Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Avoid manual delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

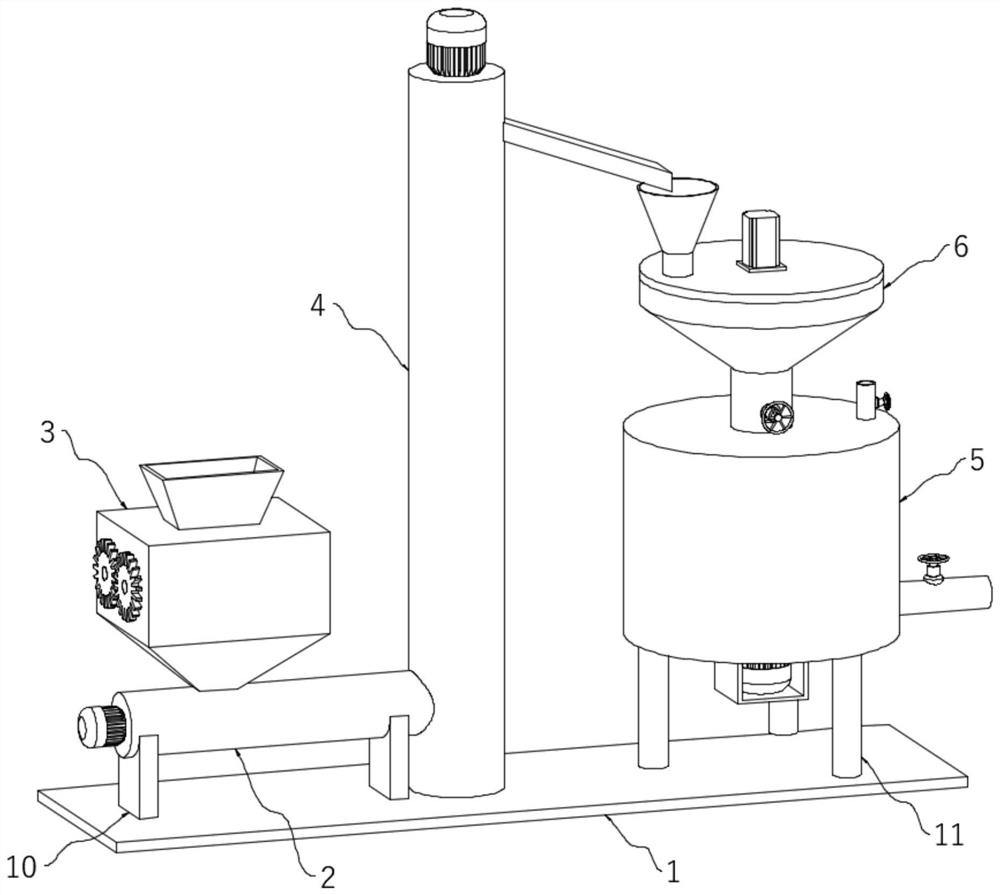

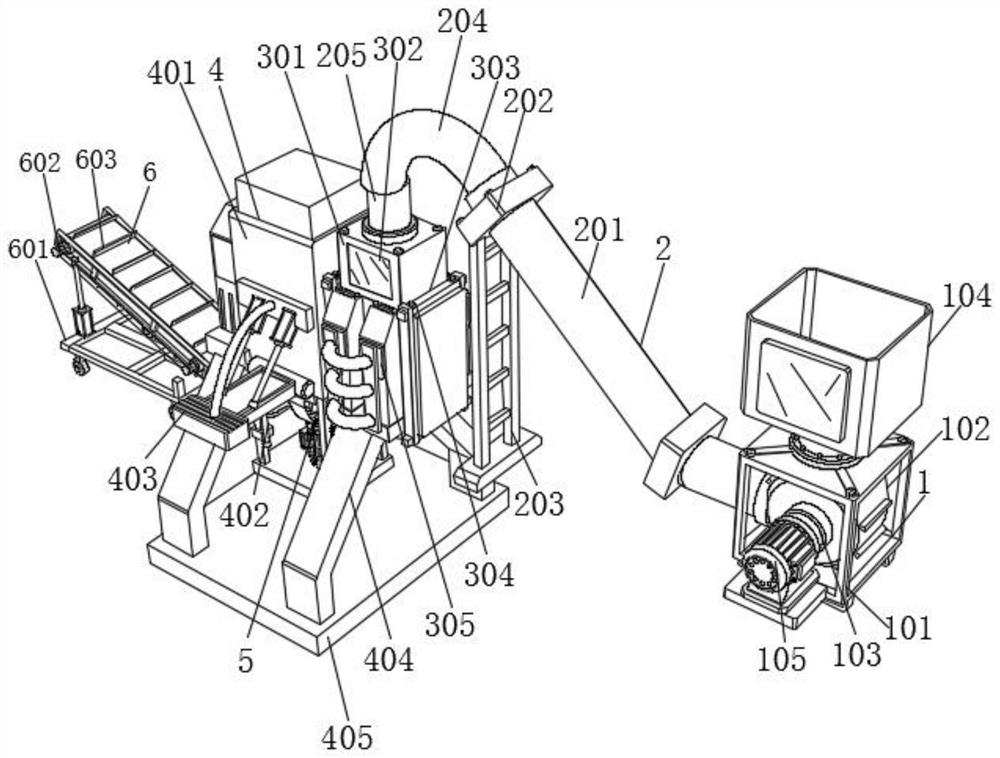

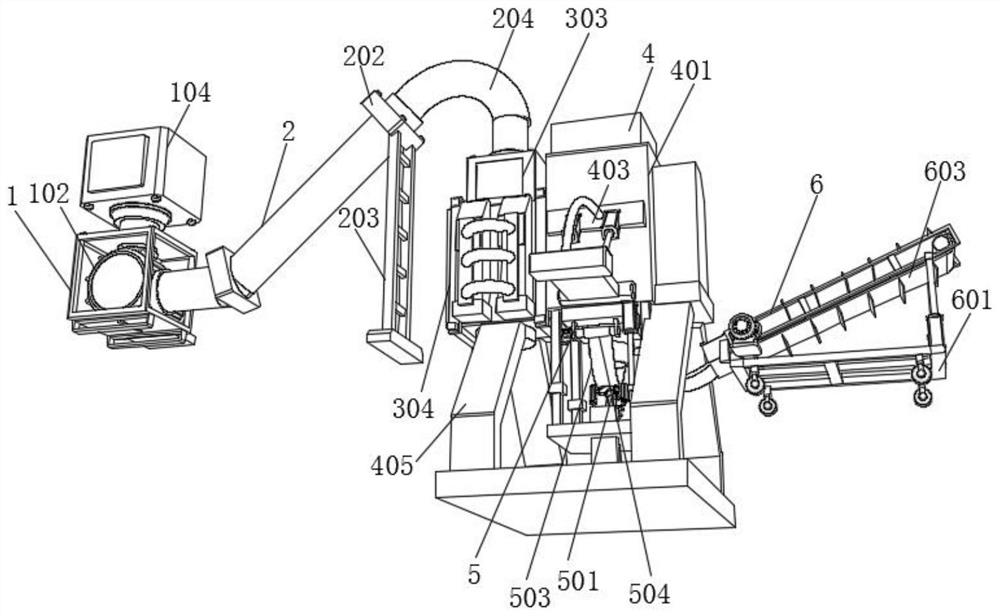

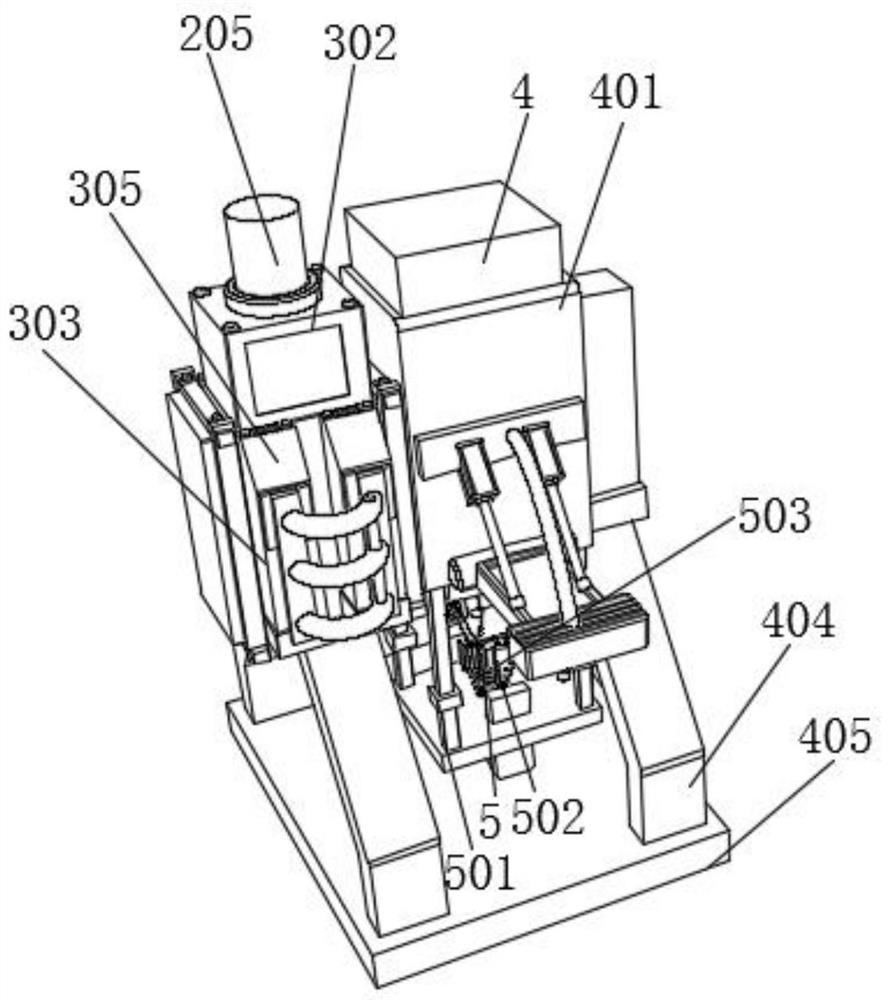

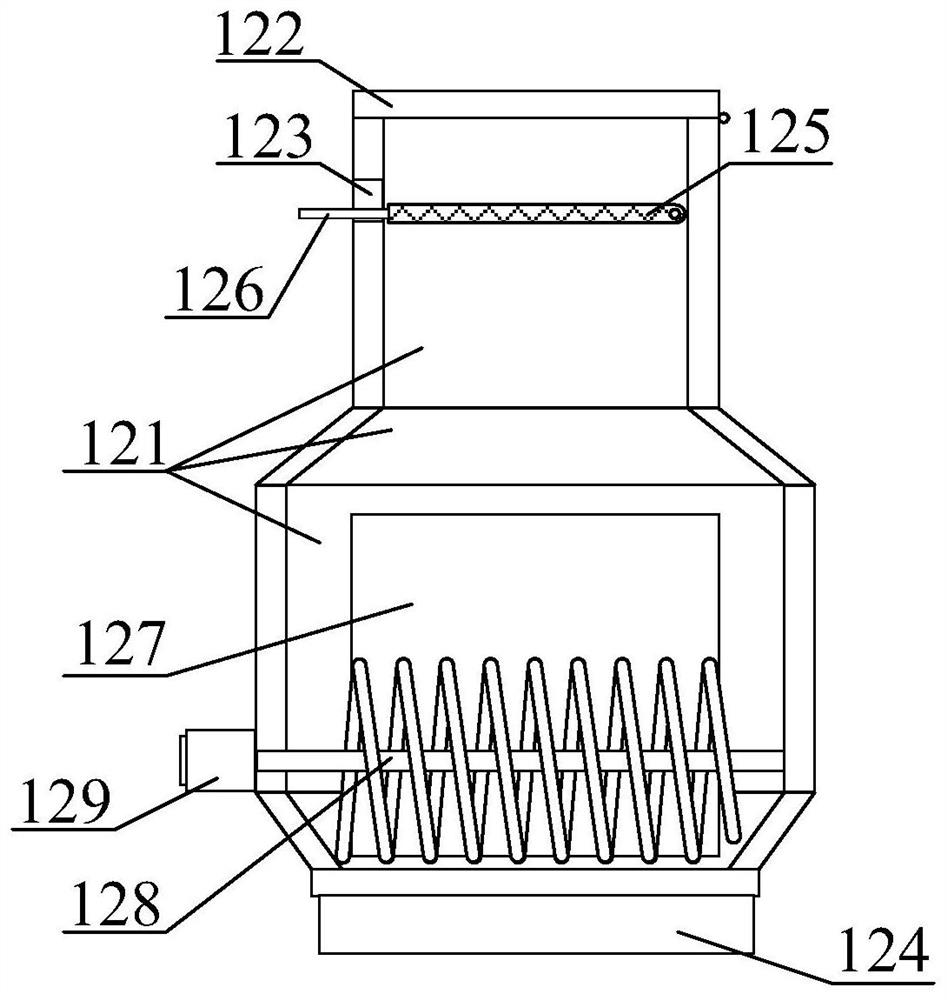

Biological fermentation feed processing equipment and method

InactiveCN112808379AAvoid manual deliveryImprove processing efficiencyFeeding-stuffPackagingFeed processingGrinding mill

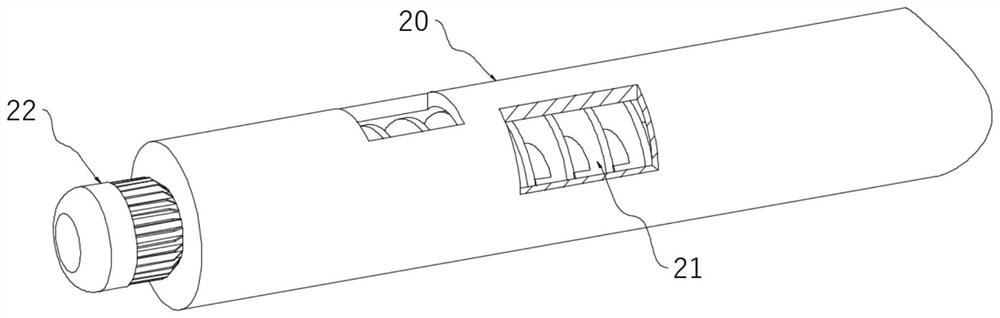

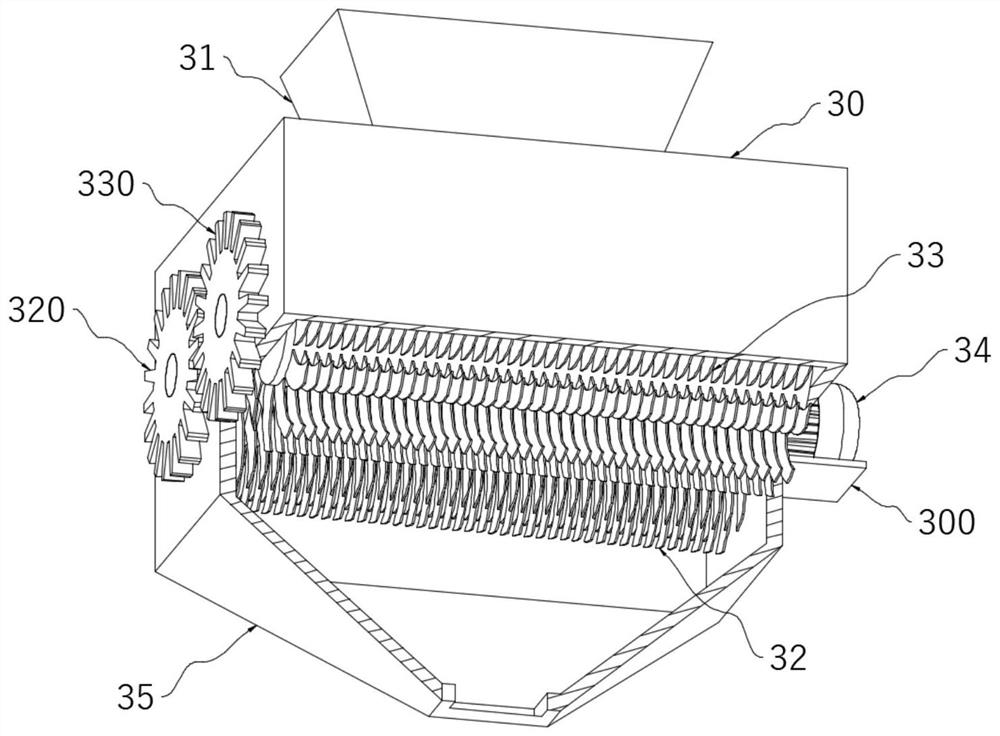

The invention relates to the technical field of feed processing, in particular to biological a fermentation feed processing equipment and method. The biological fermentation feed processing equipment comprises a fixed base, symmetrically-distributed supporting blocks are arranged at the positions, close to the left end, of the surface of the fixed base, and a first conveying mechanism is supported by the tops of the two supporting blocks. The first conveying mechanism comprises a horizontally-arranged first conveying pipe, a smashing mechanism is arranged at the position, close to the left end, of the top of the outer wall of the first conveying pipe, three supporting legs distributed in an annular array mode are arranged at the position, close to the right end, of the surface of the fixed base, a fermentation mechanism is supported by the tops of the three supporting legs, the fermentation mechanism comprises a fermentation barrel, and a grinding mechanism is arranged in the middle of the top of the fermentation barrel. According to the biological fermentation feed processing equipment, materials are smashed through the smashing mechanism, the smashed materials are automatically conveyed to the grinding mechanism through the two material conveying mechanisms, the smashed materials are ground through the grinding mechanism, fermentation of the smashed materials in the fermentation mechanism is facilitated, and therefore continuous processing is achieved.

Owner:CHONGQING KAIZHOU JIUDING ANIMAL HUSBANDRY SCI & TECH DEV

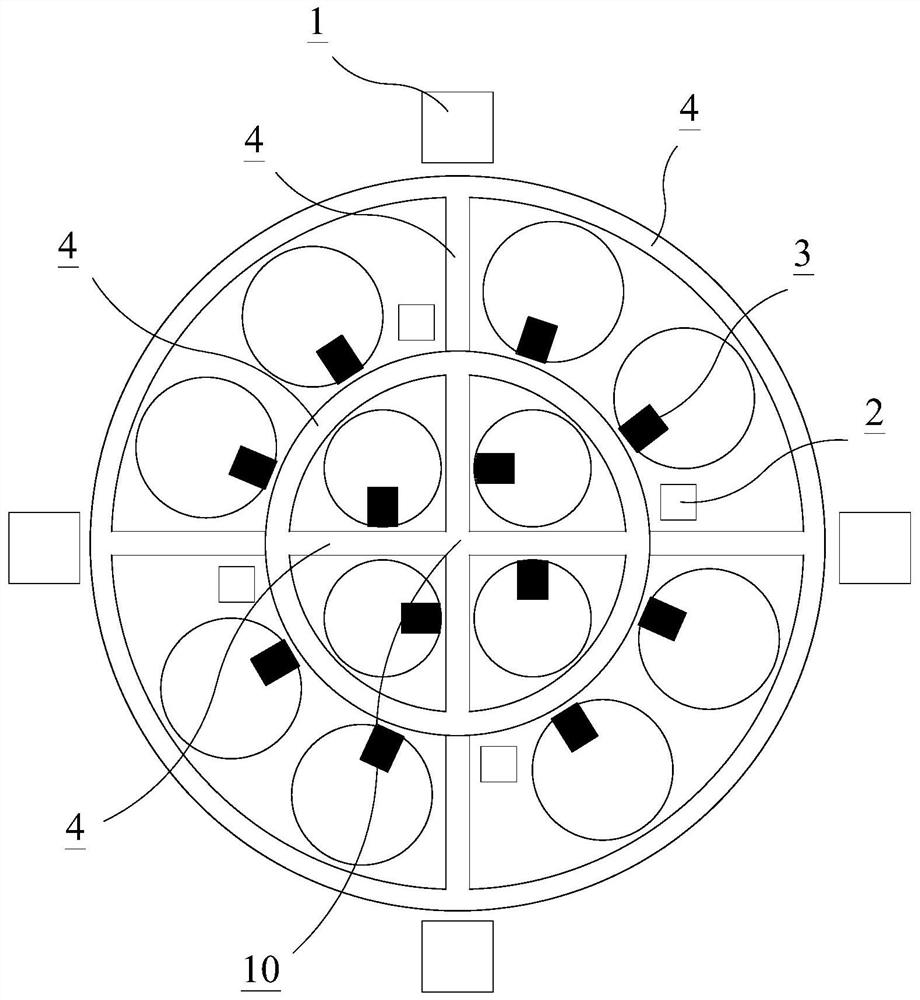

Raw material screening device for roller production

PendingCN111957436AAvoid manual deliveryConvenience fillerMagnetic separationLoading/unloadingGear driveElectric machine

The invention discloses a raw material screening device for roller production. According to the device, cast iron raw materials are placed in a storage hopper; a motor I is started to drive a conveyorbelt and a baffle to rotate; the baffle brings the raw materials in the storage hopper to a high position; a motor II is started to drive a gear I to rotate; the gear I is meshed with a half gear todrive the half gear to rotate; the half gear drives a transmission shaft to rotate; the transmission shaft drives a discharging groove to rotate, so that the discharging groove reaches the upper portion of an outer cylinder; by driving the discharging groove to rotate, in the working process of the outer cylinder, the discharging groove and the outer cylinder cannot make contact with each other, so that equipment can run more smoothly and cannot be damaged while the outer cylinder can be filled with materials conveniently; the motor is started to drive a rotating disc to rotate so as to drivethe outer cylinder to rotate, and each outer cylinder is filled with the materials; and after the filling is completed, the discharging groove is withdrawn. According to the invention, manual conveying of raw materials is avoided, only one outer cylinder is used for impurity removal, and the working efficiency is low.

Owner:马鞍山欧凯新材料科技有限公司

Inoculation equipment for biological fermentation and biological fermentation process

PendingCN113136312AIncrease the probability of contaminationImprove cultivation efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention discloses inoculation equipment for biological fermentation and a biological fermentation process. The equipment comprises a box body and a fermentation tank, wherein the fermentation tank is positioned on the rear side of the box body; a partition plate is fixedly connected to the inner side of the box body, and a prefabrication cavity and an inoculation cavity are formed between the two sides of the partition plate and the two sides of the inner wall of the box body respectively; a culture box is slidably connected into the prefabricated cavity, and an inner box is inserted into the culture box; a separation cavity is formed between the bottom of the separation plate and the inner wall of the box body. Through the arrangement of the prefabricated cavity and the inoculation cavity, after microorganisms are cultured in the prefabricated cavity in advance, the microorganisms can directly act on the push-pull plate, so that the culture box containing the microorganisms can slide in the prefabricated cavity.The incubator is located in the prefabricated cavity, and in the process, microorganisms are transmitted from one independent space to another independent space; thereby, the contact time of microorganisms and the external environment is prevented from being too long, so that the probability that organisms are polluted by external bacteria is increased, operation is convenient, and the biological culture efficiency is improved.

