Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Avoid squeeze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

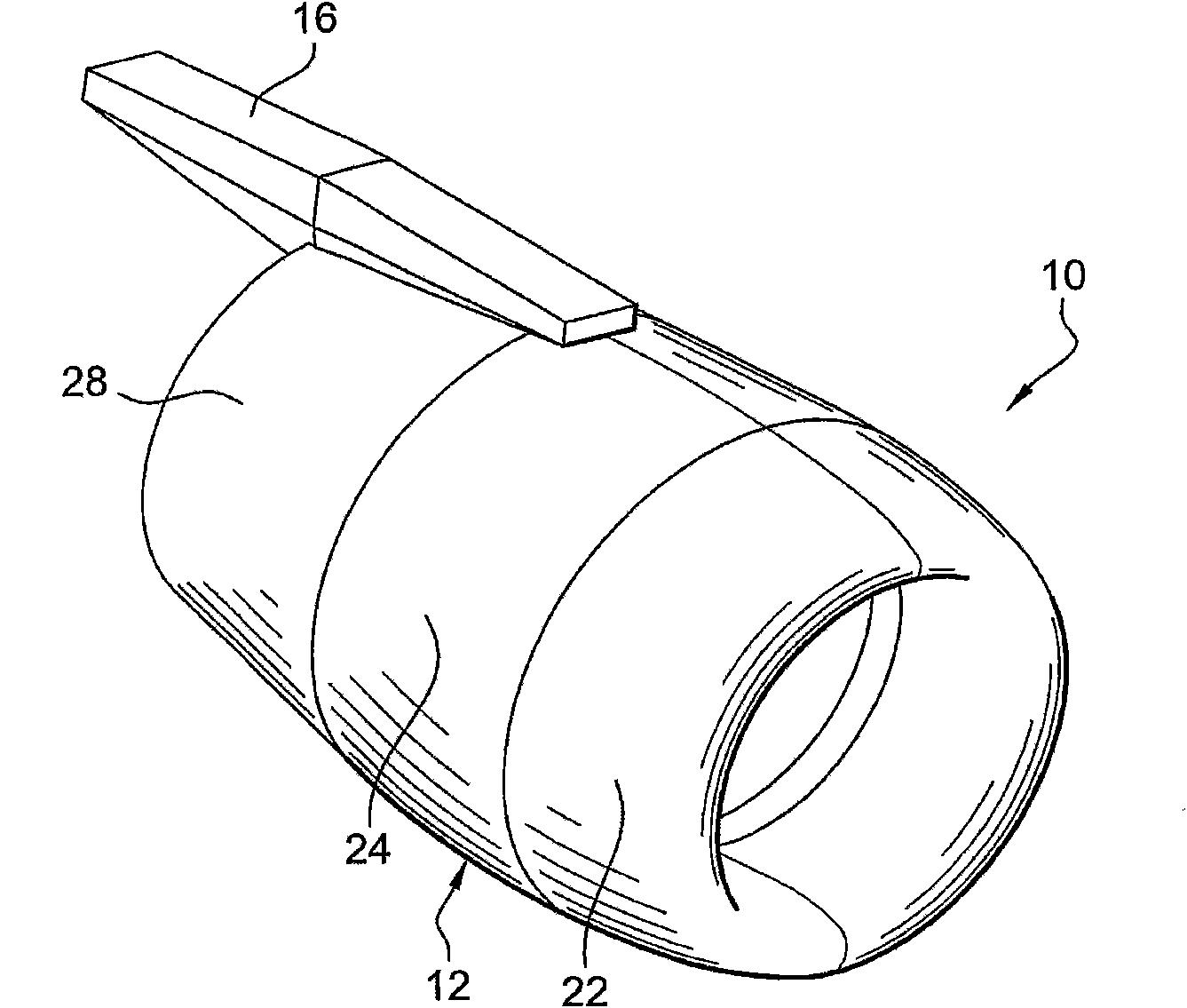

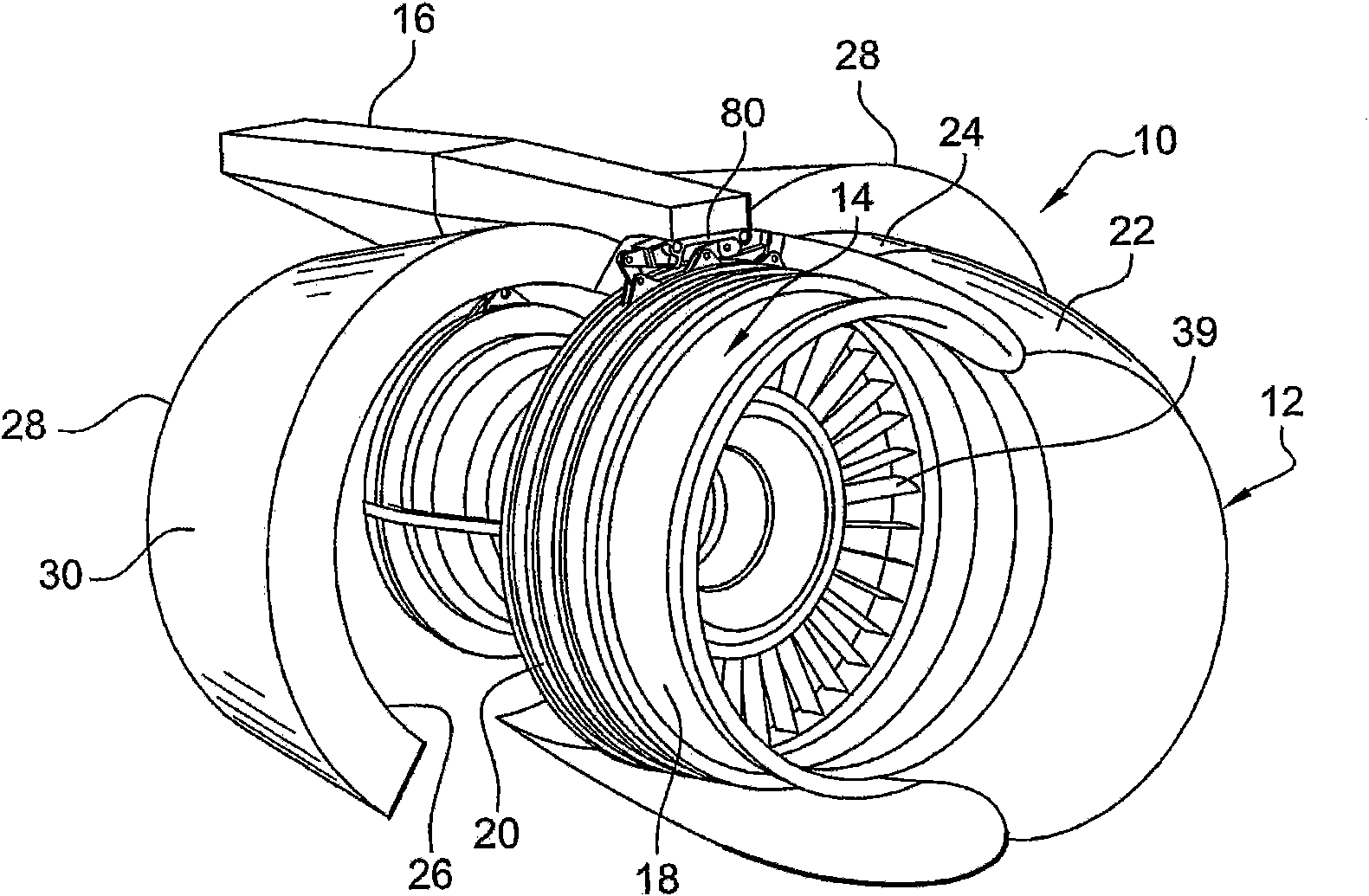

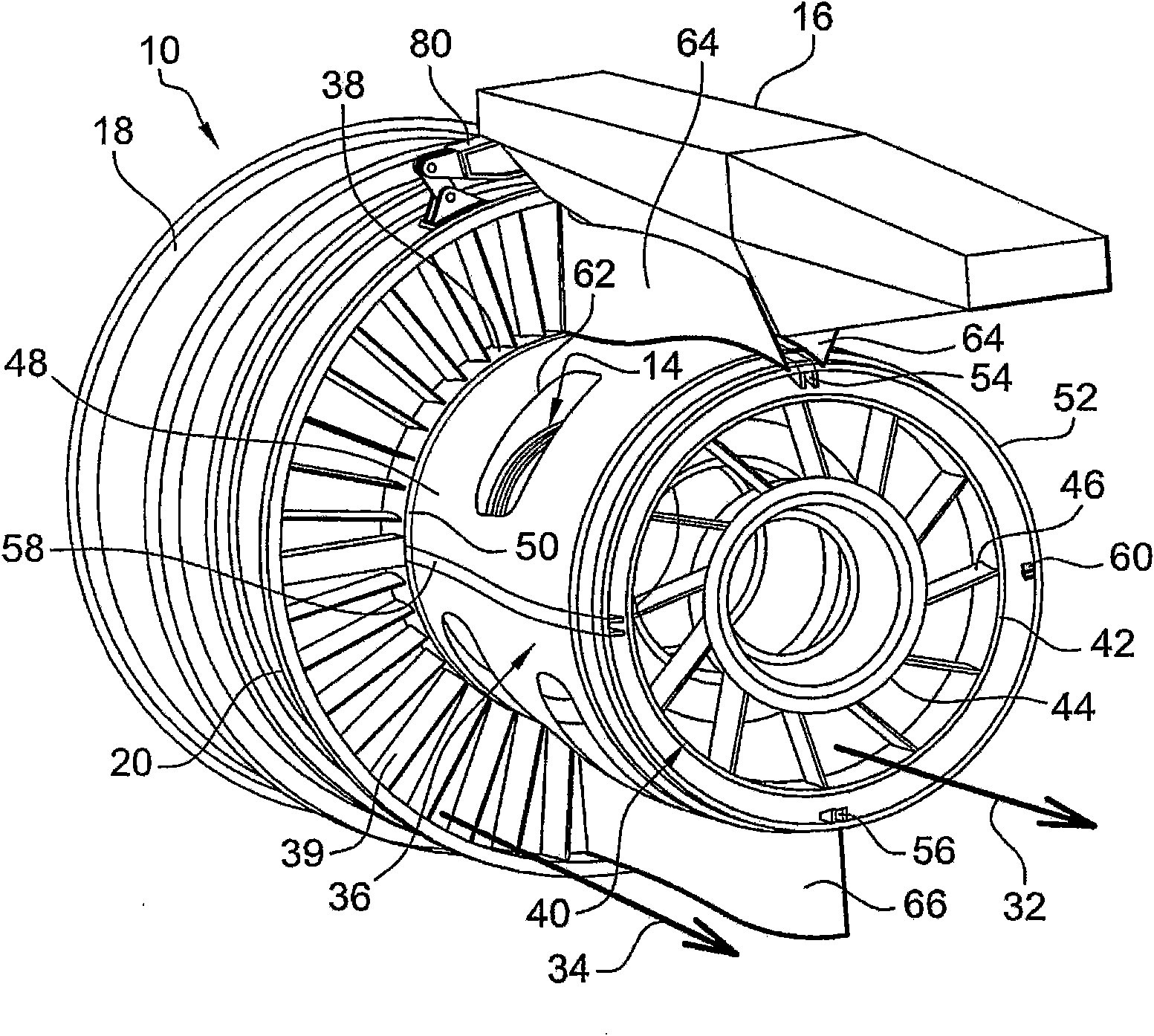

Aircraft propulsion system

ActiveCN102076563AAvoid squeezeReduce gapPower plant constructionAircraft power plant componentsSpacecraft propulsionNacelle

The invention provides an aircraft propulsion system (10) comprising a bypass turbojet engine which is surrounded by a nacelle, and means (80) of attaching the engine to a pylon (16) of an aircraft, the nacelle (12) comprising an internal structure exhibiting symmetry of revolution with a rigid framework formed of an upstream annular frame (50) attached to an intermediate casing (38) of the engine, of a downstream annular frame (52) supporting the exhaust casing (40) of the engine, and of longitudinal arms (54, 56, 58, 60) connecting these frames (50, 52), the downstream annular frame (52) being fixed to the pylon (16) by resilient or articulated suspension means.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

