Cutting device and method for machining iron art guardrail accessories

A cutting device and guardrail technology, applied in metal processing, positioning devices, metal processing equipment, etc., can solve problems such as low efficiency and operator injury, and achieve the effects of high reliability, avoidance of transportation, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

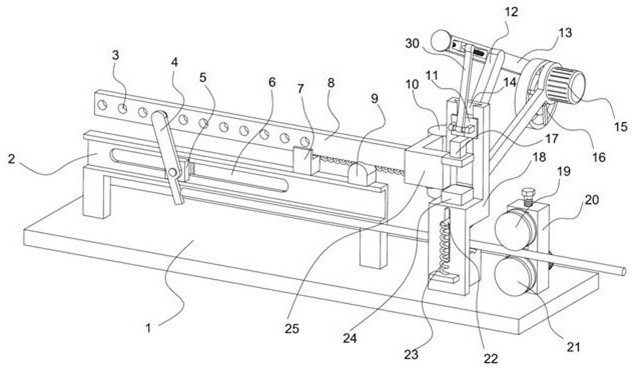

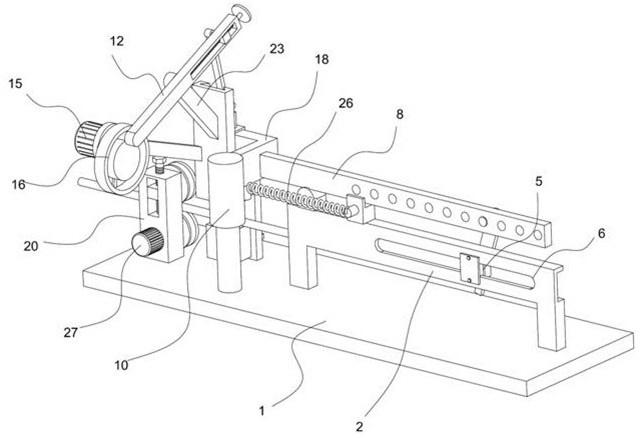

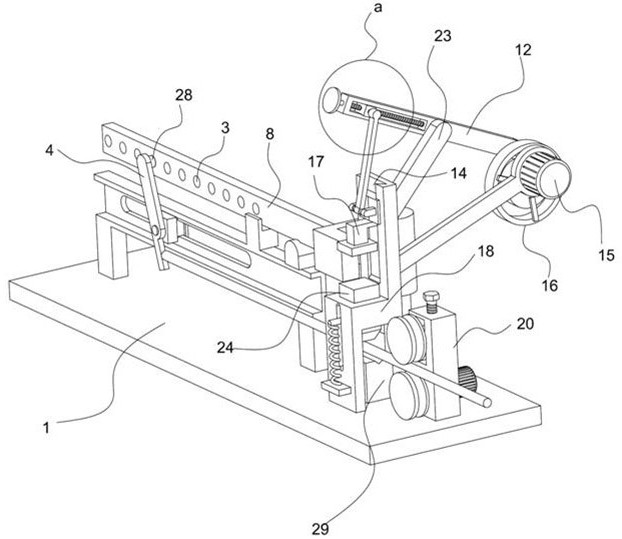

[0035] refer to Figure 1-7 , in an embodiment of the present invention, a cutting device for processing wrought iron guardrail accessories, including a fixed base 1, one end of the upper side of the fixed base 1 is fixedly mounted with a guide rail plate 2, and a guide groove 6 is arranged inside the guide rail plate 2, and the inside of the guide groove 6 The guide block 5 is detachably installed. In this embodiment, bolts can be installed on the upper and lower sides of the back of the guide block 5, thereby realizing the retention of the guide block 5 at a specific position inside the guide groove 6, and finally adjusting the length of the cut wrought iron guardrail. Adjust to ensure the scope of application of the entire cutting device. The guide block 5 is rotated and installed with the interference rod 4. A horizontal translation mechanism is installed on the top of the interference rod 4. The movement direction of the translation mechanism contacts the compensation bloc...

Embodiment 2

[0049] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that the power mechanism includes a power frame 13, and the power frame 13 is installed on the cutting frame 18 through the connecting frame 12. One side of the power frame 13 slides and installs a power block 36, the power block 36 is hinged on the lifting block 11 by a power rod 30, and a lead screw 37 is installed on the power block 36 through a threaded structure, so that the rotary motion of the lead screw 37 is converted into The linear movement of the power block 36 inside the power frame 13, the screw 37 passes through the power frame 13 and is connected with a handle 35, which facilitates the staff to effectively drive the screw 37 to rotate, and the power frame 13 is far away from the power block 36 A power column 32 is fixedly installed on one side, and a power disc 16 is installed on the power column 32. A power motor 15 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com