Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Cost-effectively formed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

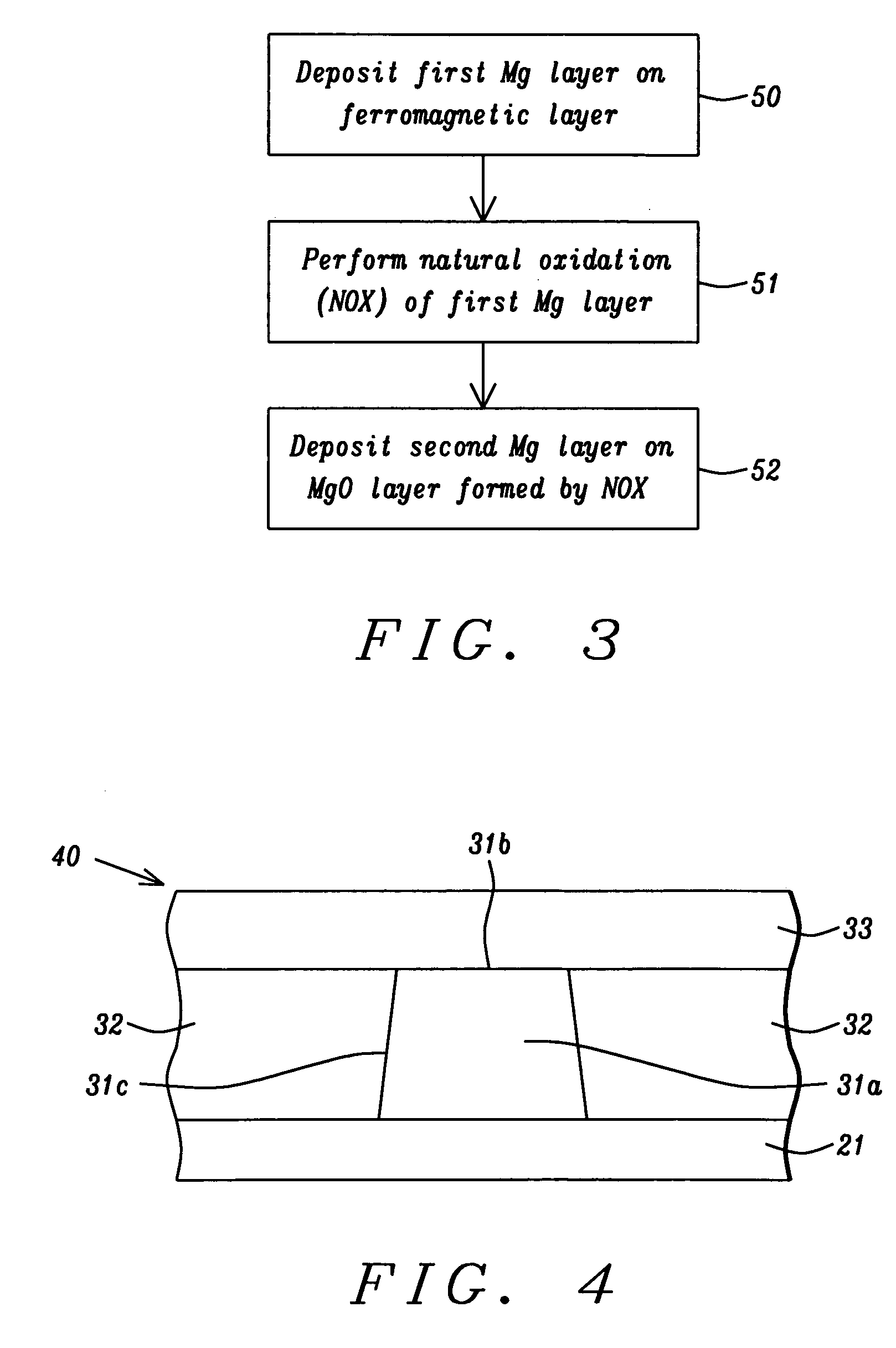

Low resistance tunneling magnetoresistive sensor with natural oxidized double MgO barrier

ActiveUS20070111332A1Improve uniformityHigh MR ratioNanomagnetismMagnetic measurementsSpin valveMaterials science