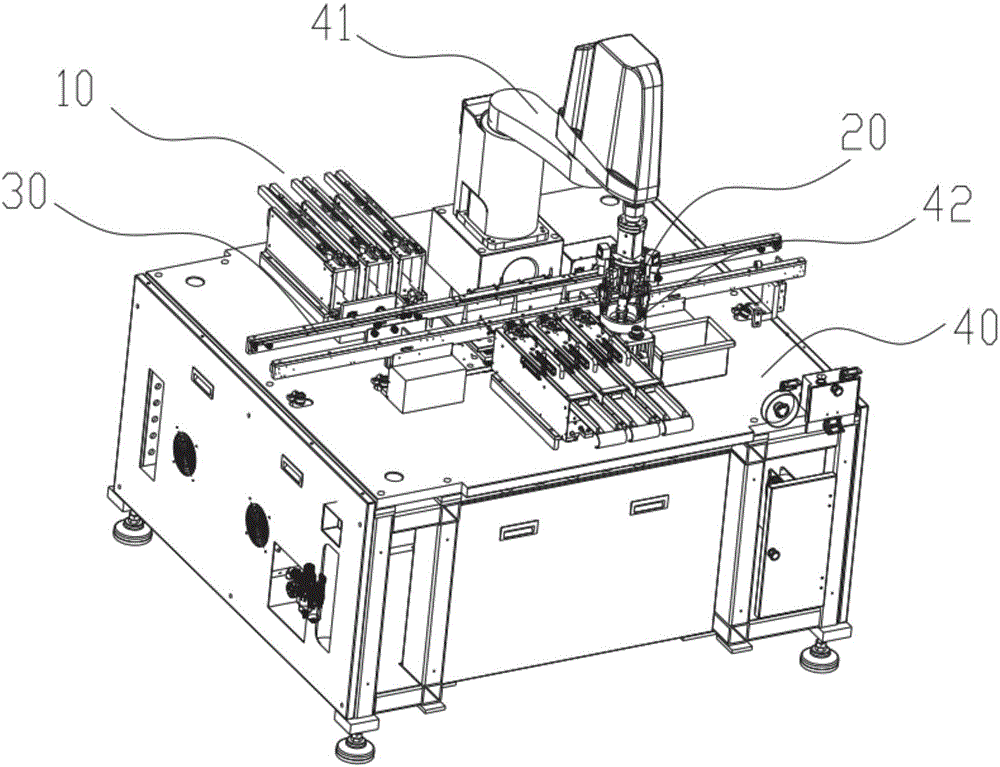

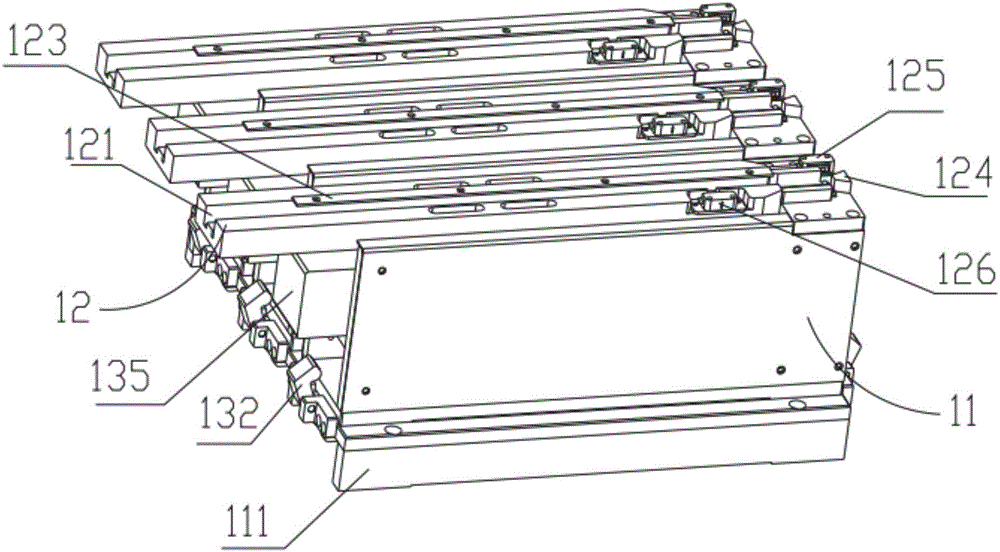

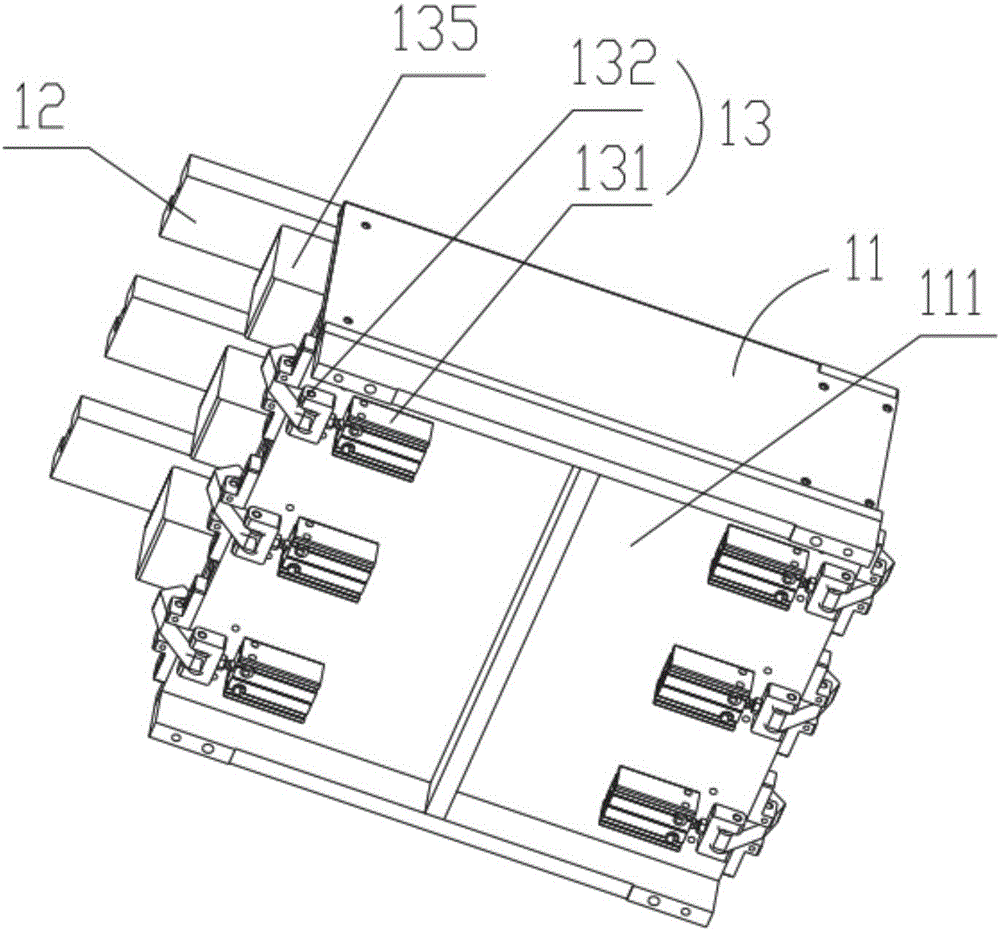

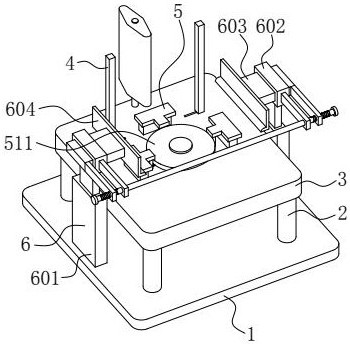

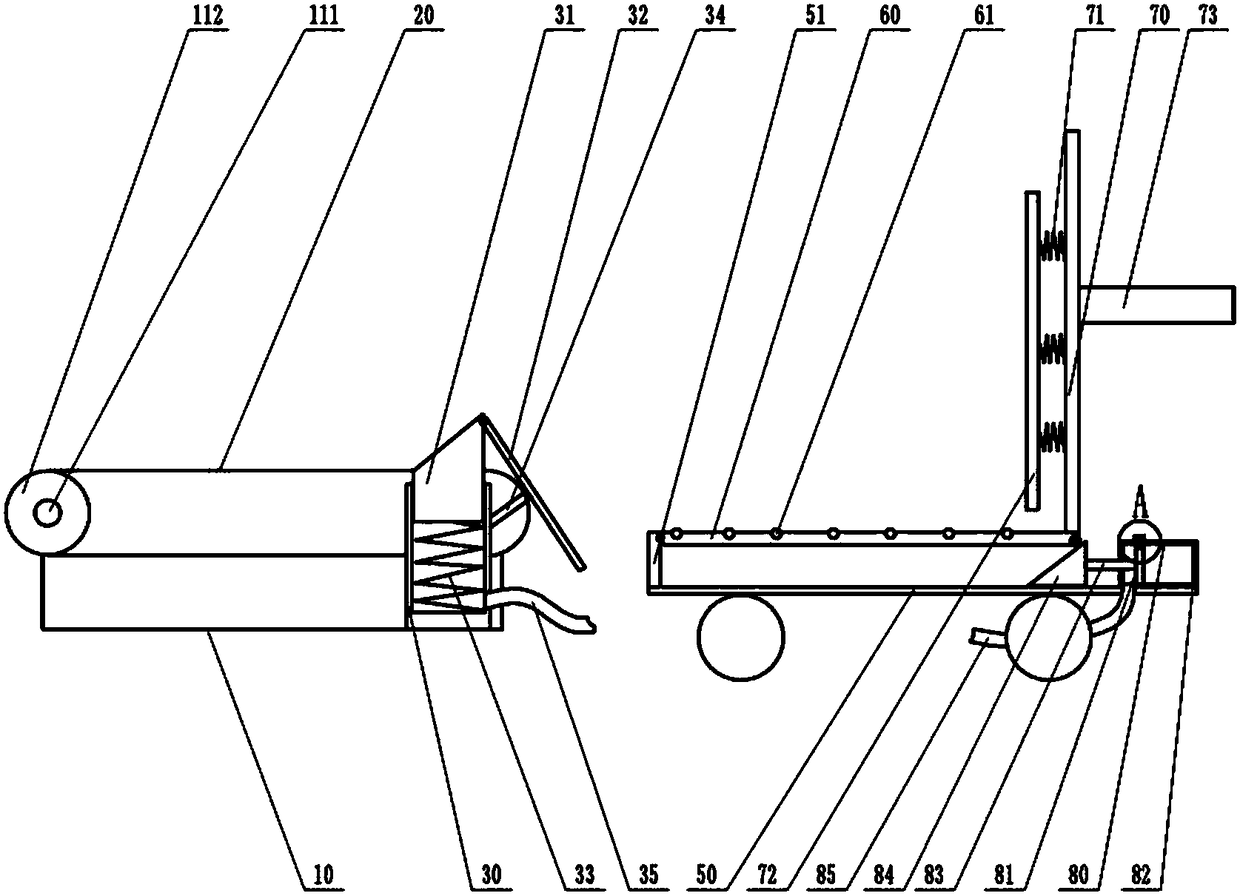

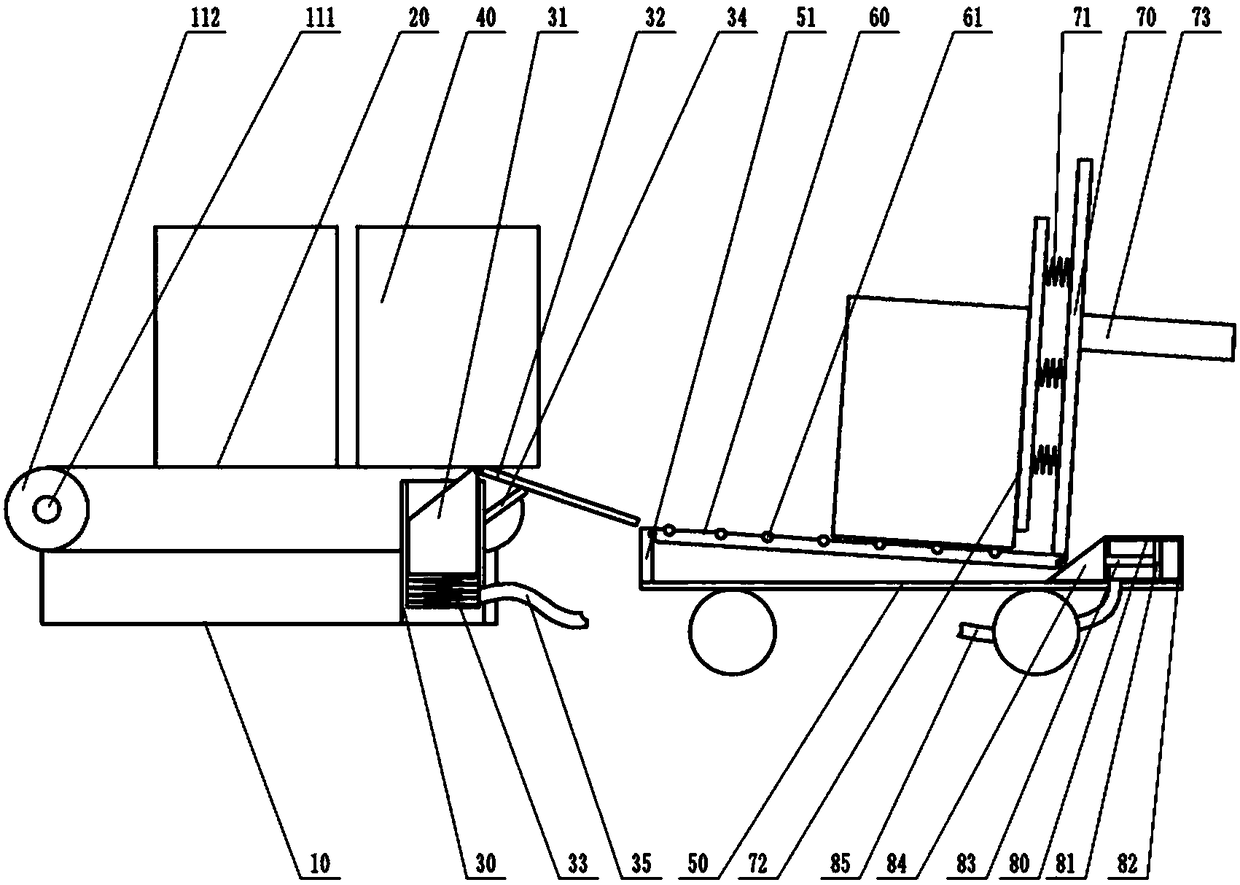

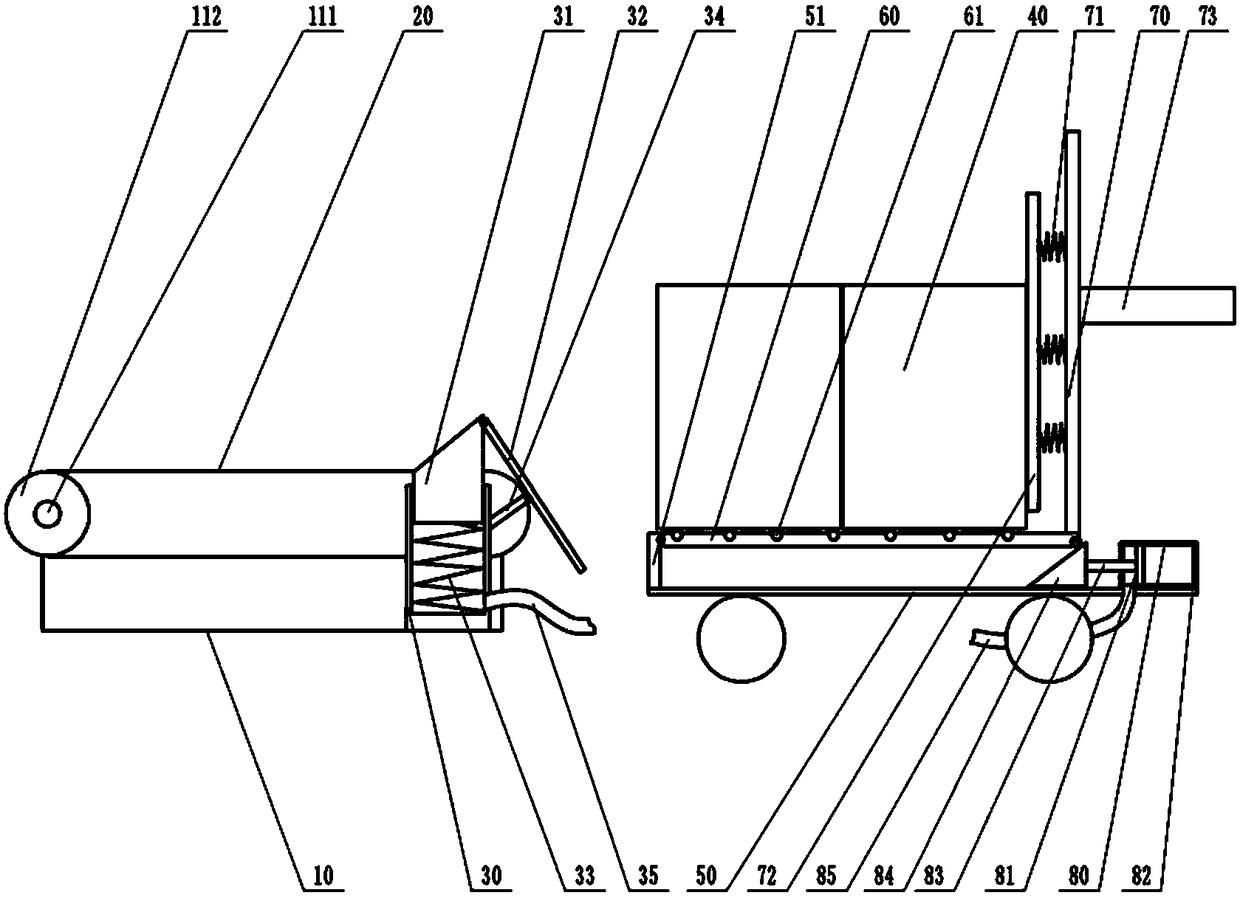

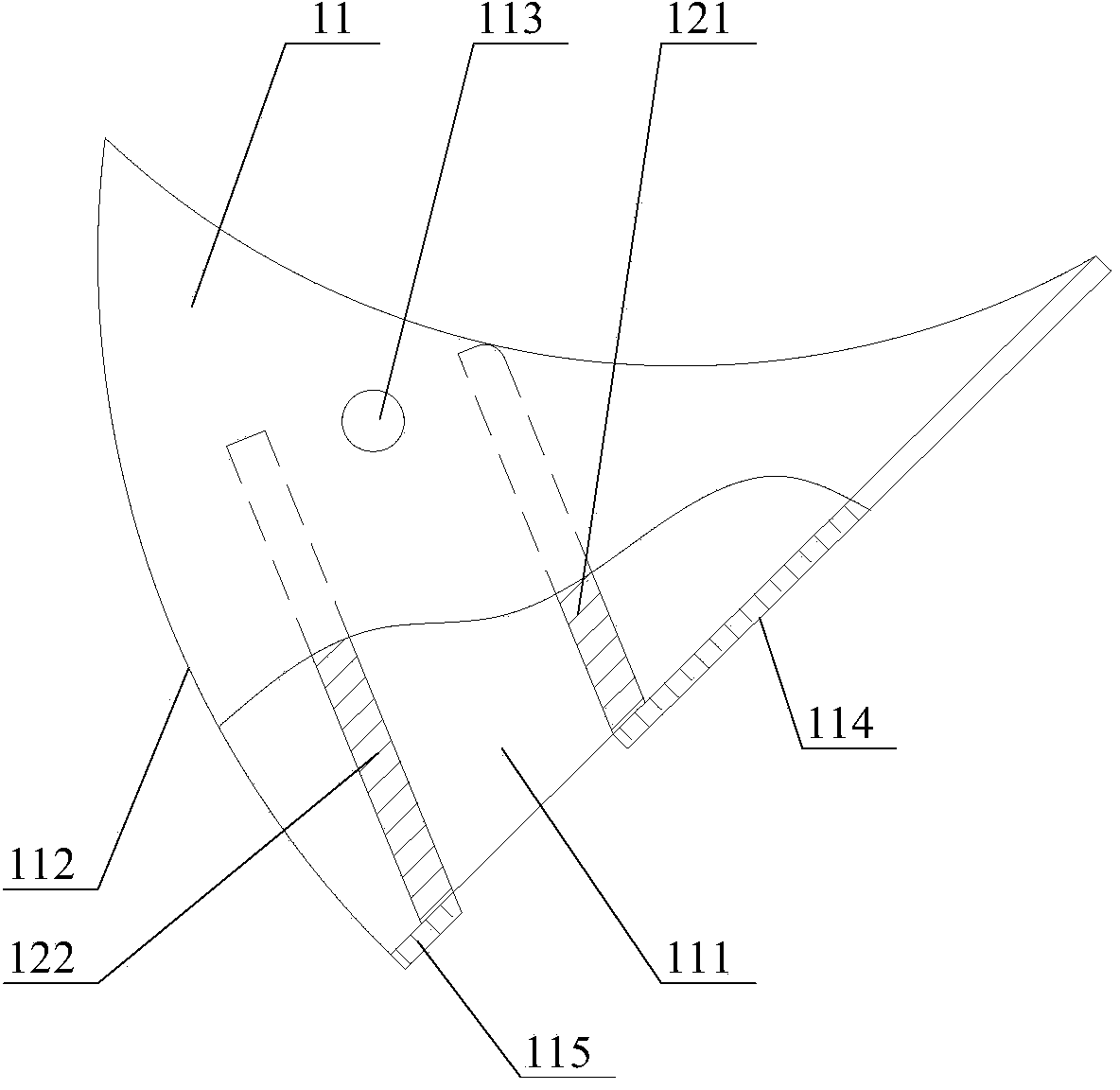

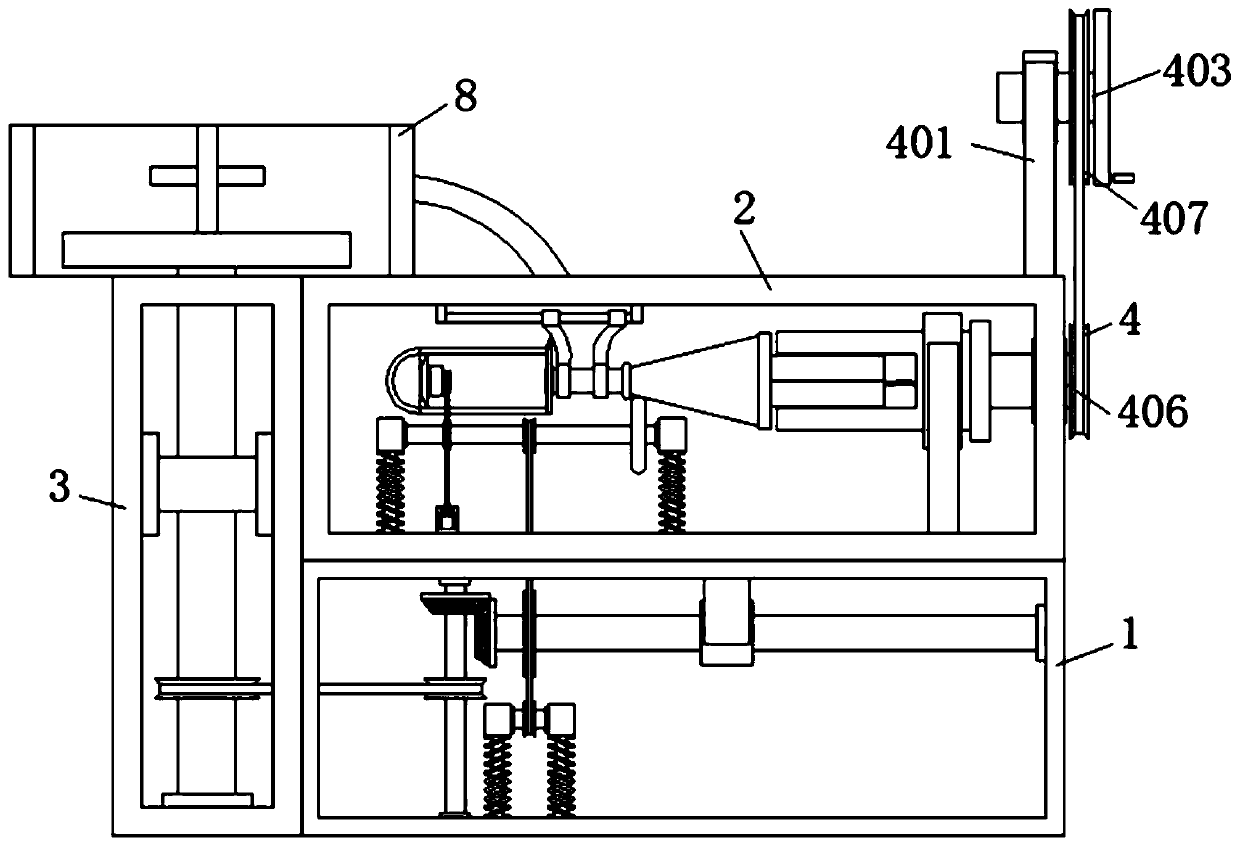

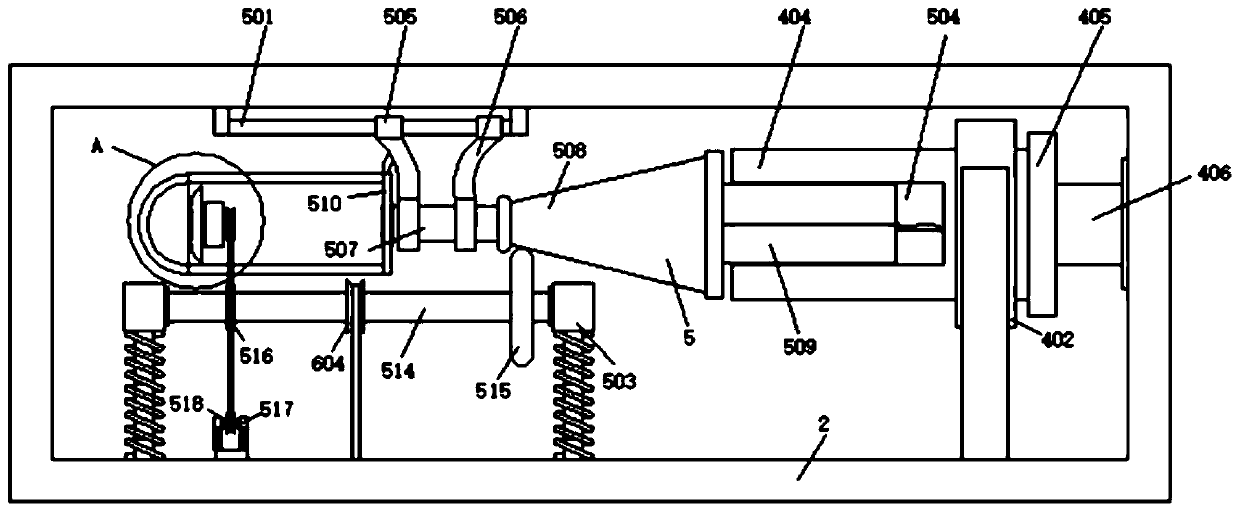

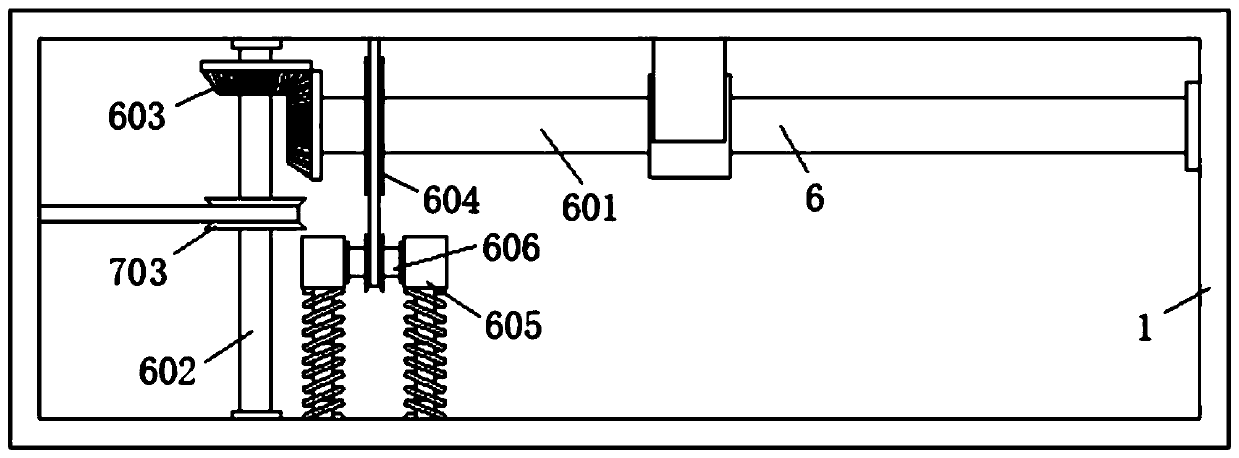

Electronic component inserter and insertion method

PendingCN106793750AReduce labor costsIncrease productivityElectrical componentsElectronic componentEngineering

The invention discloses an electronic component inserter. The electronic component inserter comprises a rack, an electronic component feeding device, an electronic component grabbing device, a material conveying device, a position capturing device, a sensing mechanism and a control device. The electronic component inserter disclosed by the invention has the advantages of being high in production efficiency and high in automatic degree. The invention further discloses an insertion method using the electronic component inserter.

Owner:长沙市赛稳柒智能设备有限公司

Assembling device for medical glass slide

InactiveCN107052747ARealize self-assemblyEasy to operateMetal working apparatusDrive wheelDrive motor

The invention discloses an assembling device for a medical glass slide. The assembling device comprises a machine frame and a supporting plate which are used for playing a supporting role. The machine frame is provided with a driving wheel and a driven wheel. The front side of the machine frame is provided with a start key and a stop key. The driving wheel and the driven wheel are connected together through a material conveying belt. Two support plates are fixed to the supporting plate. A driving motor is installed on the support plates and stretches out of a motor shaft. The motor shaft and the driving motor are connected through a motor buffer plug. The motor shaft and the driving wheel are connected together through a deceleration conveying belt. The assembling device has the advantages that the medical glass slice can be automatically assembled, operation is easy, and the automation degree is high.

