Temperature transmitter housing capable of heat dissipating and sealing

A technology of temperature transmitter and shell, applied in the direction of thermometer, thermometer parts, instruments, etc., can solve the problem of inability to carry out data communication, and achieve the effect of convenient follow-up maintenance, improved processing speed and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

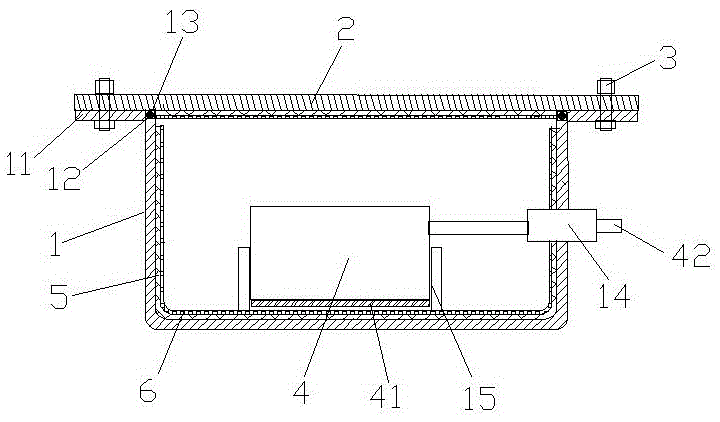

Image

Examples

Embodiment 1

[0054] 50 parts of nitrile rubber, 40 parts of silicone rubber, 20 parts of polyether polyurethane rubber, 10 parts of aromatic polyhydroxybenzoate heat-resistant resin, 5 parts of fluorocarbon, 2 parts of activated magnesium oxide, 1 part of antioxidant And self-lubricating agent unsaturated fatty acid 1.2 parts.

[0055] The material of above-mentioned sealing ring is made by conventional method by the raw material of following weight part, as:

[0056] (1) Weigh the materials specified in the above formula;

[0057](2) Mixing is carried out at a temperature of 45°C±5°C, and debinding is performed when the temperature reaches 100°C±5°C;

[0058] (3) Manufacture the sealing ring under the conditions of a temperature of 180° C., a time of 300 seconds, and a pressure of 15 MPa to obtain the sealing ring of the present invention.

Embodiment 2

[0060] 54 parts of nitrile rubber, 43 parts of silicone rubber, 22 parts of polyether polyurethane rubber, 14 parts of aromatic polyhydroxybenzoate heat-resistant resin, 8 parts of fluorocarbon, 3 parts of activated magnesium oxide, 1.5 parts of antioxidant And self-lubricating agent unsaturated fatty acid 1.6 parts.

[0061] The material of above-mentioned sealing ring is made by conventional method by the raw material of following weight part, as:

[0062] (1) Weigh the materials specified in the above formula;

[0063] (2) Mixing is carried out at a temperature of 45°C±5°C, and debinding is performed when the temperature reaches 100°C±2°C;

[0064] (3) Manufacture the sealing ring under the conditions of a temperature of 180° C., a time of 300 seconds, and a pressure of 15 MPa to obtain the sealing ring of the present invention.

Embodiment 3

[0066] 60 parts of nitrile rubber, 50 parts of silicone rubber, 30 parts of polyether polyurethane rubber, 20 parts of aromatic polyhydroxybenzoate heat-resistant resin, 15 parts of fluorocarbon, 5 parts of activated magnesium oxide, 3 parts of antioxidant And self-lubricating agent unsaturated fatty acid 2.5 parts.

[0067] The material of above-mentioned sealing ring is made by conventional method by the raw material of following weight part, as:

[0068] (1) Weigh the materials specified in the above formula;

[0069] (2) Mixing is carried out at a temperature of 45°C±5°C, and debinding is performed when the temperature reaches 100°C±2°C;

[0070] (3) Manufacture the sealing ring under the conditions of a temperature of 180° C., a time of 300 seconds, and a pressure of 15 MPa to obtain the sealing ring of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com