Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Ease concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor apparatus and method of manufacturing the same

ActiveUS7361952B2Prevent decrease in device breakdown toleranceSmall sizeTransistorSolid-state devicesOptoelectronicsSemiconductor

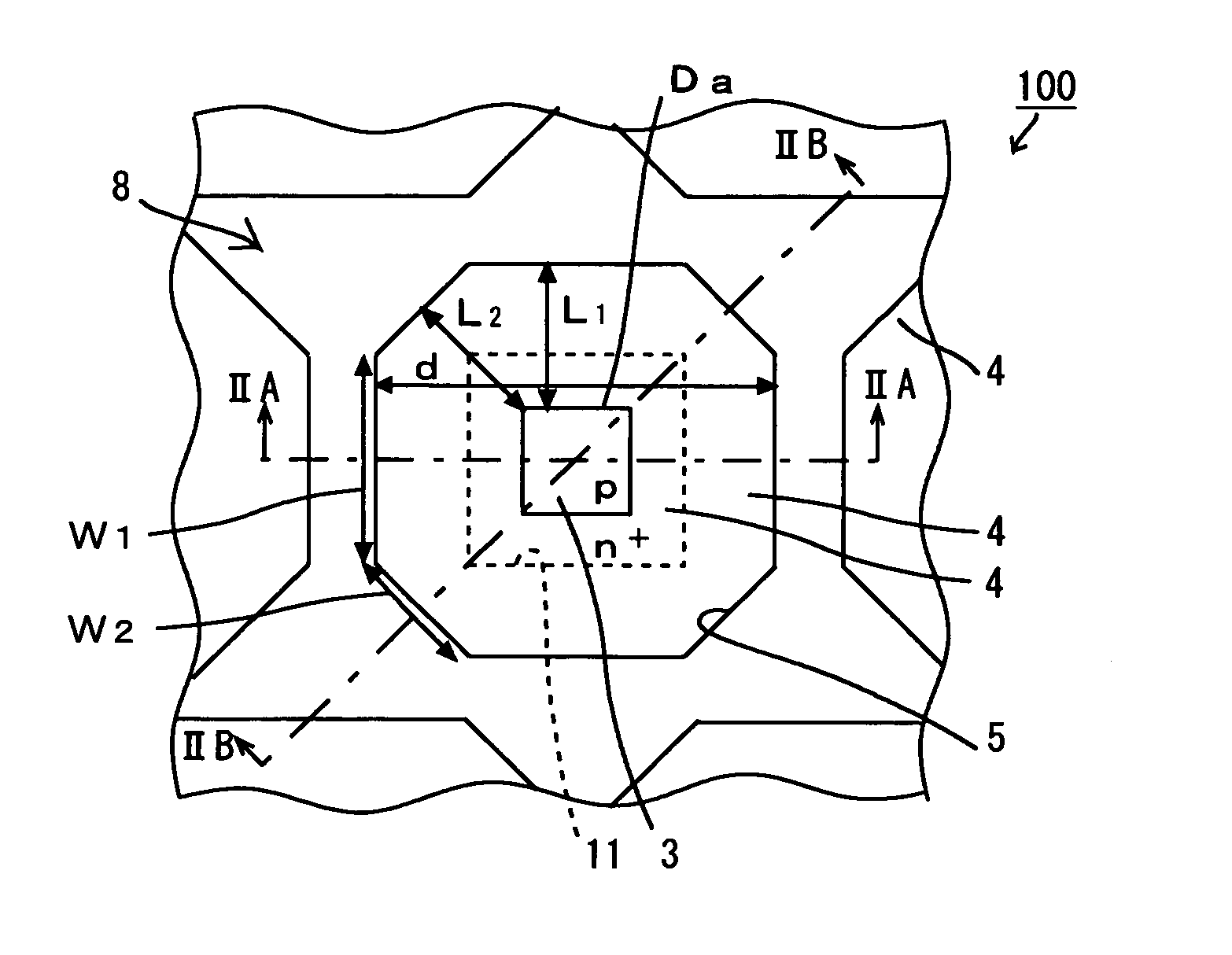

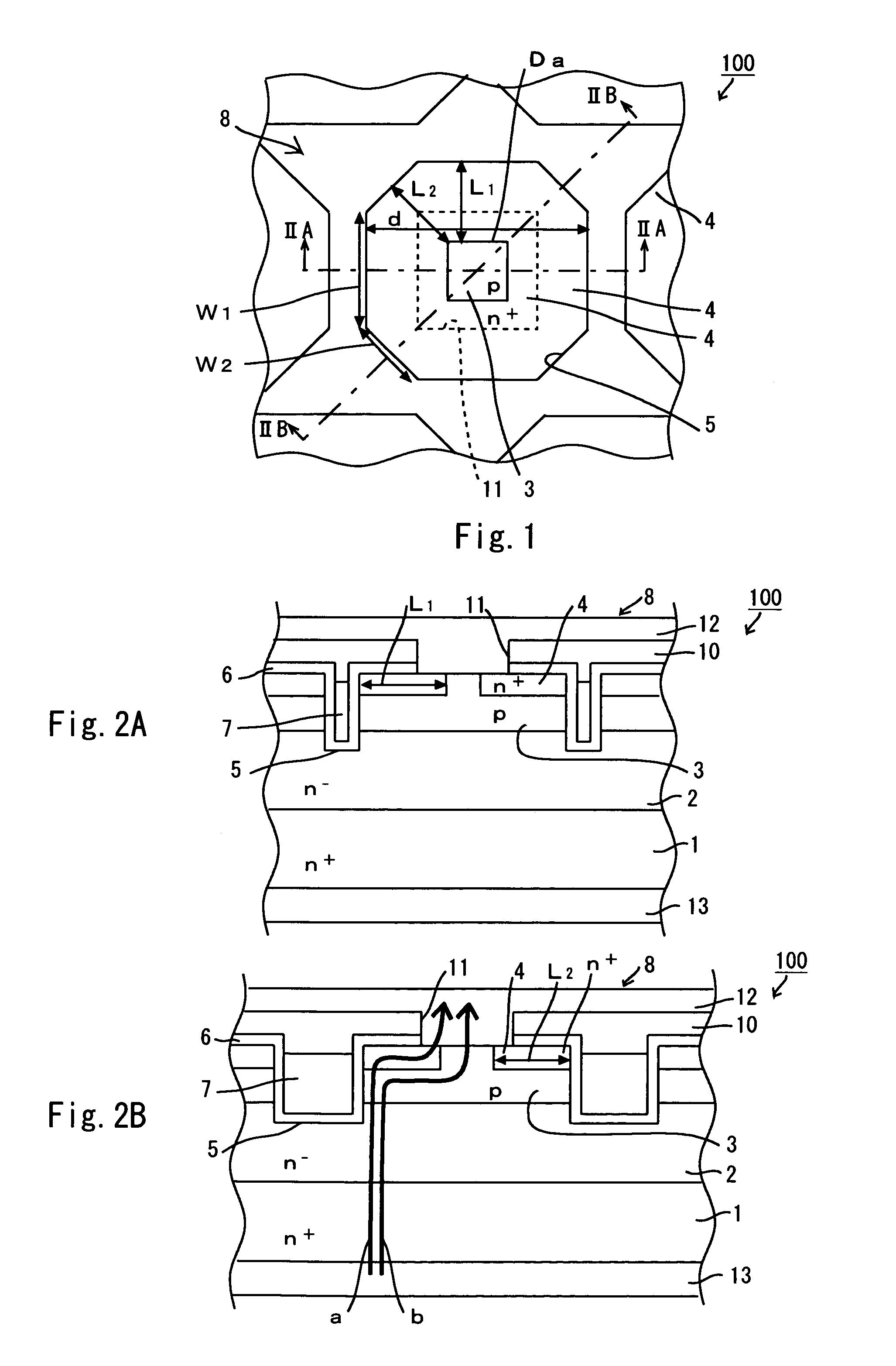

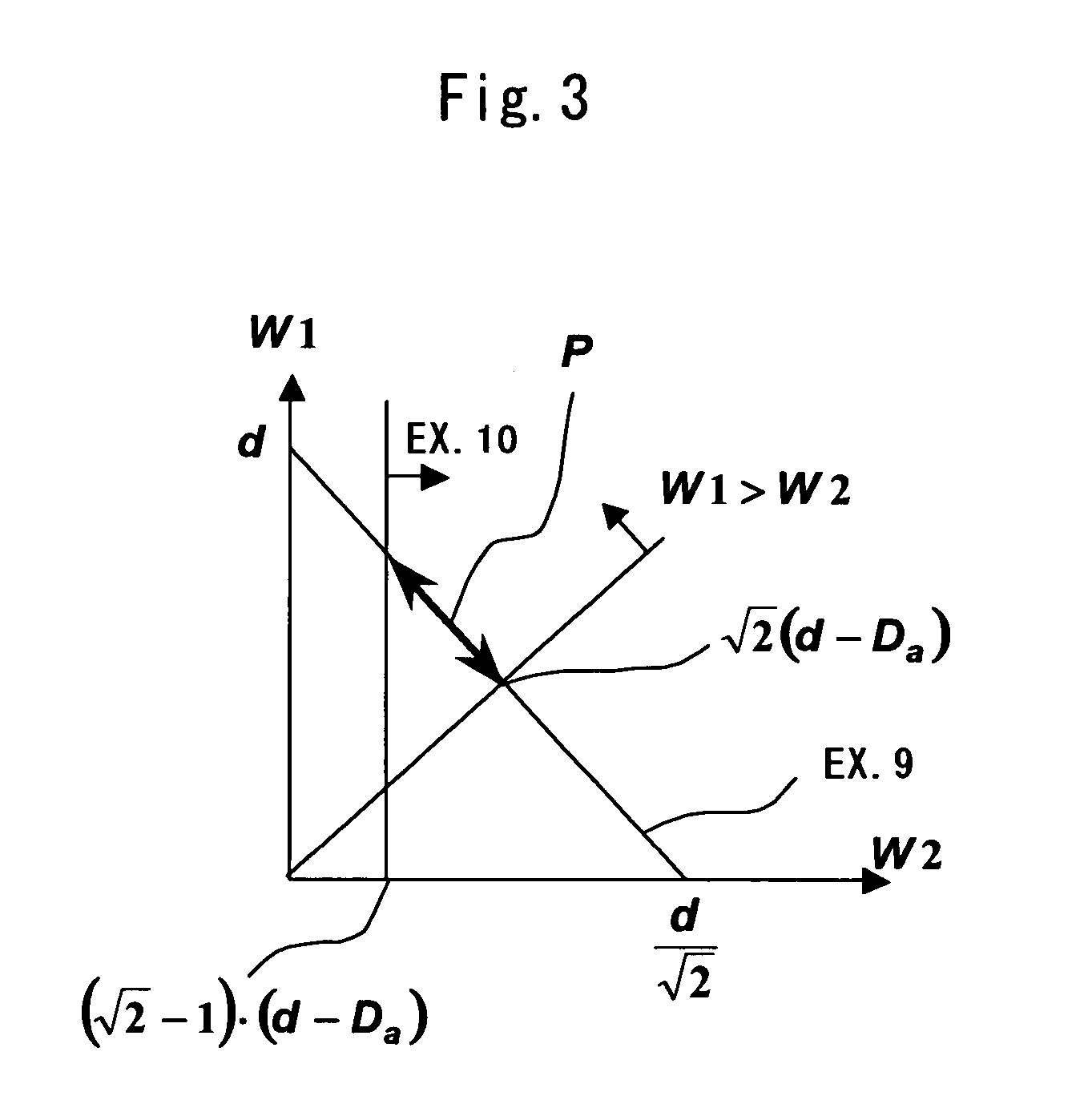

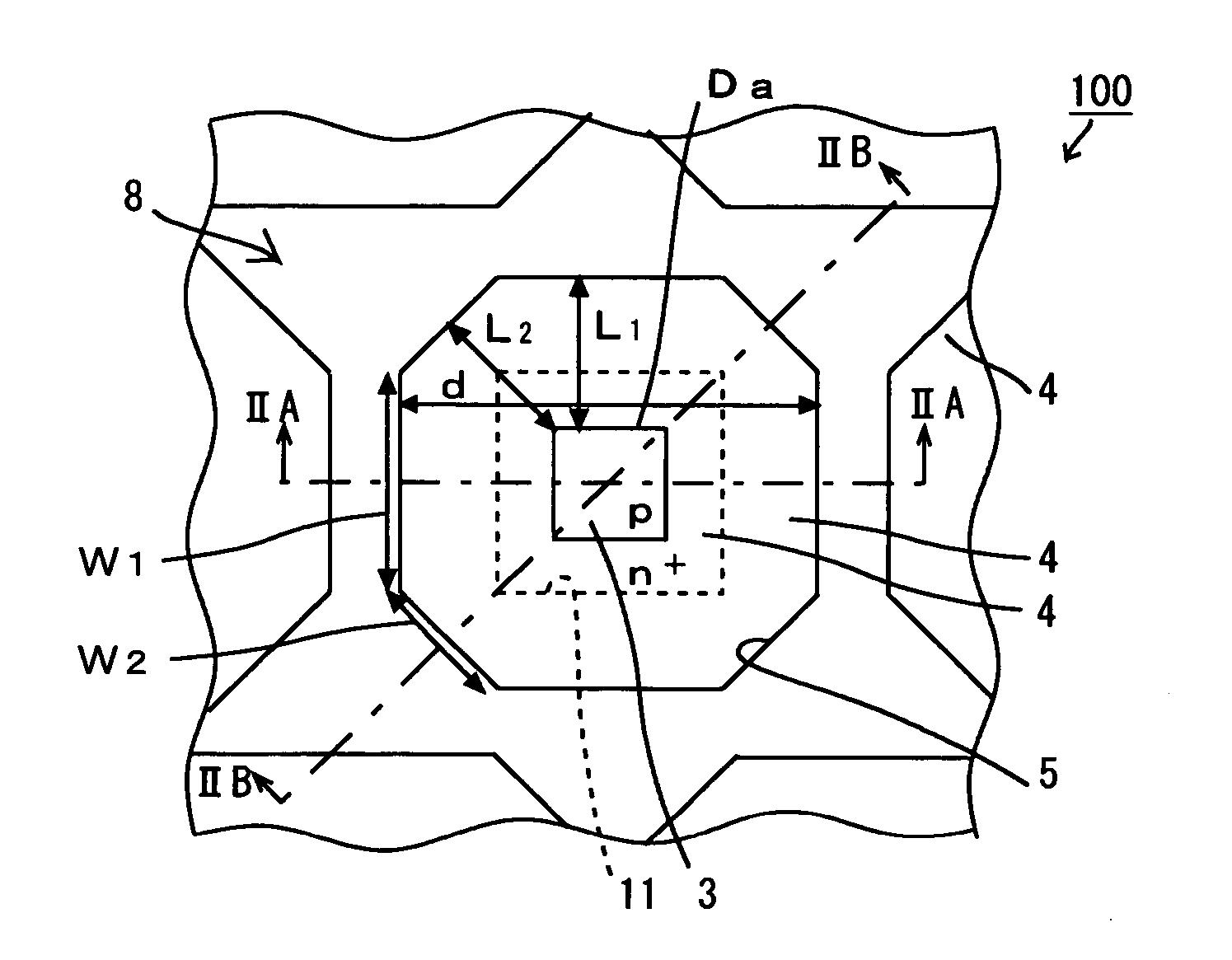

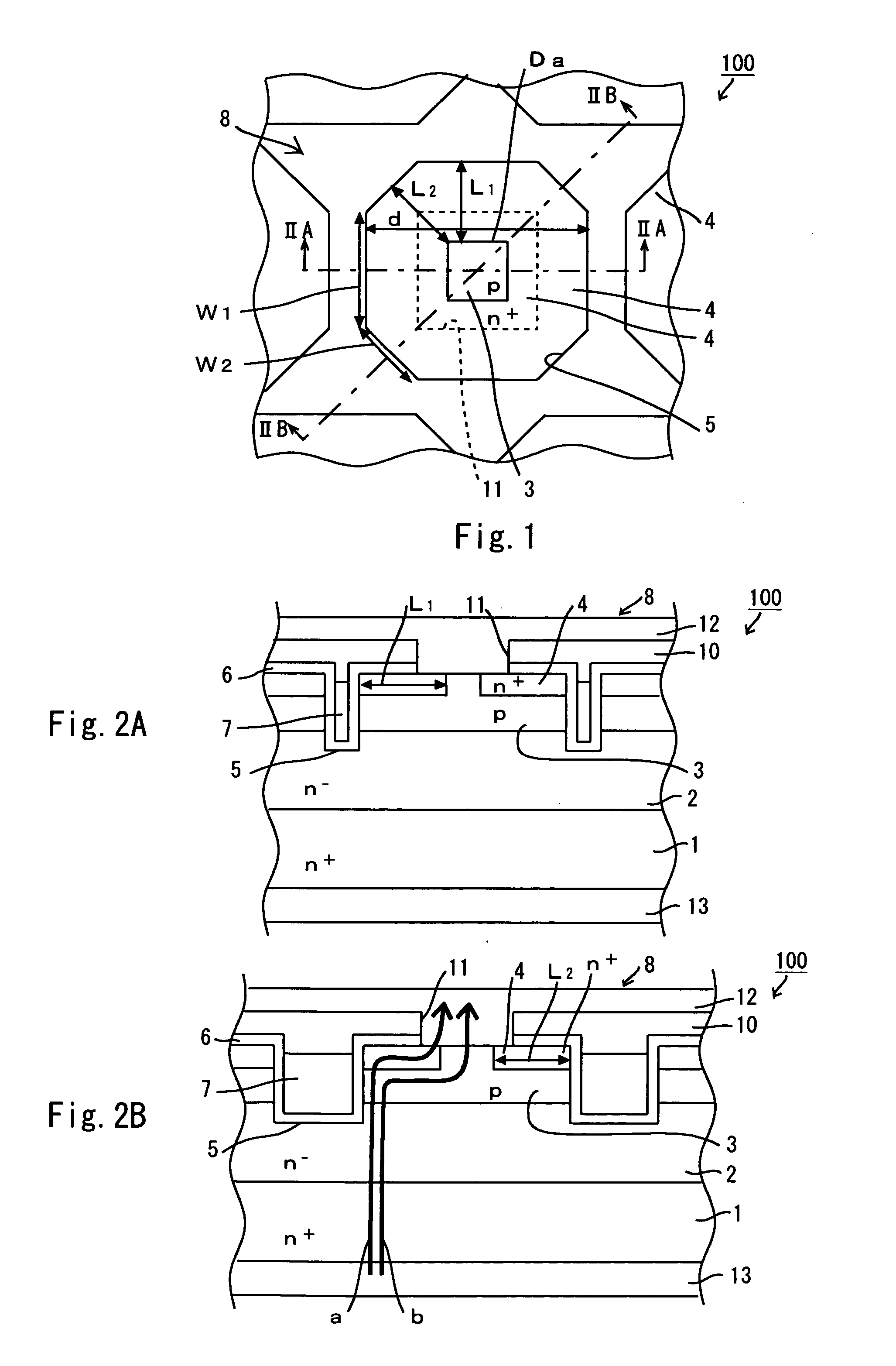

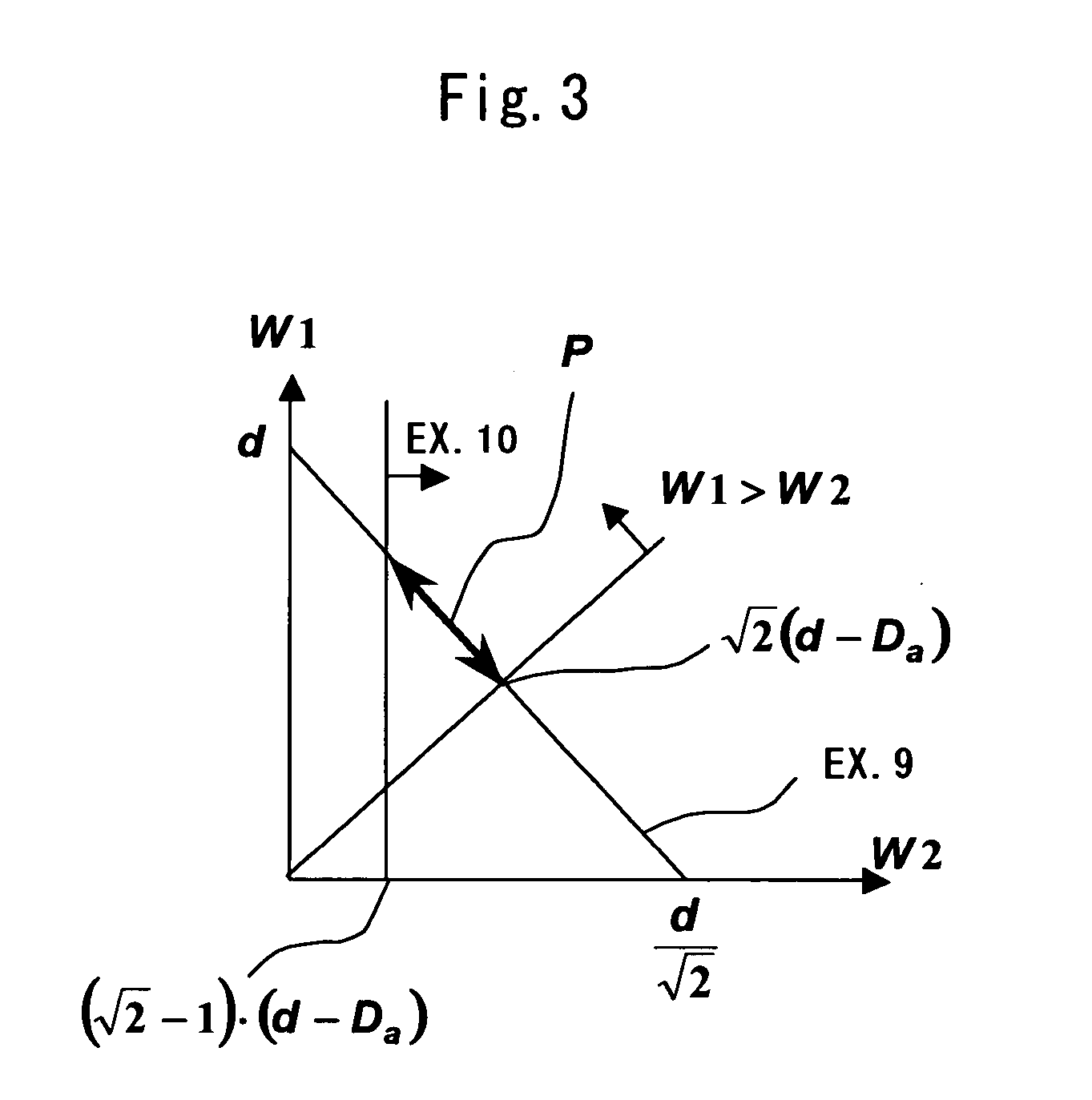

A semiconductor apparatus includes a semiconductor substrate of a first conductivity type, a base region of a second conductivity type formed on a principal surface of the semiconductor substrate, a trench formed in a periphery of the base region, and an endless source region of the first conductivity type formed on a surface of the base region along the trench. In this semiconductor apparatus, the principal planes on side surfaces of the trench are composed of planes [100] and [110]. The interior angle of intersection of adjacent side surfaces of the trench is 135°. A minimum distance between the base region and the plane [110] facing each other through the source region is shorter than a minimum distance between the base region and the plane [100] facing each other through the source region.

Owner:RENESAS ELECTRONICS CORP

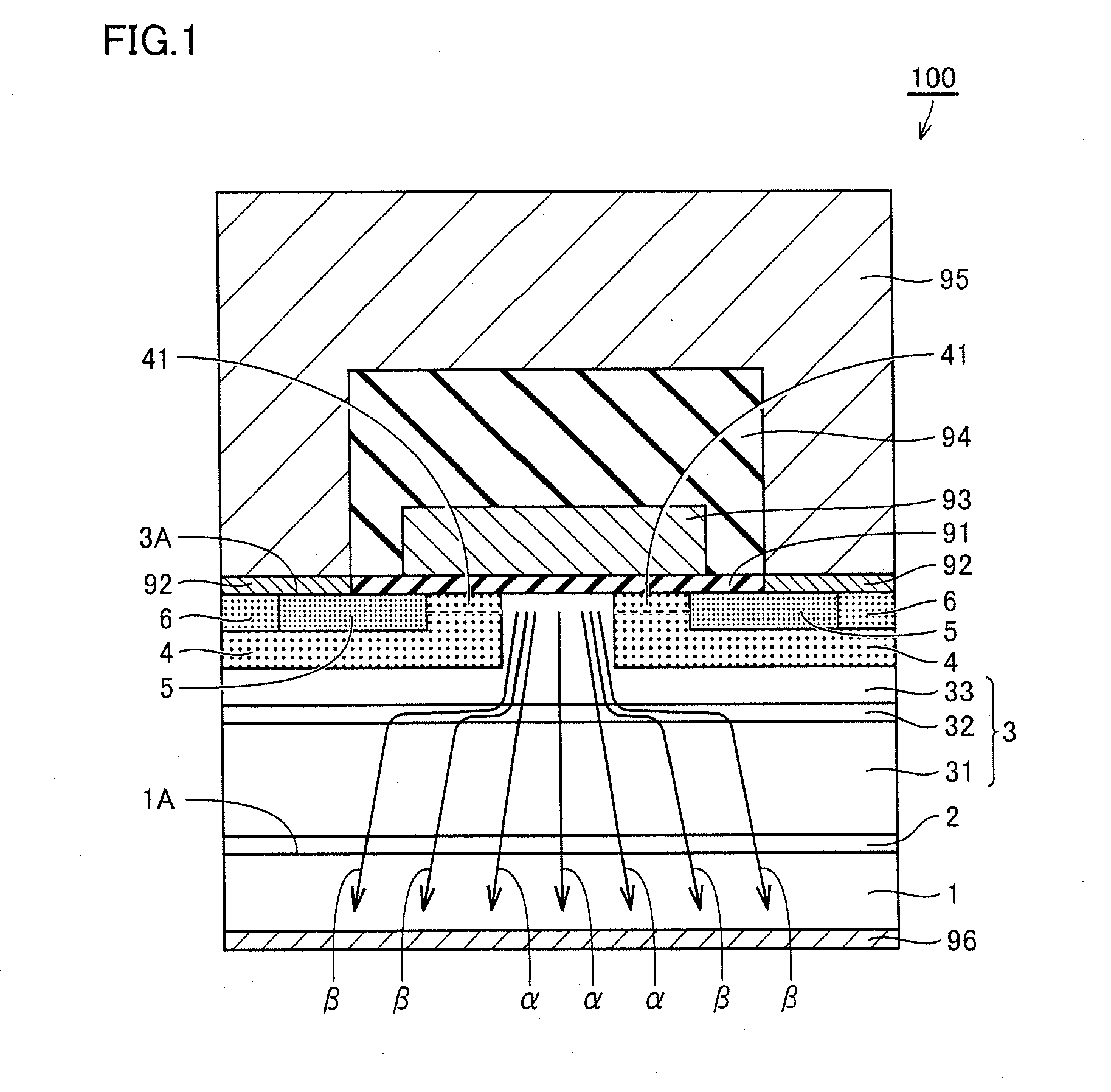

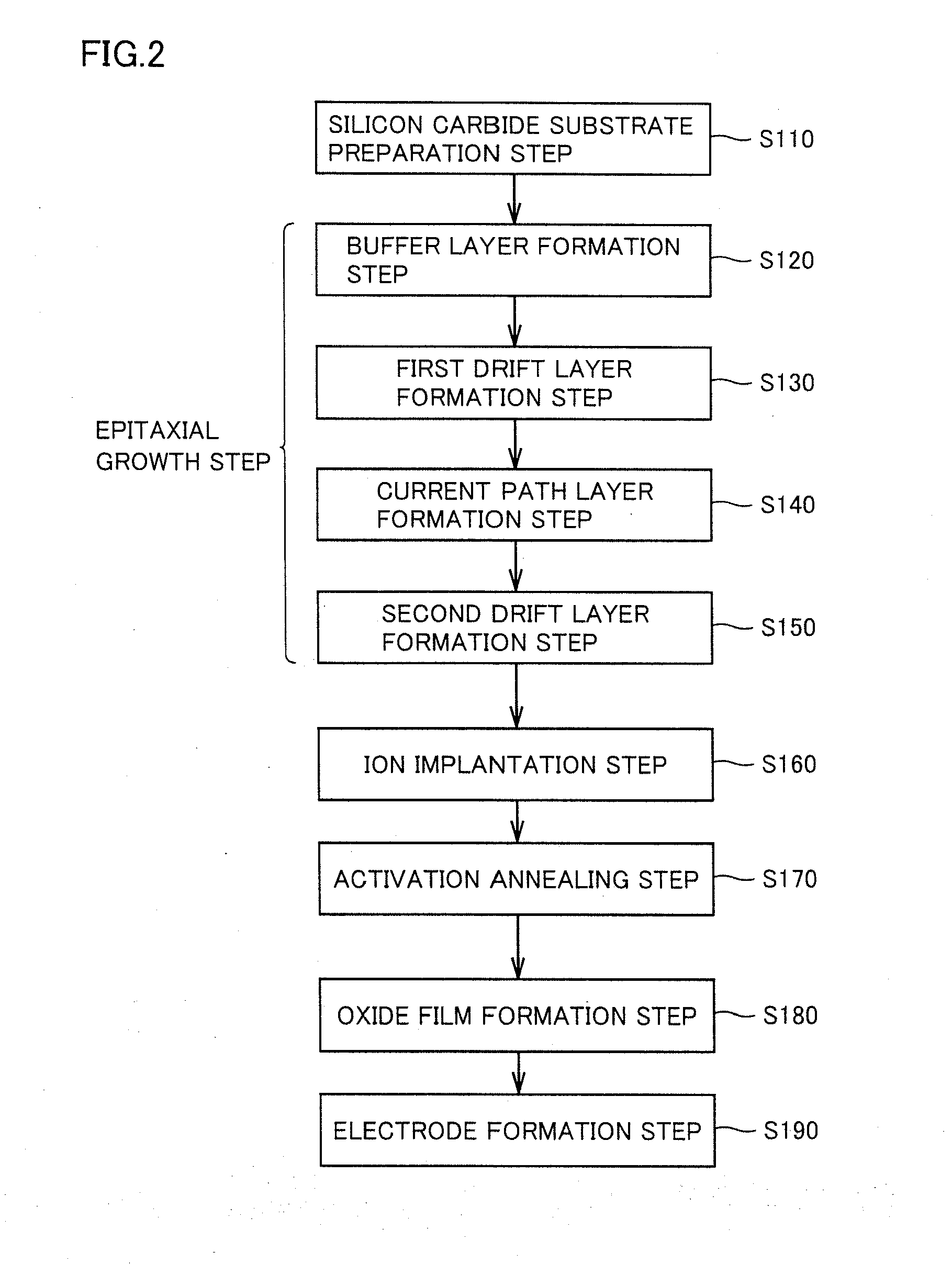

Semiconductor device

InactiveUS20120292742A1Lower on-resistanceEase concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceMOSFET

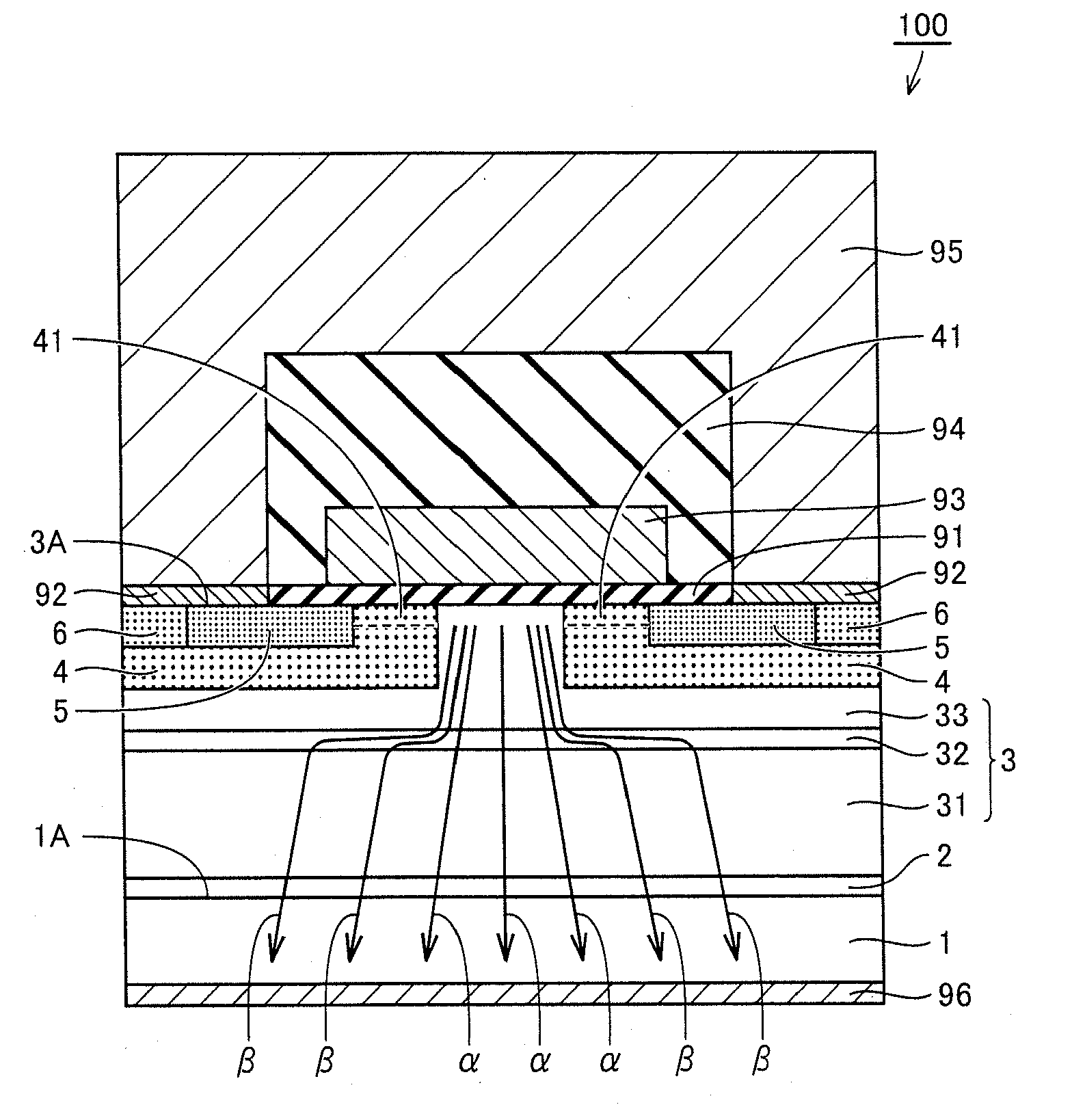

A MOSFET includes a silicon carbide substrate, a buffer layer made of silicon carbide formed on the silicon carbide substrate, a drift layer made of silicon carbide of an n conductivity type formed on the buffer layer, a p type body region of a p conductivity type formed in the drift layer to include a main surface of the drift layer opposite to the buffer layer, a source contact electrode formed on the p type body region, and a drain electrode formed on a main surface of the silicon carbide substrate opposite to the buffer layer. A current path region having an impurity concentration higher than that of another region in the drift layer is formed in a region in the drift layer sandwiched between the buffer layer and the body region.