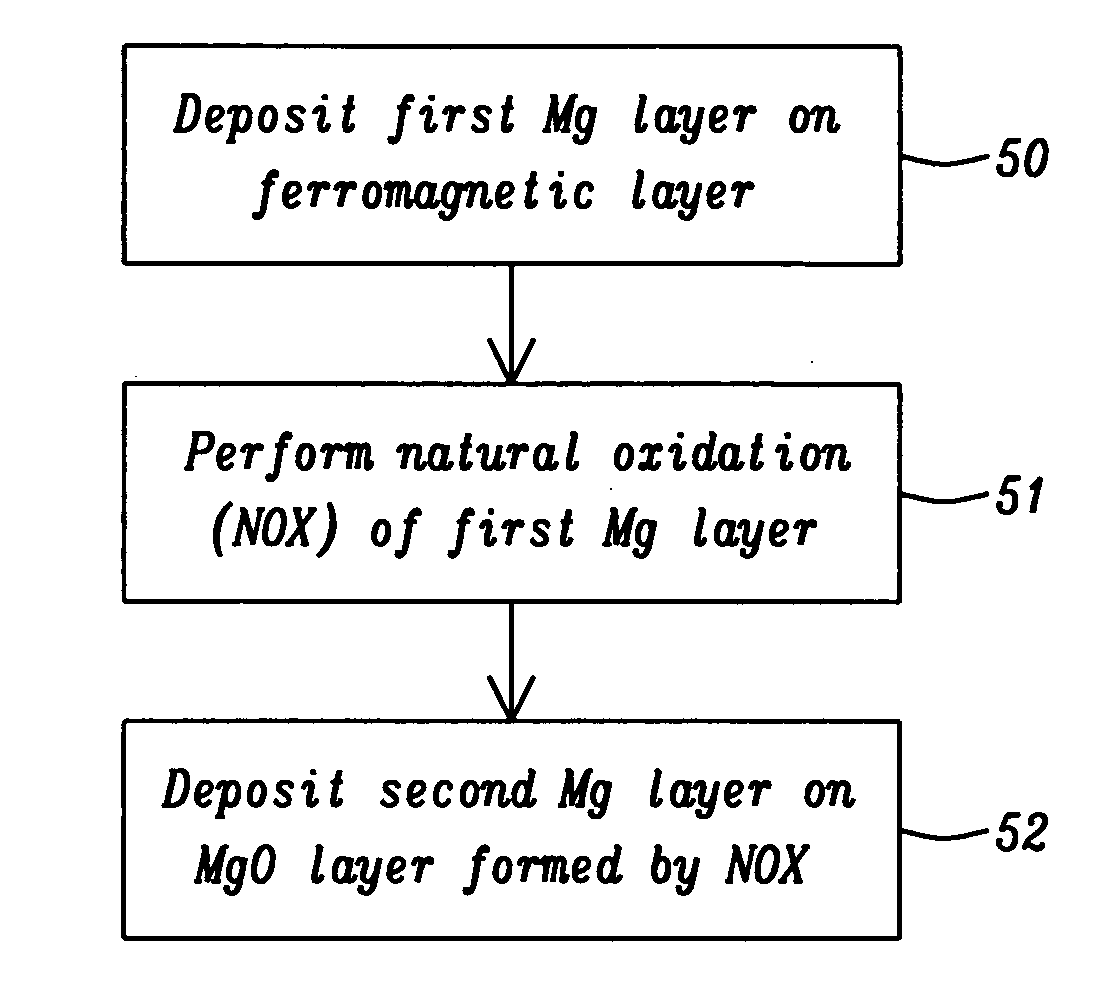

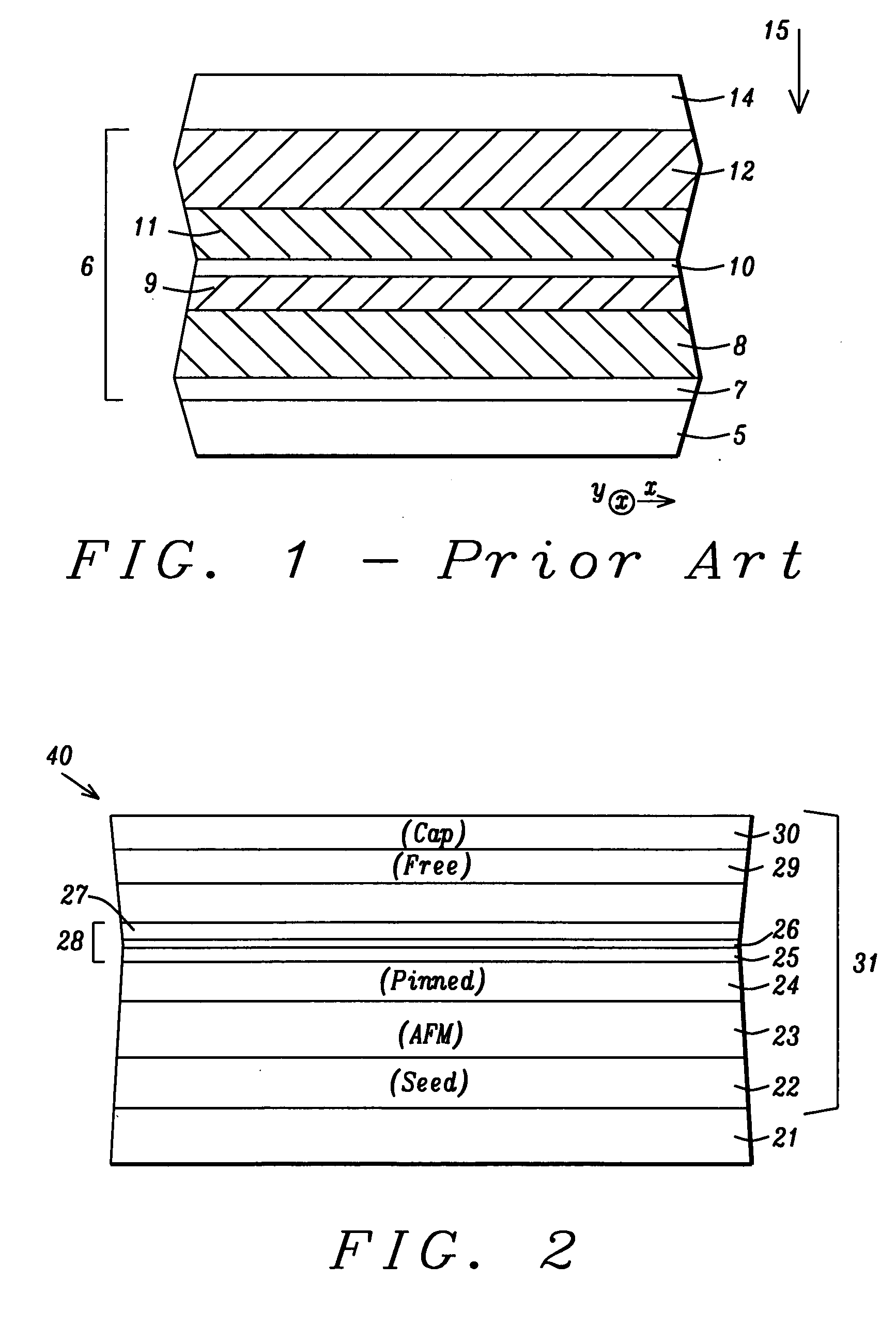

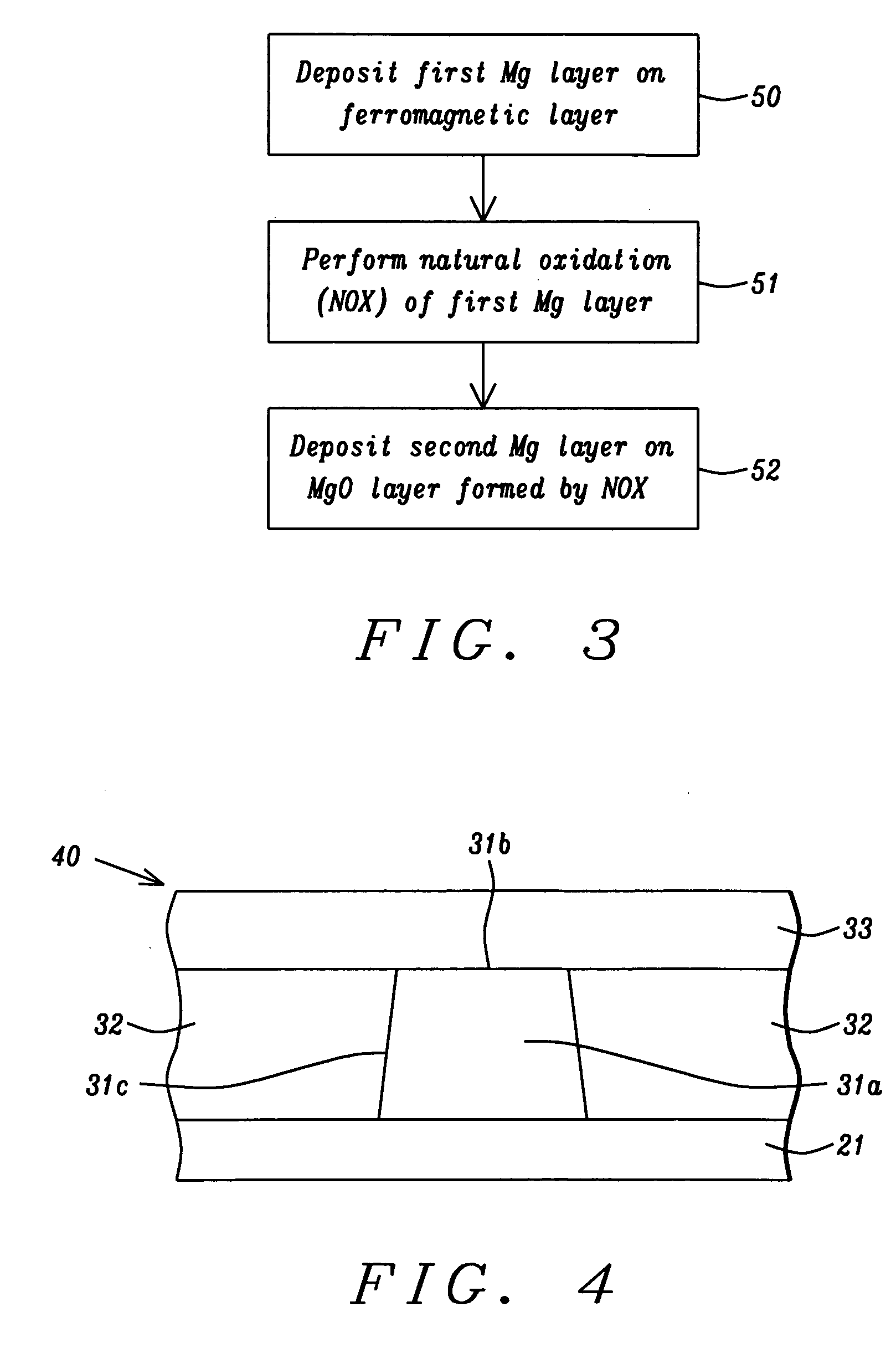

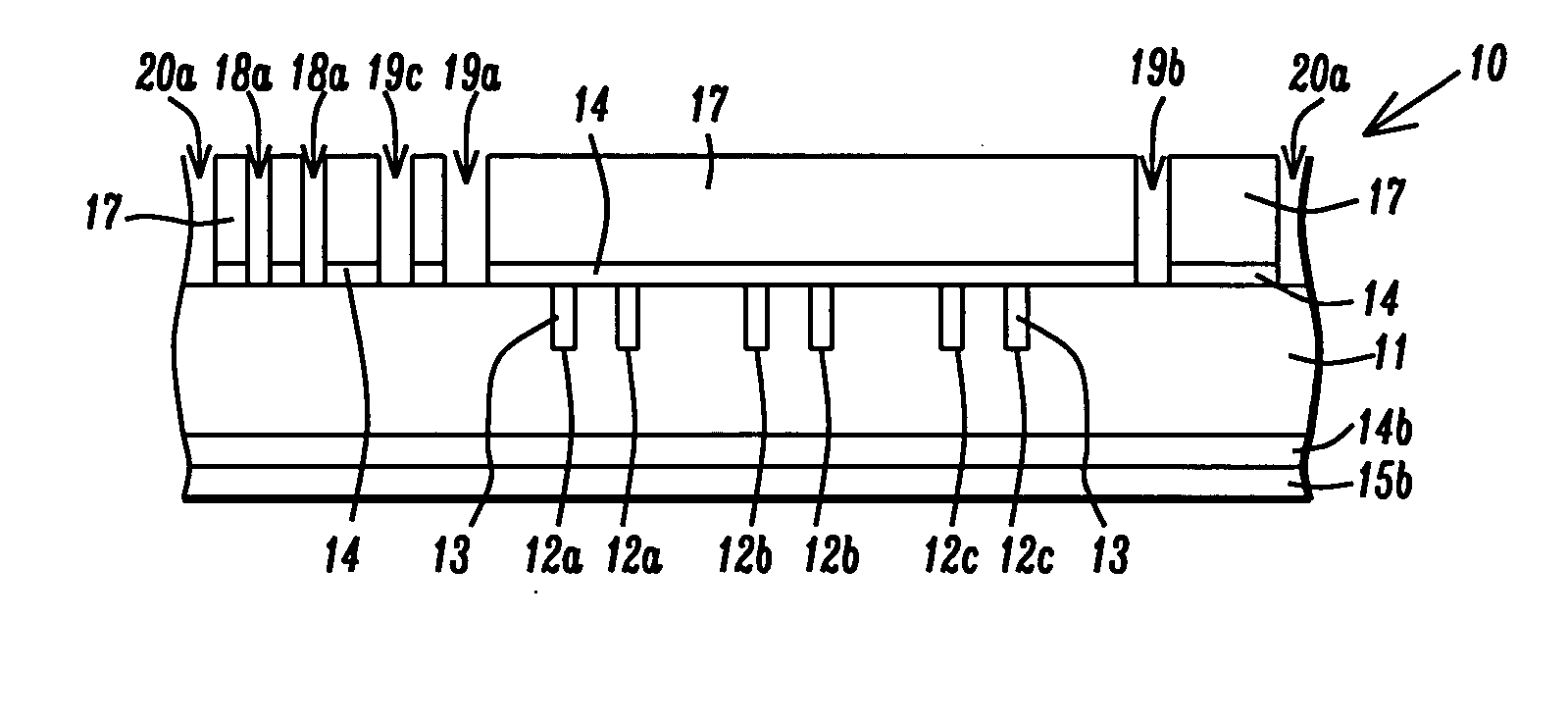

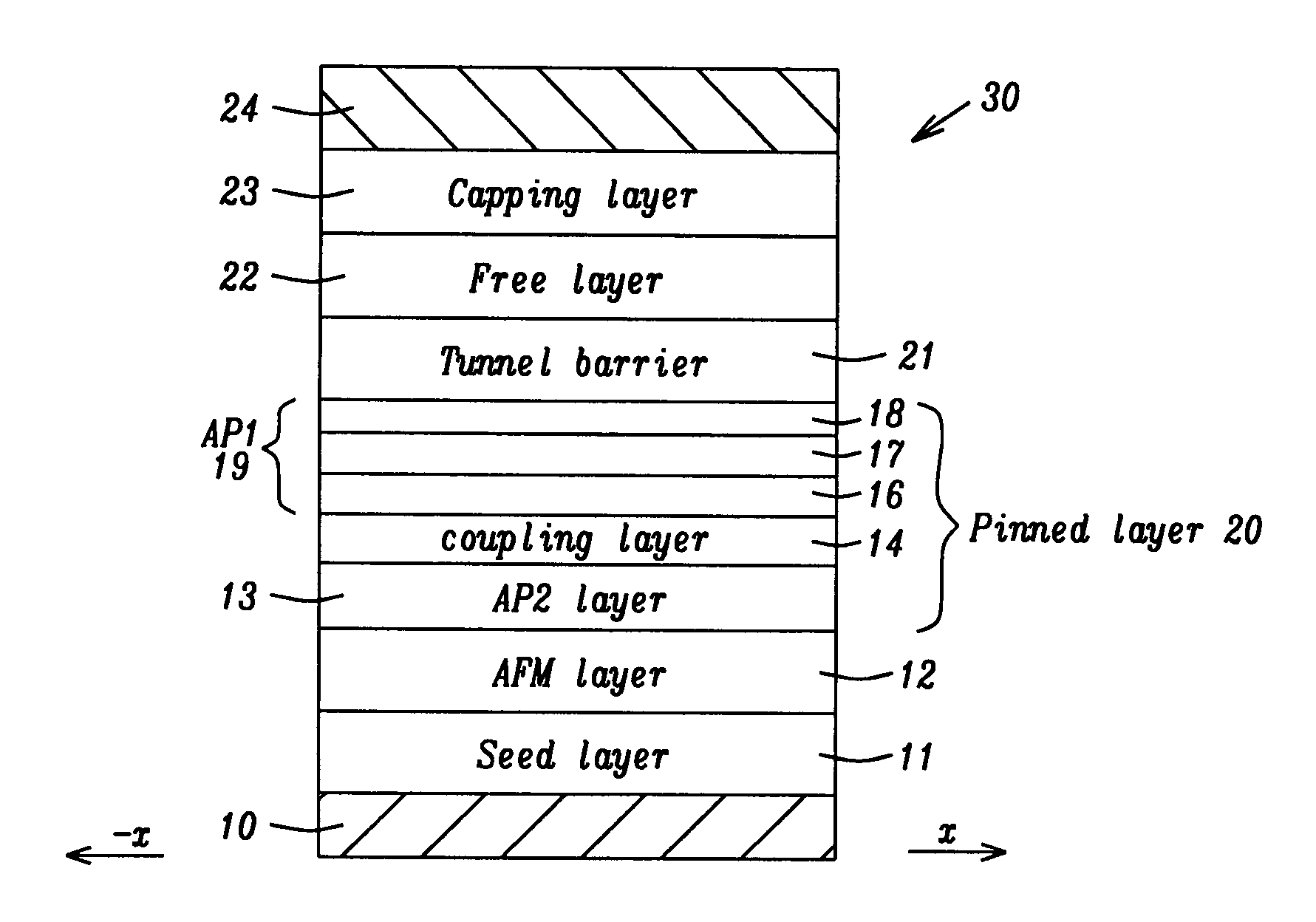

A high performance TMR sensor is fabricated by incorporating a tunnel barrier having a Mg / MgO / Mg configuration. The 4 to 14 Angstroms thick lower Mg layer and 2 to 8 Angstroms thick upper Mg layer are deposited by a DC sputtering method while the MgO layer is formed by a NOX process involving oxygen pressure from 0.1 mTorr to 1 Torr for 15 to 300 seconds. NOX time and pressure may be varied to achieve a MR ratio of at least 34% and a RA value of 2.1 ohm-um2. The NOX process provides a more uniform MgO layer than sputtering methods. The second Mg layer is employed to prevent oxidation of an adjacent ferromagnetic layer. In a bottom spin valve configuration, a Ta / Ru seed layer, IrMn AFM layer, CoFe / Ru / CoFeB pinned layer, Mg / MgO / Mg barrier, CoFe / NiFe free layer, and a cap layer are sequentially formed on a bottom shield in a read head.

Owner:HEADWAY TECH INC

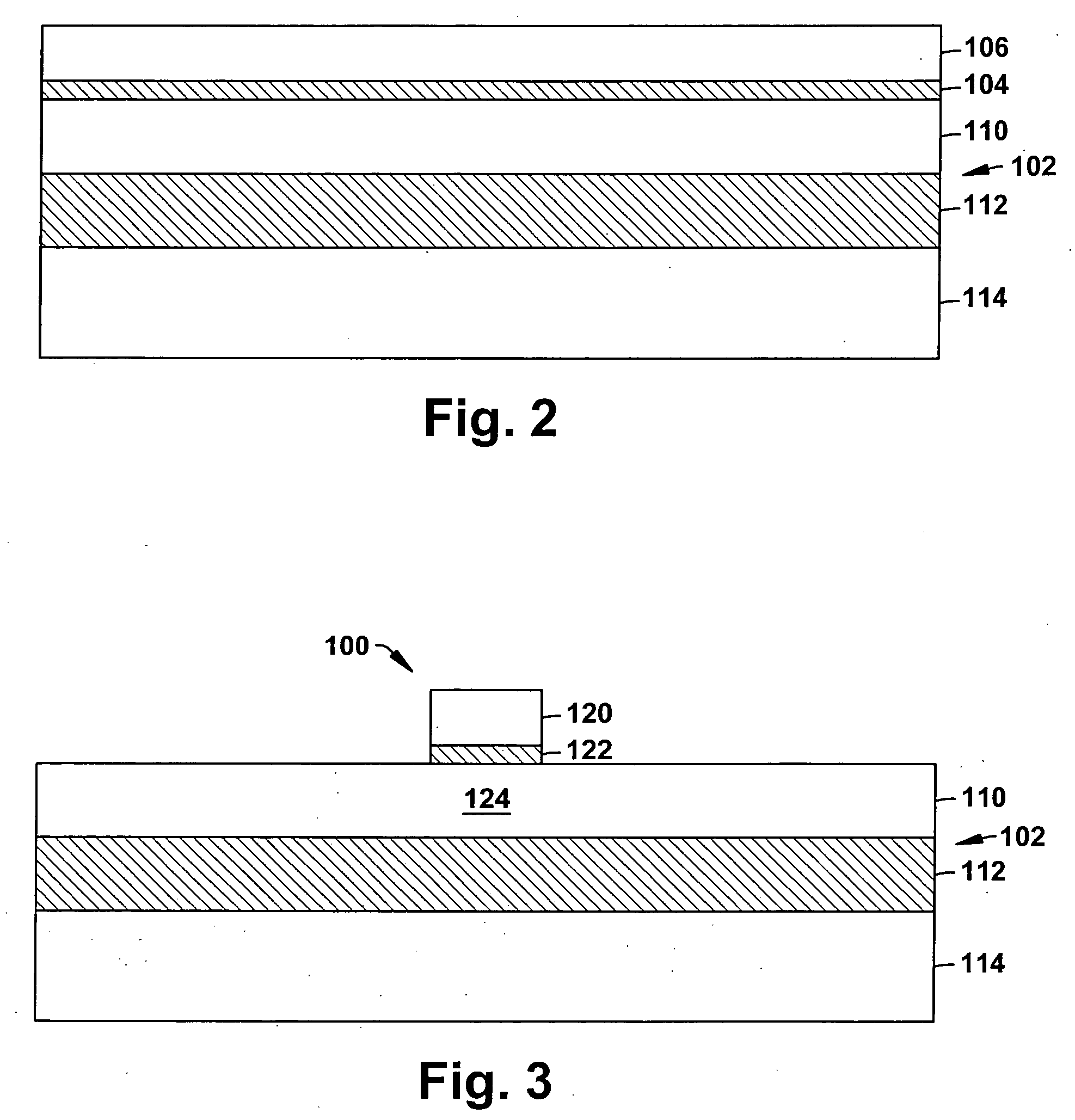

Silicon microphone with softly constrained diaphragm

ActiveUS20060093171A1Reduce stressSimple methodSemiconductor electrostatic transducersFluid pressure measurement by electric/magnetic elementsParyleneEngineering

