Fixedly installed PCB

A technology of PCB board and fixed through holes, applied in the direction of printed circuit components, etc., can solve problems such as PCB board damage, achieve high fit, avoid sliding, and ensure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

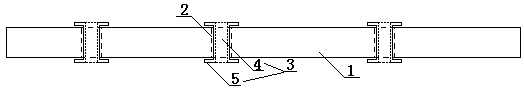

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] like figure 1 As shown, the present invention designs a fixed mounting PCB board, including a PCB body 1 and a fixed through hole 2 arranged on the PCB body 1, the number of the fixed through hole 2 is at least one, and the PCB body 1 includes a circuit conductive layer; It also includes locking ferrules 3 respectively arranged in each fixing through hole 2, the locking ferrules 3 are not in contact with the circuit conductive layer in the PCB body 1, the number of locking ferrules 3 is consistent with the number of fixing through holes 2, and the locking ferrules The sleeve 3 includes a cylindrical sleeve 4 with openings at both ends, and protruding edges 5 respectively arranged on the opening edges at both ends of the cylindrical sleeve 4. The protruding edges 5 are on the plane where the edge of the opening is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com