Owner:SUMITOMO ELECTRIC IND LTD

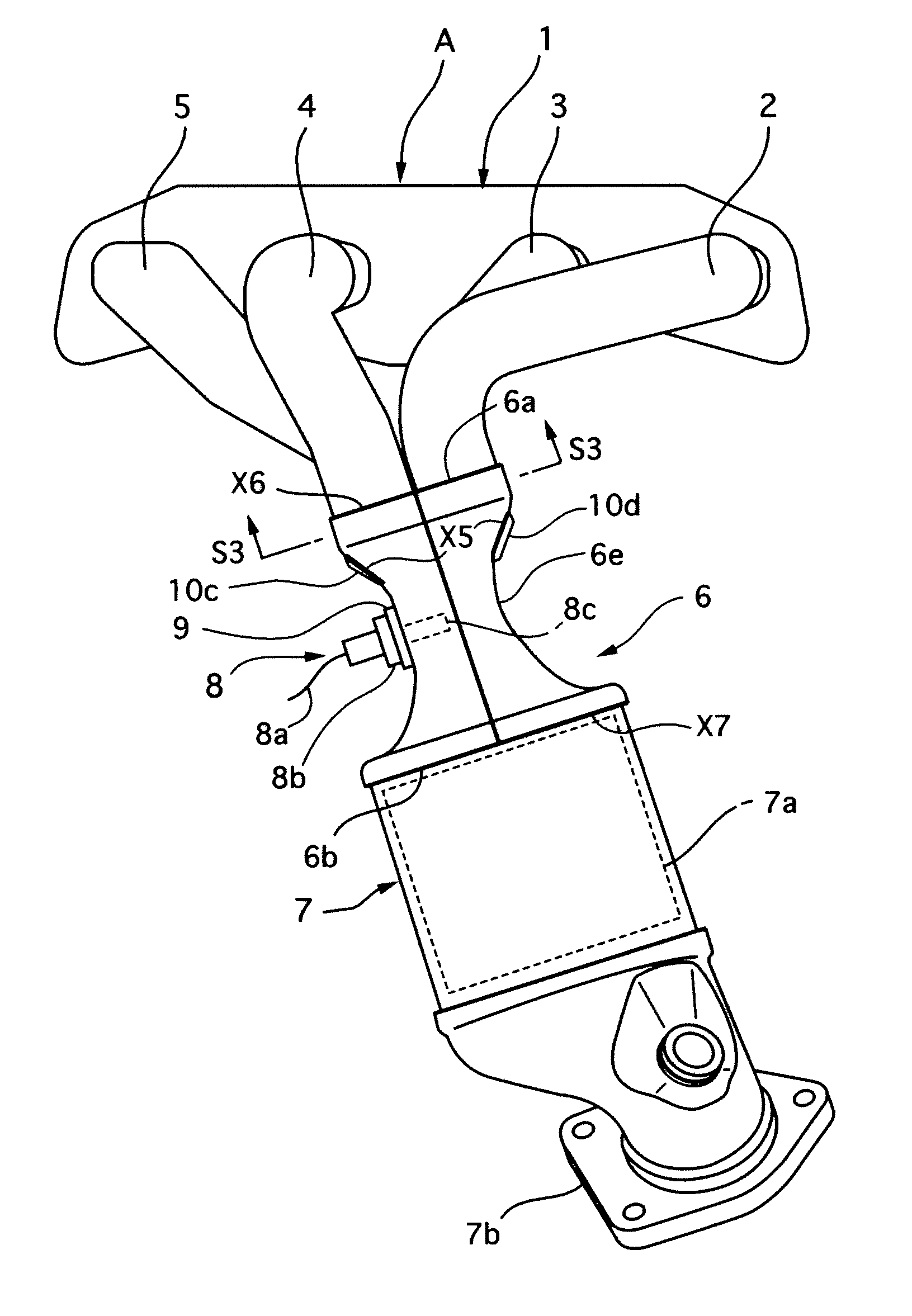

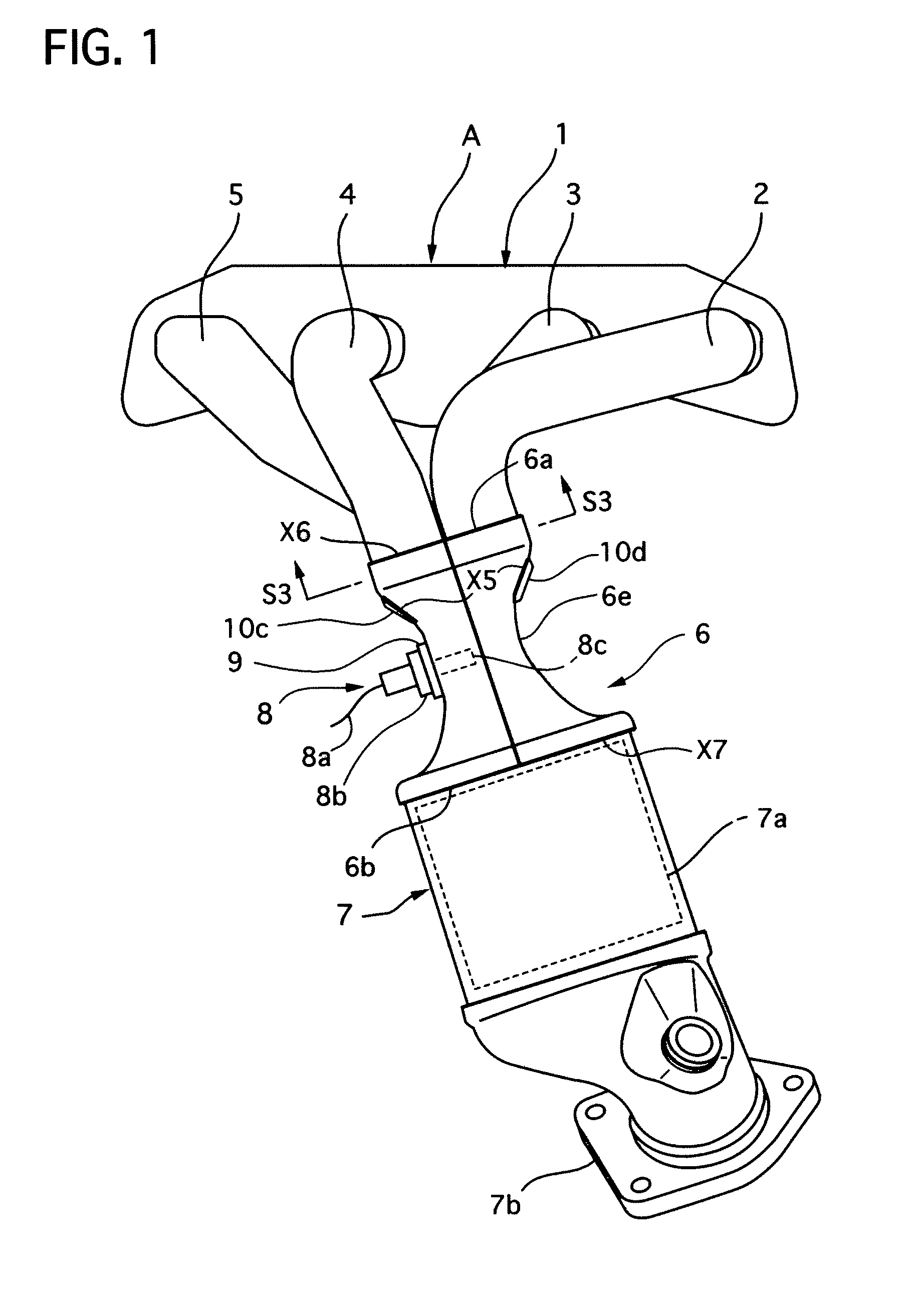

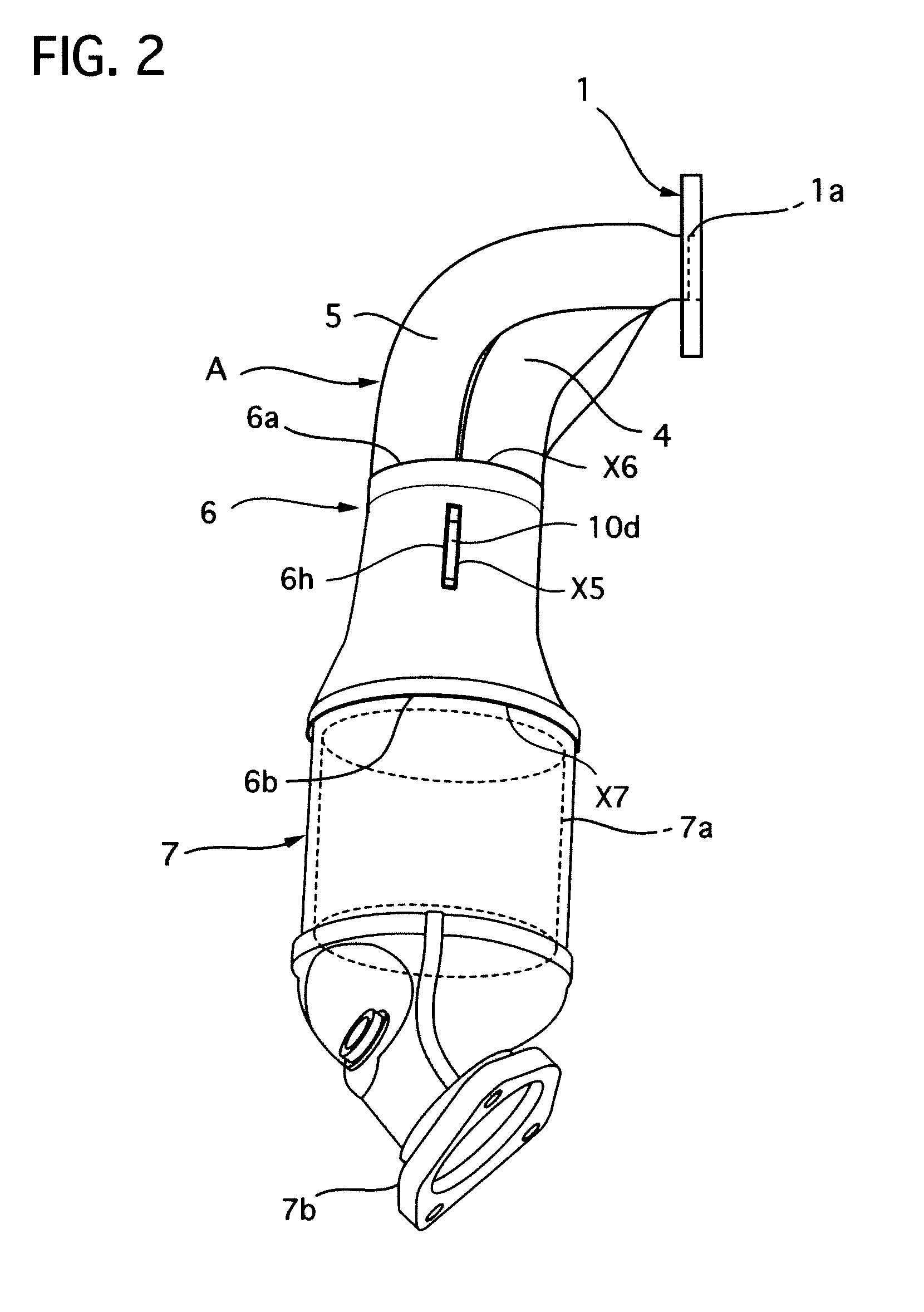

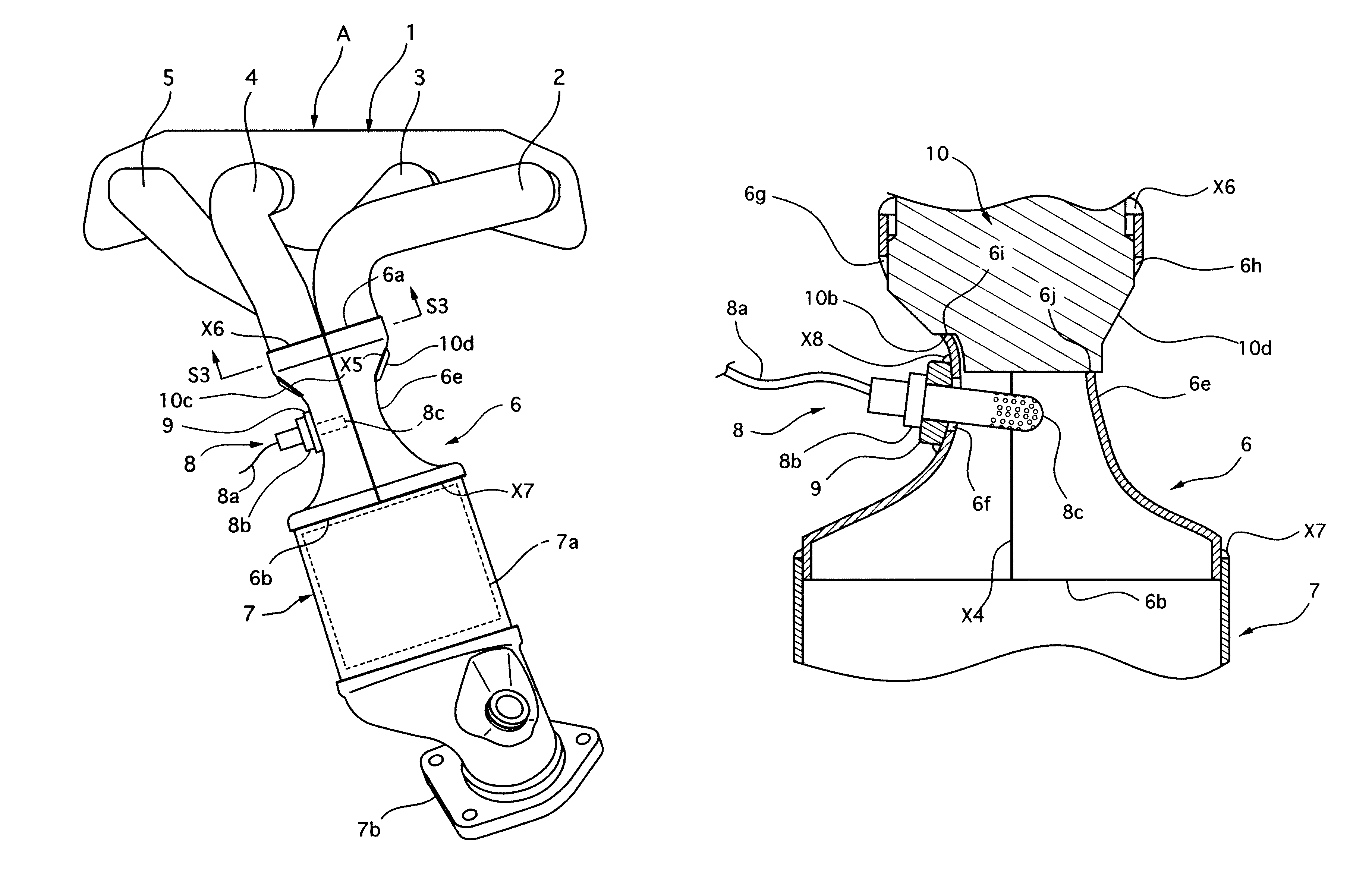

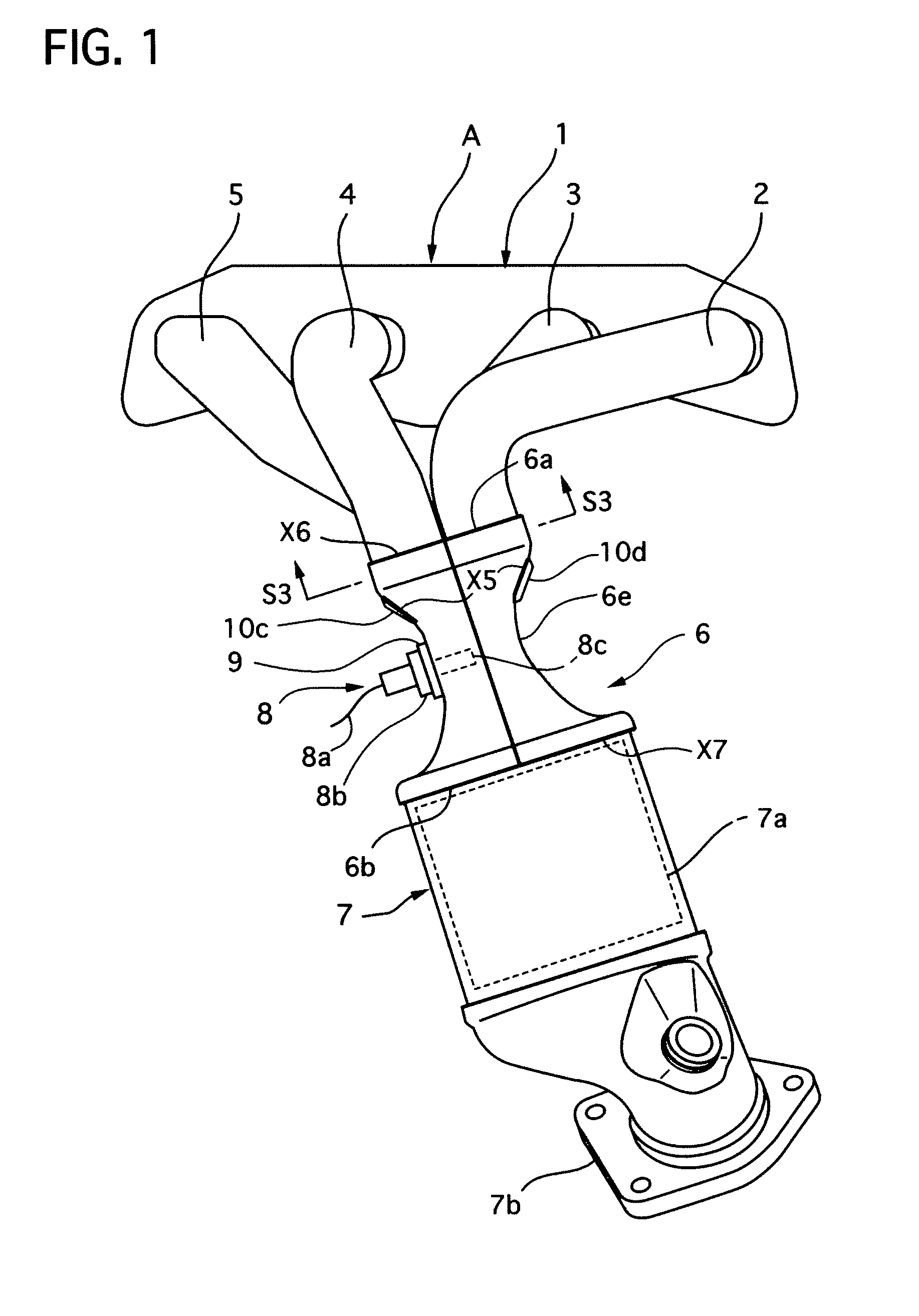

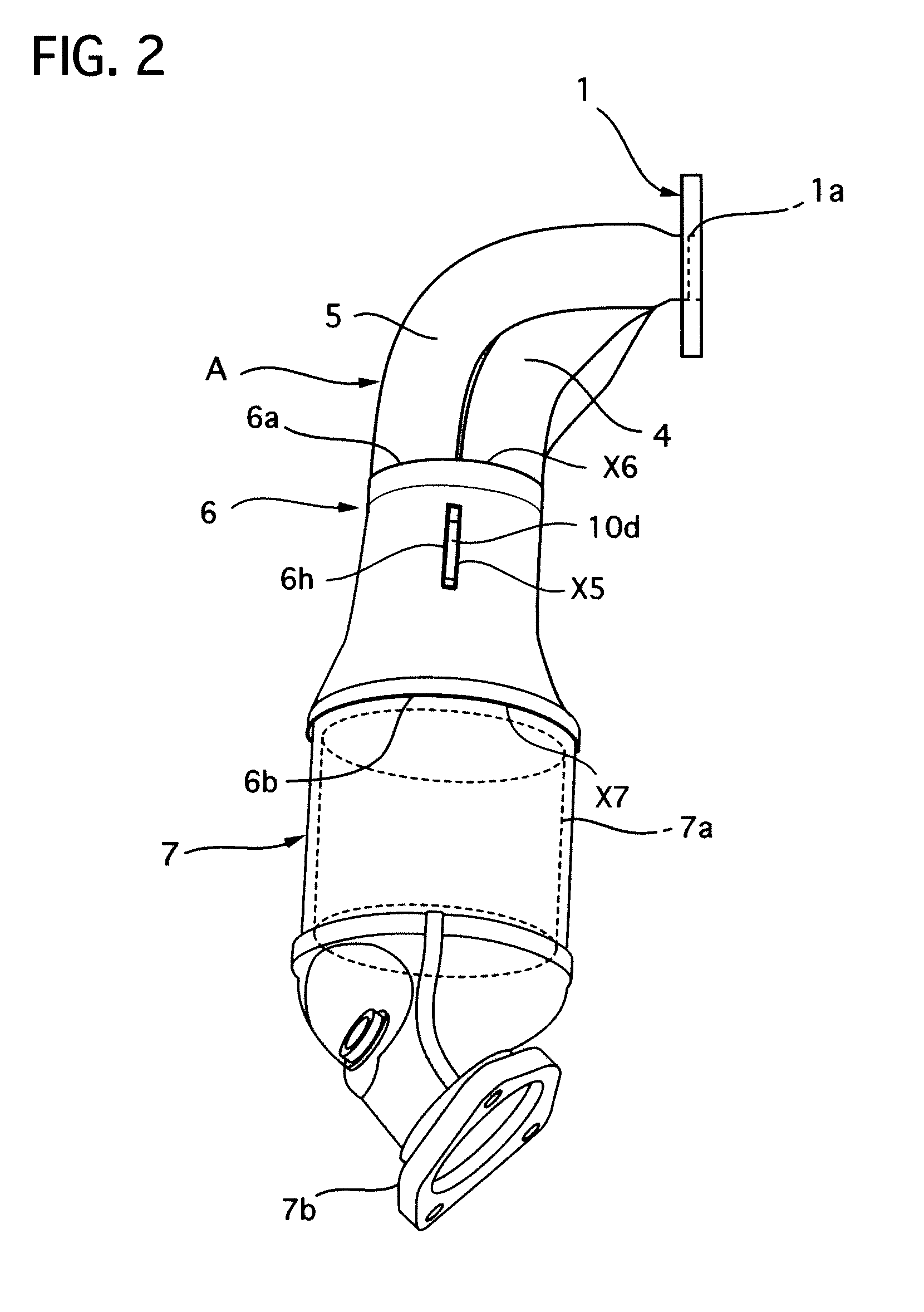

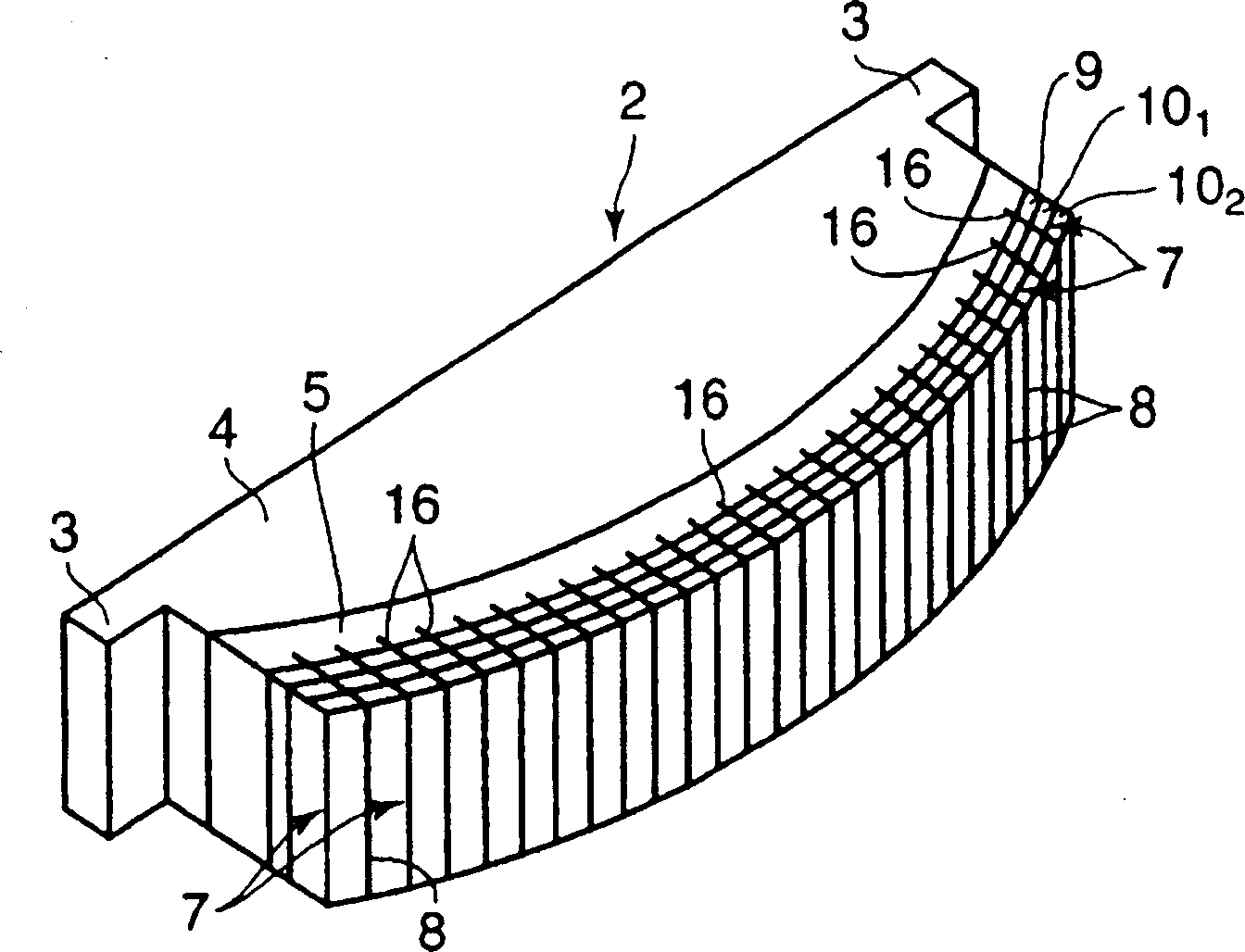

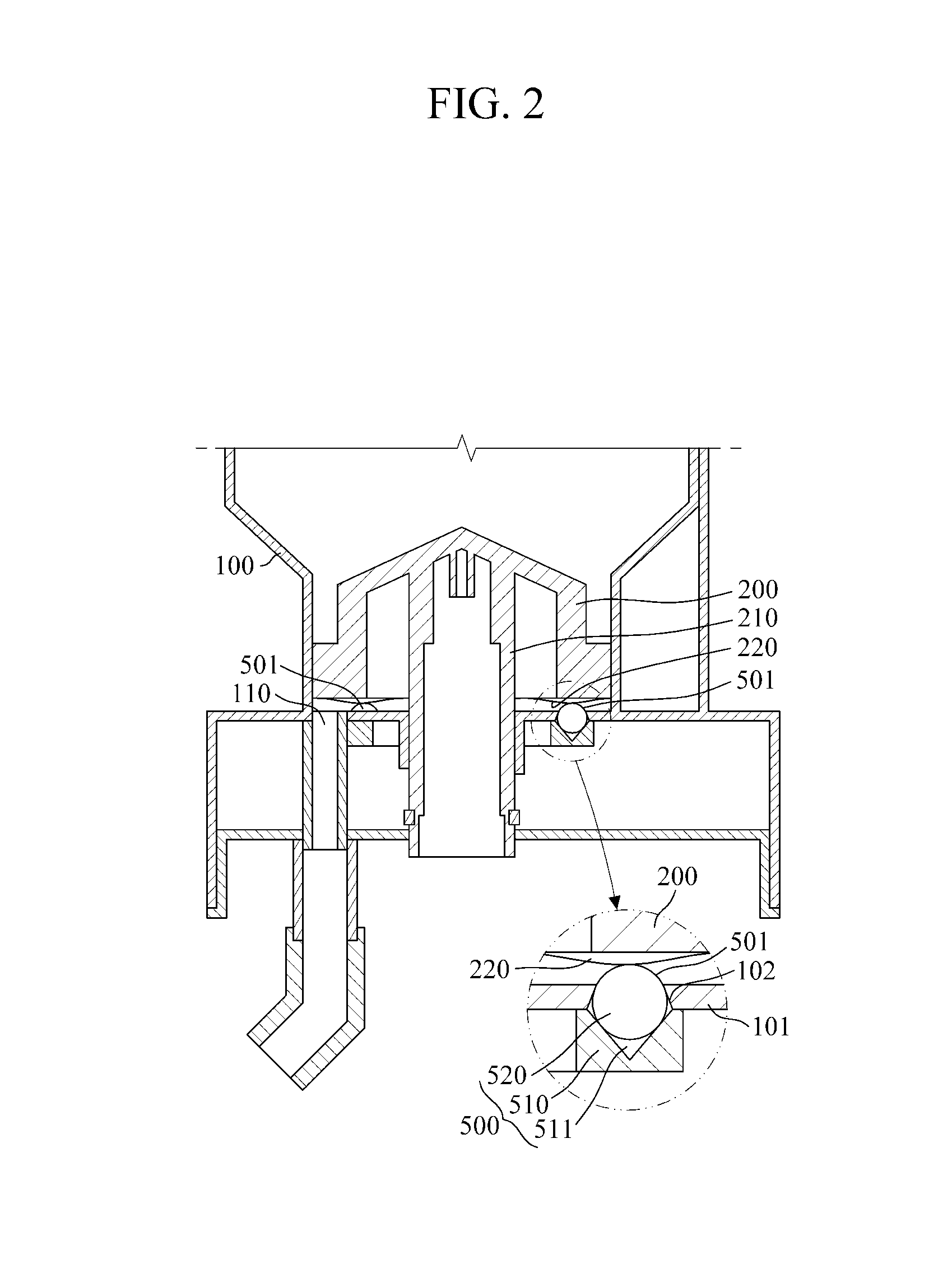

Collecting part structure of exhaust manifold

An exhaust manifold A includes, in its collecting part structure, a plurality of branch pipes 2 to 5 that are connected with a flange head 1, a collecting part 6 that collects and contains exhaust-gas downstream side end portions 2a to 5a of the branch pipes 2 to 5, a partition plate 10 that is arranged in a state where its exhaust-gas downstream side end portion 10a projects in the interior of the collecting part 6, and a sensor attachment boss part 9 that is fixed by weld line X on a part of an outer circumferential portion of the collecting part 6 in a state where it faxes an insertion hole 6f formed in the collecting part 6. Insertion holes 6g and 6h are formed in a reduced diameter portion 6e of the collecting part 6 of the exhaust manifold A, and the partition plate 10 is fixed by a weld line X5 with a portion of the outer circumferential portion of the collecting part 6 in a state where portions 10c and 10d of both end portion of the partition plate 10 are inserted in and positioned to the insertion holes 6g and 6h.