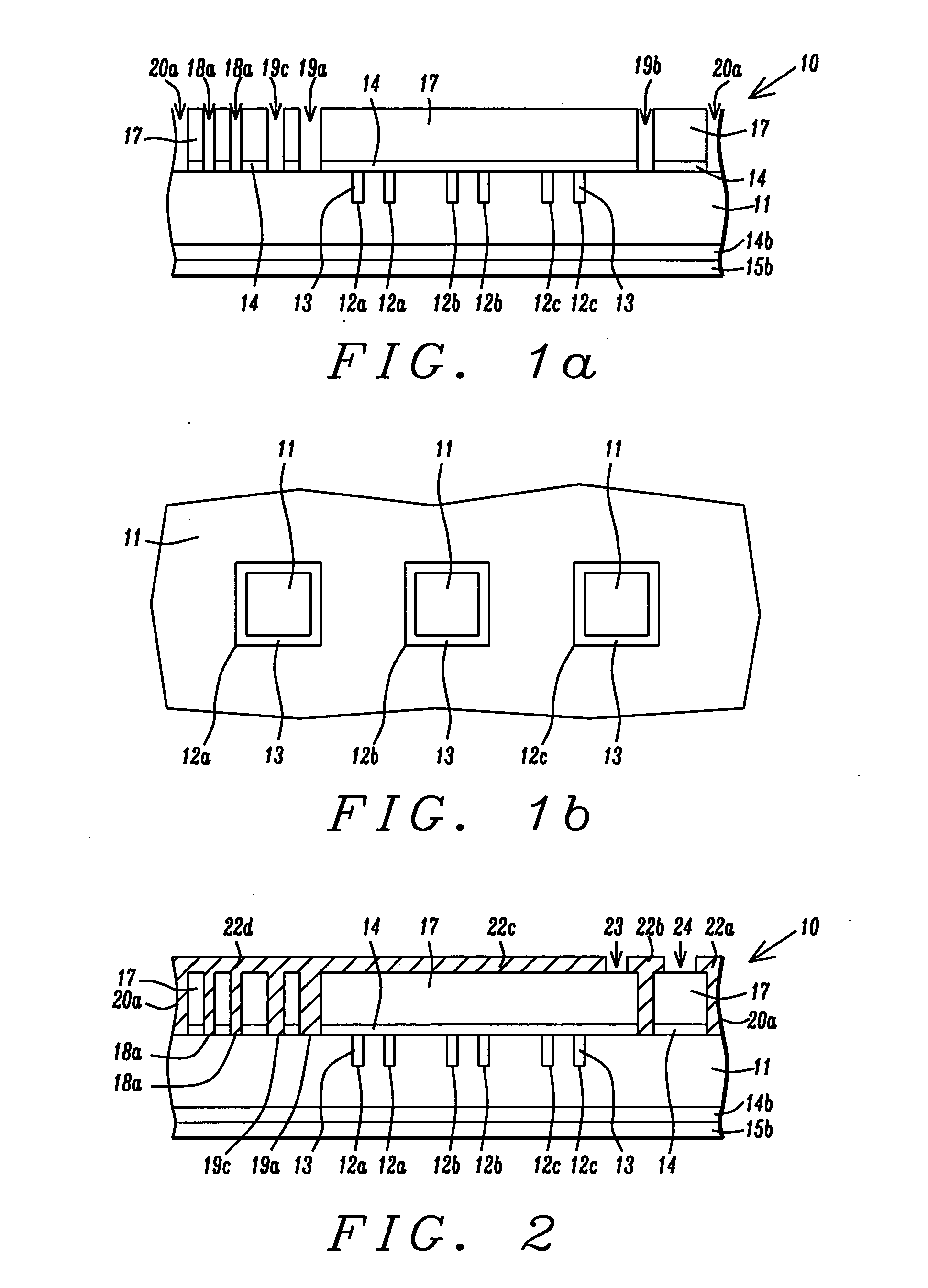

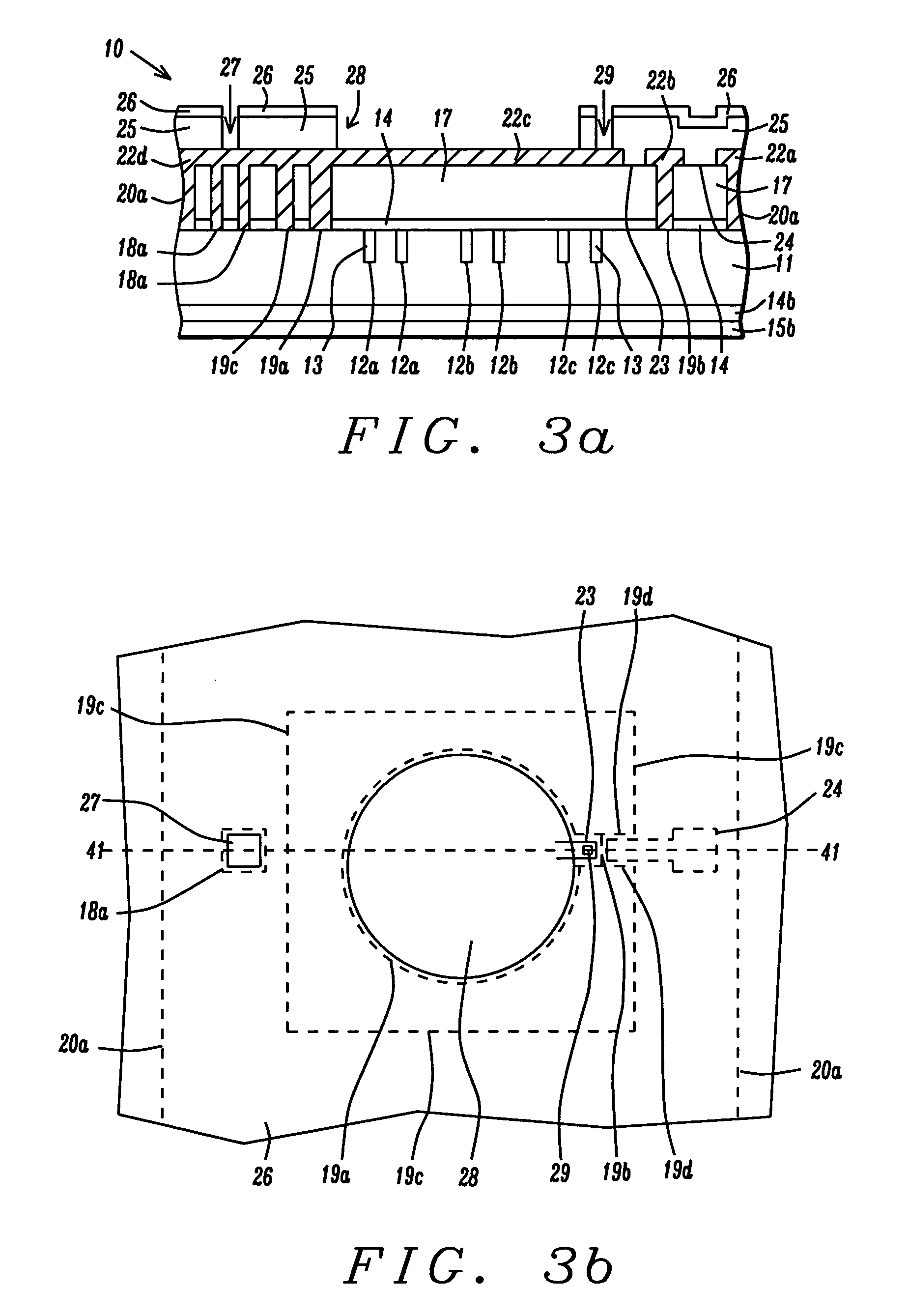

A microphone sensing element and a method for making the same are disclosed. The sensing element has a diaphragm and an attached electrical lead-out arm preferably made of polysilicon that are separated by an air gap from an underlying backplate region created on a conductive silicon substrate. The backplate region has acoustic holes created by removing an oxide filling in a continuous trench that surrounds hole edges and by removing oxide to form the air gap. The diaphragm is softly constrained along its edge by an elastic element that connects to a surrounding rigid polysilicon layer. The elastic element is typically a polymer such as parylene having a Young's modulus substantially less than that of the diaphragm. First and second electrodes are connected to the diaphragm through the lead-out arm and to the substrate through polysilicon via fillings, respectively, and thereby establish a variable capacitor circuit for acoustic sensing.

Owner:SHANDONG GETTOP ACOUSTIC

Low resistance tunneling magnetoresistive sensor with composite inner pinned layer

Owner:HEADWAY TECH INC

Low resistance tunneling magnetoresistive sensor with composite inner pinned layer