Owner:侯磊

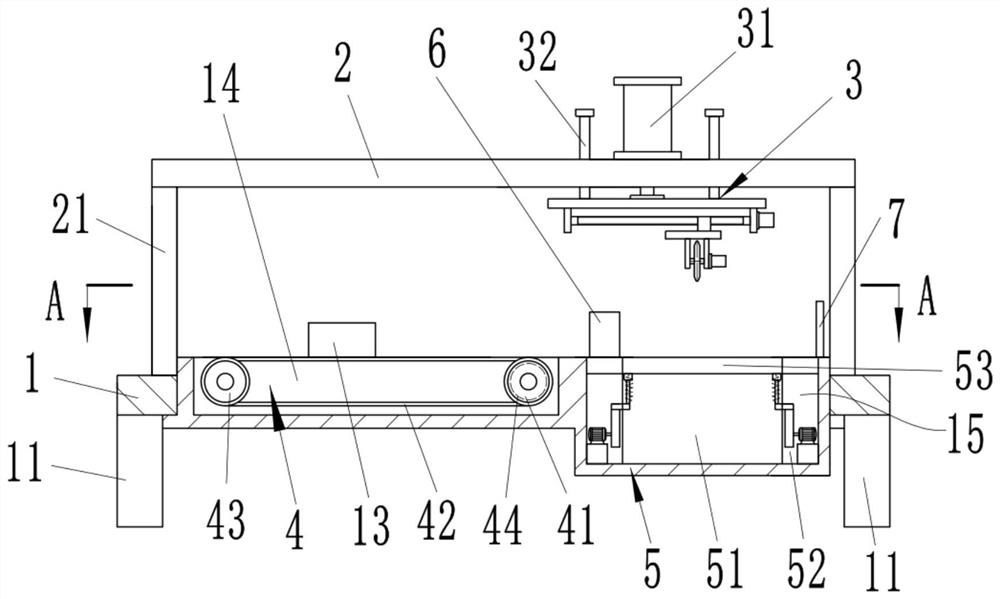

Efficient plastic pipe cutting machine

ActiveCN110370339APromote accumulationEasy to take awayMetal working apparatusEngineeringUltimate tensile strength

The invention provides an efficient plastic pipe cutting machine. The efficient plastic pipe cutting machine comprises a machine platform, a mounting frame, a cutting mechanism, a conveying mechanism,a collection device and a clamping mechanism, wherein the mounting frame is arranged on the machine platform; the cutting mechanism is arranged on the lower side of the mounting frame; the cutting mechanism comprises a cutting wheel, a lifting mechanism for driving the cutting wheel to lift, a transverse motion mechanism for driving the cutting wheel to move transversely, and a first motor for driving the cutting wheel to rotate; the conveying mechanism is used for conveying to-be-cut plastic pipes; the collection device comprises two driving mechanisms which are respectively arranged at twoends of a sinking cavity, and a pair of movable panels which are hinged at the upper end of the sinking cavity; and the driving mechanisms are used for driving the movable panels to be opened and closed. The efficient plastic pipe cutting machine provided by the invention is capable of solving the technical problem that the existing plastic pipe cutting machines are high in labor intensity and lowin cutting efficiency.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Automatic cargo home-entry method and system

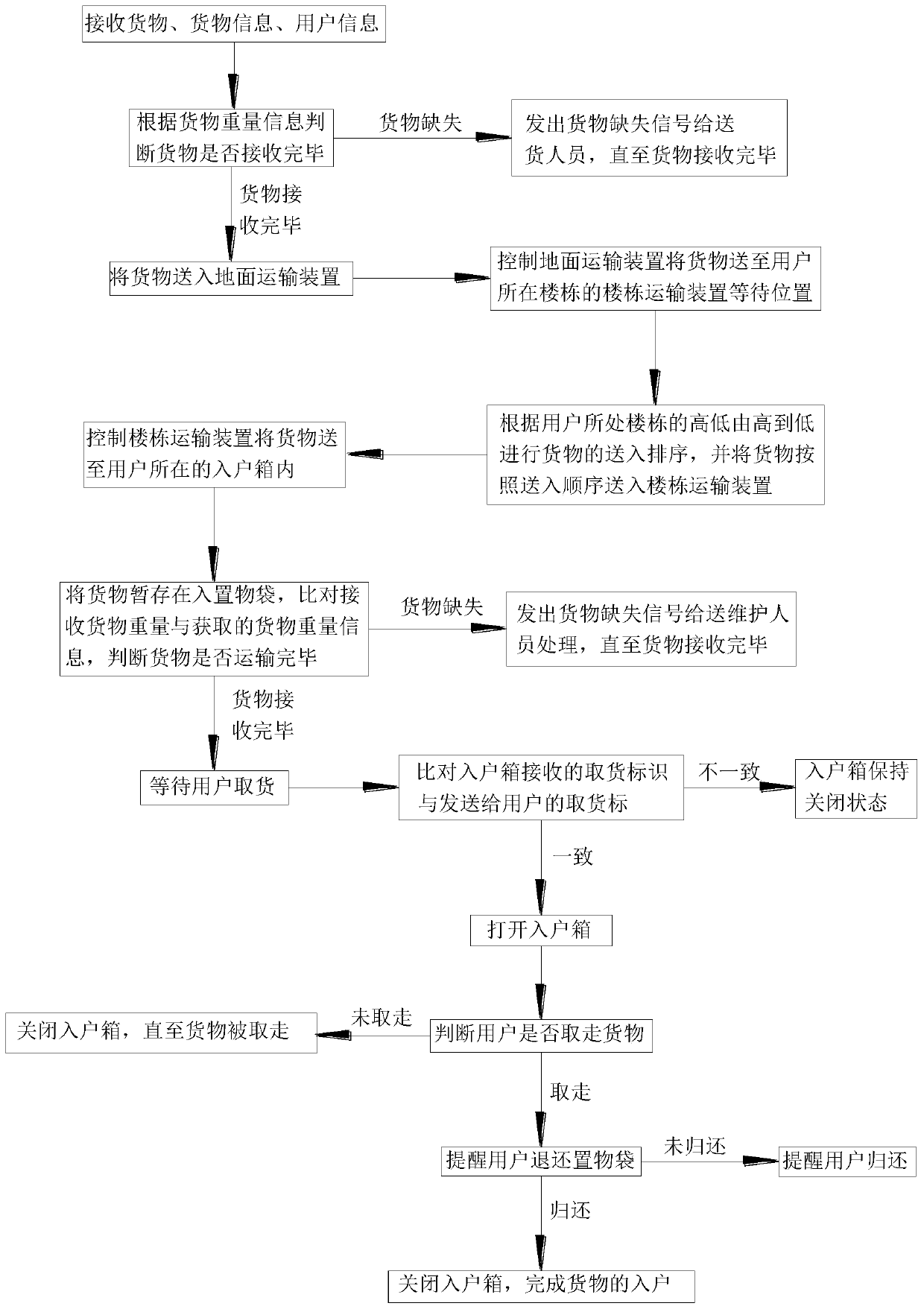

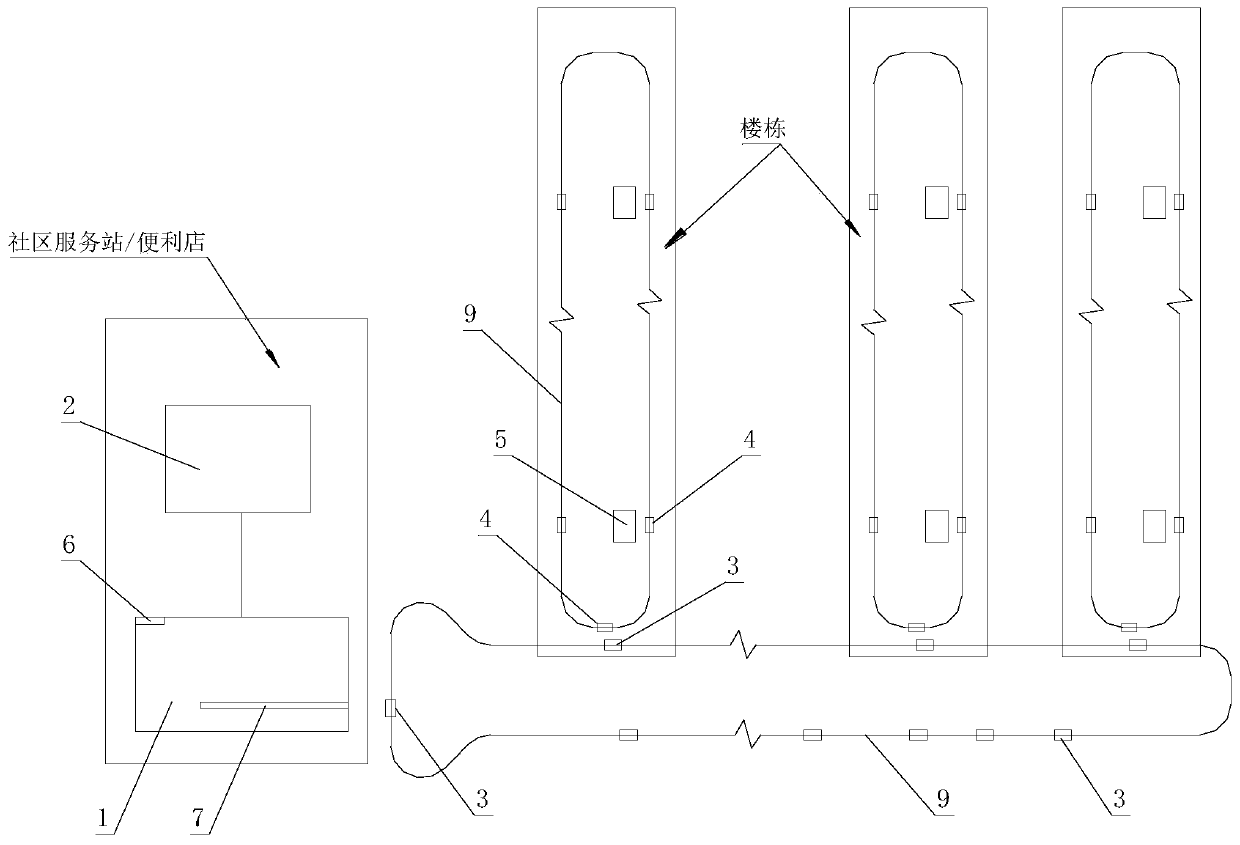

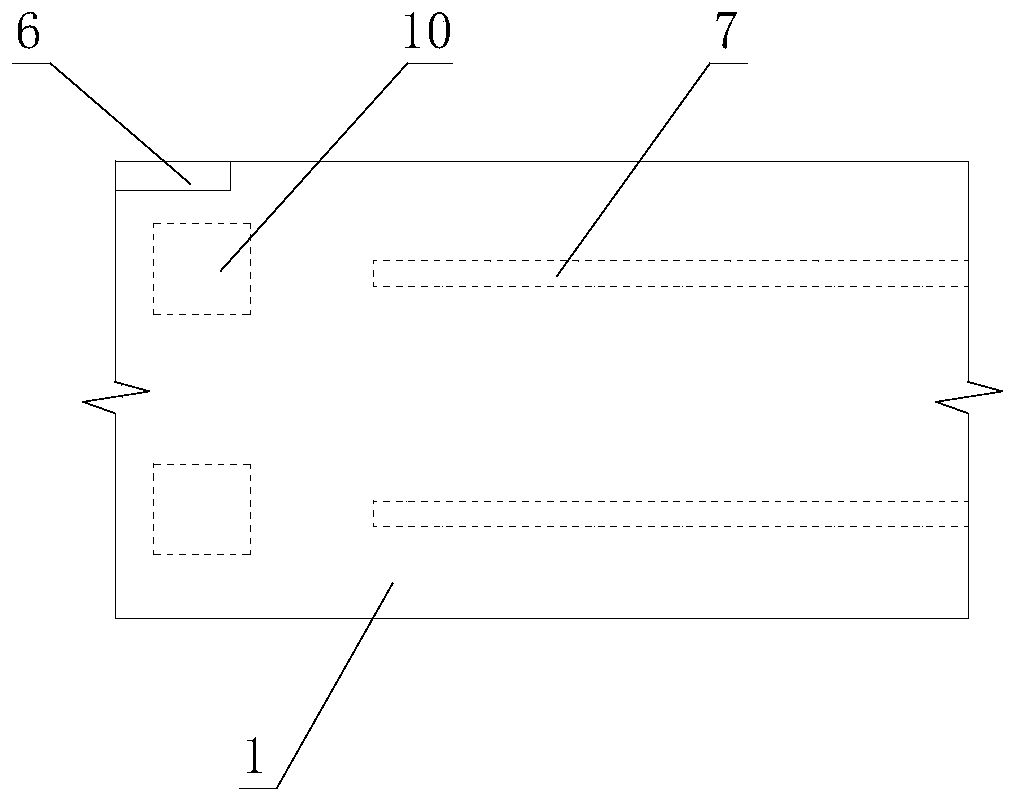

PendingCN110135784AHigh login efficiencyImprove shopping experienceApparatus for meter-controlled dispensingLogisticsLogistics managementGround transportation

The invention relates to the technical field of logistics, in particular to an automatic cargo home-entry method, and aims to provide an automatic cargo home-entry method. According to the technical scheme, the method comprises the following steps of receiving goods, goods information and user information; selecting a ground transportation device to contain goods according to the goods informationand the user information; loading the cargos into a ground transportation device, controlling the ground transportation device to send the cargos to a waiting position of a building transportation device of a building where a user is located according to the user information, and sending the cargos into the building transportation device; according to the user information, controlling the building transportation device to send the goods into a home-entry box where the user is located; temporarily storing goods in the home-entry box, and goods taking information is sent to a user; comparing the goods taking information received by the home-entry box with the goods taking information sent to the user, opening the home-entry box if the goods taking information is consistent with the goods taking information, and keeping the home-entry box closed if the goods taking information is inconsistent with the goods taking information. Goods can be sent to a user, and the shopping experience of the user is improved.

Owner:朱继伟

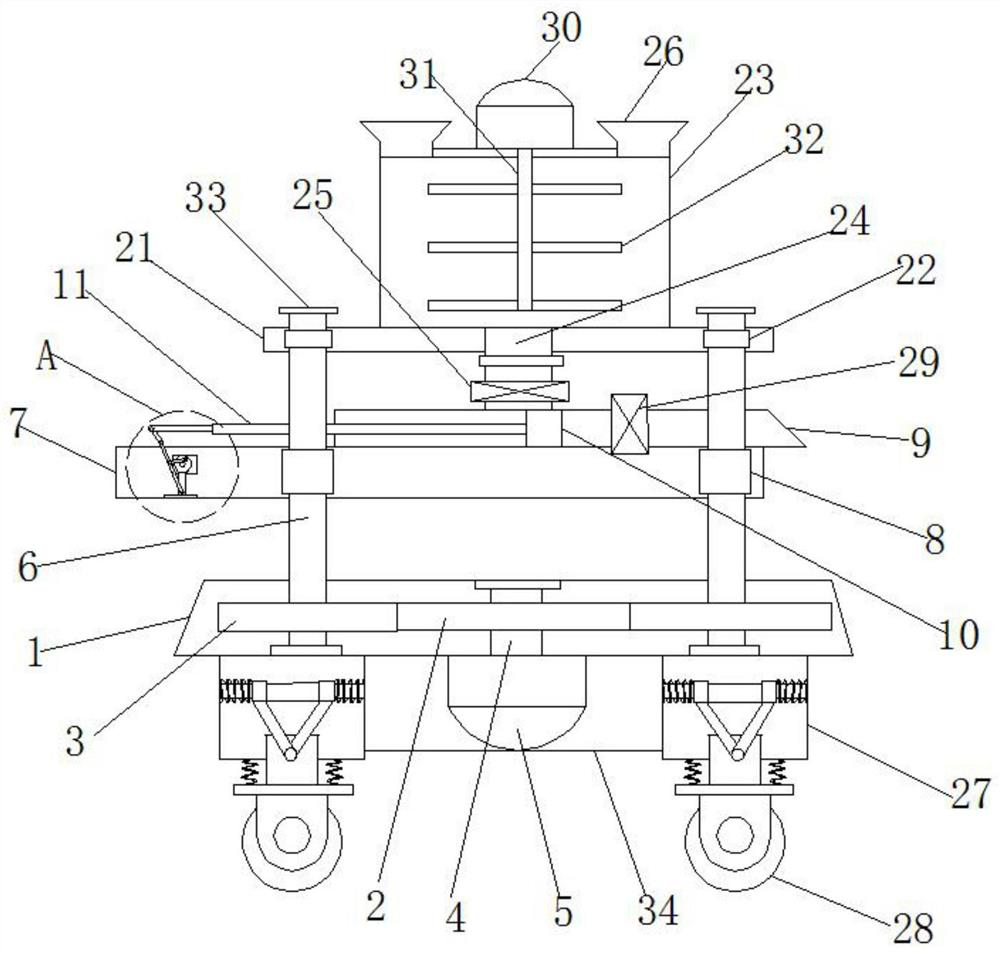

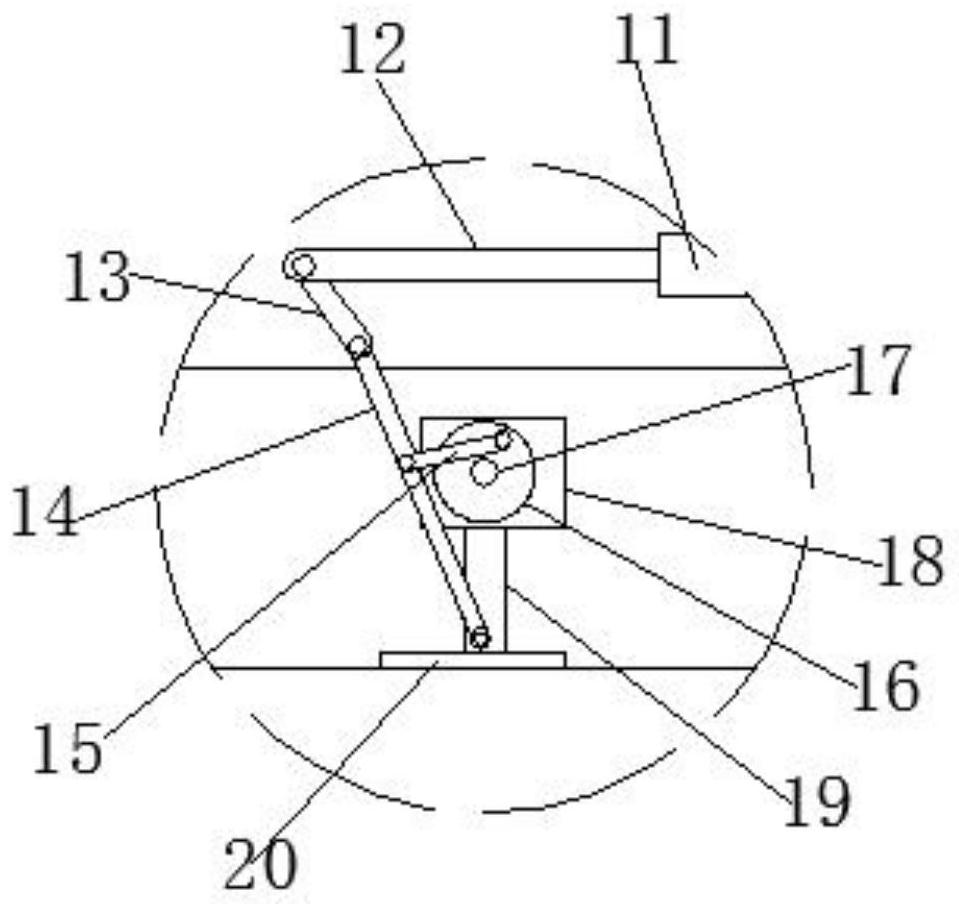

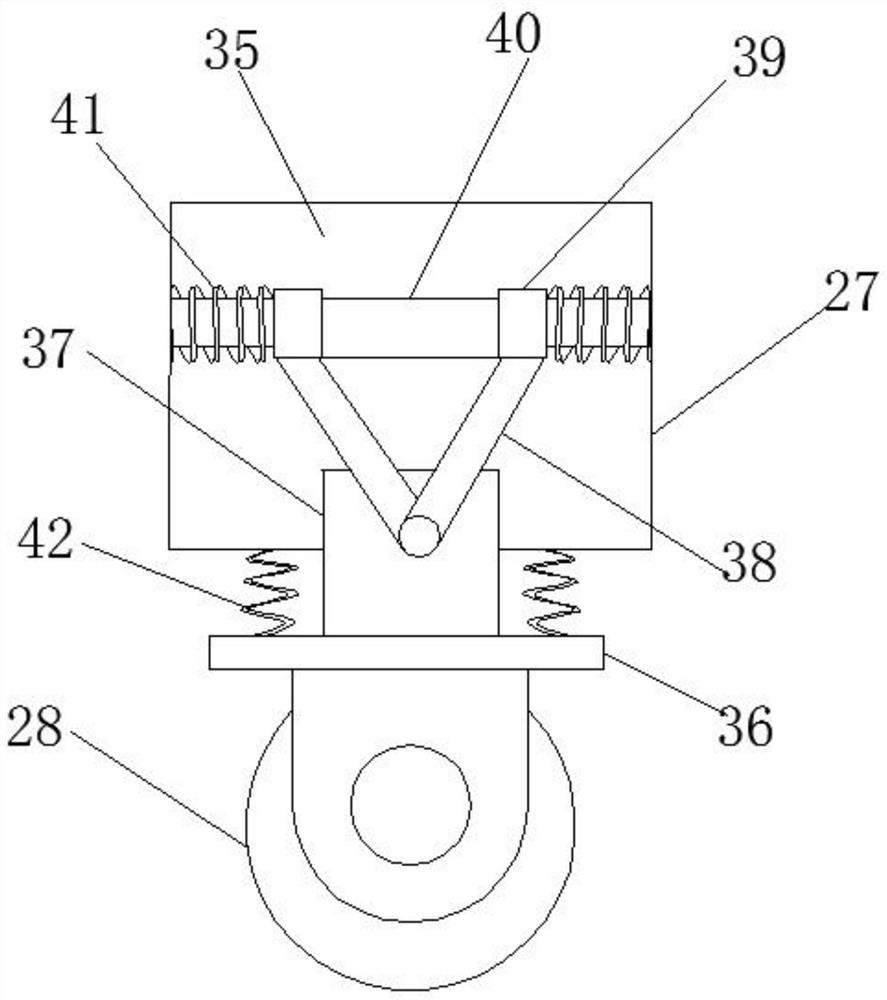

Multifunctional construction cart with load reminding function

ActiveCN108818950ASimple structurePrevent overloadCement mixing apparatusArchitectural engineeringMagnet

The invention discloses a multifunctional construction cart with a load reminding function. The multifunctional construction cart comprises a cart body, wherein the cart body is of a U-shaped structure. The multifunctional construction cart with the load reminding function, disclosed by the invention, is simple in structure; a disc and a second magnet are driven to rotate by utilizing a motor, andthe disc drives a stirring rod to rotate and stir, so that concrete which is subjected to primary stirring can be stirred again, and the uniformity of the concrete can be further improved; meanwhile,two iron blocks are intermittently and rightwards absorbed through the rotating of the second magnet, a T-shaped rod pushes a rotating rod to move rightwards under the action of a third spring, the rotating rod can be in rotary type horizontal back-and-forth movement because a gear is meshed with a gear rack when the rotating rod horizontally moves back and forth, and a stirring blade can be in rotary type horizontal back-and-forth movement and stirring, so that the stirring efficiency is further increased, and the uniformity of the concrete is improved; the stirring blade is driven to move up and down by utilizing a moving rod, so that the concrete which is still in caking can be smashed for further stirring.