Owner:CALSONIC KANSEI CORP

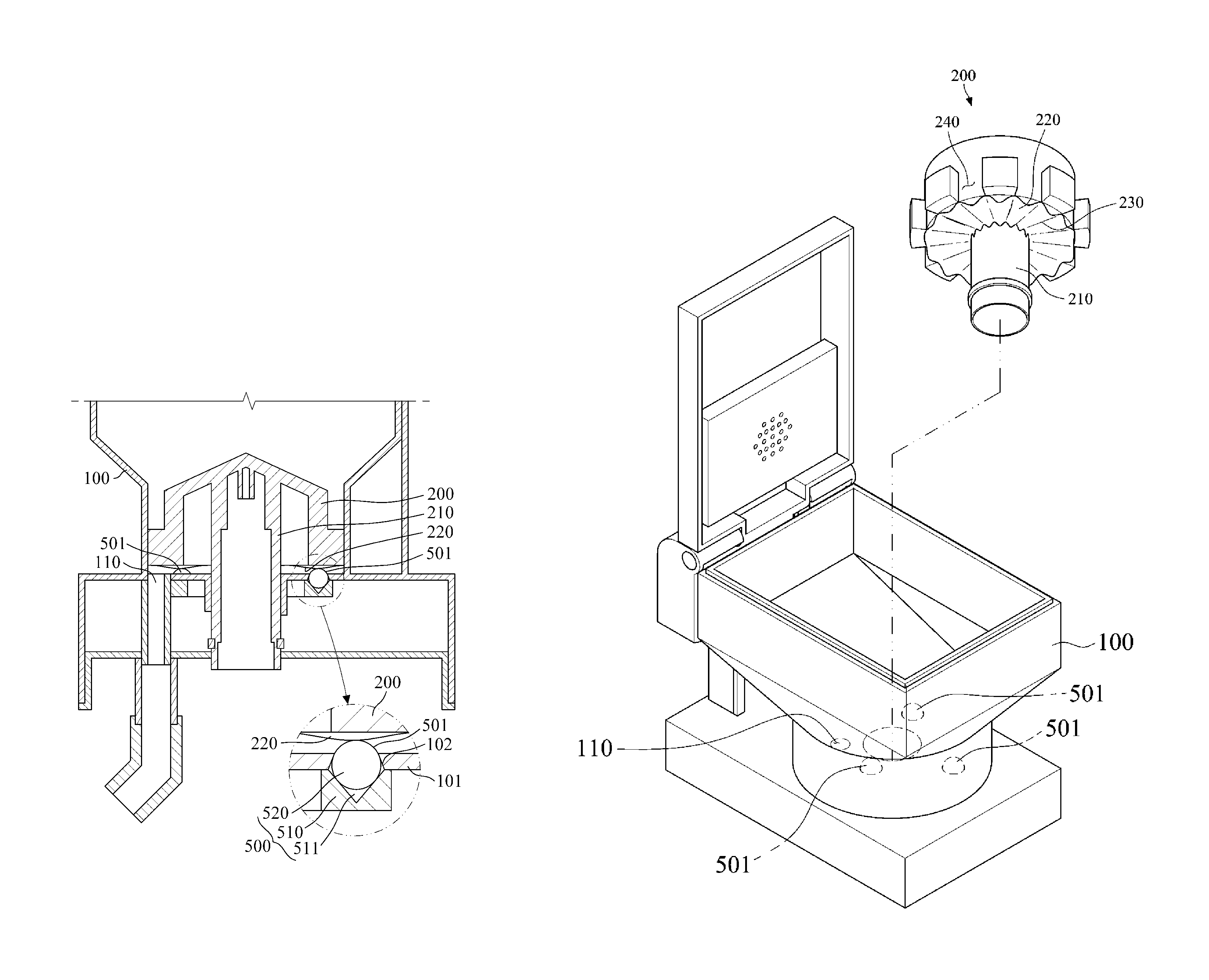

Cartridge for medication dispensing apparatus having roll-rotating drum

InactiveUS9238545B2Ease concentrationSmall article dispensingCoin-freed apparatus detailsEngineeringMechanical engineering

There is provided a cartridge for a medication dispensing apparatus having a roll-rotating drum, the cartridge including a cartridge case having an open outlet formed on a bottom thereof so as to dispense medication; a drum installed inside of the cartridge case so as to selectively open and / or close the outlet; and a cartridge base having the cartridge case installed thereto, wherein projections projected downward and grooves recessed upward are formed on a bottom of the drum, alternatively, and a concave-convex part having protruding portion protruding upward are formed on a bottom surface of the cartridge case at intervals.

Owner:LCK +1

Collecting part structure of exhaust manifold

An exhaust manifold A includes, in its collecting part structure, a plurality of branch pipes 2 to 5 that are connected with a flange head 1, a collecting part 6 that collects and contains exhaust-gas downstream side end portions 2a to 5a of the branch pipes 2 to 5, a partition plate 10 that is arranged in a state where its exhaust-gas downstream side end portion 10a projects in the interior of the collecting part 6, and a sensor attachment boss part 9 that is fixed by weld line X on a part of an outer circumferential portion of the collecting part 6 in a state where it faxes an insertion hole 6f formed in the collecting part 6. Insertion holes 6g and 6h are formed in a reduced diameter portion 6e of the collecting part 6 of the exhaust manifold A, and the partition plate 10 is fixed by a weld line X5 with a portion of the outer circumferential portion of the collecting part 6 in a state where portions 10c and 10d of both end portion of the partition plate 10 are inserted in and positioned to the insertion holes 6g and 6h.

Owner:CALSONIC KANSEI CORP

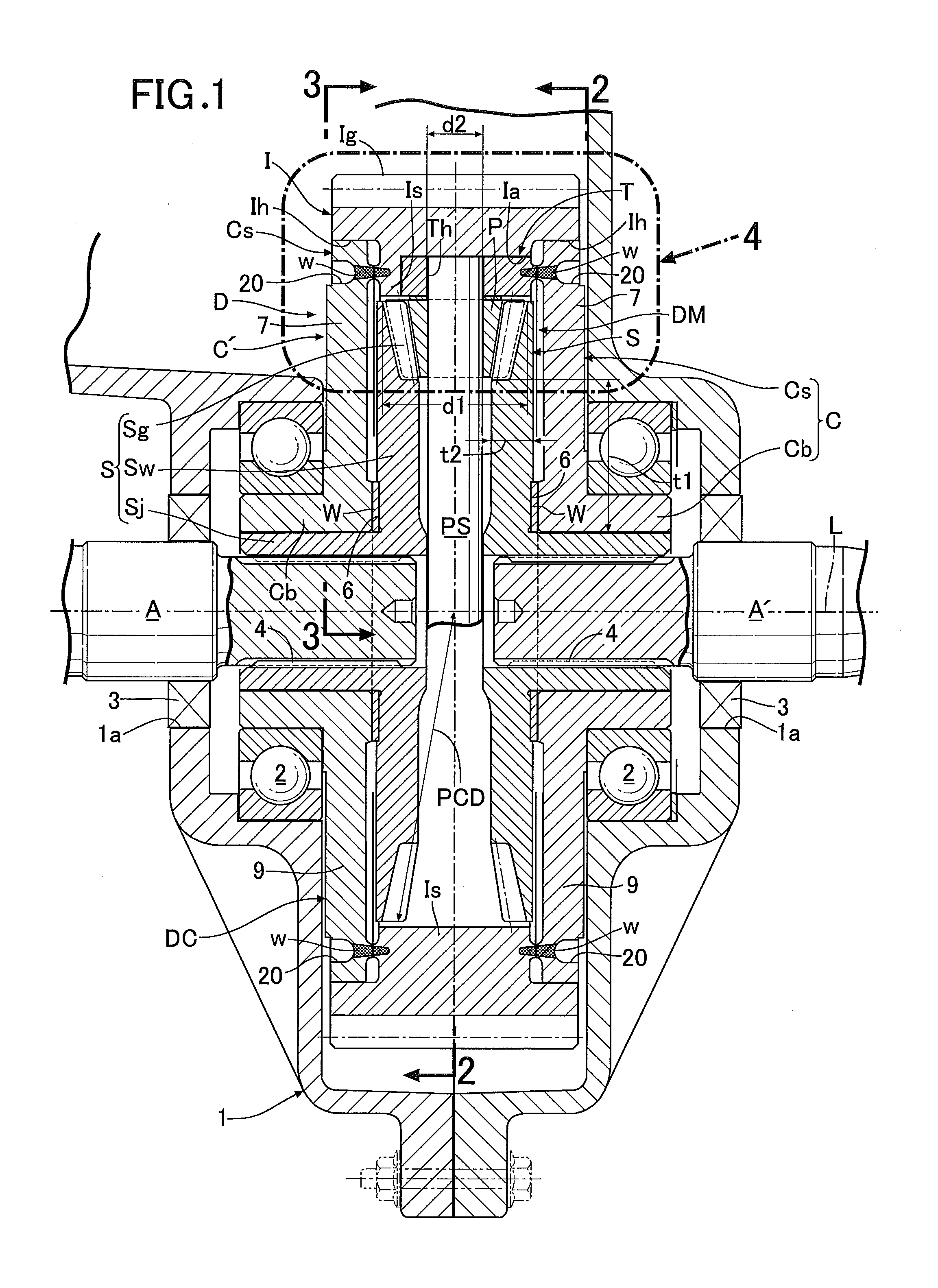

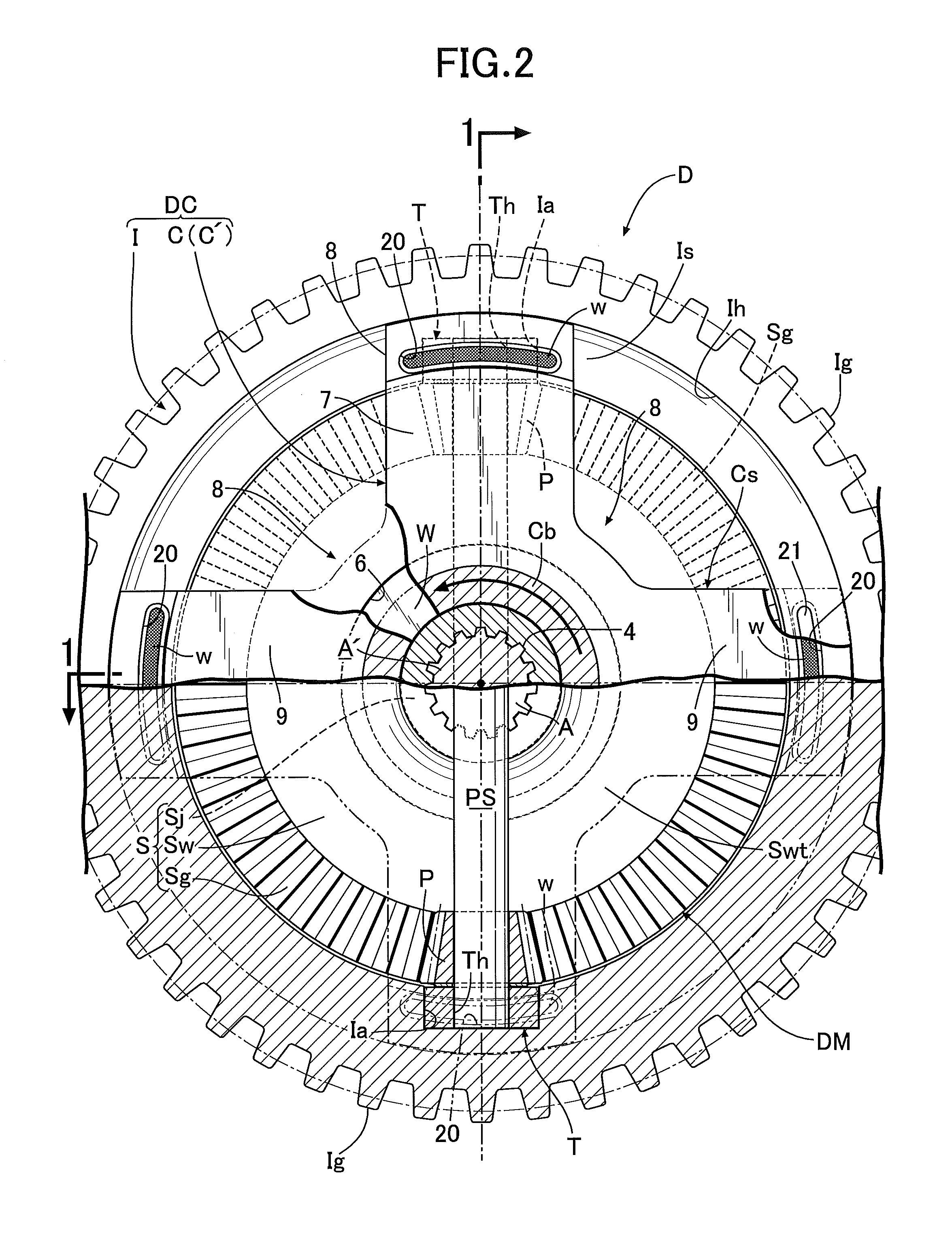

Differential device

InactiveUS20160169360A1Prevent occurrenceAvoid assemblyDifferential gearingsExternal connectionEngineering

To prevent decrease in assembling precision of the differential device and enable avoiding decrease in transmission efficiency even when a tooth portion is formed in an outer peripheral portion of an input member. The differential device includes: a differential case; and a differential mechanism housed in the differential case and distributively transmitting rotational force of the differential case to a pair of mutually-independent output shafts. The differential case includes the input member including an input part which receives the rotational force, an end portion of the input member on at least one side in an axial direction thereof being opened, and at least one cover portion covering the opened end portion of the input member on the one side in the axial direction. The input member includes a fitting hole opened in an outer side surface of the input member, an outer peripheral portion of the cover portion being fitted in the fitting hole, and a support wall portion facing an inner side surface of the cover portion fitted in the fitting hole. The cover portion and the support wall portion are joined together by lap welding from outside of the cover portion, in a position separating inward in a radial direction of the input member from a fitting portion between the fitting hole and the cover portion.

Owner:MUSA PRECISION IND CO LTD

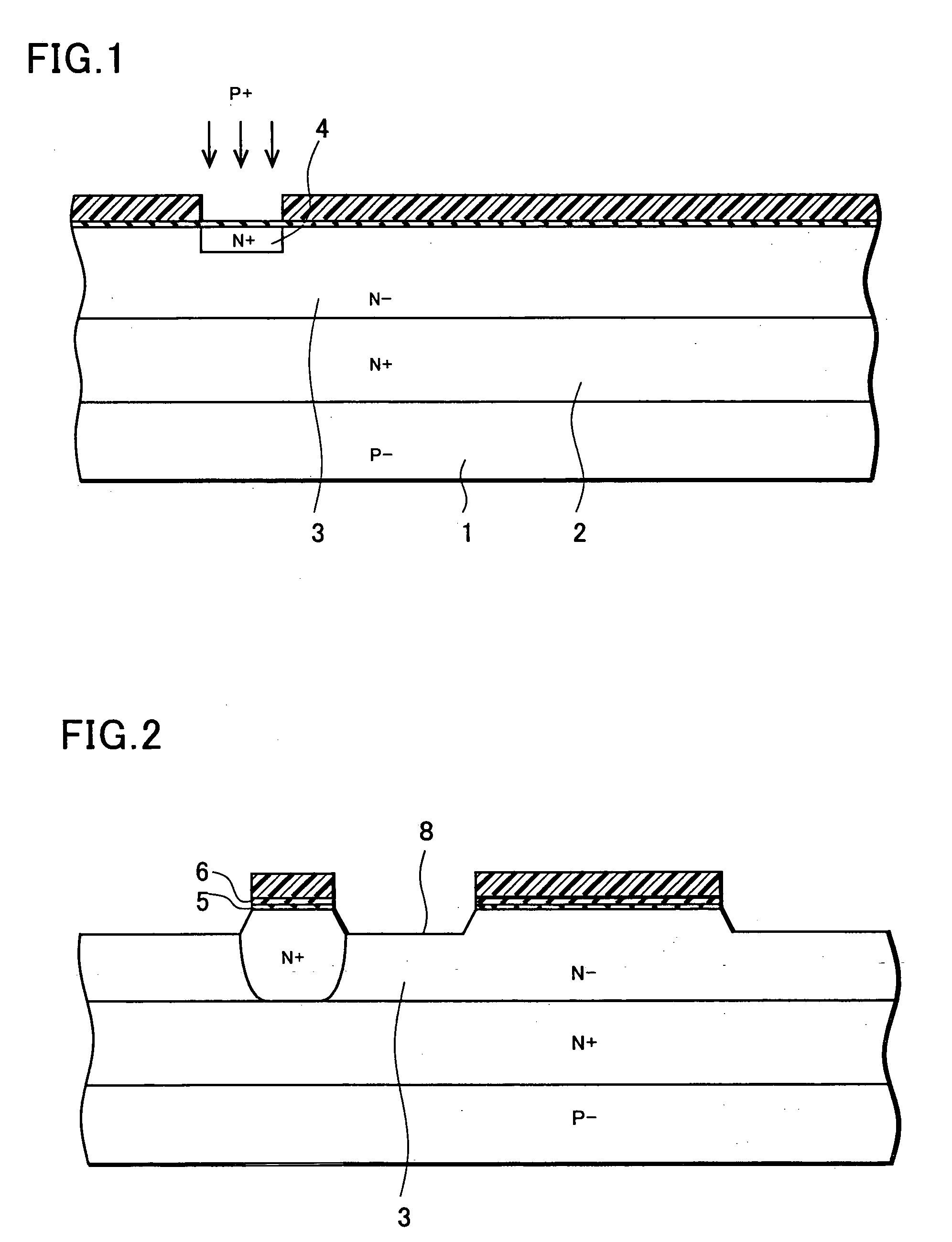

Semiconductor apparatus and method of manufacturing the same

ActiveUS20060102953A1Decrease breakdown toleranceReduce in sizeTransistorSolid-state devicesPrincipal planeSemiconductor

A semiconductor apparatus includes a semiconductor substrate of a first conductivity type, a base region of a second conductivity type formed on a principal surface of the semiconductor substrate, a trench formed in a periphery of the base region, and an endless source region of the first conductivity type formed on a surface of the base region along the trench. In this semiconductor apparatus, the principal planes on side surfaces of the trench are composed of planes [100] and [110]. The interior angle of intersection of adjacent side surfaces of the trench is 135°. A minimum distance between the base region and the plane [110] facing each other through the source region is shorter than a minimum distance between the base region and the plane [100] facing each other through the source region.

Owner:RENESAS ELECTRONICS CORP

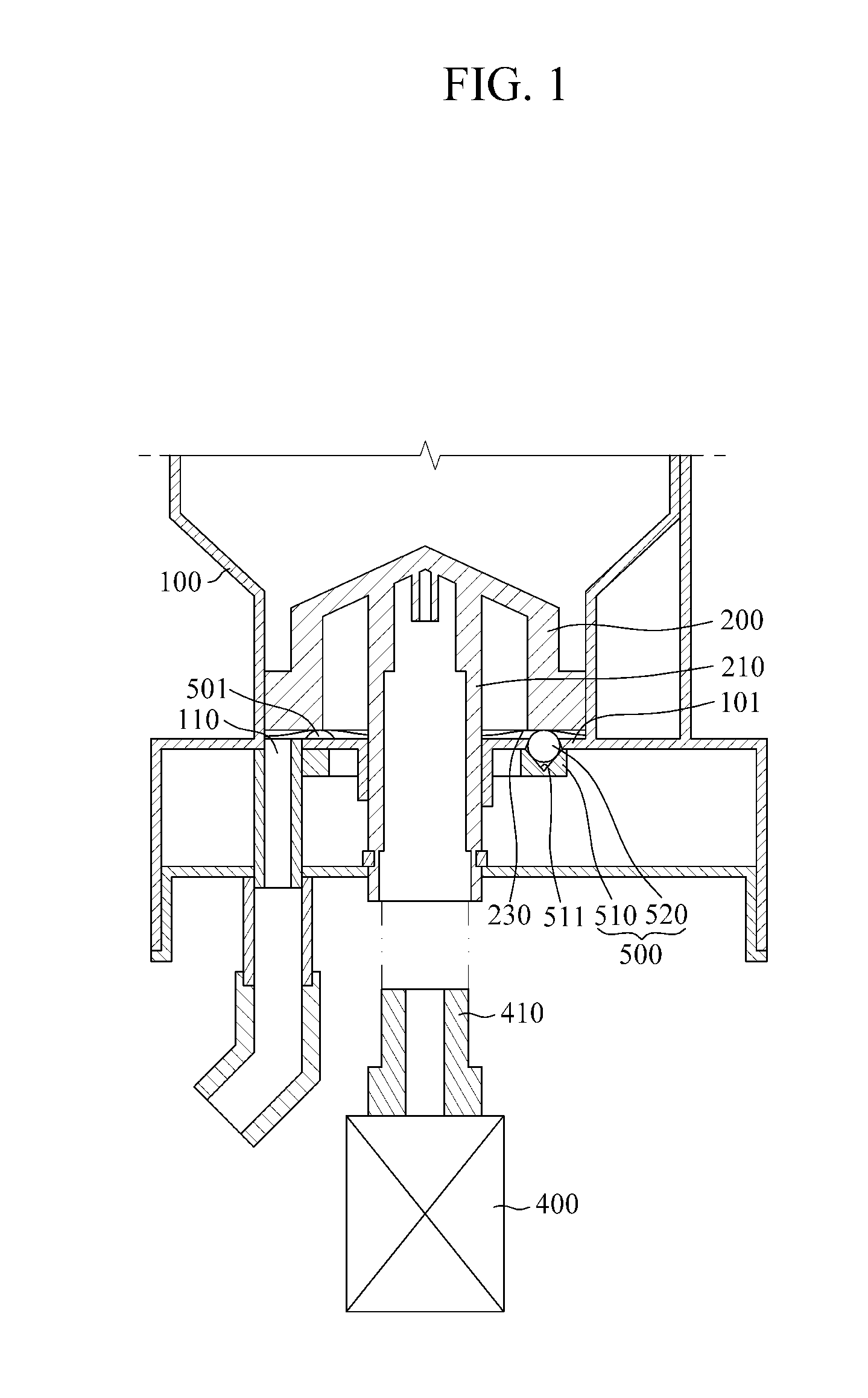

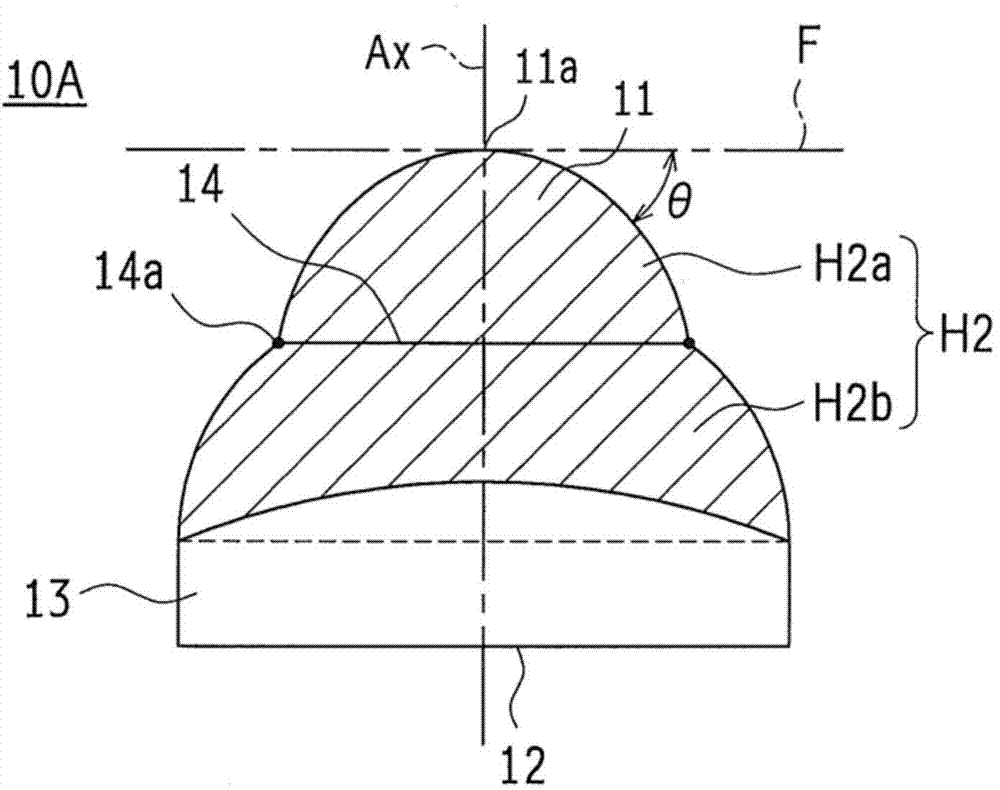

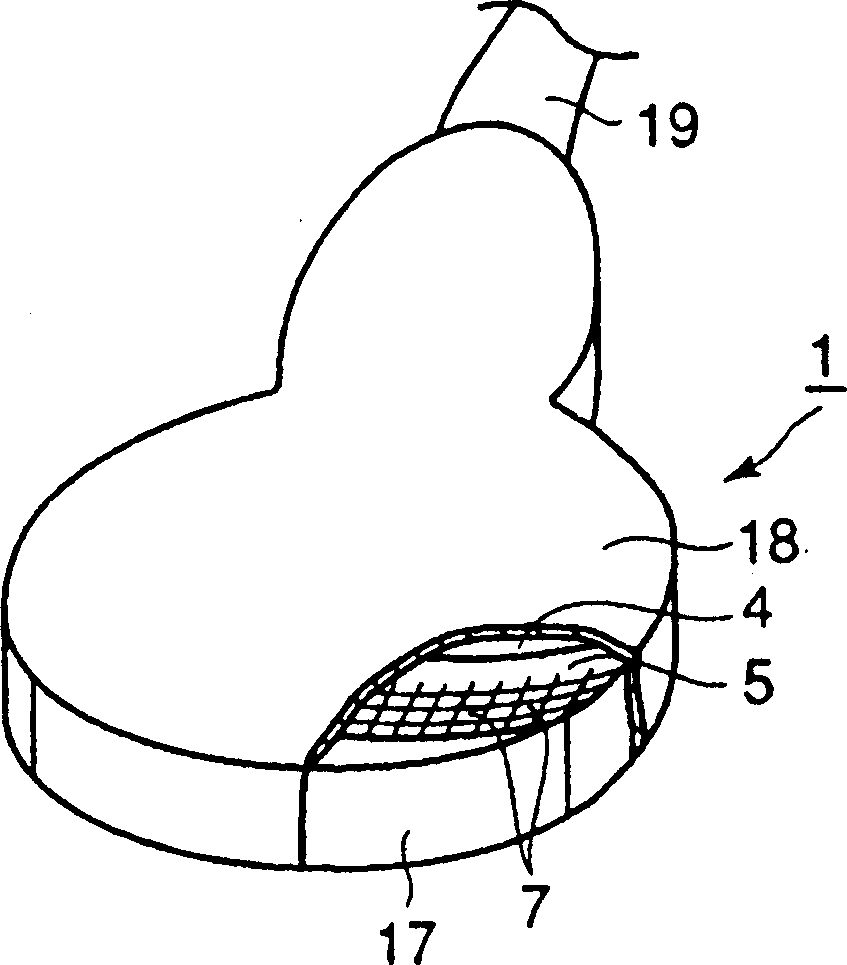

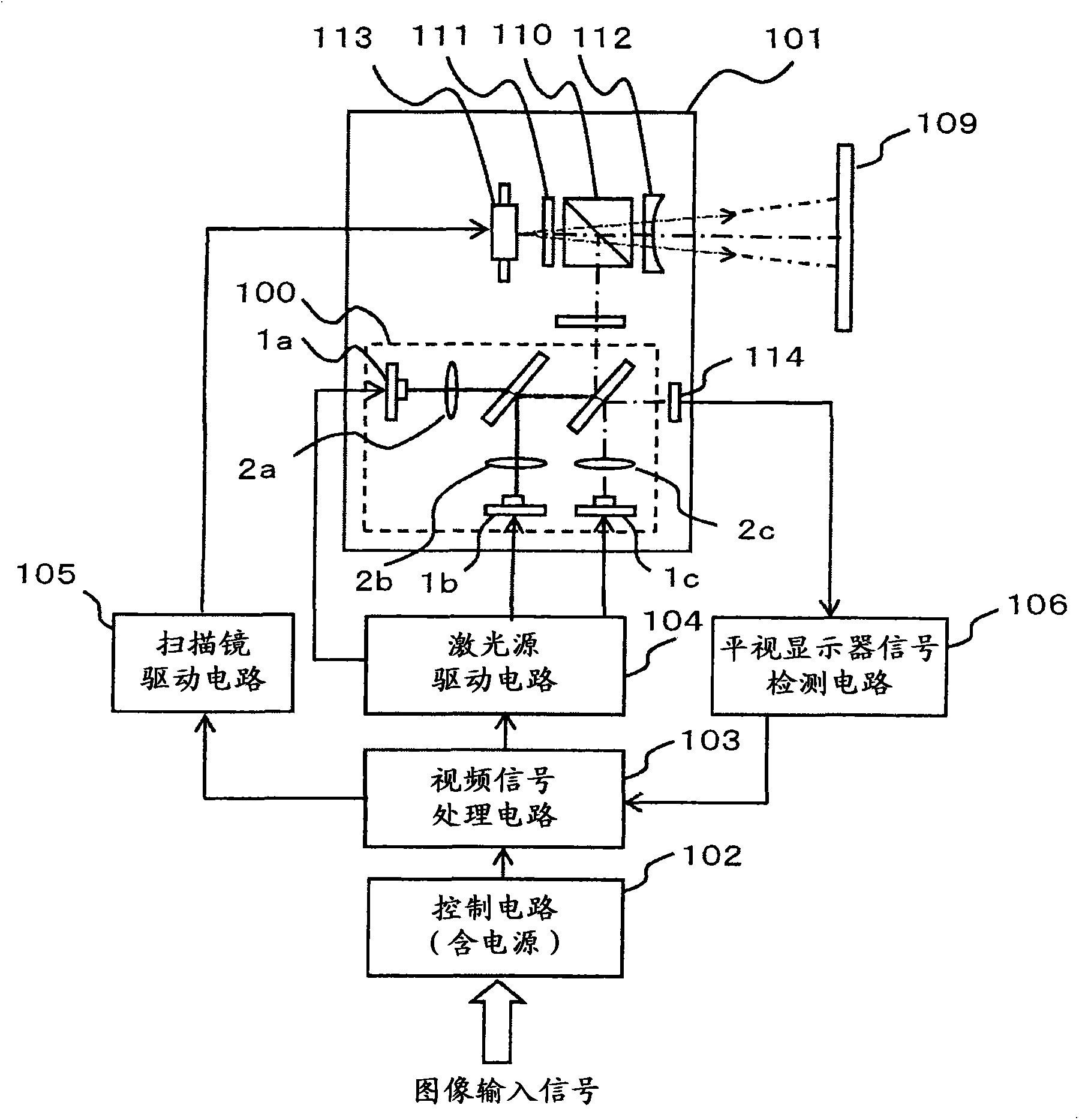

Secondary lens, solar cell mounting body, light gathering solar energy unit, light gathering solar energy device, and light gathering solar energy module

InactiveCN104205620AEase concentrationImprove power generation efficiencyPhotovoltaicsPhotovoltaic energy generationOptical axisLight beam

Provided is a secondary lens (10A), comprising a first face (11) whereby a gathered light beam from a light gathering lens enters, and a second face (12) which emits the gathered light beam from the light gathering lens toward a solar cell, said secondary lens (10A) guiding entry light to the solar cell by an optical refraction face (H2) which is disposed in the first face (11). A cross-section area of a direction which is perpendicular to an optical axis (Ax) of the gathered light beam of the first face (11) monotonically increases approaching the solar cell side from the light gathering lens side, and there is at least one inflection point (14a) whereat an oblique angle (theta) with respect to the plane of the direction which is perpendicular to the optical axis of the first face (11) declines approaching the solar cell side from the light gathering lens side.

Owner:SHARP KK

Convex ultrasonic probe and ultrasonic diagnostic apparatus

InactiveCN1892211AAttenuation of ultrasonic wavesSuppresses sensitivity fluctuationsUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringUltrasound probe

The invention provides a convex ultrasonic probe which can sufficiently damp ultrasonic waves heading for the back side from the piezoelectric elements of a plurality of channels in a backing member having a convex curved surface, has a good heat dissipation property and can lessen the concentration of generated heat. The convex ultrasonic probe is characterised by that it has the backing member including a plurality of channels arranged at required intervals and having the piezoelectric elements and sound matching layers formed on the piezoelectric elements, a supporting body having a convex curved surface and heat conductivity of 70 W / m*K or higher, a sheetlike sound absorbing layer whose entire thickness is uniform, which is stuck to the convex curved surface of the supporting body, on which the piezoelectric elements of the channels are mounted, and has grooves formed in the positions corresponding to the spaces of the channels and has a uniform thickness, and sonic lenses formed on the sound matching layers of the channels. When the thickness of the sound absorbing layer is t1 and the thickness of the piezoelectric elements is t2, the probe satisfies the relation of t1 / t2=6 to 20.