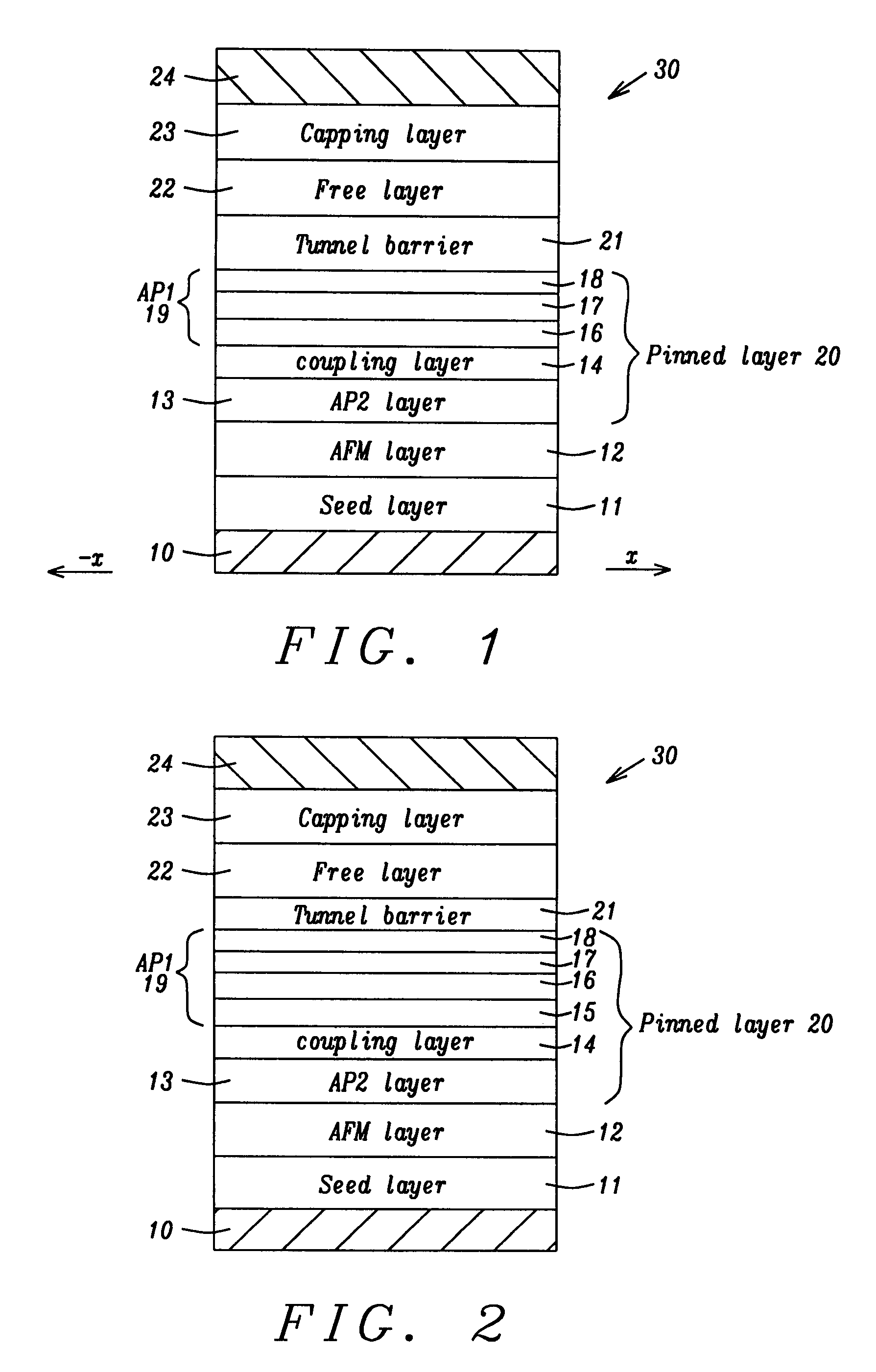

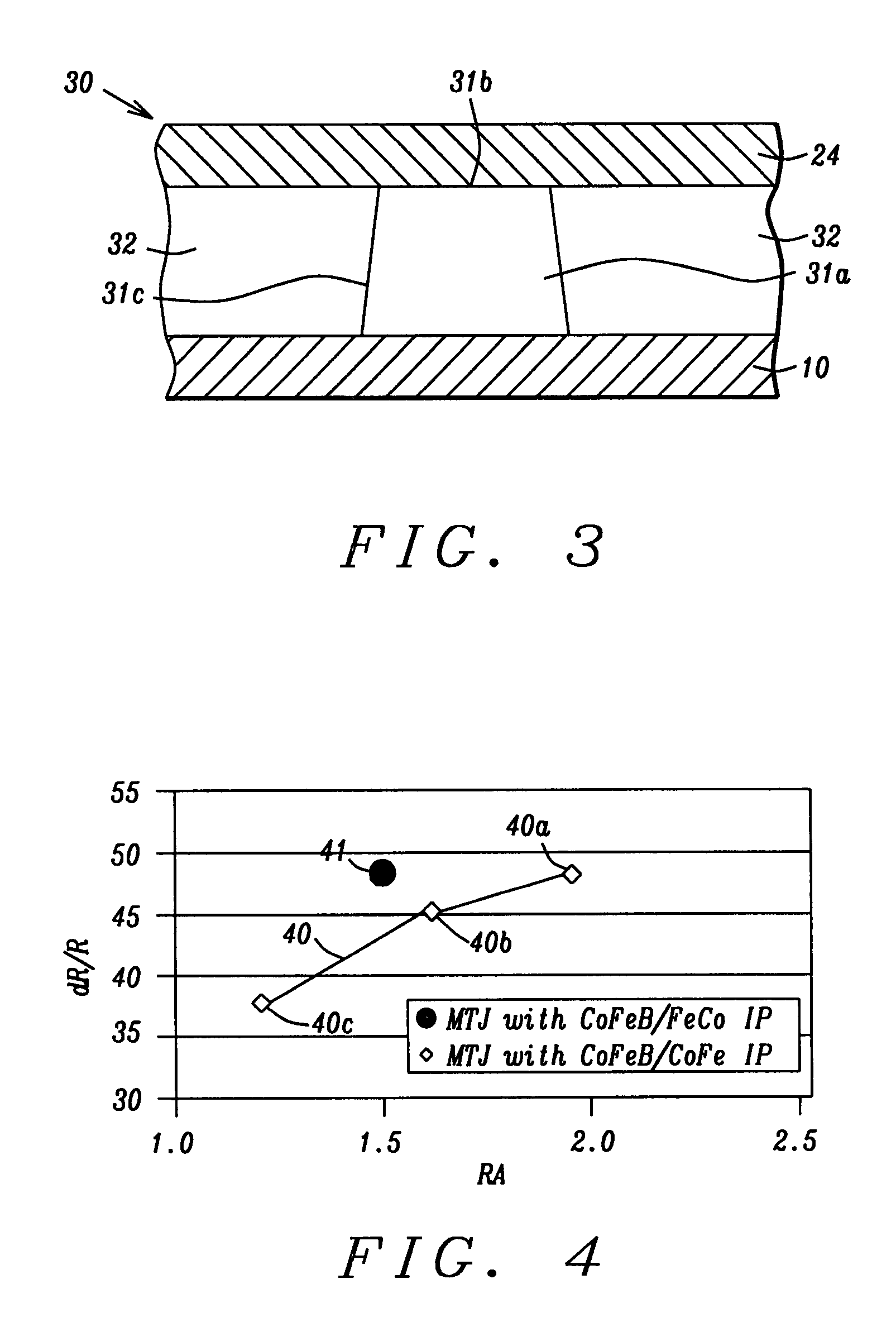

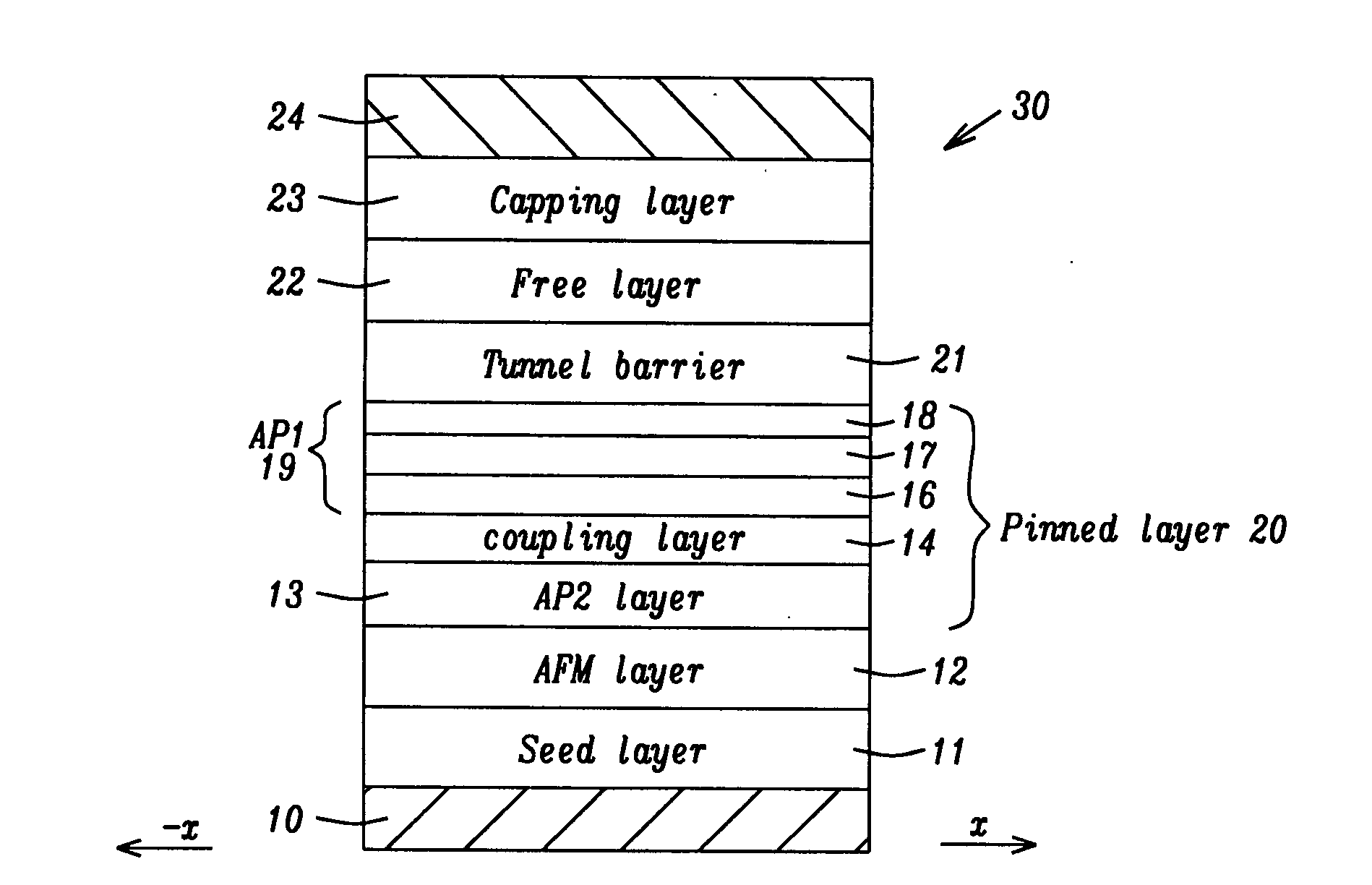

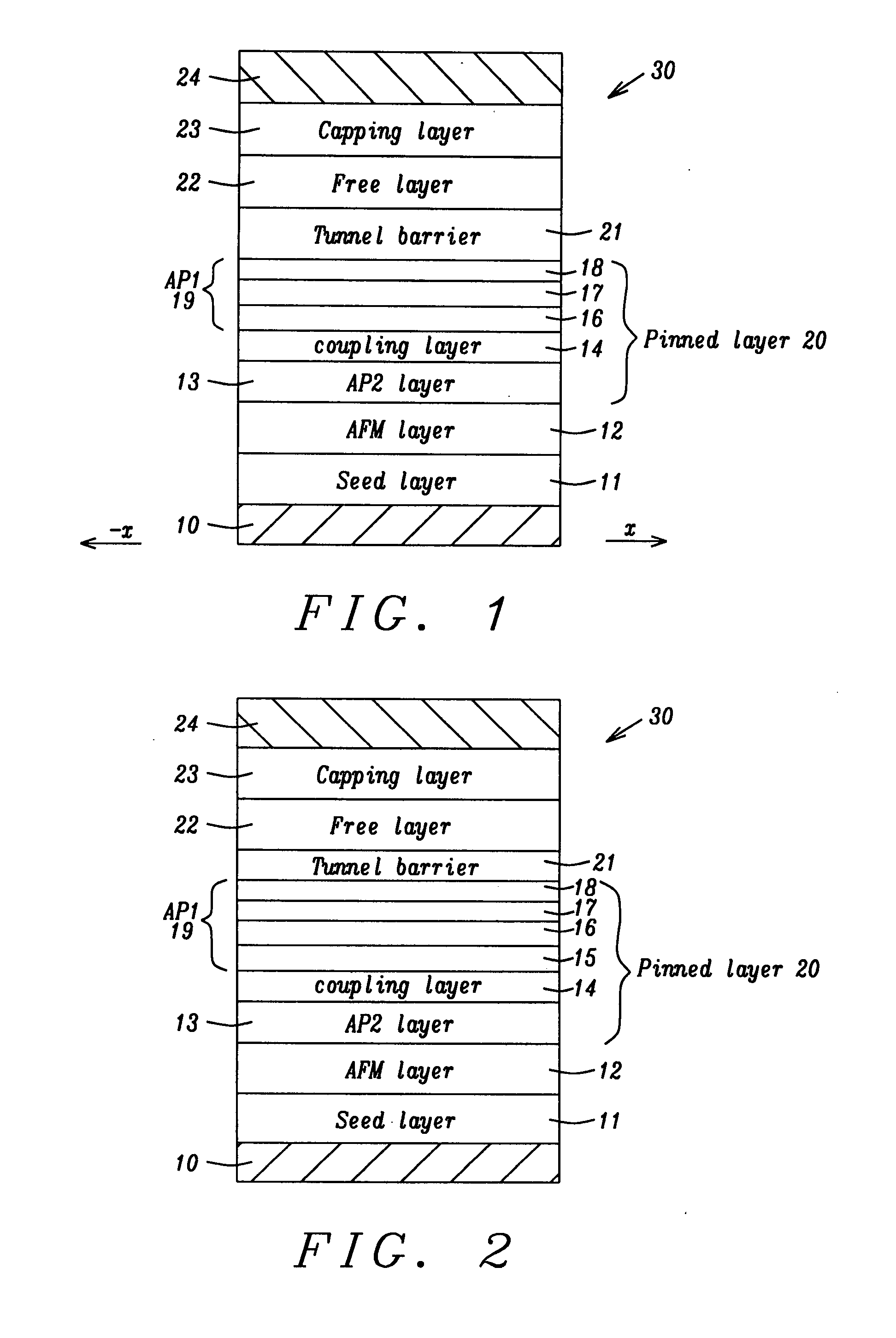

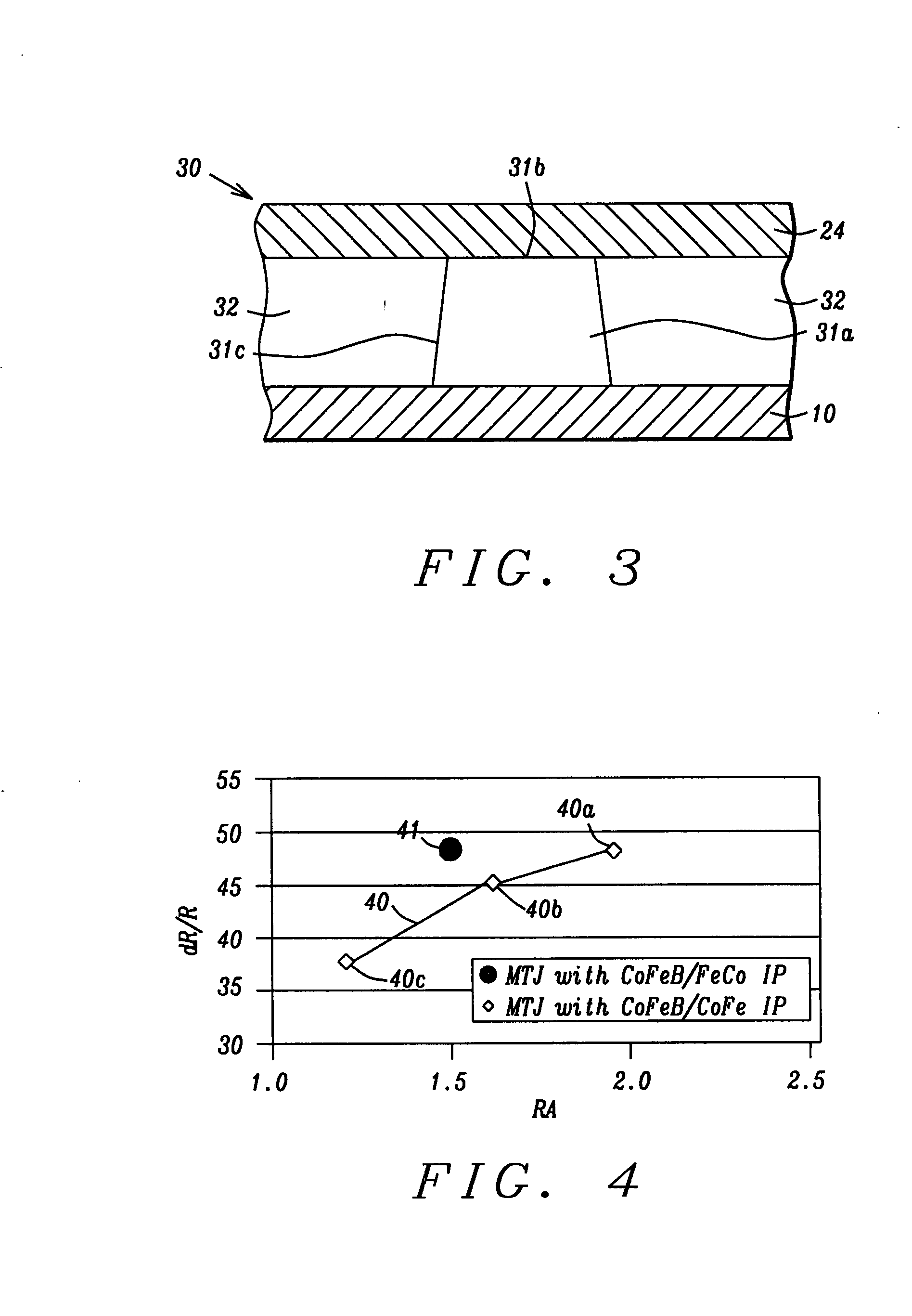

A high performance TMR sensor is fabricated by employing a composite inner pinned (AP1) layer in an AP2 / Ru / AP1 pinned layer configuration. In one embodiment, there is a 10 to 80 Angstrom thick lower CoFeB or CoFeB alloy layer on the Ru coupling layer, a and 5 to 50 Angstrom thick Fe or Fe alloy layer on the CoFeB or CoFeB alloy, and a 5 to 30 Angstrom thick Co or Co rich alloy layer formed on the Fe or Fe alloy. A MR ratio of about 48% with a RA of <2 ohm-um2 is achieved when a CoFe AP2 layer, MgO (NOX) tunnel barrier, and CoFe / NiFe free layer are used in the TMR stack. Improved RA uniformity and less head noise are observed. Optionally, a CoFe layer may be inserted between the coupling layer and CoFeB or CoFeB alloy layer to improve pinning strength and enhance crystallization.