Owner:鲁曦

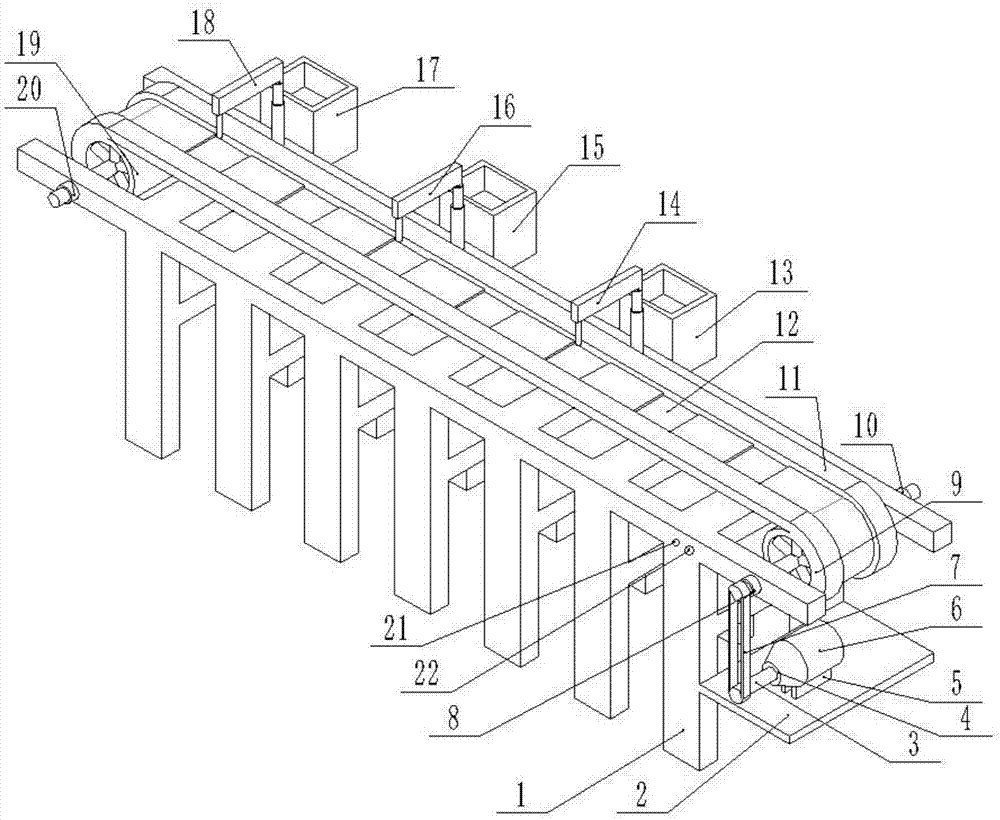

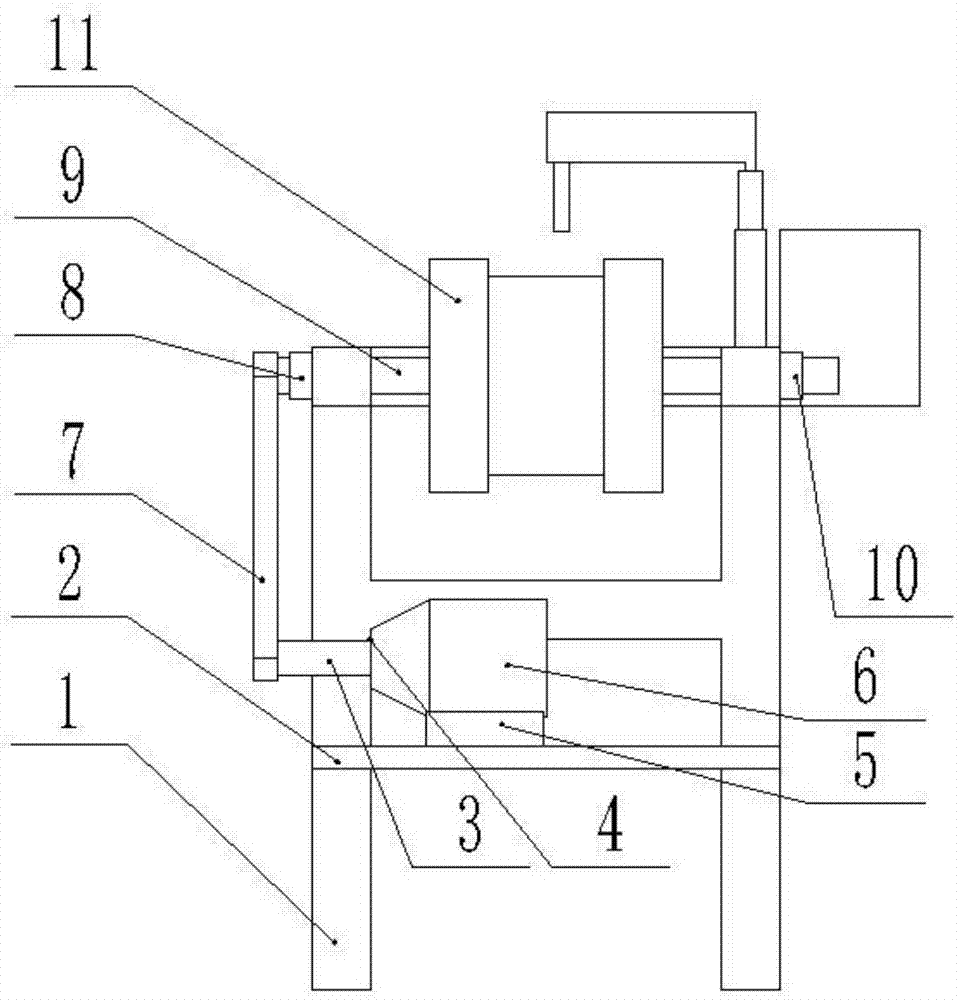

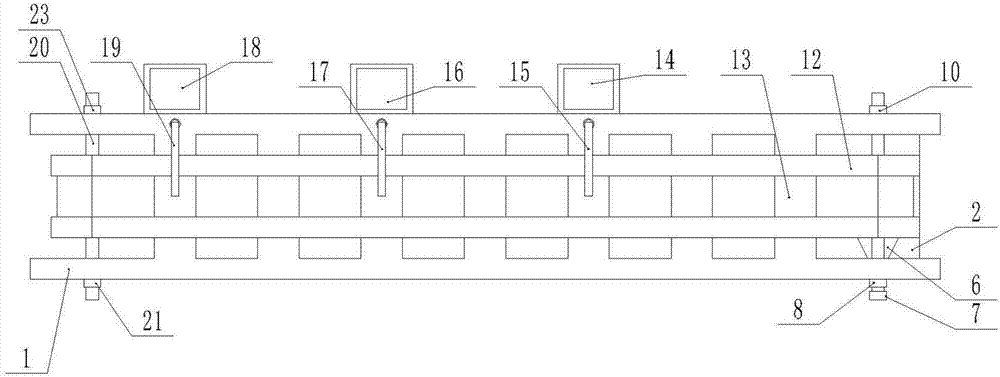

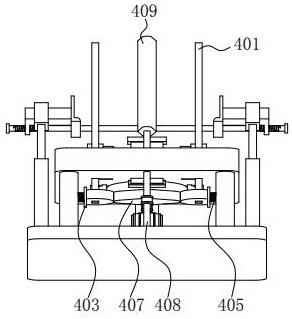

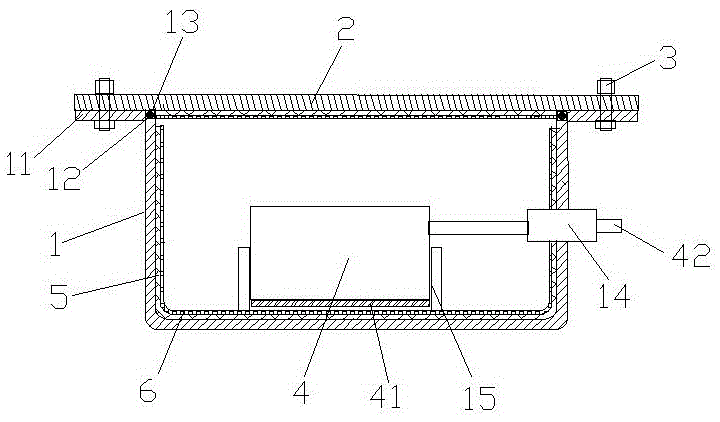

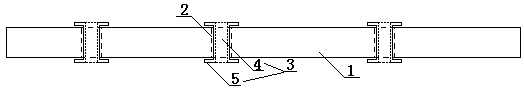

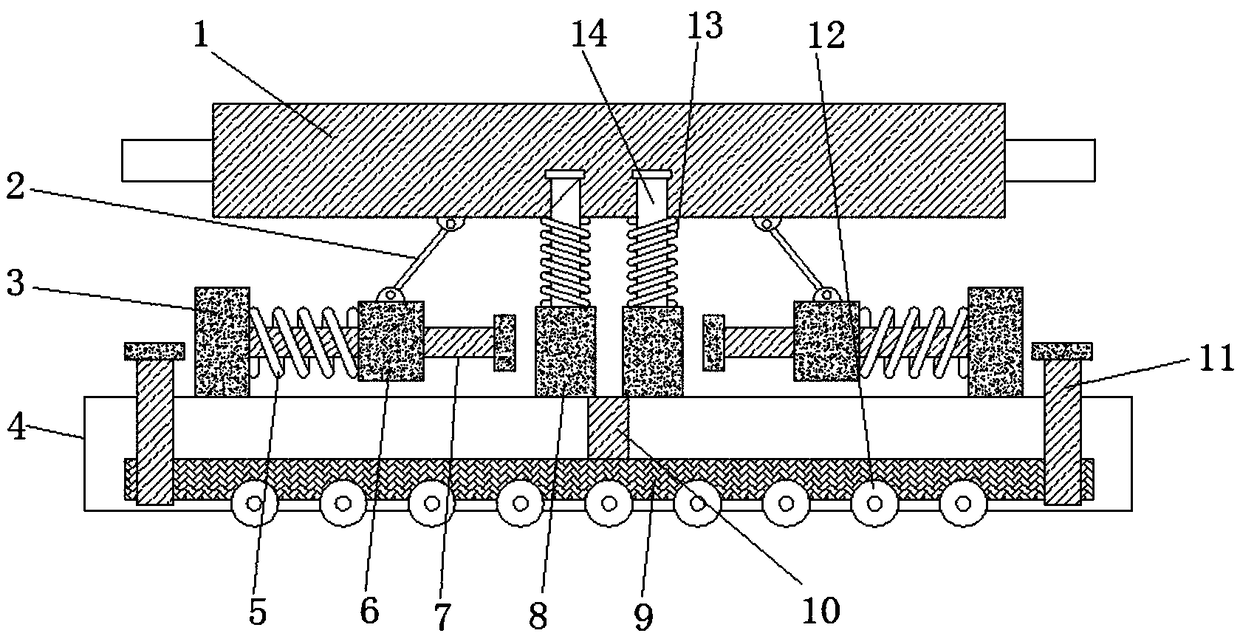

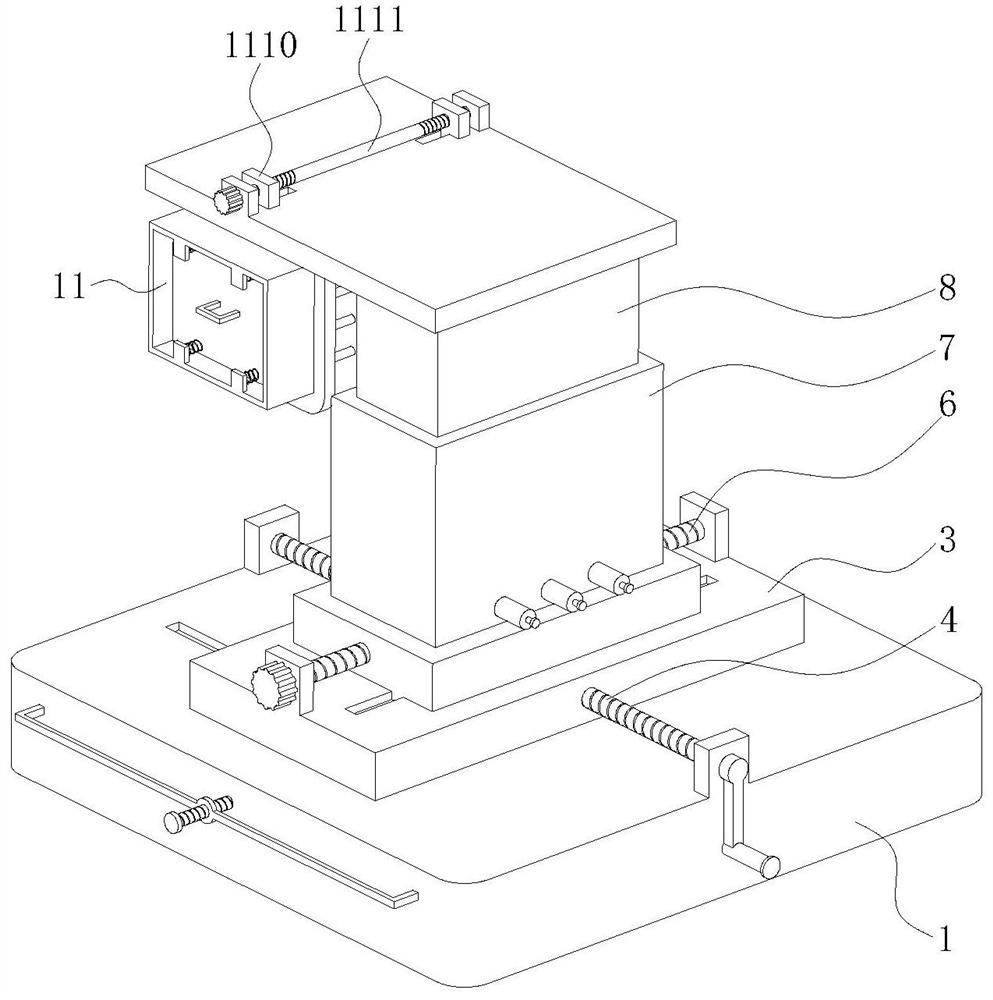

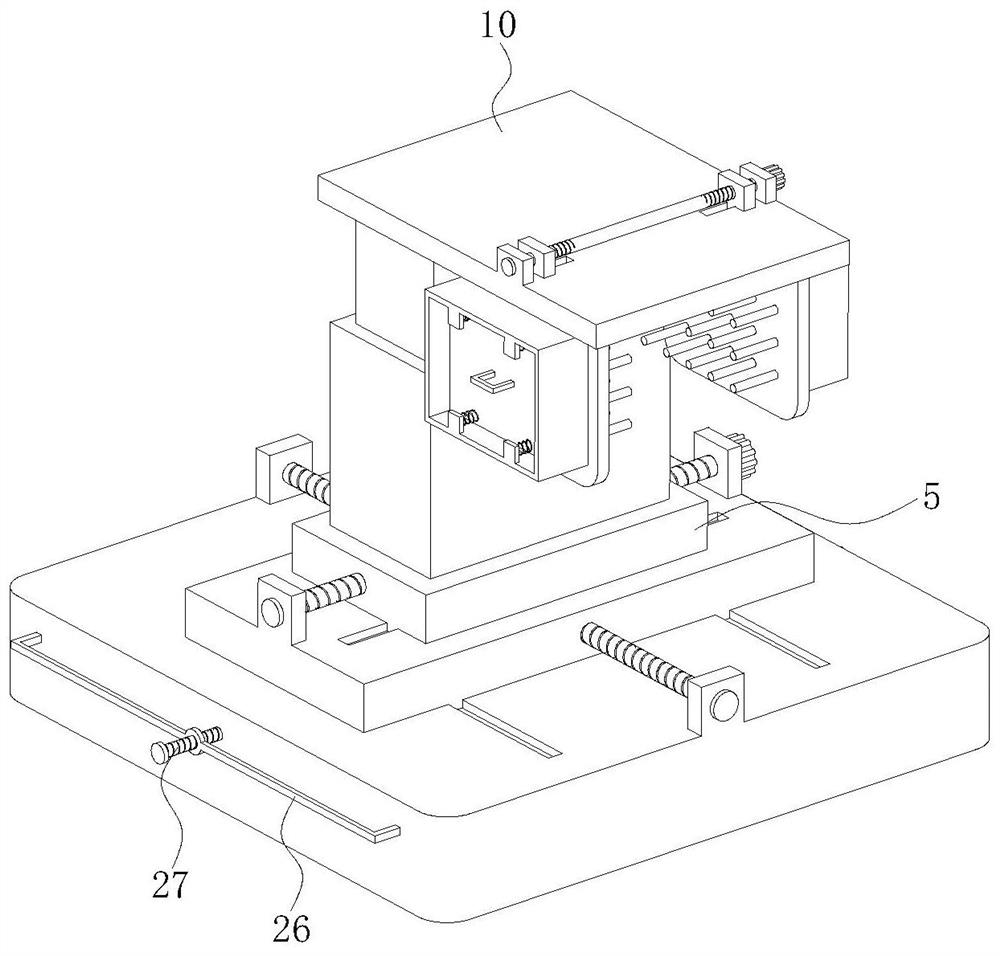

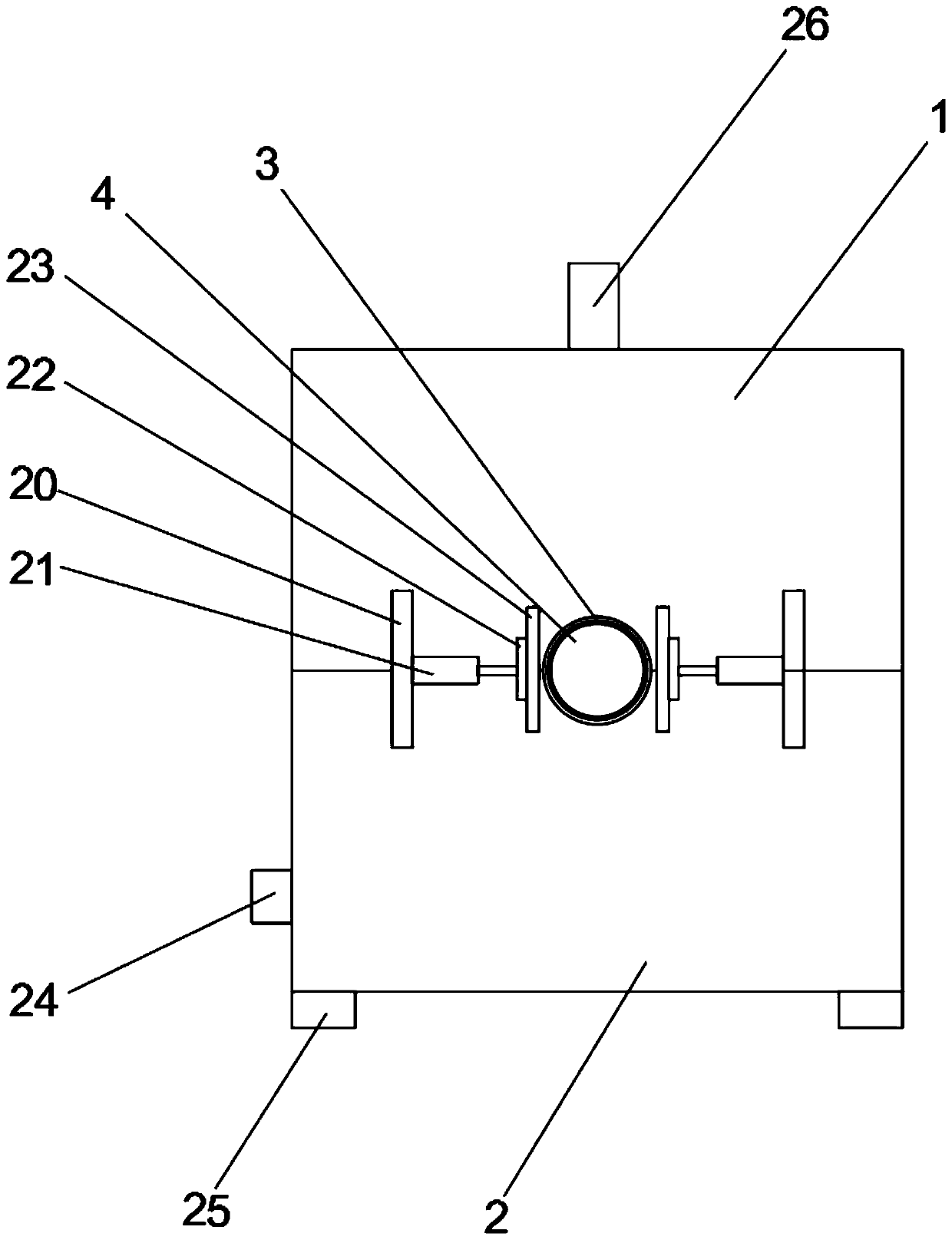

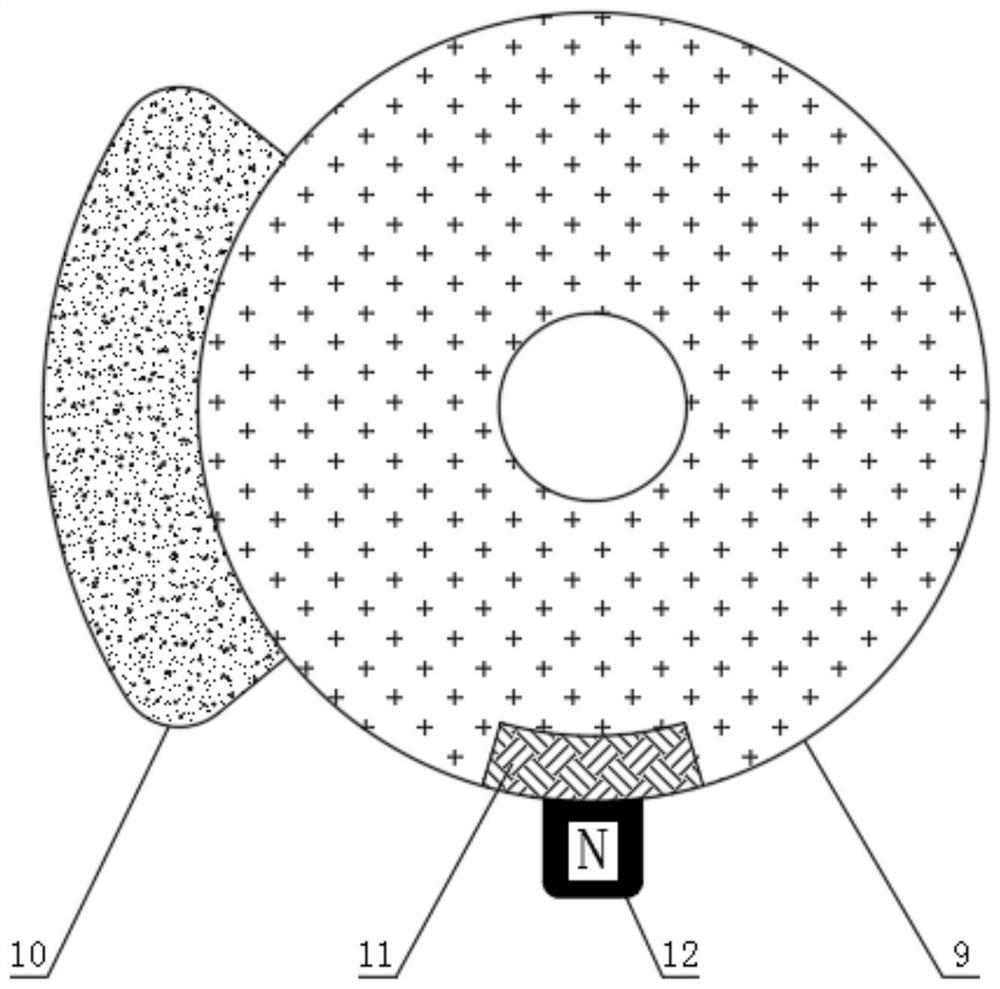

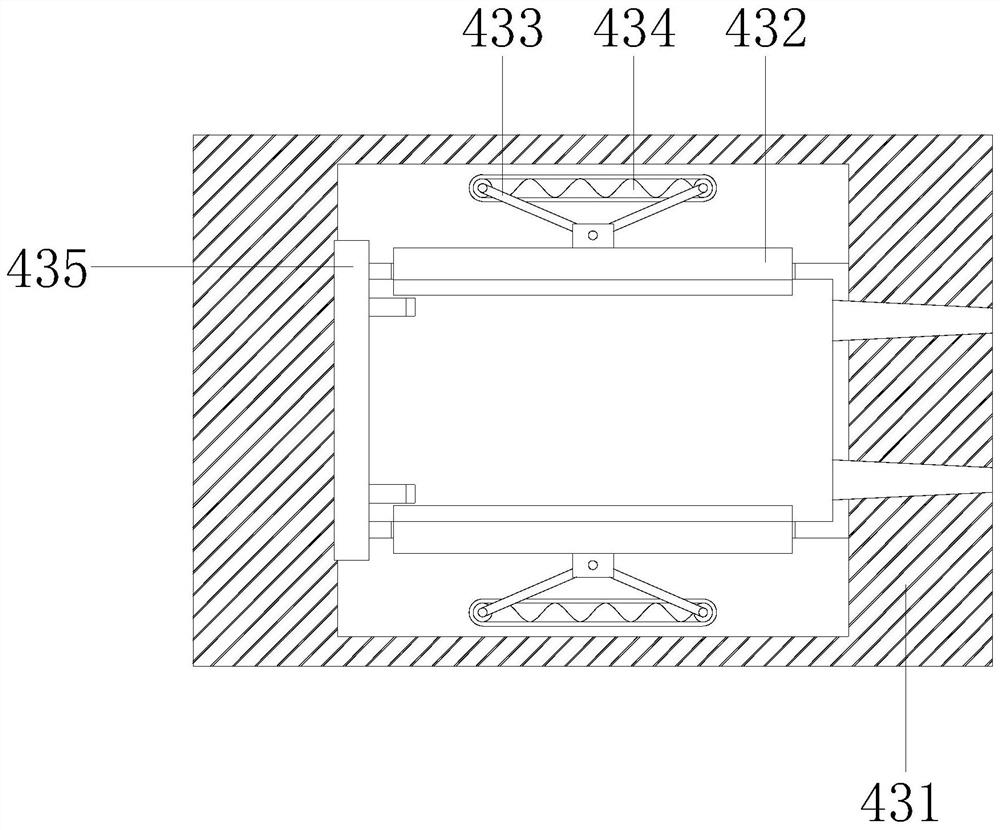

Transformer iron core automatic lamination device

ActiveCN113470965APlay a positioning roleAvoid frictional situationsTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerEngineering

The invention belongs to the technical field of transformer accessory manufacturing, and particularly relates to a transformer iron core automatic lamination device which comprises a horizontal bottom plate, a platform is fixedly installed above the bottom plate through supporting columns, a positioning mechanism and a bearing mechanism are installed above the bottom plate, and a stacking mechanism is installed on the bottom plate; in the process of stacking upper-layer silicon steel sheets on lower-layer silicon steel sheets, the silicon steel sheets do not make contact with vertical rods, and the situation that friction is generated between the edges of the silicon steel sheets and the vertical rods is avoided; in the process of mounting a clamping plate after the silicon steel sheets are stacked into an iron core, the limiting effect on a single wedge-shaped block is sequentially relieved, so that a lifting block and a bearing plate move downwards under the action of self gravity, the bearing plate is separated from the bottom surface of the silicon steel sheet on the lowest layer, and the effect of mounting the clamping plate under the condition that the silicon steel sheets are not lifted is achieved; and the condition that extrusion force and friction force are generated between the silicon steel sheets and the vertical rods is avoided.

Owner:昌航电气有限公司

Cargo transfer transportation device

InactiveCN108341238AReduce labor intensityImprove loading efficiencySupporting partsConveyor partsEngineeringCylinder block

The invention belongs to the technical field of cargo transportation, and particularly discloses a cargo transfer transportation device. The cargo transfer transportation device comprises a transporting unit and a transferring unit; the transferring unit comprises a piston cylinder and a conveying mechanism; a plunger is connected in the piston cylinder in a sliding mode; a transferring plate is hinged to the plunger; the transporting unit comprises a conveying trolley provided with a base; a cylinder block is fixed to one side of the base; a supporting block is fixed to the other side of thebase; a receiving plate is hinged to the supporting block; a limiting hole is formed in the side wall of the cylinder block; a piston is connected in the cylinder block in a sliding mode; a clamping groove is formed in the side wall of the piston; a limiting block is connected in the clamping groove in a sliding mode; a first spring is connected between the clamping groove and the limiting block;a piston rod is fixed to the piston; a wedge block is fixed to the piston rod; a slope is arranged on the upper surface of the wedge block; the end part, away from the supporting block, of the receiving plate can be attached to the slope of the wedge block; an exhaust pipe is connected to the piston cylinder; and an air inlet pipe which can be connected to the exhaust pipe is connected to the cylinder block. The device has the advantages that cargoes can be automatically and orderly arranged on the conveying trolley.