Owner:阜南县申通机械制造有限公司

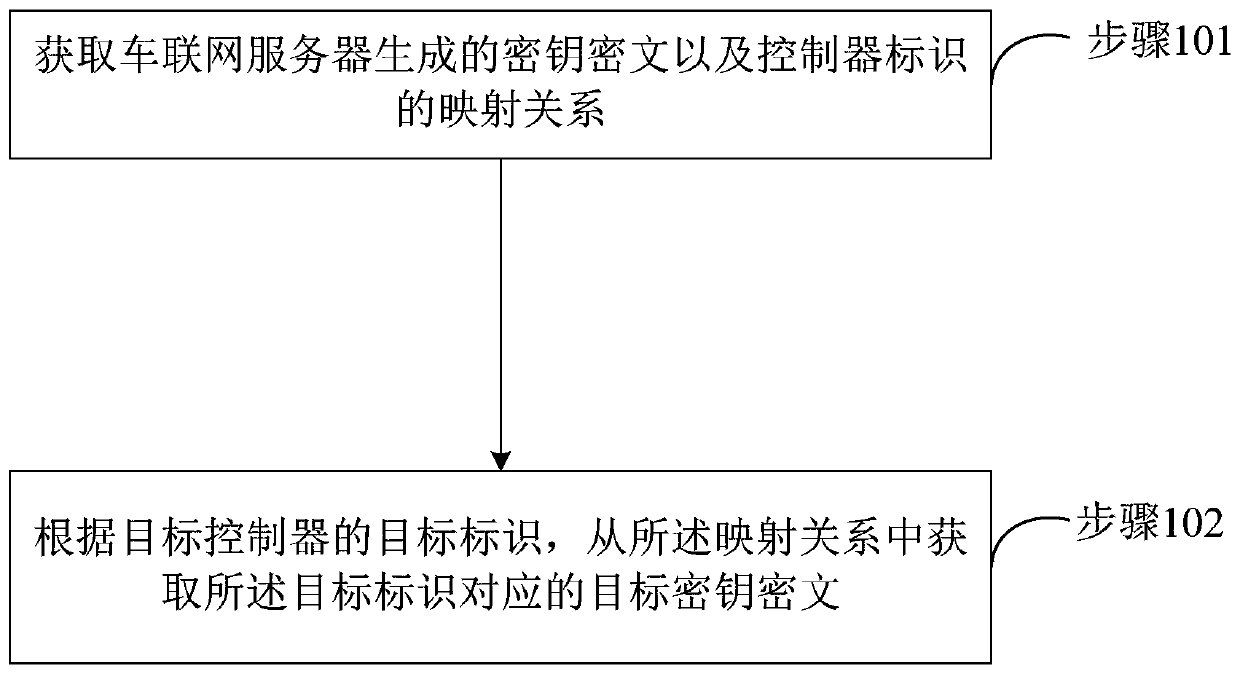

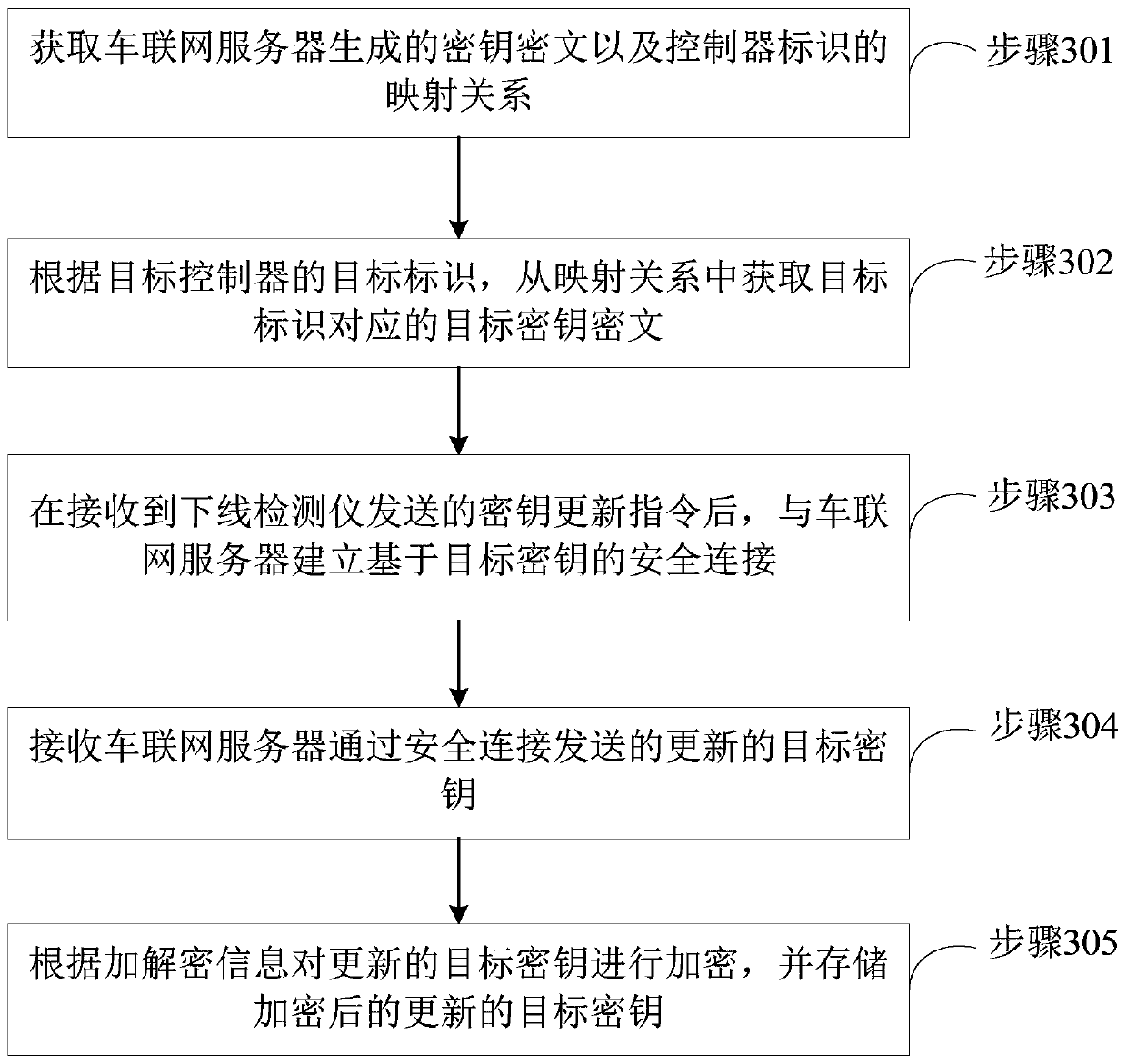

Symmetric key distribution method and device, vehicle and storage medium

ActiveCN110830243AReduce complexityLow costKey distribution for secure communicationCiphertextTarget control

The invention discloses a symmetric key distribution method and device, a vehicle and a storage medium. The method comprises the following steps: 1, ; obtaining a mapping relationship between a key ciphertext generated by an Internet of Vehicles server and the controller identifier, acquiring a target identifier of the target controller; obtaining a target key ciphertext corresponding to the target identifier from the mapping relationship, compared with the prior art, the target controller does not need complex operation, the requirement for the operation performance of the target controller is low, extra hardware is not added. Meanwhile, manual password card transmission is avoided, and therefore the symmetric key distribution method is low in complexity, low in cost and high in distribution efficiency.

