Mirror surface object three-dimensional shape measurement method and device based on double-screen transmission display

A technology of three-dimensional shape and measurement method, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of affecting the measurement accuracy and measurement field of view, the inability to accurately determine the incident light, and the inability to measure large-sized objects, etc., to achieve measurement The effect of unrestricted field of view, elimination of measurement errors, and simple measurement system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

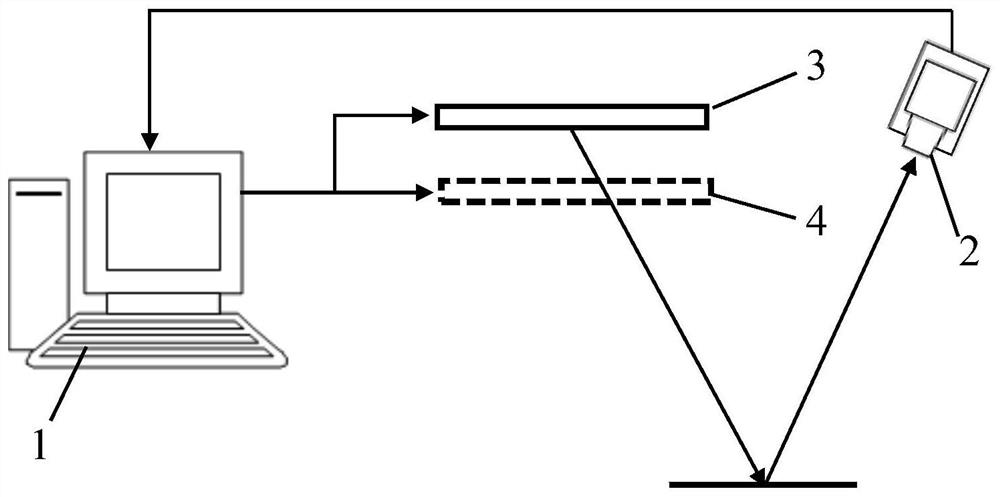

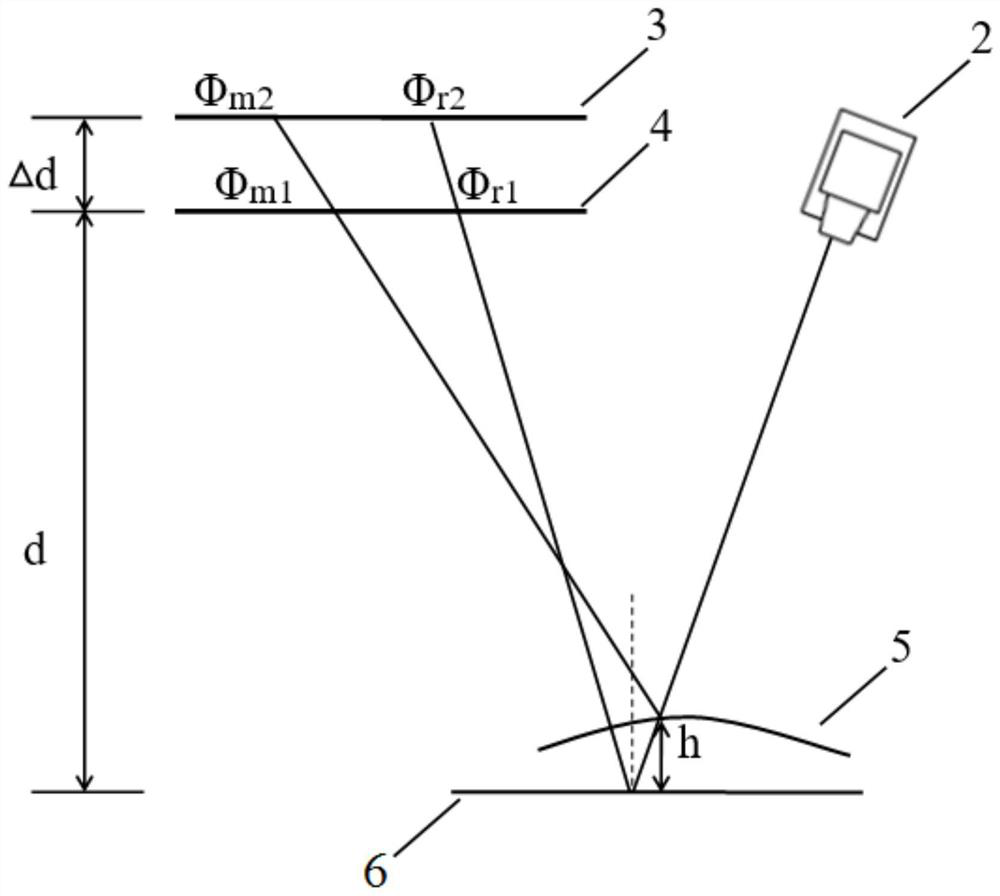

[0060] In the present embodiment, computer 1 is connected with liquid crystal display 3 and transparent display 4 by HDMI interface, is connected with CCD camera 2 by Gigabit network interface, and described fringe image adopts MATLAB software to generate;

[0061] In this embodiment, the numbers of the three groups of sinusoidal straight fringes selected for projection are 36, 35, and 30 respectively; the absolute phase expansion diagram is calculated by using the best three fringe selection method.

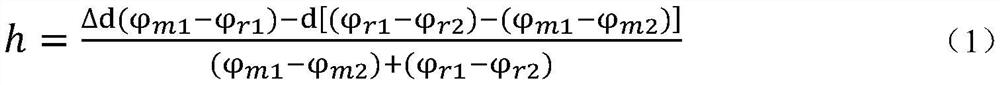

[0062] The three-dimensional shape measuring device of the specular object provided by the present invention uses a measurement method to directly obtain the three-dimensional surface topography of the specular object based on the principle of fringe reflection method. A liquid crystal display 3 and a transparent display 4 are used to display the sinusoidal straight stripes generated by the software. Since the specular object 5 to be measured has specular reflection properties, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com