Owner:重庆市妙涵商贸有限公司

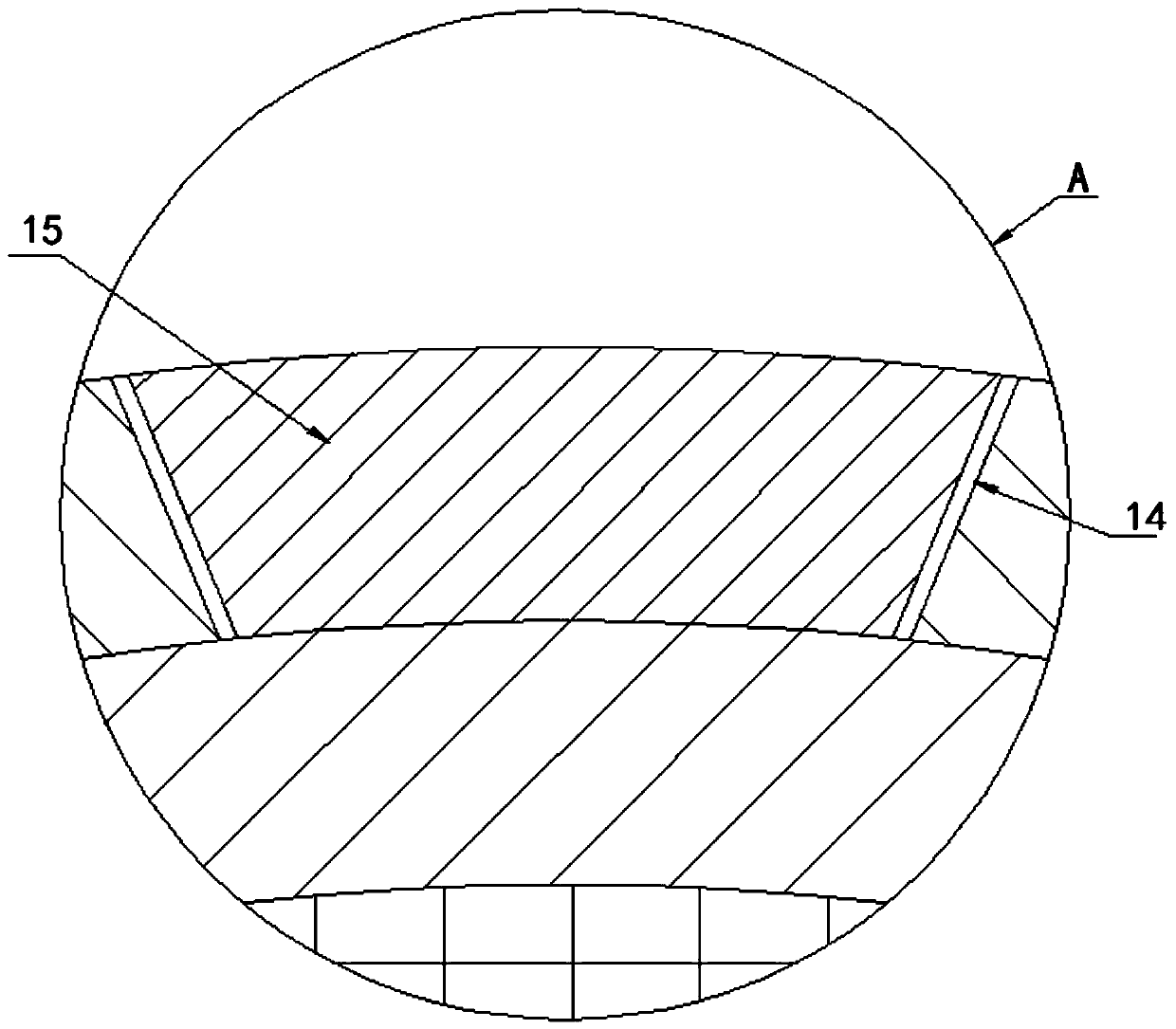

Crushing tooth assembly and tooth holder thereof

ActiveCN103406182ASimple and reliable assembly structureReduce or avoid crushing forcesGrain treatmentsEngineeringAssembly structure

The invention discloses a tooth holder used for a crushing tooth assembly. The tooth holder comprises a body; a cutter tooth mounting hole matched with a crushing cutter tooth is formed in the middle of the front end surface of the body; the lower bottom surface of the body is a circular arc surface; the lower bottom surface of the body is tangent with the conveying direction of the material. In the working process, the lower bottom surface of the body is the circular arc surface which is tangent with the conveying direction of the material, the extrusion force to material caused by the tooth holder, the crushing tooth assembly and related parts can be effectively reduced or avoided in the running process of equipment, and the abrasion between a scraper conveyor arranged at the lower part and related parts can be further avoided; furthermore, the tooth holder is simpler and more reliable in a whole assembly structure. The invention also discloses the crushing tooth assembly adopting the tooth holder.

Owner:HUNAN WANTONG TECH

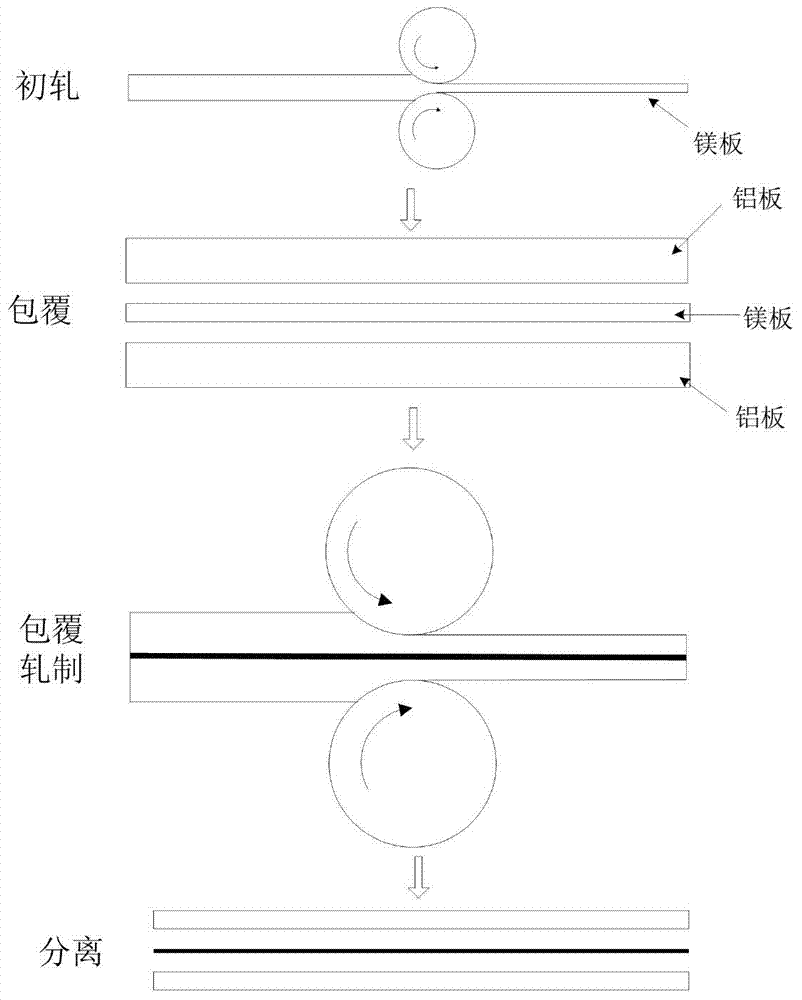

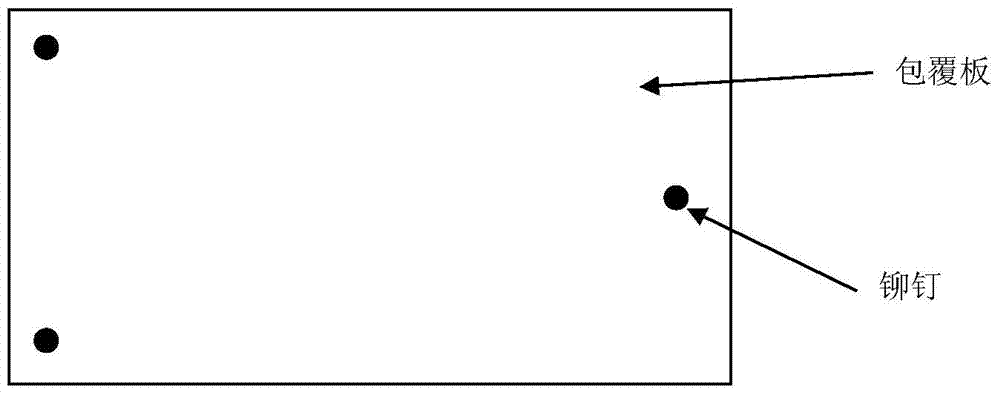

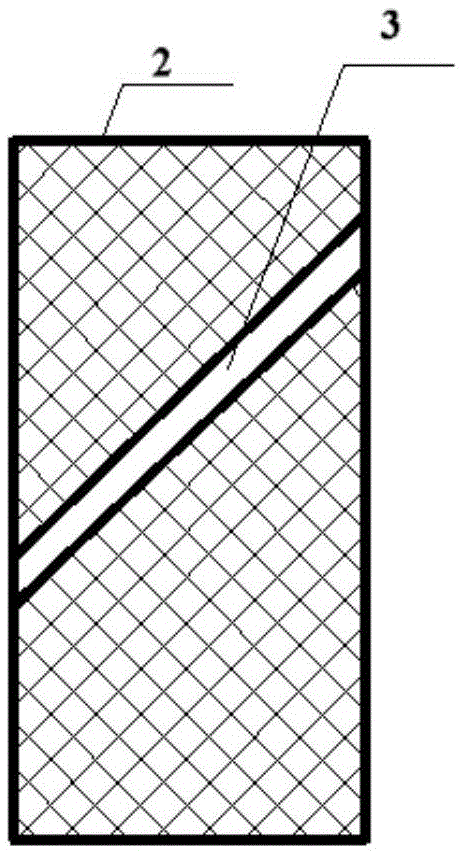

Preparation method for rolling ultrathin magnesium alloy sheet or foil by using double-side coated aluminum plate

The invention provides a preparation method of an ultrathin magnesium alloy sheet or foil with excellent performance, belonging to the technical field of metal material manufacture. According to the better plasticity of pure industrial Al plates, pure Al plates are coated on two faces of a magnesium alloy sheet, and the stress state of the magnesium alloy in an intermediate layer is changed in the coating and rolling processes to ensure that the thickness of the rolled magnesium alloy sheet is up to 0.1mm and below. According to the invention, the foil with the thickness of 0.1mm and below, excellent magnesium alloy mechanical performance and better surface quality is obtained by using an optimized annealing process and a special rolling process, thereby laying a foundation for meeting the requirements of industrial production and electronic product devices.

Owner:UNIV OF SCI & TECH BEIJING

Temperature transmitter housing capable of heat dissipating and sealing

InactiveCN105606237AEase of subsequent maintenanceExtended service lifeThermometer detailsAntioxidantEngineering

The invention discloses a temperature transmitter housing capable of heat dissipating and sealing, and an U-shaped metal housing and a metal cover plate which are connected through a bolt. The external surfaces of the U-shaped metal housing and the metal cover plate are coated with insulating layers, and the internal surfaces of the same are coated with aluminum foil layers and modified nanometer diamond layers in sequence. The bottom of a control plate of a temperature transmitter is pasted with a heat dissipating fin, and the bottom of the heat dissipating fin contacts with the modified nanometer diamond layers; a groove is arranged on the top of an opening of the U-shaped metal housing, and a sealing ring is arranged in the groove. The sealing ring is prepared through a conventional method with the following raw materials by weight: 50-60 parts of Buna-N rubber, 40-50 parts of silicone rubber, 20-30 parts of polyether urethane rubber, 10-20 parts of aromatic poly-parabens heat-resistant resin, 5-15 parts of carbon fluoride, 2-5 parts of active magnesium oxide, 1-3 parts of antioxidant and 1.2-2.5 parts of self-lubricating agent unsaturated fatty acid. By adopting the above structure and constituents, the sealing ring has good sealed waterproof performance and high self-heat dissipating efficiency, and can prevent signal interference.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

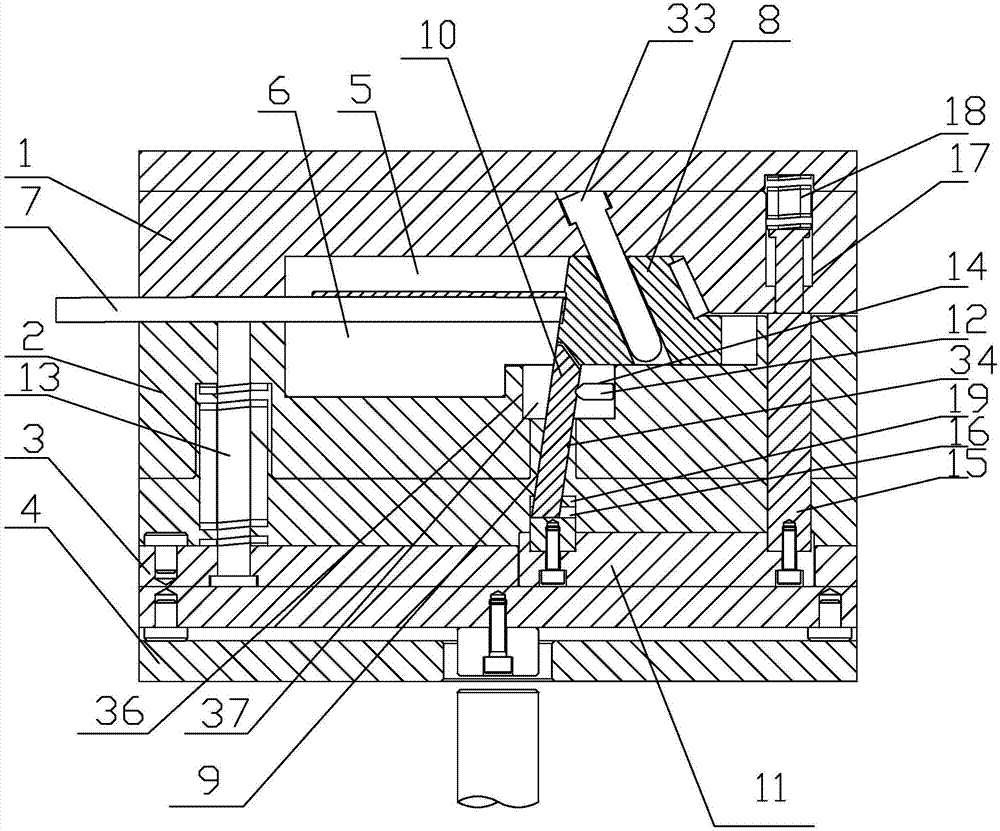

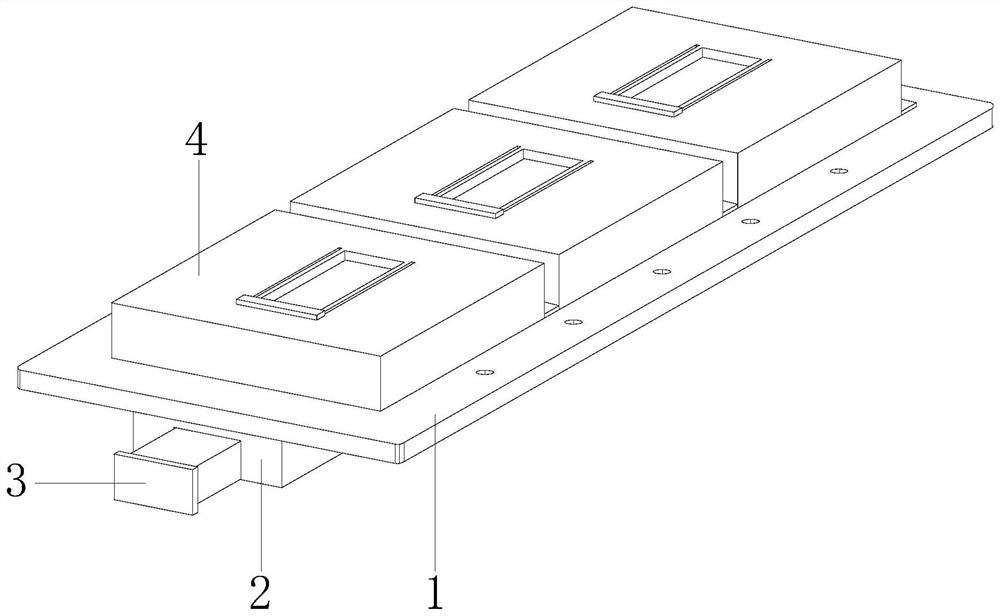

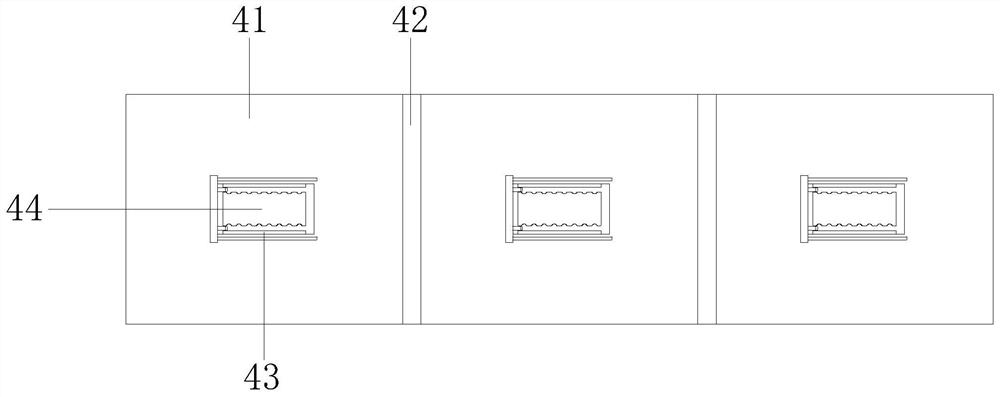

Injection mold for embedding of automobile sealing strip insert

PendingCN107160630AImprove securityNo personal injuryDomestic articlesComposite materialSafety coefficient

The invention discloses an injection mold for embedding of an automobile sealing strip insert. The injection mold comprises an upper mold plate (1), a lower mold plate (2), an ejection plate (3), a base plate (4) and a sealing strip (7). The ejection plate (3) is located on the base plate (4). The lower mold plate (2) is located between the upper mold plate (1) and the ejection plate (3). An upper mold plate (5) is arranged below the upper mold plate (1). A lower mold plate (6) is arranged above the lower mold plate (2). The lower mold plate (2) is provided with an oblique slide block (8) used for forming the rubber coating part of the front end face of the sealing strip (7), a slide block (22) used for forming the rubber coating part of the inner side face of the sealing strip (7) and a mobile slide block (36) positioning the outer side face of the front end of the sealing strip (7). The upper mold plate (1) is provided with an oblique guide column (33) slidably matched with the oblique slide block (8). By adoption of the injection mold for embedding of the automobile sealing strip insert, personal injury cannot be caused, so that the safety coefficient is high.

Owner:NINGHAI HESHI PLASTIC CO LTD

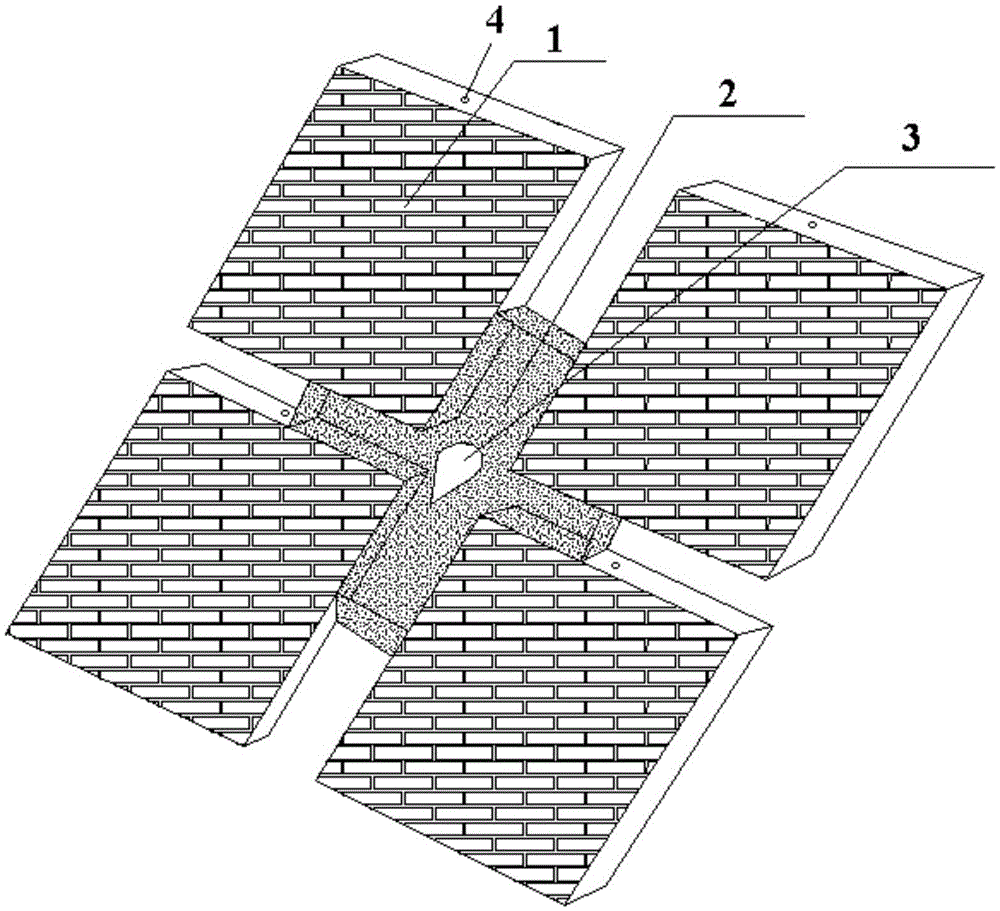

Method for constructing heat-preserving plates

InactiveCN105544752ARealize the moisture removal functionAvoid the phenomenon of resurgenceHeat proofingEngineeringSealant

The invention discloses a method for constructing heat-preserving plates. The method is simple and easy to implement. When the heat-preserving plates are fixed to a wall through the method, a overall through cavity does not occur between the heat-preserving plates, safety hidden hazards can be eliminated, the heat-preserving plates are prevented from cracking, moisture removing of the wall is achieved, and the indoor moisture regain phenomenon is avoided. The method includes the following steps that fixing holes are formed; adhesive mortar is smeared to the lower bottom face edges, attached to the wall, of the heat-preserving plates and in the fixing holes formed in the side faces of the heat-preserving plates without any gaps; the heat-preserving plates are aligned according to rows and columns to be attached to the wall and compacted, fixing components are inserted into the fixing holes, and the fixing components are fixedly connected with the wall through fasteners matched with the fixing components; crossed exhaust components are installed on seam intersections between every two adjacent rows of heat-preserving plates and between every two columns of heat-preserving plates, and exhaust channels are formed in the exhaust components; other seams between the heat-preserving plates are filled with the mortar; the crossed exhaust components are fixed, and the seams between the heat-preserving plates are sealed with waterproof sealant.

Owner:ZHUO DA NEW MATERIAL TECH GRP

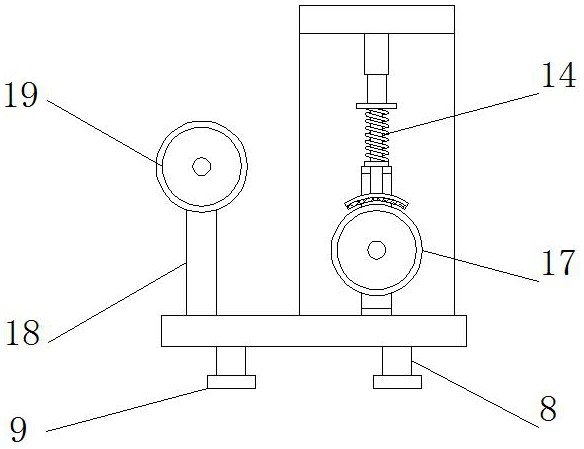

Piano wire winding mechanism for automobile seat system

The invention relates to a piano wire winding mechanism for an automobile seat system. The piano wire winding mechanism comprises a rack. The rack comprises a left rack body and a right rack body. Theleft rack body is vertically provided with a first connecting rod and a second connecting rod. The first connecting rod is provided with a first wire feeding wheel, and the second connecting rod is provided with a second wire feeding wheel and a third wire feeding wheel. The right rack body is provided with an elevating telescopic assembly, a power assembly, a coiling block assembly and a wire unloading assembly. The piano wire winding mechanism can solve the problem that in the rolling process of a traditional steel wire winding device, extrusion force is generated between steel wires.