Owner:HEADWAY TECH INC

Silicon microphone with softly constrained diaphragm

ActiveUS7329933B2Reduce stressSimple methodSemiconductor electrostatic transducersFluid pressure measurement by electric/magnetic elementsParyleneYoung's modulus

A microphone sensing element and a method for making the same are disclosed. The sensing element has a diaphragm and an attached electrical lead-out arm preferably made of polysilicon that are separated by an air gap from an underlying backplate region created on a conductive silicon substrate. The backplate region has acoustic holes created by removing an oxide filling in a continuous trench that surrounds hole edges and by removing oxide to form the air gap. The diaphragm is softly constrained along its edge by an elastic element that connects to a surrounding rigid polysilicon layer. The elastic element is typically a polymer such as parylene having a Young's modulus substantially less than that of the diaphragm. First and second electrodes are connected to the diaphragm through the lead-out arm and to the substrate through polysilicon via fillings, respectively, and thereby establish a variable capacitor circuit for acoustic sensing.

Owner:SHANDONG GETTOP ACOUSTIC

TMR device with low magnetostriction free layer

InactiveUS20090122450A1Increasing TMR ratioRaise the ratioNanomagnetismNanoinformaticsSputteringMagnetostriction

Owner:HEADWAY TECH INC

TMR device with novel free layer structure

ActiveUS20100073827A1Reduce noiseSolution value is not highNanomagnetismMagnetic measurementsNoise reductionLayer thickness

Owner:HEADWAY TECH INC

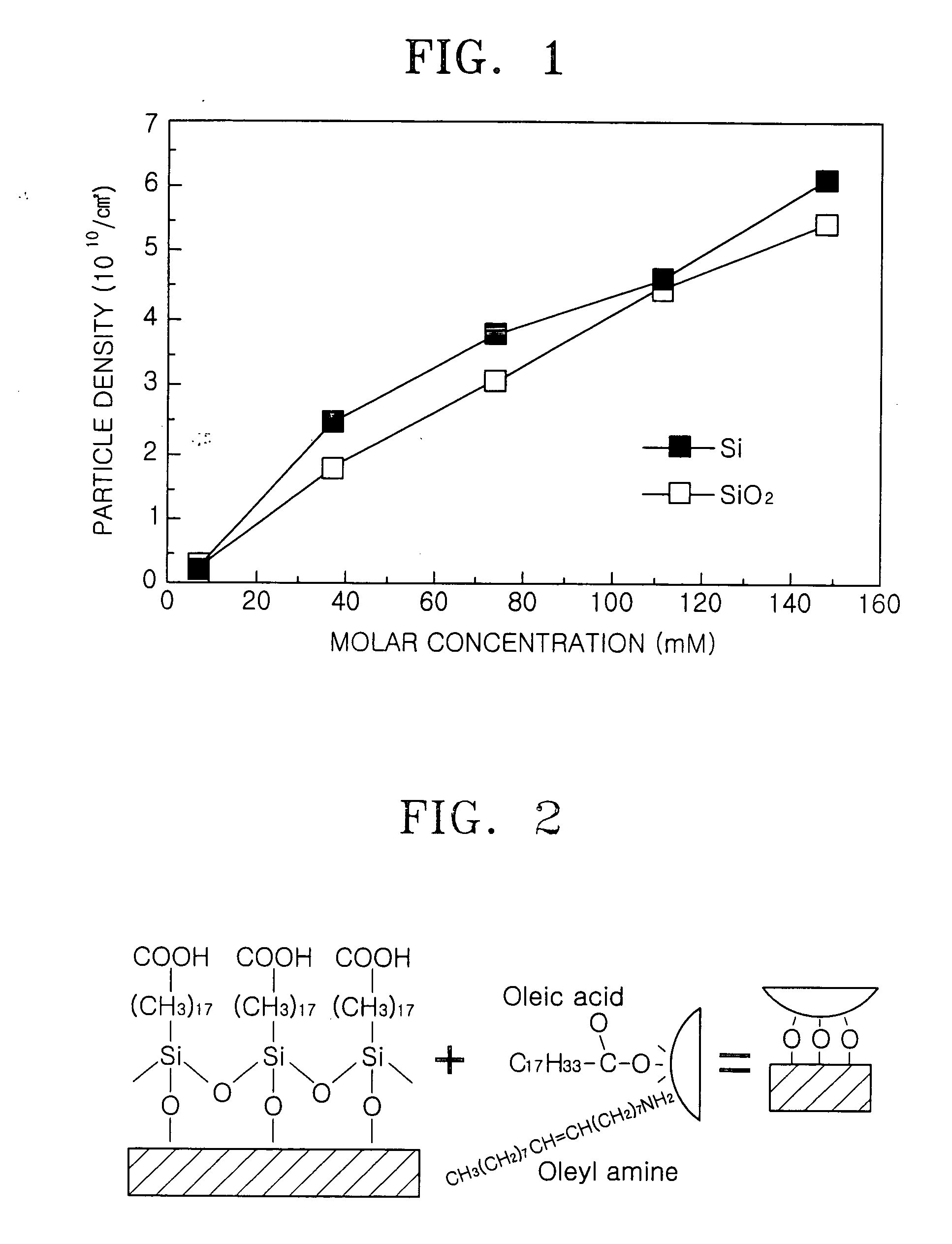

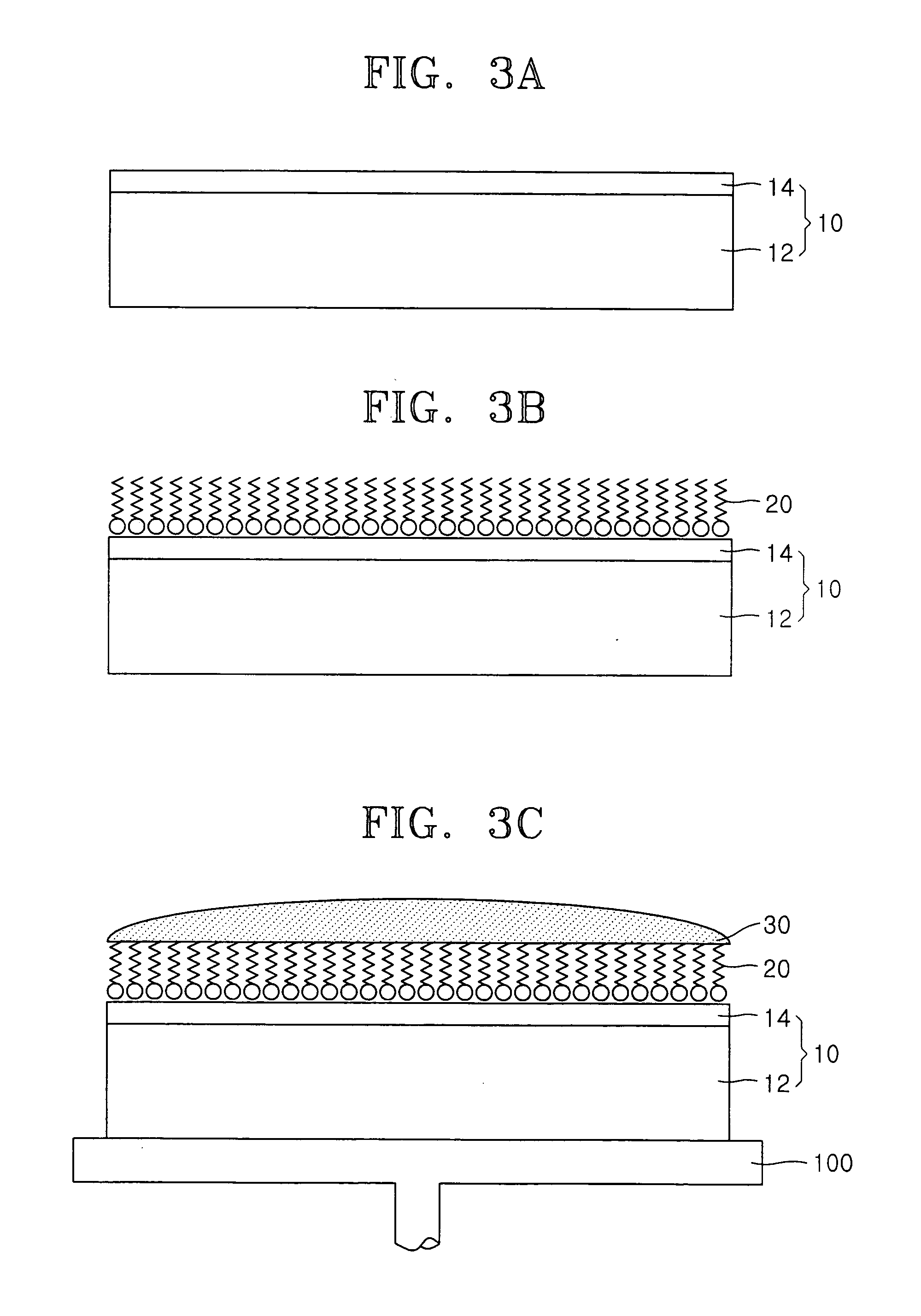

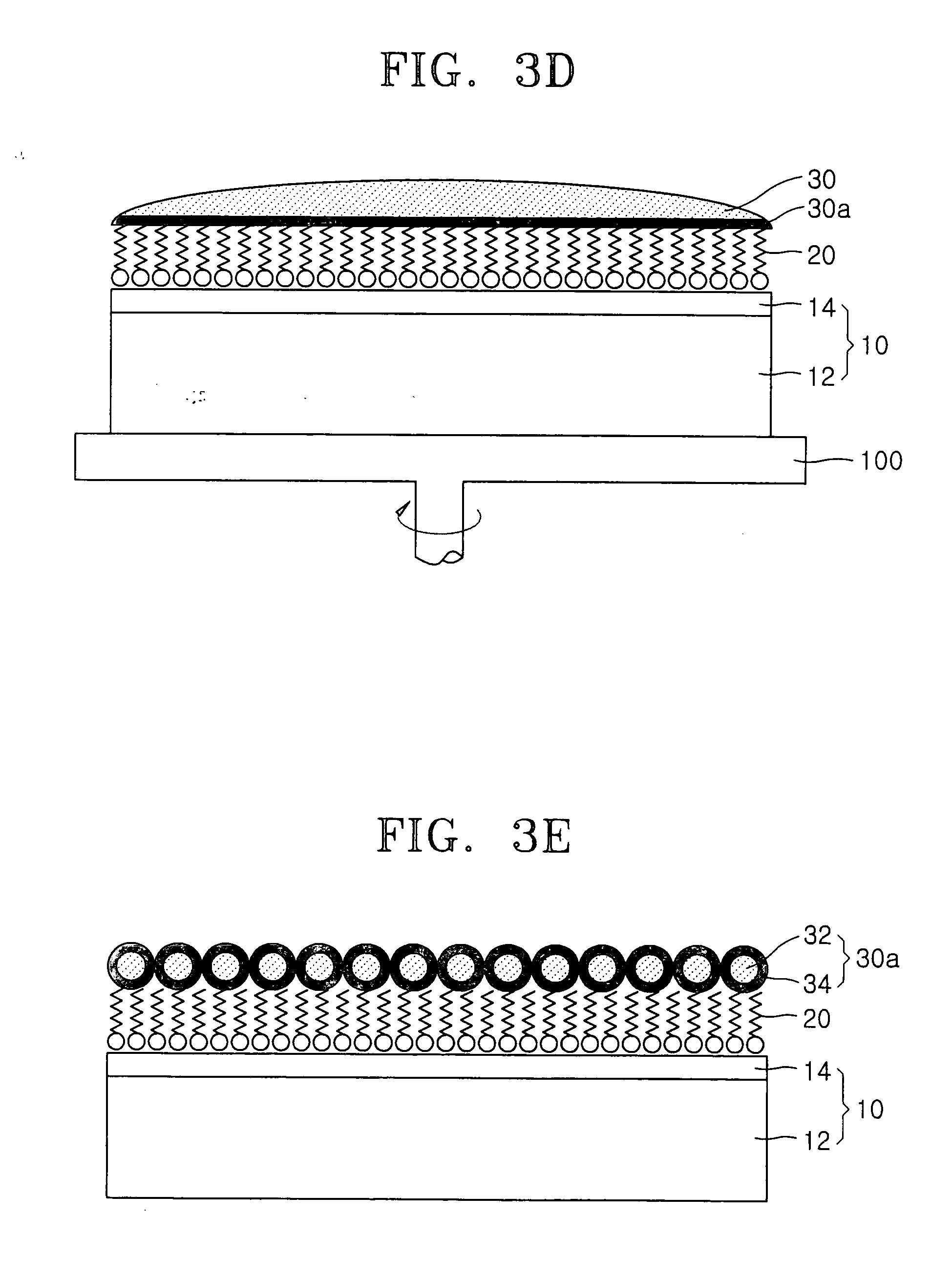

Methods of forming nanoparticle based monolayer films with high particle density and devices including the same

InactiveUS20060099430A1Enhanced particle densityCost-effectively formedMaterial nanotechnologyLiquid surface applicatorsNanoparticleParticle density

The present invention provides methods of forming uniform nanoparticle based monolayer films with a high particle density on the surface of a substrate comprising (a) forming a surface modifying layer on a substrate using a material comprising a first functional group that chemically binds to the substrate and a second functional group comprising a group capable of forming van der Waals forces, (b) applying to the surface modifying layer a solution comprising nanoparticles, and (c) curing the resultant structure formed at step (b) for a predetermined time to form a nanoparticle based monolayer film. The present invention further provides substrates and devices comprising the nanoparticle based monolayer films.