Owner:CHINA FIRST AUTOMOBILE

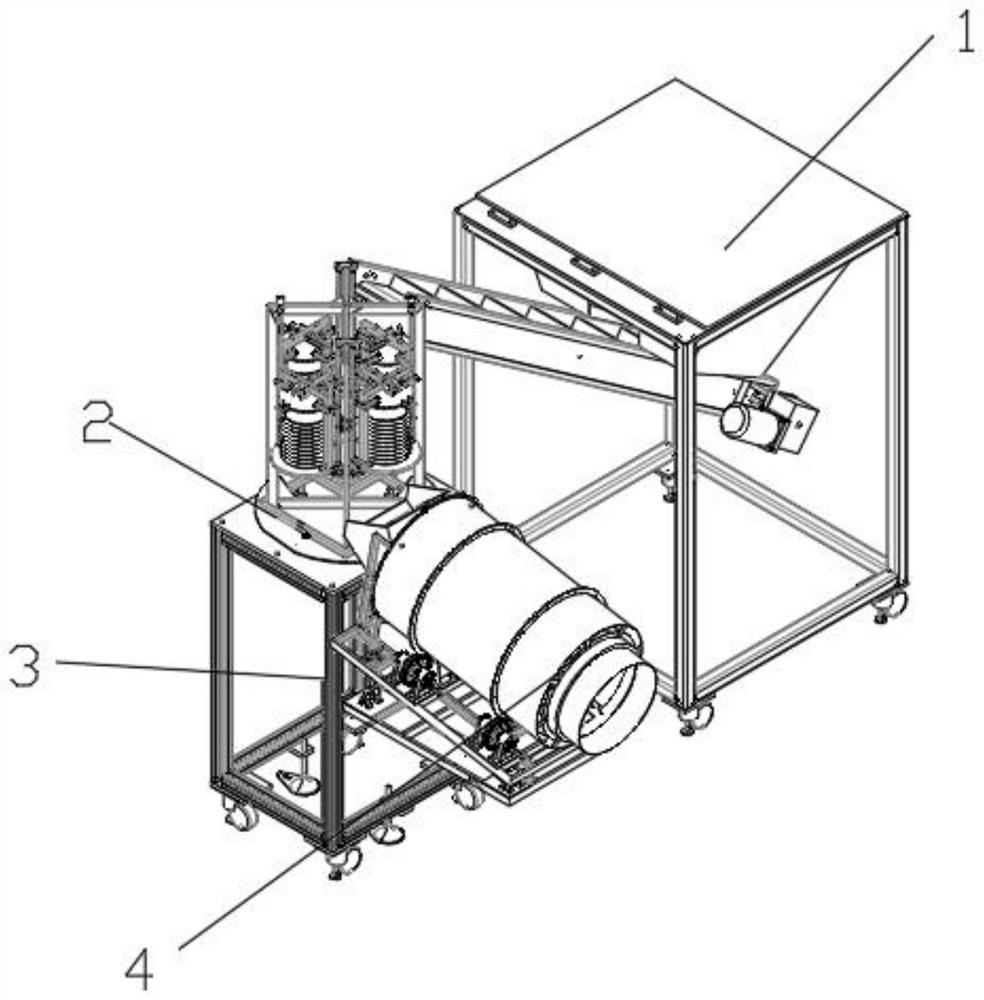

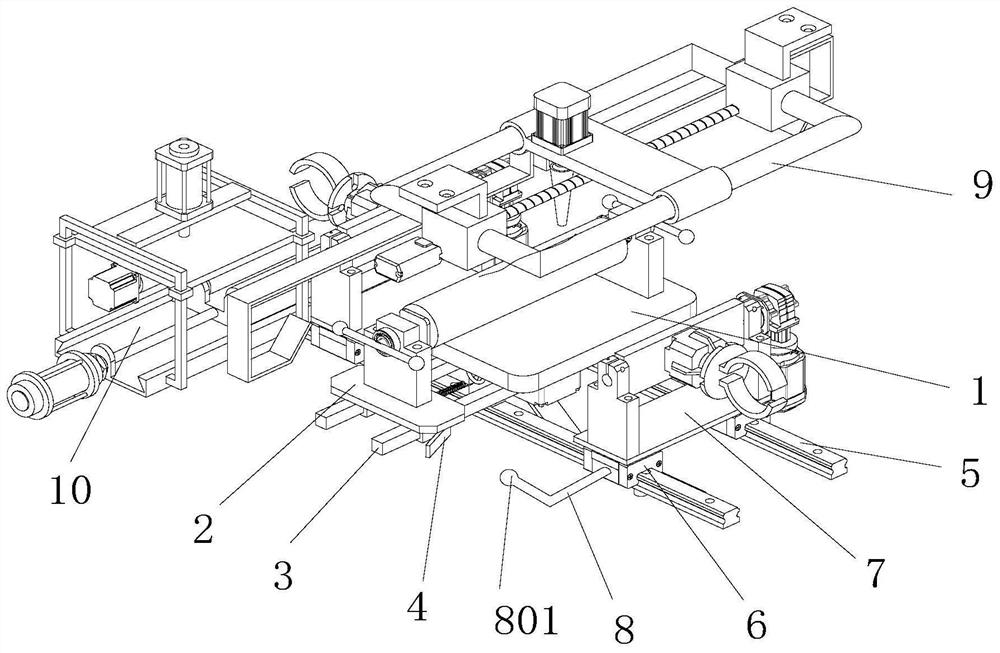

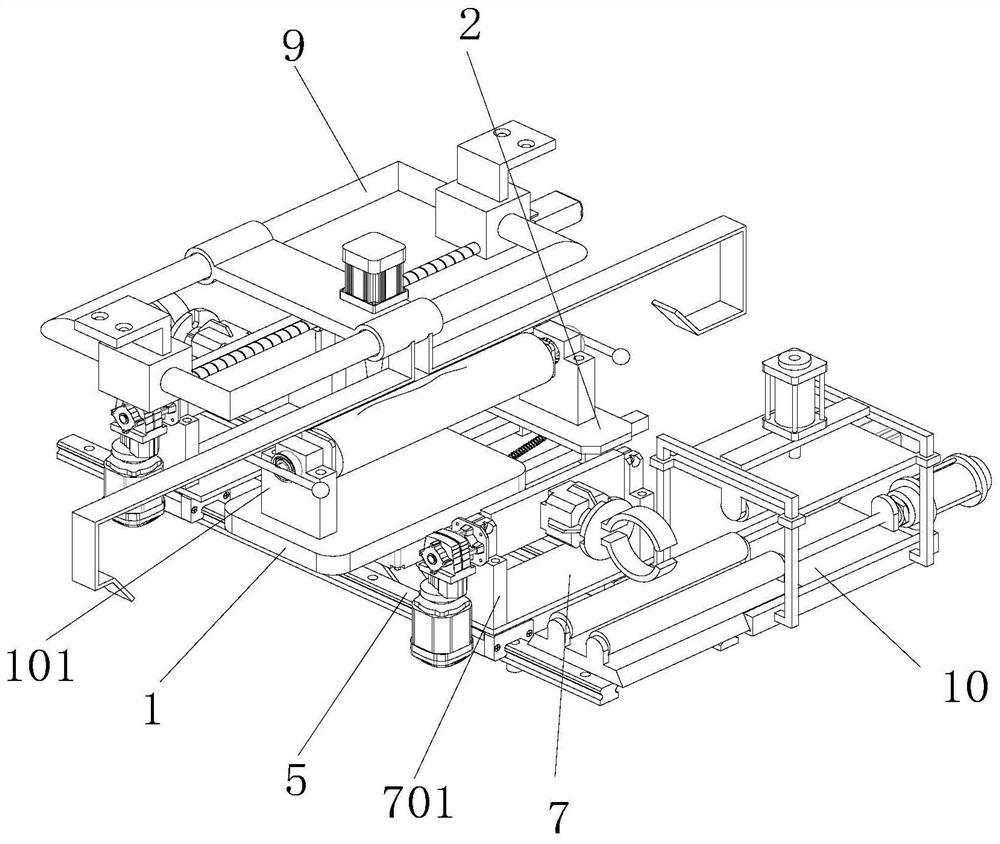

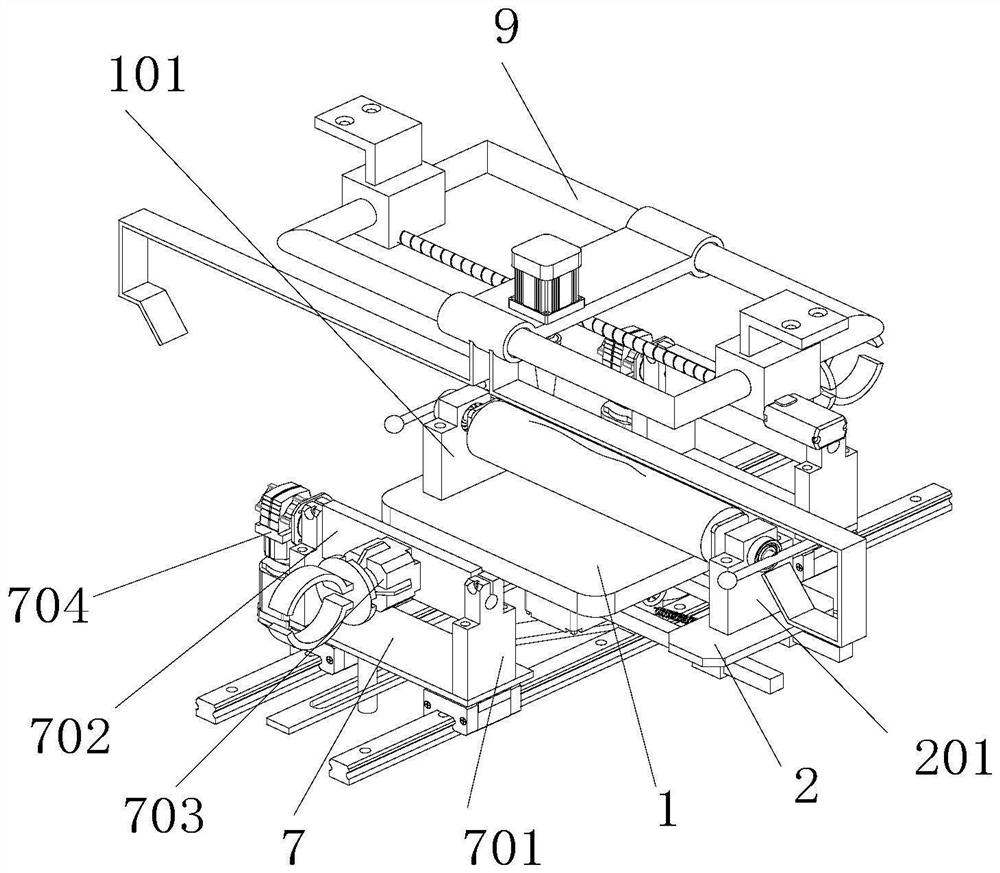

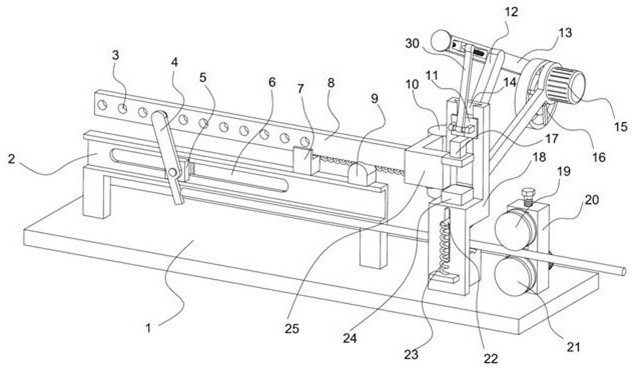

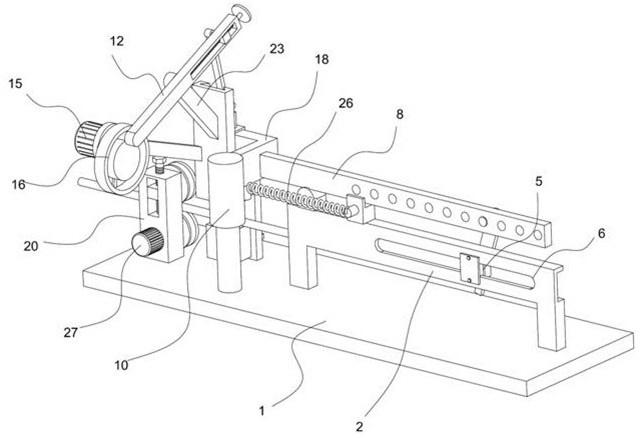

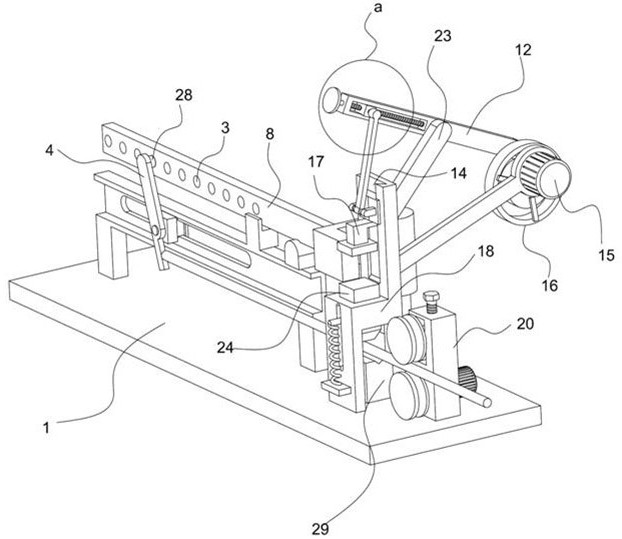

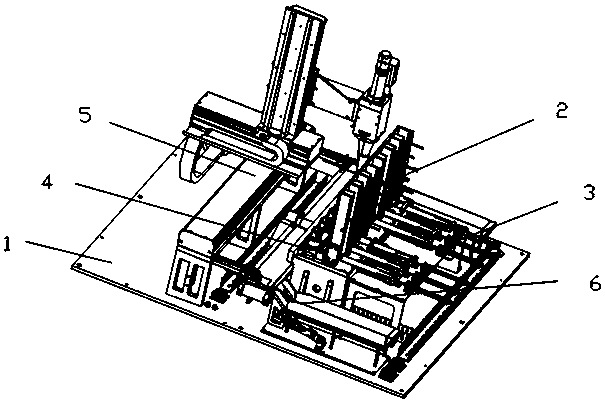

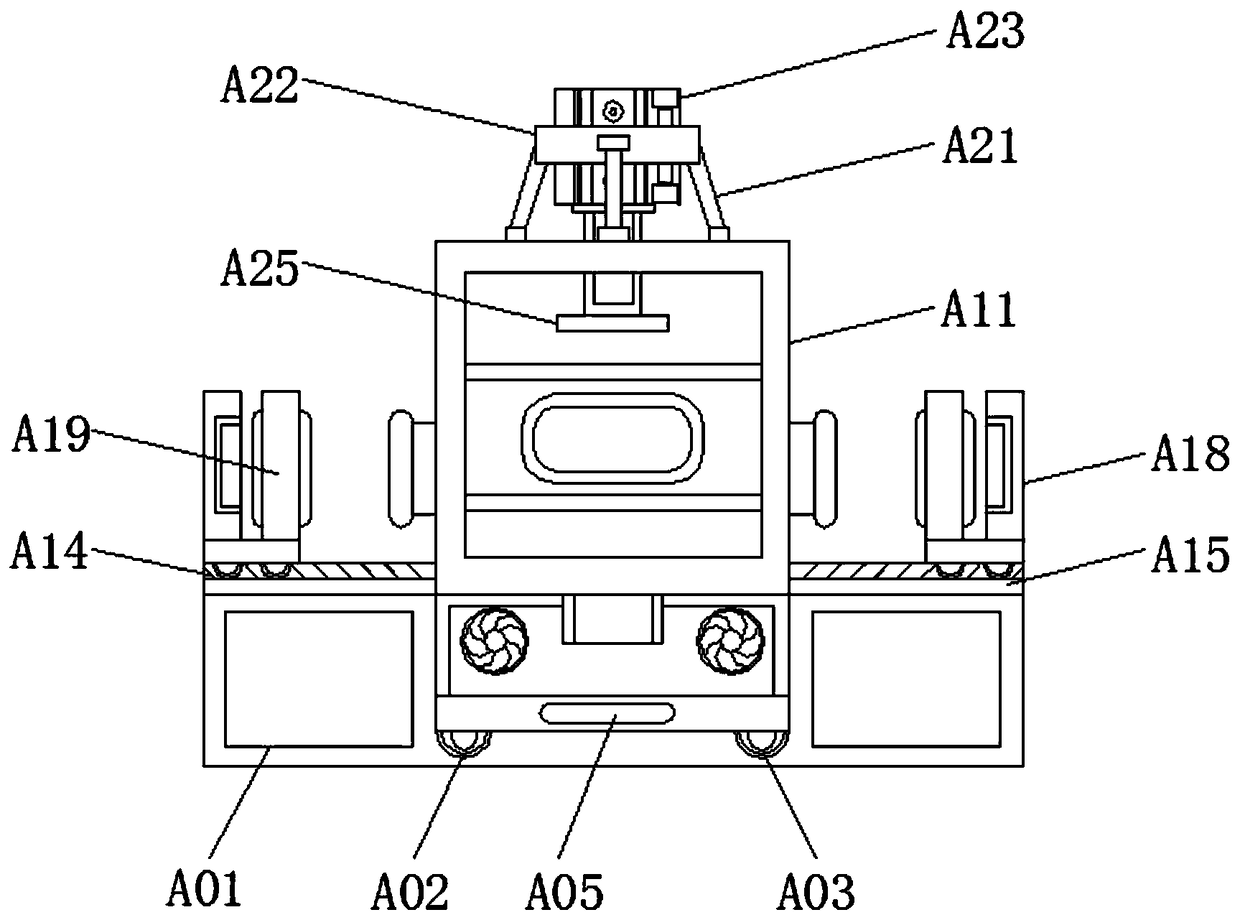

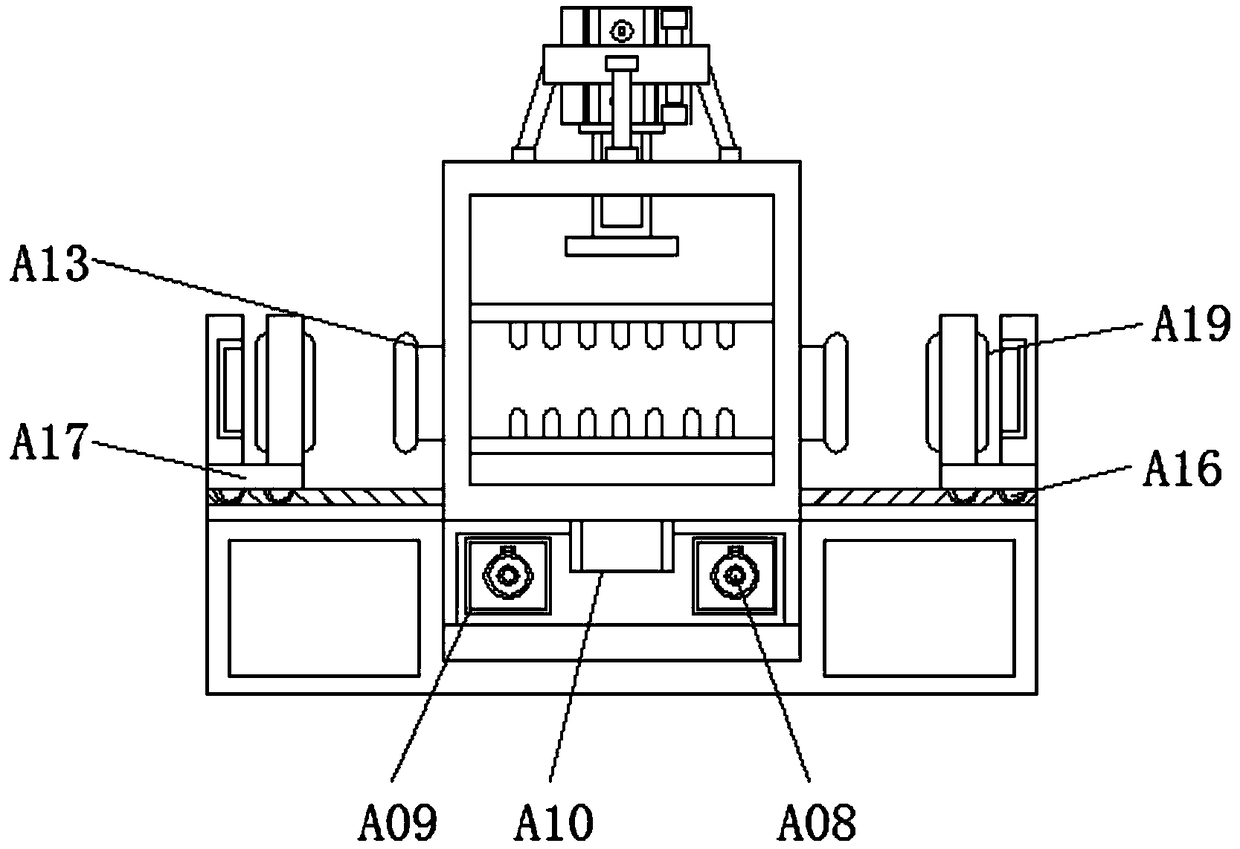

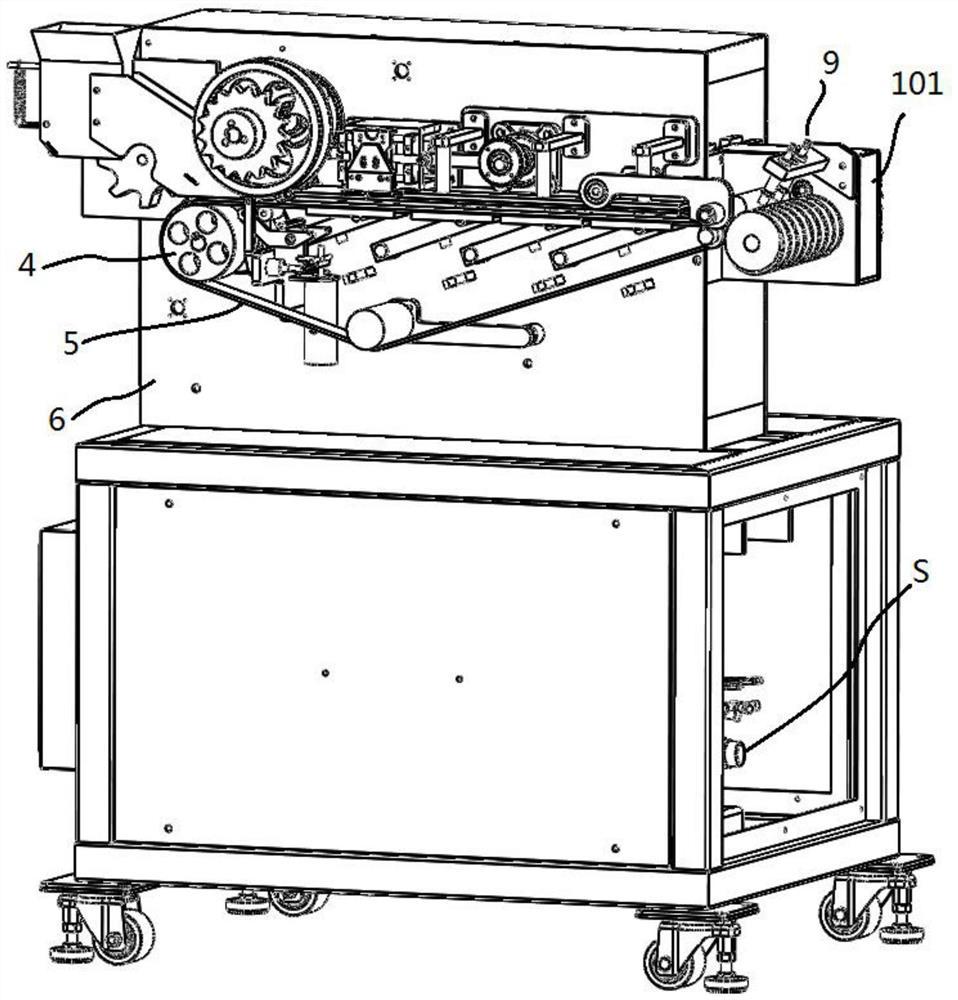

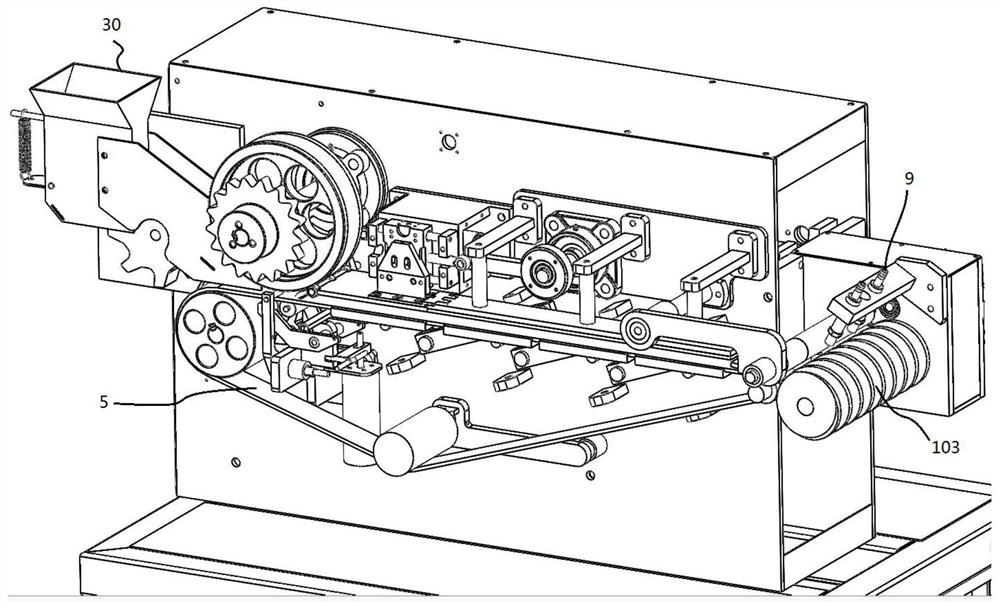

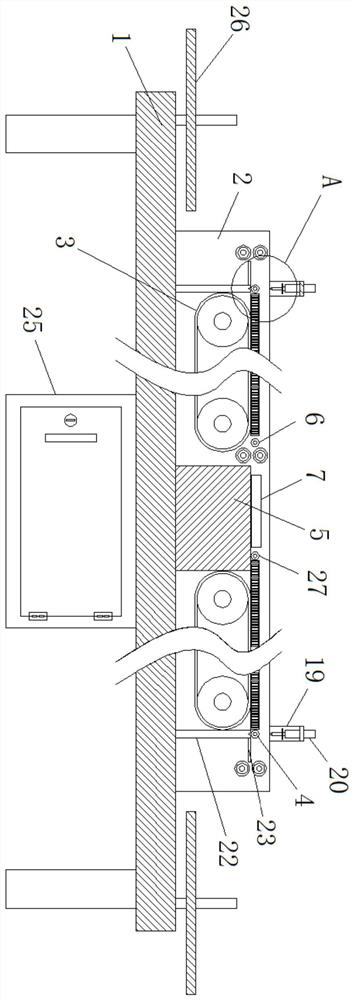

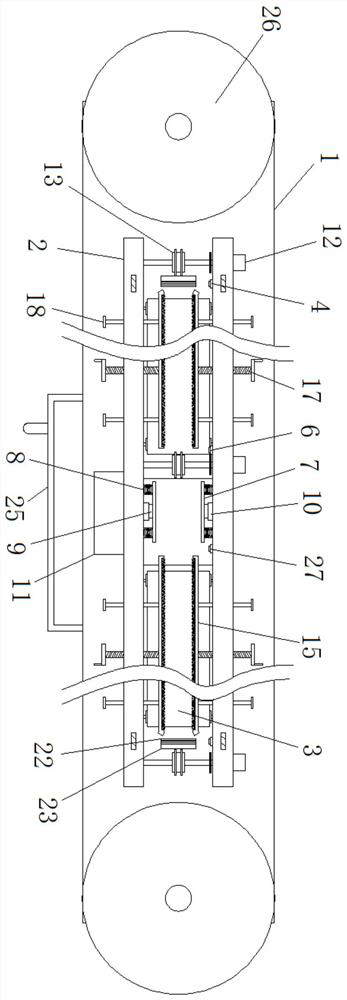

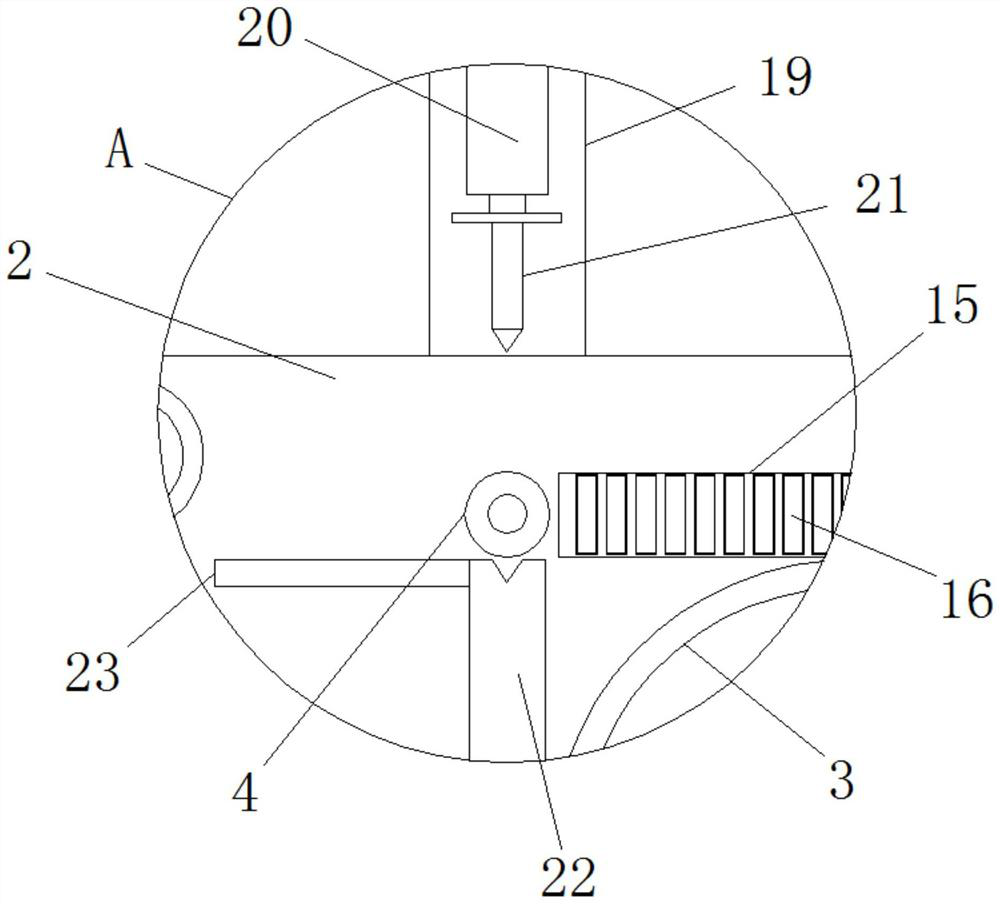

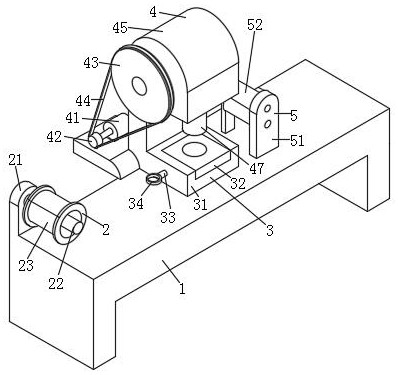

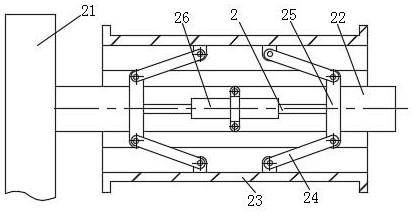

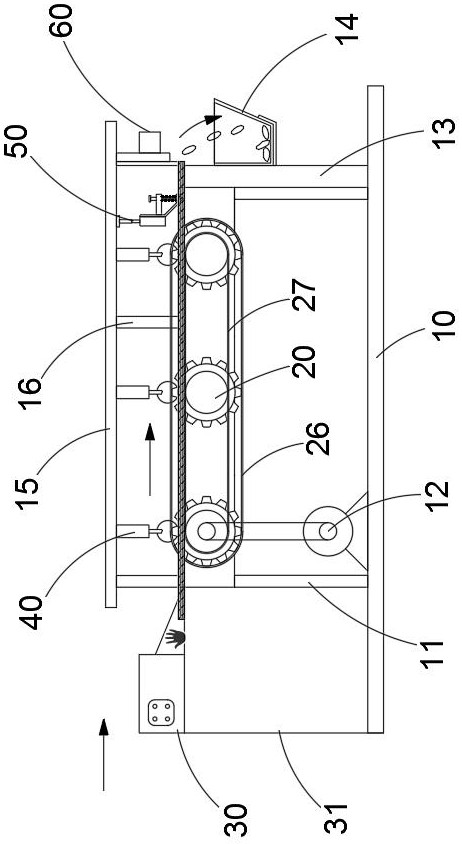

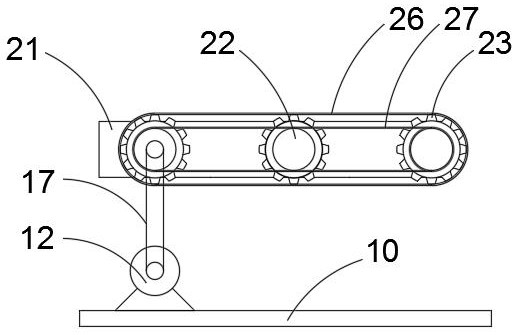

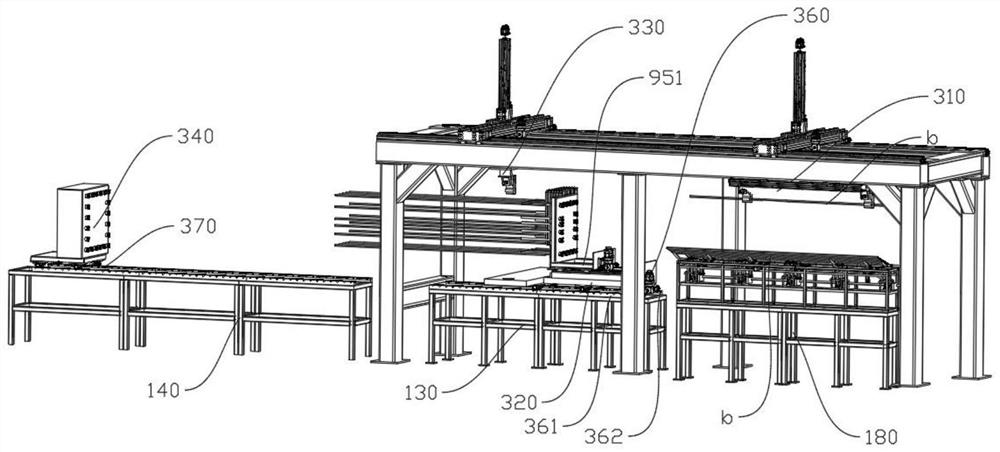

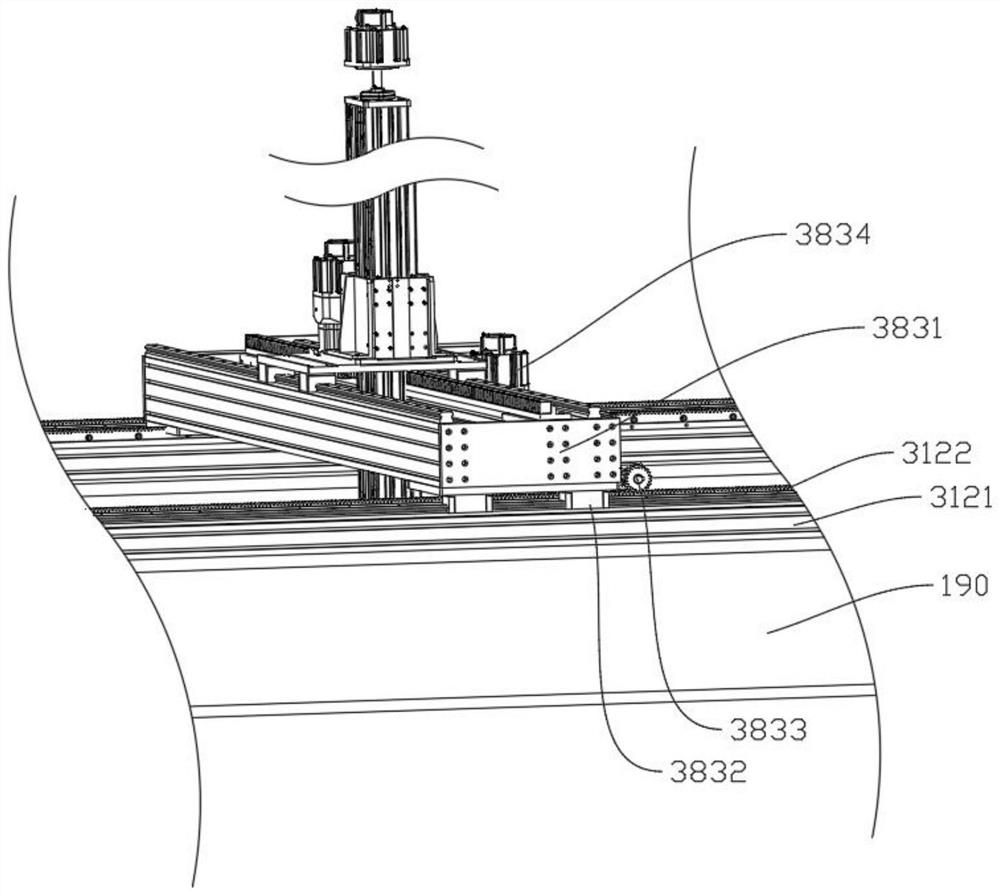

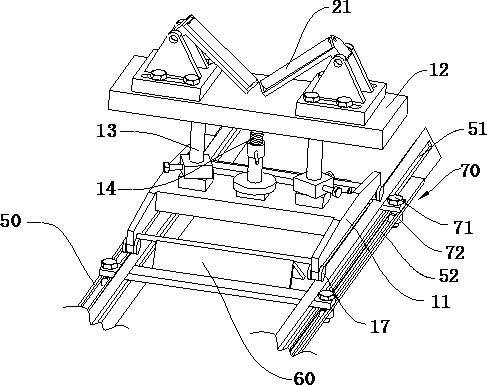

Laser cladding synchronous grinding system for roller repair and grinding process of laser cladding synchronous grinding system

ActiveCN113787391ARealize the effect of automatic processingSave resourcesRevolution surface grinding machinesGrinding drivesEngineeringLaser heating

The invention discloses a laser cladding synchronous grinding system for roller repair and a grinding process of the laser cladding synchronous grinding system, and belongs to the field of roller repairing. The laser cladding synchronous grinding system for roller repair comprises a base table plate fixedly connected with a building, two extending guide rails are arranged at the bottom end of the base table plate, a clamping table is arranged at the top ends of the extending guide rails, inserting square sleeves arranged on the extending guide rails in a sleeving mode are arranged at the bottom end of the clamping table, the inserting square sleeves are in sliding connection with the extending guide rails, a fixed shaft seat is arranged at the top end of the base table plate, a movable shaft seat is arranged at the top end of the clamping table, two transposition guide rails are fixedly mounted at the bottom end of the base table plate, the transposition guide rails are sleeved with two sets of transposition sliding blocks, the transposition sliding blocks are slidably connected with the transposition guide rails, a carrying table is fixedly installed at the top end of each set of transposition sliding blocks, a laser heating assembly is arranged above the base table plate, and a grinding assembly is arranged on one side of the base table plate.

Owner:YIXING YONGCHANG ROLL

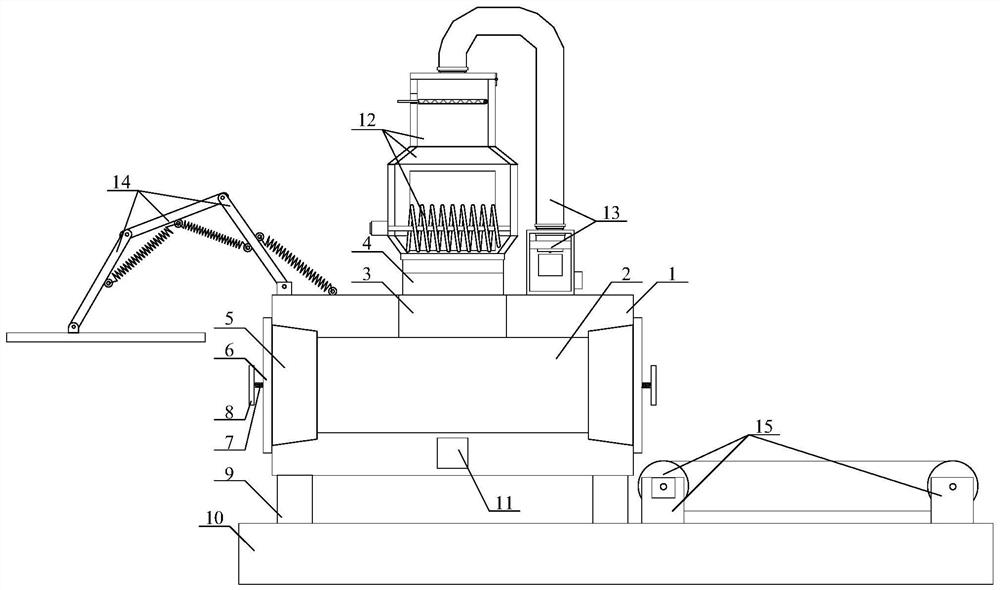

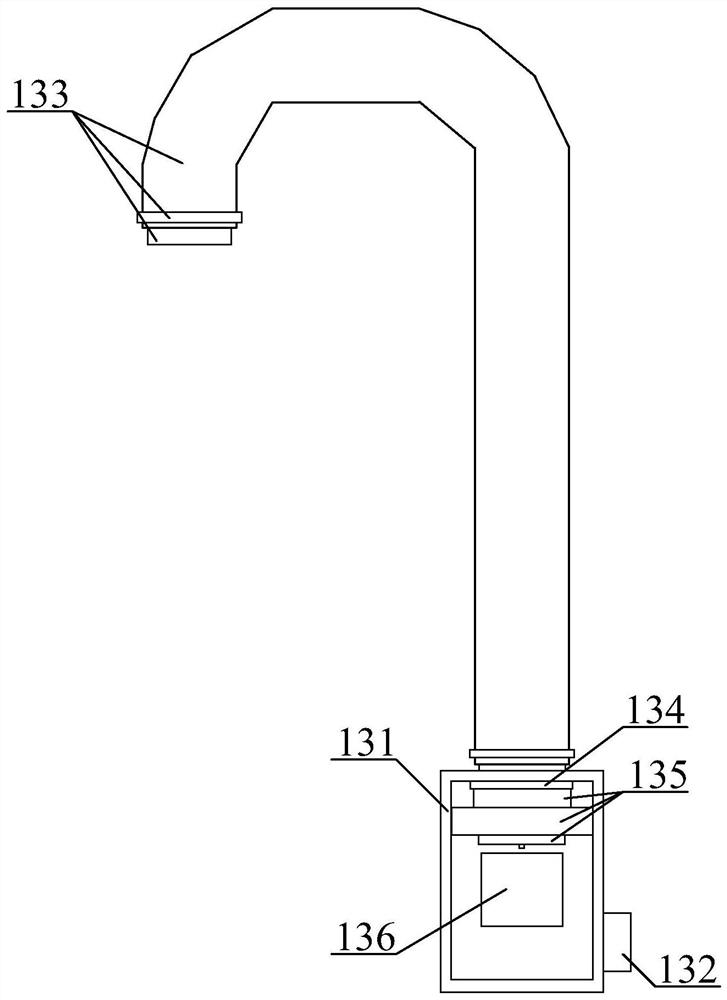

Corn packaging device capable of automatically quantifying

InactiveCN114435639AEasy to transport and handleHigh outputWrapper twisting/gatheringSolid materialAgricultural engineeringCorn kernel

The invention provides a corn packaging device capable of automatically quantifying, which belongs to the technical field of agricultural product packaging and comprises a conveying mechanism, a moving mechanism is fixedly mounted at one end of the conveying mechanism, a weighing mechanism is arranged at the end of the moving mechanism, a packaging mechanism is arranged at one end of the weighing mechanism, and a wrapper is arranged at the bottom of the packaging mechanism. According to the corn kernel packaging machine, through the arrangement of the conveying mechanism, the supporting frame, the auger conveying tank and the coupler, corn kernels can be conveniently conveyed in the using process, and materials placed in the discharging hopper can be conveniently output under the driving of the discharging hopper and an auger motor; the conveying efficiency of materials is improved, immediately-put corn kernels can roll and move along with rotation of the stirrer, and then under the high-speed rotation effect of the auger motor, the conveying auger at the output end can be rotated conveniently.

