Novel special-shaped cushion strip suitable for winding around tubular heat exchanger

A winding tube type, heat exchanger technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of heat exchange tube rupture, expansion of winding diameter, affecting heat exchange efficiency of heat exchanger, etc. , to avoid radial expansion and upward displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

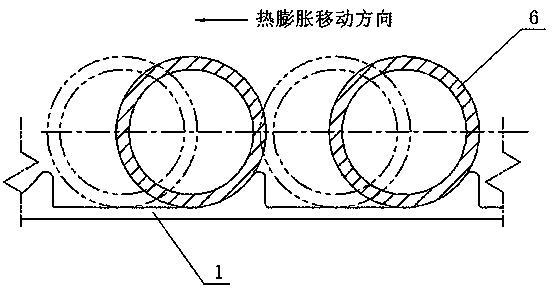

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

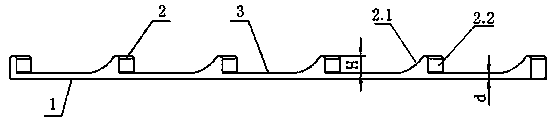

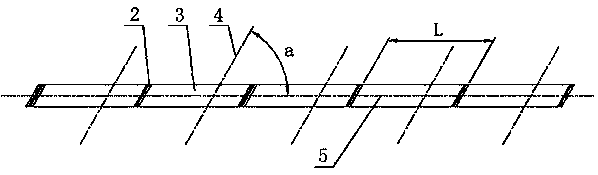

[0026] Such as Figure 1-3 As shown, the special-shaped gasket involved in the present invention includes a base 1, on the upper surface of the base 2, along the length direction, several grooves 3 are made according to the design requirements under the specific use, and between each groove 3 is Plate-shaped tooth-shaped protrusions 2, tooth-shaped protrusions 2 are parallel to each other and distributed at equal intervals, so that the axes 5 of each groove 3 are parallel to each other, and are used to place the involved tube body 6, for example, the heat exchanger of a wound heat exchanger. heat bundle.

[0027] The front side 2.1 of the tooth-shaped protrusion can adopt a circular arc surface or a similar cylindrical surface in the prior art, and the rear side 2.2 adopts a plane and is preferably perpendicular to the bottom plane of the groove. When installing, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com