Owner:SAMSUNG ELECTRONICS CO LTD

Thermal transfer image-receiving sheet

InactiveUS6165938AReduce the temperatureEasy to superviseSynthetic resin layered productsAblative recordingImaging qualityWater vapor

A thermal transfer image-receiving sheet is provided which causes none of a dimensional change, curling, misregistration of image and can produce a printed image having satisfactory image quality and density. The thermal transfer image-receiving sheet comprises: a paper substrate; and a dye-receptive layer provided on one side of the substrate, a water vapor barrier layer composed mainly of a resin being provided on at least the side of the thermal transfer image-receiving sheet remote from the dye-receptive layer.

Owner:DAI NIPPON PRINTING CO LTD

Low resistance tunneling magnetoresistive sensor with natural oxidized double MgO barrier

A high performance TMR sensor is fabricated by incorporating a tunnel barrier having a Mg / MgO / Mg configuration. The 4 to 14 Angstroms thick lower Mg layer and 2 to 8 Angstroms thick upper Mg layer are deposited by a DC sputtering method while the MgO layer is formed by a NOX process involving oxygen pressure from 0.1 mTorr to 1 Torr for 15 to 300 seconds. NOX time and pressure may be varied to achieve a MR ratio of at least 34% and a RA value of 2.1 ohm-um2. The NOX process provides a more uniform MgO layer than sputtering methods. The second Mg layer is employed to prevent oxidation of an adjacent ferromagnetic layer. In a bottom spin valve configuration, a Ta / Ru seed layer, IrMn AFM layer, CoFe / Ru / CoFeB pinned layer, Mg / MgO / Mg barrier, CoFe / NiFe free layer, and a cap layer are sequentially formed on a bottom shield in a read head.

Owner:HEADWAY TECH INC

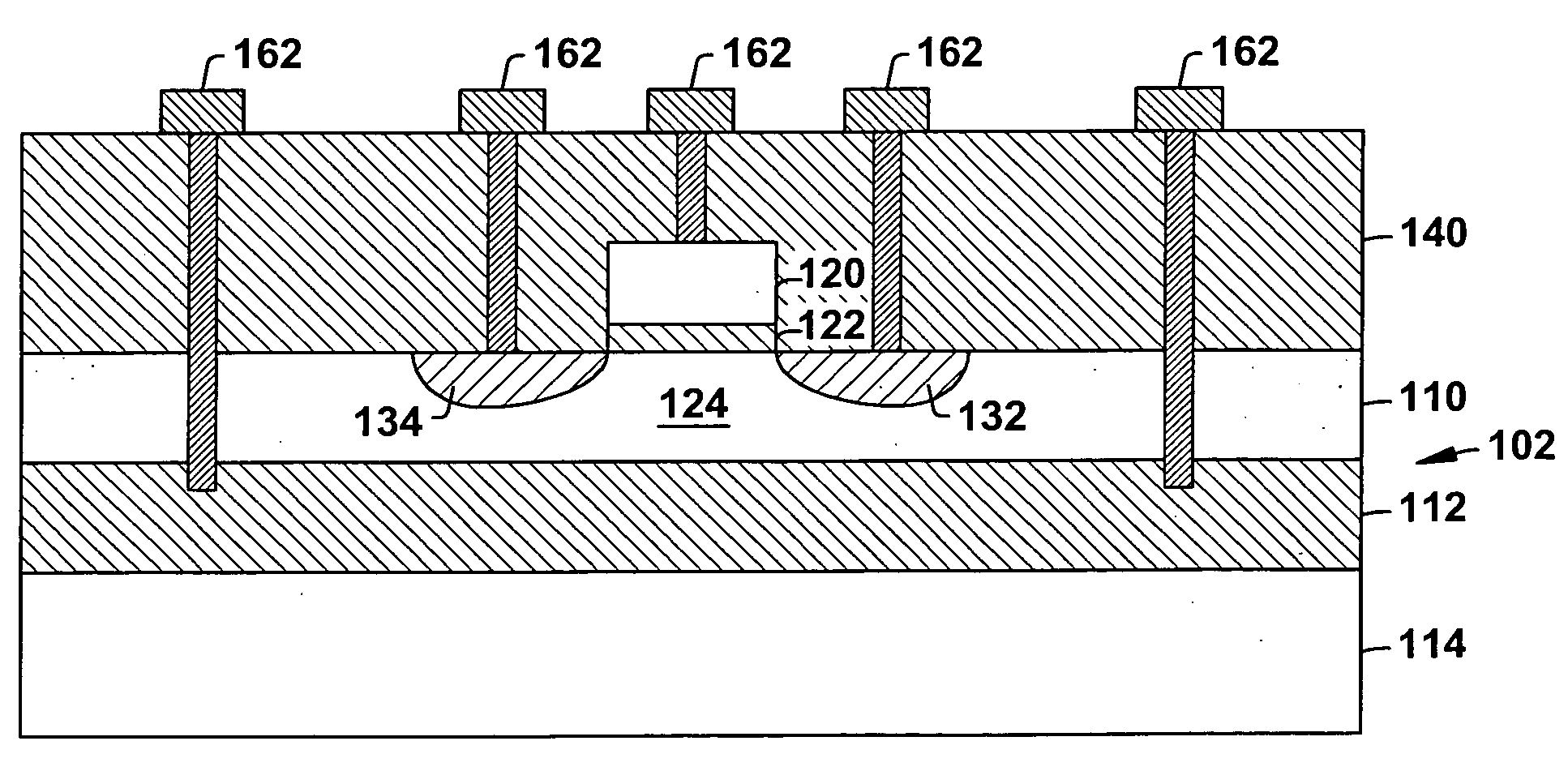

Wafer bonded MOS decoupling capacitor

ActiveUS20060128092A1Well formedCost-effectively formedSemiconductor/solid-state device detailsSolid-state devicesCapacitanceManufacturing technology

A technique for forming a MOS capacitor (100) that can be utilized as a decoupling capacitor is disclosed. The MOS capacitor (100) is formed separately from the particular circuit device (170) that it is to service. As such, the capacitor (100) and its fabrication process can be optimized in terms of efficiency, etc. The capacitor (100) is fabricated with conductive contacts (162) that allow it to be fused to the device (170) via conductive pads (172) of the device (170). As such, the capacitor (100) and device (170) can be packaged together and valuable semiconductor real estate can be conserved as the capacitor (100) is not formed out of the same substrate as the device (170). The capacitor (100) further includes deep contacts (150, 152) whereon bond pads (180, 182) can be formed that allow electrical connection of the capacitor (100) and device (170) to the outside world.

Owner:TEXAS INSTR INC

TMR device with novel free layer

Owner:HEADWAY TECH INC

Indication change instrument cluster

InactiveUS20070090939A1More cost-effectivelyCost-effectively formedIndicator componentsMeasurement apparatus componentsComputer scienceInstrument cluster

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Protective cover and tool splash for vehicle components

InactiveUS20060234010A1Increased durabilityCost effectiveWrappersWood working apparatusEngineeringMultiple layer

A method of manufacturing a protective cover (24) for a component of a vehicle includes assembling multiple layers to form a charge (22). The charge (22) is formed within a mold (50) of the component to form a multi-contoured laminate (58). The protective cover (24) is separated from the multi-contoured laminate (58). A method of forming a down stream part structure or mold (167) for a component includes assembling multiple layers to form a charge (78). The charge (78) is formed within an original mold of the component to form a multi-contoured laminate (76). A splash is separated from the multi-contoured laminate (76). A protective cover, such as the cover (24), is for a vehicle component and includes a contour holding layer (36) and a protective laminate layer (34). The contour holding layer (36) and the protective laminate layer (34) are formed within a mold of the vehicle component to form the protective cover.

Owner:THE BOEING CO

Novel method to reduce void formation during trapezoidal write pole plating in perpendicular recording

ActiveUS20110011744A1Minimize formation of voidCost effectiveRecord information storageHeads for perpendicular magnetisationsAlloyBiological activation

A method of forming a write pole in a PMR head is disclosed that involves forming an opening in a mold forming layer. A conformal Ru seed layer is formed within the opening and on a top surface. An auxiliary layer made of CoFeNi or alloys thereof is formed as a conformal layer on the seed layer. All or part of the auxiliary layer is removed in an electroplating solution by applying a (−) current or voltage during an activation step that is controlled by activation time. Thereafter, a magnetic material is electroplated with a (+) current to fill the opening and preferably has the same CoFeNi composition as the auxiliary layer. The method avoids Ru oxidation that causes poor adhesion to CoFeNi, and elevated surfactant levels that lead to write pole impurities. Voids in the plated material are significantly reduced by forming a seed layer surface with improved wettability.

Owner:HEADWAY TECH INC

Hydrodynamic torque converter

InactiveUS20070068759A1Easy to assembleLower assembly costsYielding couplingRotary clutchesImpellerTurbine wheel

In a hydrodynamic torque converter including a working fluid for the transmission of a torque from an engine to an output shaft, a pump impeller, a stator with guide vanes, a turbine wheel connected to the output shaft via a hub-like support, a converter lock-up clutch for locking the pump impeller to the turbine wheel and a torsional vibration damper connected between the turbine wheel and the output shaft and including disk-shaped support elements, annular axially and radially extending gap seals are provided between two adjacent disk-shaped support elements of the vibration damper so as to form a labyrinth seal structure for controlling the flow of fluid through the converter lock-up clutch for cooling the clutch.

Owner:DAIMLER AG

Process to manufacture an ion-permeable and electrically conducting flat material, the material obtained according to the process, and fuel cells

InactiveUS20050233200A1Cost-effective manufacturingCost-effectively formedSolid electrolytesFinal product manufacturePolymer scienceFuel cells

A fibrous, flat and ion-permeable material made of synthetic fibers, in particular of synthetically spun fibers such as acrylic fibers or aramid fibers, is processed into staple fibers of a specific length and then fibrillated. In a wet-laid inclined machine (paper machine), the fibrillated fibers are formed into a continuous web and then the web or portions of it are subjected to a temperature treatment to make the web electrically conducting by carbonizing / graphitizing the web through heating.