Owner:夏志勇

Cutting device and method for machining iron art guardrail accessories

PendingCN114433954AEffective Depth of Cut AdjustmentRealize continuous cuttingMetal working apparatusPositioning apparatusReciprocating motionStructural engineering

The invention relates to the technical field of guardrail machining equipment, and discloses a cutting device for iron art guardrail accessory machining, which comprises a fixed base, a guide rail plate is fixedly mounted at one end of the upper side of the fixed base, a guide groove is formed in the guide rail plate, a guide block is detachably mounted in the guide groove, and an abutting rod is rotatably mounted on the guide block. A horizontally-moving translation mechanism is mounted at the top of the abutting rod, a compensation block is in contact with the translation mechanism in the moving direction, a rotating cylinder rotationally arranged on the fixed base is fixed to the compensation block, a feeding mechanism is mounted on the side, away from the guide rail plate, of the upper side of the fixed base, and a cutting frame mounted on the fixed base is arranged in the feeding direction of the feeding mechanism. A power mechanism used for driving the lower pressing block to reciprocate is further installed on the upper side of the cutting frame. The invention further discloses a cutting method. According to the iron art guardrail accessory cutting device, the cutting requirement for iron art guardrail accessories of different lengths is met, meanwhile, effective depth cutting adjustment can be conducted on an iron art guardrail, and the cutting efficiency is further improved.

Owner:徐州科美瑞门窗科技有限公司

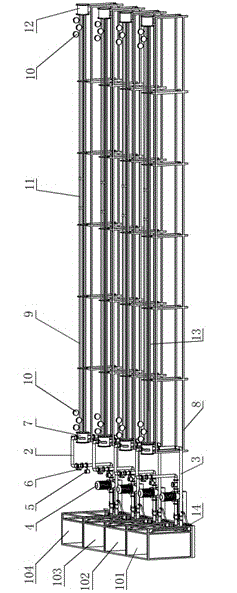

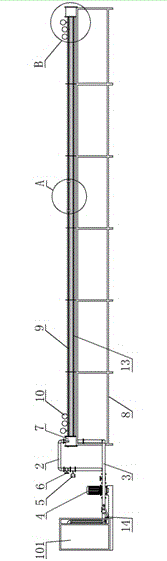

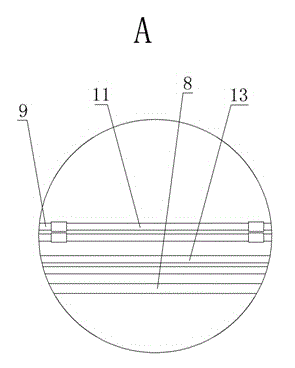

Logistics system

PendingCN114139921AImprove efficiencyGuaranteed continuityOffice automationResourcesLogistics managementConveyor belt

The invention discloses a logistics system which comprises an initial distribution center, a transfer distribution center, a target distribution center, a plurality of conveying pipelines, an unmanned freight vehicle, a transfer platform, a vertical freight elevator and an unloading platform. Objects are conveyed among the initial distribution center, the transfer distribution center and the target distribution center through conveying pipelines; objects are conveyed between the target distribution center and the transfer platform through a conveying pipeline or an unmanned freight vehicle. Articles are conveyed between the transfer platform and the unloading platform through a vertical cargo elevator; the conveying pipeline comprises a shell and a first conveying belt. The unmanned freight vehicle comprises a freight bin and a second conveyor belt; the transfer platform comprises a transfer bin and a third conveyor belt; the vertical goods elevator is arranged on the side edge of a balcony of a residential building and comprises a channel, a lift car and a fourth conveying belt. The unloading platform is arranged in the balcony and comprises an unloading bin and a fifth conveying belt. Automatic unmanned object conveying can be achieved by means of the conveying pipeline and all levels of conveying belts.