Owner:KK TOSHIBA

Catridge for medication dispensing apparatus having roll-rotating drum

InactiveUS20140203036A1Ease concentrationSmall article dispensingAmpoulesDispensing medicationsMechanical engineering

There is provided a cartridge for a medication dispensing apparatus having a roll-rotating drum, the cartridge including a cartridge case having an open outlet formed on a bottom thereof so as to dispense medication; a drum installed inside of the cartridge case so as to selectively open and / or close the outlet; and a cartridge base having the cartridge case installed thereto, wherein projections projected downward and grooves recessed upward are formed on a bottom of the drum, alternatively, and a concave-convex part having protruding portion protruding upward are formed on a bottom surface of the cartridge case at intervals.

Owner:LCK +1

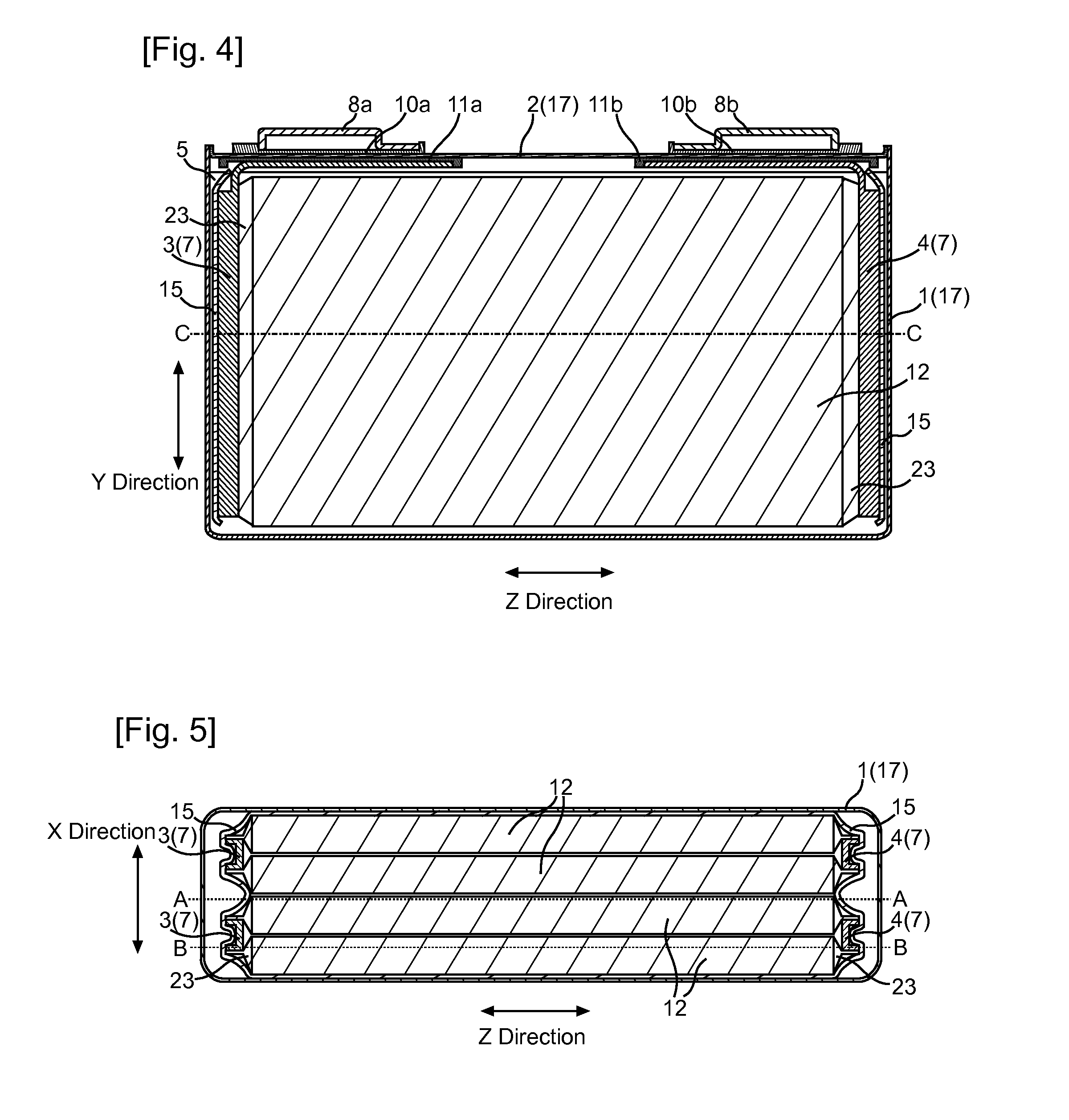

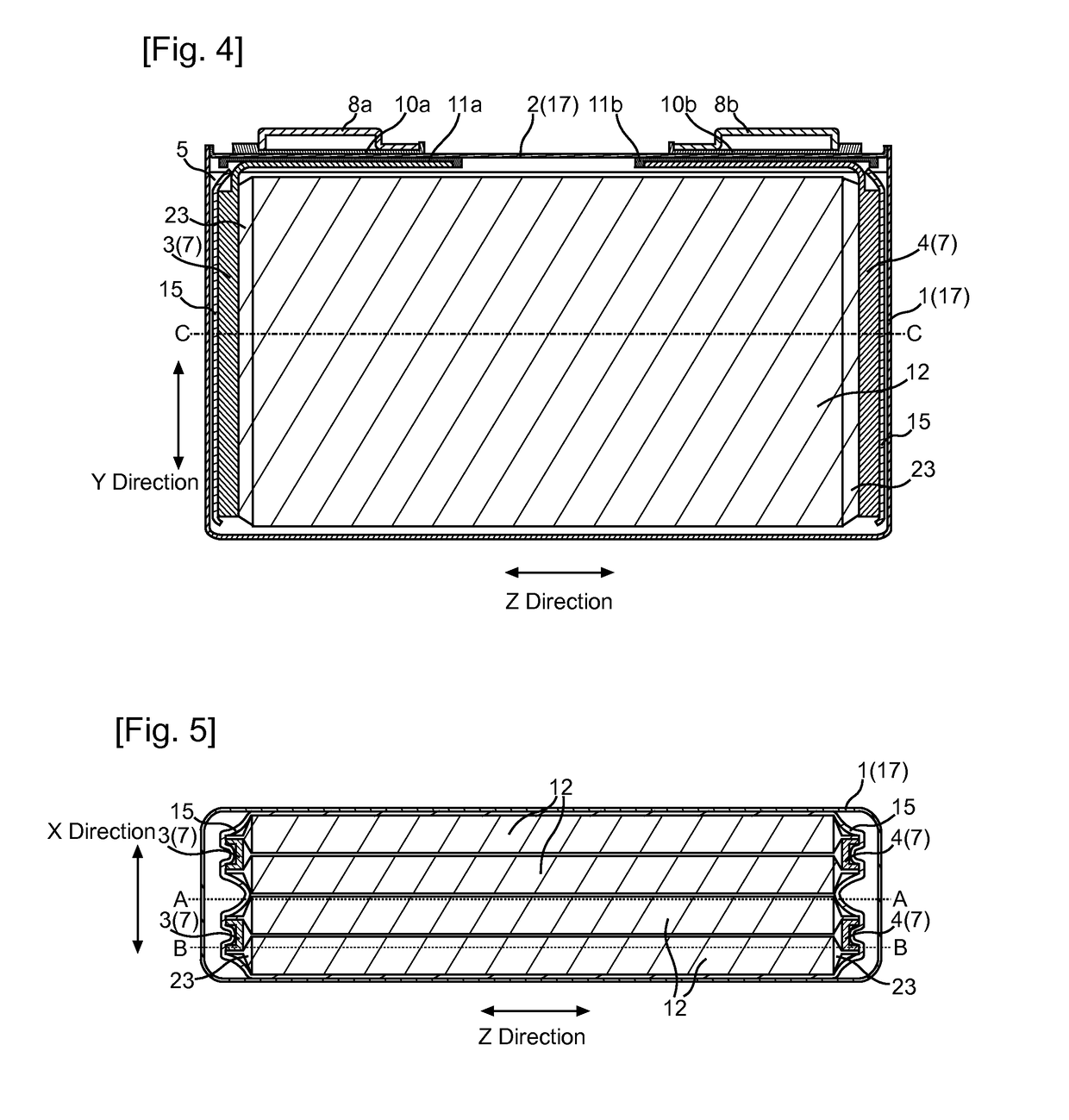

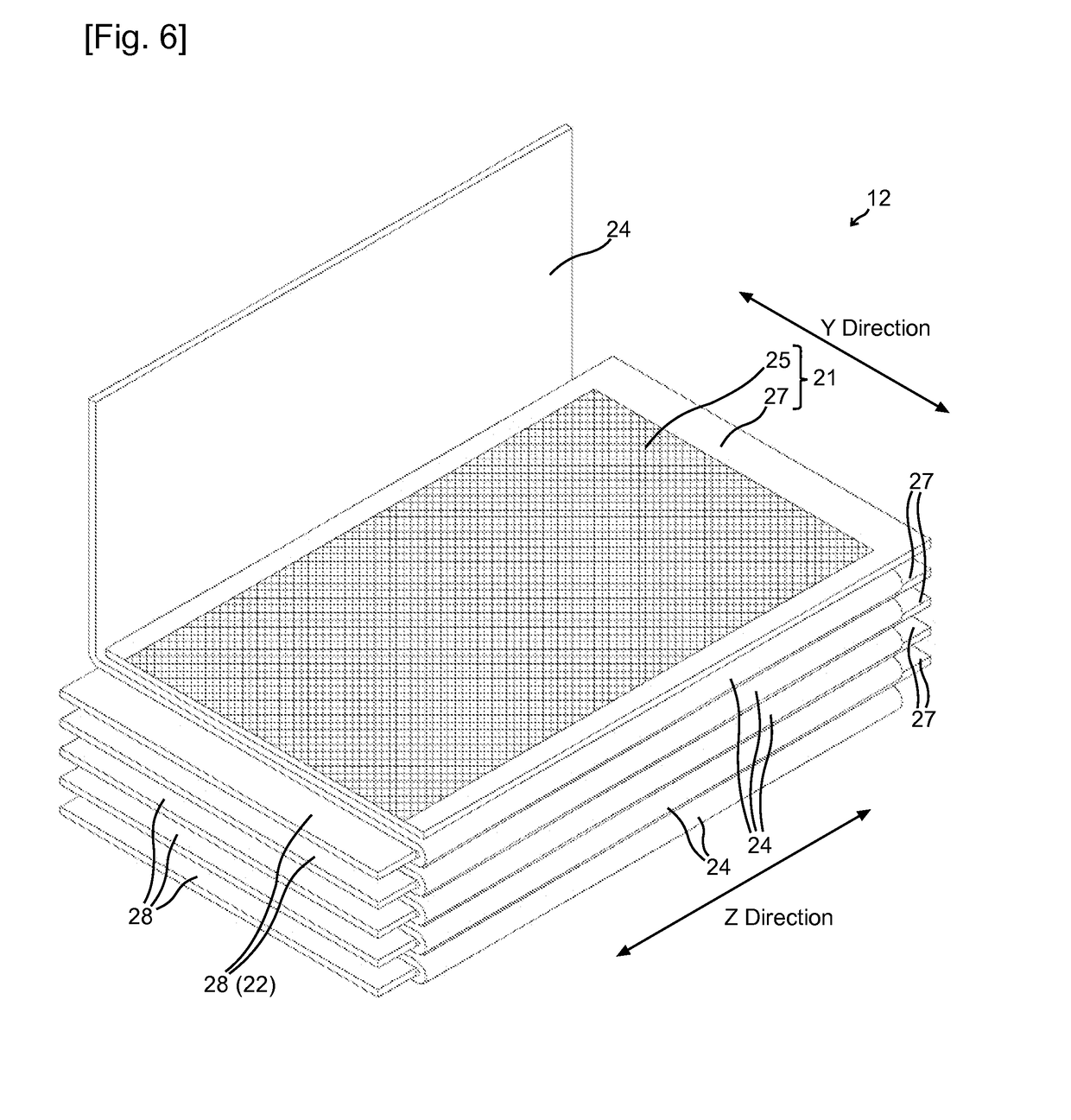

Non-aqueous electrolyte secondary battery and method for producing non-aqueous electrolyte secondary battery

ActiveUS20150318580A1Reduce pointsImprove battery safetyFinal product manufacturePrimary cellsEngineeringFire retardant

The present invention provides a non-aqueous electrolyte secondary battery that can suppress a drop in a flash point of an electrolyte solution even if the non-aqueous electrolyte secondary battery is used for a long time. The non-aqueous electrolyte secondary battery includes: an electrode body having a structure in which a positive electrode including a positive-electrode active material and a negative electrode including a negative-electrode active material are stacked with a separator interposed therebetween; a non-aqueous electrolyte solution containing a flame retardant; and an outer casing accommodating the electrode body and the non-aqueous electrolyte solution. The non-aqueous electrolyte solution in the electrode body has a flame retardant concentration lower than a flame retardant concentration in the non-aqueous electrolyte solution between the electrode body and the outer casing.

Owner:ELIIY POWER

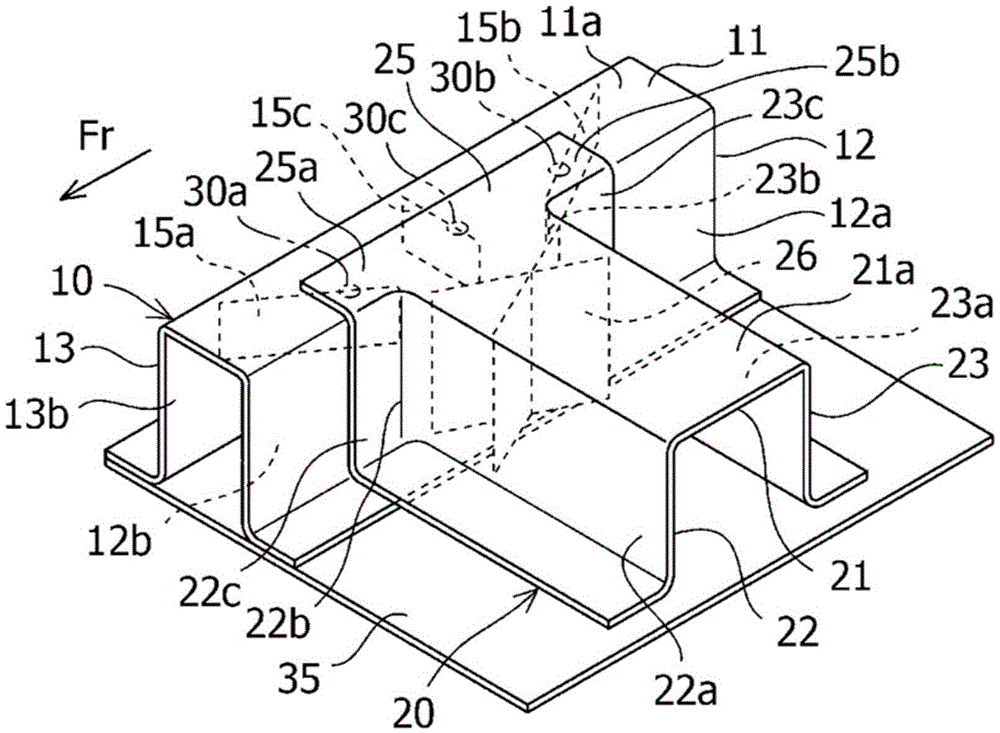

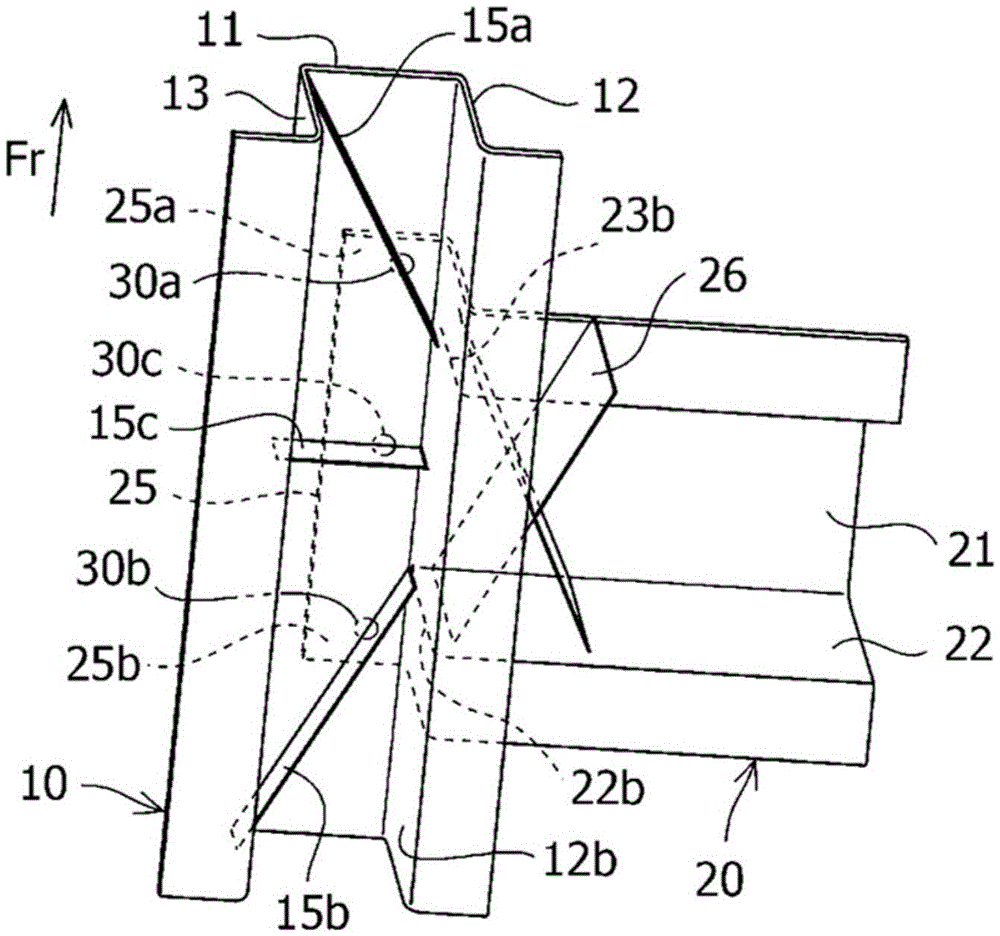

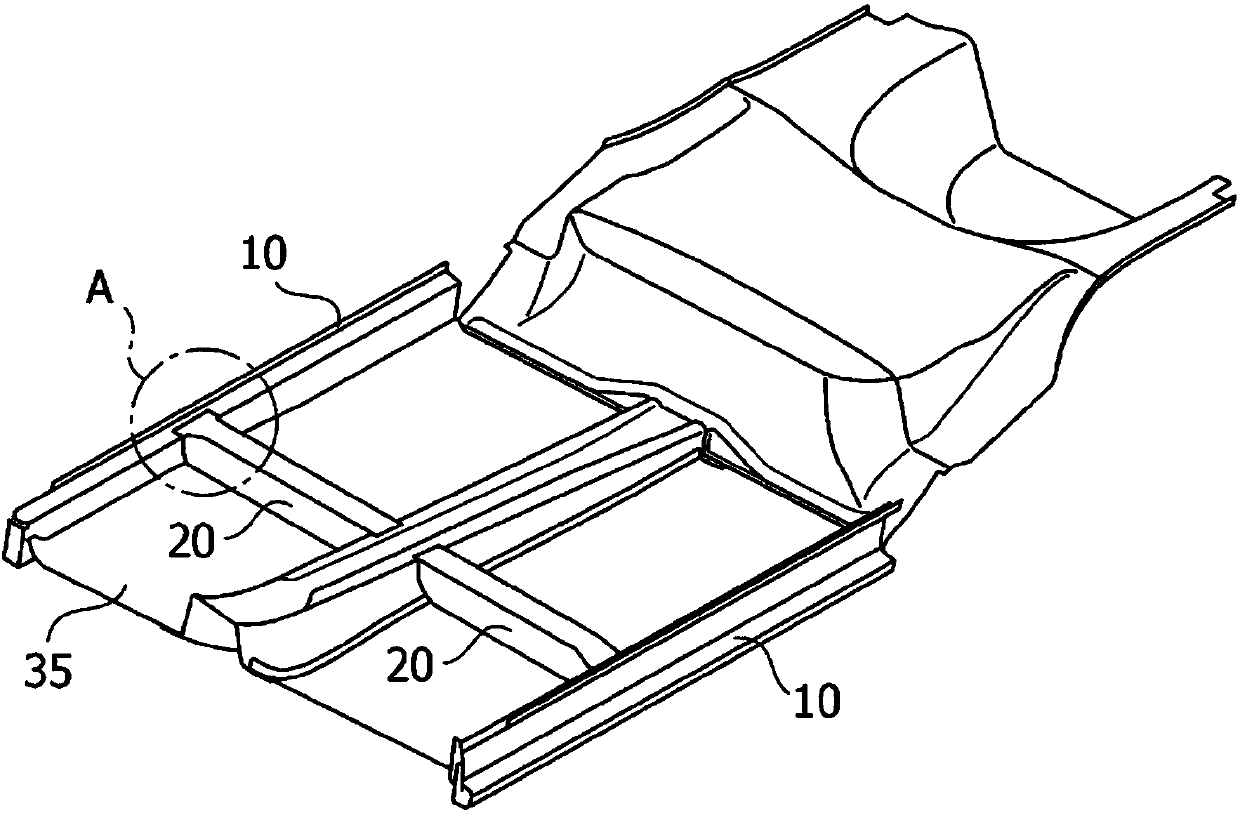

Joining structure

The present invention enables the rigidity of a bending load that acts on a T-shaped joining section to be improved. The joining structure has a second member 20 joined to a side section of the first member 10, forms a T shape, and has a first upper surface 11a and a flange 25 that are joined at a joining section 30. A long rib 15a is provided on the rear surface of the first upper surface 11a. The total length of the long rib 15a is set to at least twice the length to a joining section 30a from a contact section between the first member 10 and the second member 20. Of the angles formed between the extension directions of the long rib 15a and the longitudinal direction of the second member 20, the angle formed on the opposite side to the second member 20 is acute.

Owner:SUZUKI MOTOR CORP

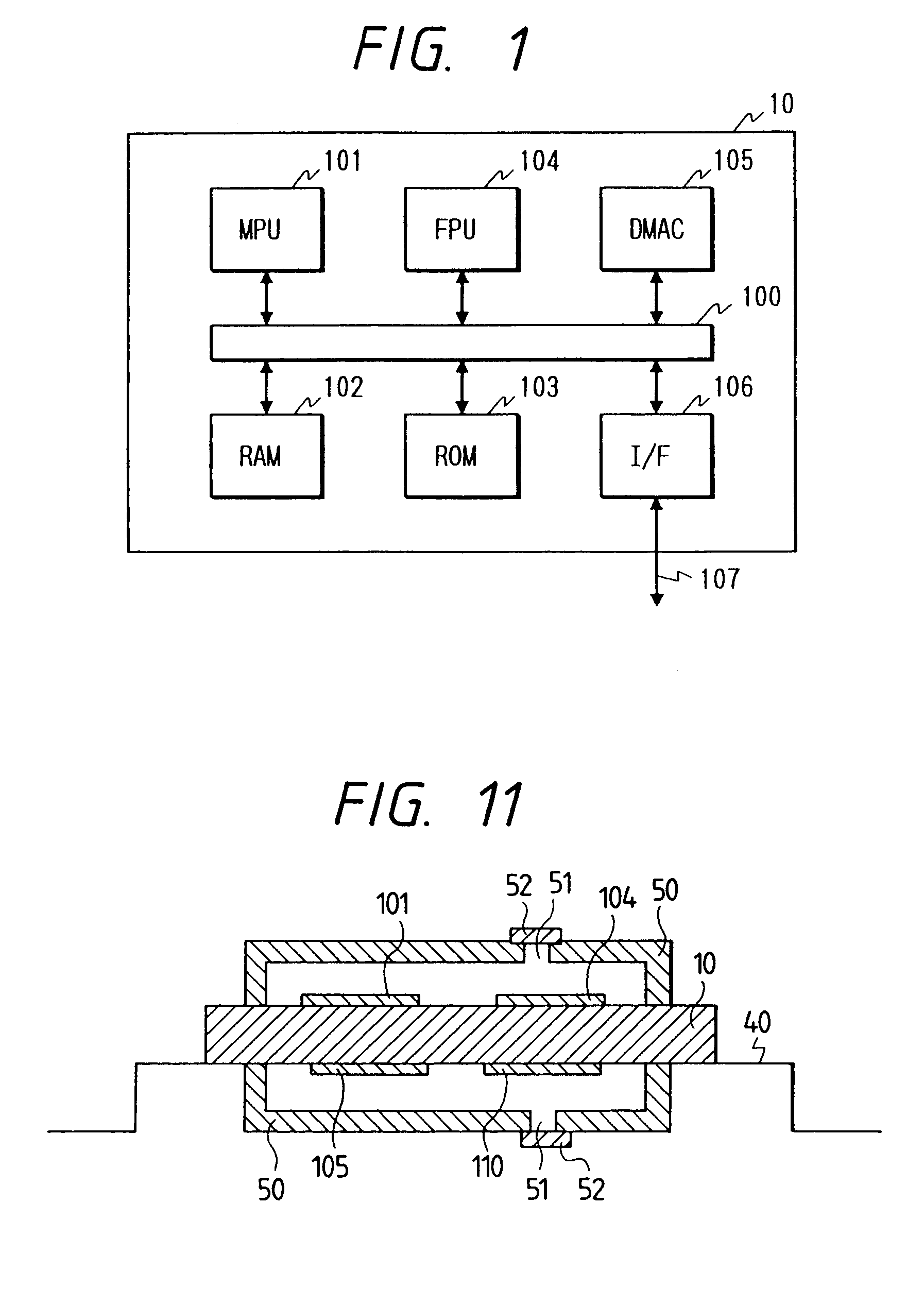

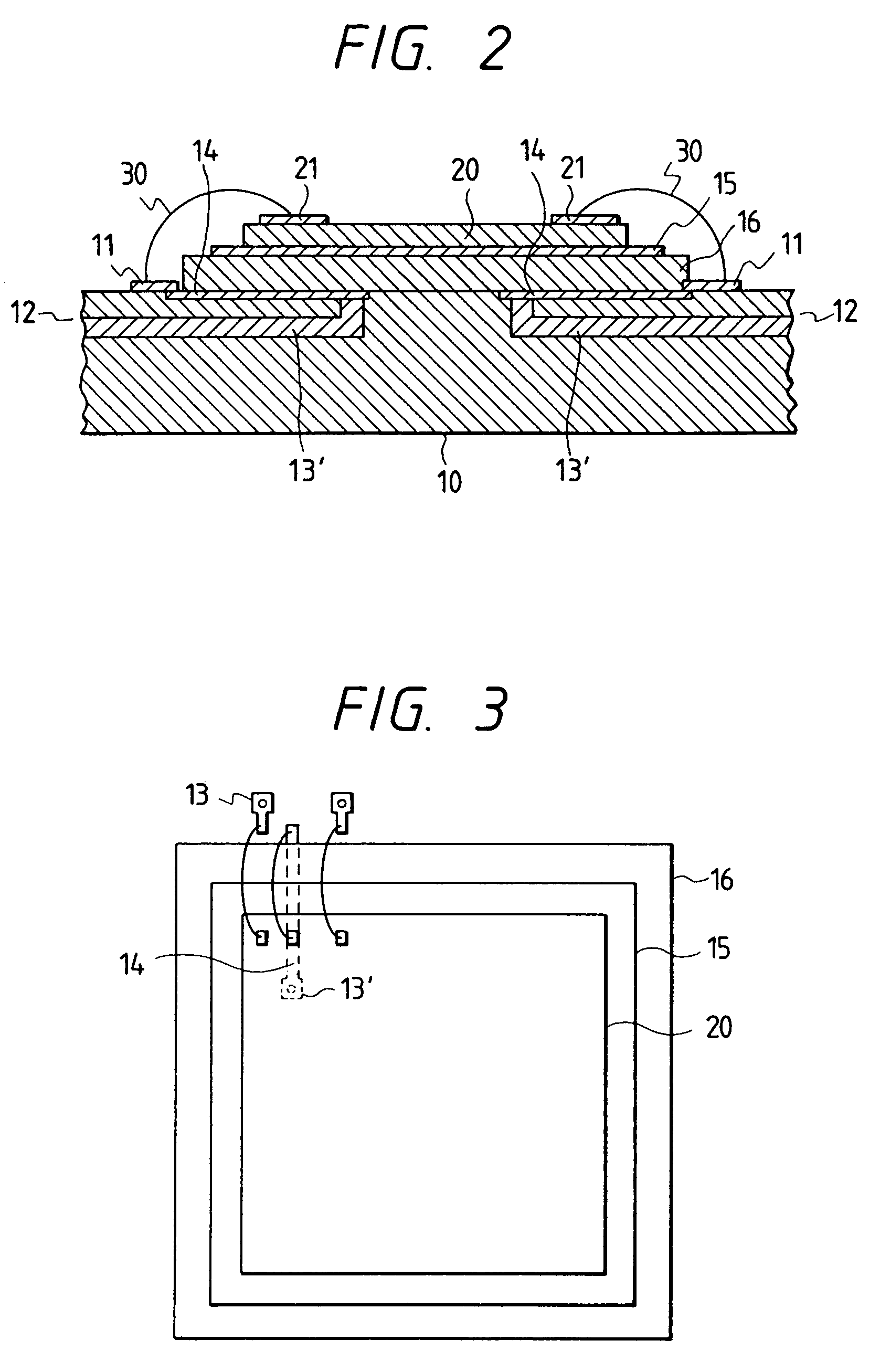

Electronic circuit package

InactiveUS7120069B2Improve reliabilityIncrease in sizeSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

An electronic apparatus which includes a wiring substrate which includes wiring conductors, and a plurality of semiconductor bare chips that are formed on the wiring substrate. The semiconductor bare chips include a processor for processing data and a circuit having a checking function for detecting faults of the processor.

Owner:RISING SILICON

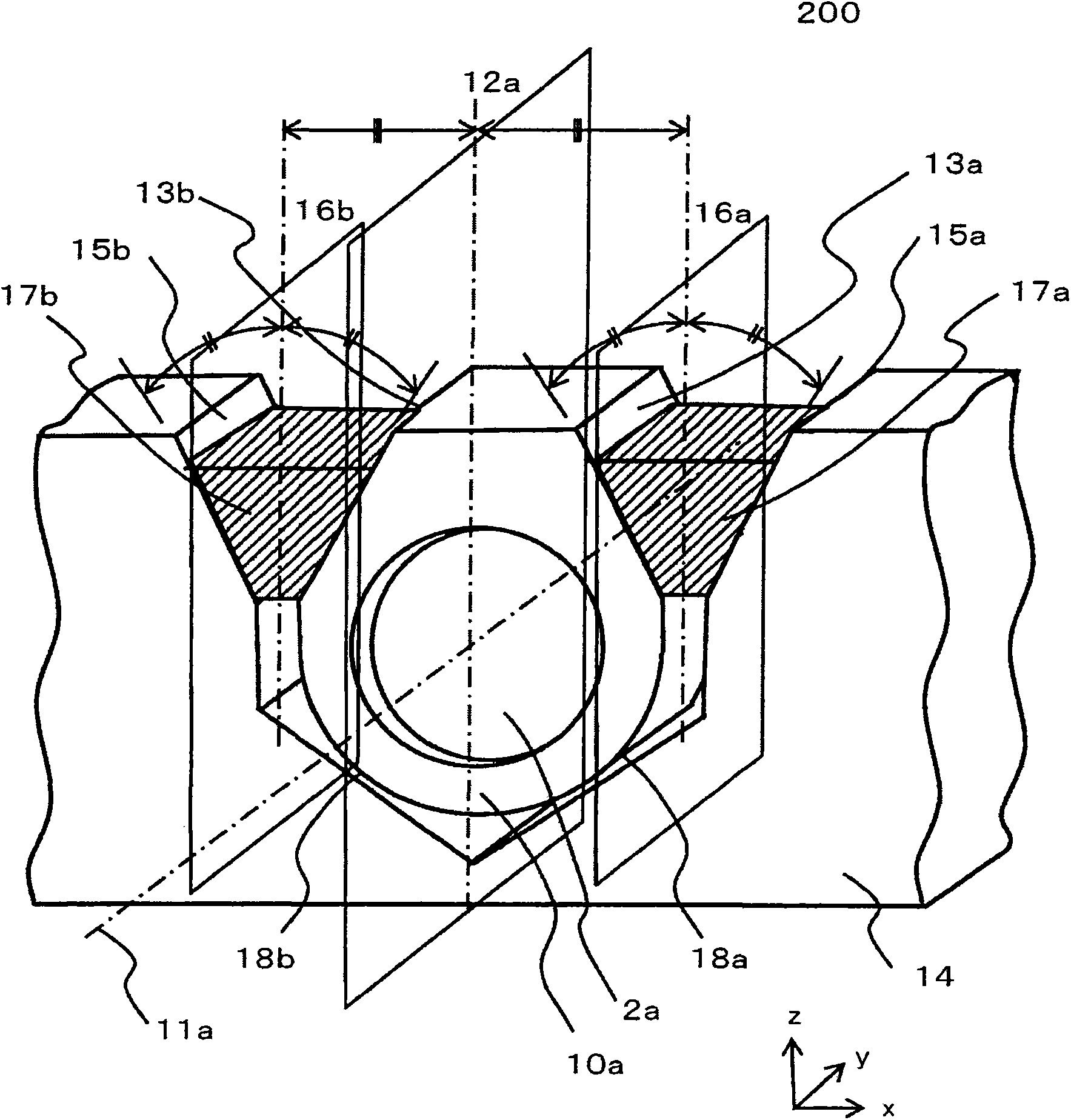

Method of manufacturing semiconductor device

InactiveUS20060030111A1Reduce stepsElectric field concentration is easedSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

There has heretofore been a problem that desired withstanding characteristics cannot be obtained since a buried diffusion layer climbs up more than necessary in other heat treatment steps. In the present invention, after an N-type buried diffusion layer is formed, dry etching is performed in order to round off corner portions of a groove used for inter-element isolation and the like. Moreover, the groove is filled up with an NSG film formed by use of a CVD method, for example. Furthermore, a trench forming an isolation region is filled up with a HTO film and a polycrystalline silicon film, which are formed by use of the CVD method, for example. By use of the manufacturing method described above, it is possible to realize a semiconductor device capable of obtaining desired withstanding characteristics by preventing the N-type buried diffusion layer from climbing up more than necessary.