Owner:MILLER BALTHASAR

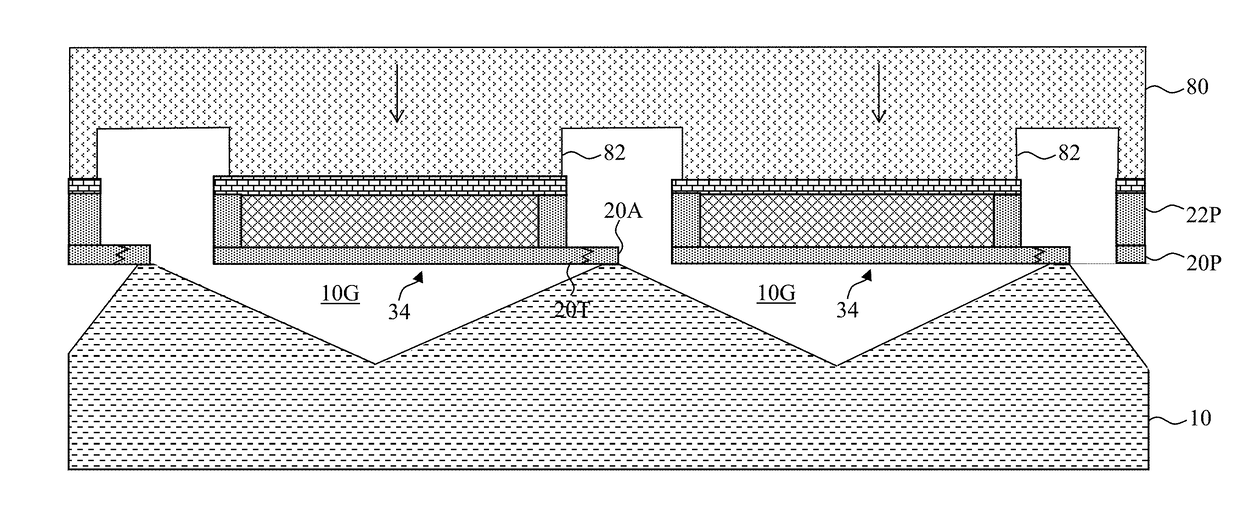

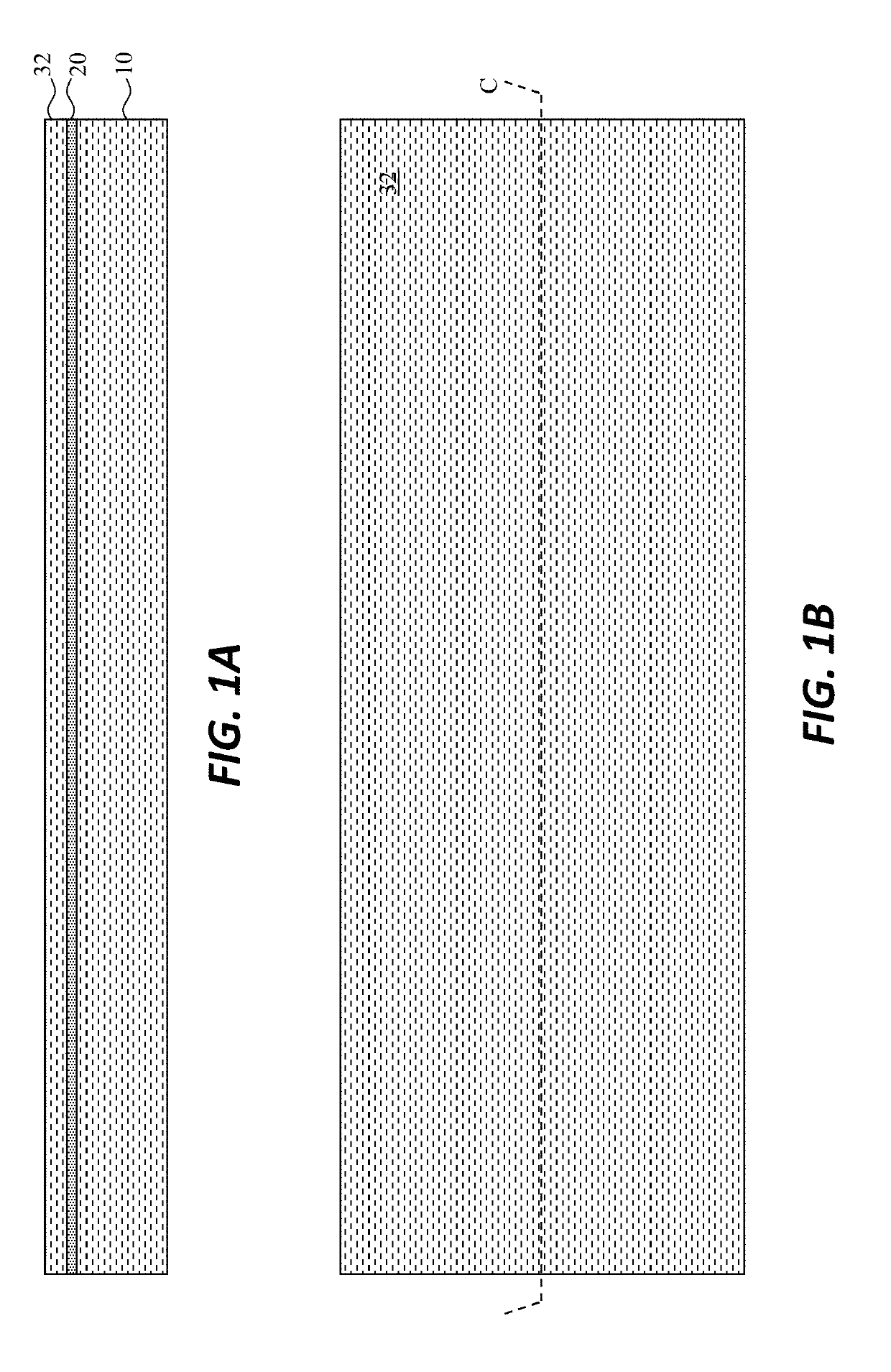

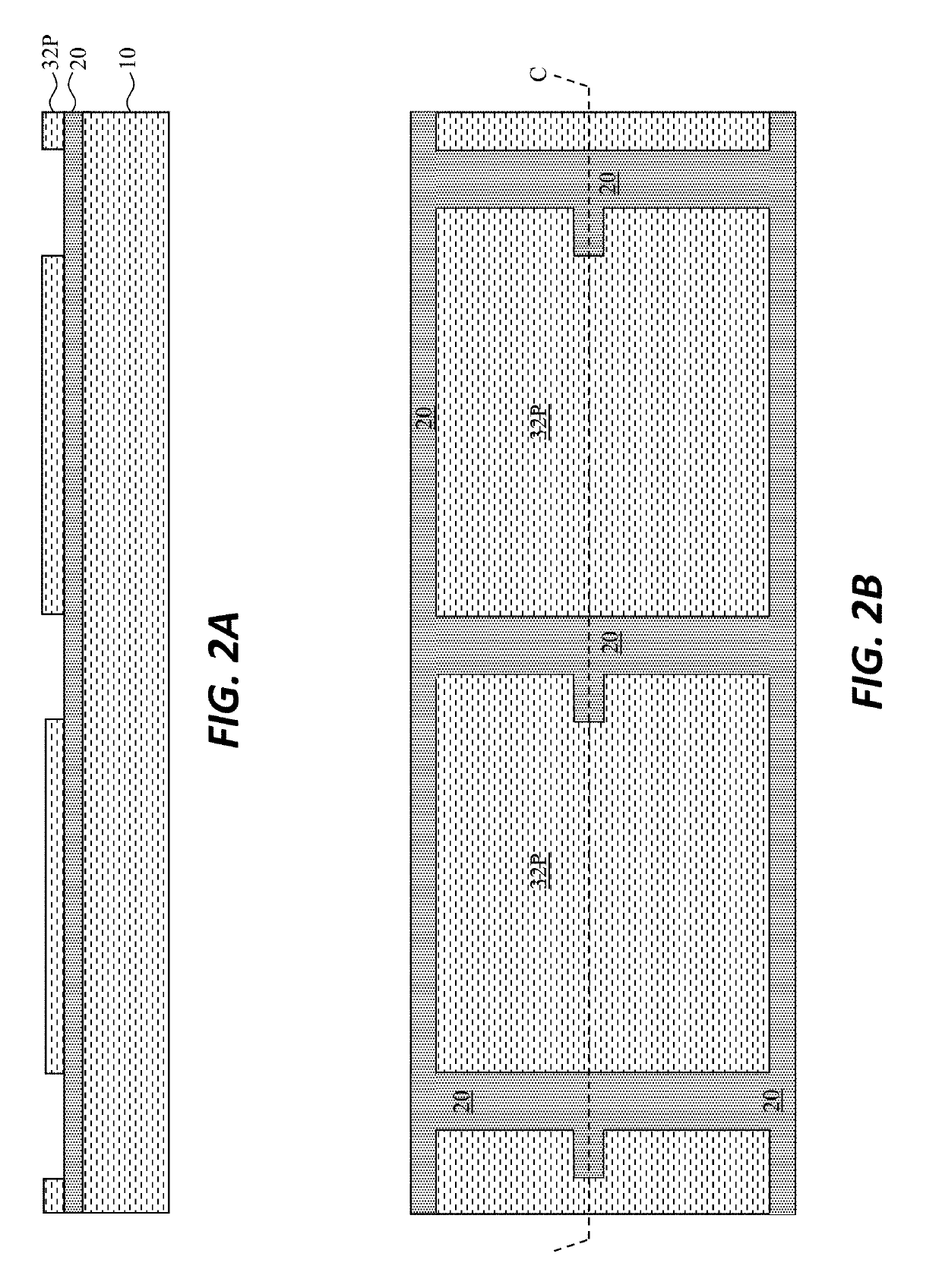

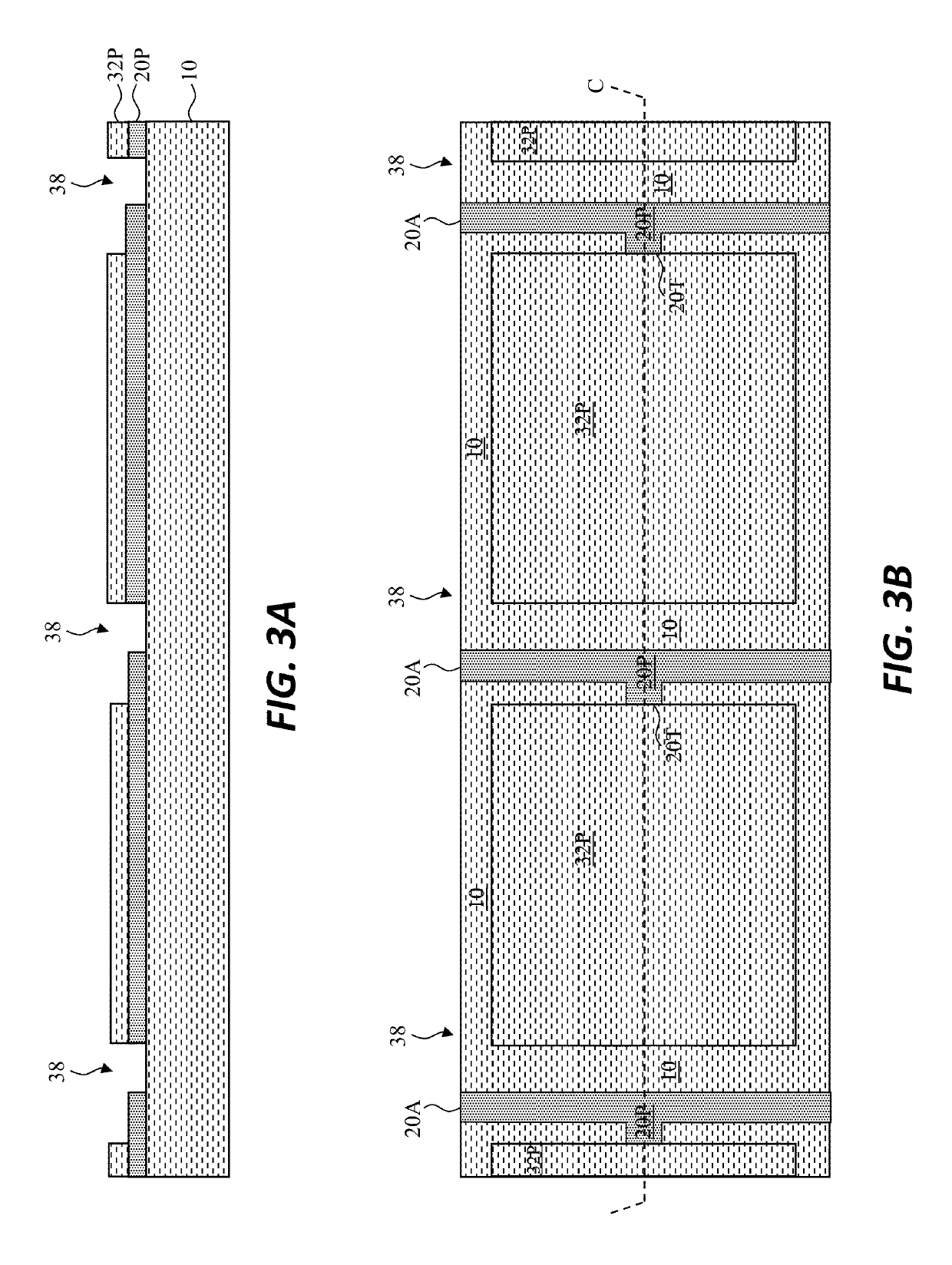

Isolation structure for micro-transfer-printable devices

ActiveUS20180174910A1Efficiently formedSimple processSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsInsulation layer

A semiconductor structure suitable for micro-transfer printing includes a semiconductor substrate and a patterned insulation layer disposed on or over the semiconductor substrate. The insulation layer pattern forms one or more etch vias in contact with the semiconductor substrate. Each etch via is exposed. A semiconductor device is disposed on the patterned insulation layer and is surrounded by an isolation material in one or more isolation vias that are adjacent to the etch via. The etch via can be at least partially filled with a semiconductor material that is etchable with a common etchant as the semiconductor substrate. Alternatively, the etch via is empty and the semiconductor substrate is patterned to form a gap that separates at least a part of the semiconductor device from the semiconductor substrate and forms a tether physically connecting the semiconductor device to an anchor portion of the semiconductor substrate or the patterned insulation layer.

Owner:X FAB SEMICON FOUNDRIES +1

Techniques for detecting cancerous cells in excised tissue samples using impedance detection

ActiveUS20180206755A1The process is fast and accurateCost-effectively formedDiagnostic signal processingPreparing sample for investigationCancer cellTissue sample

One embodiment of the present application sets forth a method for detecting cancerous cells in a sample of excised tissue. The method includes a first subset of electrodes included in an electrode array measuring, at a first operating frequency, a first impedance of a first section of the sample. The method also includes computing a first Cole relaxation frequency for the first section of the sample based on the first impedance. The method also includes determining that the first section of the sample contains cancerous cells based on the first Cole relaxation frequency.

Owner:NOVASCAN INC

Method for producing a cushion element and method and tool for the production thereto

ActiveUS20140132054A1Improve comfortSimple introductionBack restsTailstocks/centresThree dimensional shapeHardness

A method for producing a cushion element for a vehicle seat, in which a component suitable for forming a three-dimensional separation zone is inserted in a tool, subsequently at least one first foamable mass is introduced into a first space of the tool. On foaming the mass, the component forms a three-dimensional separating element between a first foamed cushion region and a further space within the tool. The component is pressed against a counter-support in the tool during the forming to give a three-dimensional separating element. A suitable tool comprises an upper tool, a lower tool and a counter support for contacting a component taking on a three-dimensional shape. By introducing the three-dimensional mouldable shape into the tool and the subsequent forming thereof to give a three-dimensional separating element, complex formed regions with differing properties, in particular, differing degrees of hardness can be economically generated in a foamed cushion element.

Owner:ADIENT US LLC

Vacuum pipette for gripping electrical components by suction

InactiveUS7000311B1Increased functional reliabilityLittle additional outlayGripping headsKitchen equipmentMesh gridSuction force

A vacuum pipette has a filter grid that is shifted into its extended interior and whose cross section is considerably greater than the cross section of an end-side suction opening. The gaps formed in the filter grid can be so narrow that even very small components are reliably retained. Nevertheless, the entire passage cross section available is considerably greater than in the case of a filter grid arranged at the end side. As a result, favorable suction forces are generated under constant suction conditions.

