Method for quickly calibrating zero position of straightener

A straightening machine and zero-position technology, applied in the field of cold-rolled steel, can solve the problems of inaccurate precision and cumbersome calibration methods, and achieve the effect of eliminating calibration errors, eliminating the need for regular testing and simplifying the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

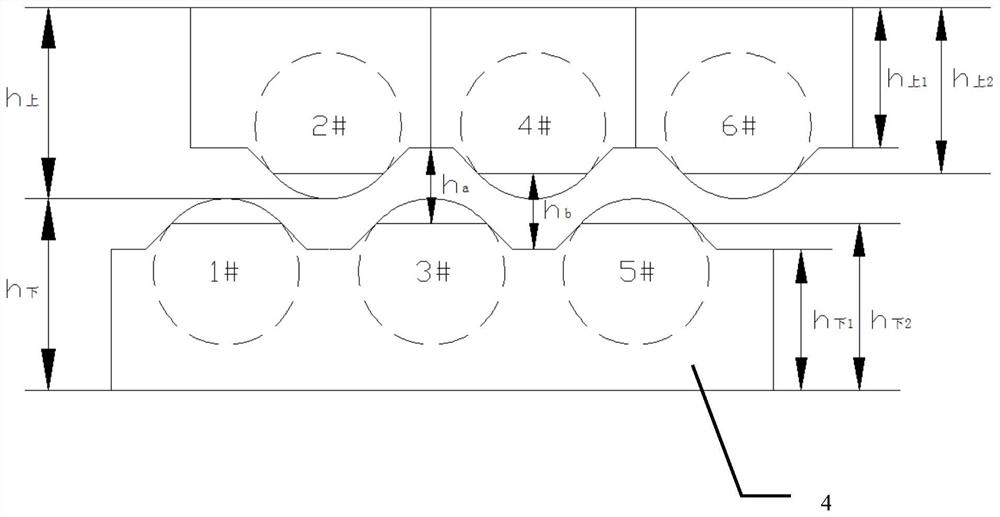

[0048] Embodiment 1: see figure 1 , a kind of method of quick calibration leveler zero position, described method comprises the following steps:

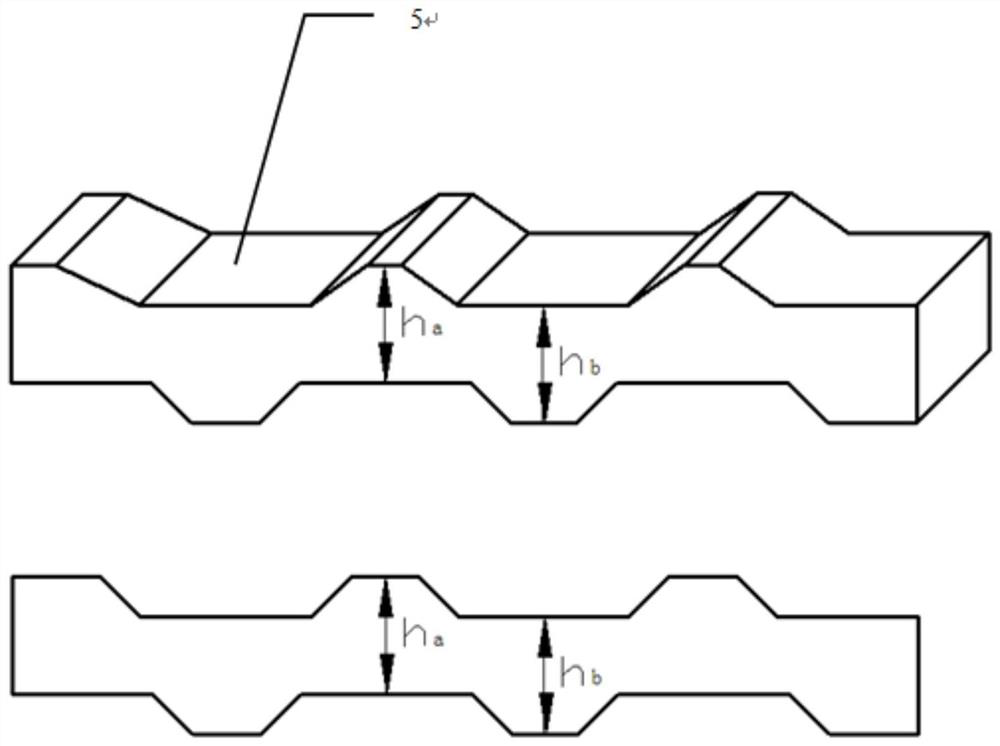

[0049] 1) Preparation of standard calibration backing plate;

[0050] 2) Accurately measure the actual value of the height from the installation bottom of each straightening roller box to the highest point of the roller;

[0051] 3) Find the deviation value between the actual value and the standard value of the height from the installation bottom of each straightening roller box to the highest point of the roller;

[0052] 4) Zero calibration;

[0053] 5) Zero correction.

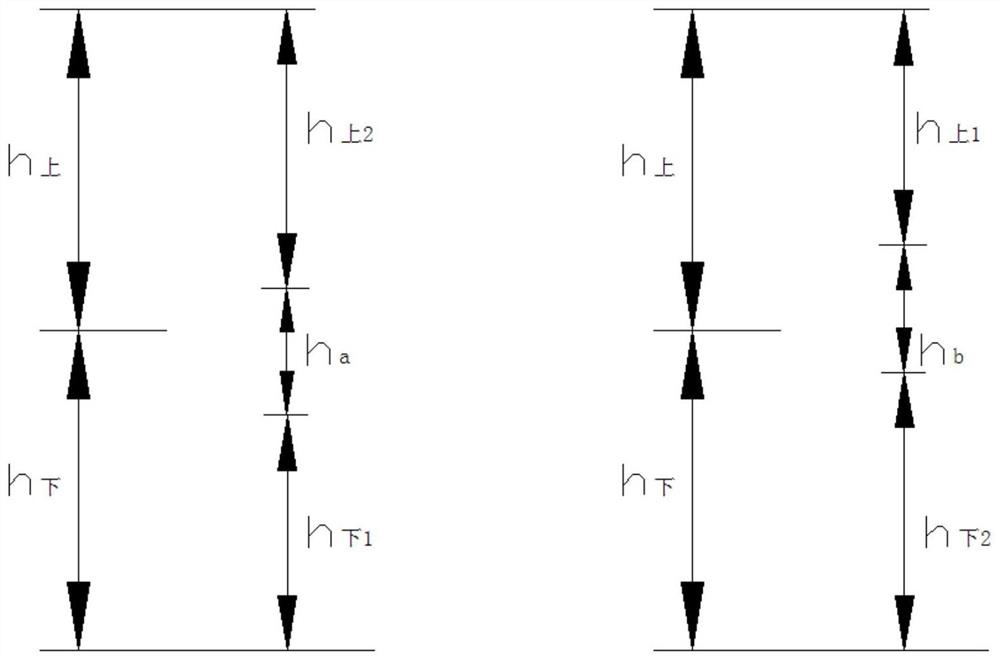

[0054] Said step 1) preparation of the standard calibration backing plate, specifically as follows, respectively calculate the standard value h of the height from the mounting base of the upper straightening roller box to the highest point of the roller according to the design drawings 上 and the standard value h of the height from the installation base of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com