Owner:李金卫

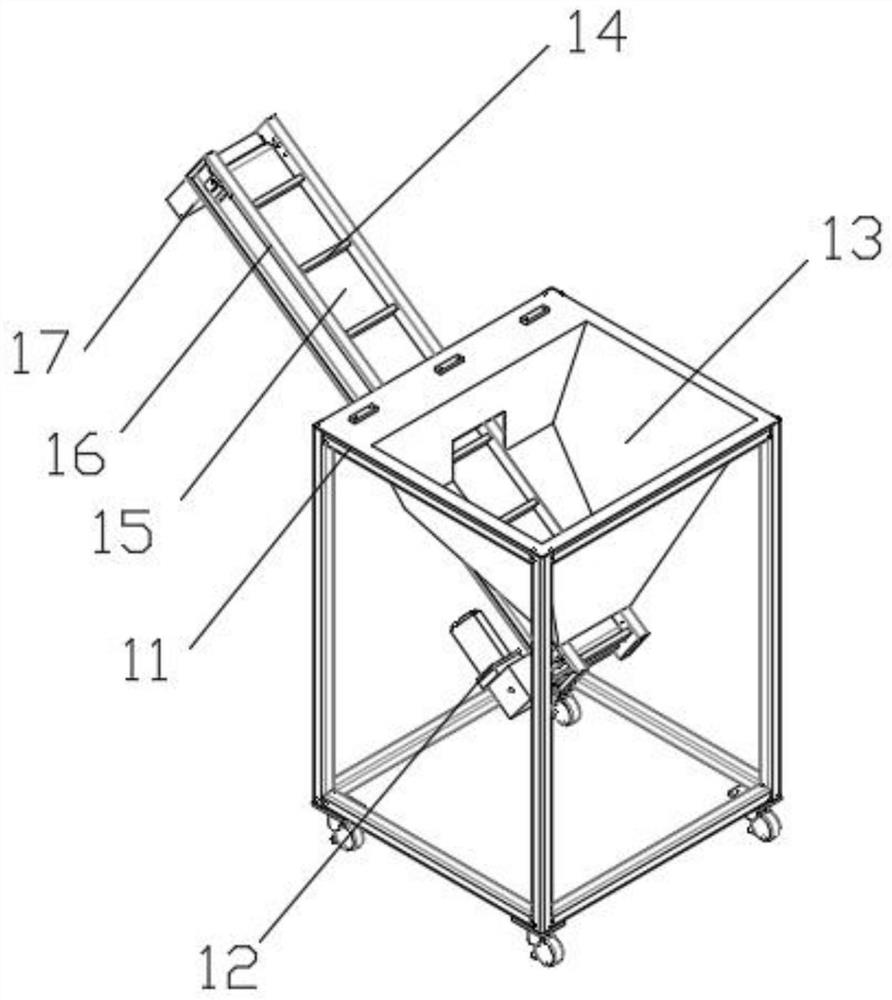

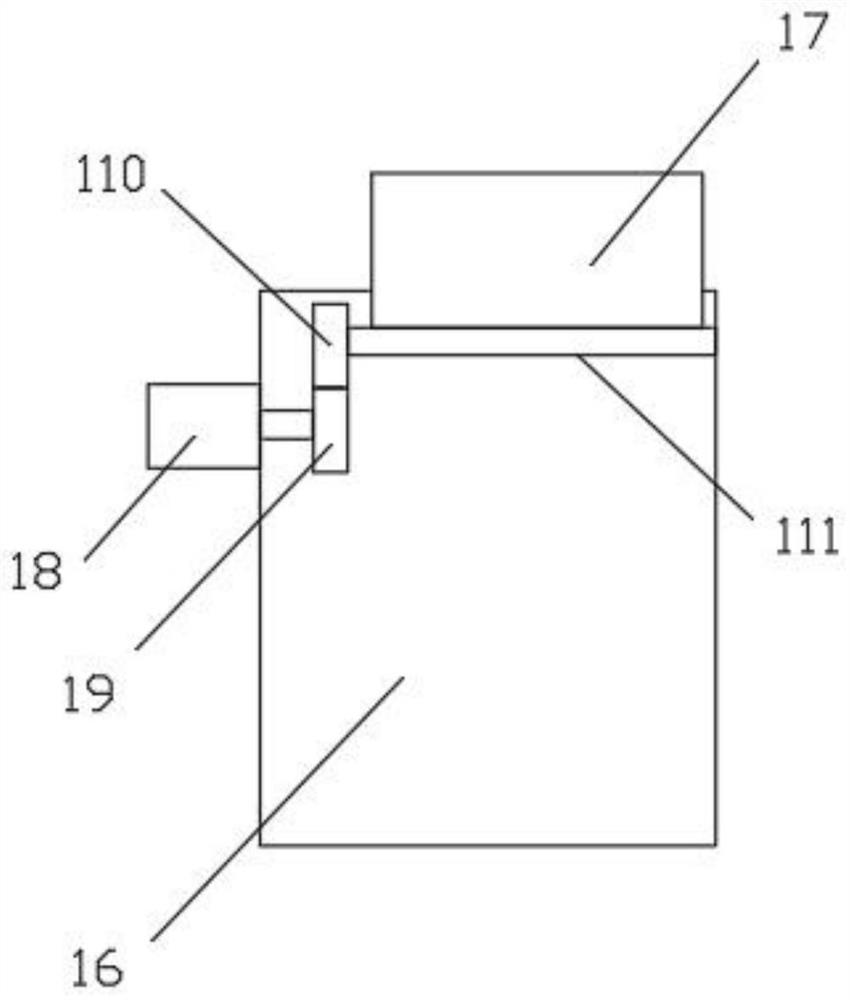

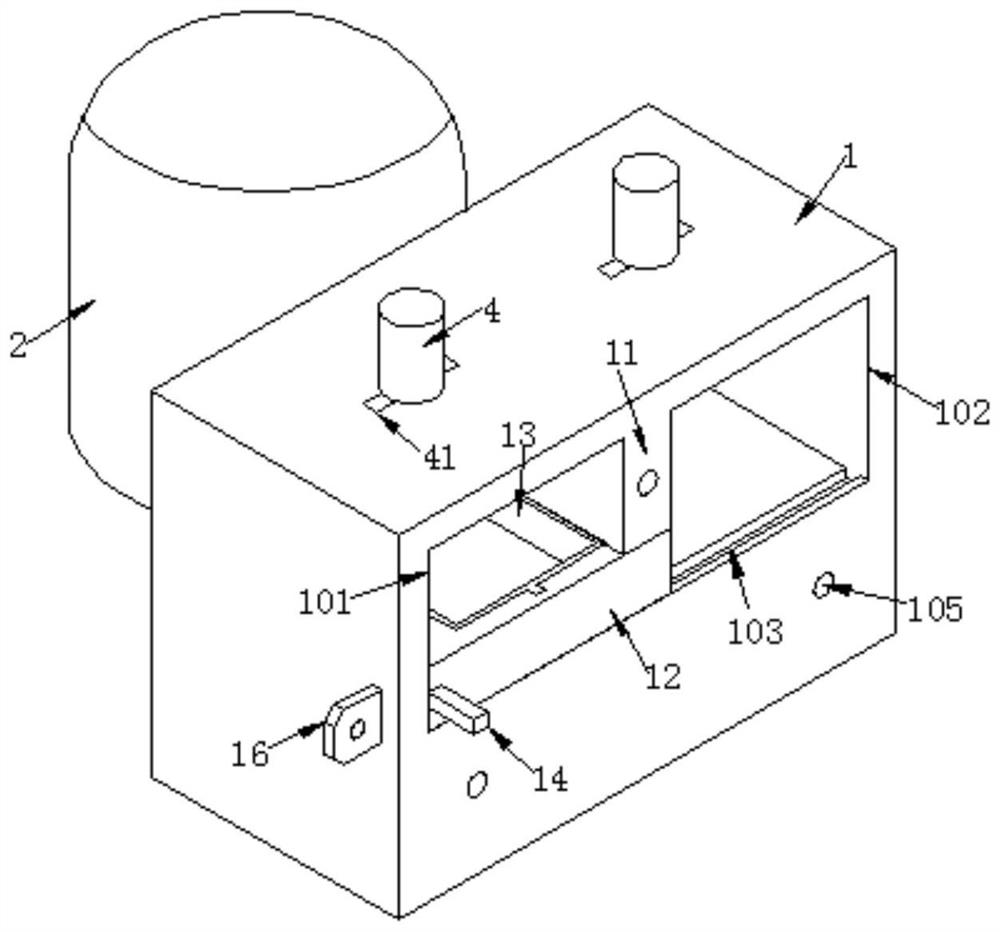

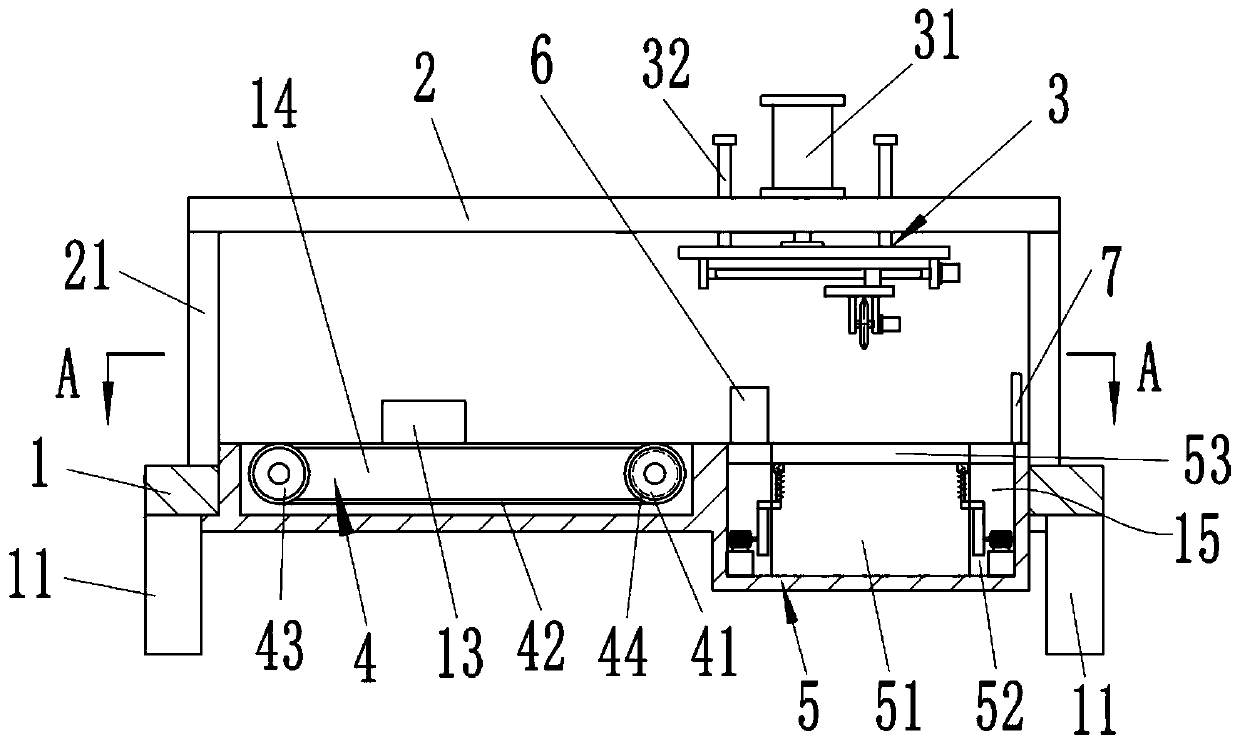

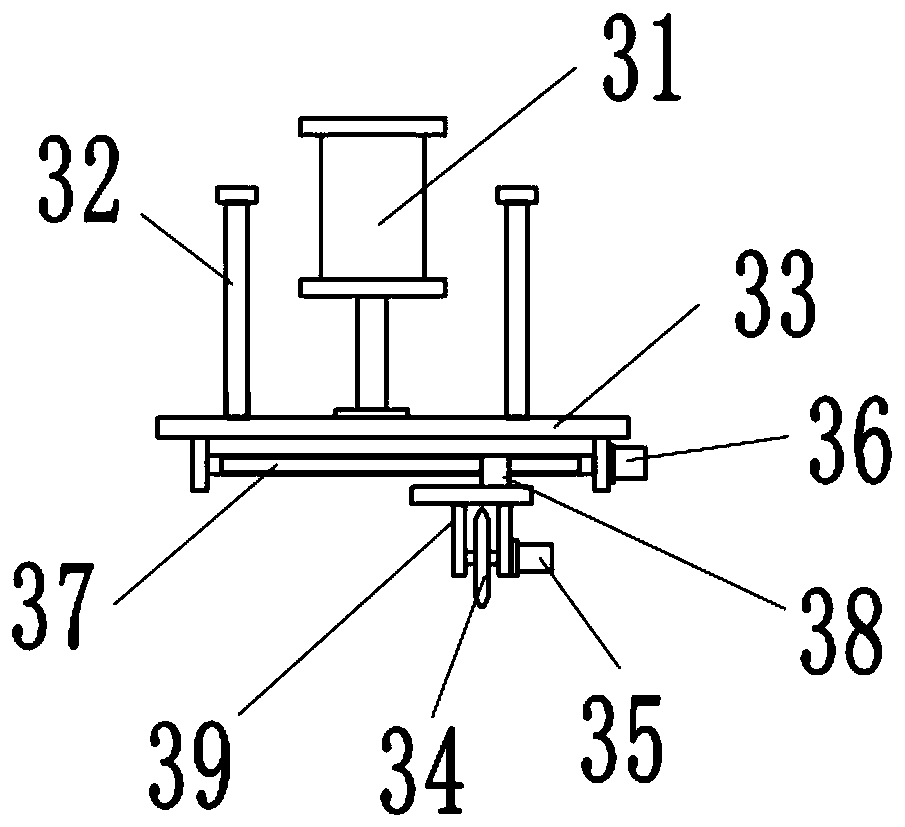

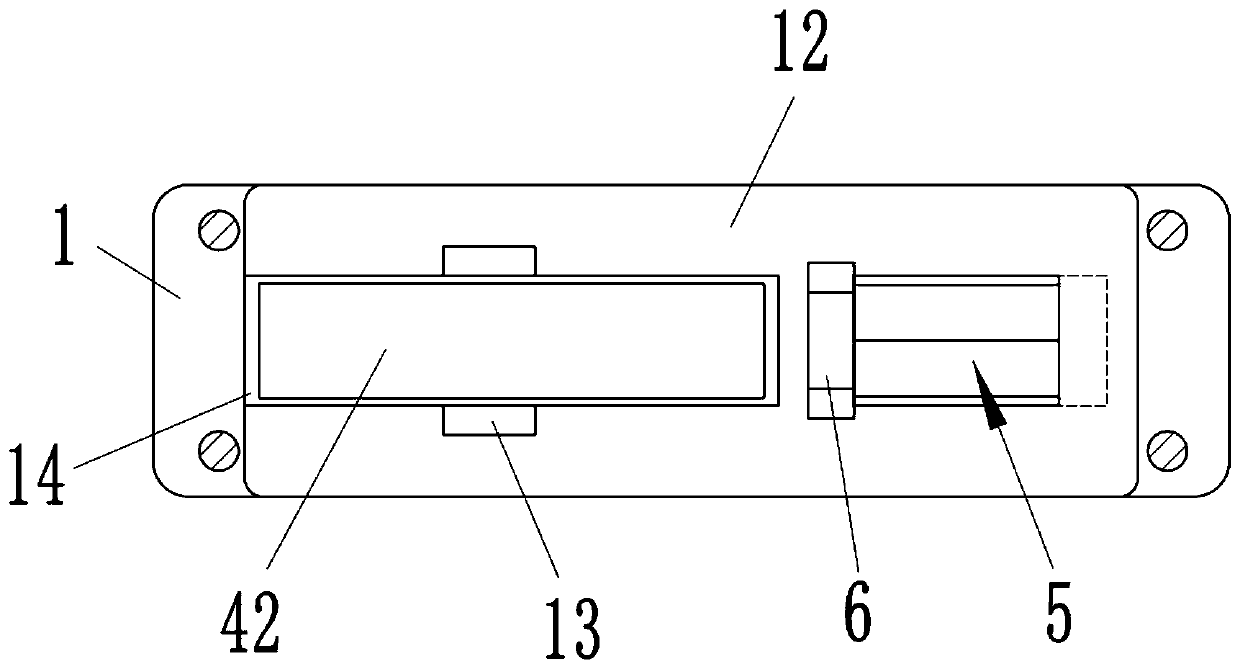

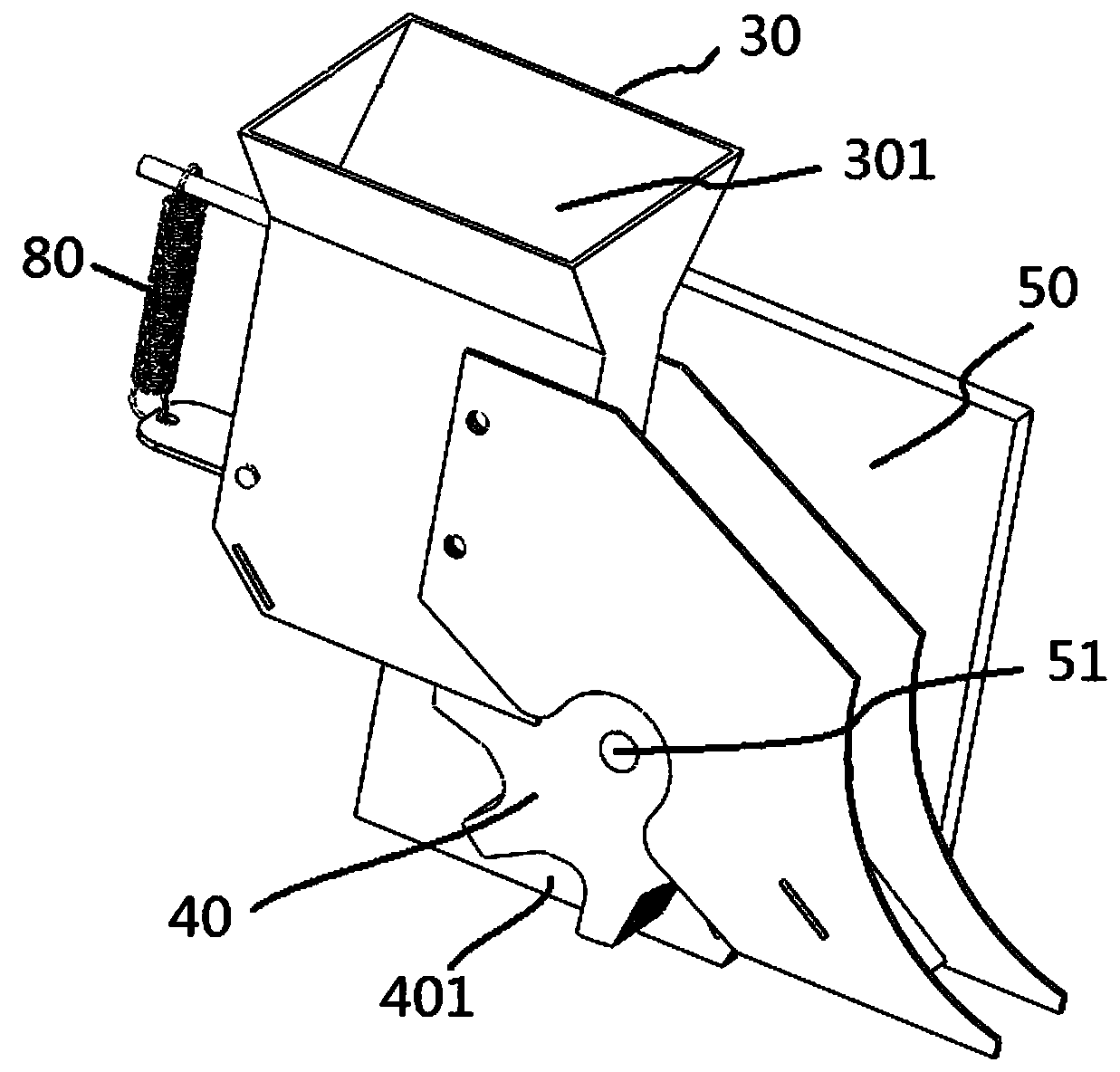

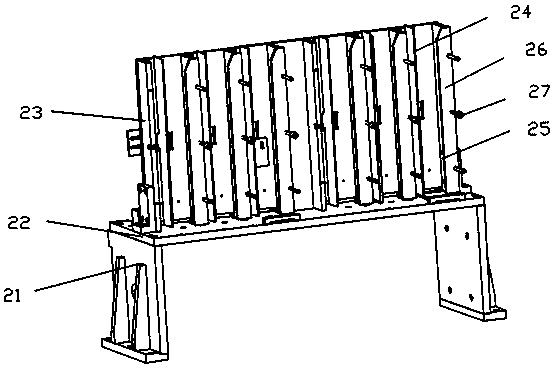

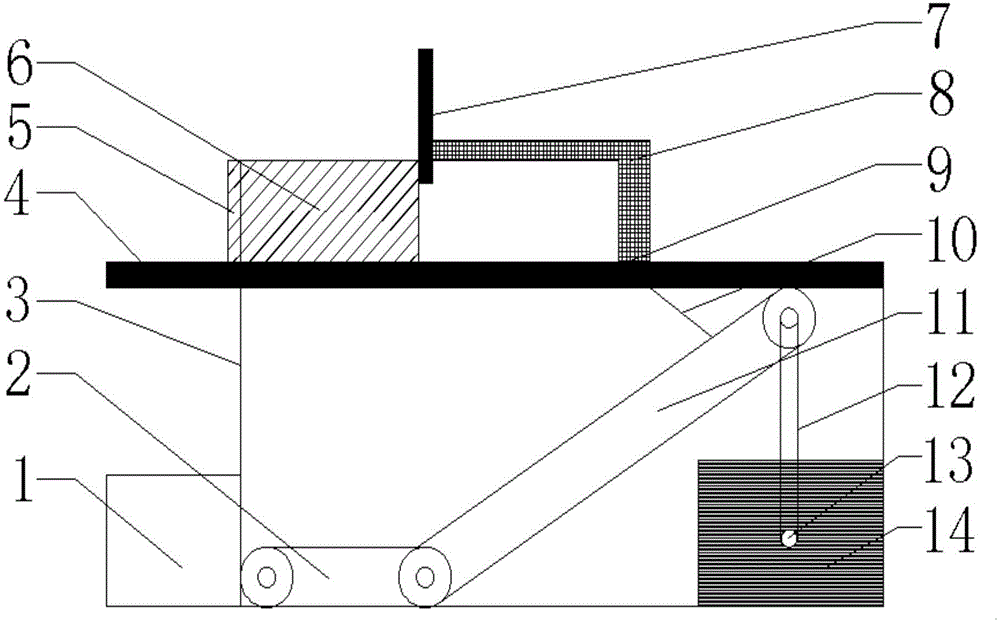

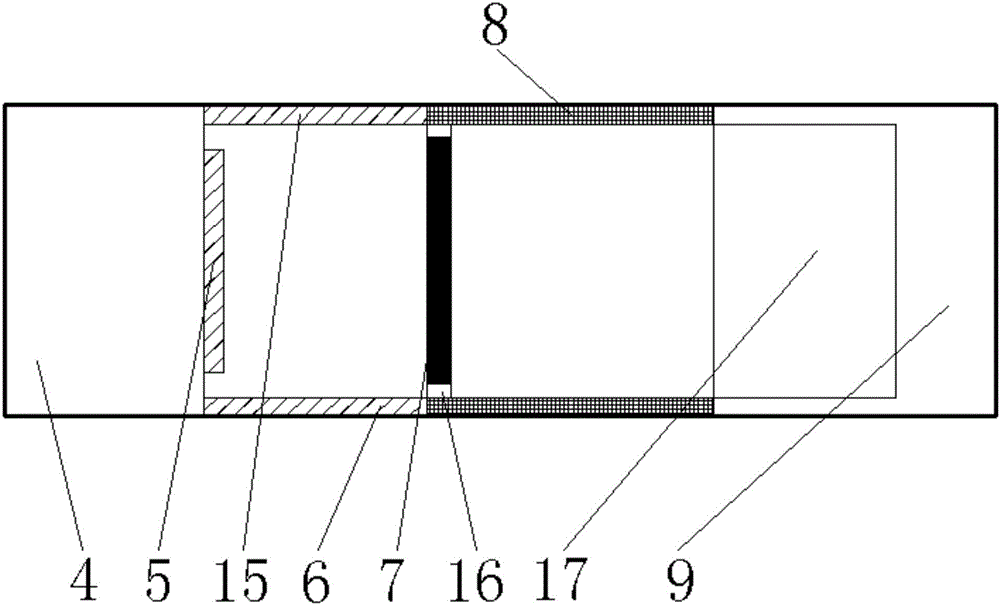

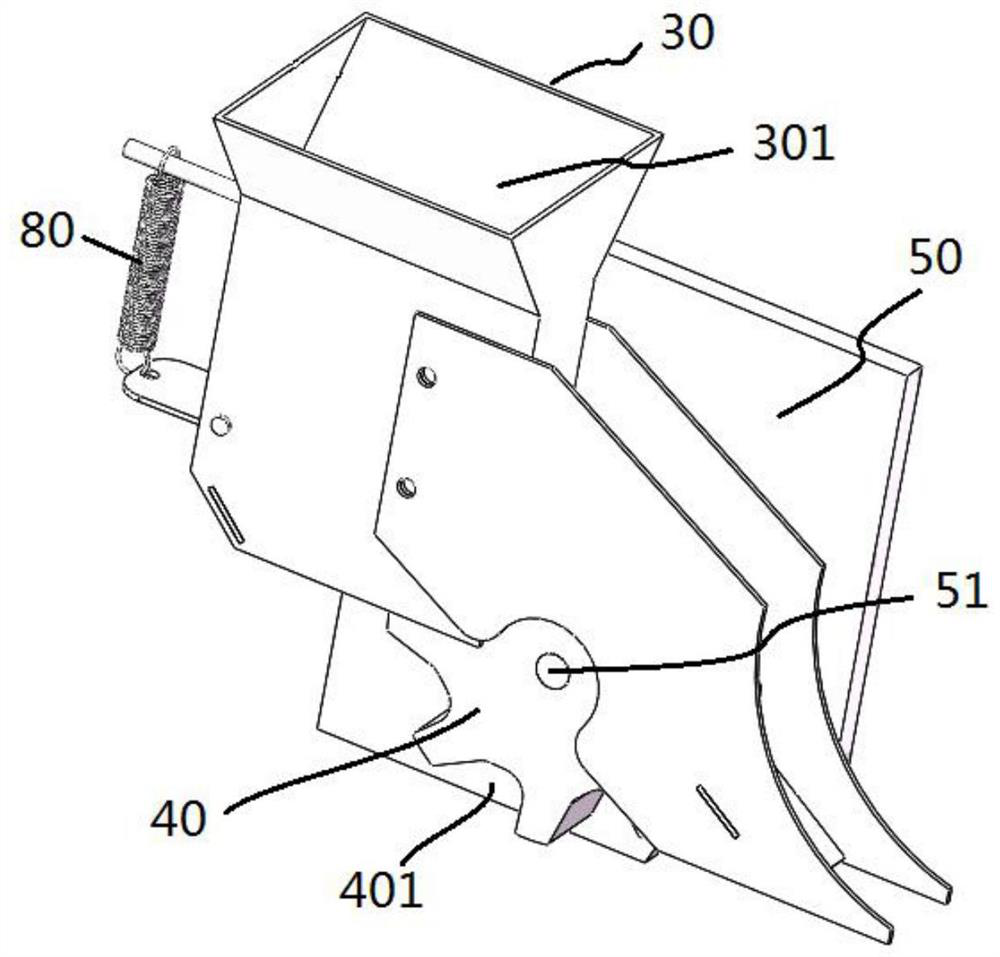

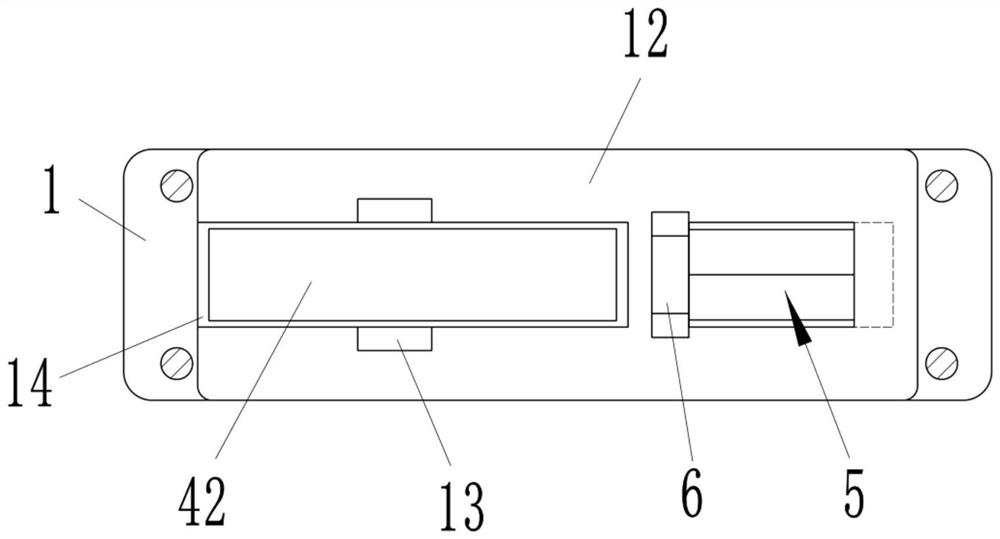

Article transfer assembly and processing device

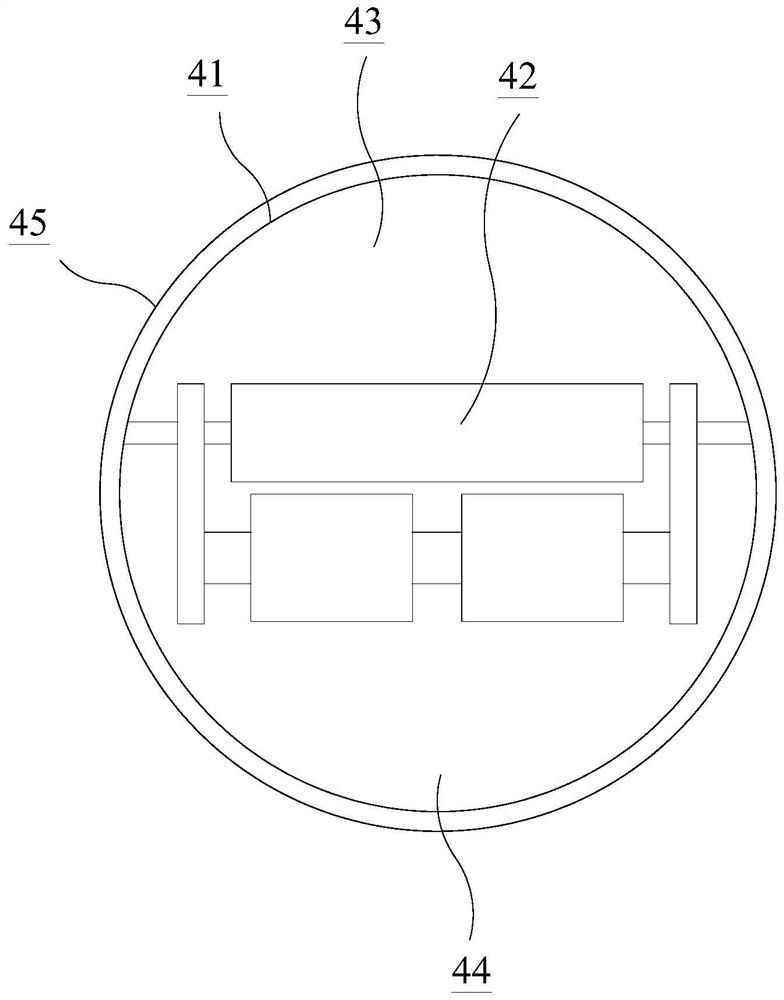

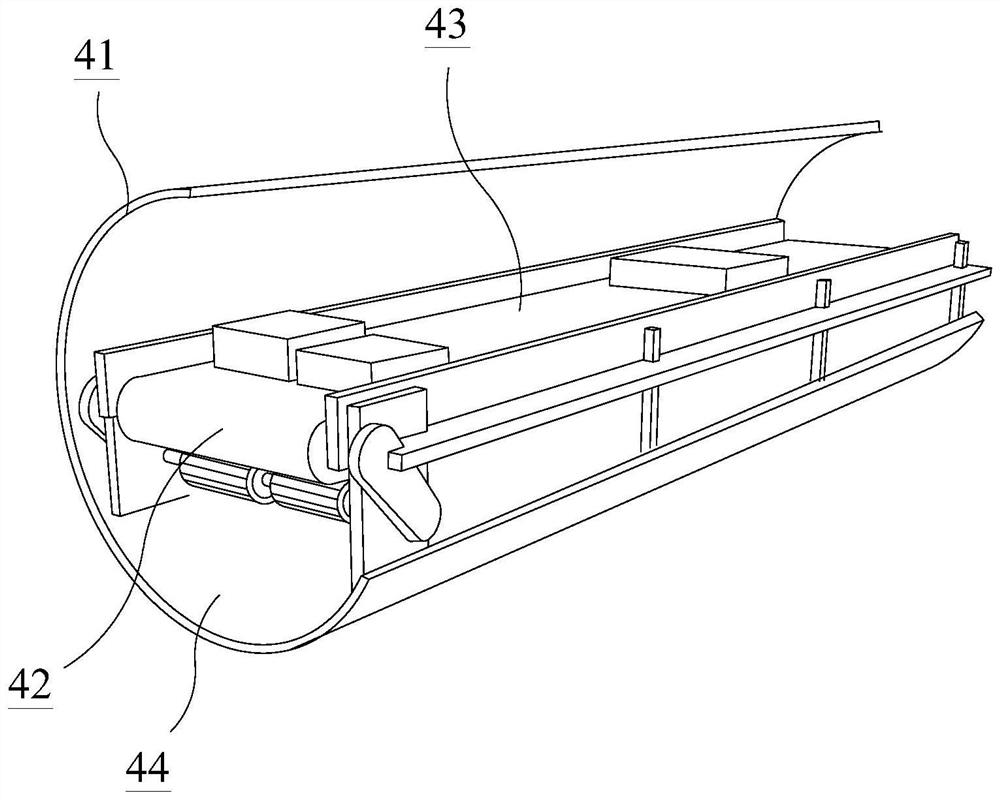

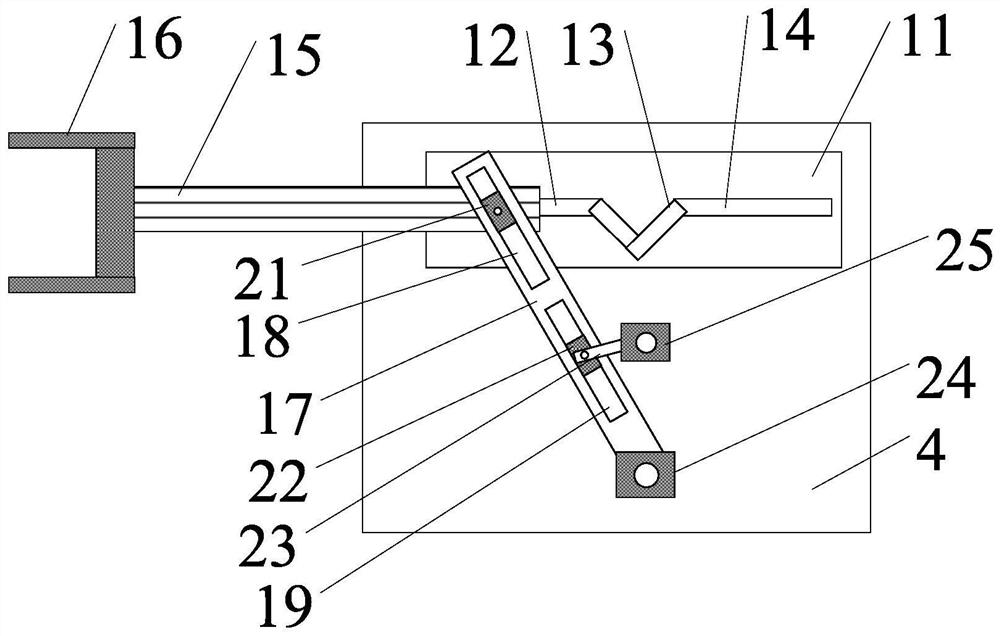

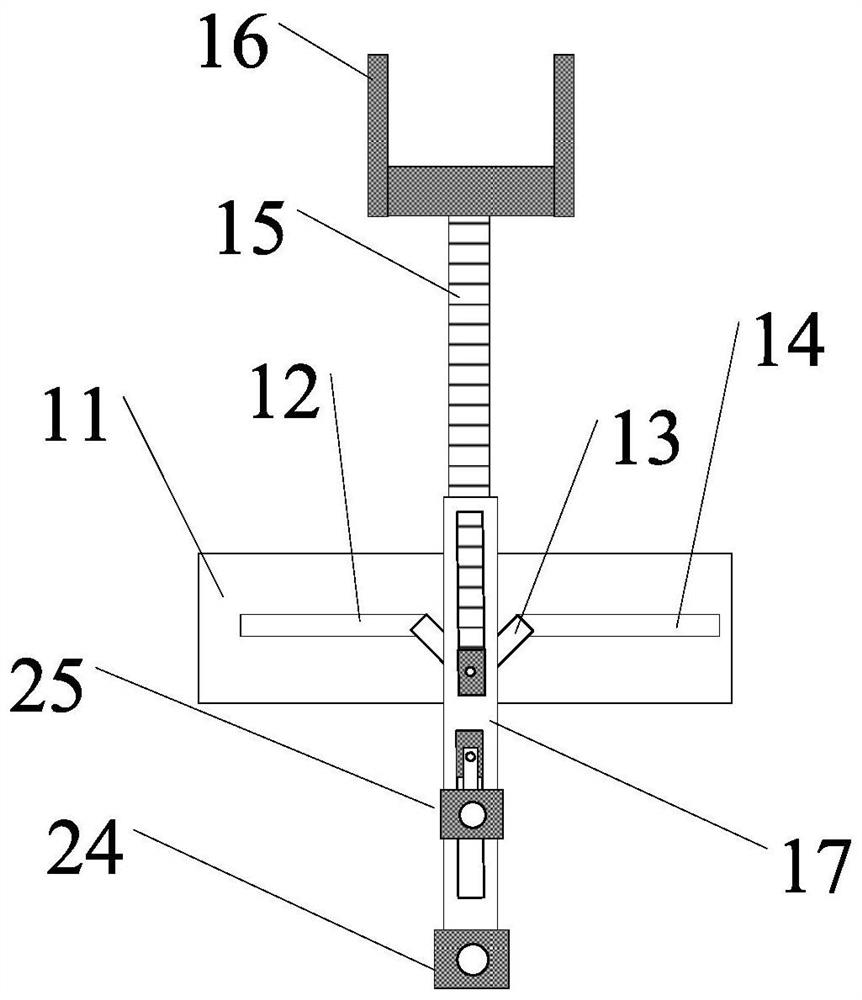

ActiveCN111453351AAvoid manual deliveryImprove processing efficiencyHuskingHullingEngineeringMechanical engineering

The invention discloses an article transfer assembly. The article transfer assembly comprises a support portion, a movable member and an execution unit, wherein the movable member is configured to cooperate with the support portion to form a first transfer space for transmitting an article, and the first transfer space is provided with a first position and a second position; and the execution unitis used for causing the movable member to move between the first position and the second position, when the movable member is in the first position, an external article can enter the first transfer space, and when the movable member is in the second position, the article located in the first transfer space can be prevented from being separated from the first transfer space. The article located within the first transfer space is capable of moving along the first transfer space under the action of gravity, the movable member or / and the support portion. According to the article transfer assembly, the lotus seeds can be effectively processed.

Owner:江西鲜莲设备制造有限公司

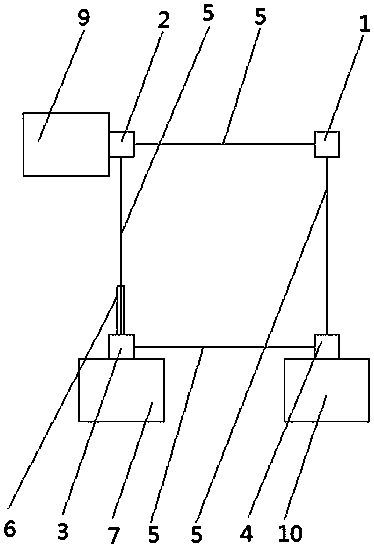

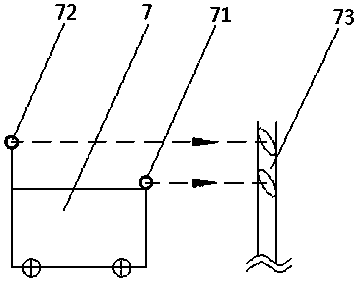

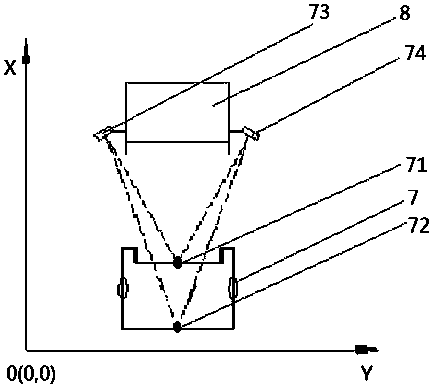

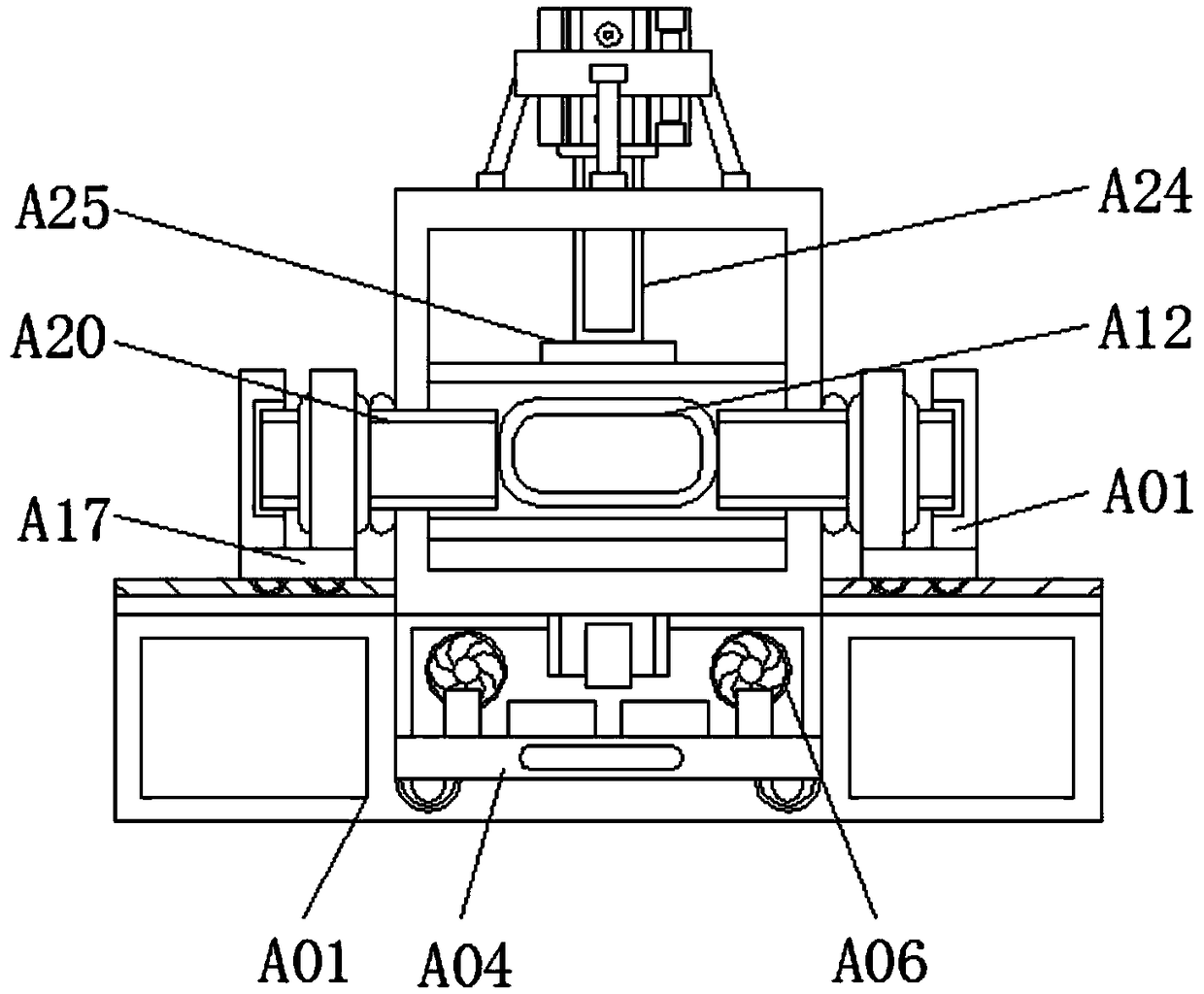

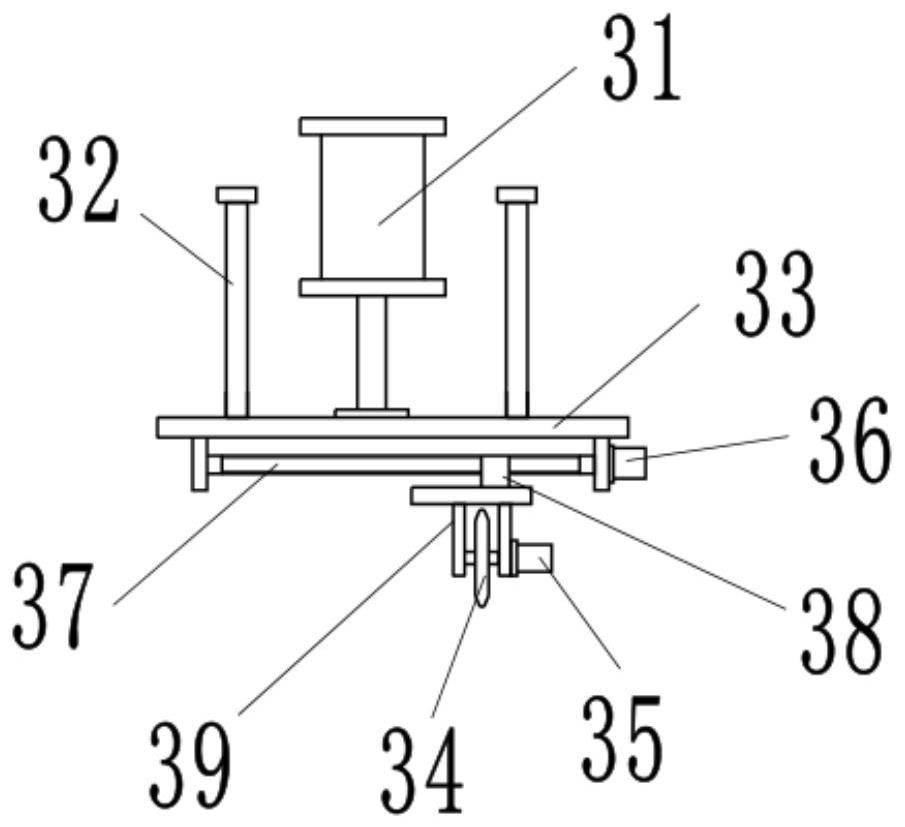

Warping machine warp beam transfer robot and control method thereof

InactiveCN108189045AStable removalRealize automated productionProgramme-controlled manipulatorButt jointNavigation system

