Shearing amount calibration device and method for transverse shearing interference wavefront sensor

A wavefront sensor and transverse shearing technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of difficulty in accurately determining the relative position and large errors, and achieve the goal of eliminating calibration errors, reducing complexity and accurate calibration results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the content, implementation process and advantages of the present invention clearer, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the examples do not limit the protection scope of the present invention. The numbers, symbols and other expressions in the following content correspond to the drawings in the specification.

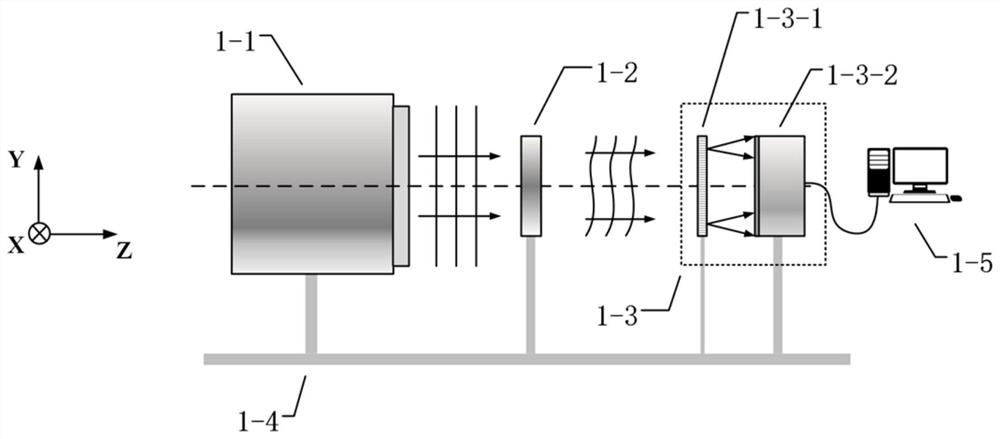

[0032] see figure 1 , as shown in the figure, a shear amount calibration device for a transverse shear interference wavefront sensor, including a wavefront generating device 1-1, a phase step calibration plate 1-2, a wavefront sensor to be calibrated 1-3, and a bracket 1-4, computer 1-5.

[0033] The wavefront generating device 1-1 is used to generate a plane wavefront. The emitted plane wavefront is generated by a point light source after being collimated and beam expanded, and the surface quality of the plane wavefront meets the accuracy requirements of shear c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com