Owner:SANYO ELECTRIC CO LTD +1

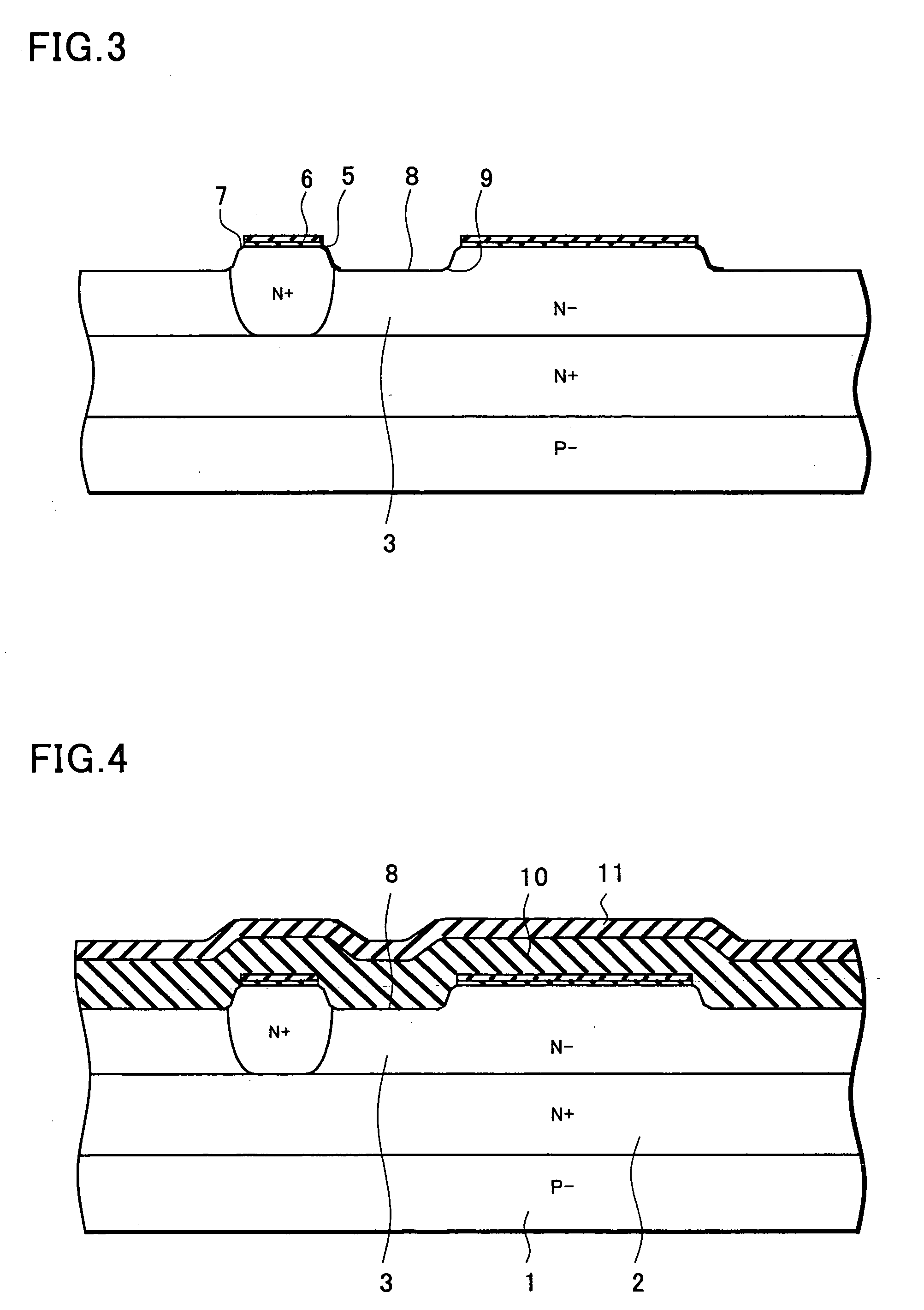

Optical module and scanning type image display device

InactiveCN103576321AReduce relative positional deviationPrevent peelingMountingsOptical ModuleOptical axis

An optical module including a case to hold the optical module, and two sloped surfaces symmetrically formed to enclose a first surface including the optical axis of the optical component in an optical component holder retaining a portion of the optical component, a sloped surface is formed in the case at one position each so as to be formed opposite to the sloped surfaces at two positions of the optical component or optical component holder, and the one sloped surface of the optical component or optical component holder and the one sloped surface of the case at opposite side are symmetrical to the second surface parallel to the first surface and including the side intersecting the surface extending from the sloped surface of the case and the sloped surface of optical component or optical component holder, and the section between these sloped surfaces contains adhesive.

Owner:HITACHI MEDIA ELECTORONICS CO LTD

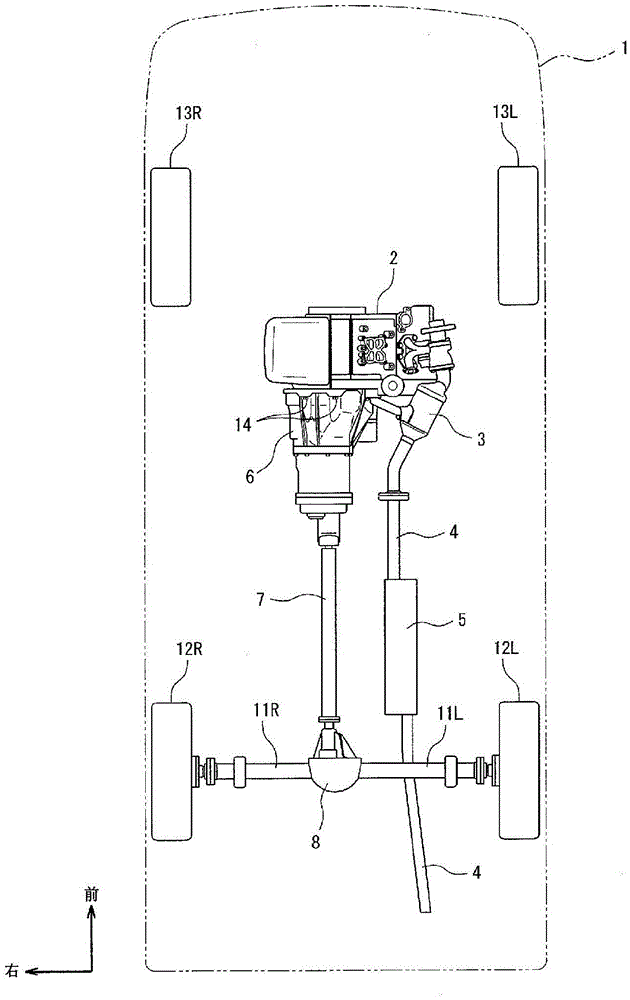

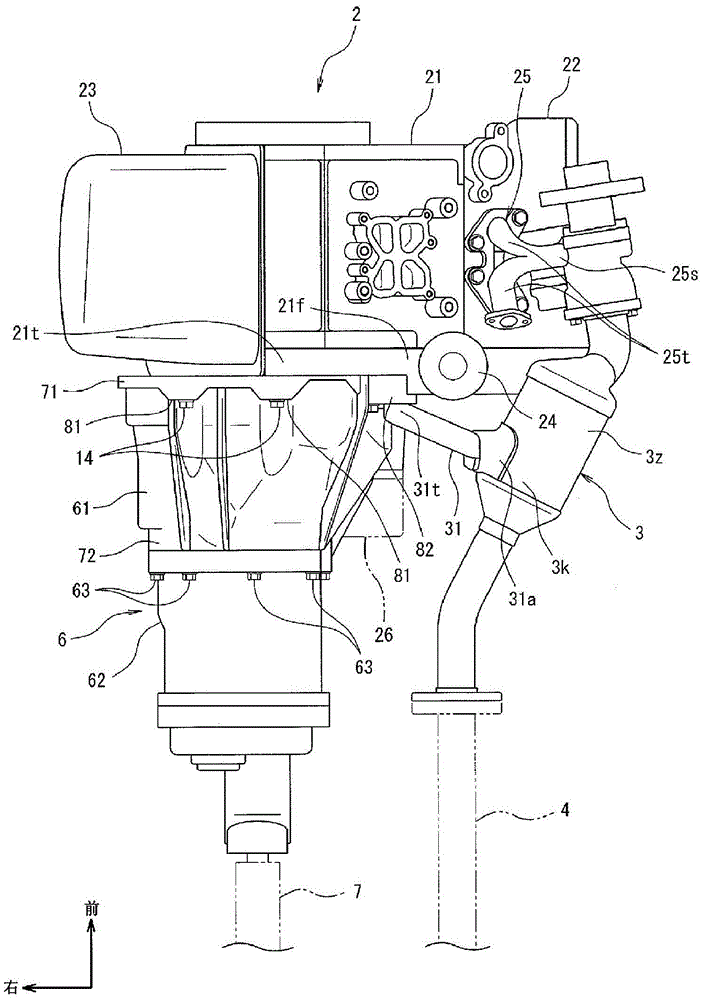

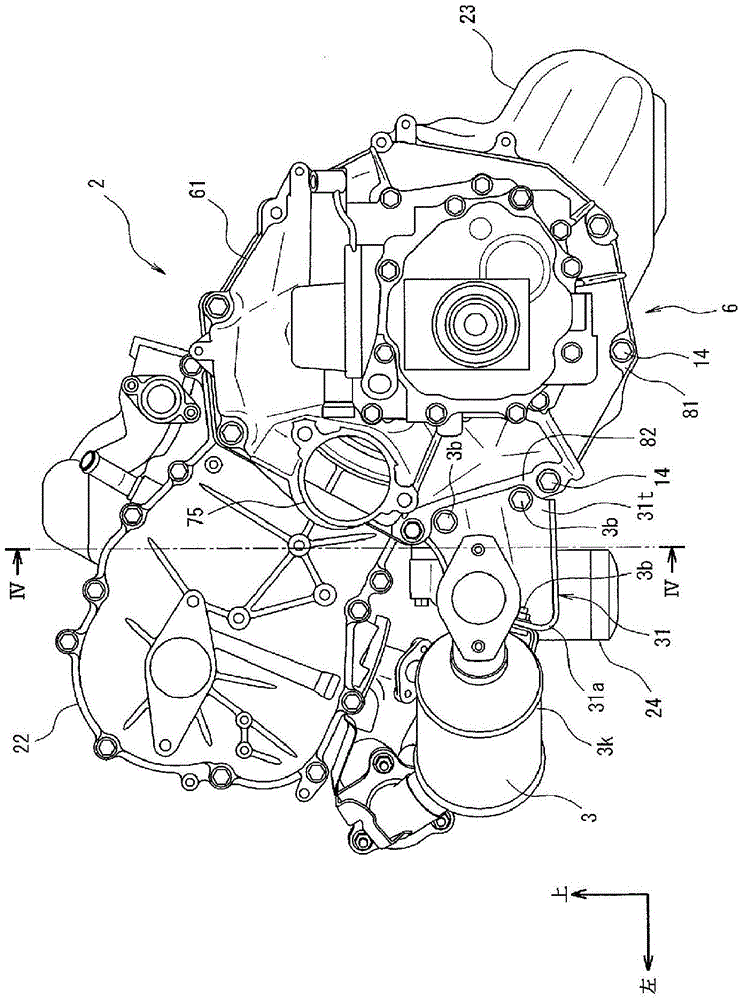

Power transmitting device

InactiveCN105556177AGuaranteed contact areaImprove rigidityCasingsGearboxesFlangeElectrical and Electronics engineering

A power transmitting device comprises a first case (61) for housing a transmission and having an annular engine-fastening section (71) located at the front end of the first case (61) in the front-rear direction, the engine-fastening section (71) being fastened to an engine by bolts. The engine-fastening section (71) has a bracket mounting flange (82), to which a bracket for supporting an exhaust gas purification device is mounted by bolts, the exhaust gas purification device being disposed at a side of the engine-fastening section (71). The bracket mounting flange (82) protrudes outward from a side surface of the first case (61) by a height (h) and a thickness (t), is formed so as to extend vertically and linearly by a length (l), has formed therein an upper engine-fastening hole (82a) and a lower engine-fastening hole (82b), the upper and lower engine-fastening holes (82a, 82b) allowing the bolts to be passed therethrough. An upper bracket-fastening hole (82c) and a lower bracket-fastening hole (82d) are formed between the upper engine-fastening hole (82a) and the lower engine-fastening hole (82b).