Owner:无锡熠卿锋金属科技有限公司

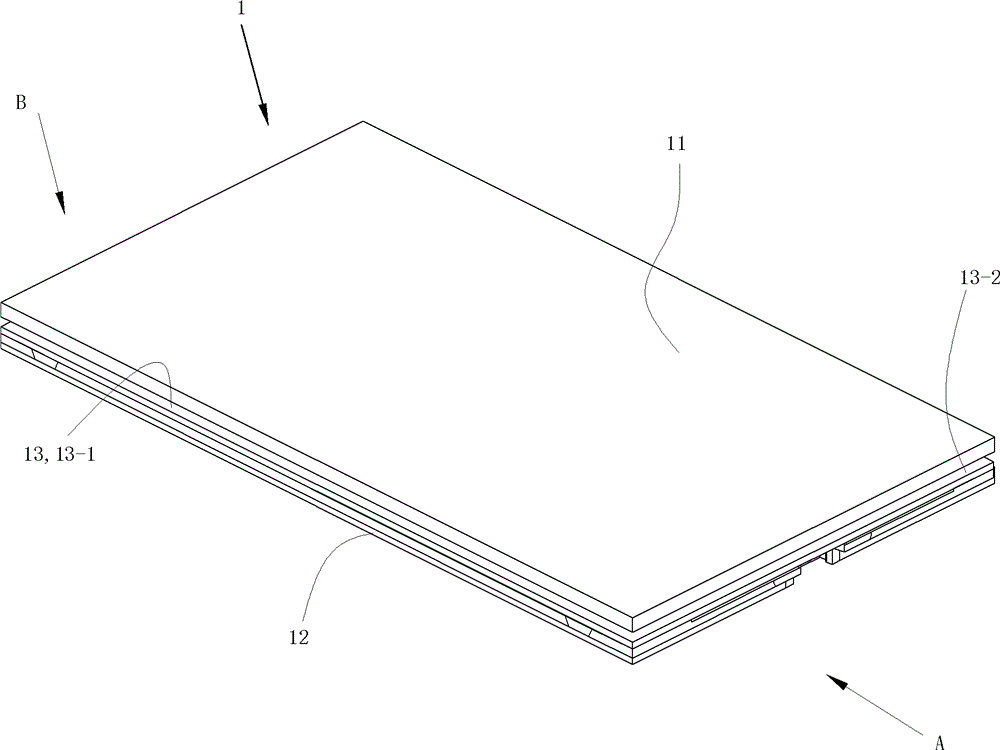

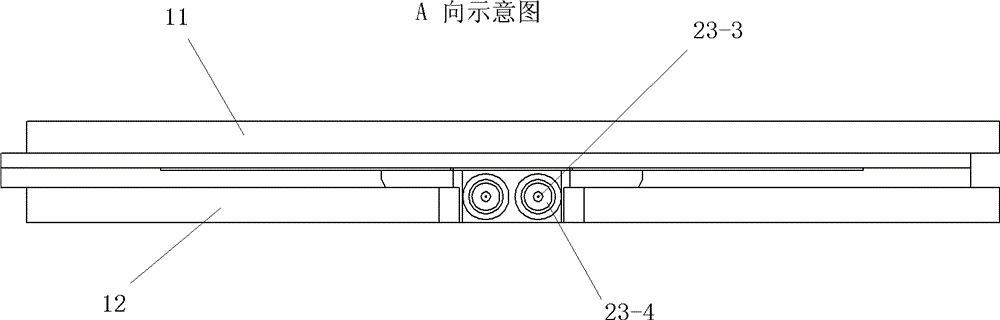

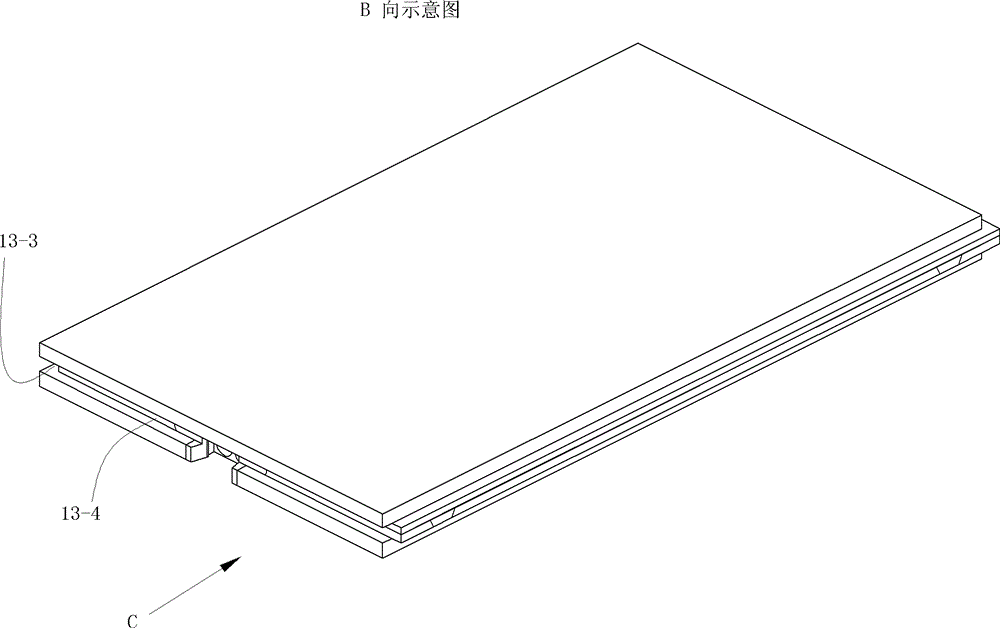

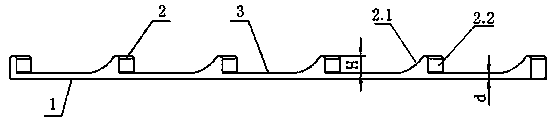

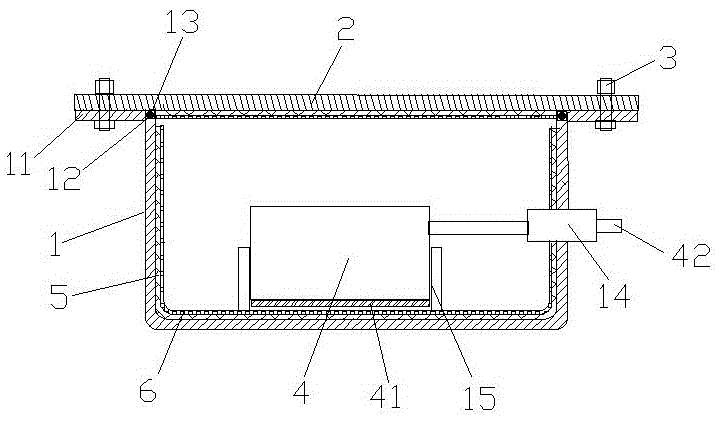

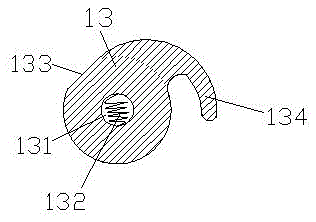

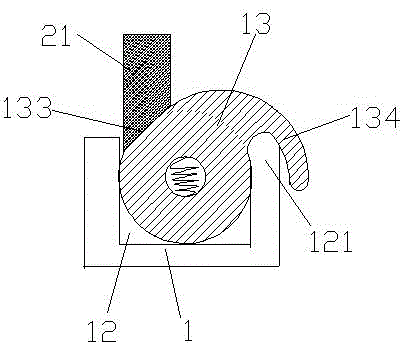

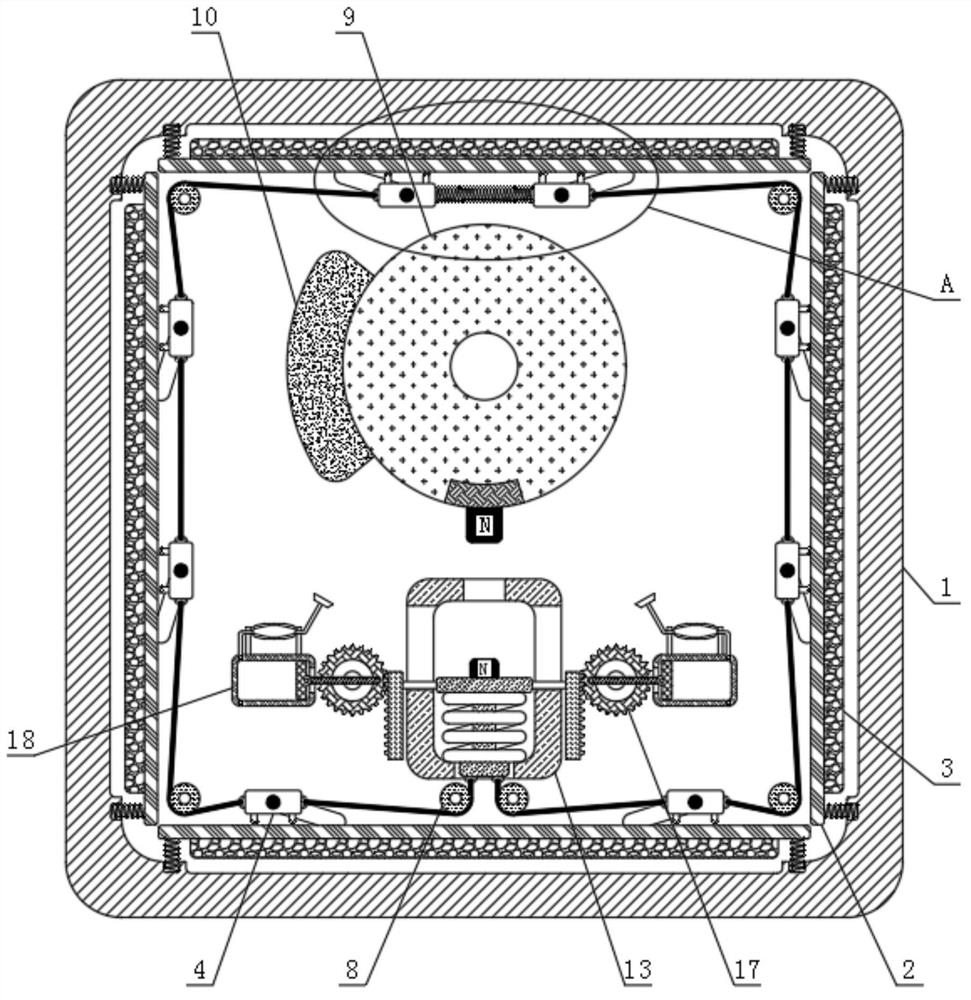

Integrated spontaneous heating floor board and bi-directional electric connecting plug

InactiveCN103132673BAvoid squeezeSo as not to damageLighting and heating apparatusElectric heating systemElectricityEngineering

The invention discloses an integrated spontaneous heating floor board which comprises a floor board main body and a spontaneous heating assembly. The floor board main body comprises a face plate and a bottom main body. The spontaneous heating assembly is arranged between the face plate and the bottom main body. The face plate is fixedly connected with the bottom main body from top to bottom. The integrated spontaneous heating floor board is characterized in that the floor board main body is provided with an internal cavity. Plug-in portions are arranged on the periphery of the floor board main body. The spontaneous heating assembly is a waterproof electric heating assembly which comprises electric heating pieces, a transmission unit and two mounting seats, wherein the two mounting seats are respectively arranged at the left end and the right end of the electric heating pieces. The electric heating pieces are electrically connected with the transmission unit through electrodes of the electric heating pieces and corresponding electric connection components. The electric heating pieces of the spontaneous heating assembly are arranged in the internal cavity of the floor board main body. The mounting seats of the spontaneous heating assembly are fixedly connected and embedded in the floor board main body, and the two mounting seats are respectively exposed out of the left side and the right side of the floor board main body. Therefore, the left mounting seat and the right mounting seat of the spontaneous heating assembly are used as corresponding power supply plug connecting pieces on the left side and the right side of the integrated spontaneous heating floor board.

Owner:江苏德威木业有限公司

Preparation machine of high-temperature structural ceramic

InactiveCN112374898AUniform high temperatureCalcination temperature is highShaping press ramPipeCeramic

The invention discloses a high-temperature structural ceramic preparation machine, which structurally comprises a placement box, a supporting plate, a workbench, a preparation box, a handle and a boxdoor, wherein the bottom of the placement box is welded to the top of the supporting plate, and the lower end of the supporting plate is welded to the upper surface of the workbench. According to theinvention, heat is conducted into a transmission pipe through a pipeline and is conducted through hot air of a conduction rod in a sealed mode, so that the outer side of a forming cavity is subjectedto high temperature more uniformly, and the overall calcining temperature of a ceramic sealing ring is increased; after an extrusion mechanism completely enters a box body, and an opening and closingplate is automatically closed, so that the high-temperature loss in the forming device is reduced; an extrusion round block is subjected to extrusion buffer adjustment through a spring, so that the extrusion round block is prevented from generating excessive extrusion force on the formed ceramic sealing ring; and a sliding outer ring abuts against the ceramic sealing ring through upward lifting ofan air cylinder and downward pressing of the sliding outer ring, and the ceramic sealing ring is prevented from falling off from the extrusion round block, so that the ceramic sealing ring is prevented from being embedded in the outer side of the extrusion round block.

Owner:泉州市勤裕鼎工业设计有限公司

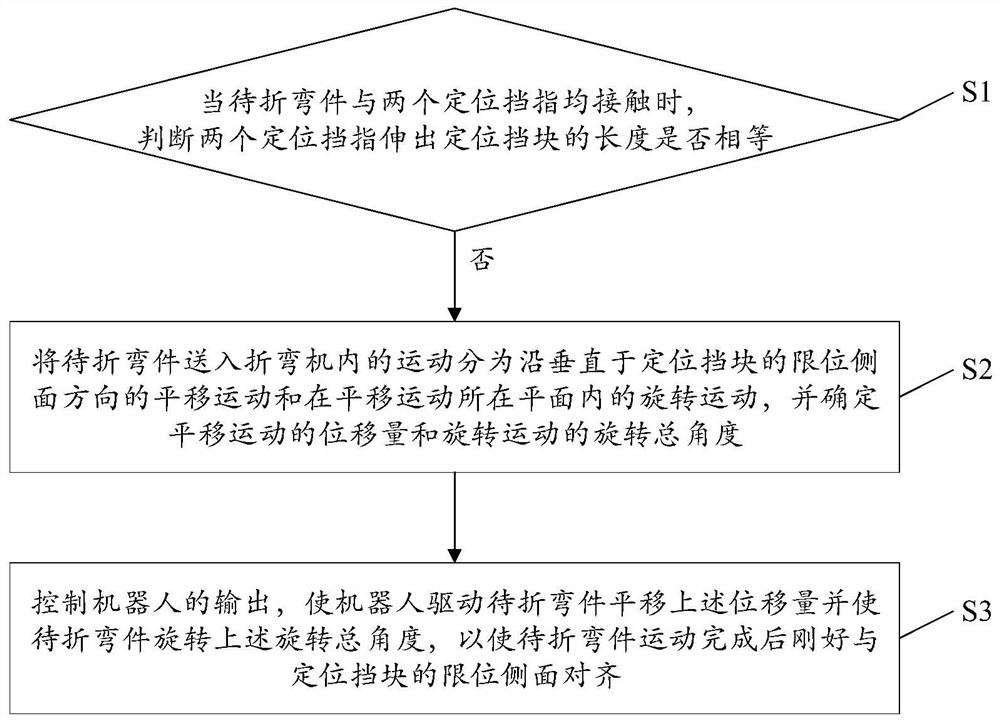

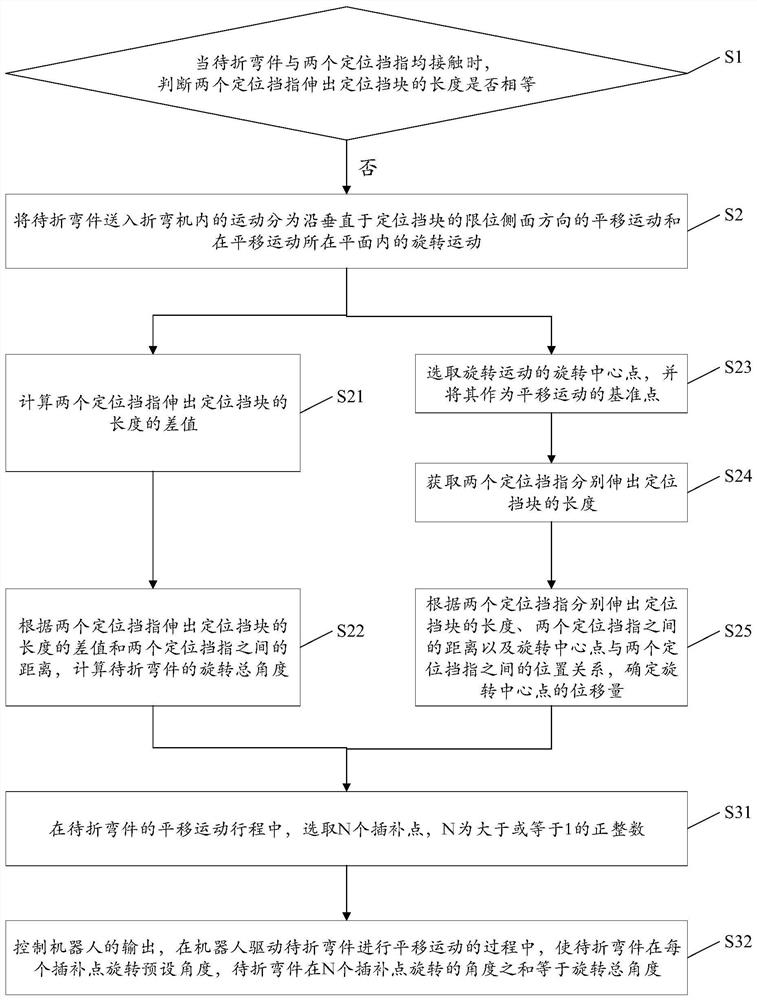

Positioning method, device and equipment for to-be-bent part of bending machine and storage medium

The invention discloses a positioning method, device and equipment for a to-be-bent part of a bending machine and a storage medium. The positioning method, device and equipment are applied to processcontrol over feeding of the to-be-bent part into the bending machine by a robot. The bending machine comprises a positioning stop block, wherein two telescopic positioning stop fingers are arranged onthe side, used for limiting the to-be-bent part, of the positioning stop block. The positioning method comprises the steps that when the to-be-bent part makes contact with the two positioning stop fingers, whether the lengths, stretching out of the positioning stop block, of the two positioning stop fingers are equal or not is judged; if not, the motion of feeding the to-be-bent part into the bending machine is divided into translation motion in the direction perpendicular to the limiting side face of the positioning stop block and rotation motion in the plane where the translation motion islocated, and the displacement of the translation motion and the total rotation angle of the rotation motion are determined; and the output of the robot is controlled, so that the robot drives the to-be-part part to horizontally move by the displacement and rotate by the total rotation angle, the to-be-bent part is just aligned with the limiting side face after moving is completed, and extrusion force generated between the to-be-bent part and the stop block is avoided.

Owner:BEIJING A&E TECH

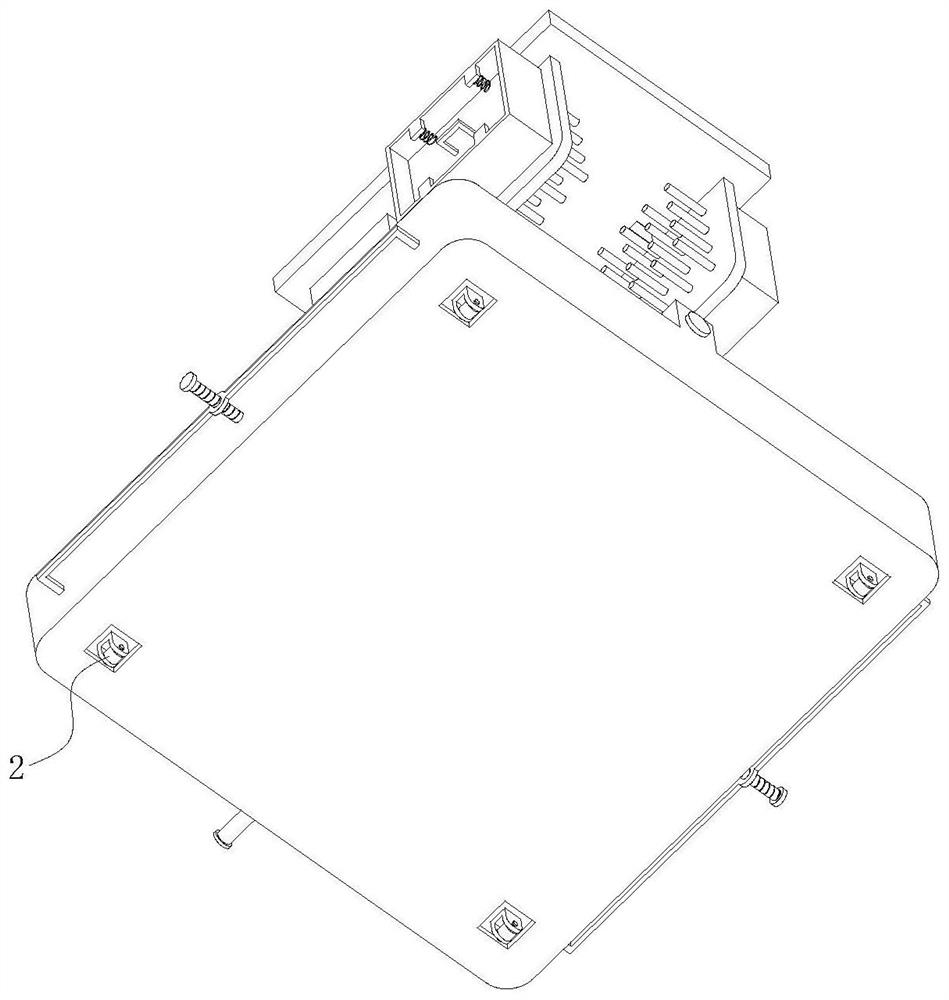

Fixedly installed PCB

InactiveCN104144560ASimple structureGuaranteed service lifePrinted circuit detailsEngineeringMechanical engineering

The invention relates to a fixedly installed PCB. The PCB comprises a PCB body (1), fixing through holes (2) formed in the PCB body (1), and locking clamping sleeves (3) arranged in the fixing through holes (2) respectively. The PCB body (1) comprises a circuit conducting layer. The locking clamping sleeves (3) do not make contact with the circuit conducting layer of the PCB body (1). The number of the locking clamping sleeves (3) is consistent with the number of the fixing through holes (2). Each locking clamping sleeve (3) comprises a cylindrical sleeve (4) with the two ends open, and protruding edges (5) arranged on the edges of the openings in the two ends of the cylindrical sleeve (4) respectively, the protruding edges (5) on the plane where the opening edges are located extend in the direction far away from the center of the openings along the opening edges, and the external diameter of each cylindrical sleeve (4) is matched with the internal diameter of the corresponding fixing through hole (2). The structural improvement is made on an existing PCB, the PCB can be effectively prevented from being extruded in the installing process, and the service life of the PCB is guaranteed.