The invention discloses a warping machine warp beam transfer robot and a control method thereof. The problems that in the prior art, for the warping machine warp beam replacement process, the efficiency is low, the labor intensity of workers is large and potential safety hazards exist are solved. The working point positions of the warping machine warp beam transfer robot comprise a standby charging position, a hollow shaft taking position, a warping machine front butt joint position and a full shaft storage position; an electromagnetic navigation system and a laser positioning system are usedfor guiding the warping machine warp beam transfer robot to move between all the working point positions, and the movement sequence of the warping machine warp beam transfer robot comprises five stepsof hollow shaft taking, hollow shaft sending, full shaft replacing, full shaft storage and standby charging. The warping machine warp beam transfer robot has the advantages that the movement steps are simple, the operation sequence is reasonable, the automatic operation is realized, and the warp beam replacement efficiency is directly improved; and the control method is accurate and reliable, sothat rapid replacement and storage of the warping machine warp beam is realized.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Chinese medicine slicer

Owner:昌乐县人民医院

Small-sized track plate grooving equipment

ActiveCN110449748AAvoid manual deliveryImprove work efficiencyLaser beam welding apparatusAutomatic controlBiochemical engineering

Owner:常州欧爱欧履带有限公司

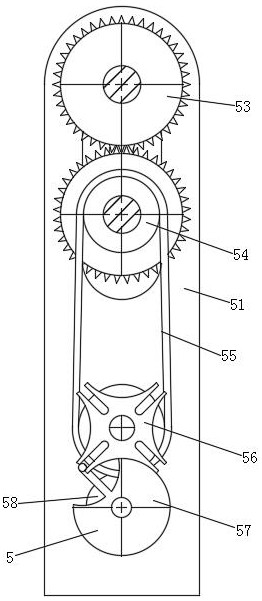

Feed feeding device for animal husbandry

InactiveCN109169324BEasy to carryEasy to moveNon-rotating vibration suppressionAnimal feeding devicesAnimal scienceGear wheel

The invention discloses a feed feeding device for animal husbandry, which comprises a base, wherein the base is internally provided with a first cavity, the first cavity is internally provided with afirst gear, both sides of the first gear are provided with a second gear, the first gear is meshed with the second gears, the middle of the first gear is provided with a first rotating shaft in a penetrating manner, one end of the first rotating shaft penetrates through the bottom of the base and is connected with the output end of a first motor, the middle of each second gear is provided with a second rotating shaft in a penetrating manner, one end of each second rotating shaft penetrates through the top of the base and extends upward, the other end of each second rotating shaft is provided with a bearing pedestal, each bearing pedestal is connected with the base at the end away from the corresponding second rotating shaft, and one side of the base is provided with a first supporting plate. The beneficial effects are that the carrying of feed is facilitated, a lot of labor and time are saved at the same time, the adjustment for the height is facilitated, resources are greatly saved, and the working efficiency is greatly improved.

Owner:嘉兴大力精密紧固件股份有限公司

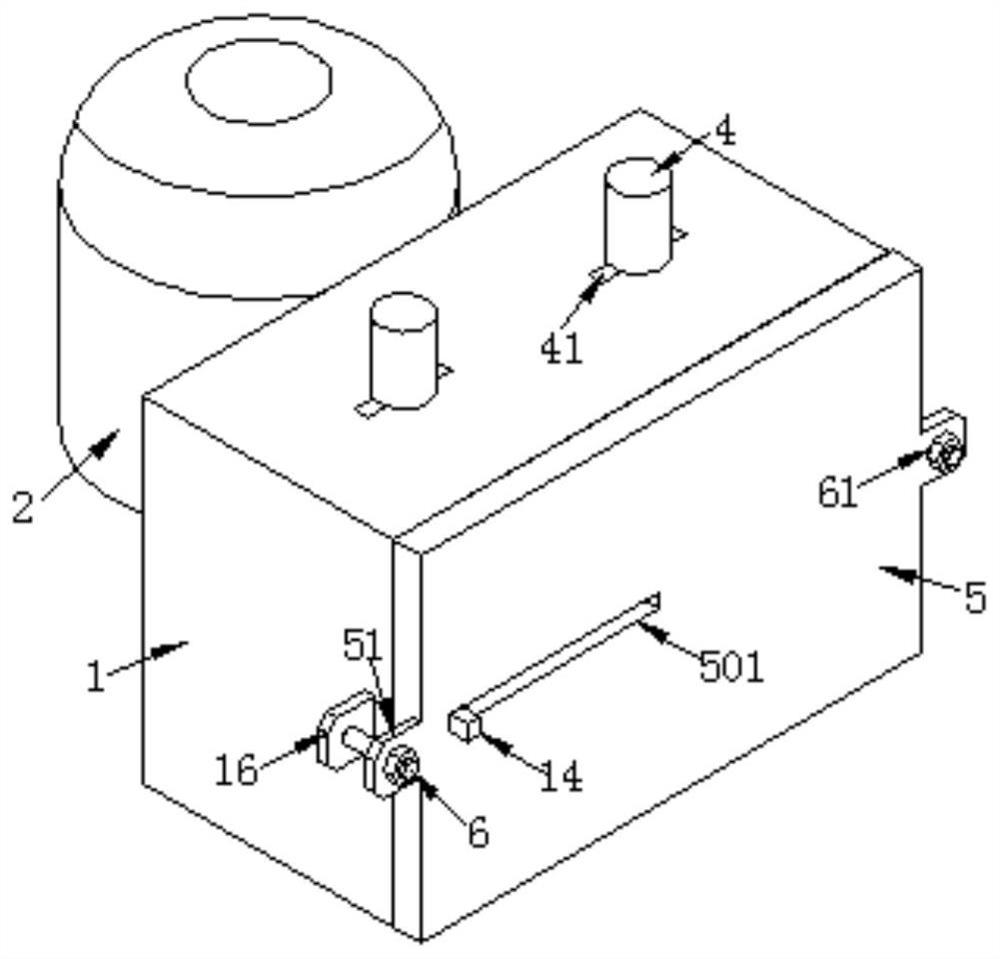

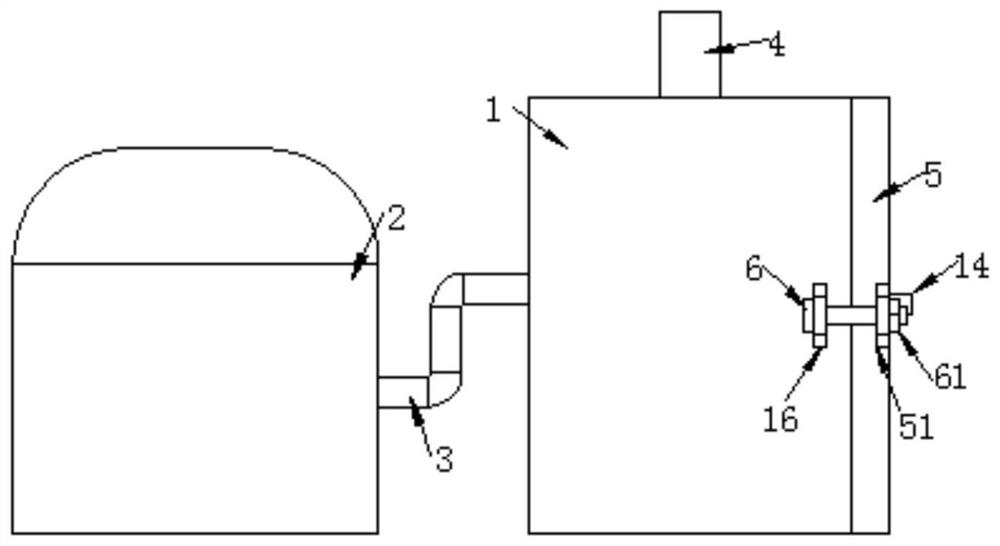

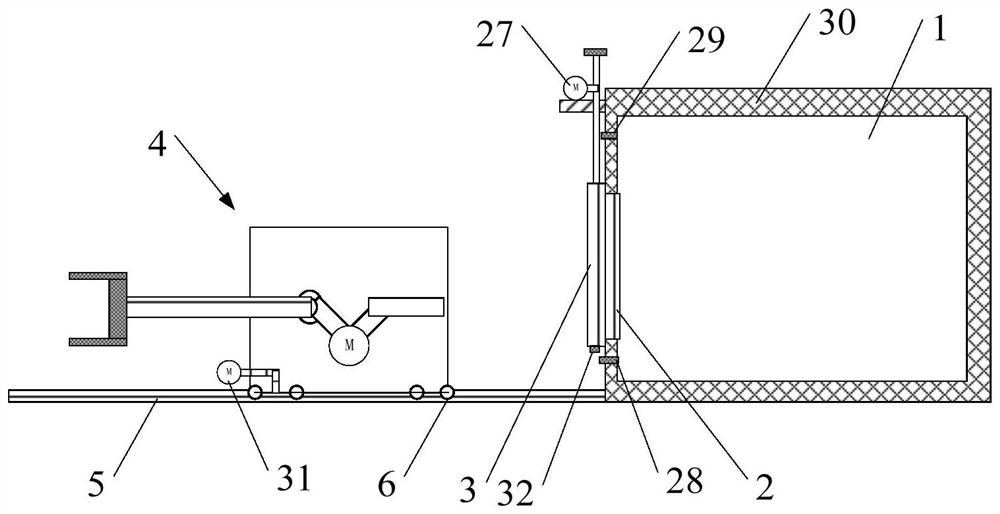

a heat treatment furnace

ActiveCN110438323BSmooth temperature changeAvoid manual deliveryFurnace typesHeat treatment process controlEngineeringMechanical engineering

The invention provides a novel heat treatment furnace. A furnace opening is formed in one side of a heat treatment furnace body, a lifting furnace door is arranged on the furnace opening, the liftingfurnace door is connected with a lifting driving device, a hub conveying picking placing device is arranged on the furnace opening, the hub conveying picking placing device is provided with a pickingand placing mechanism, a rail is arranged on the bottom of the hub conveying picking placing device, and extends to the furnace opening, a wheel set matched with the rail is arranged on the bottom ofthe hub conveying picking placing device, and is connected with a moving driving device, the picking and placing mechanism achieves conveying of hubs in the heat treatment process and before and afterheat treatment, manual conveying is avoided, in the transmission process, the heat treatment furnace does not need to be cooled, hub picking and placing can be achieved, the temperature change in thefurnace is stable, and energy consumption is reduced. A sensor is arranged, on the basis of the actual needs, the lifting height of the lifting furnace door can be arranged, the cooling amount of theheat treatment furnace can be reduced, and the heat treatment effect and the process stability and durability are prevented from being affected.

Owner:BINZHOU DAISEN WHEEL TECH CO LTD

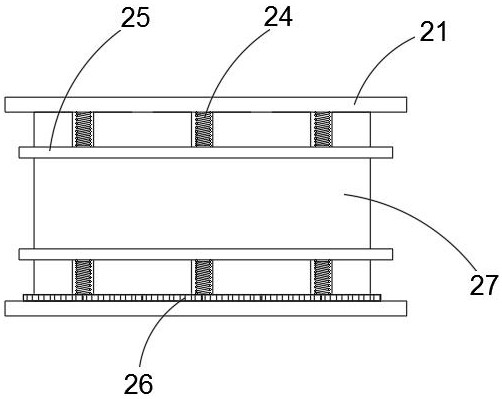

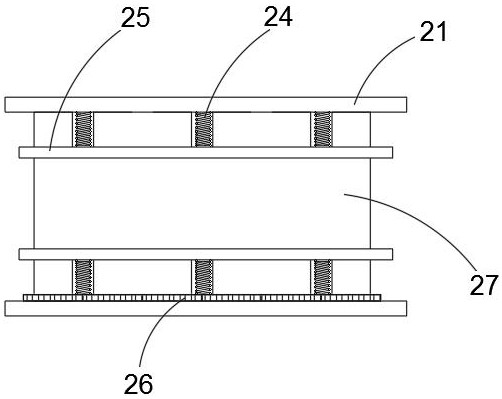

Glass fiber compressing device with ejection structures

The invention discloses a glass fiber compressing device with ejection structures. The glass fiber compressing device comprises a base, a storage tank, a discharge outlet and a support. First slide rails are arranged on the upper surface of the middle of the base, first pulleys are mounted inside the first slide rails, a handle is mounted on a surface of the storage tank, the storage tank is positioned above the first pulleys, fans are mounted inside the storage tank, transmission shafts are connected with the rears of the fans, a mixing tank is arranged above the discharge outlet, a fixing platform is welded on the upper side of the support, and the support is positioned on the upper side of the mixing tank. The glass fiber compressing device has the advantages the ejection structures forglass fiber products have complete functions, good ejection effects can be realized, manual alignment can be omitted in procedures for pushing materials, and accordingly the ejection difficulty can be lowered; the ejection structures can be in a push-in mode and a push-out mode, the glass fiber compressing device is provided with the fans, the materials inside the storage tank can be cooled by the fans, and accordingly excessively high temperatures of processed materials can be prevented.

Owner:JIANGSU SHENXIANG ELECTROMECHANICAL

Slicer for preventing Poria cocos from being broken

InactiveCN106426362AAvoid manual deliverySimple structureMetal working apparatusElectric machineryKnife blades

Owner:张宇

An article conveying component and processing device

The invention discloses an article conveying assembly, comprising: a support part; a moving part, capable of cooperating with the support part to form a first conveying space for conveying the article, having a first position and a second position; an execution unit for causing the moving member to move between a first position and a second position, when the moving member is in the first position, external articles can enter the first conveying space; when the moving member is in the second position , which can prevent the item located in the first transmission space from leaving the first transmission space; wherein, the item located in the first transmission space can be controlled by its own gravity, the moving part or / and the Move along the first conveying space under the action of the supporting part. The invention can effectively process lotus seeds.

Owner:江西鲜莲设备制造有限公司

Noctilucent plastic product production equipment

InactiveCN112873621AMiscellaneous realizationRealize the filtering functionCoatingsElectric machineryHot melt

The invention provides noctilucent plastic product production equipment which comprises a plastic product forming machine body, a plastic mold cavity, a feeding opening, a feeding pipe, a ceramic sealing plug, a discharging door, a screw rod, an operating hand wheel, supporting legs, a workbench, a control panel, a raw material impurity filtering, melting and mixing hopper structure, a raw material melting peculiar smell antifouling treatment box structure, a self-restored product pushing rod structure and a manpower-free product conveyor belt structure. The plastic mold cavity is formed in the middle in the plastic product forming machine body, and threaded blind holes are formed in the left front side and the right front side of the middle of the interior of the plastic product forming machine body. As the noctilucent plastic hot melting hopper, the hot melting hopper cover, the limiting groove, the discharging valve, the raw material impurity filtering net, the operating hand lever, the hot melting plate, the packing auger and the mixing and stirring motor are arranged, impurity filtering, melting and stirring of plastic raw materials are achieved, so that the quality of processed plastic products is improved.

Owner:滨州市沾化区凯煌机械科技有限公司

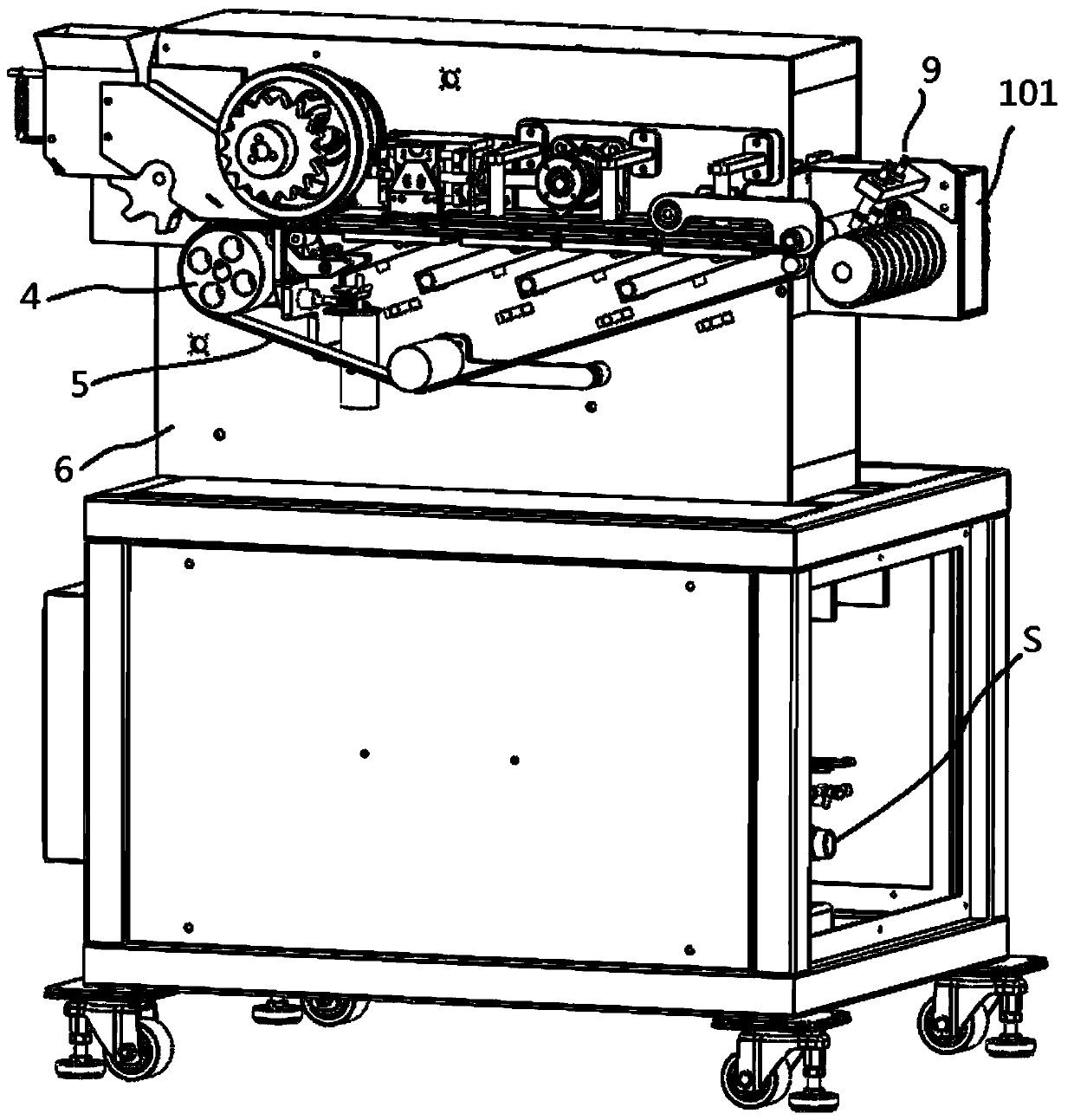

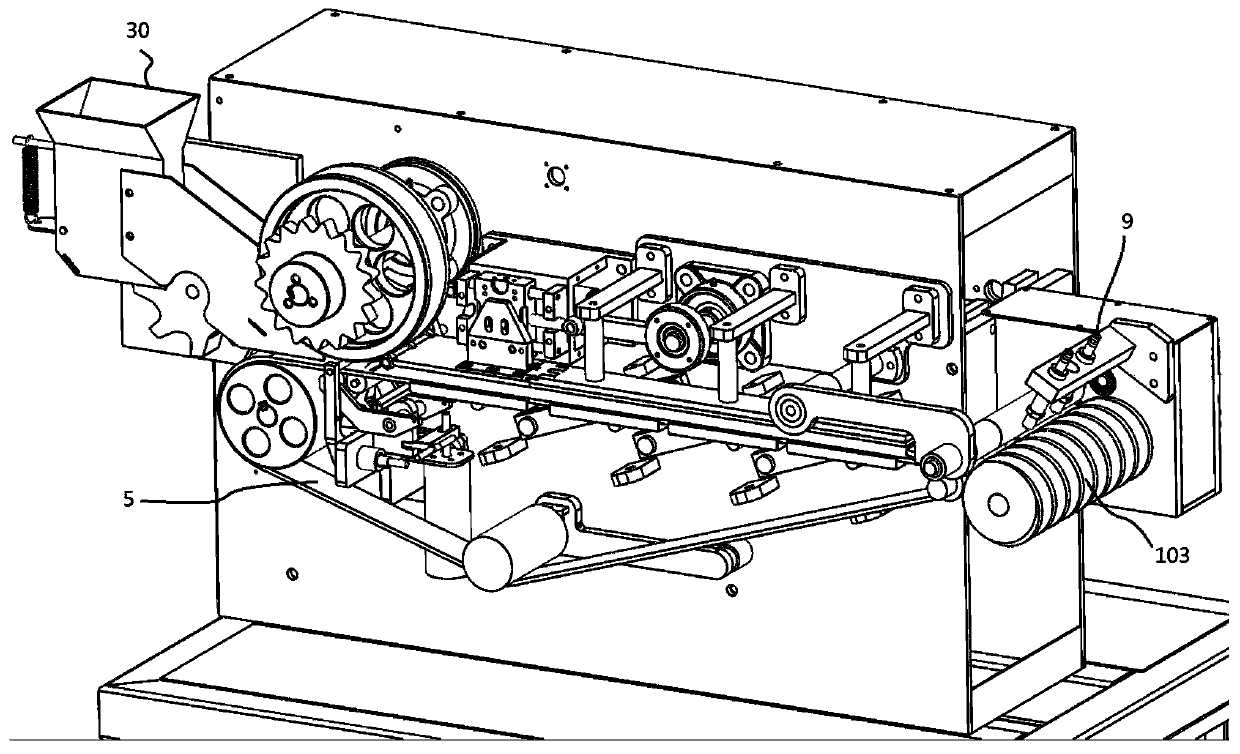

Refrigerator door sealing strip assembling machine for refrigerator assembling

The invention relates to the technical field of refrigerator accessory assembling, and discloses a refrigerator door sealing strip assembling machine for refrigerator assembling. The refrigerator doorsealing strip assembling machine comprises an assembling table, wherein supporting plates are fixedly arranged on the front side and the rear side of the upper end of the assembling table, conveyingbelt assemblies are arranged on the left side and the right side between the two supporting plates, supporting shafts are rotationally connected to the left side and the right side of the upper end ofthe assembling table through first rolling bearings, placing plates are fixedly arranged at the lower ends of the shaft walls of the two supporting shafts, and conveying mechanisms are arranged between the two supporting plates and located between the left and right sides of one conveying belt assembly and the right side of the other conveying belt assembly. The refrigerator door sealing strip assembling machine for refrigerator assembling can be used for conducting automatic assembling, greatly improves the production efficiency, reduces the labor amount of workers and can guide conveyed magnetic strips and jackets, thereby avoiding insertion failure caused by conveying deviation and being suitable for the magnetic strips and jackets with different widths and wide in application range.

Owner:CHUZHOU ASPIRE IND TECH

Internal twisted tape testing system

InactiveCN105628530AVerify availabilityVerify reliabilityWeather/light/corrosion resistanceMaterial thermal analysisEngineeringPerformance index

The invention discloses an internal twisted tape testing system. The system comprises four testing platforms, wherein each testing platform comprises a water tank, a flow dividing tank, a water inlet pipe, a water outlet pipe, a circulating pump, a flow meter, a pressure valve, a bracket, a testing pipe, pressure gauges, an observation pipe, a return tank and a return branch pipe; the circulating pumps, the flow meters and the pressure valves are mounted on the water inlet pipes; an internal twisted tape is mounted in each testing pipe; the water tanks are used for accommodating a medium for simulating environment; the observation pipes are mounted on the testing pipes; the pressure gauges are mounted at the two ends of the testing pipes and on the flow dividing tanks; the medium sequentially passes through the water tanks, the water inlet pipes, the flow dividing tanks, the testing pipes, the return tanks, the return branch pipes, the flow dividing tanks, the water outlet pipes and the water tanks under the action of the circulating pumps, so as to form circulating flow in the testing platforms and further simulate the real service environment of the internal twisted tapes. According to the internal twisted tape testing system, after testing, the performance indexes of products are tested and the reliability of the system in a practical environment is verified, so that a real and reliable data support is provided for product production.