Owner:SUZUKI MOTOR CORP

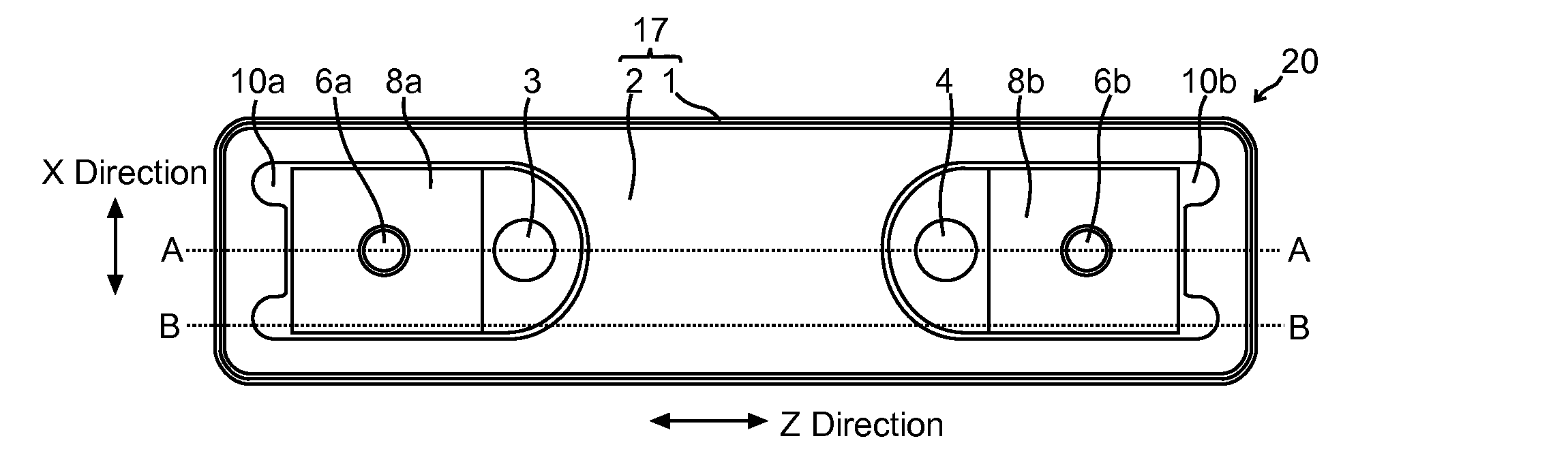

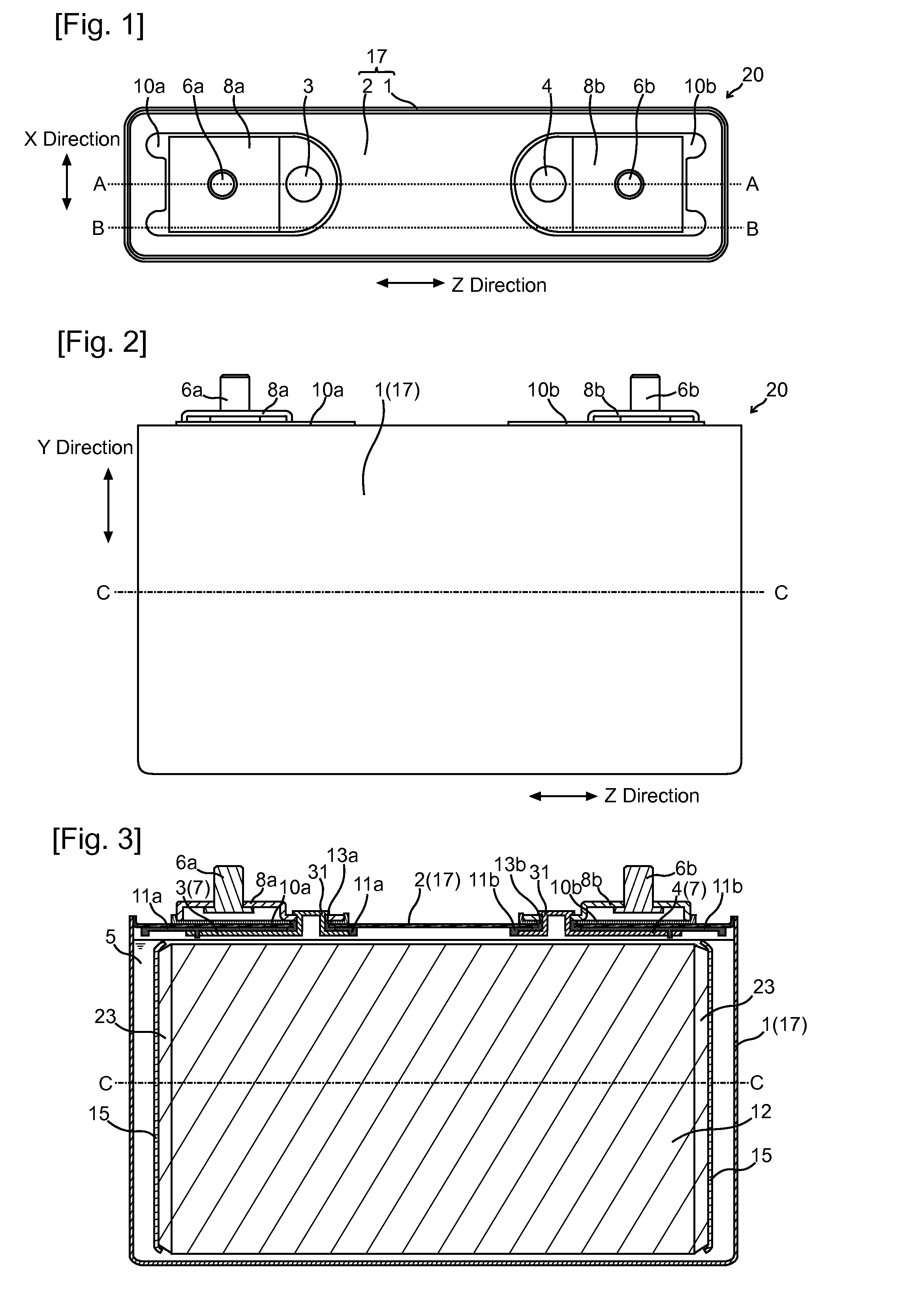

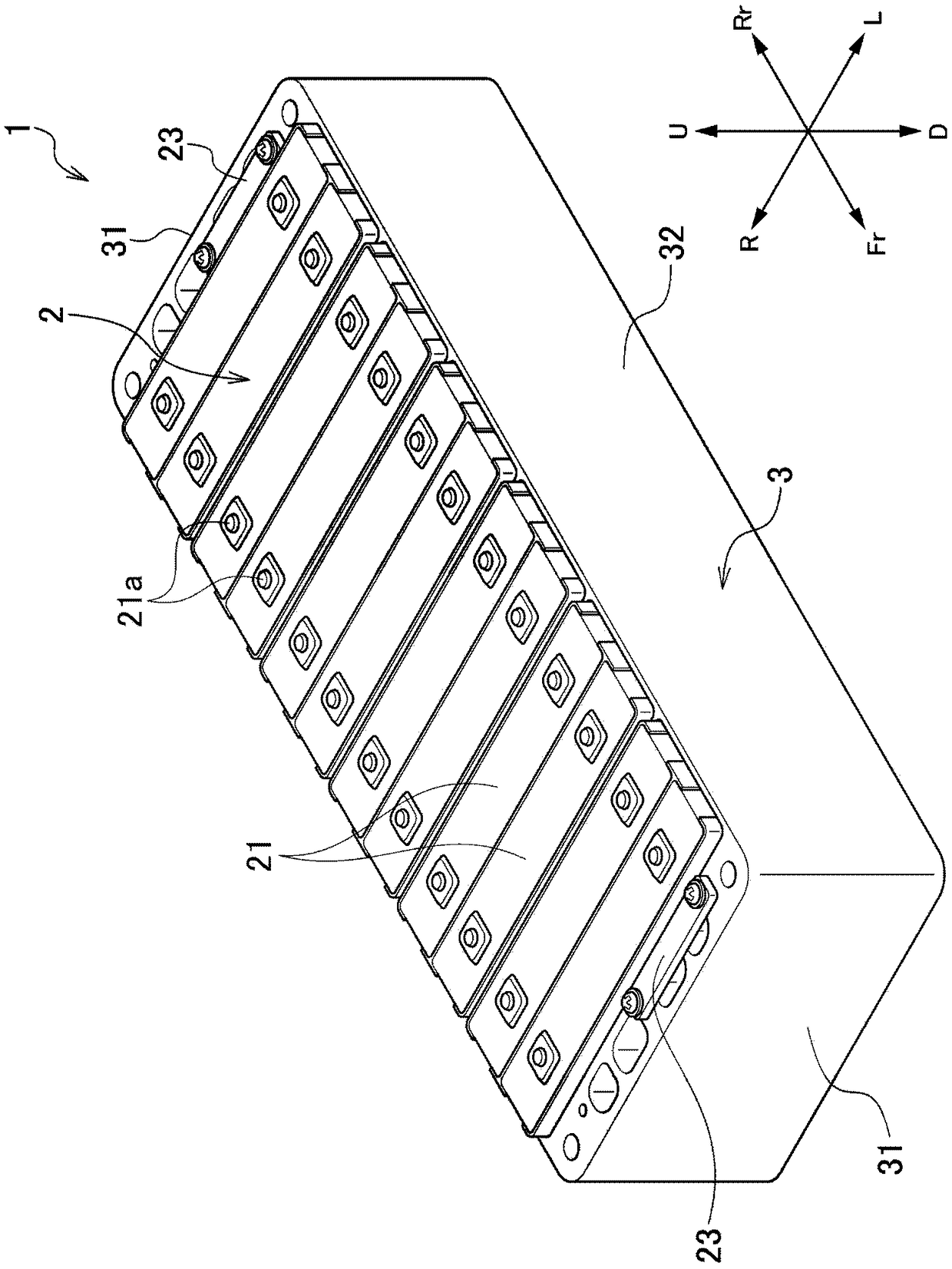

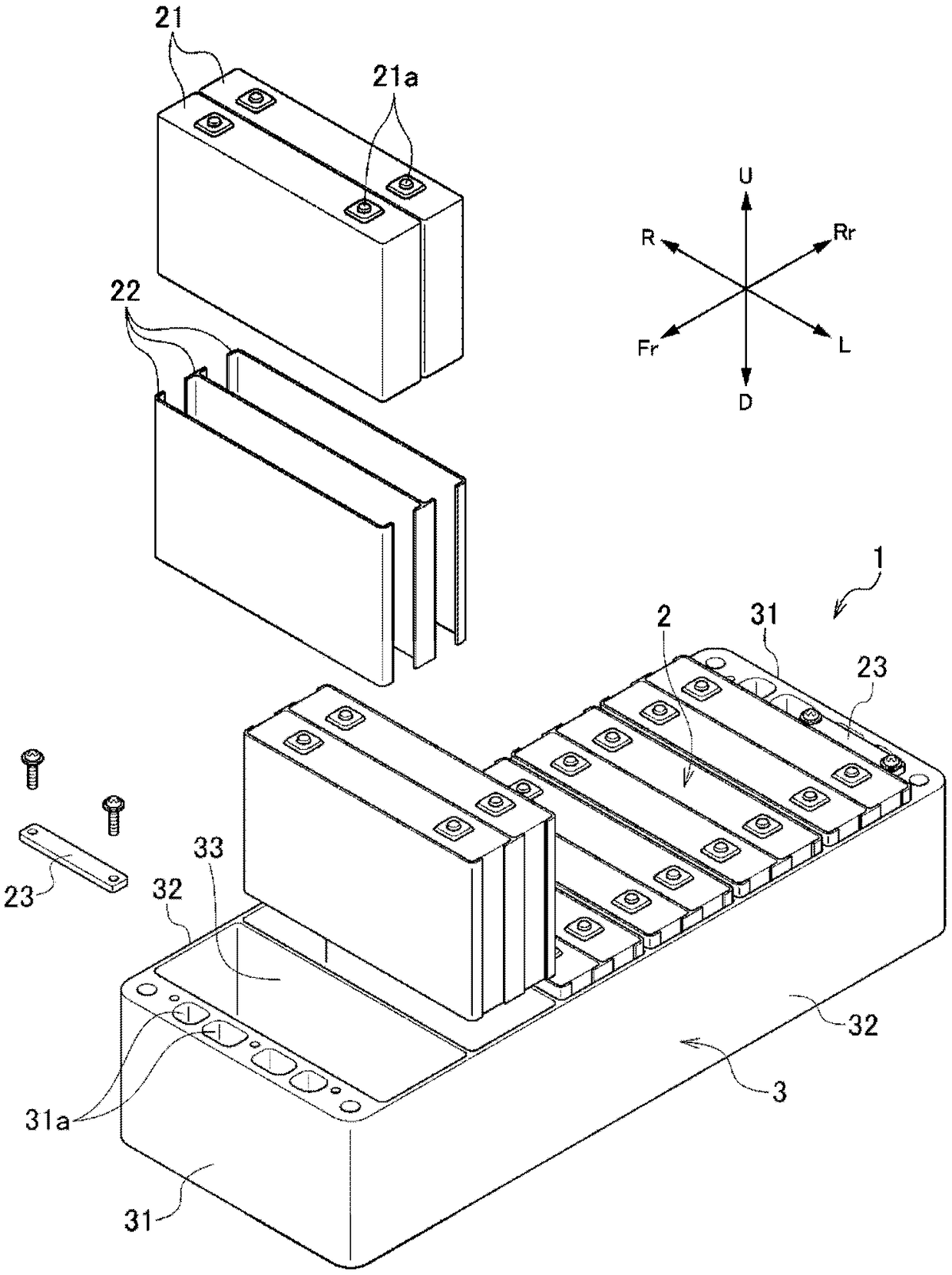

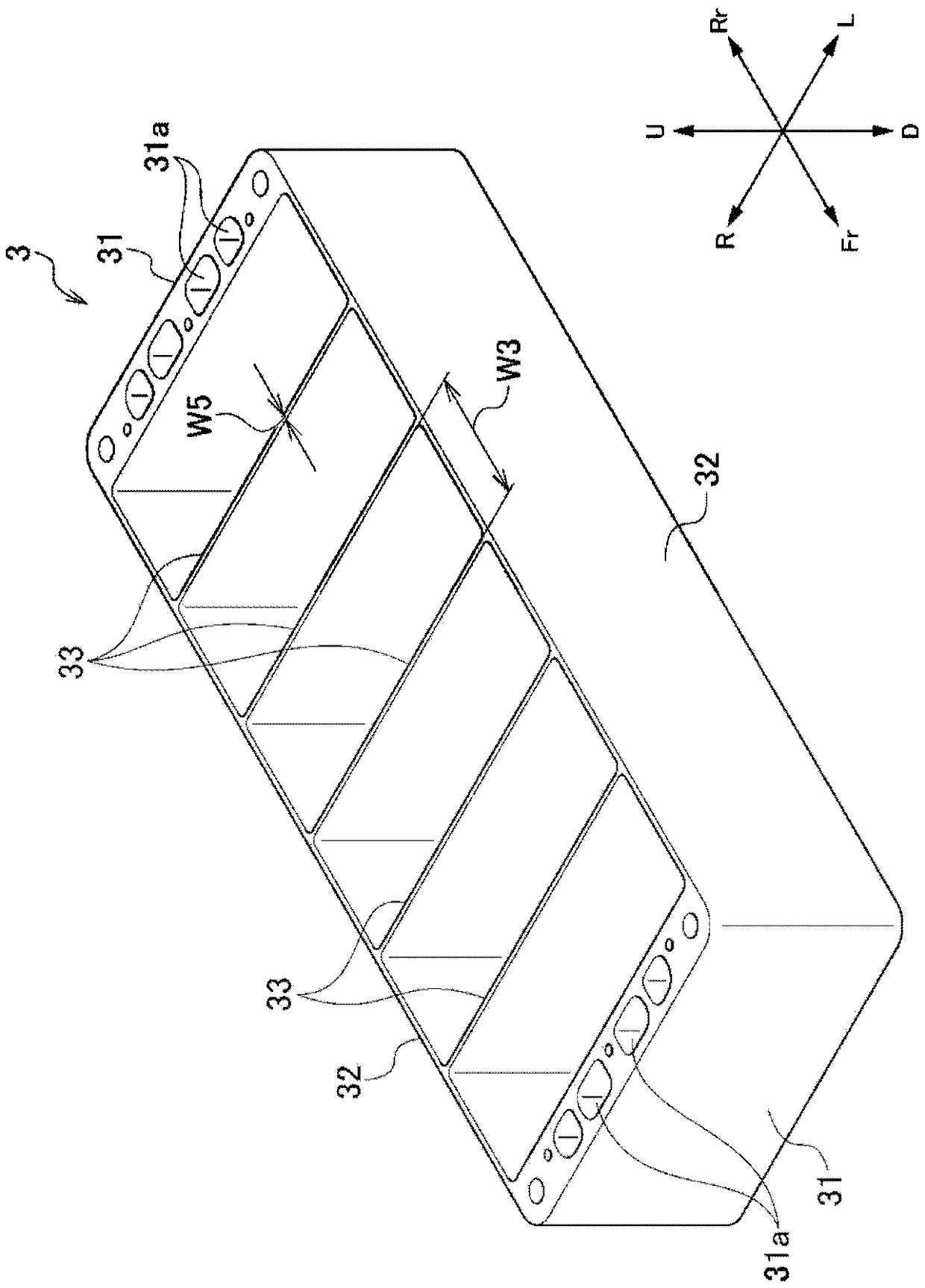

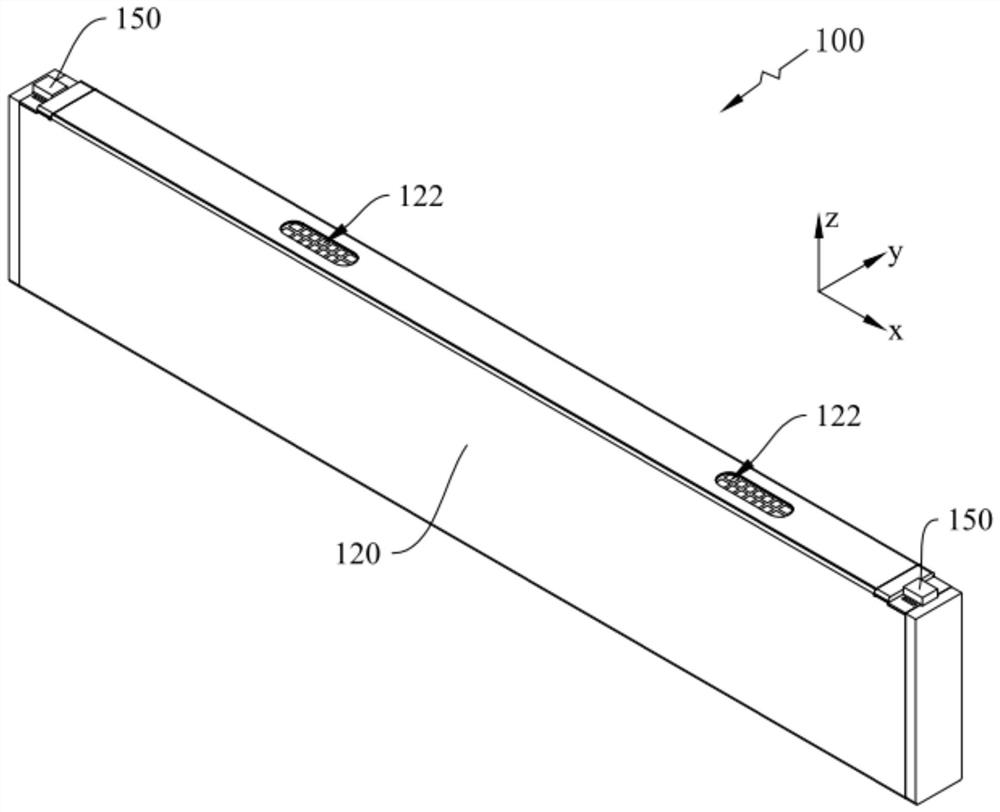

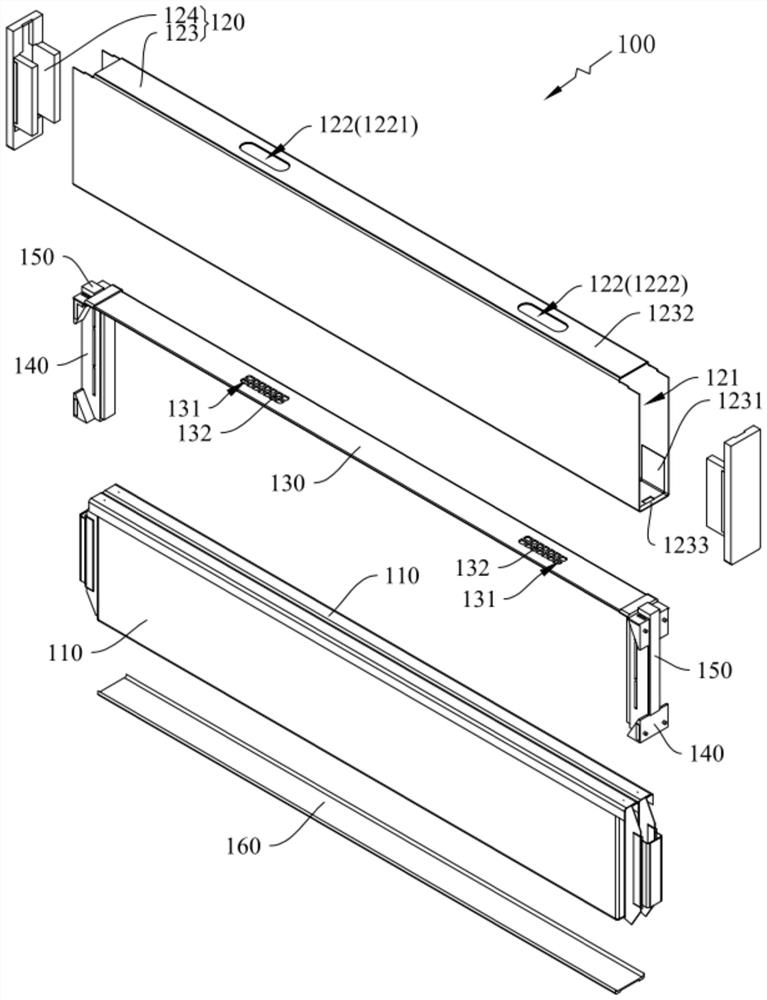

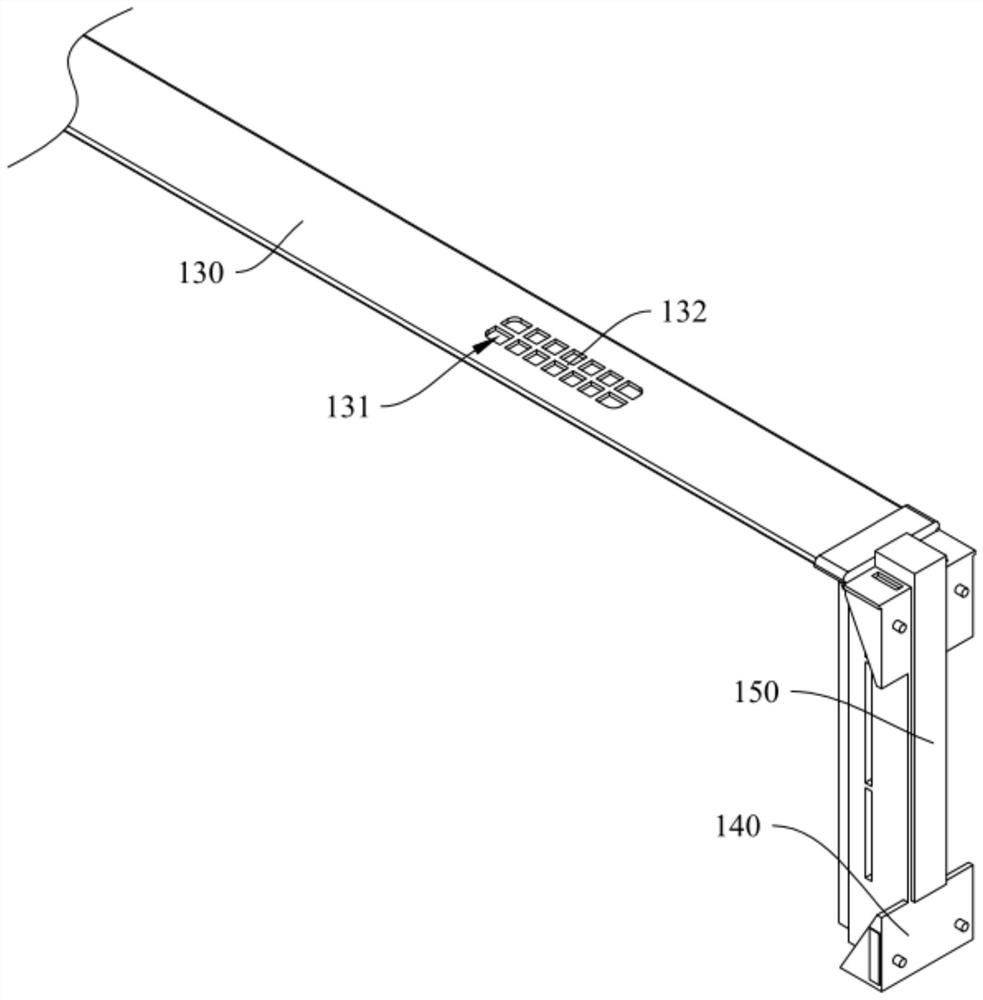

Battery module and manufacturing method thereof

InactiveCN109148754AEase concentrationLarge-sized flat cells/batteriesFinal product manufactureStructural engineeringMechanical engineering

The invention provides a battery module capable of mitigating concentration of stress and receiving a load in a cell stacking direction caused by expansion of a unit cell, and a method of manufacturing the same. The battery module 1 includes: a cell stack body 2 that is constituted by a plurality of cells 21 stacked in a front-rear direction and includes a front surface, a rear surface, a left surface, a right surface, an upper surface, and a lower surface; and a casing 3 that accommodates the cell stack body 2. In the battery module, the casing 3 includes: a pair of end portions 31 extendingalong the front surface and the rear surface of the cell stack body 2; and a side portions 32 extending along the left surface and the right surface of the cell stack body 2. A width W1 in the front-rear direction of the end portion is larger than a width W2 in the left-right direction of the side portion 32.

Owner:HONDA MOTOR CO LTD

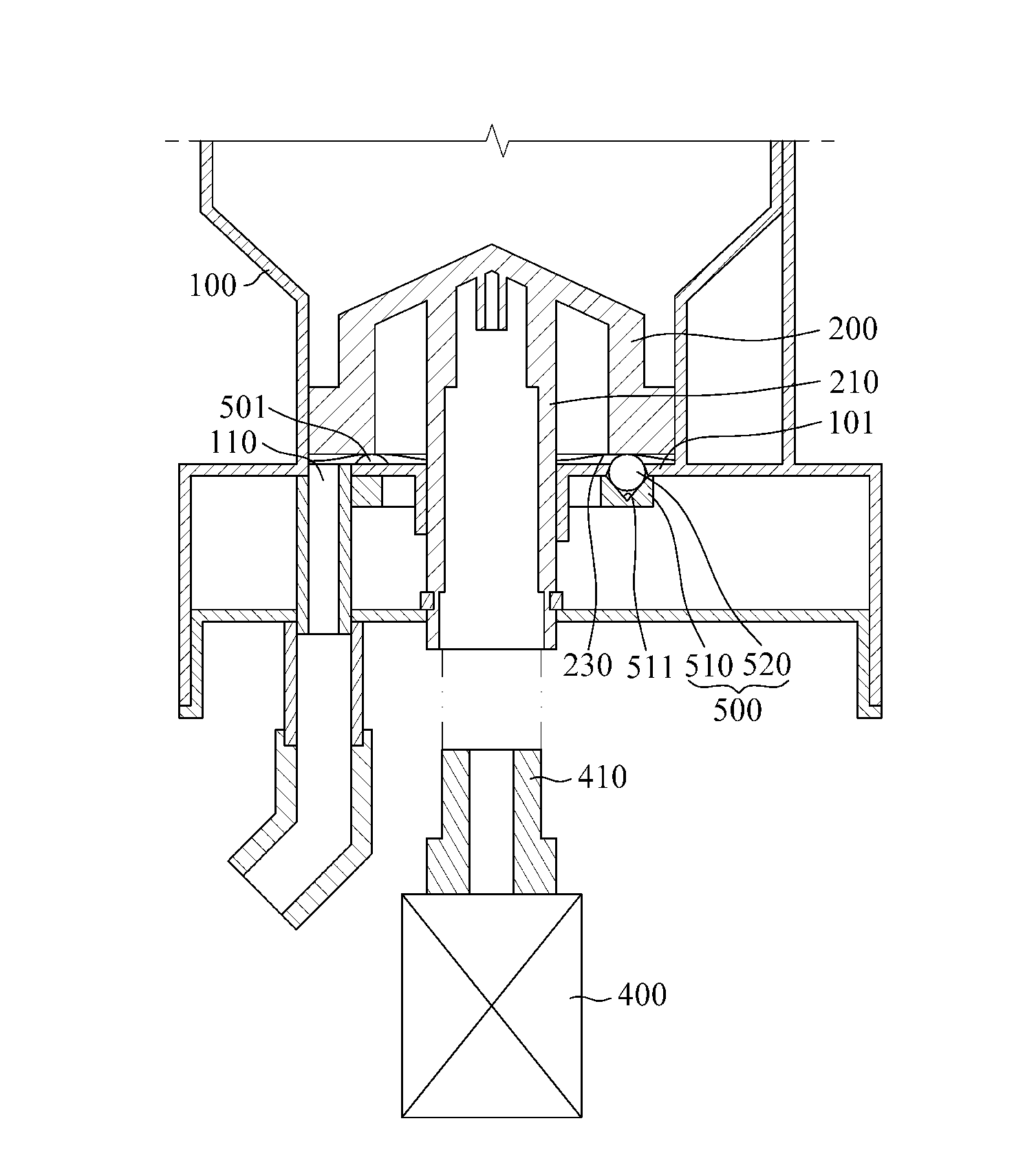

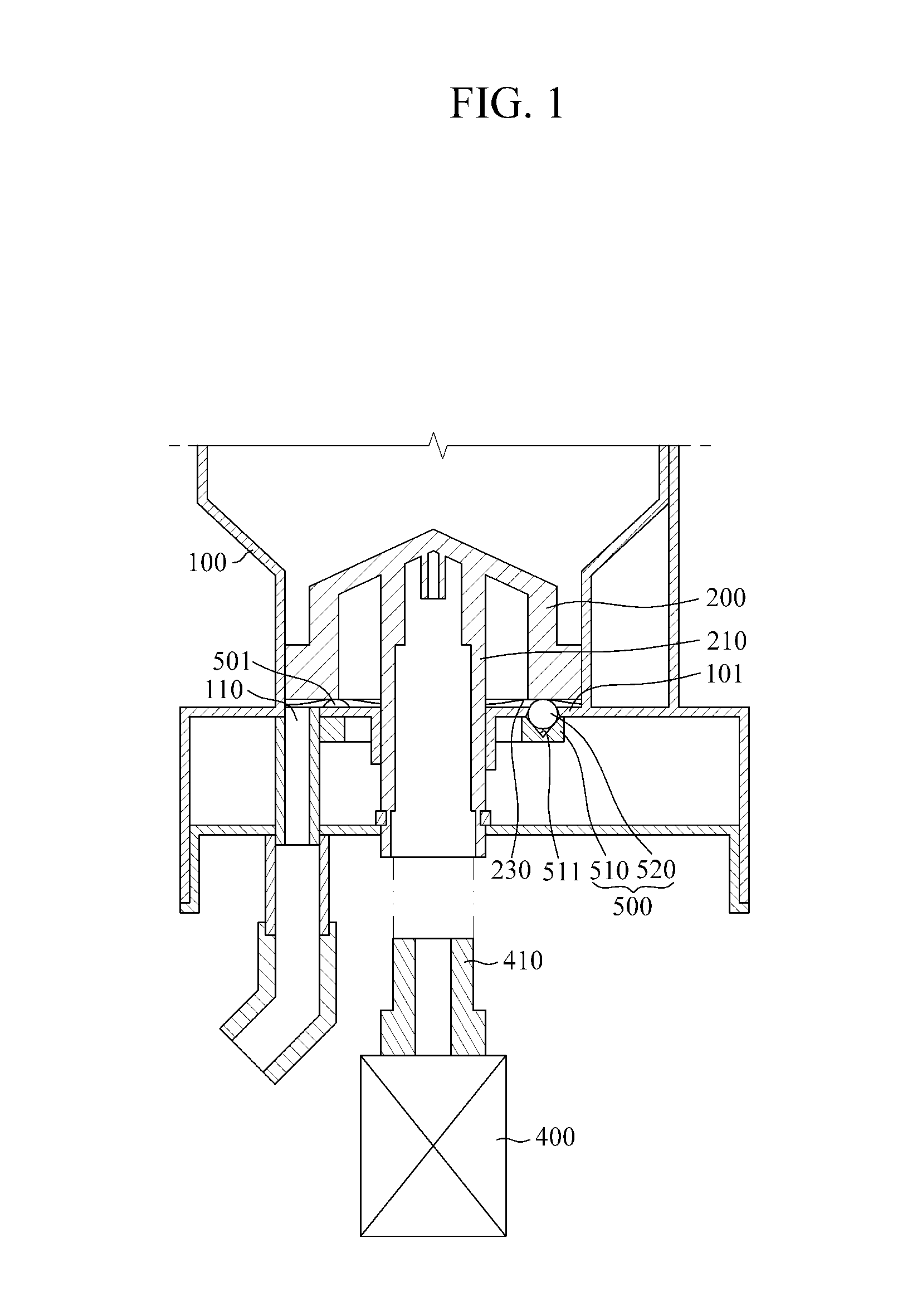

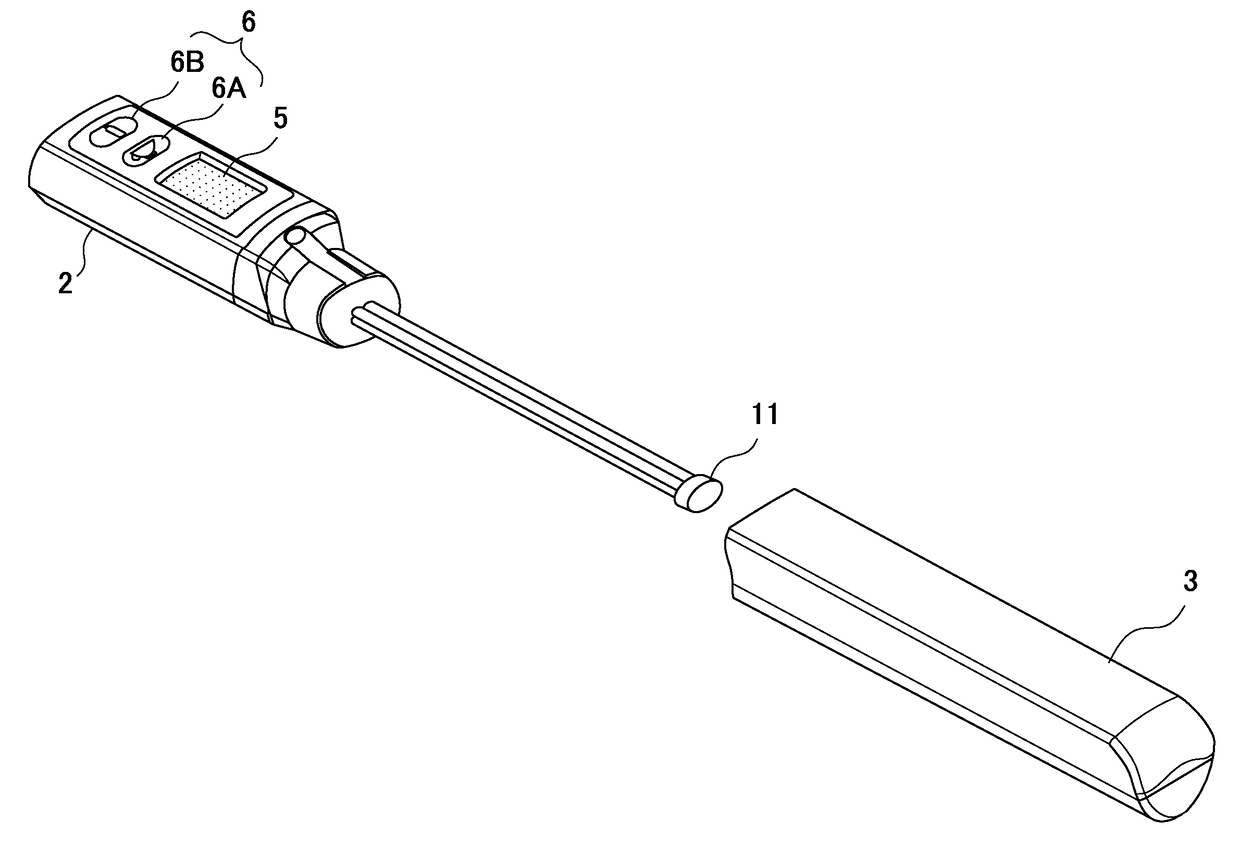

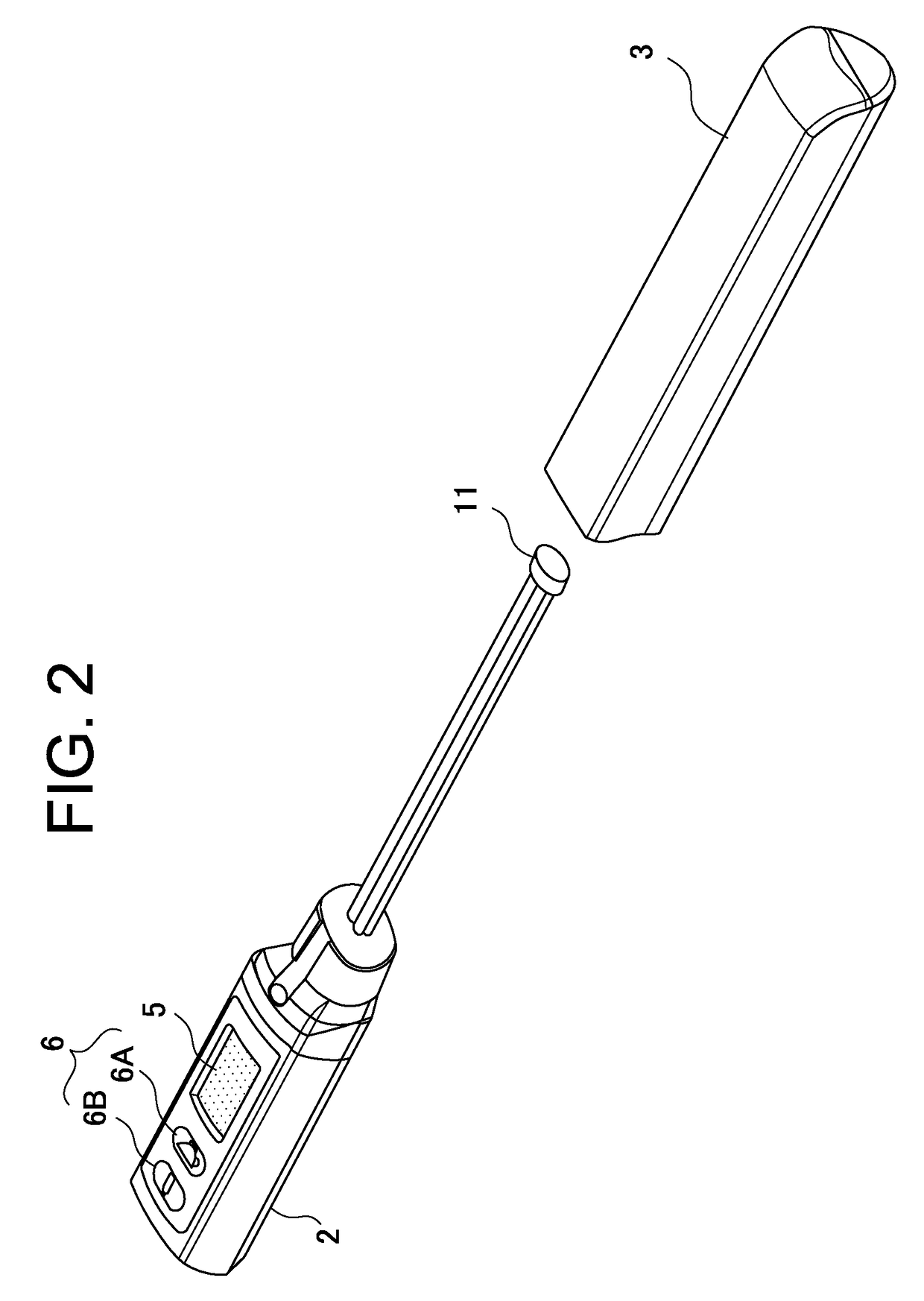

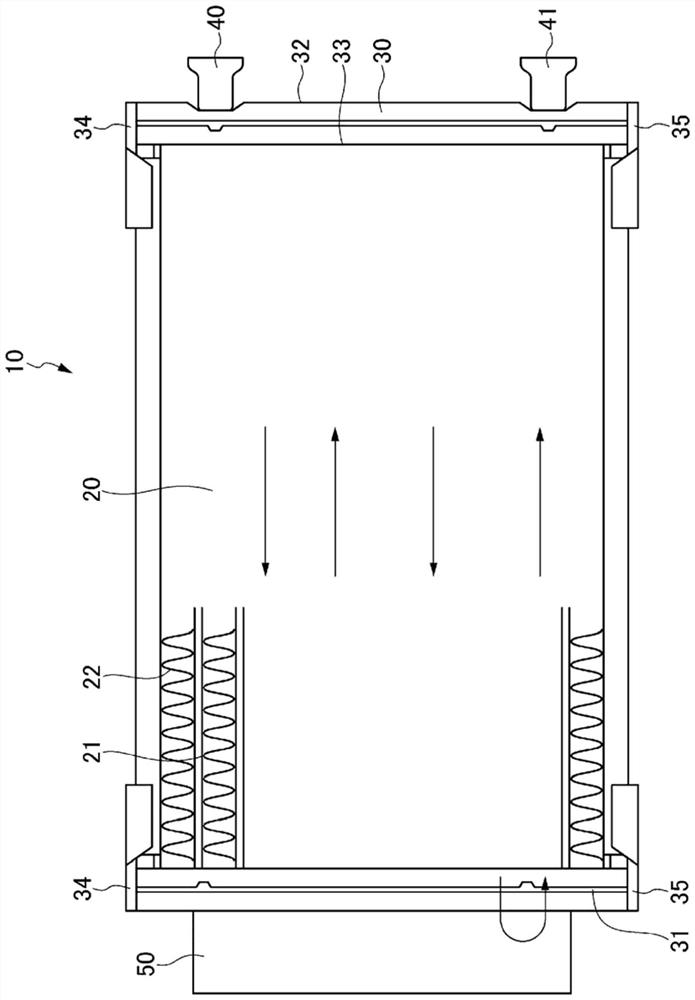

Hydrogen water generator

ActiveUS20170166460A1Diameter can be preventedEase concentrationWater treatment locationWater/sewage treatment apparatusHydrogenElectrolysis

The present invention provides a hydrogen water generator capable of efficiently generating hydrogen with a structure in which anode electrode(s) and cathode electrode(s) are arranged in a container in an approximately vertical direction. The electrode portion 4 which includes two or more of anode electrodes 4A or cathode electrodes 4B is supported by a generator body cover portion 2. The generator body cover portion 2 is held and the electrode portion 4 is immersed in drinking water in a beverage container 12 such as a cup. Then, electrolysis is caused owing to that a controller 11 applies voltage obtained by boosting supply voltage from a battery 8 to the electrode portion 4 for a predetermined time. At this time, since a plurality of energizing paths between the anode electrode(s) and the cathode electrode(s) are formed, hydrogen can be effectively generated in the drinking water.

Owner:FUJI KEIKI CO LTD

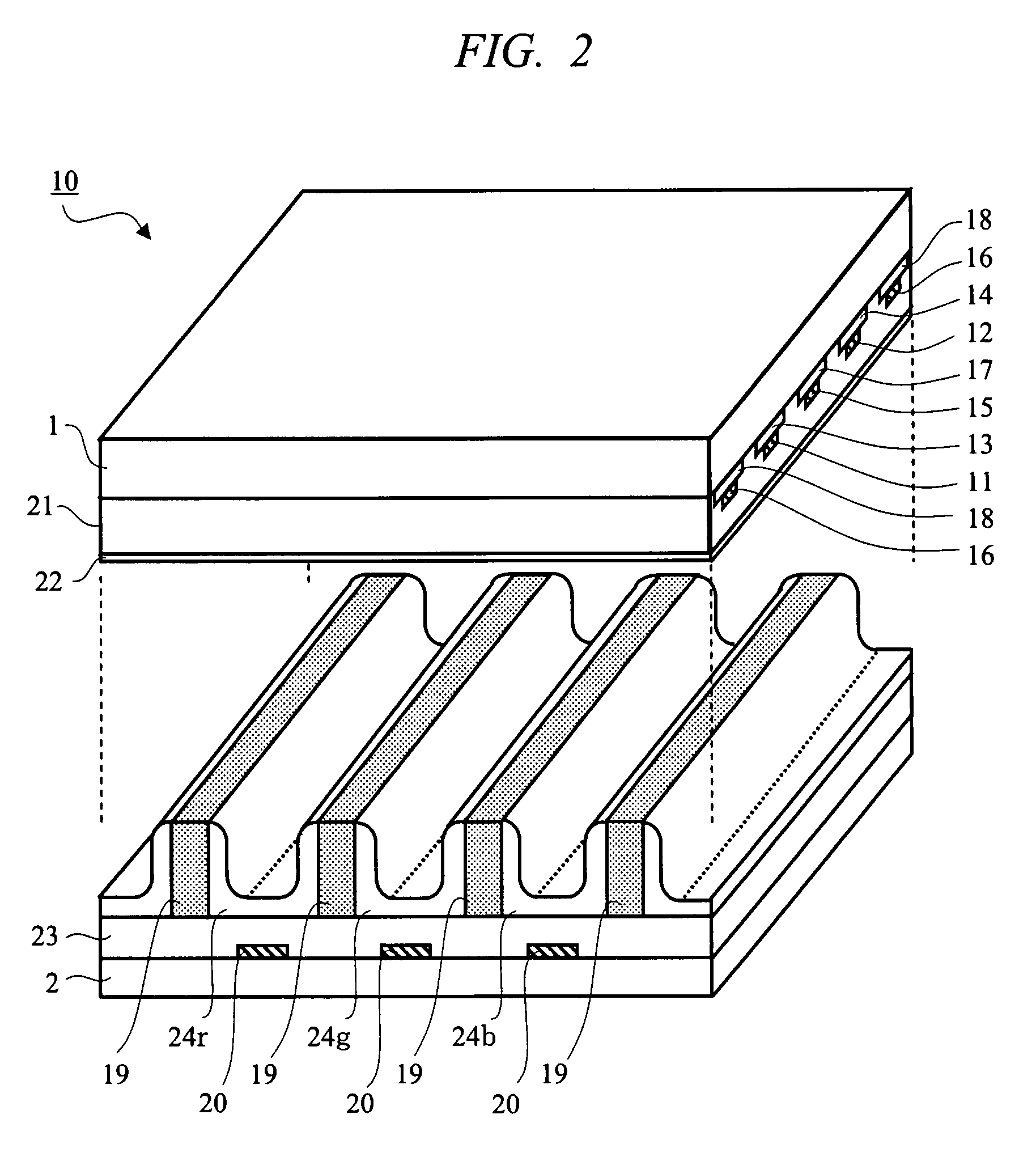

Plasma Display panel and plasma display

InactiveUS20090160739A1High color temperatureLuminance can be restrainedSustain/scan electrodesStatic indicating devicesPhosphorLoad ratio

A technology for the four-electrode type PDP for preventing the lowering of luminance depending on the display load ratio due to the voltage drop at electrode by mitigating concentration of discharge timing. On a front substrate of a PDP (10), a first (X) electrode, a second (Y) electrode, and a third (Z) electrode therebetween are arranged in parallel in a first direction. Between Substrates, barrier ribs for sectioning cells 3 of respective colors of R, G, B and phosphor layers of respective colors are provided. In the respective cells (3), an interval of the X, Y electrodes is roughly constant. It is a structure where intervals between the X, Y electrodes and the Z electrode (XZ, YZ) are different. Particularly, an interval of R is narrow and an interval of B is wide.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