Owner:SIEMENS AG

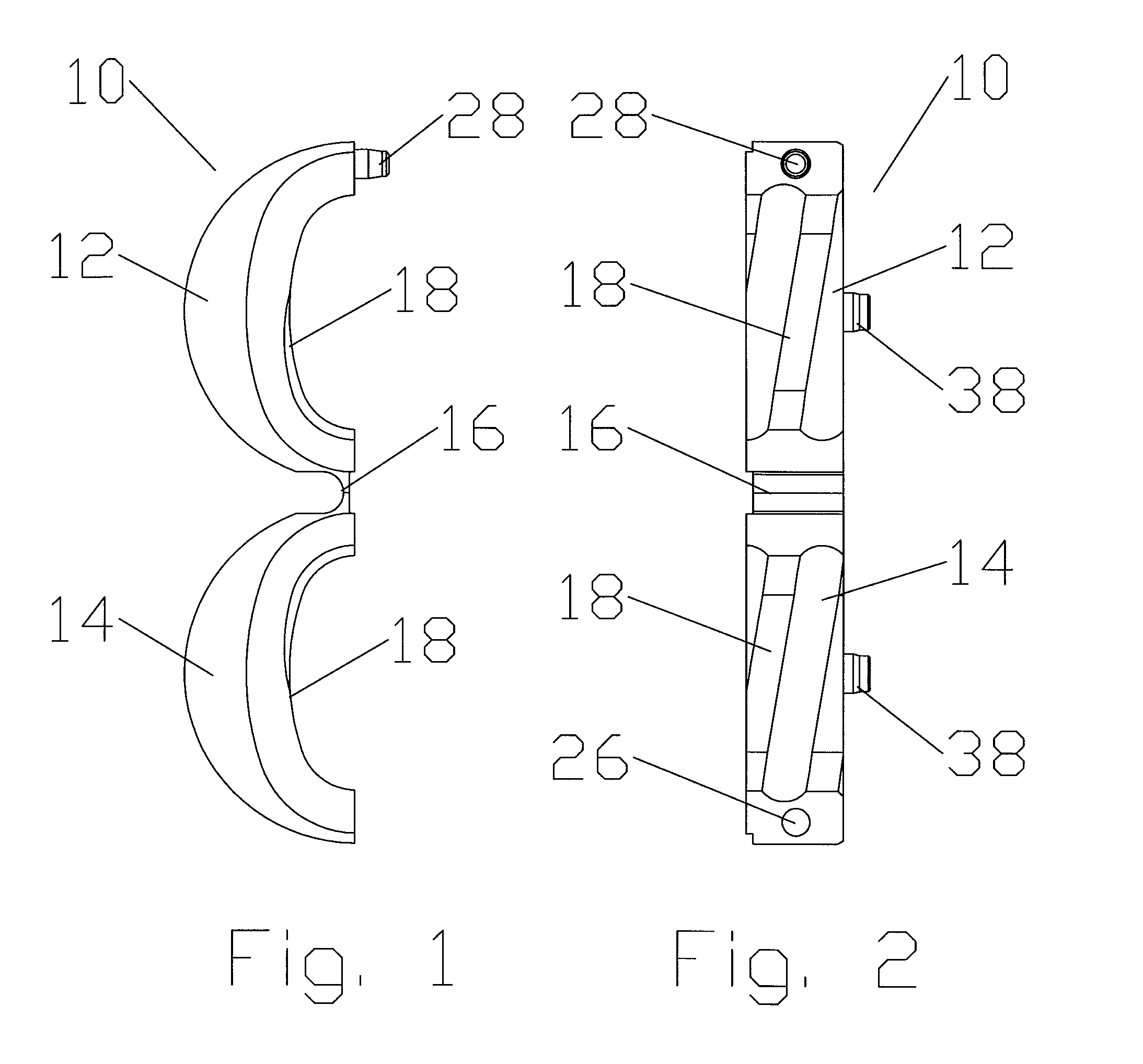

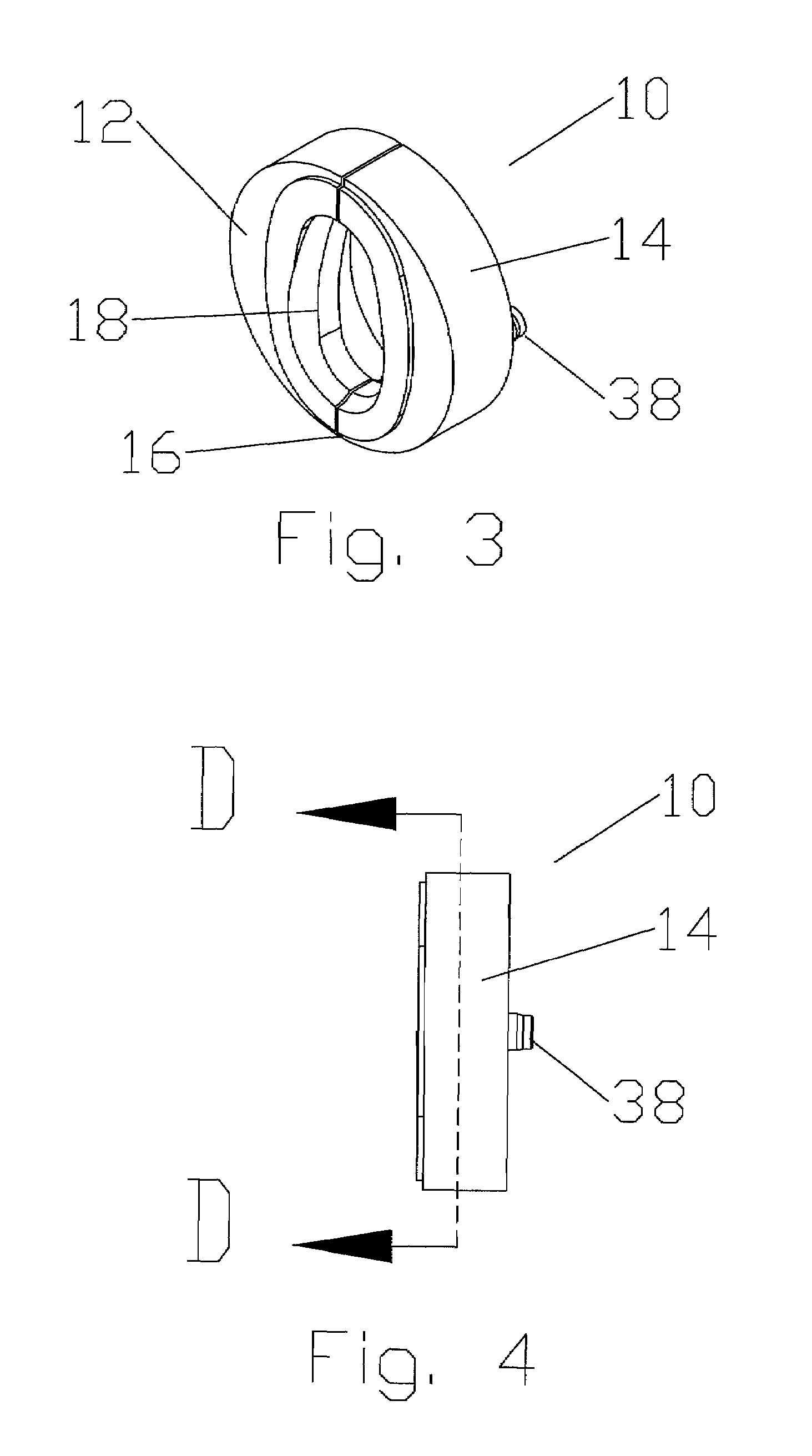

Waveguide interface adapter and method of manufacture

A waveguide interface for a waveguide having a split ring with a first half and a second half joined by a web portion. The split ring first half and second half having an inner surface configured to mate with an exterior of the waveguide, the first half and the second half foldable towards each other and around the exterior of the waveguide, along the web portion. An overbody with a bore is dimensioned to receive the waveguide therethrough; the bore having a shoulder at an interface end dimensioned to receive the split ring.

Owner:COMMSCOPE TECH LLC

Method and apparatus for gasifying raw material and gaseous product

ActiveUS20170313951A1Reduce nitrogen contentHigh calorific valueGasification catalystsGasification processes detailsCatalytic oxidationFixed bed

A method and apparatus for gasifying raw material. The method includes feeding the raw material into an upper part of a fixed-bed gasifier, introducing the raw material from the upper part of the gasifier to a pyrolysis zone of the gasifier to form the fixed-bed and pyrolyzing the raw material in the presence of pyrolysis air to form a pyrolysis product. Introducing the pyrolysis product from the pyrolysis zone to a lower part of the gasifier, introducing primary air countercurrently to the lower part, carrying out a final gasification in a lower part of the gasifier in order to form a gasified gas. Introducing the gasified gas to a catalytic oxidation part and through a catalyst layer of the catalytic oxidation part, and reforming the gasified gas by way of the catalytic oxidation in the presence of reforming air in the catalytic oxidation part, forming a gaseous product.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

Method to reduce void formation during trapezoidal write pole plating in perpendicular recording

ActiveUS8273233B2Minimize formation of voidCost effectiveRecord information storageHeads for perpendicular magnetisationsPower flowAlloy

A method of forming a write pole in a PMR head is disclosed that involves forming an opening in a mold forming layer. A conformal Ru seed layer is formed within the opening and on a top surface. An auxiliary layer made of CoFeNi or alloys thereof is formed as a conformal layer on the seed layer. All or part of the auxiliary layer is removed in an electroplating solution by applying a (−) current or voltage during an activation step that is controlled by activation time. Thereafter, a magnetic material is electroplated with a (+) current to fill the opening and preferably has the same CoFeNi composition as the auxiliary layer. The method avoids Ru oxidation that causes poor adhesion to CoFeNi, and elevated surfactant levels that lead to write pole impurities. Voids in the plated material are significantly reduced by forming a seed layer surface with improved wettability.

Owner:HEADWAY TECH INC

Waveguide interface adapter and method of manufacture

A waveguide interface for a waveguide having a split ring with a first half and a second half joined by a web portion. The split ring first half and second half having an inner surface configured to mate with an exterior of the waveguide, the first half and the second half foldable towards each other and around the exterior of the waveguide, along the web portion. An overbody with a bore is dimensioned to receive the waveguide therethrough; the bore having a shoulder at an interface end dimensioned to receive the split ring.

Owner:COMMSCOPE TECH LLC

Overhead baggage rack unit of railway car

InactiveUS20060219716A1Light weightCost-effectiveLarge containersAxle-box lubricationRack unitFront edge

The invention provides an improved overhead baggage rack for a railway car. An overhead baggage rack unit 50 provided at a shoulder portion between a side frame 10 and a roof frame 20 of a railway car comprises an overhead baggage rack body 100 and a pole 200. The overhead baggage rack body 100 comprises a front edge portion 110, a rear edge portion 112 and a transverse member 114 formed by mechanically cutting out portions from an extruded aluminum alloy member, and thereby, an opening 130 is formed to which an overhead baggage rack panel is attached. A grip bar 150 is cut and formed to an area lower than the front edge portion 110. The front edge portion 110 is fixed via a bracket 160 to the pole 200.

Owner:HITACHI LTD

Container and Code of System for Preparing a Beverage or Foodstuff

ActiveUS20180177331A1Well formedCost-effectively formedContainer decorationsLevel indicationsEngineeringSystematic code

A container for a foodstuff or beverage preparation machine, the container for containing beverage or foodstuff preparation material and comprising a code encoding preparation information, the code comprising: a data sequence having a plurality of marker locations, whereby said marker locations either comprise or do not comprise a marker as a variable to at least partially encode the preparation information therein, with adjacent marker locations separated by a distance of Δx; at least one locator marker to enable location of the data sequence of the code, the locator marker having a read distance X2, which is distinct from a read distance X1 of the data markers to enable a locator marker to be identified.

Owner:SOC DES PROD NESTLE SA

Rotor hub, spindle motor and hard disk drive

InactiveUS20090103207A1Easy to separateAvoid separationElectrical transducersRecord information storageHard disc driveEngineering

In a method for manufacturing a rotor hub for use in a spindle motor, free-cutting stainless steel is used as a material of the rotor hub. A slug of free-cutting stainless steel is subjected to a plastic working to form a disk mounting portion and a cylindrical surface positioned radially inwardly of the disk mounting portion. Then, a cylindrical disk fitting surface is formed by machining substantially the entirety of the cylindrical surface. The rotor hub contains A-type inclusions appearing in a cross section taken along a center axis of the disk mounting portion. The A-type inclusions are oriented in directions different than the center axis.

Owner:TOKUSEN IND CO LTD +1

Isolation structure for micro-transfer-printable devices

ActiveUS10297502B2Efficiently formedSimple processSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerSemiconductor materials

Owner:X FAB SEMICON FOUNDRIES +1

Techniques for predicting recurrence of cancerous cells using impedance detection

ActiveUS20190216358A1The process is fast and accurateCost-effectively formedSurgical needlesSurgical instrument detailsCancer cellRelaxation frequency

One embodiment of the present application sets forth a method for predicting recurrence of cancerous cells in a patient that includes measuring, by a first subset of electrodes included in an electrode array operating at a first frequency, a first impedance of a first section of a first sample of tissue excised from the patient, computing a first Cole relaxation frequency for the first section of the first sample based on the first impedance, and generating a first prediction relating to cancerous cells in the patient based at least in part on the first Cole relaxation frequency.

Owner:NOVASCAN INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com