Method for constructing heat-preserving plates

A construction method and thermal insulation board technology, applied in thermal insulation, building components, construction, etc., can solve problems such as potential safety hazards, cracking of board seams, and inability to discharge moisture, and achieve the effect of simple design and avoiding moisture return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0027] A construction method for a thermal insulation board, comprising the following steps:

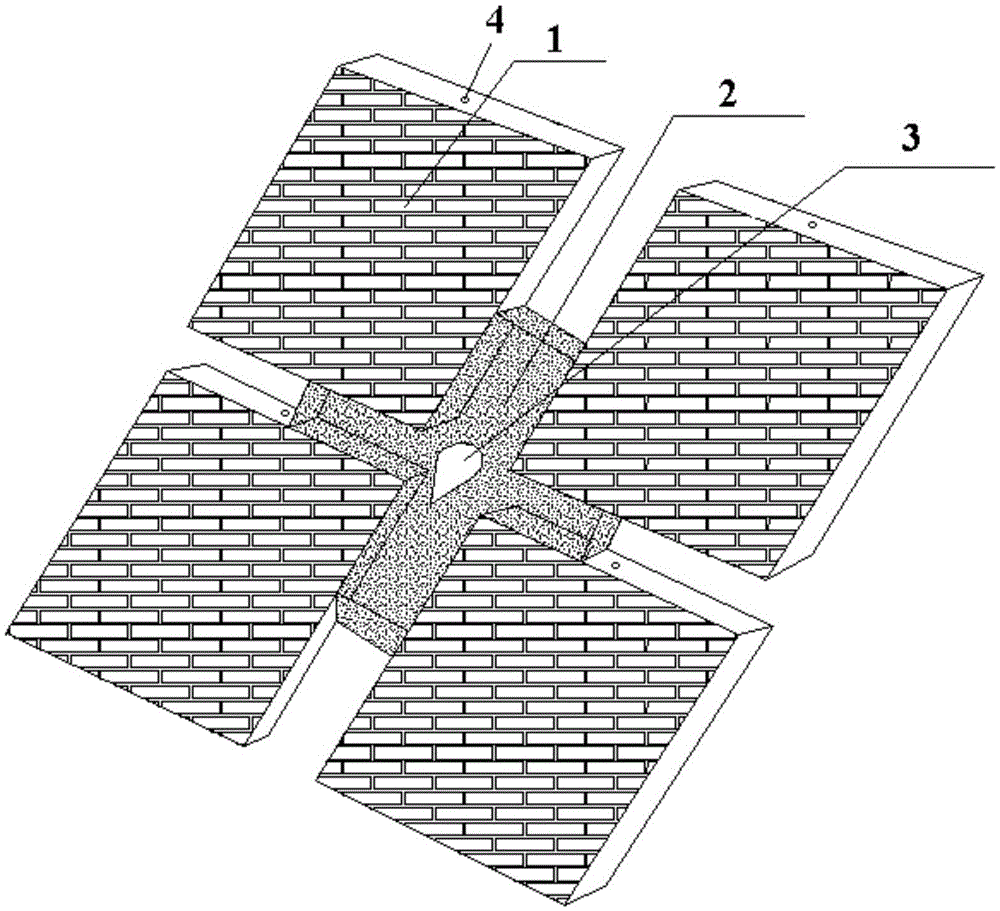

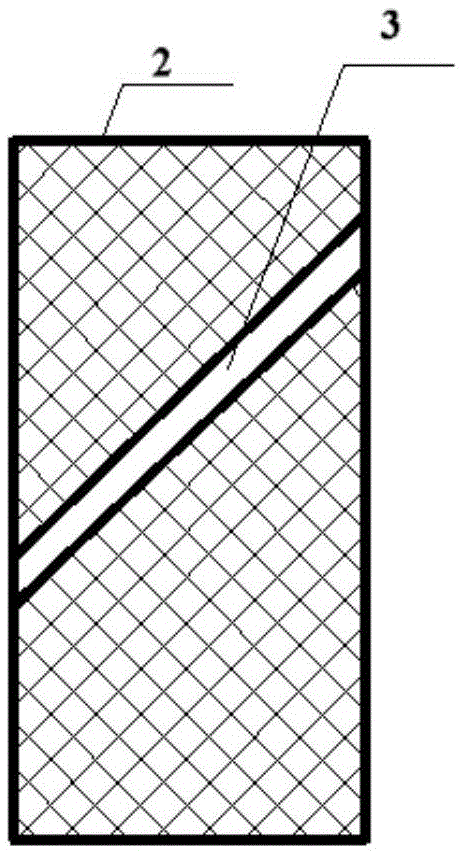

[0028] 1. If figure 1 As shown, according to the size of the insulation board, the position of the fixing member and the size of the seam reserved between adjacent insulation boards, the position of the fixing hole on the side of the insulation board is determined, and the position of the fixing hole is marked with a positioning elastic line or a positioning strip Use the steel shape template to be close to the side of the insulation board, then drill the fixed hole 4 of the corresponding shape on the side of the insulation board through the heated electric heating wire through the template, that is, set the fixing hole on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com