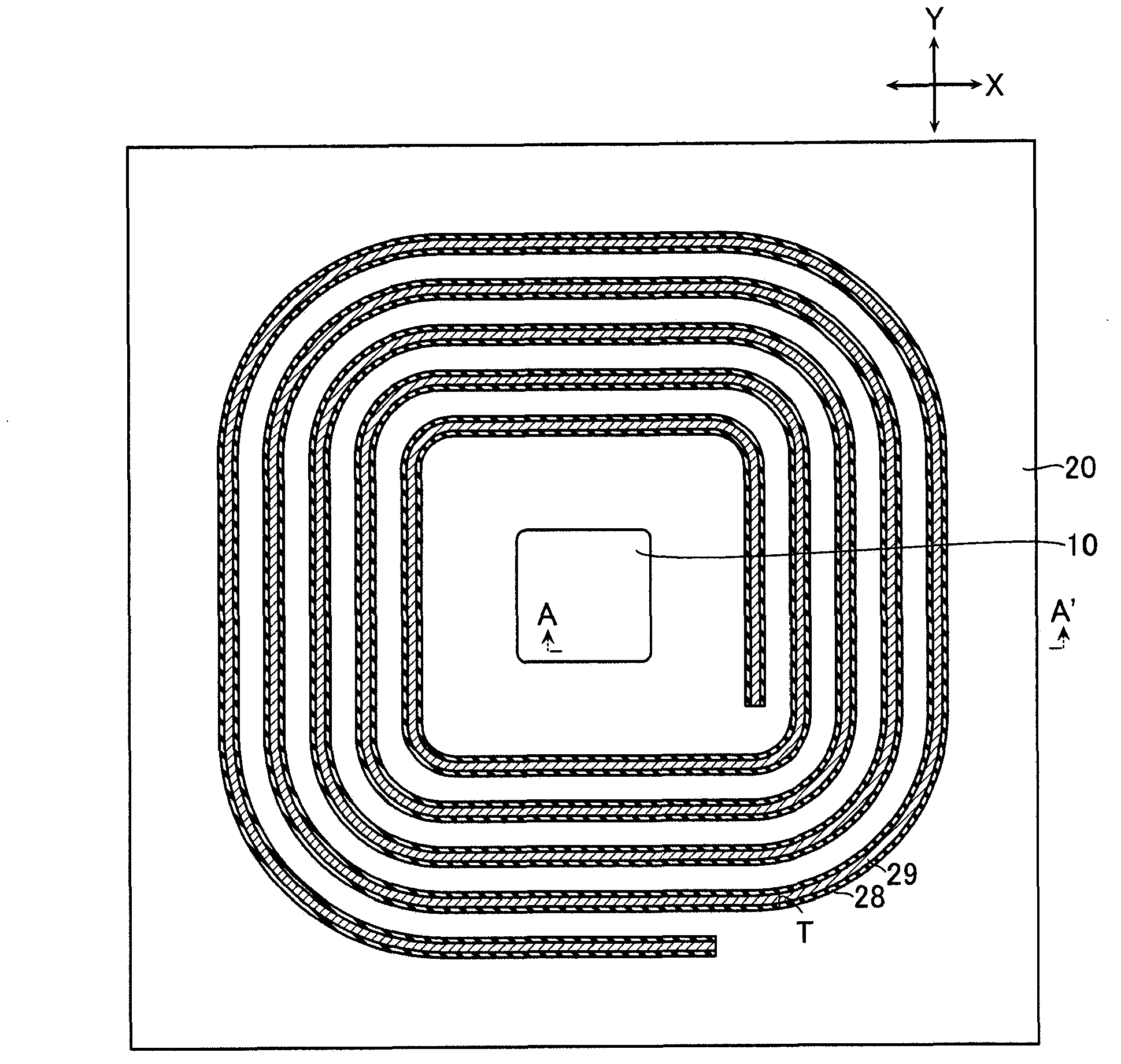

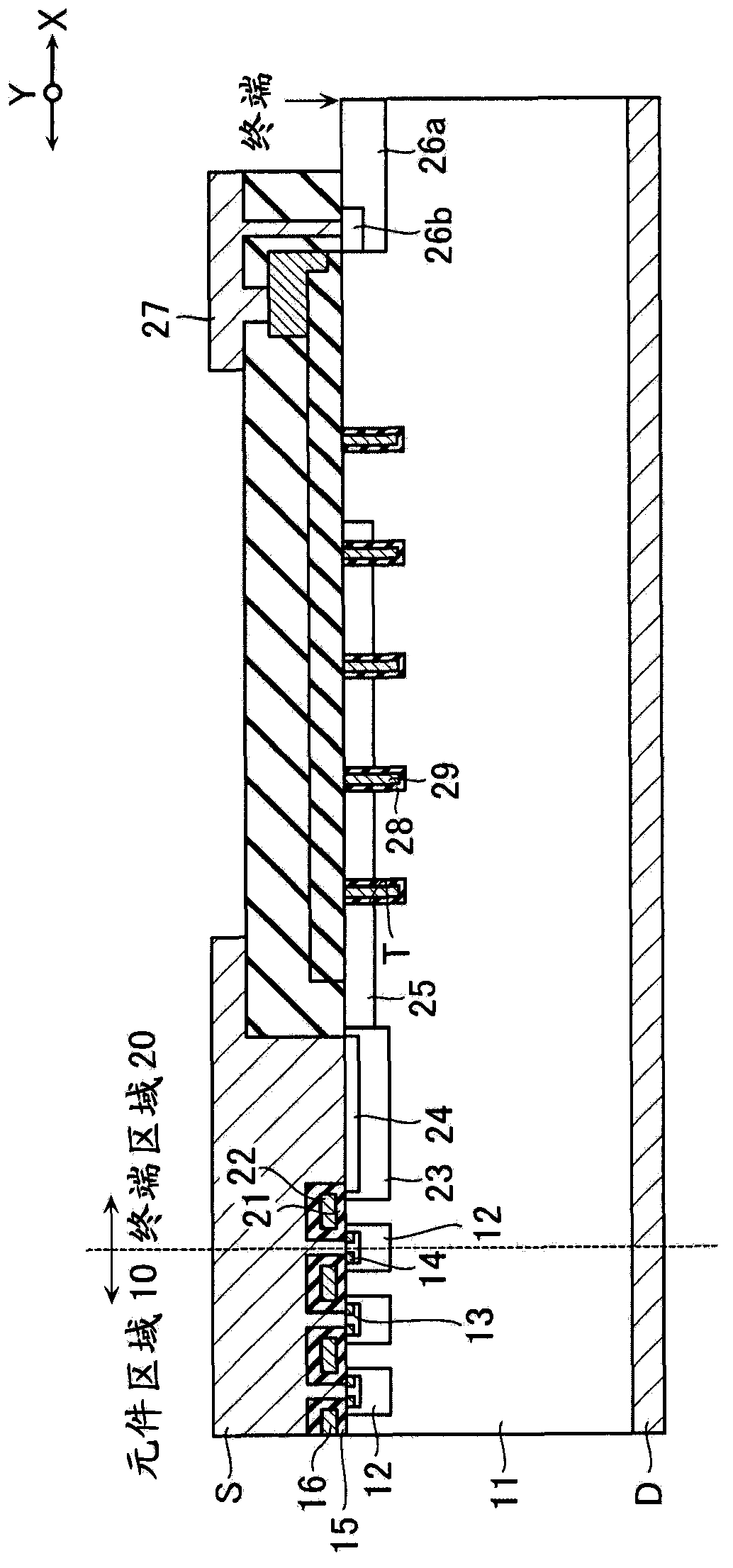

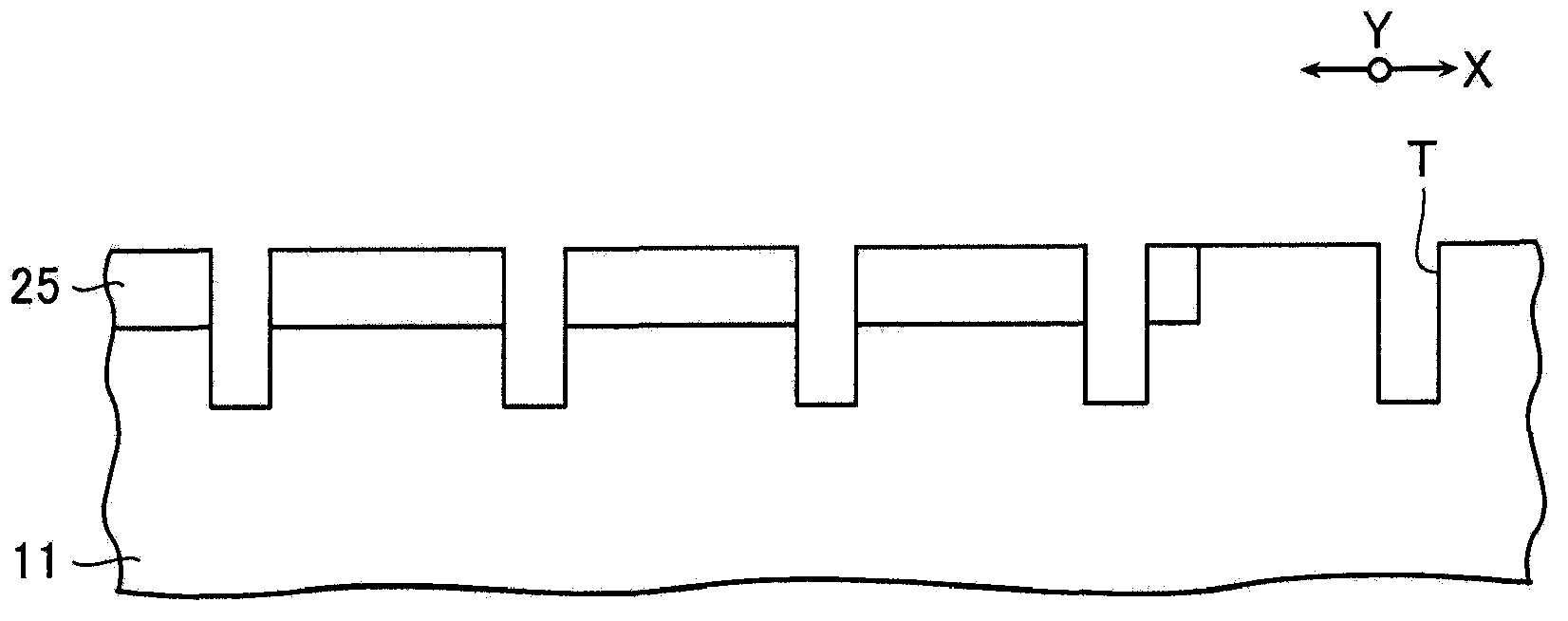

Semiconductor device and method of manufacturing same

InactiveCN103681797AEase concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorSemiconductor device

The invention provides a semiconductor device and a method of manufacturing same. The semiconductor device includes an element region and an end region, the element region having a semiconductor element formed therein, and the end region surrounding the element region. The semiconductor device includes a semiconductor substrate, a trench, an insulating layer, and a field plate conductive layer. The trench is formed in the semiconductor substrate so as to surround the element region in the end region. The field plate conductive layer is formed in the trench via the insulating layer.

Owner:KK TOSHIBA

Fortified vitamin beverage with zero pigment addition

The invention discloses a fortified vitamin beverage with zero pigment addition. The fortified vitamin beverage is prepared from components of water, high fructose corn syrup, white granulated sugar,crystalline trehalose, erythritol, passion fruit juice, pineapple juice, citric acid, sodium citrate, edible essence, a guarana extract, taurine, coffee powder, sodium cyclamate, acesulfame potassium,potassium sorbate, edible salt, nicotinic acid, and vitamins C, B6 and B12. The fortified vitamin beverage with zero pigment addition is adopted, no pigment is added, thus environmental friendlinessand safety are achieved, and the fortified vitamin beverage has the functions of sleepiness relieving, refreshing and energy supplementing.

Owner:NANNING KENYANG BIOTECH

Unit module and battery pack

PendingCN113937403ARealize heat dissipationEase concentrationSecondary cellsCell component detailsProcess engineeringMechanical engineering

The invention relates to the field of batteries, and provides a unit module and a battery pack. Each unit module comprises at least one soft package battery cell and a shell assembly, an accommodating cavity for accommodating each soft package battery cell is formed in the shell assembly, and an exhaust hole for communicating the accommodating cavity to the outside is formed in one side, in the height direction of the soft package battery cell, of the shell assembly. Based on the structure, a unit module which is regularized, modularized, independent, better in strength and better in rigidity can be formed. No matter the position where thermal runaway happens to the soft package battery cell in the shell assembly is located at the tab, the edge sealing position or other positions of the soft package battery cell, heat and gas discharged by the soft package battery cell with thermal runaway are directionally discharged out of the unit module along the exhaust holes. Therefore, the battery pack can take thermal runaway protection measures based on directional exhaust path pre-design, the risk / speed of thermal runaway spreading to other unit modules can be reduced when a certain unit module is in thermal runaway, and the safety performance of the battery pack can be guaranteed and improved.

Owner:EVERGRANDE NEW ENERGY TECH SHENZHEN CO LTD

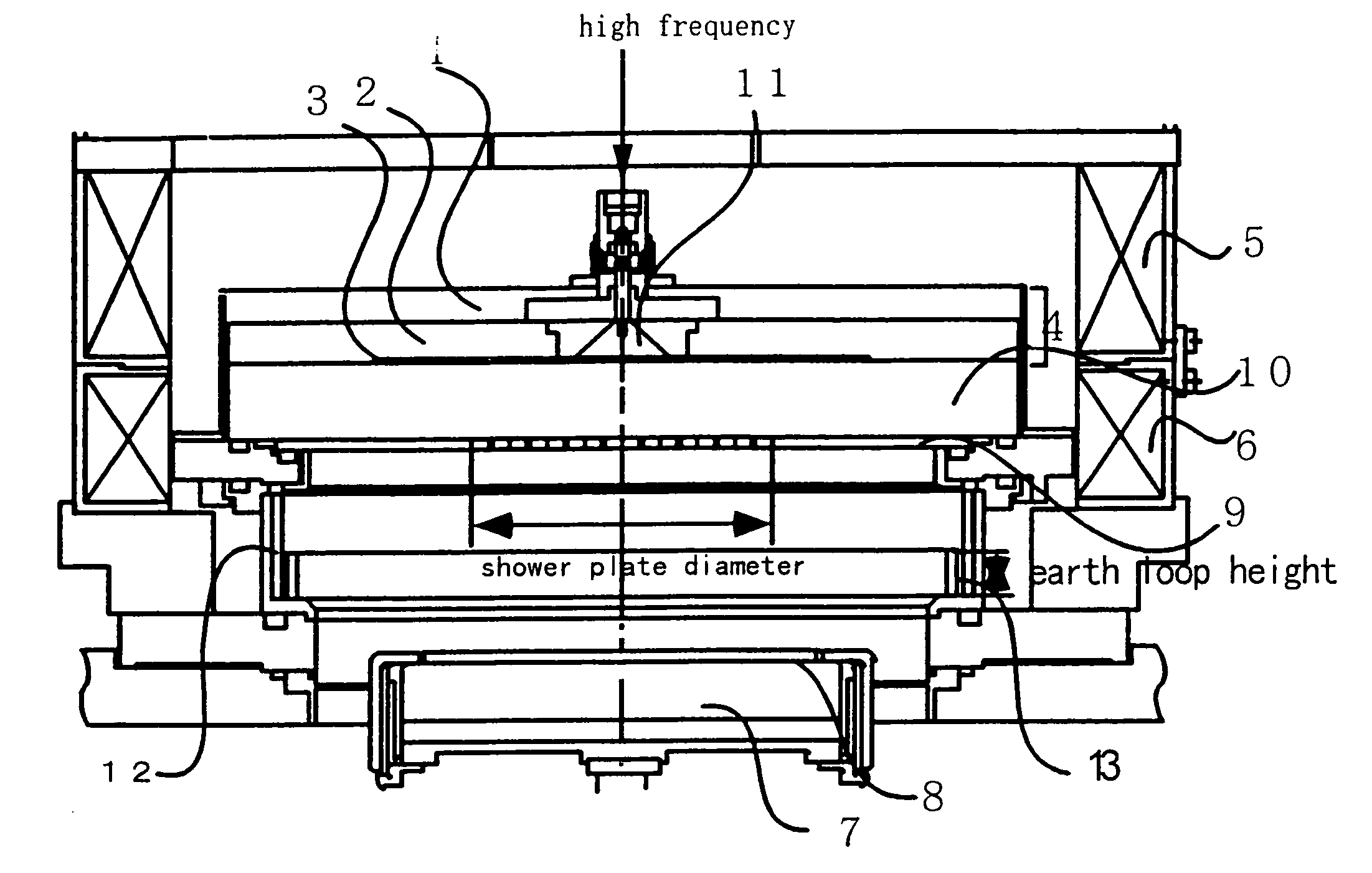

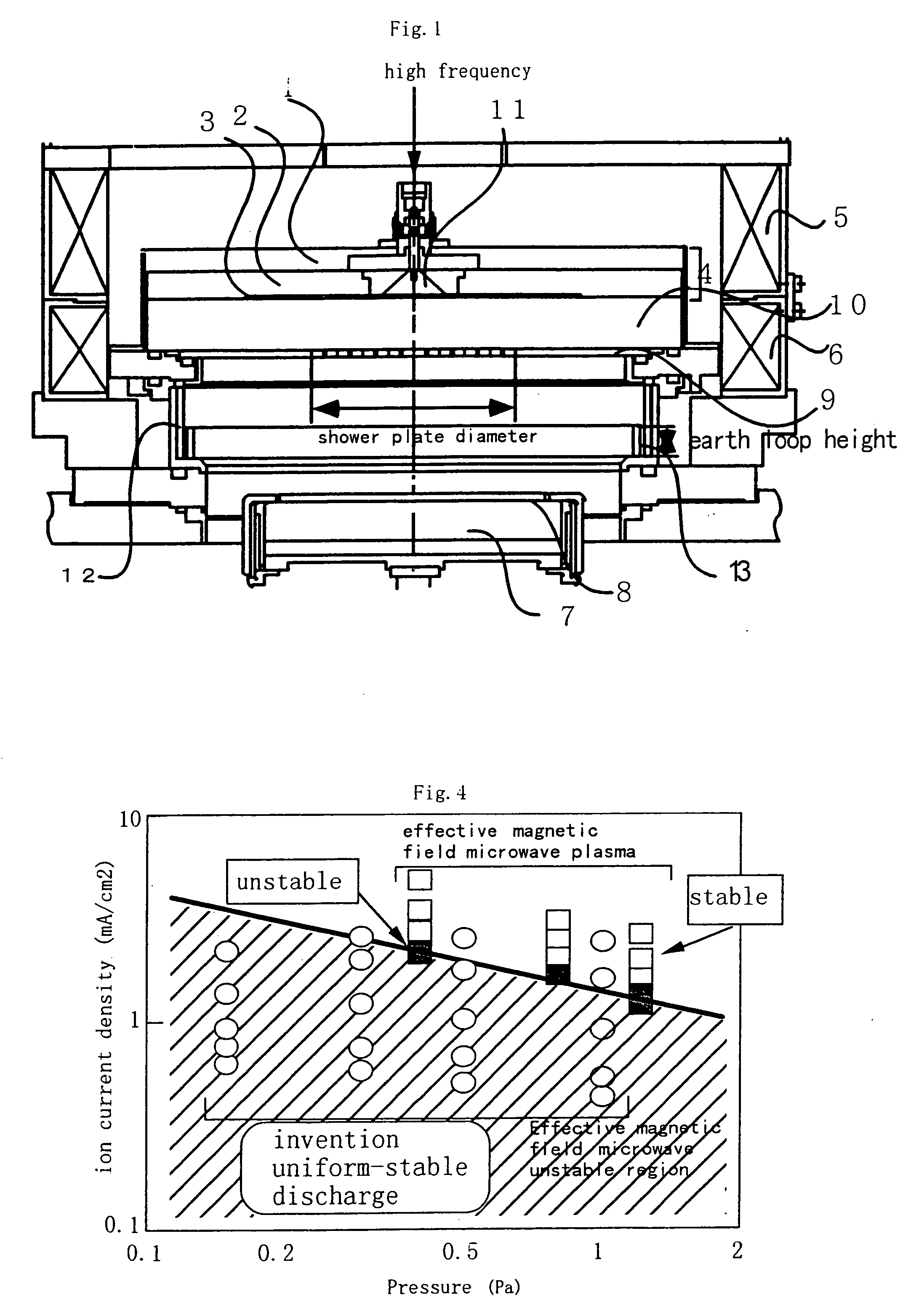

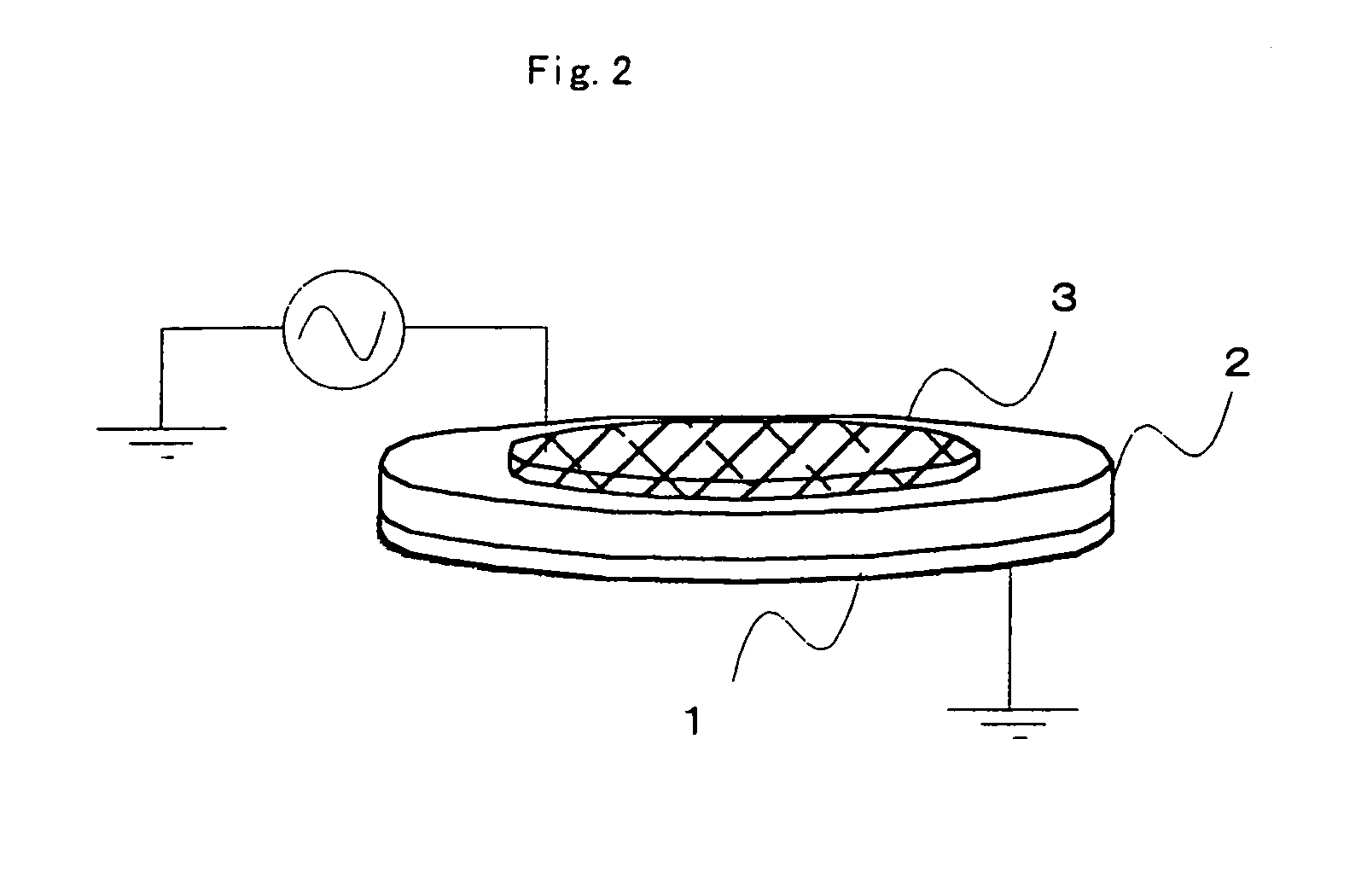

Dry etching apparatus and a method of manufacturing a semiconductor device

InactiveUS20060096706A1Ignitionability is improvedReduce electric field concentrationElectric discharge tubesSemiconductor/solid-state device manufacturingElectric forceDevice material

The processing with a low gate rate of destruction and high anisotropy is achieved in dry etching. Plasma is generated by ECR resonance of electromagnetic wave which arose by supplying Ultra High Frequency electric power in microstripline 4 arranged on the atmosphere side of a dielectric 2, which separates a vacuum inside and an outside and magnetic field. A conducting layer is etched by this plasma, which is stable and uniform plasma.

Owner:HITACHI LTD

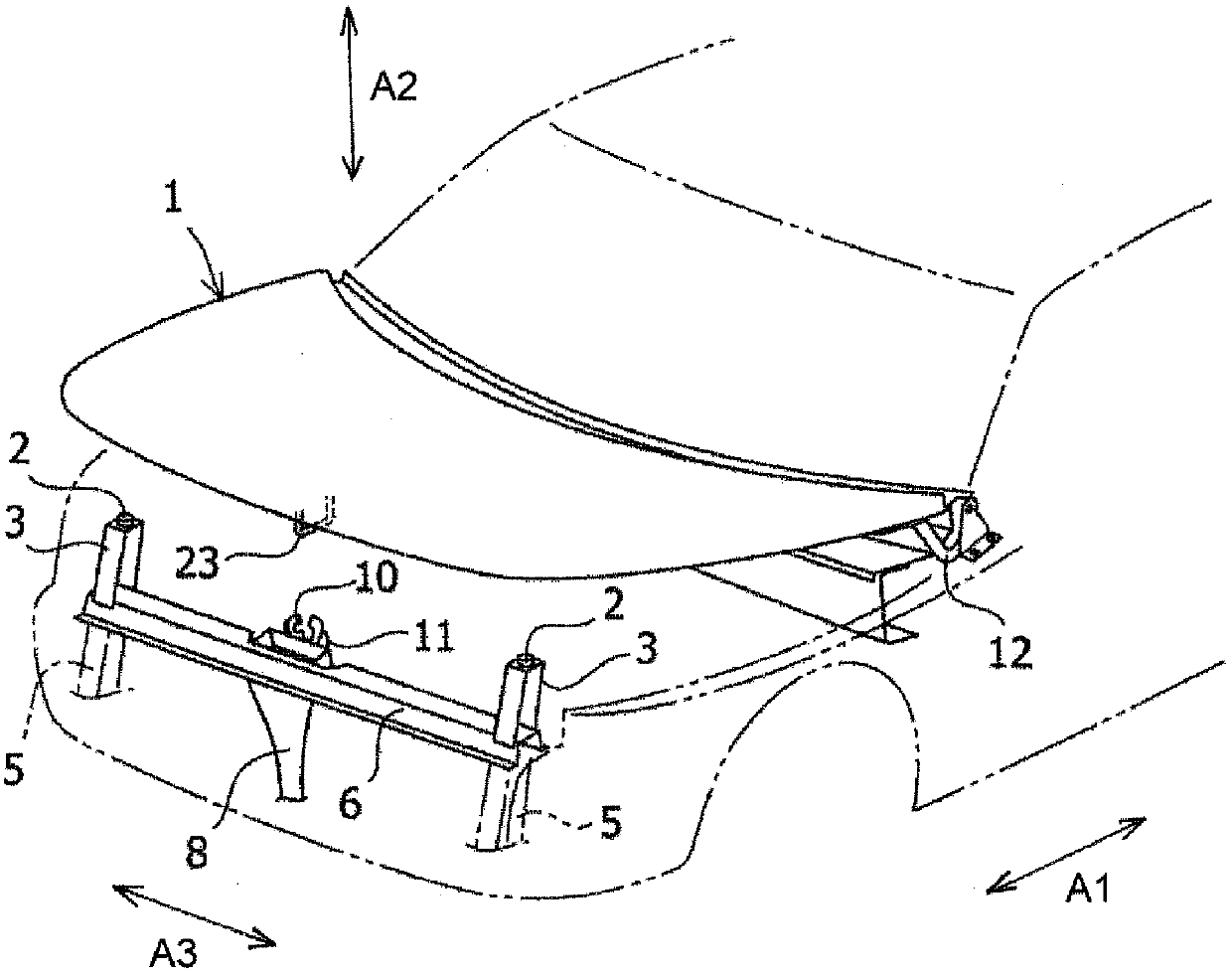

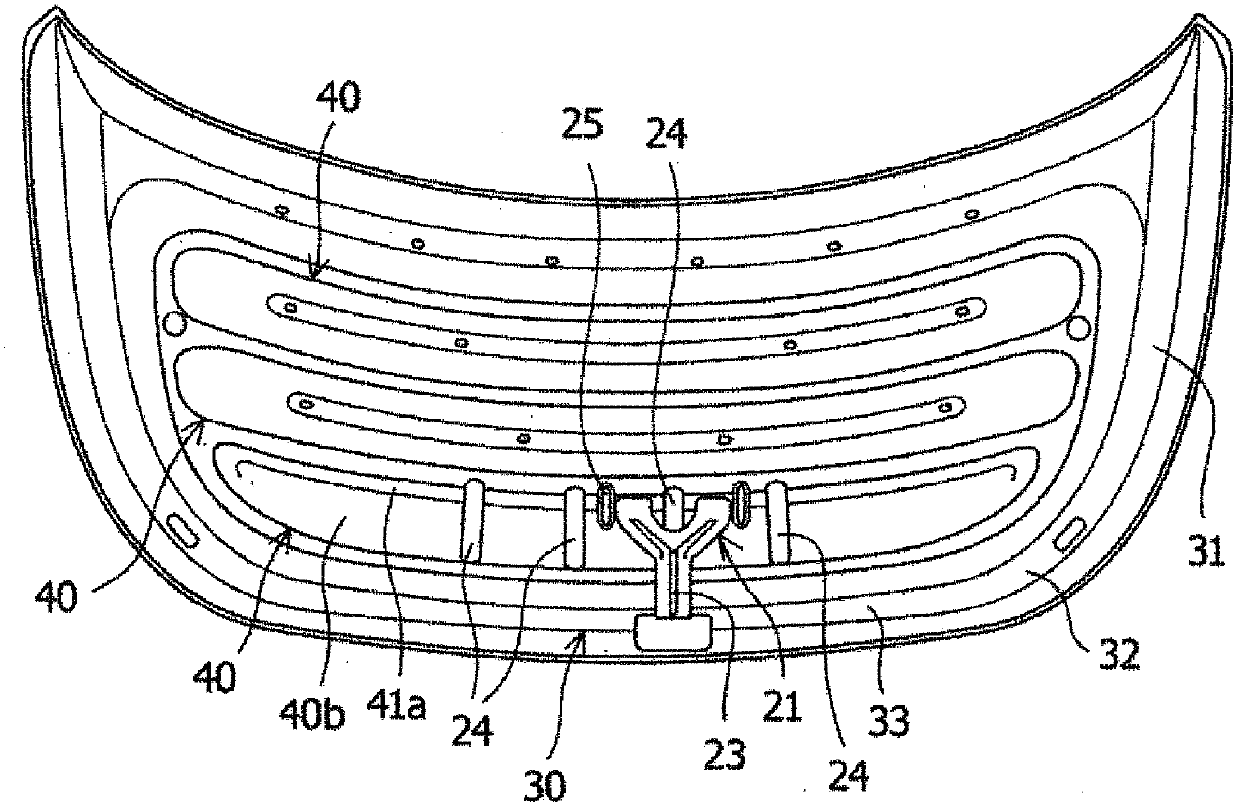

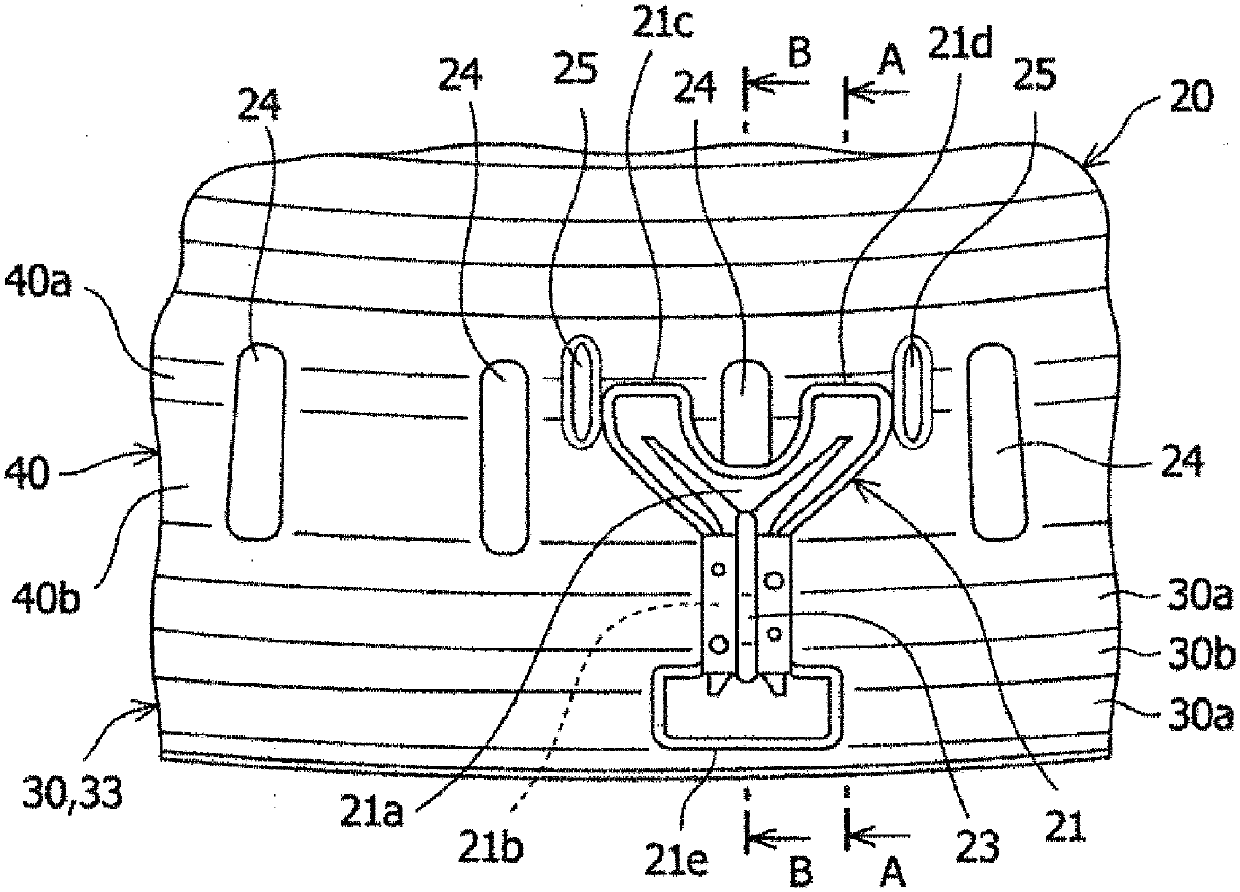

Hitch bracket mounting structure for vehicle hood

ActiveCN105873810BTo ensure the joint stiffnessDoes not hinder bending deformationVehicle locksSuperstructure subunitsEngineeringMechanical engineering

A hood inner panel (20) to which a striker bracket (21) is attached is made of aluminum and is provided with an outer peripheral rib (30) and an inner rib (40). Slits (24) are formed in the inner rib (40) on the front side. The striker bracket (21) is branched on the rear side in a Y shape that opens toward the rear of the vehicle when viewed from below. The vehicle rear end parts (21c, 21d) of the striker bracket are connected to the inner rib (40) on respective sides of a single slit (24). The front end part (21e) of the striker bracket (21) is connected to the outer peripheral rib (30).

Owner:KOBE STEEL LTD

Non-aqueous electrolyte secondary battery and method for producing non-aqueous electrolyte secondary battery

ActiveUS10147977B2Increase pointsImprove battery safetyFinal product manufactureCell electrodesEngineeringFire retardant

The present invention provides a non-aqueous electrolyte secondary battery that can suppress a drop in a flash point of an electrolyte solution even if the non-aqueous electrolyte secondary battery is used for a long time. The non-aqueous electrolyte secondary battery includes: an electrode body having a structure in which a positive electrode including a positive-electrode active material and a negative electrode including a negative-electrode active material are stacked with a separator interposed therebetween; a non-aqueous electrolyte solution containing a flame retardant; and an outer casing accommodating the electrode body and the non-aqueous electrolyte solution. The non-aqueous electrolyte solution in the electrode body has a flame retardant concentration lower than a flame retardant concentration in the non-aqueous electrolyte solution between the electrode body and the outer casing.

