Construction Technology of Insulation Decorative Board for External Wall

A technology of thermal insulation decorative panels and construction technology, which is applied in covering/lining, construction, building structure, etc., can solve problems such as cracking of thermal insulation decorative panels, and achieve the effects of avoiding moisture return, easy operation and simple design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

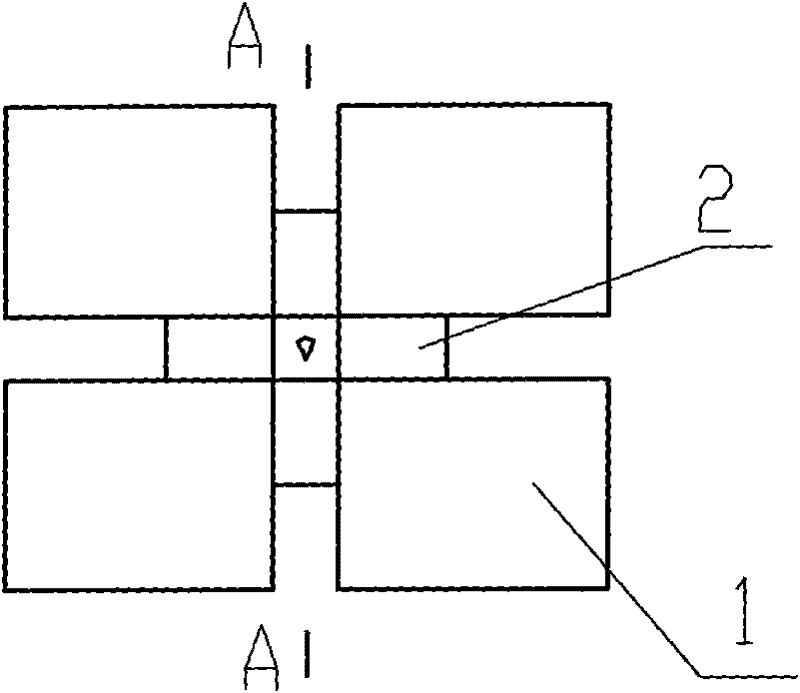

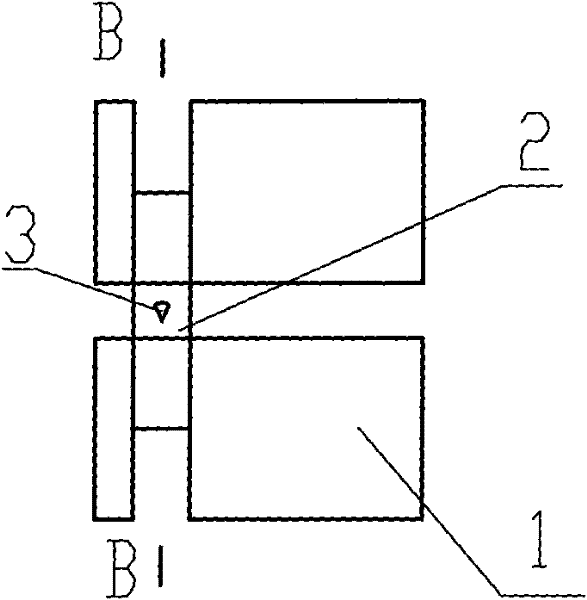

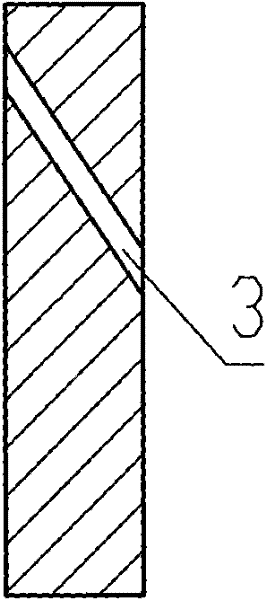

Image

Examples

Embodiment 1

[0021] The construction process of the present invention includes pasting and fixing the thermal insulation decorative board, and the key point is that it also includes the step of installing the exhaust component, specifically including the following steps:

[0022] ①According to the size of the thermal insulation decorative board, the setting of the position of the fasteners, and the size of the seam reserved between adjacent thermal insulation decorative boards, the outer frame of the thermal insulation decorative board and the fixing of the fasteners are fixed by positioning elastic wires or positioning strips. hole marked;

[0023] ② Drill holes at the positions of the fixed holes marked above, and apply adhesive mortar on the outer frame of the thermal insulation decorative board and the positions of the fixed holes. No cavity is left during the application process, that is, the solid paste method is adopted. The above method can make the wall The paste with the thermal ...

Embodiment 2

[0029] For the corner of the wall, the exhaust component installed is in a straight line, see figure 2 . The remaining steps are the same as in Embodiment 1.

[0030] The construction technology of the thermal insulation decorative board for exterior walls provided by the present invention adds the installation of exhaust components to the existing construction plan, which not only solves the problem that the moisture cannot be discharged in the solid pasting method, but also solves the problem that the thermal insulation decorative board and the wall Sticking and fixing are more firm, and the decorative effect is beautiful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com