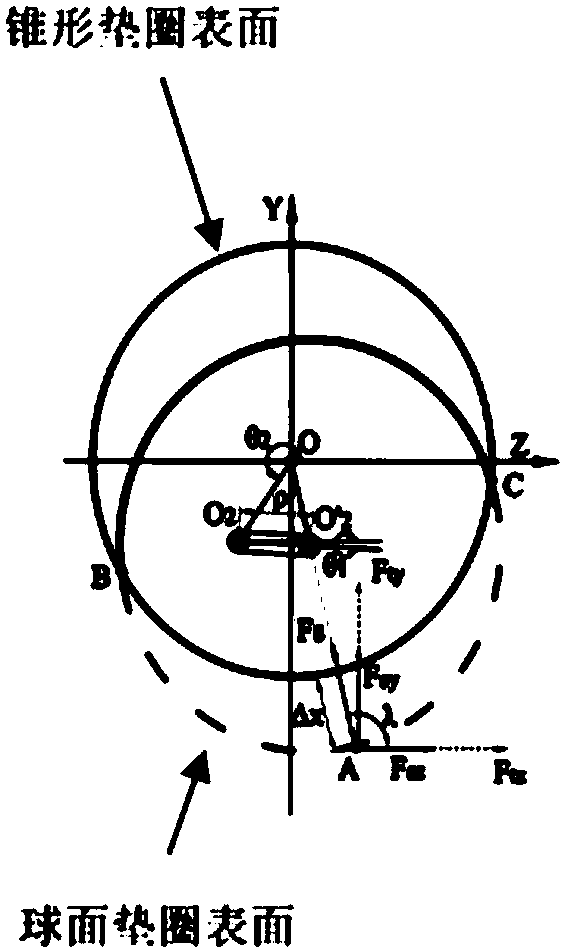

[0060] The present invention is a rotary calibration method for thrust vector calibration of a rocket engine. The method starts with the structural principle of a dynamometer, first builds a vector force test system, and analyzes the error source, and obtains Calculate the required calibration matrix, establish the sensitivity analysis model of the calibration accuracy to the coupling coefficient, and conclude that the interference coefficient between the main direction and the lateral direction is the most important factor affecting the test accuracy; then through the calibration system of the force vector offset The error analysis was carried out to explore the mechanism of the interference of the main direction to the lateral force; the mathematical model of the contact force between the calibration rod a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com