Owner:ELIIY POWER

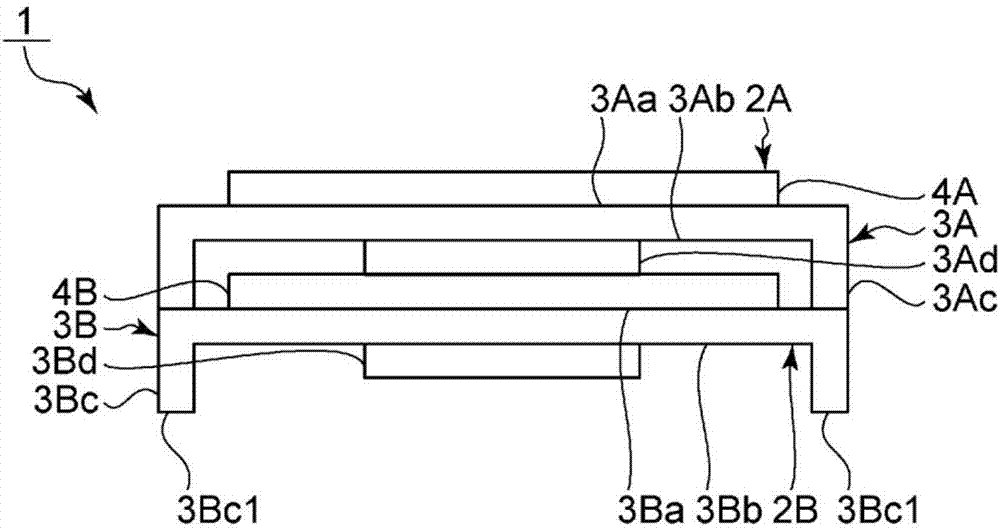

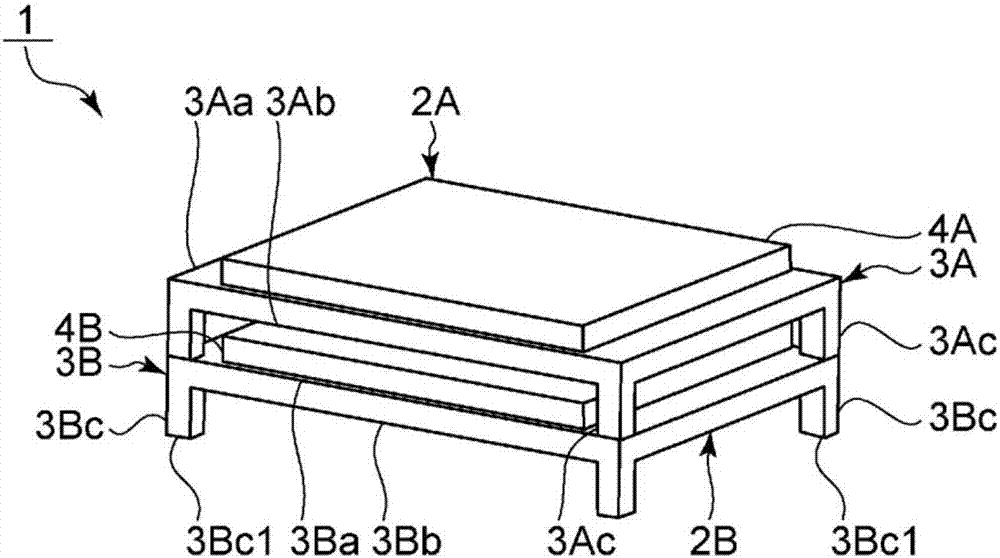

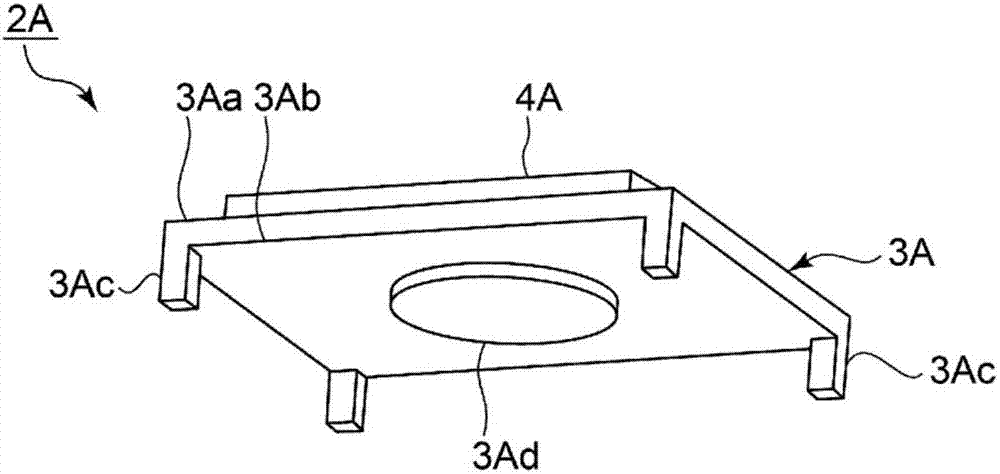

Piezoelectric power generator

ActiveCN107431448AImprove power generation efficiencyEase concentrationPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesStructural engineeringMechanical engineering

Provided is a piezoelectric power generator that has high power generation efficiency and minimal likelihood of damaging piezoelectric bodies. The piezoelectric power generator 21 is provided with a plurality of power generation elements 22, each of which having: a support body 3A provided with a plate-shaped flat-surface part that has a main surface 3Aa and another main surface 3Ab, and a projecting part 3Ad that protrudes from the central part of the other main surface 3Ab; and a piezoelectric body 4A provided on the main surface 3Aa. The piezoelectric body 4A is disposed so as to overlap the projecting part when the support body 3A is viewed in plan view along the direction perpendicular to the main surface 3Aa. The plurality of power generation elements 22 overlap in the direction perpendicular to the main surfaces 3Aa. The support body 3A of at least one of a pair of adjacent power generation elements 22 is provided with a plurality of support parts 3Ac (legs) that protrude from a peripheral edge part further outward from the central part of the flat surface part. The plurality of power generation elements overlap, interposed by the legs 3Ac, so that the main surface 3Aa and the another main surface 3Ab of the mutual support bodies 3A face each other in the pair of adjacent power generating elements 22.

Owner:MURATA MFG CO LTD

joint structure

InactiveCN105492304BAvoid deformationFully distributed stressSuperstructure subunitsAcute angleEngineering

The present invention provides a joint configuration. This joint structure can increase the rigidity against the bending load acting on the T-shaped joint. The joining structure has a second member (20) joined to the side of the first member (10) in the shape of a letter T, and the first upper surface (11a) and the flange (25) are joined through the joining portion (30). Long ribs (15a) are provided on the back side of the first upper surface (11a). The full length of the long rib (15a) is set to a length more than twice the distance from the contact portion between the first member (10) and the second member (20) to the joint portion (30a), and the long rib (15a ), among the angles formed by the direction in which ) extends and the longitudinal direction of the second member (20), the angle formed on the opposite side to the second member (20) is an acute angle.

Owner:SUZUKI MOTOR CORP

Heat exchanger

PendingCN113924449AEase concentrationReduce stress concentrationReinforcing meansEvaporators/condensersEngineeringMechanical engineering

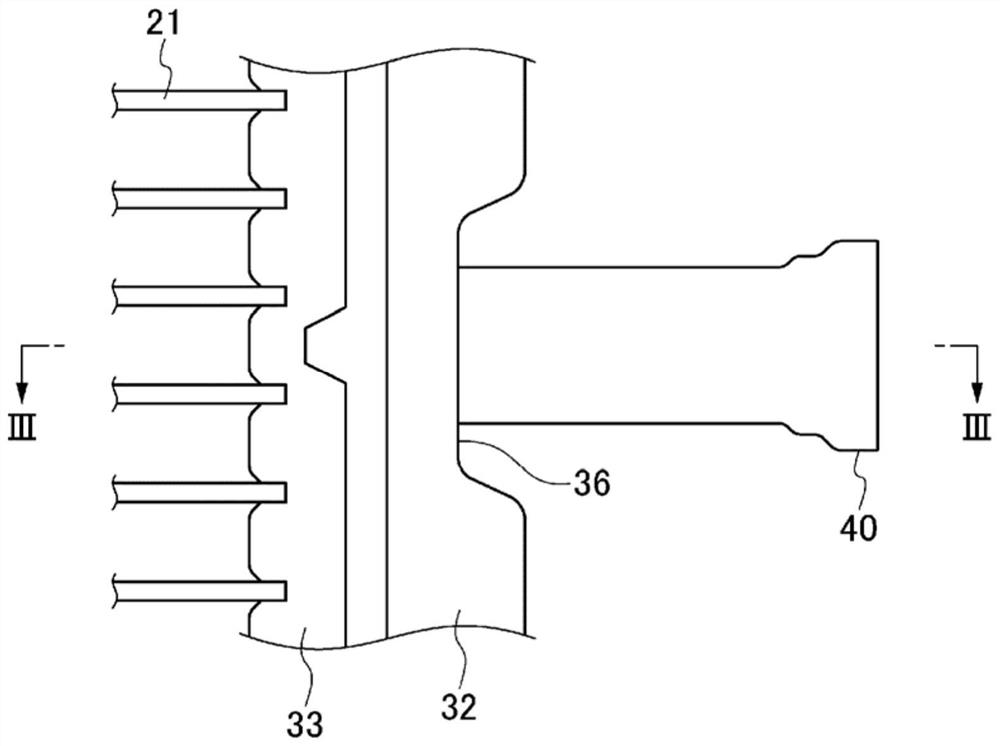

This heat exchanger comprises: a pair of tanks that are provided at both ends of a plurality of stacked tubes (21) and have a longitudinal direction along the direction in which the tubes are stacked; and a connector (40) on the side surface of a connection tank (30), which is at least one of the pair of tanks, the connector being for connecting a pipe to the connection tank. The connection tank has a tubular shape having a flat portion (36) on at least a portion of the side surface. The connector is joined to the flat portion such that at least a portion of the facing surface (42) facing the flat portion projects from the flat portion in the lateral direction of the connection tank.

Owner:DENSO CORP

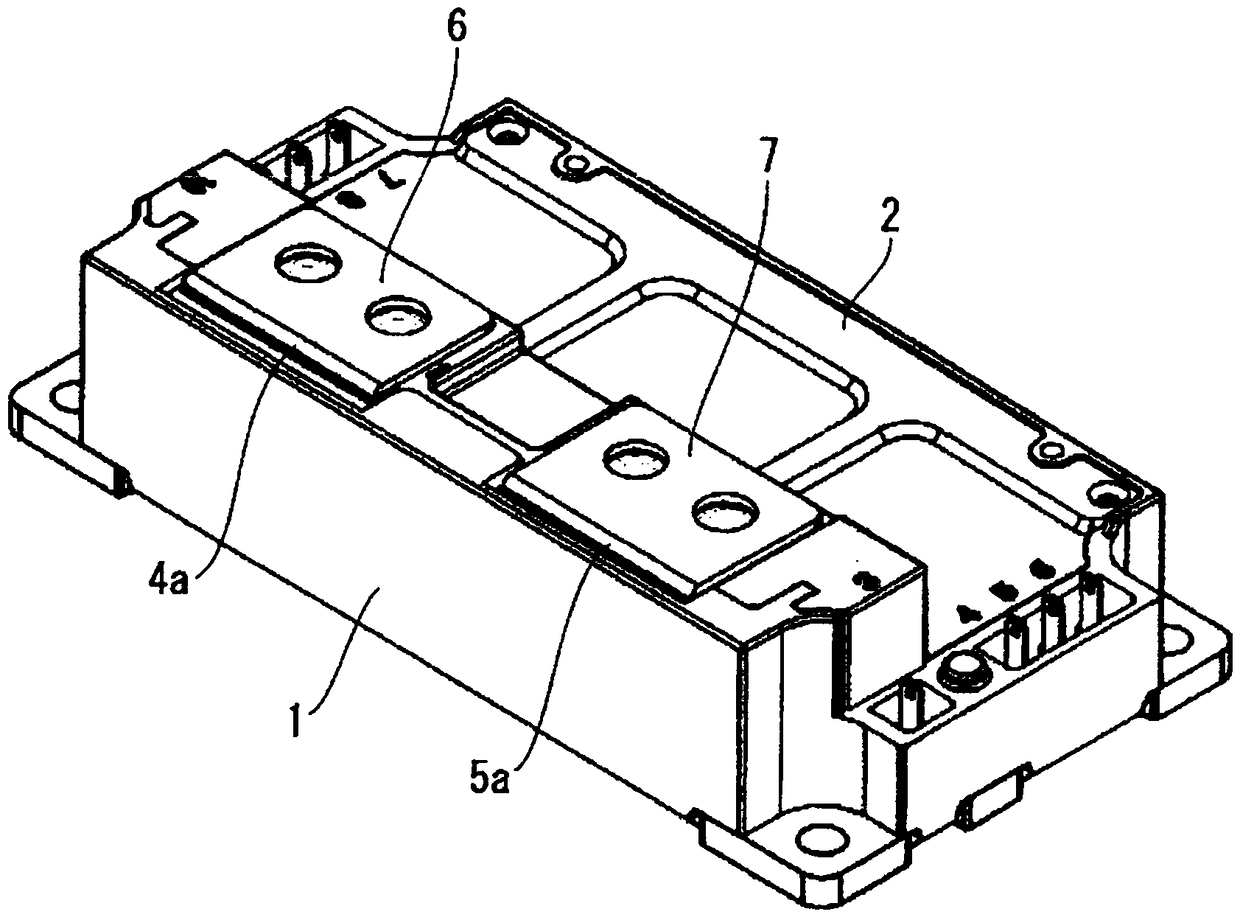

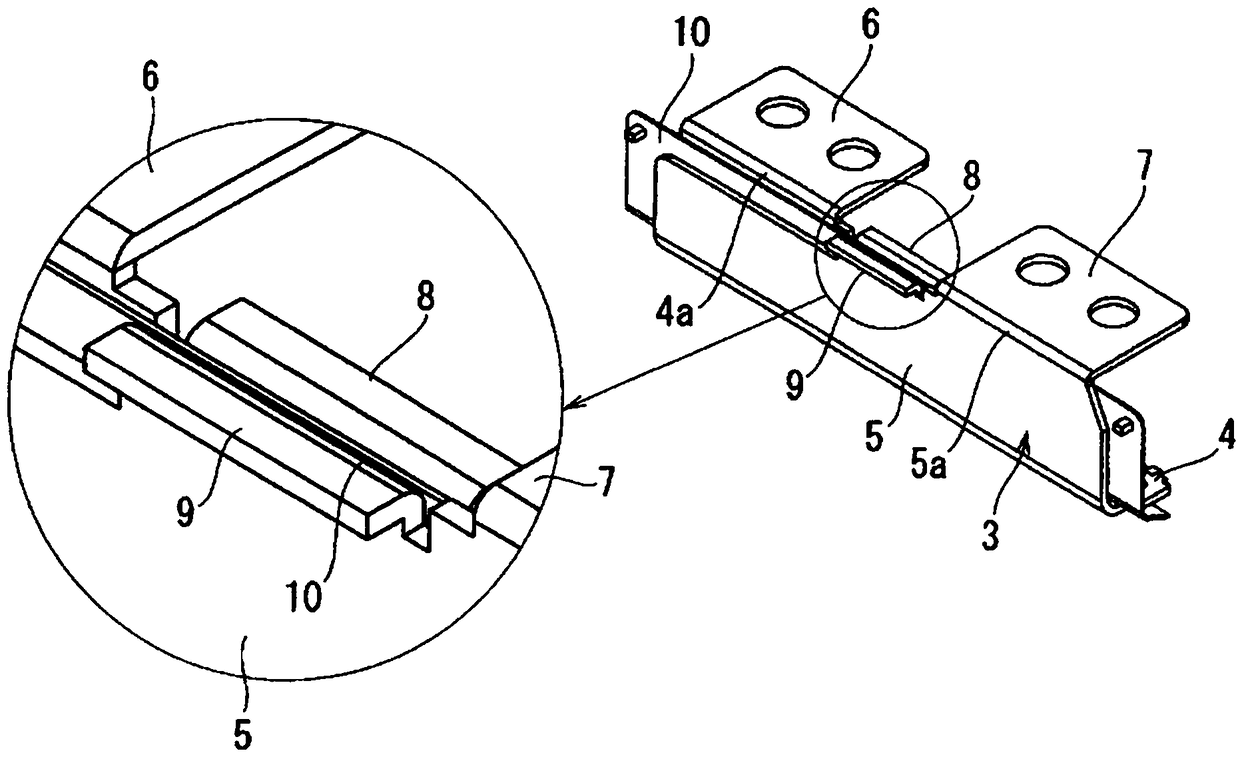

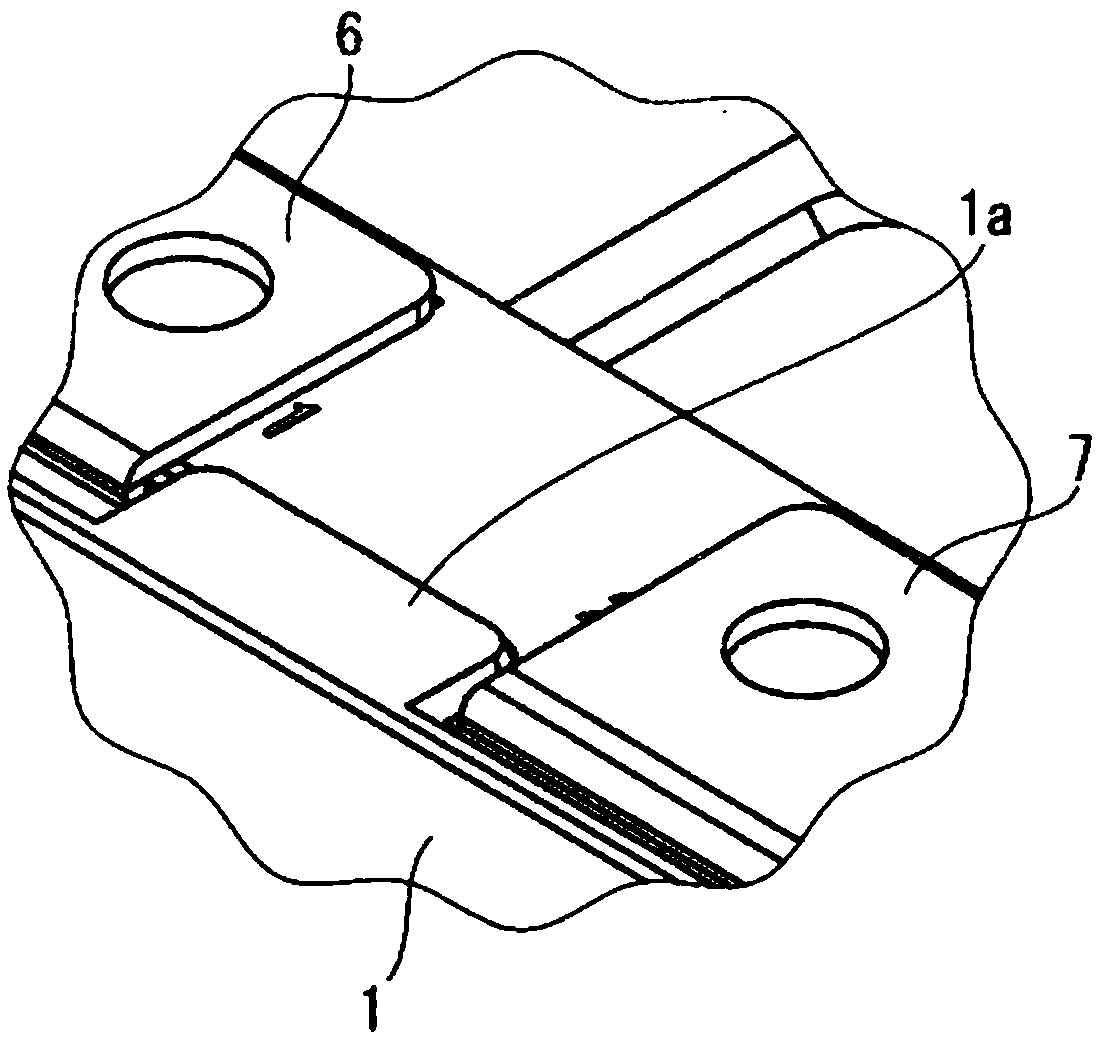

Semiconductor device

ActiveCN106024748BLower self-esteemEase concentrationSemiconductor/solid-state device detailsSolid-state devicesParallel plateEngineering

The object is to provide a semiconductor device capable of reducing self-inductance. The semiconductor device has: a resin case (1), which accommodates a semiconductor element; a parallel plate (3), which is connected to the semiconductor element and arranged in the resin case (1), and is parallel to each other through an insulating material (10). and two electrodes (6, 7), which are respectively drawn out from the upper ends of the parallel plates (3), and arranged in the resin case (1) at predetermined intervals. ) on the upper surface. The upper ends of the parallel plates (3) between the two electrode lead-out parts (4a, 5a) from which the two electrodes (6, 7) lead out are respectively bent outward in directions away from each other.

Owner:MITSUBISHI ELECTRIC CORP

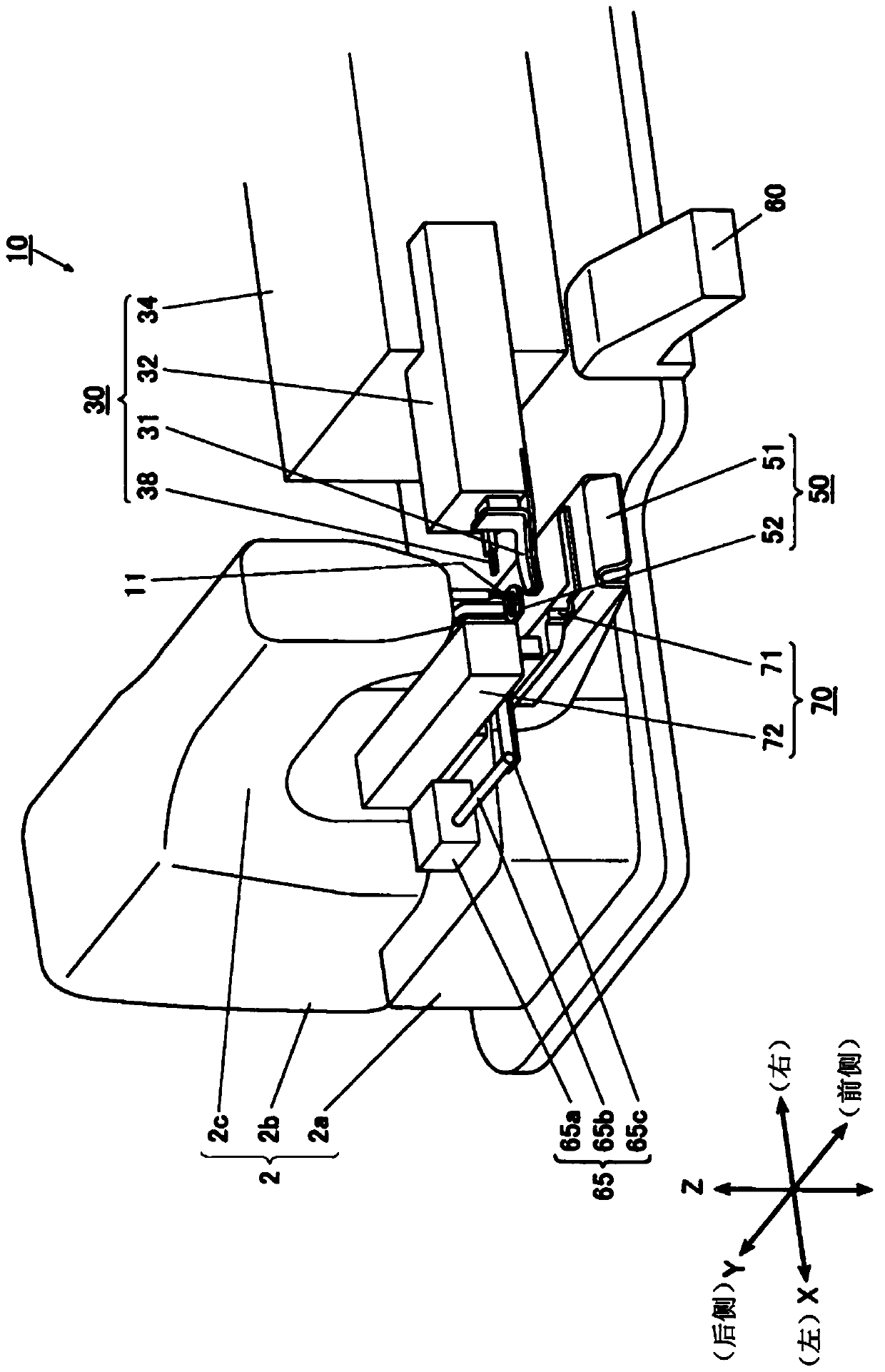

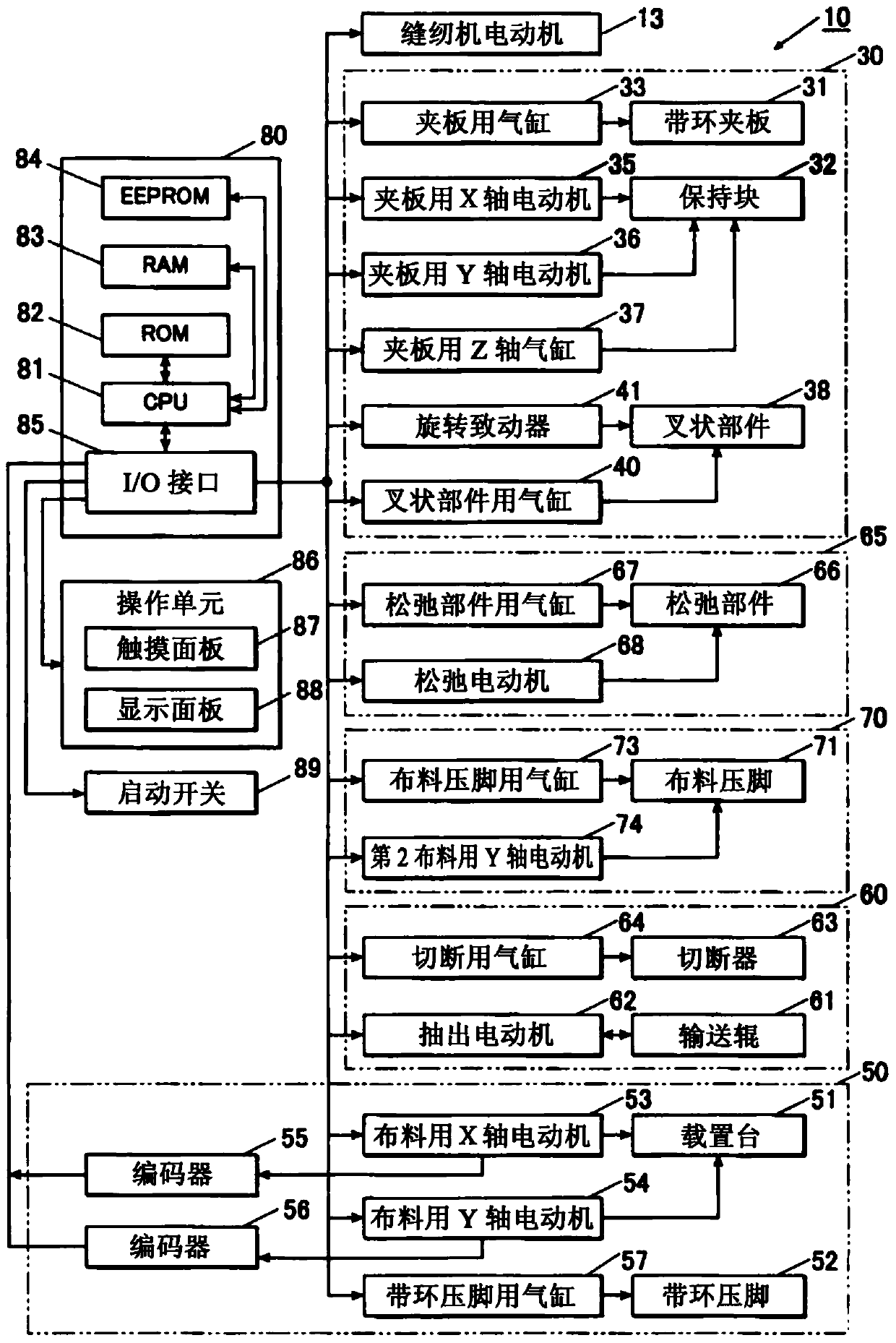

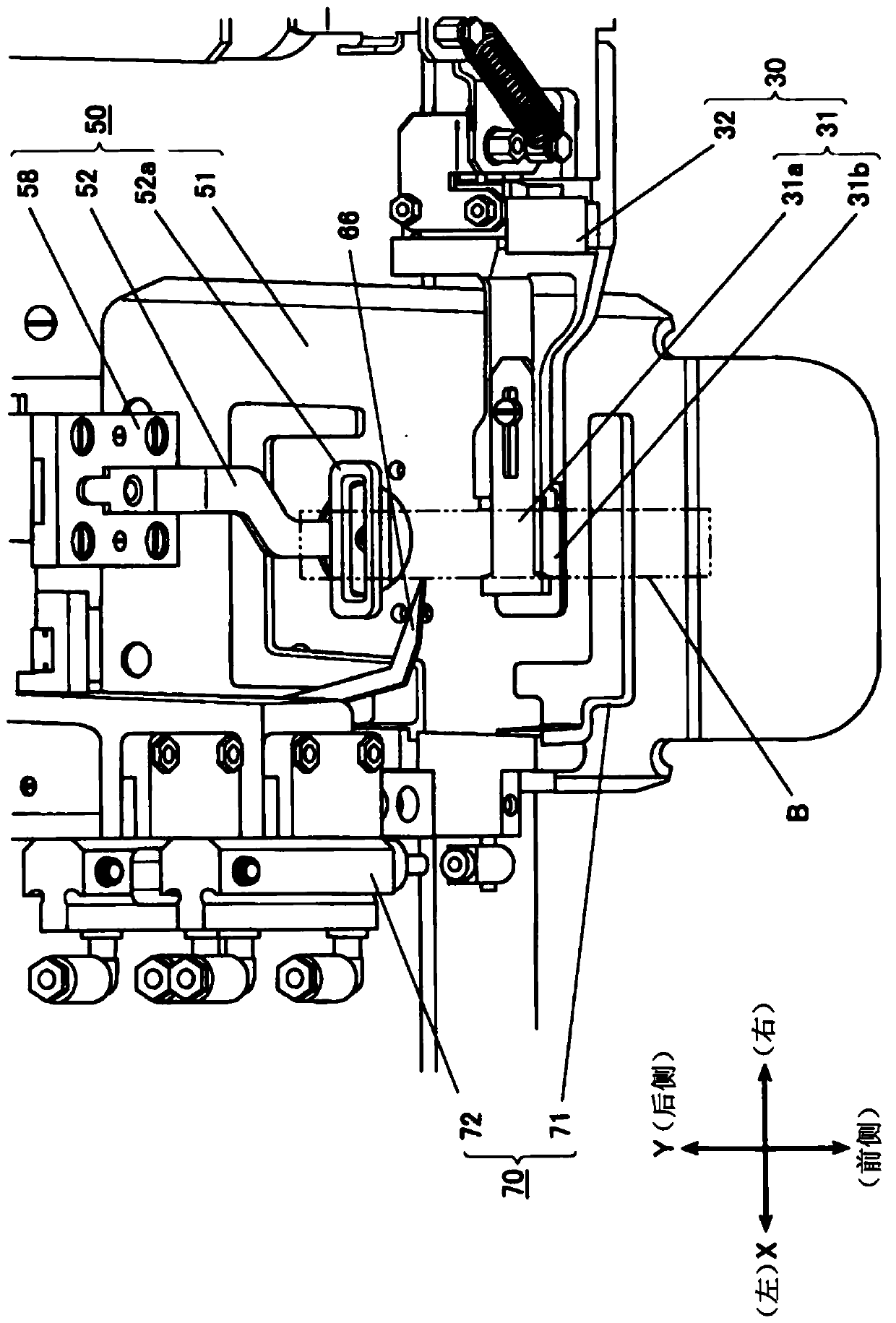

Belt loop sewing method and belt loop sewing sewing machine

The invention provides a band ring sewing machine, and the machine achieves the Z-shaped sewing of one end part of band ring and reduces the stitch number. The machine is provided with a sewing needle up / down movement mechanism; a band ring clamping board; a band ring pressing pin; a carrying table; a cloth pressing pin; a first moving mechanism which enables the band ring pressing pin and the carrying table to move; a second moving mechanism which enables cloth to move; a clamping board moving mechanism which enables the band ring clamping board to move; a control device; an insertion part; and an insertion part movement mechanism. The control device carries out the following control: folding stitch forming control: forming a folding stitch at one end part of the band ring clamped by the band ring clamping board; insertion part configuration control: configuring an insertion part in a gap between the cloth and the band ring between the folding stitch and a clamping position referred by the band ring clamping board; folding control: enabling the insertion part to move towards the folding stitch, and forming a state of band ring folding through the insertion part; folding sewing control: forming a stitch which enables the band ring to be sewed towards the stitch, so as to maintain the folding state of the band ring.

Owner:JUKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com