Heat exchanger

A technology of heat exchangers and connectors, which is applied in the direction of fixing heat exchangers, heat exchange equipment, heat exchanger shells, etc., and can solve problems such as increased operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, this embodiment will be described with reference to the drawings. In order to facilitate understanding of the description, in each drawing, the same reference numerals are assigned to the same constituent elements as much as possible, and overlapping descriptions are omitted.

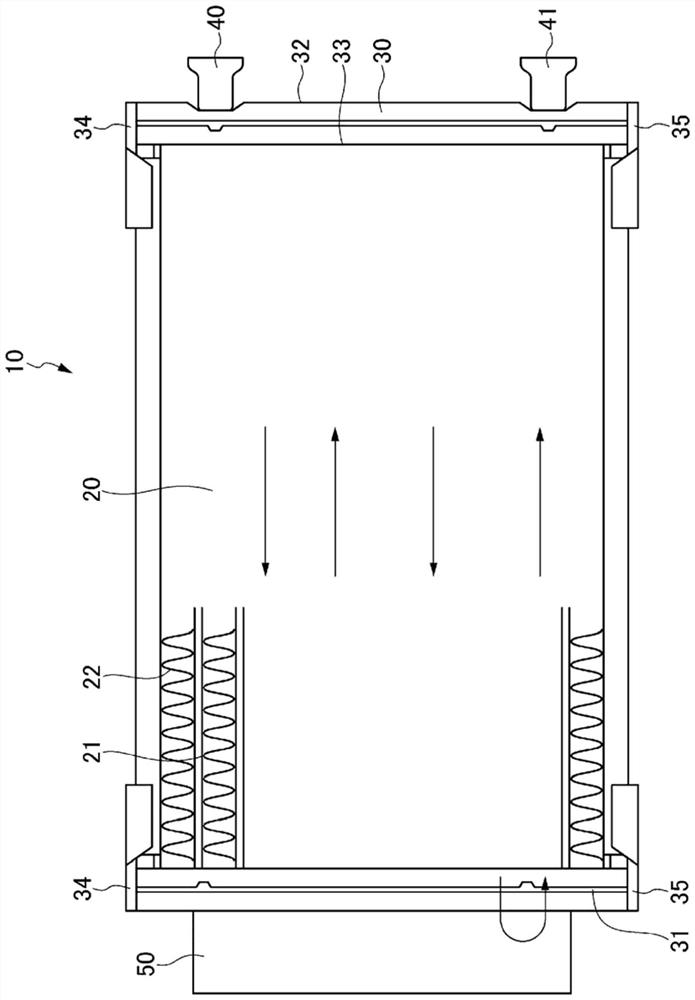

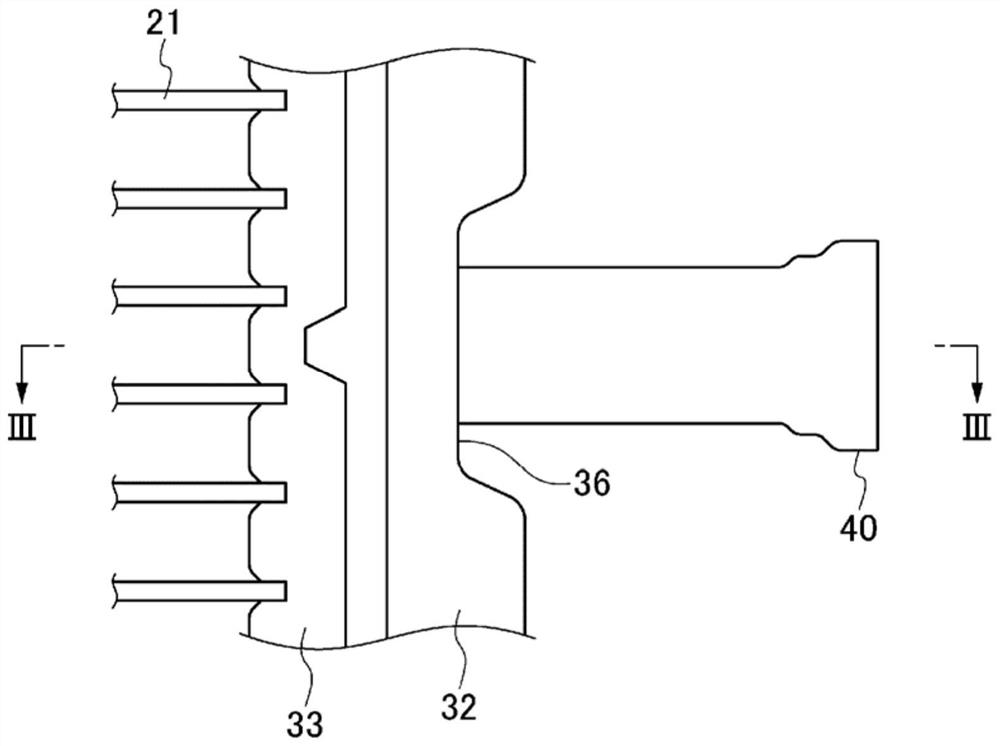

[0022] refer to figure 1 , and a heat exchanger according to one embodiment will be described. The heat exchanger 10 is used, for example, as a condenser of an air conditioner mounted on a mobile body such as a vehicle. Such as figure 1 As shown, the heat exchanger 10 includes, for example, a core 20 , a pair of tanks 30 and 31 , connectors 40 and 41 , and a conditioning tank 50 . Each member is made of, for example, aluminum or an aluminum alloy, and is fixed by brazing after being temporarily fixed by fitting, riveting, clamping, or the like.

[0023] The core 20 includes a plurality of tubes 21 and a plurality of fins 22 . Refrigerant flows inside the plurality of tubes 21 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com