joint structure

A technology of structure and joint, applied in the direction of superstructure, subassembly of superstructure, transportation and packaging, etc., can solve problems such as poor mechanical properties, achieve the effect of improving rigidity, reducing deformation and relieving stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

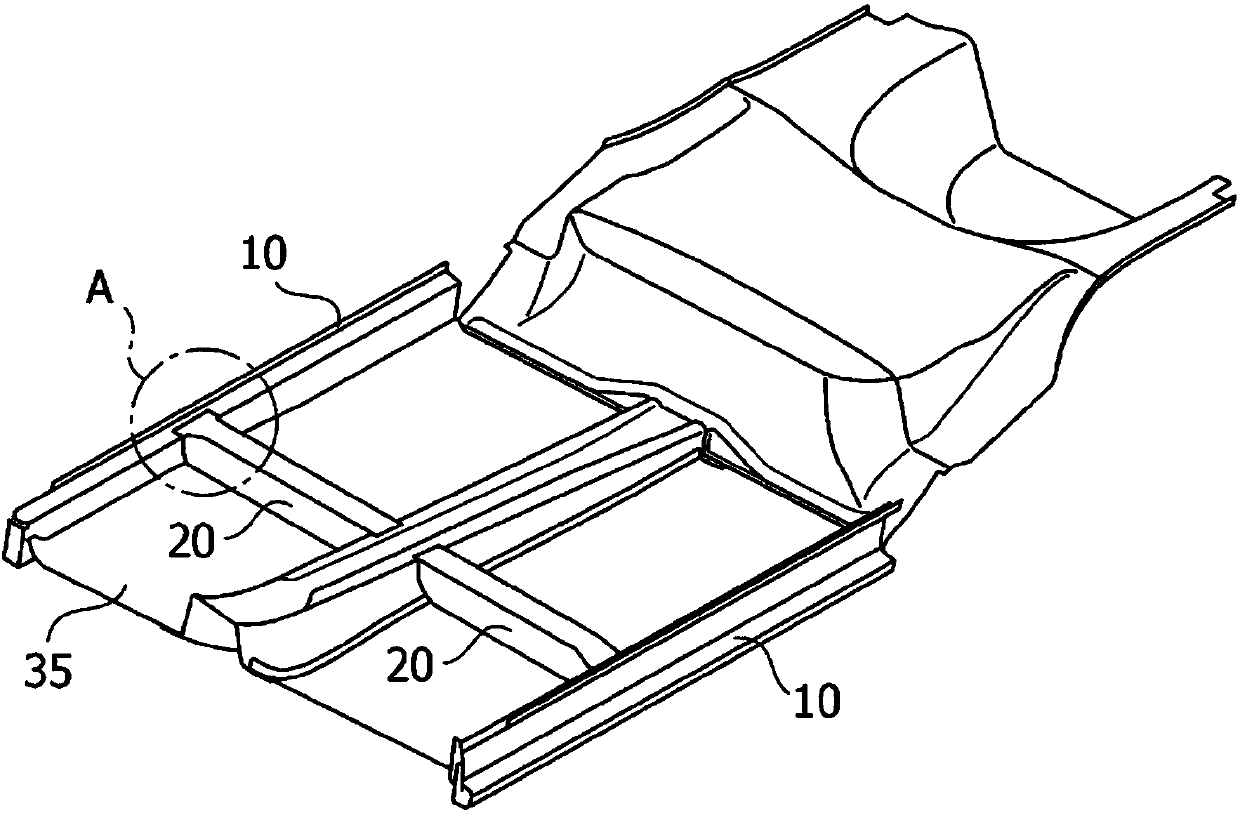

[0037] use Figure 1 ~ Figure 4 The first embodiment will be described. Such as figure 1 As shown, the side members 10 of the present embodiment are members that constitute the frame of the vehicle body, and are members that extend in the vehicle front and rear direction and are arranged in pairs on both sides in the vehicle width direction. The side member 10 of this example is formed of a fiber-reinforced resin material. The cross member 20 is a member constituting the frame of the vehicle body, like the side member 10. The cross member 20 is a member extending in the vehicle width direction, and is joined to the side of the side member 10.

[0038] As mentioned above, resin materials have a lower specific gravity than metal materials such as iron and aluminum, but have poor mechanical properties. Fiber-reinforced resin materials are materials that use carbon fiber and glass fiber to supplement poor mechanical properties. In this example, it is formed of, for example, a gla...

no. 2 Embodiment approach

[0067] use Figure 5 The second embodiment will be described. This embodiment is the first embodiment ( Figure 1 ~ Figure 4 In the modified example of ), the same or similar parts as in the first embodiment are given the same reference numerals, and repeated descriptions are omitted.

[0068] In this embodiment, as Figure 5 As shown, a Japanese katakana U-shaped rib 29 is provided on the inner side of the beam 20. The Japanese katakana U-shaped rib 29 is composed of a rectangular plate that is attached to the back of three surfaces, the second upper surface 21a, the front vertical wall surface 22a, and the rear vertical wall surface 23a, respectively.

[0069] The Japanese katakana U-shaped rib 29 may be arranged in the vicinity of the junction in the same manner as the letter X-shaped rib 26.

[0070] According to this embodiment, by providing Japanese katakana U-shaped ribs 29 and the like on the beam 20 in the same way as the letter X-shaped ribs 26, the rigidity near the junct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com