Owner:江苏联康信息股份有限公司

Experiment trolley for classroom teaching of analytical chemistry

InactiveCN108201904AAvoid squeezeChange heightEducational modelsSupporting apparatusEngineeringTraveling block

The invention discloses an experiment trolley for classroom teaching of analytical chemistry. The experiment trolley comprises a bottom plate, wherein the bottom plate is of a hollow cuboidal structure, an opening is formed in the bottom end of the bottom plate, two electric telescopic columns which are arranged symmetrically are connected to the middle position of the top end of the bottom plate,top ends of the electric telescopic columns are connected with guiding rods, second springs sleeve the guiding rods, two fixing blocks which are arranged symmetrically are arranged at the two sides of the top end of the bottom plate, the electric telescopic columns are arranged between the two fixing blocks, a cross rod is connected to each of the sides, close to each other, of the two fixing blocks, a first spring sleeves each cross rod, one end of each first spring is connected with the corresponding fixing block, and a traveling block is connected with one end, far away from the corresponding fixing block, of each first spring. According to the experiment trolley for classroom teaching of analytical chemistry, the experiment trolley for classroom teaching of analytical chemistry and chemical apparatuses on the experiment trolley can be effectively subjected to multi-directional buffering protection, and the chemical apparatuses on the experiment trolley are prevented from being damaged; and meanwhile, the operating altitude of the experiment trolley can be adjusted, and the structure is novel, so that the experiment trolley is suitable for being popularized.

Owner:佛山杰致信息科技有限公司

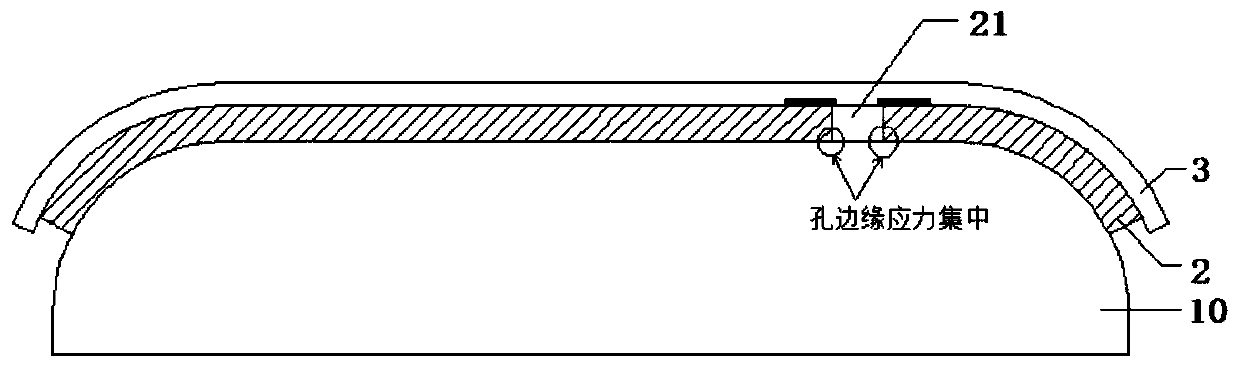

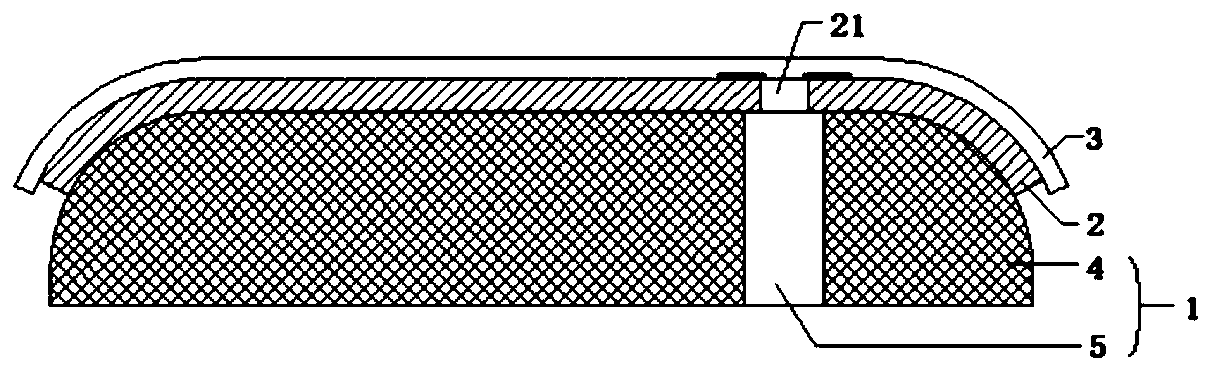

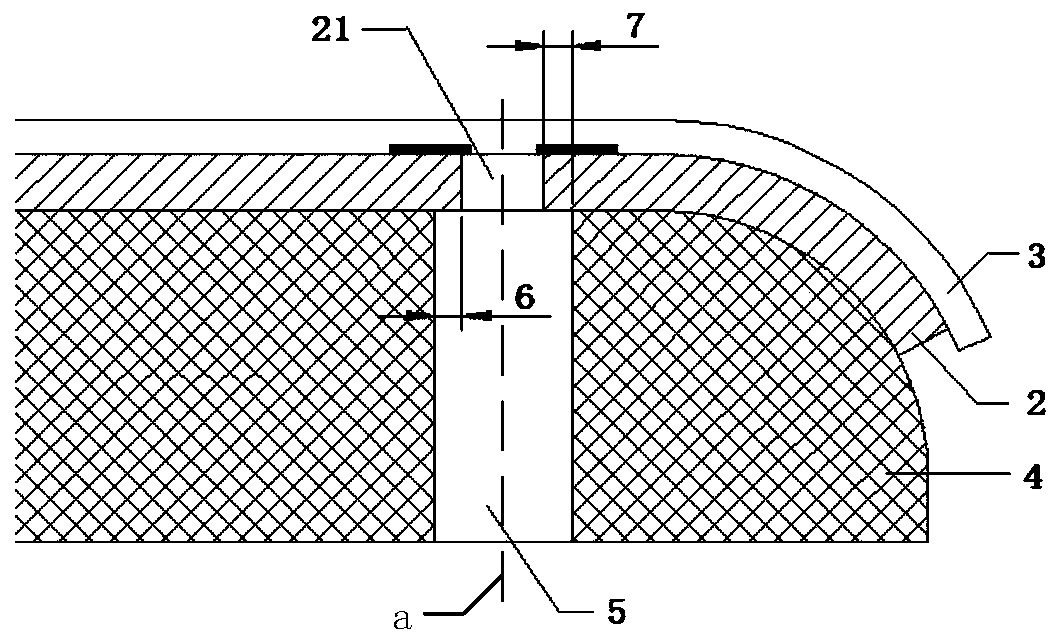

Laminating jig and method for manufacturing display module by adopting laminating jig

ActiveCN111564575AAvoid stress concentrationAvoid squeezeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMaterials science

The invention provides a laminating jig and a method for manufacturing a display module by adopting the laminating jig. The laminating jig comprises a gasket part and a through hole penetrating through the gasket part. The position of the through hole is matched with the position of an open hole, and the through hole covers the open hole in the orthographic projection area of the display panel. According to the embodiment of the invention, the through hole is formed in the gasket part; the through hole is formed in the display panel, the position of the through hole is matched with that of theopen hole, the through hole covers the open hole in the orthographic projection area of the display panel, the pressure borne by the open hole area of the display panel is reduced by structure, the phenomenon of stress concentration around the open hole is avoided, and cracks around the hole are prevented.

Owner:BOE TECH GRP CO LTD +1

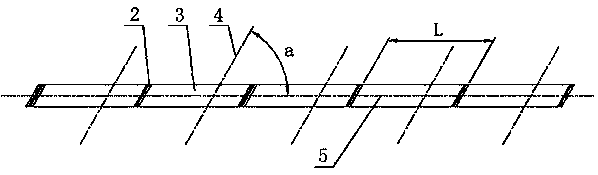

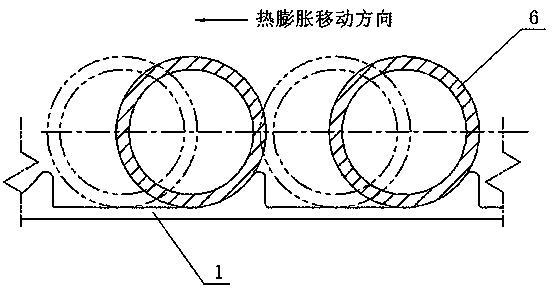

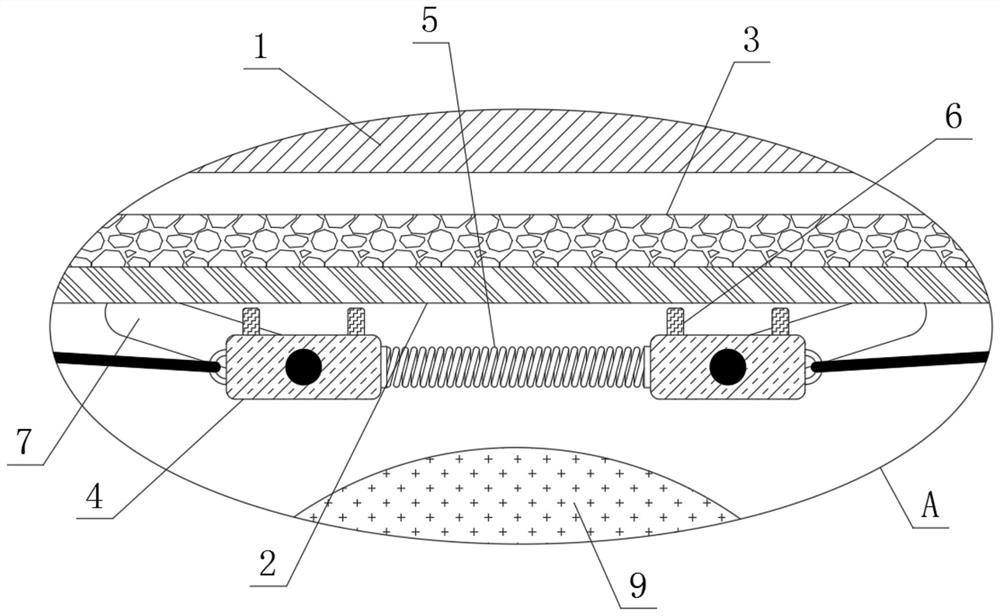

Novel special-shaped cushion strip suitable for winding around tubular heat exchanger

ActiveCN108731537AAvoid damageAvoid squeezeHeat exchanger casingsPlate heat exchangerThermal expansion

The invention relates to a novel special-shaped cushion strip suitable for winding around a tubular heat exchanger. The cushion strip comprises a strip-shaped base, a plurality of tooth-shaped protrusions are distributed at equal intervals in the length direction of the upper surface of the base, the tooth-shaped protrusions are parallel to one another, grooves are formed between the adjacent tooth-shaped protrusions, and the bottom faces of the grooves are plane. The width of the grooves can be designed according to a use requirement and is adopted to the size of a tube body and the axial movement range of the tube body, when the tube body moves forward in the axial direction due to thermal expansion, the movement of the tube body is just translational, extrusion of the tooth-shaped protrusions due to displacement is avoided, radial displacement cannot be caused due to the extrusion of the tooth-shaped protrusions so that the extrusion and damage of the cushion strip to a heat exchange tube can be effectively avoided, so that the radial expansion of a spiral tube bundle can be effectively reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

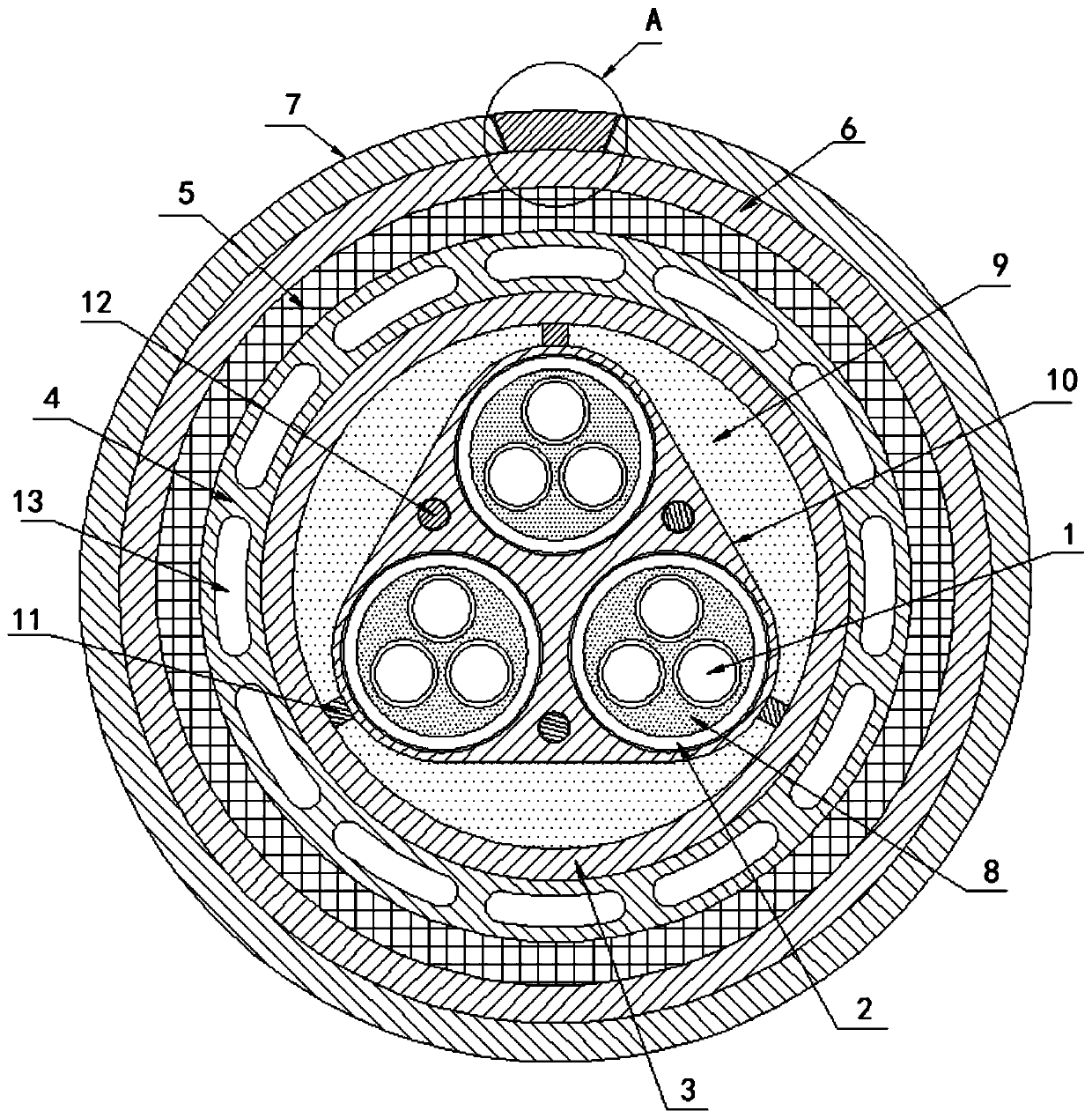

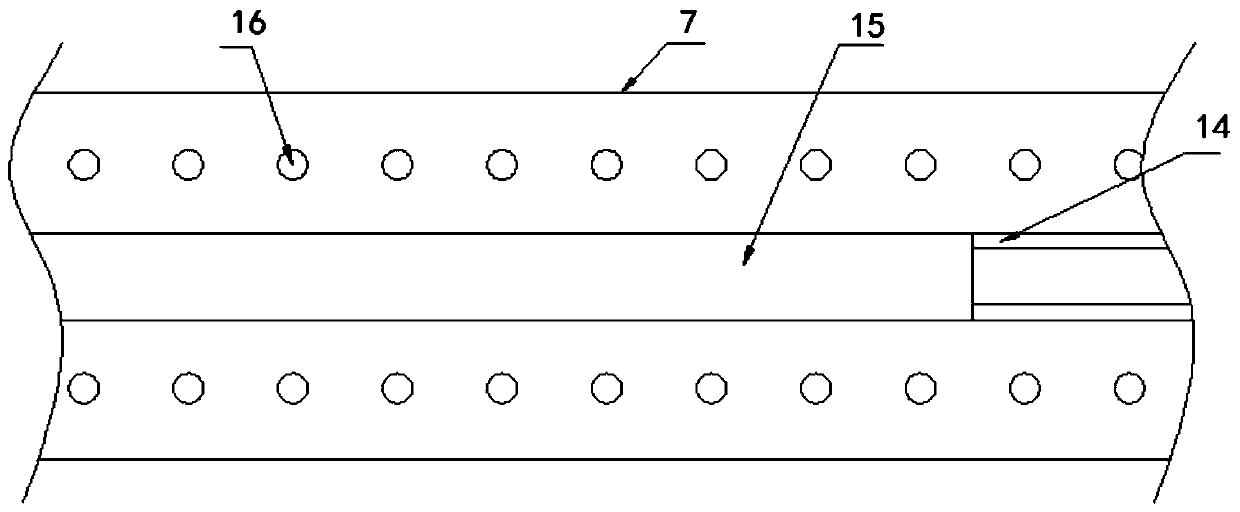

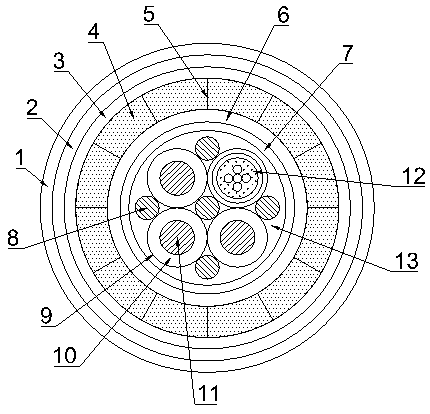

Ultra-low-temperature-resistant cable for railway vehicle

InactiveCN111508654AImprove insulation effectImprove low temperature resistanceInsulated cablesInsulated conductorsElectric cablesAutomotive engineering

The invention relates to the technical field of cables. The invention further discloses an ultra-low-temperature-resistant cable for a railway vehicle. The cable comprises conductive cores, a first protective sleeve is arranged outside the conductive cores; a second protective sleeve is arranged outside the first protective sleeve; an anti-extrusion mechanism is arranged between the first protective sleeve and the second protective sleeve; a buffer layer is arranged outside the second protective sleeve; a shielding layer is arranged outside the buffer layer, an insulating layer is arranged outside the shielding layer, a wear-resistant layer is arranged outside the insulating layer, first heat preservation cotton is set between the interior of the first protective sleeve and the exteriors of the conductive cores, and second heat preservation cotton is set in the second protective sleeve. The ultra-low-temperature-resistant cable for the railway vehicle is high in low temperature resistance, capable of preventing extrusion force between the adjacent conductive cores from being too large, high in buffering performance and convenient for workers to use.

