Integrated spontaneous heating floor board and bi-directional electric connecting plug

A self-heating, integrated technology, applied in connection, space heating and ventilation, circuits, etc., can solve problems such as potential safety hazards, pre-embedded heating wires, difficult production and processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] (Example 1, integrated self-heating floor)

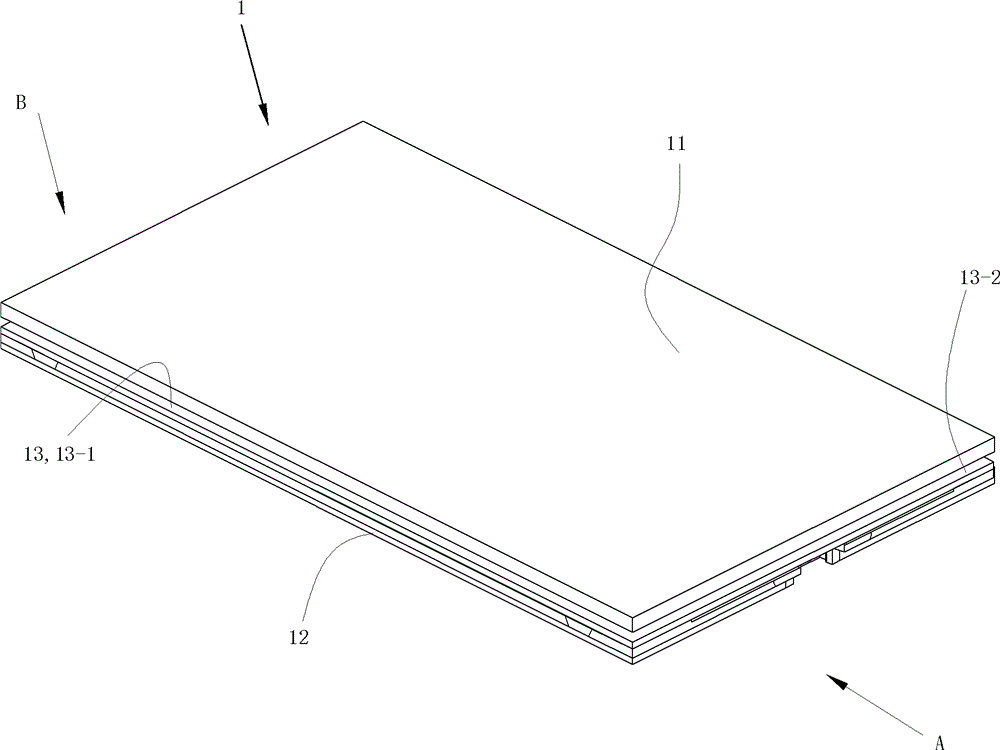

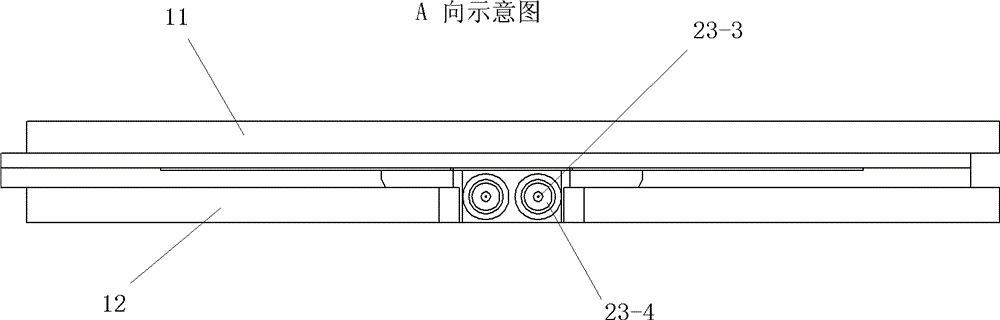

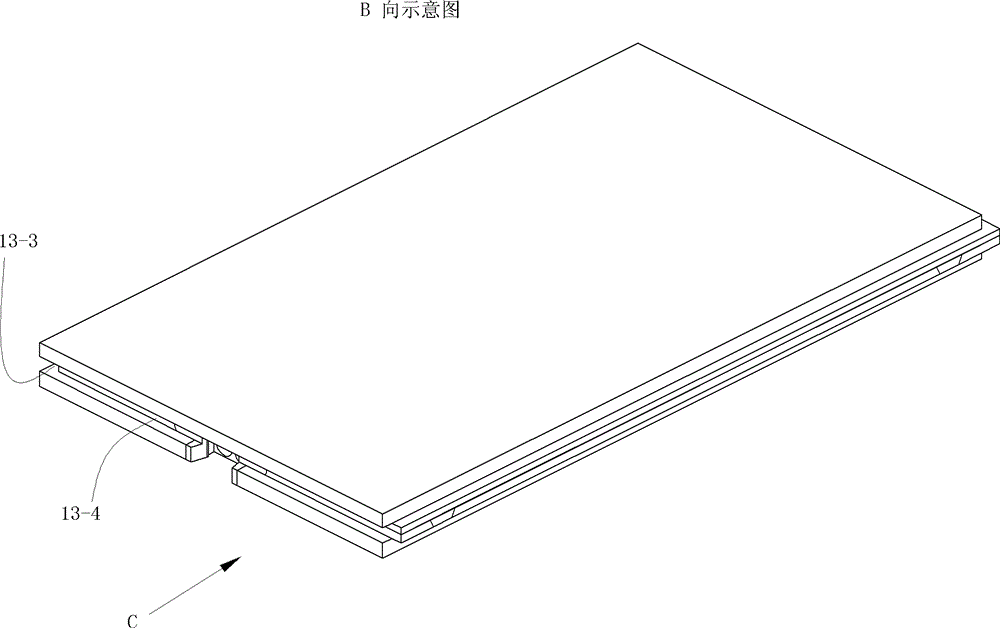

[0127] See figure 1 with Figure 8 , The integrated self-heating floor 1 of the present invention includes a panel 11 , a lower body 12 and a self-heating component 2 . The panel 11 is bonded and fixed on the lower body 12 from above to form a floor body with an internal cavity. An inserting part 13 is provided around the floor body of the integrated self-heating floor 1 . The insertion part 13 on the front side of the floor body of the integrated self-heating floor 1 is the front side insertion tenon 13-1, and the insertion part 13 on the right side of the floor body of the integrated self-heating floor 1 is the right side insertion part 13-1. Joint 13-2, the insertion part 13 located on the rear side of the floor body of the integrated self-heating floor 1 is the rear insertion groove 13-3, the insertion part located on the left side of the floor body of the integrated self-heating floor 1 Part 13 is the left insertion ...

Embodiment 2

[0162] (Example 2, integrated self-heating floor)

[0163] The rest of this embodiment is the same as that of Embodiment 1, except that the length of the integrated self-heating floor of this embodiment along the long side of the floor is the length of the integrated self-heating floor 1 of Embodiment 1 along the long side. half the length.

Embodiment 3

[0164] (Example 3, integrated self-heating floor)

[0165] The rest of this embodiment is the same as that of Embodiment 1, the difference is that: the upper surface of the middle part of the lower body 12 of the integrated self-heating floor 1 is only provided with one upper groove, and the lower body 12 is in the middle of the upper groove. Two wire slots parallel to each other with upward openings are arranged at the front-to-back middle part of the slot wall facing upward along the left-right direction. The socket base 23-1 has one heater slot formed during injection molding, which corresponds to the upper groove of the lower body.

[0166] See Figure 23 , the electric heater 21 also has only one piece corresponding to the upper groove of the lower body 12 of the integrated self-heating floor 1 . The electrical connection device 24 includes two copper wires 24-1. The two copper wires 24-1 are called first copper wire 24-1a and second copper wire 24-1b in sequence. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com