Owner:CHONGQING HUANJI LOW CARBON ENERGY SAVING TECH DEV

Blanking die

InactiveCN112246957AEasy to fixPrevent rolloverMetal-working feeding devicesPositioning devicesConfined spaceMechanical engineering

The invention relates to the field of blanking dies, in particular to a blanking die. The blanking die comprises a main body, a placement mechanism, a replacement mechanism, a stamping mechanism, a delivery mechanism and a storage mechanism. An iron coil can be conveniently fixed to the limiting position through the arrangement of the placement mechanism, so that the iron coil in use is preventedfrom rolling over, smooth operation is guaranteed, mold components can be conveniently and rapidly replaced through the arrangement of the replacement mechanism, and tedious steps during traditional replacement are avoided; through the arrangement of the stamping mechanism, die parts in the mechanism are stamped and replaced synchronously at the intermittent time of the delivery mechanism, the delivery efficiency is improved; through the arrangement of the delivery mechanism, raw materials can be automatically delivered in cooperation with the blanking interval of the stamping mechanism, so that manual delivery is avoided, industrial accidents are reduced, and the production cost is reduced; and through the arrangement of the storage mechanism, blanked materials can be conveniently and evenly placed in the storage component, the situation that the materials which are stacked in an unbalanced manner occupy the limited space of the storage component is avoided, and therefore the using effect of the main body is improved.

Owner:杭州心杨科技有限公司

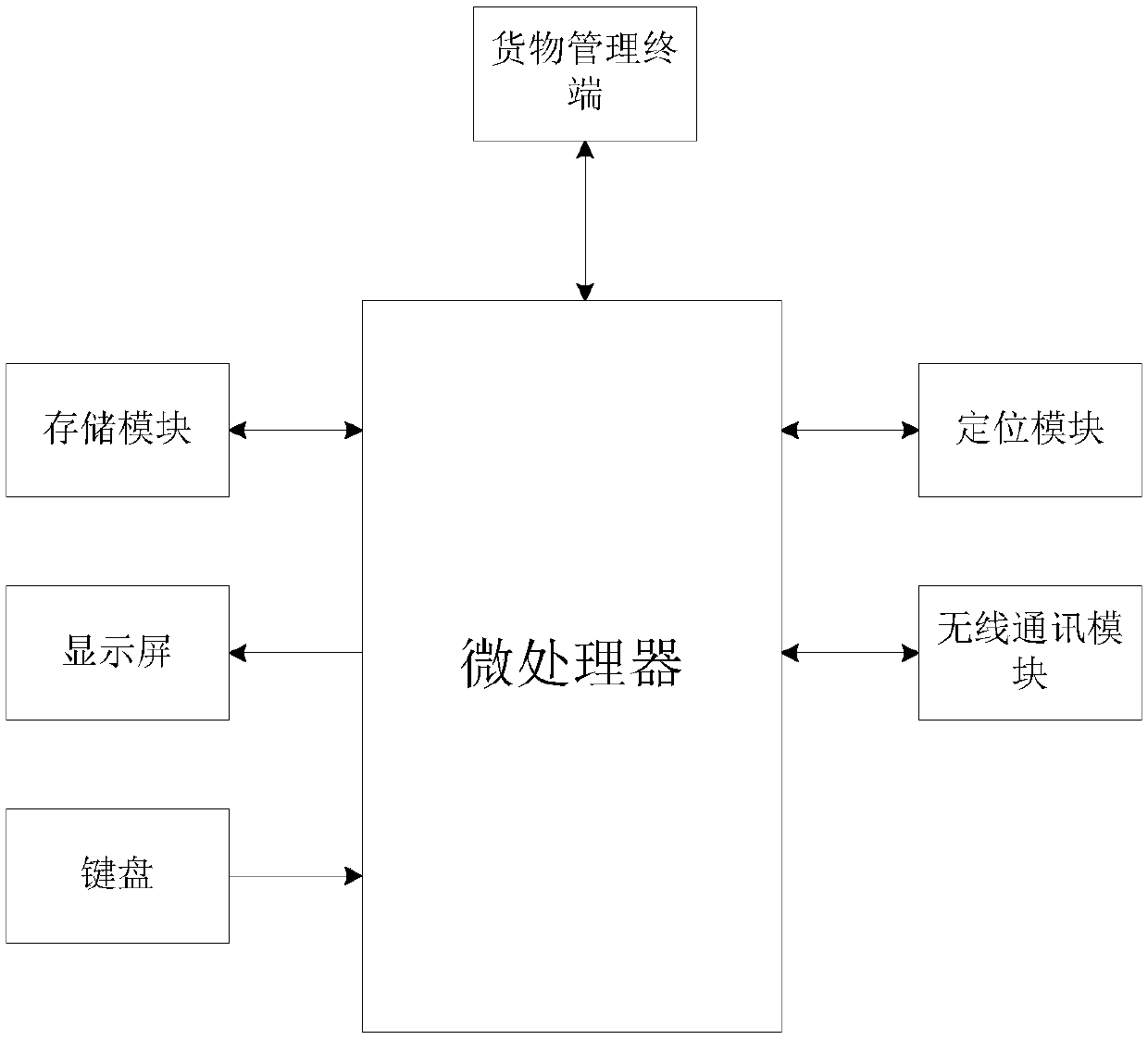

Goods delivery mechanism used for delivery of small-piece commodities

InactiveCN107679812AAvoid accidental injuryRelieve stressFreight handlingLogisticsSystems managementComputer module

The invention discloses a goods delivery mechanism used for delivery of small-piece commodities. The mechanism includes an unmanned aerial vehicle, a goods storage box, a wireless communication module, a storage module, a display screen, a keyboard, a locating module and a microprocessor. The display screen is used for receiving and displaying information sent out by the microprocessor. The keyboard is used for inputting information by a user, and transmitting the information to the microprocessor. The locating module is used for collecting location information, and transmitting the location information to the microprocessor. The storage module is used for receiving and storing information sent out by the microprocessor. The wireless communication module is used for receiving information sent out by the microprocessor, and transmitting the information to a goods delivery system management platform. The microprocessor is used for receiving the information input by the user, and controlling the goods storage box to be opened, is used for receiving the location information, and transmitting the same to the goods delivery system management platform, and is used for storing the information, and transmitting the stored information to the goods delivery system management platform. Occurrence of accidental injuries to distribution personnel in processes of artificial distribution is avoided.

Owner:CHONGQING RENTENG TECH

A high-efficiency plastic pipe cutting machine

ActiveCN110370339BPromote accumulationEasy to take awayMetal working apparatusElectric machineryStructural engineering

The invention provides an efficient plastic pipe cutting machine. The efficient plastic pipe cutting machine comprises a machine platform, a mounting frame, a cutting mechanism, a conveying mechanism,a collection device and a clamping mechanism, wherein the mounting frame is arranged on the machine platform; the cutting mechanism is arranged on the lower side of the mounting frame; the cutting mechanism comprises a cutting wheel, a lifting mechanism for driving the cutting wheel to lift, a transverse motion mechanism for driving the cutting wheel to move transversely, and a first motor for driving the cutting wheel to rotate; the conveying mechanism is used for conveying to-be-cut plastic pipes; the collection device comprises two driving mechanisms which are respectively arranged at twoends of a sinking cavity, and a pair of movable panels which are hinged at the upper end of the sinking cavity; and the driving mechanisms are used for driving the movable panels to be opened and closed. The efficient plastic pipe cutting machine provided by the invention is capable of solving the technical problem that the existing plastic pipe cutting machines are high in labor intensity and lowin cutting efficiency.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Traditional Chinese medicine slicing machine

ActiveCN114083605AReduce breakageAvoid positionMetal working apparatusMedicinal herbsMechanical engineering

The invention discloses a traditional Chinese medicine slicing machine, belongs to the field of traditional Chinese medicine production and processing, and mainly aims at strip-shaped or rod-shaped traditional Chinese medicine. The slicing machine comprises a first base plate, the upper portion of the first base plate is connected with a conveying assembly through a vertically-arranged first supporting frame, and a feeding assembly is arranged at the feeding end of the conveying assembly; a cutting supporting table and a cutting assembly correspondingly matched with the cutting supporting table are arranged at the discharging end of the conveying assembly, a first limiting assembly and a second limiting assembly which are used for pressing materials are arranged above the conveying assembly, and the second limiting assembly is arranged above a discharging end opening of the conveying assembly. According to the traditional Chinese medicine slicing machine, the limiting assembly is arranged, a two-stage cutting mode is adopted, the cutting process is stable and efficient, powder is not prone to being generated, the medicinal material breakage rate is low, and obtained medicinal material slices are uniform in thickness and good in condition.

Owner:昌乐县人民医院

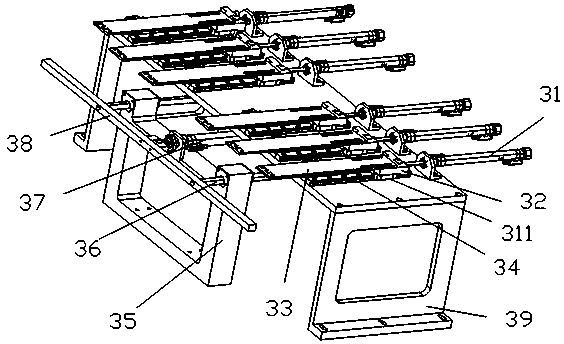

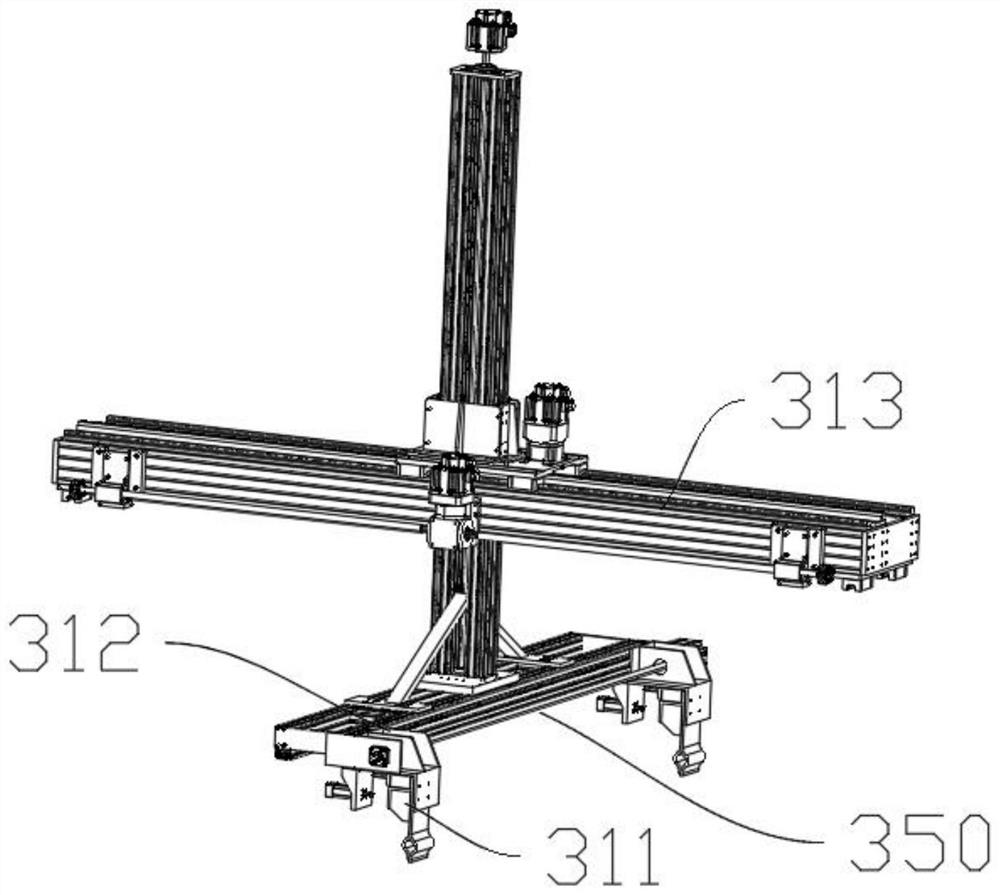

Longitudinal bar feeding assembly

PendingCN114798990AReasonable structureAvoid manual deliveryWire networkMechanical engineeringTemporary storage

The invention discloses a longitudinal bar feeding assembly which comprises a rack, a longitudinal bar temporary placing frame, a longitudinal bar gripper used for gripping longitudinal bars on the longitudinal bar temporary placing frame, a bearing platform used for placing stirrup material boxes, a longitudinal bar catcher and a longitudinal bar head end fixing piece. The longitudinal bar gripper, the bearing platform, the longitudinal bar catcher and the longitudinal bar head end fixing piece are sequentially arranged in the longitudinal bar conveying direction, and the longitudinal bar temporary placing frame, the longitudinal bar gripper, the bearing platform, the longitudinal bar catcher and the longitudinal bar head end fixing piece are all connected with the rack. The longitudinal bar feeding assembly is reasonable in structure, the requirement for the position of the longitudinal bar temporary storage frame is low, longitudinal bars on the longitudinal bar temporary storage frame can be fed, manual operation is reduced, and the production efficiency is improved.

Owner:中国核工业电机运行技术开发有限公司

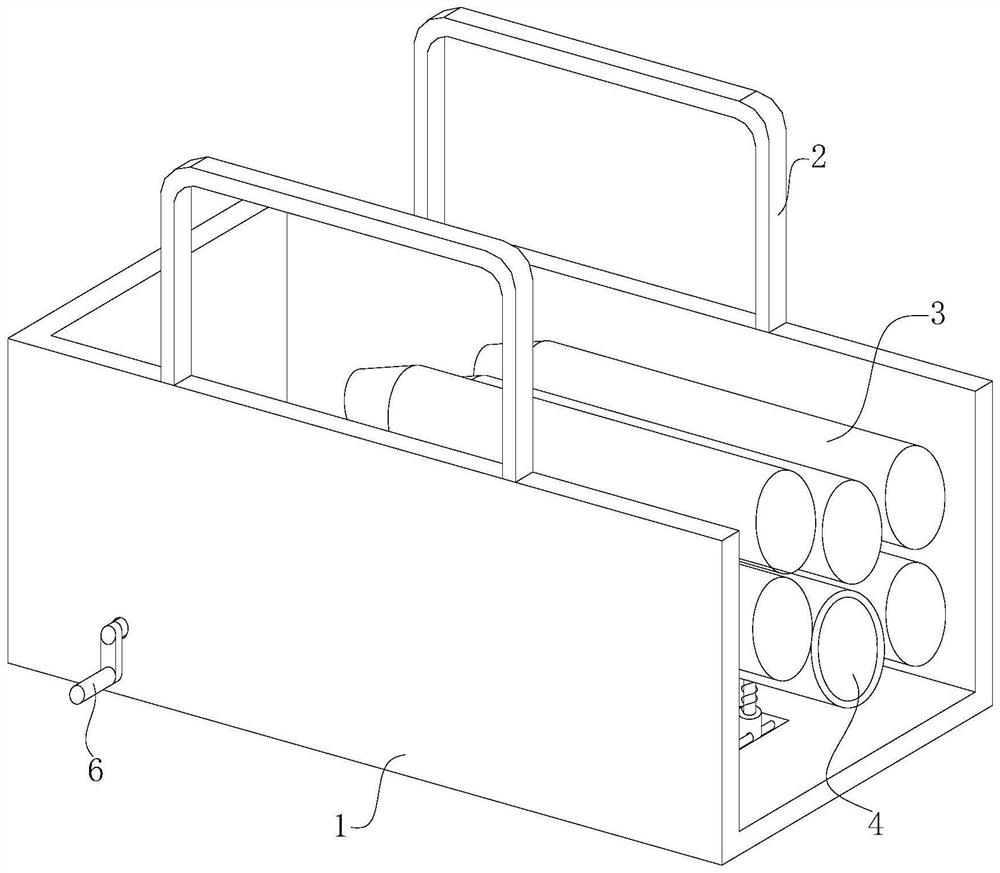

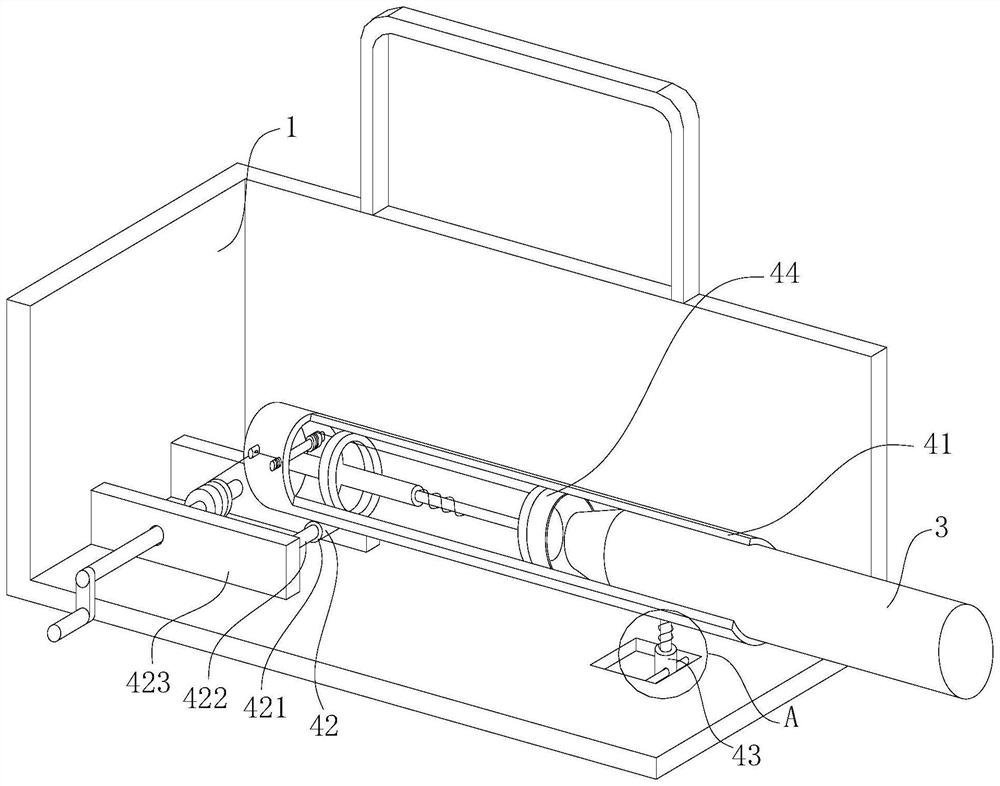

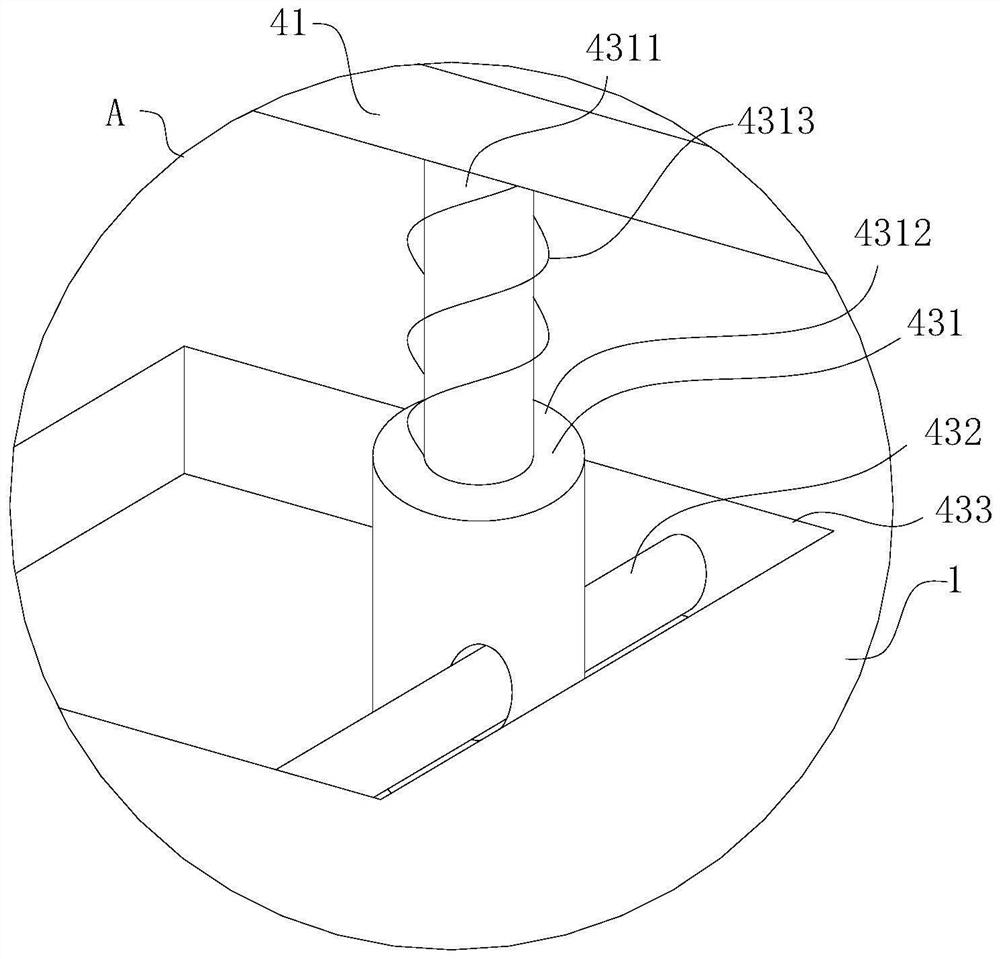

Portable buoy releasing device for hydrological survey

InactiveCN114834595AReduce volumeAvoid the manual delivery processWaterborne vesselsBuoysClassical mechanicsBuoy

The invention relates to a portable buoy throwing device for hydrological survey, which comprises a storage box and a buoy body, the buoy body is placed in the storage box, a lifting handle is arranged on the upper end face of the storage box, and a launching assembly is arranged in the storage box; according to the buoy throwing device, the structure of an existing buoy throwing device is improved, the size of the improved buoy throwing device is greatly reduced, manual throwing is not needed, in the actual buoy throwing process, the effective throwing effect can be achieved, meanwhile, the manual throwing process can be avoided, and the safety of the buoy throwing device is improved. Therefore, the safe bidding effect is achieved, and the high practical value is achieved.

Owner:陈欣欣 +6

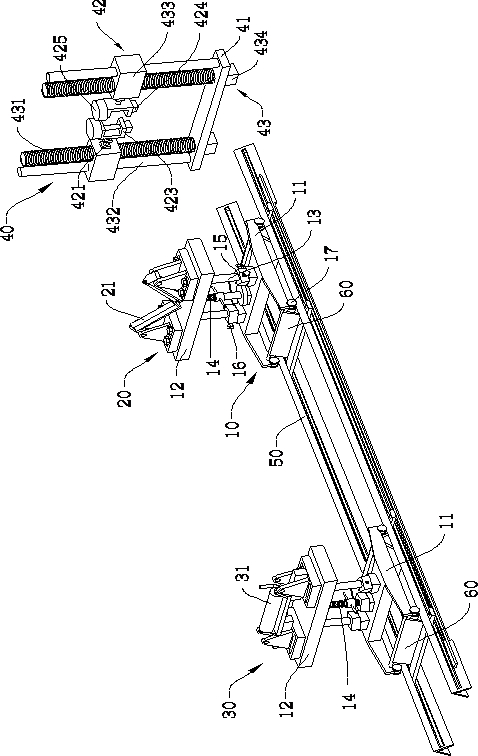

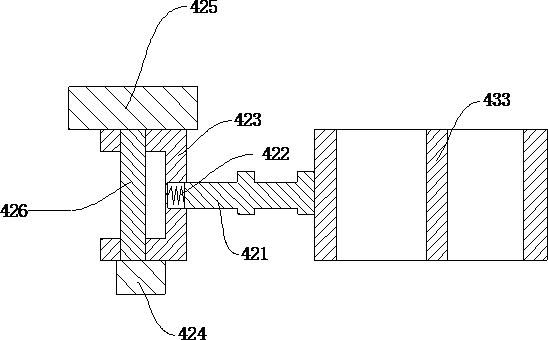

Tube delivery positioning device

The invention provides a pipe material conveying and positioning device, which includes a frame mechanism, a positioning support mechanism, a supporting mechanism and a feeding mechanism. The frame mechanism has two groups arranged at intervals along the pipe material conveying direction; the positioning support mechanism includes two support shafts that are rotatably arranged on one of the frame mechanisms, the two support shafts are V-shaped, and the two The axial direction of the supporting shaft is set at an included angle to position and support the pipe material; the supporting mechanism includes a supporting shaft that is rotatably arranged on another frame mechanism, and the axial direction of the supporting shaft is along the horizontal direction Setting; the feeding mechanism is located on the front side of the frame mechanism along the pipe material conveying direction, and is used to provide power for conveying the pipe material. The positioning device for pipe material delivery provided by the present invention aims to solve the problem that the pipe material does not have a positioning structure during the transmission process, causing the position of the pipe material to shift, and manual push is required to transfer the pipe material to the next processing station during the transmission process. , technical problems of low work efficiency.

Owner:张家口宣化昌通环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com