Owner:ANHUI KANGLIYA CO LTD

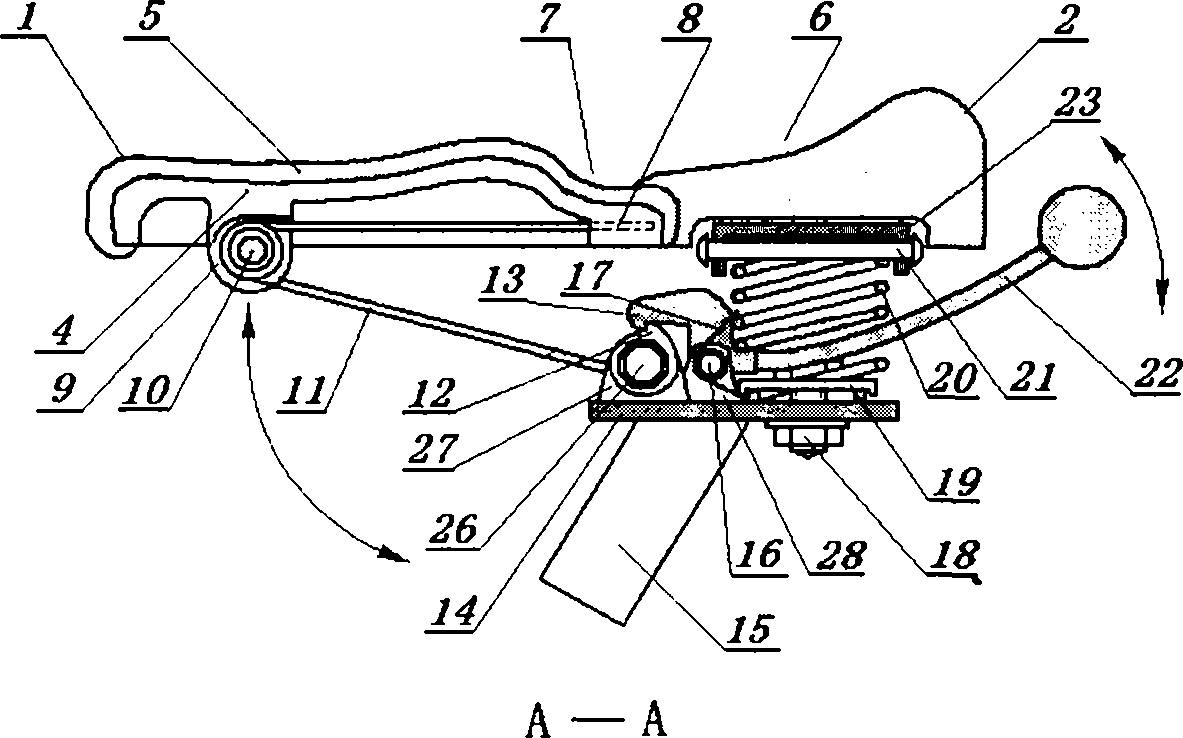

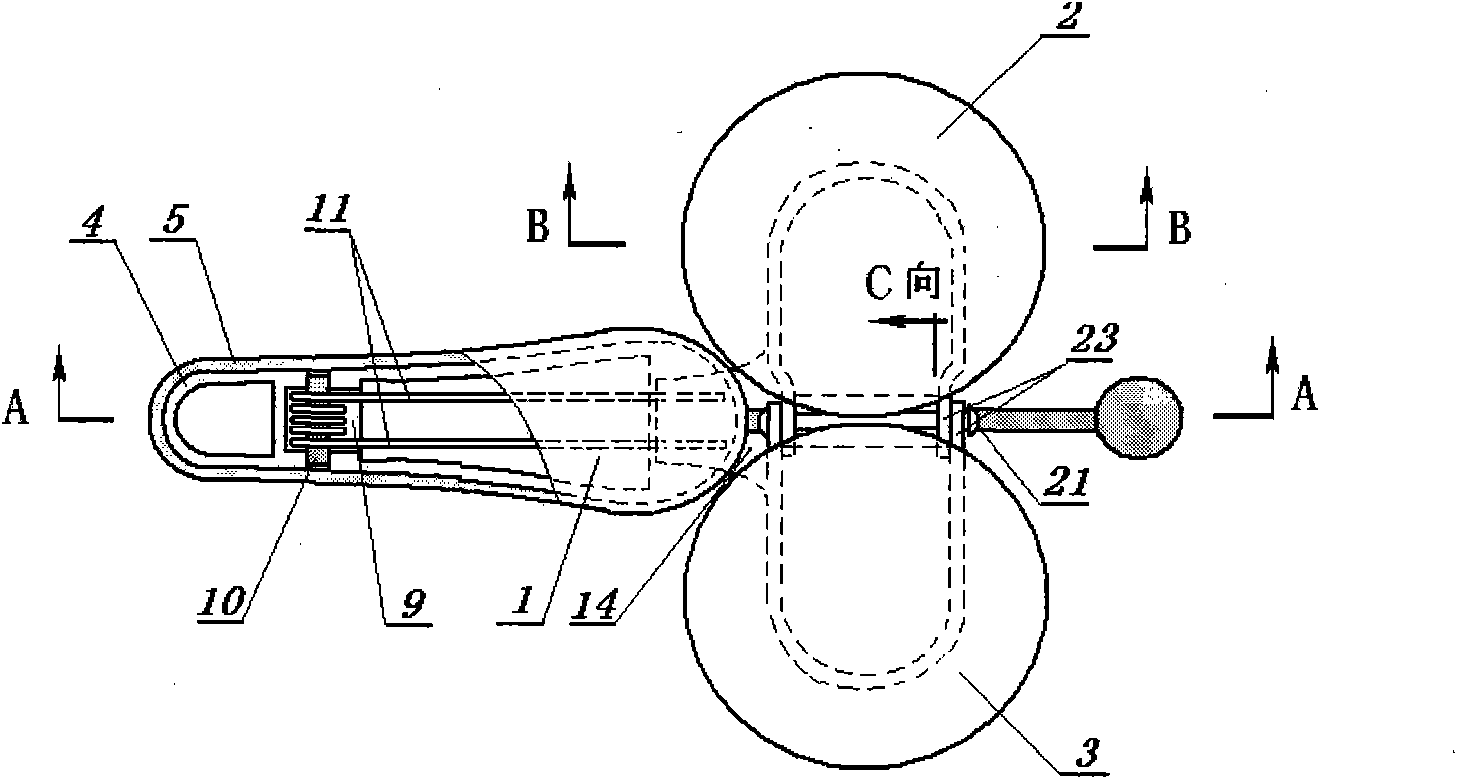

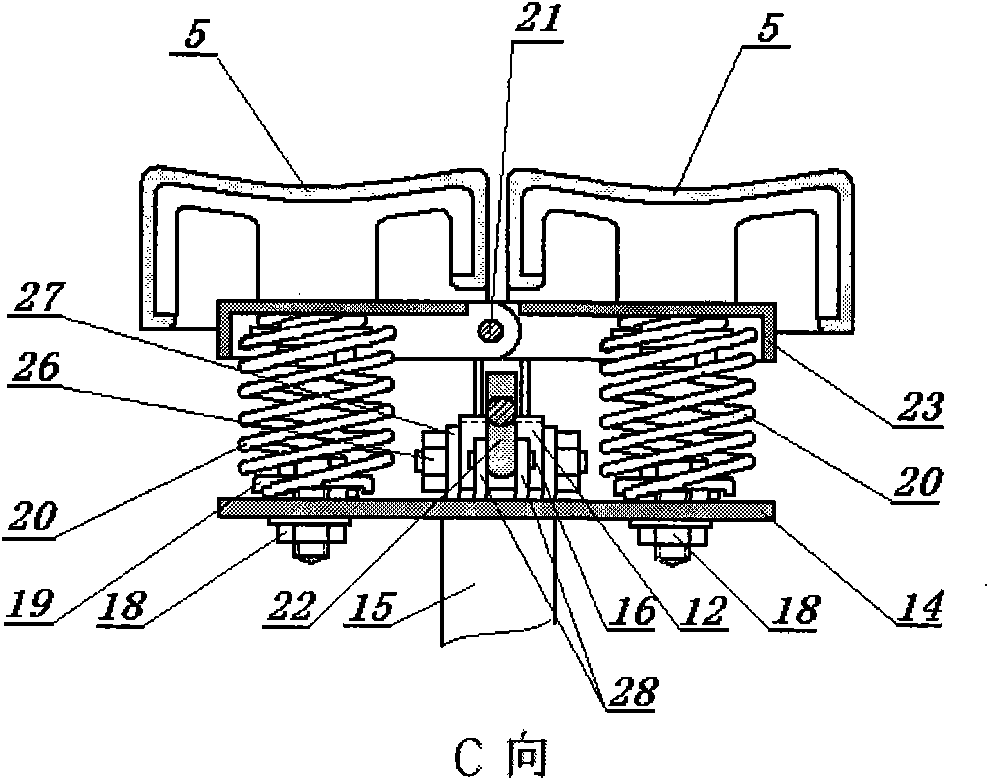

Three-point type folding bicycle saddle

A base of a three-point type folding bicycle saddle is made of ABS (acrylonitrile butadiene styrene) rigid engineering plastic, a layer of flexible polyurethane foam covers the base, and the outer surface is wrapped in leather or artificial leather; the saddle consists of a long-ladle-shaped folding front saddle cushion as well as left and right round saddle cushions, a ball head handle is installed on the rear side of the saddle, and the left and right saddle cushions can fluctuate leftwards and rightwards with forces when the forces are exerted by legs during riding, so that acting forces between the ischium of a rider and the saddle cushions are buffered, and pain caused by long-time sitting is alleviated; in addition, the folding front saddle cushion can hang forwards during riding after the ball head handle is pressed down, so that extrusion caused by the saddle cushions to pubes and prostate glands of men can be avoided effectively; when the front saddle cushion is pulled up, the front saddle cushion can be in a horizontal state; according to the saddle, structures of traditional bicycle saddles are changed, and the saddle is simple to manufacture and reliable to use.

Owner:张静远

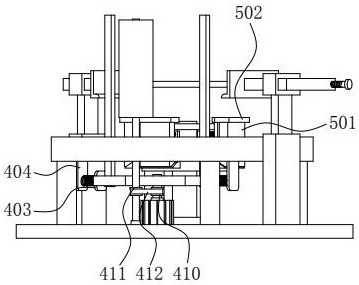

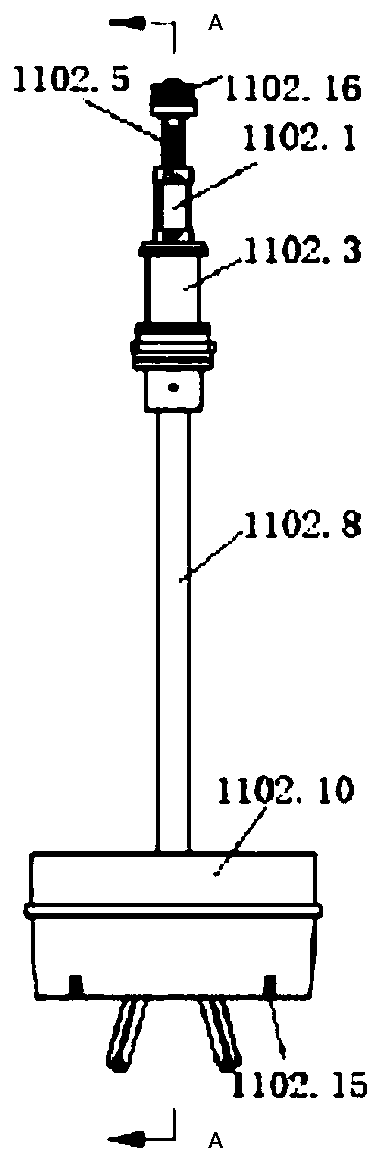

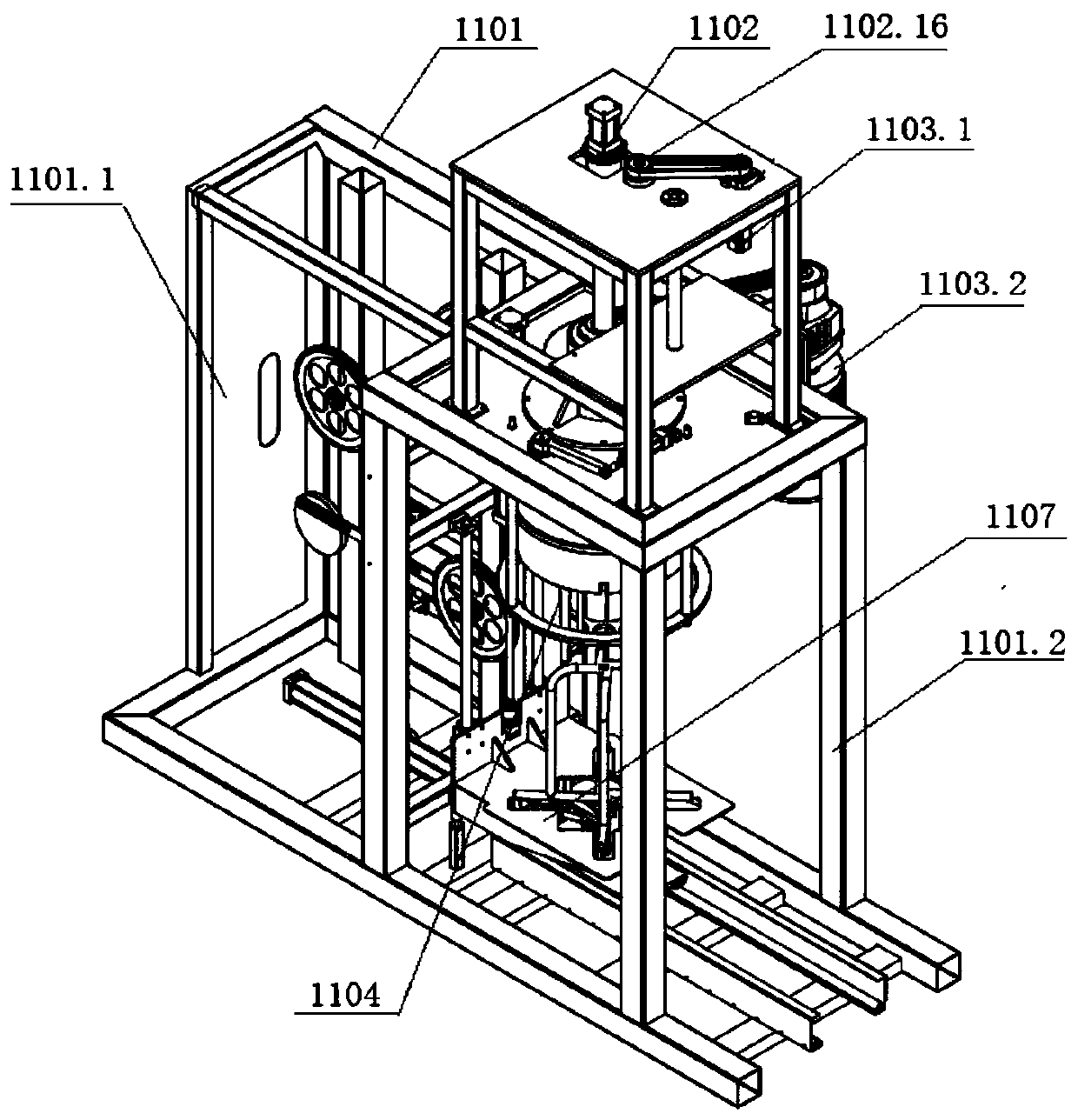

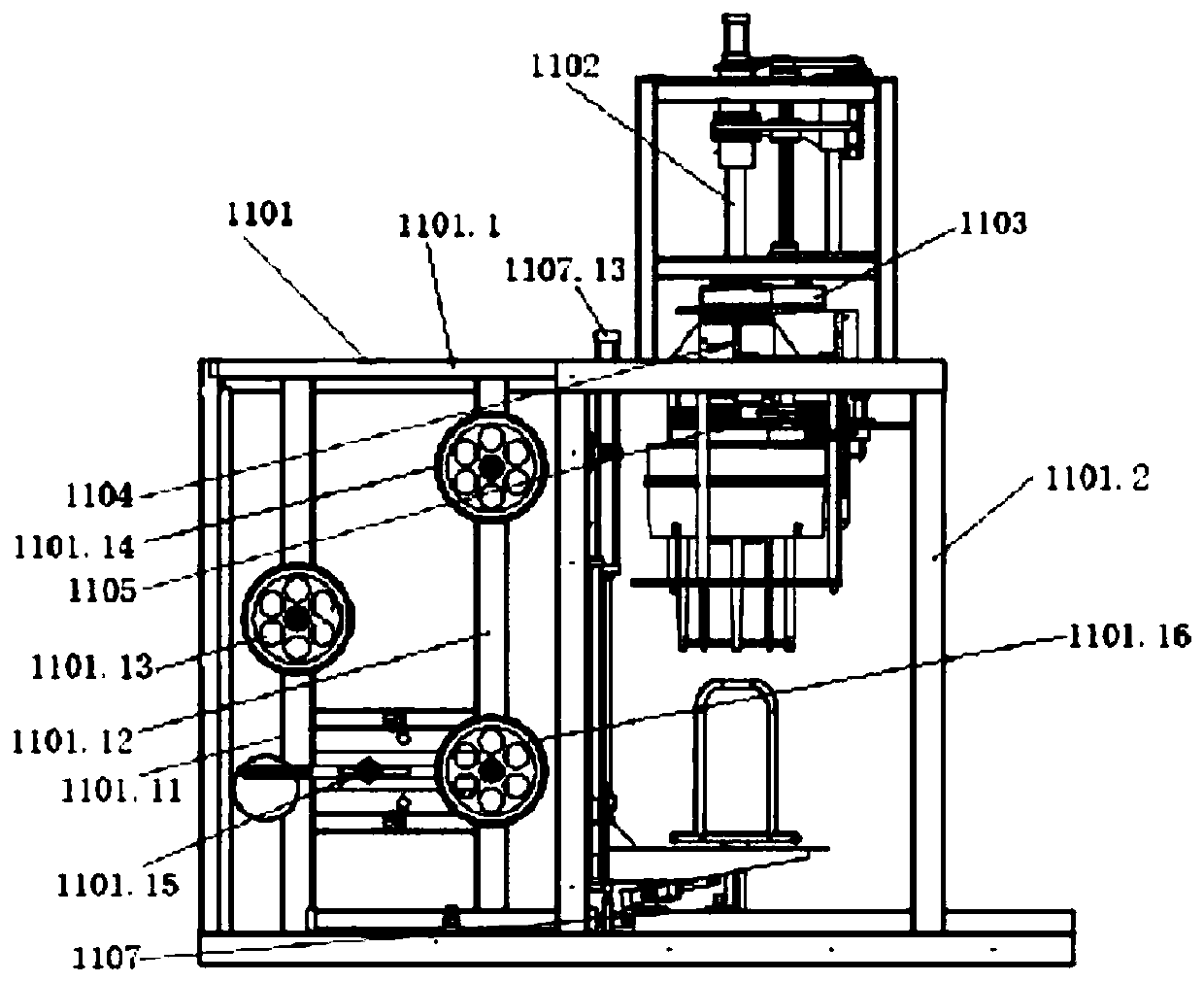

Stacking equipment for cast plunger pumps

ActiveCN111942903APrevent falling offAvoid squeezeStacking articlesDe-stacking articlesPhysicsPlunger pump

The invention belongs to the technical field of plunger pump manufacturing, and particularly relates to stacking equipment for cast plunger pumps. The stacking equipment comprises a base, wherein lifting mechanisms are installed on the lower surface of the base, a first sliding plate is arranged on the base in a sliding fit mode, a second sliding plate is in sliding fit with the first sliding plate, a limiting sleeve is vertically and fixedly installed on the upper surface of the second sliding plate, a supporting column is vertically in sliding fit with the interior of the second sliding plate, a buffer mechanism is mounted in the limiting sleeve, a horizontal top plate is fixedly mounted at the top of the supporting column; and a clamping mechanism is mounted on the top plate. Accordingto the stacking equipment, in the process of clamping the plunger pump through a clamping mechanism, a supporting rod can freely stretch out and draw back in a sealing barrel according to the shape ofthe surface of the plunger pump, so that the irregular surface of the plunger pump is supported, and stable clamping of the plunger pump is achieved; and the plunger pump can slowly descend through the buffer mechanism, so that the position of the plunger pump can be finely adjusted, and a plunger pump shell is fully matched with the inner wall of a storage box.

Owner:JIANGXI HYDRAULIC PIECES

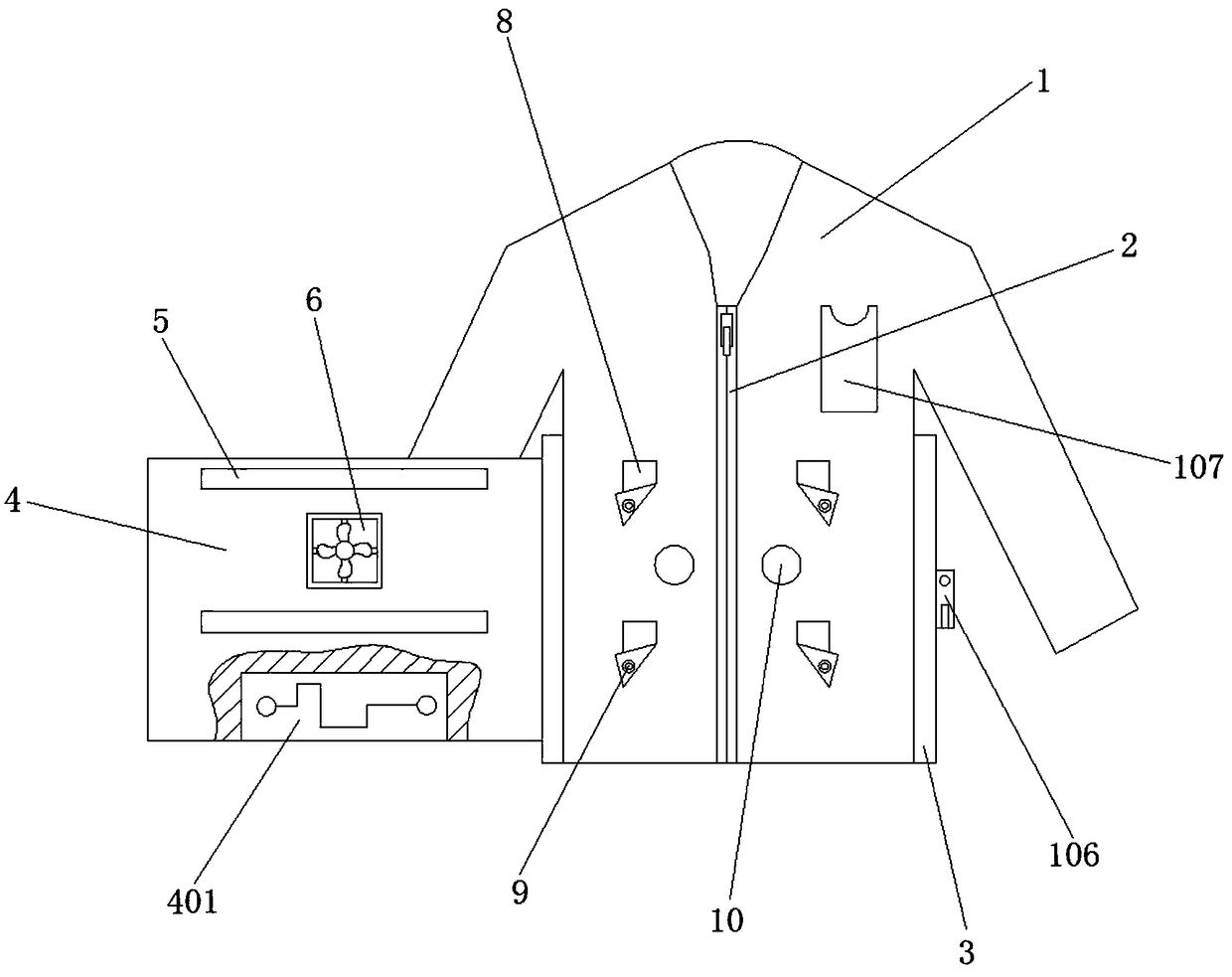

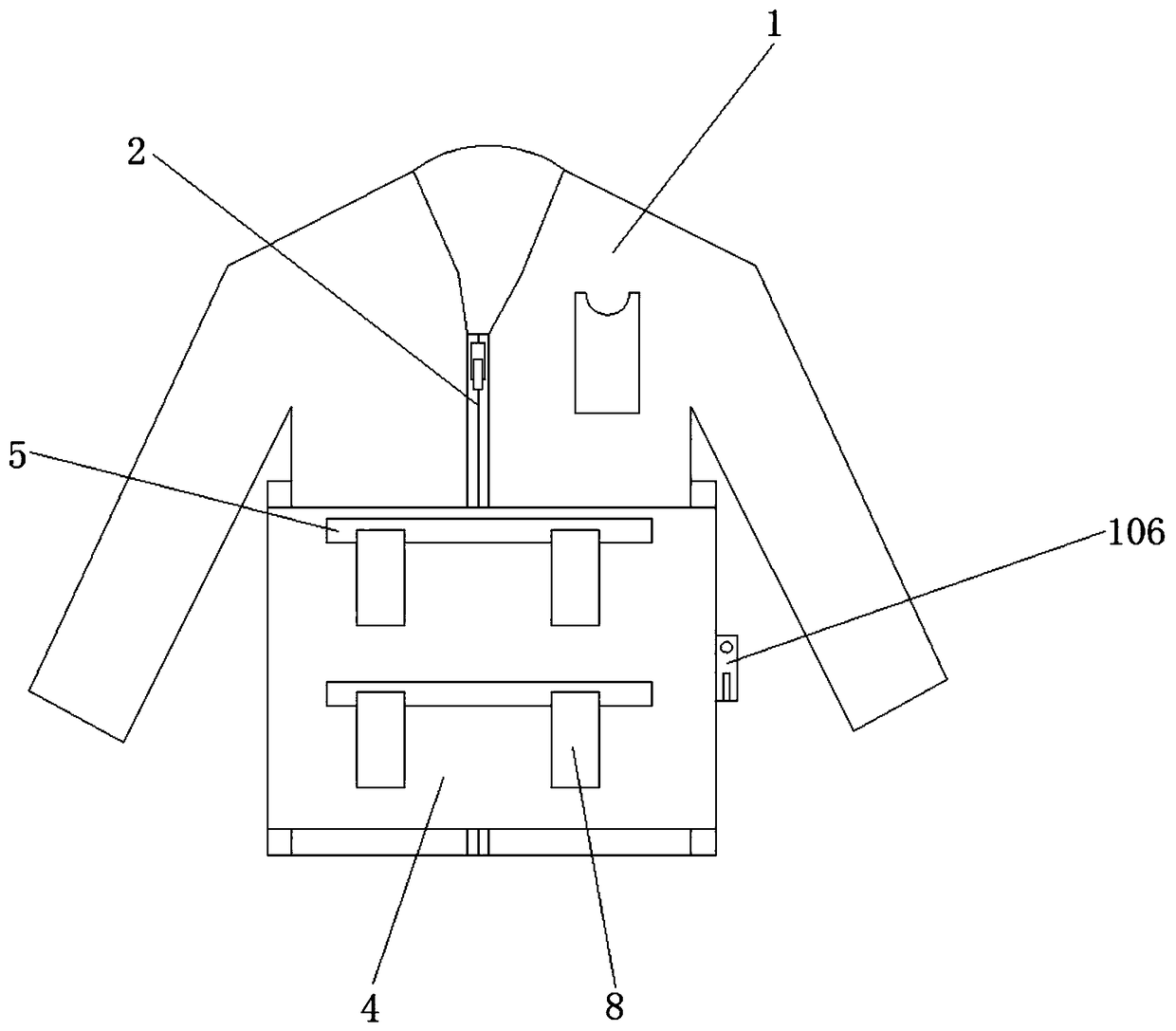

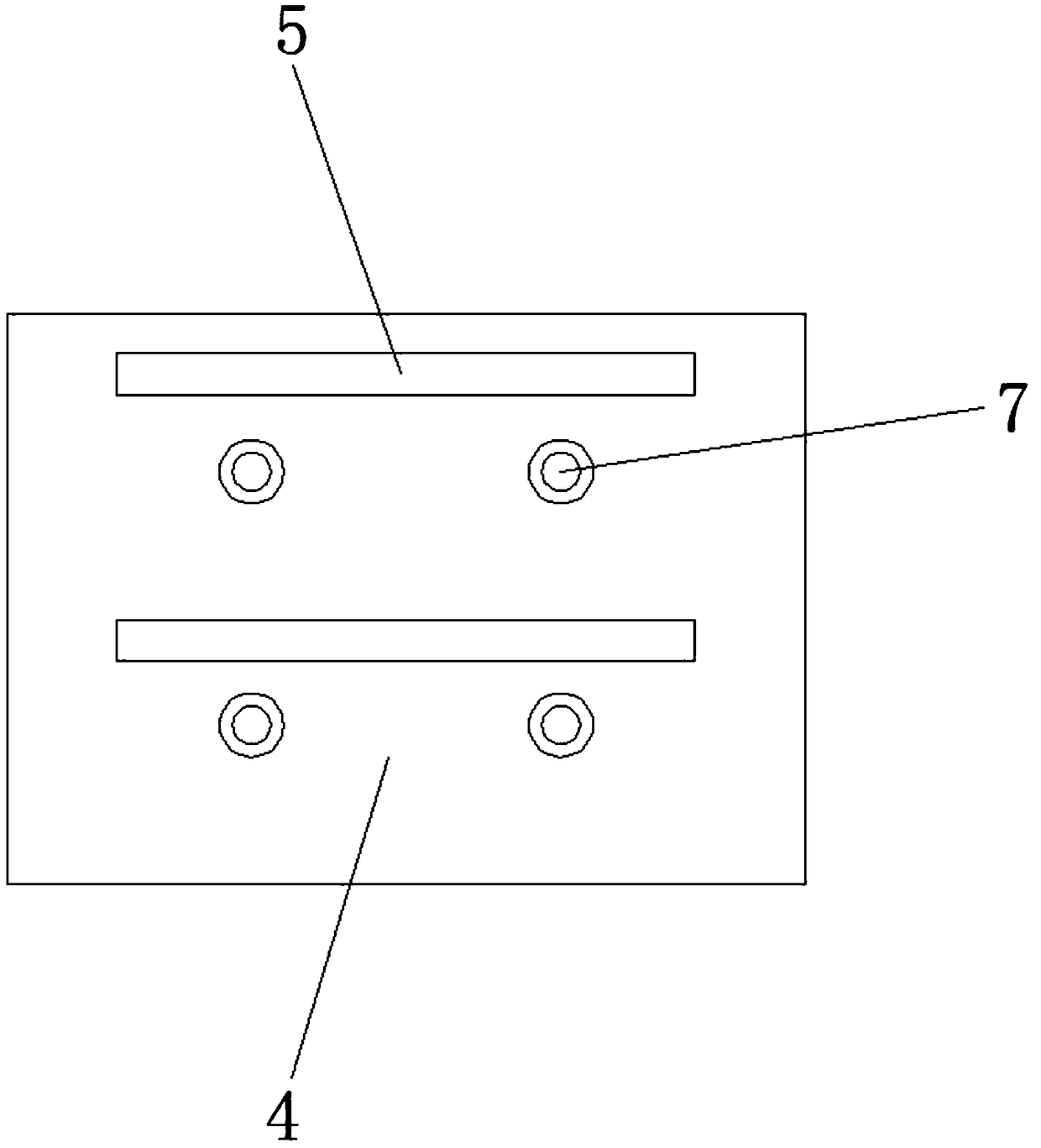

Special patient garment with protection function for burn department

InactiveCN109497640AWith protection functionPerfect protection functionProtective garmentEngineeringAbdomen

The invention discloses a special patient garment with a protection function for the burn department. The special patient garment comprises a garment body, a zipper, mounting plates, a rotating plate,receding holes, a fan, secondary buckles, connecting belts, primary buckles and exhaust holes. The special patient garment with the protection function for the burn department is ingenious in structure, powerful in structure and easy to operate. By using the garment, the burn part on the abdomen of a patient can be isolated from the garment, the garment is prevented from making direct contact with the burnt part of the abdomen of the patient, the pain of the patient is prevented from being increased, and the patient is protected. Besides, the garment can improve the flowability of air at theburn part of the abdomen of the patient, so that the air permeability of the burn part of the abdomen of the patient is ensured, and the rehabilitation progress of the patient is effectively improved.

Owner:白巧丽

Plastic bag packaging and opening device

The invention discloses a plastic bag packaging and opening device. The plastic bag packaging and opening device comprises a first accommodating box with a bottom opening, a second accommodating box with a top opening and a tubular thin film in an attachment state. The first accommodating box is in hinge joint with the second accommodating box. The two sides of the first accommodating box and thesecond accommodating box are all provided with notches. The inner wall of the first accommodating box is provided with an air bag fixedly connected with the inner wall of the first accommodating box.The inner wall of the second accommodating box is provided with a laminar film fixedly connected with the inner wall of the second accommodating box. A cavity formed between the inner wall of the second accommodating box and the laminar film is filled with fluid. A magnetic attraction mechanism is arranged on the top of the interior of the first accommodating box. An opening mechanism for openingthe tubular thin film and with the air outlet function is arranged at one end of the tubular thin film. The opening mechanism is provided with a first magnet attracted with the magnetic attraction mechanism. A filling mechanism is arranged on the opening mechanism. Heat sealing mechanisms are arranged on the two sides of the first accommodating box and the second accommodating box correspondingly.The plastic bag packaging and opening device can reduce damage to the thin film due to gravity and material fluidity and can reduce material pollution caused during packaging.

Owner:海口诚佳美塑料包装有限公司

Housing of temperature transmitter

InactiveCN105571730AEase of subsequent maintenanceExtended service lifeThermometer detailsFlangingHeat sink

The invention discloses a housing of a temperature transmitter. The housing is composed of a U-shaped metal shell and a metal cover plate, wherein the U-shaped metal shell and the metal cover plate are connected via a bolt. The outer surfaces of the U-shaped metal shell and the metal cover plate are coated with an insulating layer, respectively. The inner surfaces of the U-shaped metal shell and the metal cover plate are successively coated with an aluminum foil layer and a modified nano-diamond layer. The inner surface of the bottom of the U-shaped metal shell is further provided with a clamping groove. The control board of the temperature transmitter is clamped in the clamping groove. A heat sink is stuck to the bottom of the control board. The bottom of the heat sink is in contact with the modified nano-diamond layer. The top of the opening of the U-shaped metal shell is provided with a groove. A sealing ring is arranged in the groove. The bottom of the cover plate is provided with a clamping edge capable of extending into the groove. The bottom of the clamping edge is obliquely arranged. The sealing ring is provided with a hollow cavity, a bevel edge and a flanging. A spring is arranged in the hollow cavity of the sealing ring. The bevel edge is in linear sealed cooperation with the oblique bottom of the clamping edge. The flanging is clamped with the inner sidewall of the groove. Due to the adoption of the above structure, the housing of the temperature transmitter is good in sealing and waterproof performance and high in self-heat dissipation efficiency, which can prevent the signal interference.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

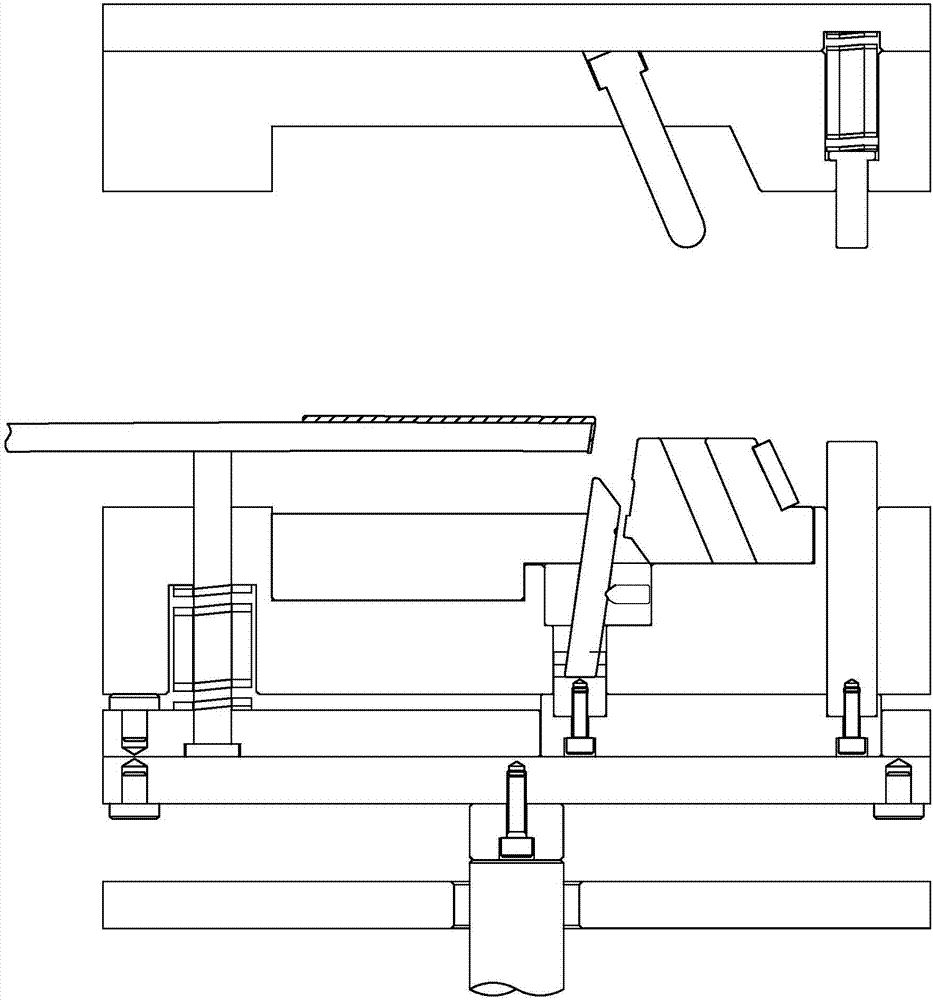

Injection moulding die used for automotive sealing strip

PendingCN107053581AGuaranteed accuracyReduce mistakesDomestic articlesInjection mouldingMechanical engineering

The invention discloses an injection moulding die used for an automotive sealing strip. The injection moulding die comprises an upper die plate (1), a lower die plate (2), an ejection plate (3), a base plate (4) and a sealing strip (7), wherein the ejection plate (3) is located on the base plate (4); the lower die plate (2) is located between the upper die plate (1) and the ejection plate (3); an upper mandrel (5) is arranged below the upper die plate (1); a lower mandrel (6) is arranged above the lower die plate (2); an oblique sliding block (8) used for moulding the front end surface rubber coating part of the sealing strip (7) and a sliding block (22) used for moulding the front end inner side surface rubber coating part of the sealing strip (7) are arranged on the lower die plate (2); and an oblique guide post (33) which is in sliding match with the oblique sliding block (8) is arranged on the upper die plate (1). The injection moulding die used for the automotive sealing strip has the beneficial effects that punching tolerance can be effectively eradicated, so that the yield is high, and cost is low.

Owner:NINGHAI HESHI PLASTIC CO LTD

Intelligent switch with waterproof function for humid environment

InactiveCN113035608AWith waterproof functionAvoid enteringElectric switchesSmart switchStructural engineering

The invention relates to the technical field of waterproof switches, and discloses an intelligent switch with a waterproof function for a humid environment. The intelligent switch comprises a shell and a movable block, the inner side wall of the shell is movably connected with movable plates, and the opposite sides of the four movable plates are fixedly connected with rubber pads. Two sliding blocks are movably connected to the opposite sides of the four movable plates, two push rods are fixedly connected to the deviating sides of the eight sliding blocks, eight inclined grooves are formed in the inner rear wall of the shell, a rotating wheel is rotatably connected to the inner rear wall of the shell, and moisture absorption cotton is fixedly connected to the left side of the rotating wheel. When the movable block moves upwards, the sliding block is driven by the pull rope to move, when the sliding block moves, the sliding block moves in the direction close to the shell under the action of the sliding rod and the inclined groove, then the movable plate and the rubber pad are driven by the push rod to move in the direction close to the shell, the rubber pad blocks the gap between the shell and the wall face, and water is prevented from entering the shell through the gap continuously, and the safety of the switch is improved.

Owner:杭州临润贸易有限公司

Anti-deviation mechanism of pyrography device for textile processing

ActiveCN112391783AEasy to replace and maintainPrevent rotationPattern makingWebs handlingPyrographyIndustrial engineering

The invention discloses an anti-deviation mechanism of a pyrography device for textile processing. The anti-deviation mechanism comprises a pyrography device body, wherein a workbench is fixedly installed on the outer wall of one side of the pyrography device body, a pressed plate is arranged at the top of the workbench, a first limiting mechanism is inserted into one end of the top of the workbench, a second limiting mechanism is inserted into the other end of the top of the workbench, each of the first limiting mechanism and the second limiting mechanism comprises a supporting plate, fixingrods are welded to the four corners of the bottom of each supporting plate, sliding blocks are fixedly connected to the bottoms of the four fixing rods, and a connecting plate is fixedly connected toone end of the top of each supporting plate. Textile passes through the first limiting mechanism and the second limiting mechanism, the textile makes contact with the pressed plate, the pyrography device conducts pyrography operation on the textile on the pressed plate, and the problem that when an existing pyrography device conducts pyrography on textile, due to the fact that the textile cannot be positioned, the position of the textile deviates can be solved.

Owner:吴江市万旺纺织有限公司

Wafer clamping device for semiconductor packaging

InactiveCN112002667AAvoid squeezeAvoid breakingSemiconductor/solid-state device manufacturingForeign matterStructural engineering

The invention discloses a wafer clamping device for semiconductor packaging. The clamping device structurally comprises a mounting plate, a sliding rail, a driving rod and a clamping mechanism. A slide rail is welded at the bottom of the mounting plate. The driving rod penetrates through the interior of the sliding rail in a clearance fit manner. The metal pins are attached and fixed through the magnetic adsorption force of the magnetic plate. Therefore, the clamping force is prevented from being too large. Excessive extrusion force on the metal pin is avoided. The sliding rod drives the supporting rod and the scraping plate to stably slide in a clamping gap groove in the fixed seat. Foreign matters in the gap groove are scraped. The metal pins of the semiconductor integrated circuit are just clamped and limited with the outer side surfaces of the clamping sheets. Meanwhile, the bottom surface of the semiconductor integrated circuit extrudes the extrusion plate downwards, so that the extrusion plate extrudes the interior of the air pressure chamber, the air pressure in the air bag film is increased to bulge, the bulged air bag film pushes against the metal pin to buffer the metal pin, and the metal pin is prevented from being broken due to overlarge clamping force.

Owner:菏泽景月装饰有限公司

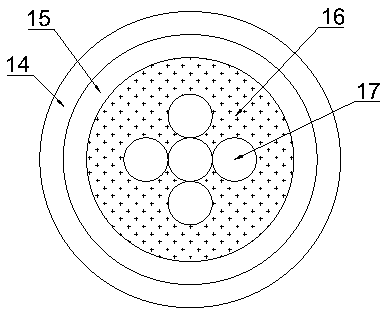

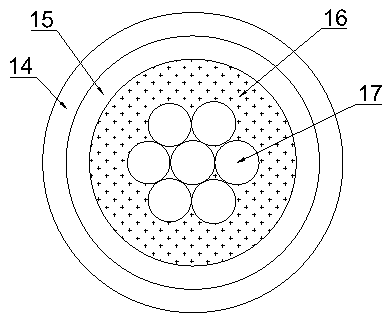

Flame-retardant optical fiber composite cable

InactiveCN108922665AImprove waterproof performanceImprove stress resistanceInsulated cablesInsulated conductorsEngineeringWater block

The invention discloses a flame-retardant optical fiber composite cable comprising a cable core. The cable core is formed by a plurality of cable wire cores, an optical cable wire core and a pluralityof filling ropes in a twisted mode. The multiple cable wire cores and the optical cable wire core are annularly arranged inside the cable core. The filling ropes are arranged at the center defined bythe cable wire cores and the optical cable wire core and the outer sides of the externally tangent positions of the adjacent cable wire cores or the optical cable wire core. The exterior of the cablecore is coated with a polyethylene inside liner, the polyethylene inside liner is sequentially coated with an outer shielding layer, a silica gel fireproof layer, a mica tape layer, a high-flame-retardance halogen-free low-smoke flame-retardant sheath layer and a water-blocking layer, and the gaps between the polyethylene inside liner and the cable wire cores, the gap between the polyethylene inside liner and the optical cable wire core, and the gaps between the polyethylene inside liner and the filling ropes are filled with insulation foaming layers. According to the flame-retardant opticalfiber composite cable, the advantages of all materials are fully utilized, so that the overall oil resistance, acid resistance and anticorrosion properties of the cable are good, the cost is saved, the compressive property and the tensile property of the cable are further improved, the overall flexible property of the cable is good, and the service life of the cable is greatly prolonged.

Owner:SHANDONG QUANXING YINQIAO OPTICAL & ELECTRIC CABLE SCI & TECH DEV

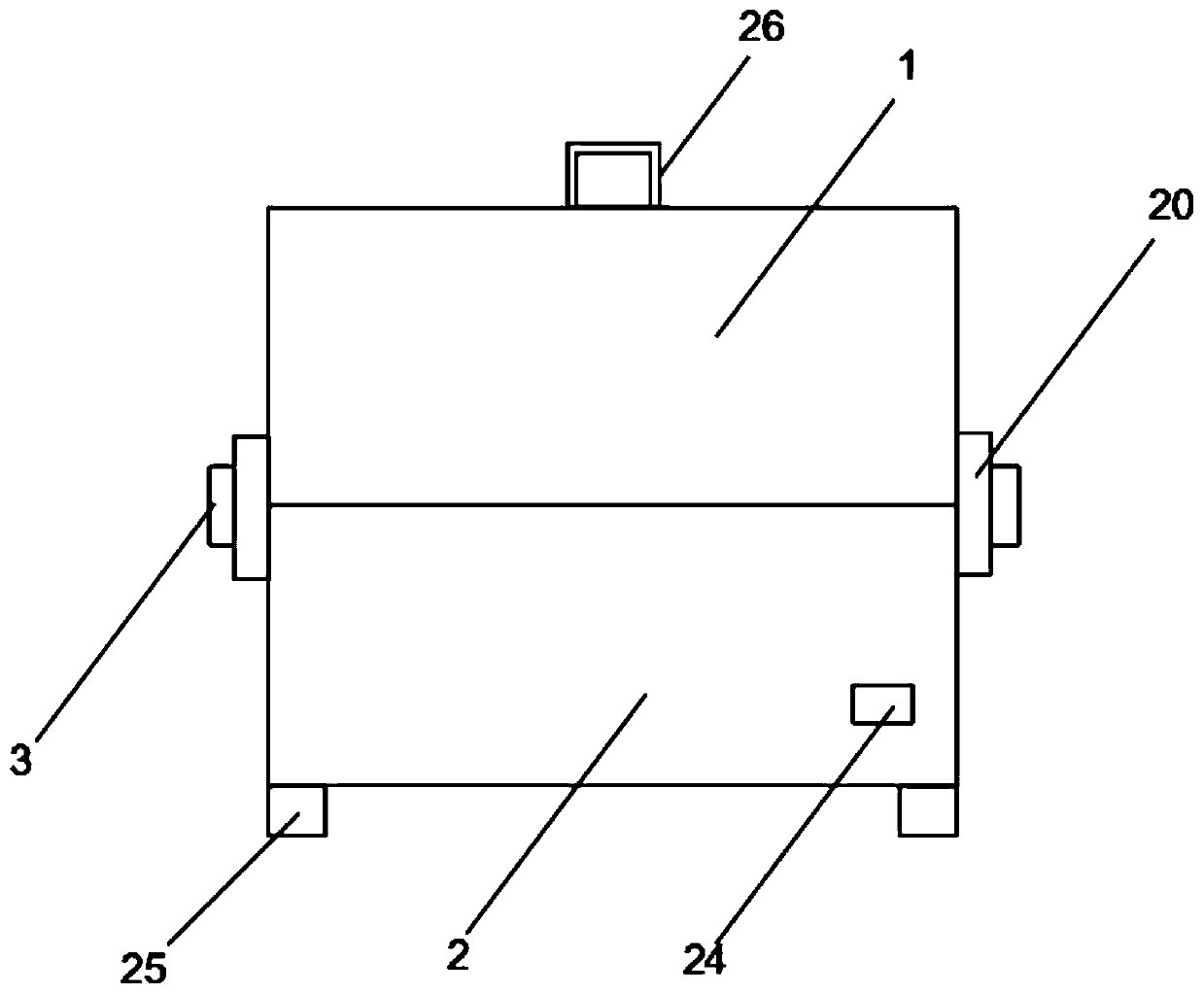

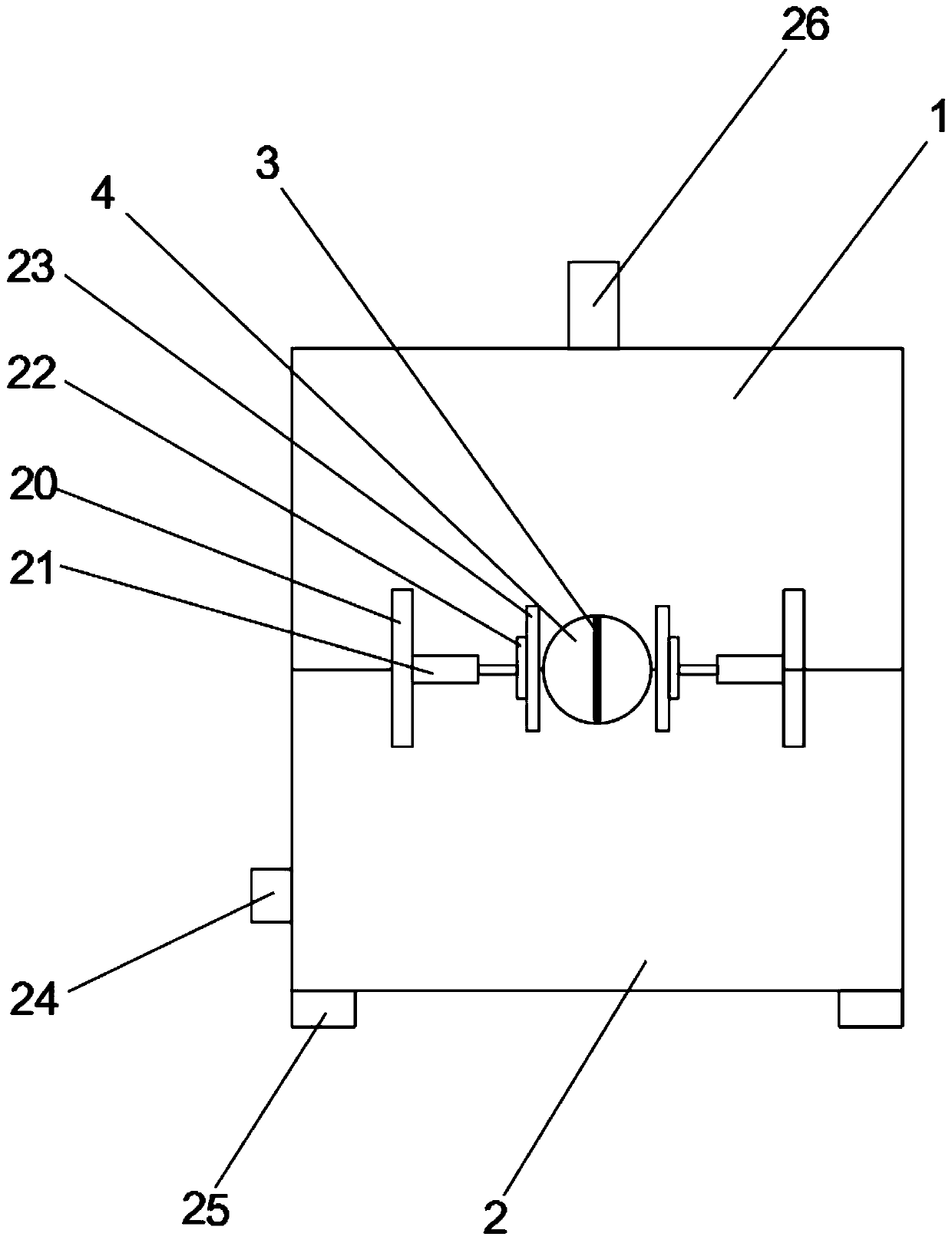

Spin-drying equipment and spin-drying method after shoe washing

ActiveCN110811483ASave energyEasy to control the rotation speedFootwear cleanersProcess engineeringHand exercises

Owner:HANGZHOU JINGLIN HOME TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com